Enhancement of the Mechanical, Self-Healing and Pollutant Adsorption Properties of Mortar Reinforced with Empty Fruit Bunches and Shell Chars of Oil Palm

Abstract

:1. Introduction

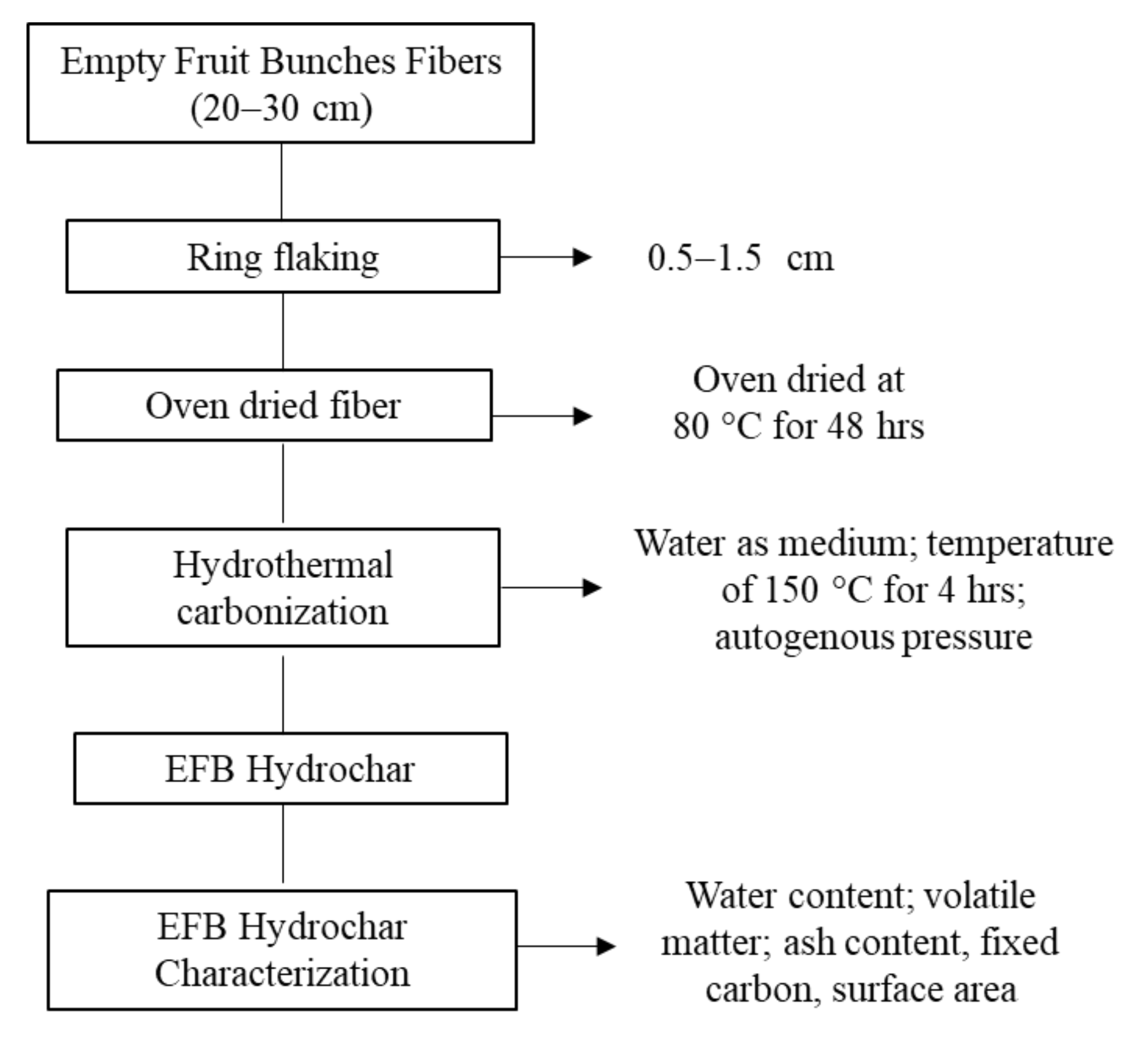

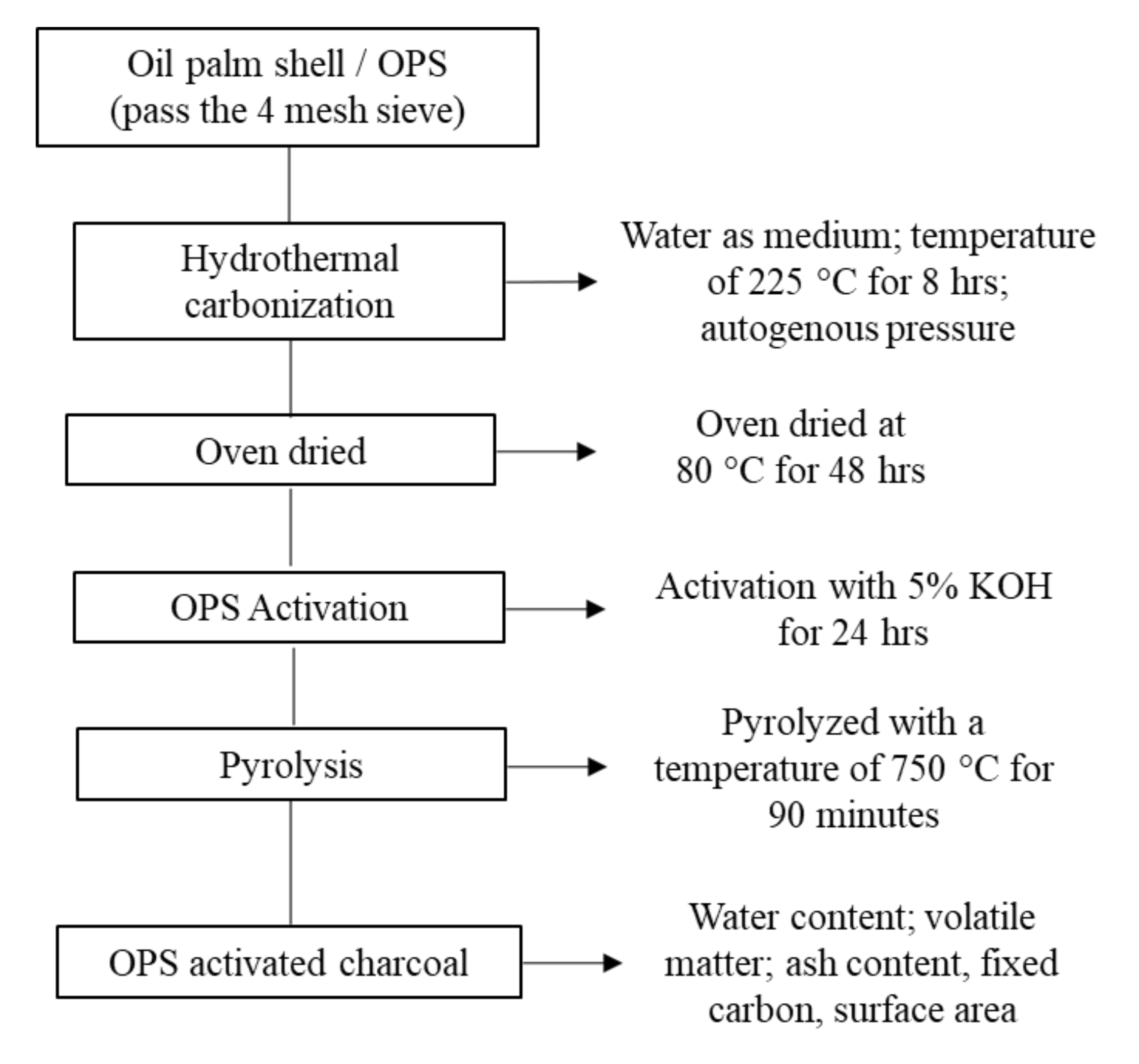

2. Materials and Methods

2.1. Materials

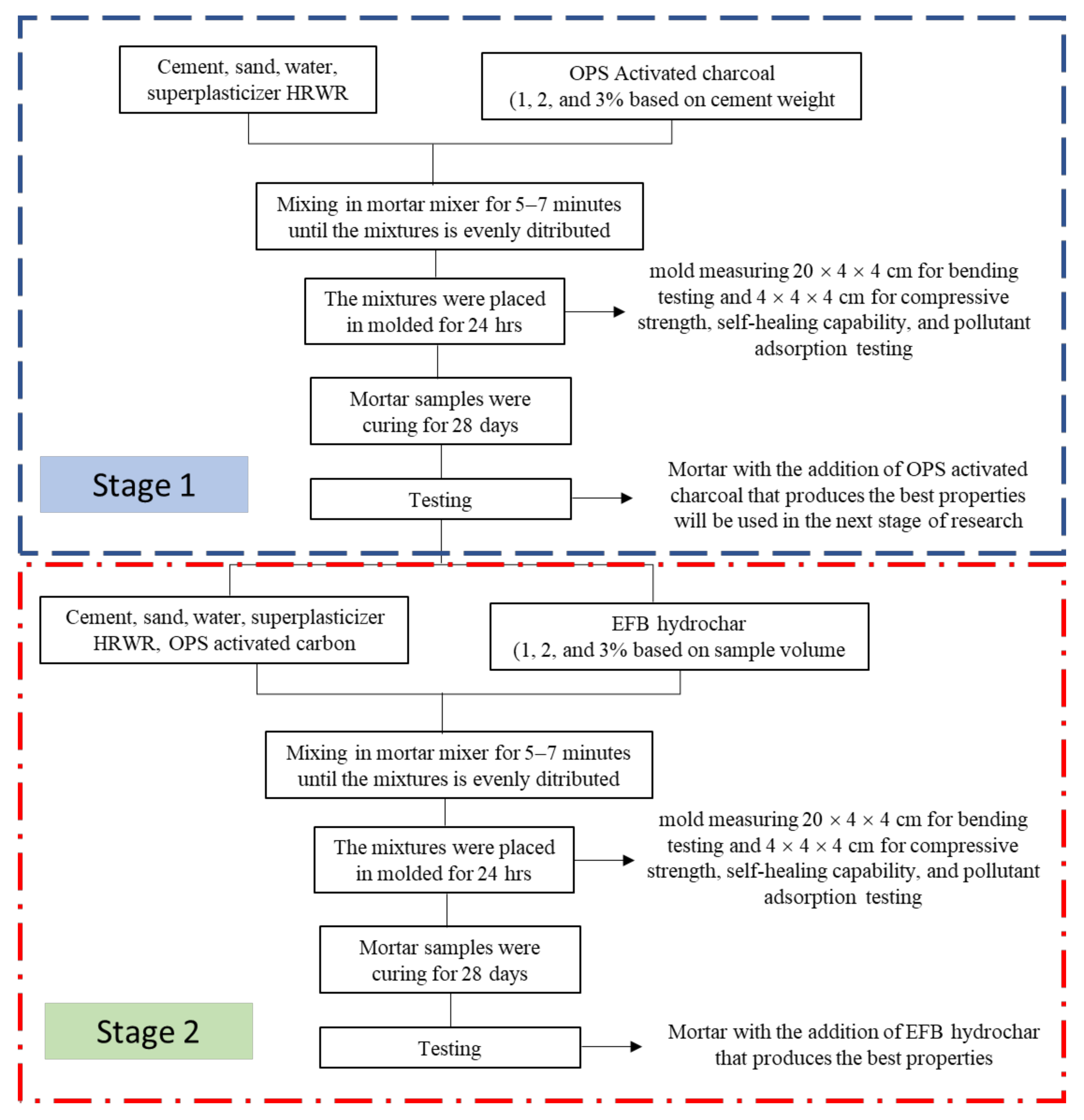

2.2. Manufacture of Mortar

2.2.1. Mortar Manufacturing with the Addition of OPS-Activated Charcoal

2.2.2. Mortar Manufacturing with the Addition of OPS-Activated Charcoal and EFB Hydrochar

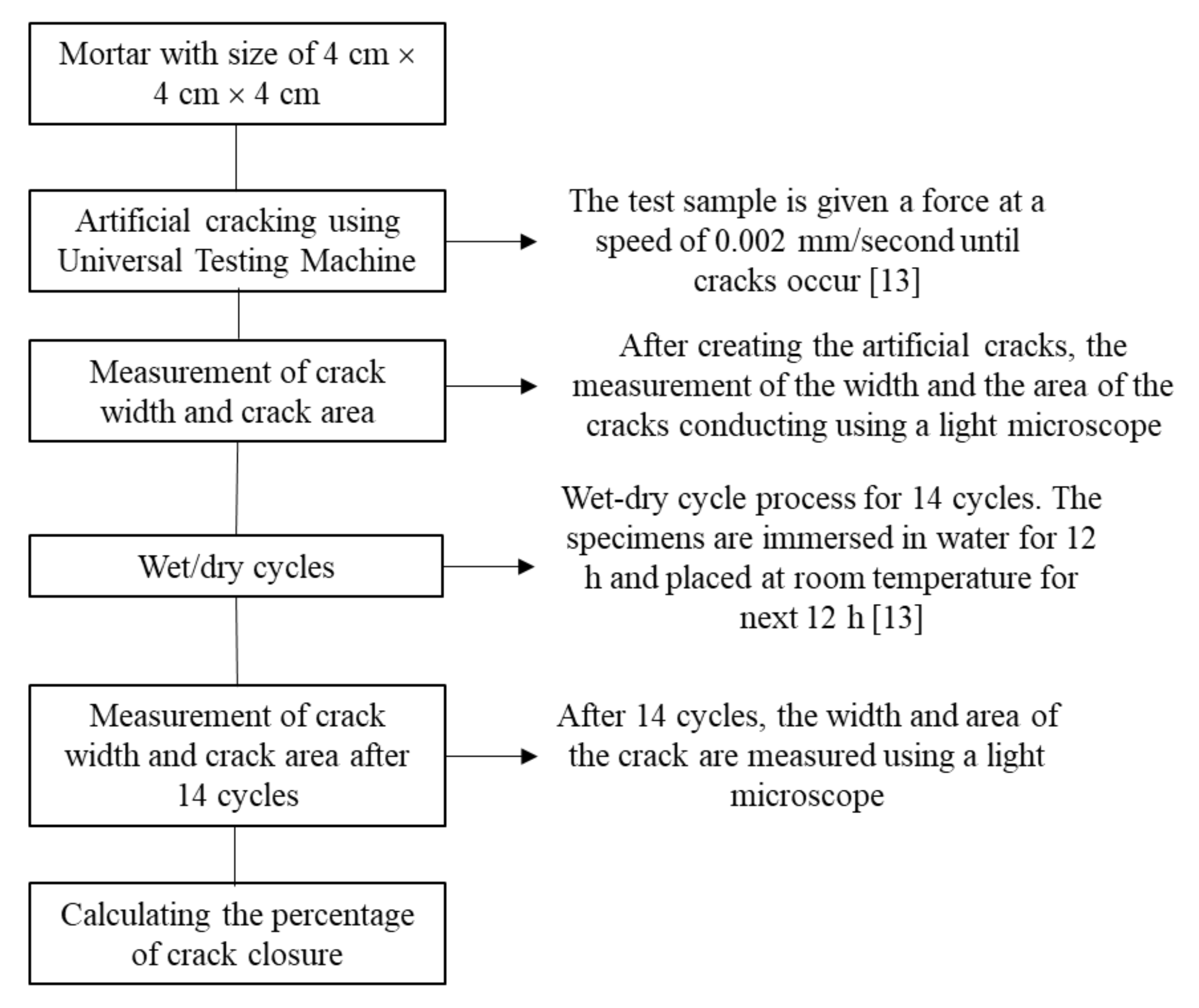

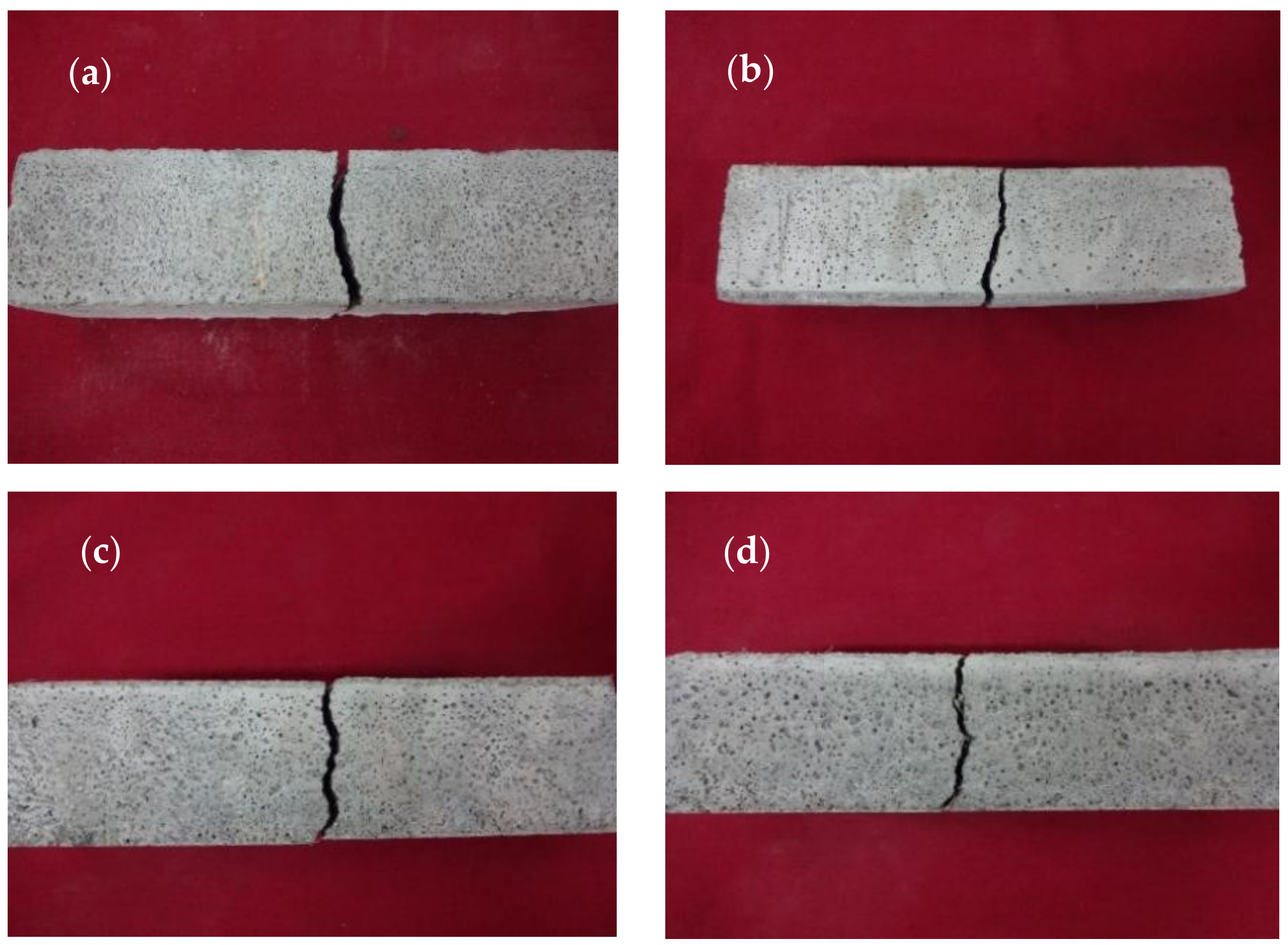

2.3. Artificial Cracking and Wet/Dry Cycles

2.4. Samples Testing

2.4.1. Compressive Strength Testing

2.4.2. Bending Test

2.4.3. Observation of Self-Healing Mortar

2.4.4. Pollutant Absorption Test

3. Results and Discussions

3.1. Properties of Mortar with Activated Carbon Addition

3.1.1. Mechanical Properties

Density

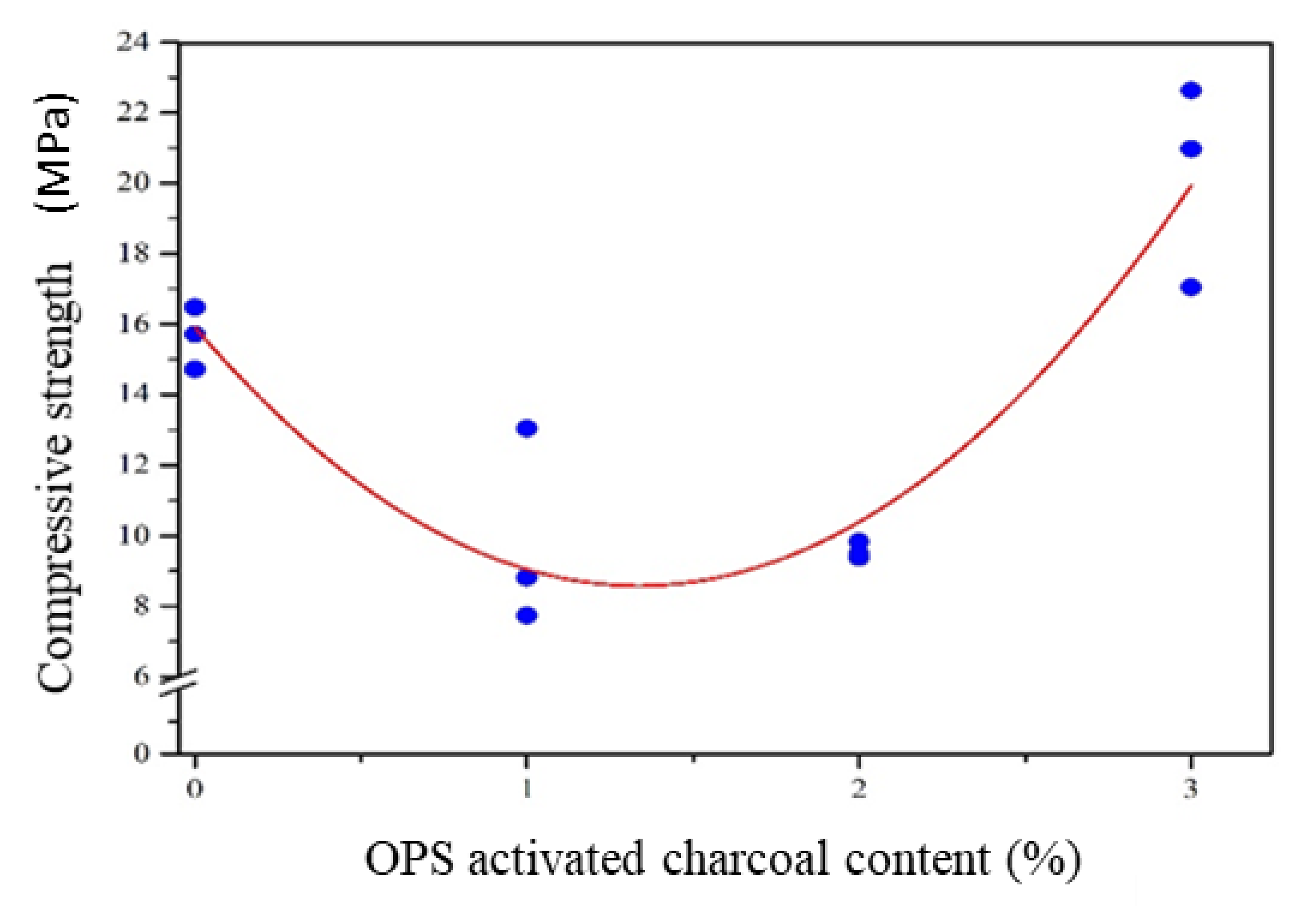

Compressive Strength

Flexural Strength

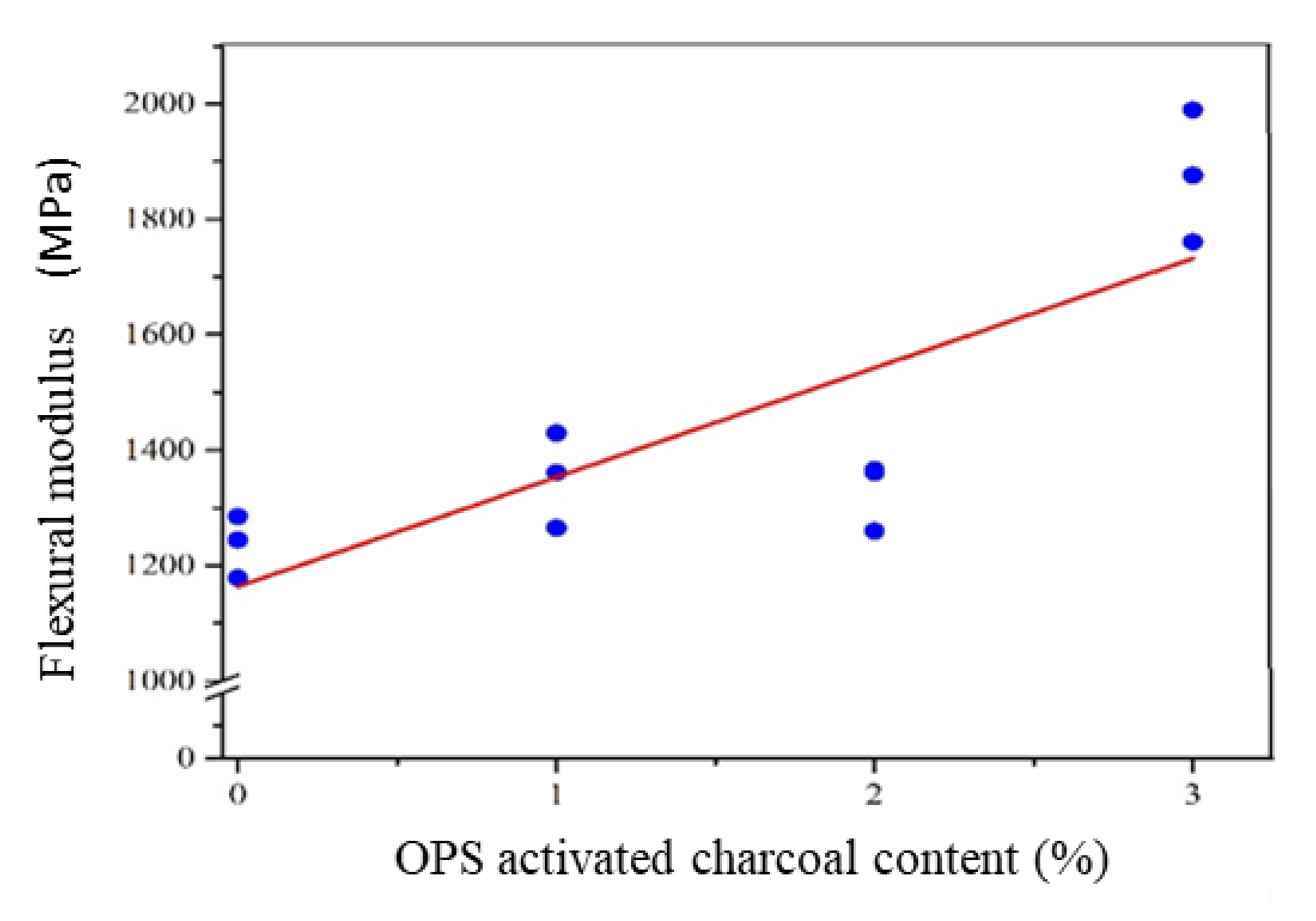

Flexural Modulus

3.1.2. Pollutant Adsorption

3.2. Properties of the Mortar with Activated Carbon and Hydrochar Addition

3.2.1. Mechanical Properties

Density

Compressive Strength

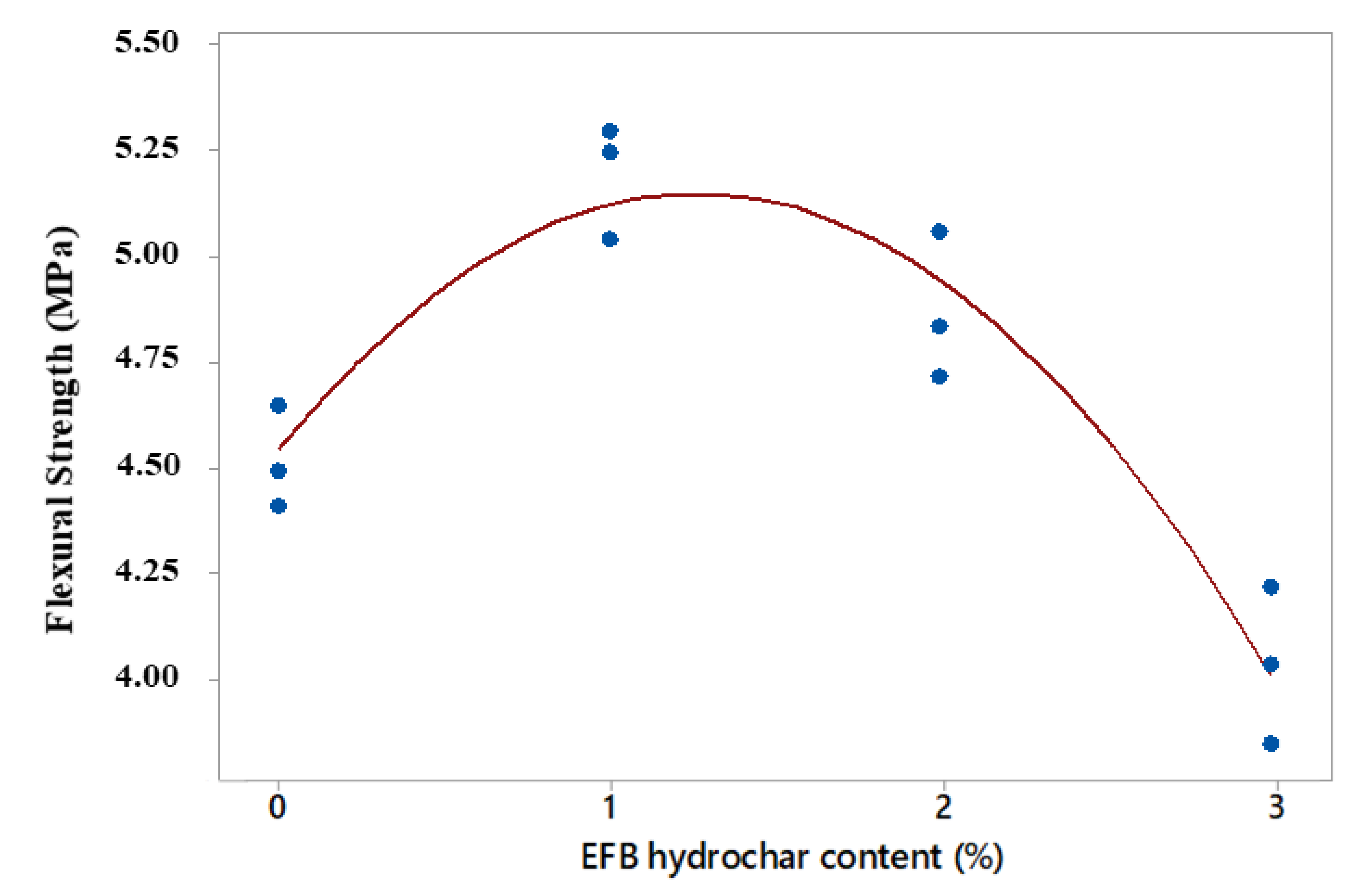

Flexural Strength

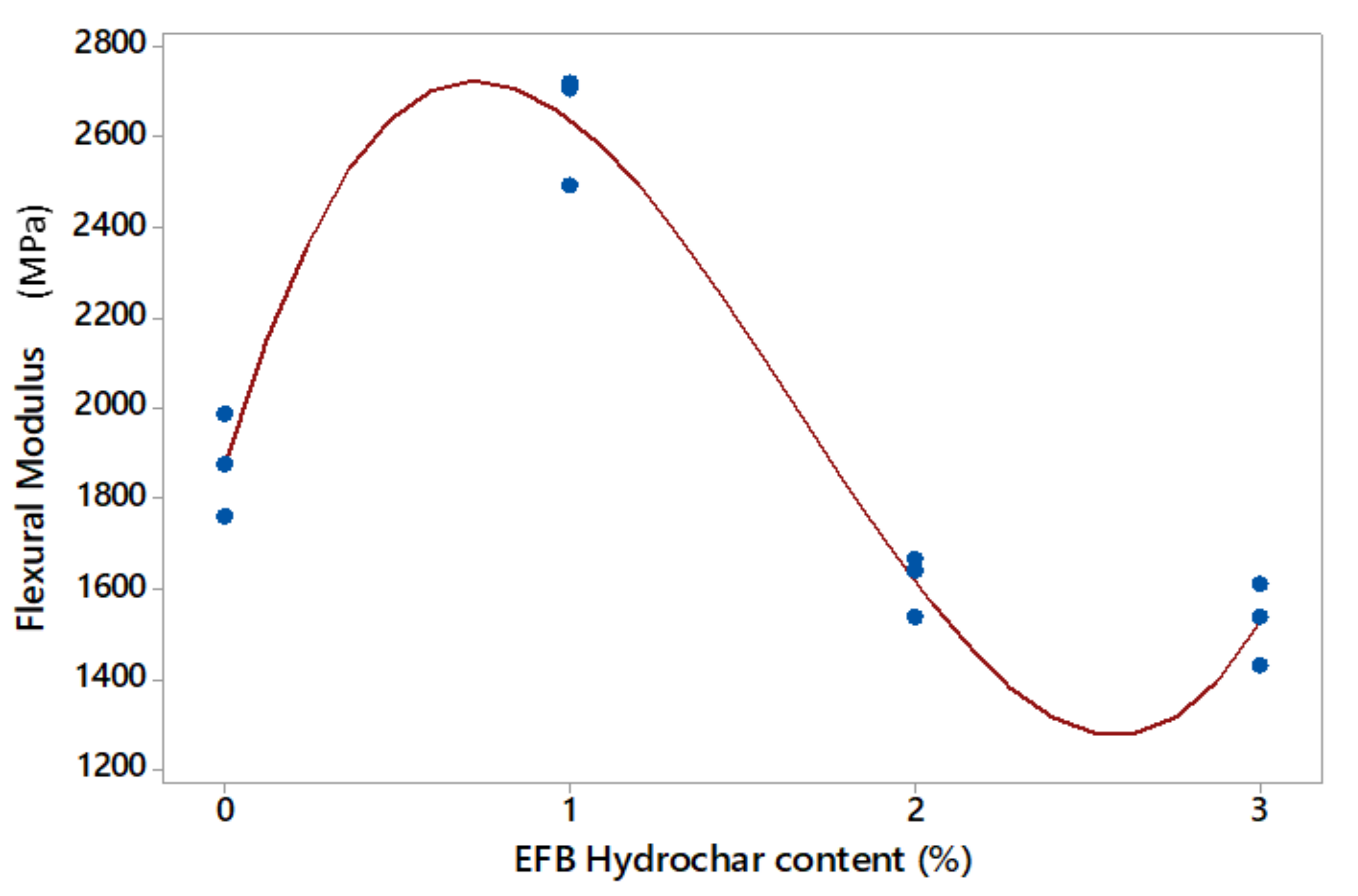

Flexural Modulus

3.2.2. Pollutant Adsorption

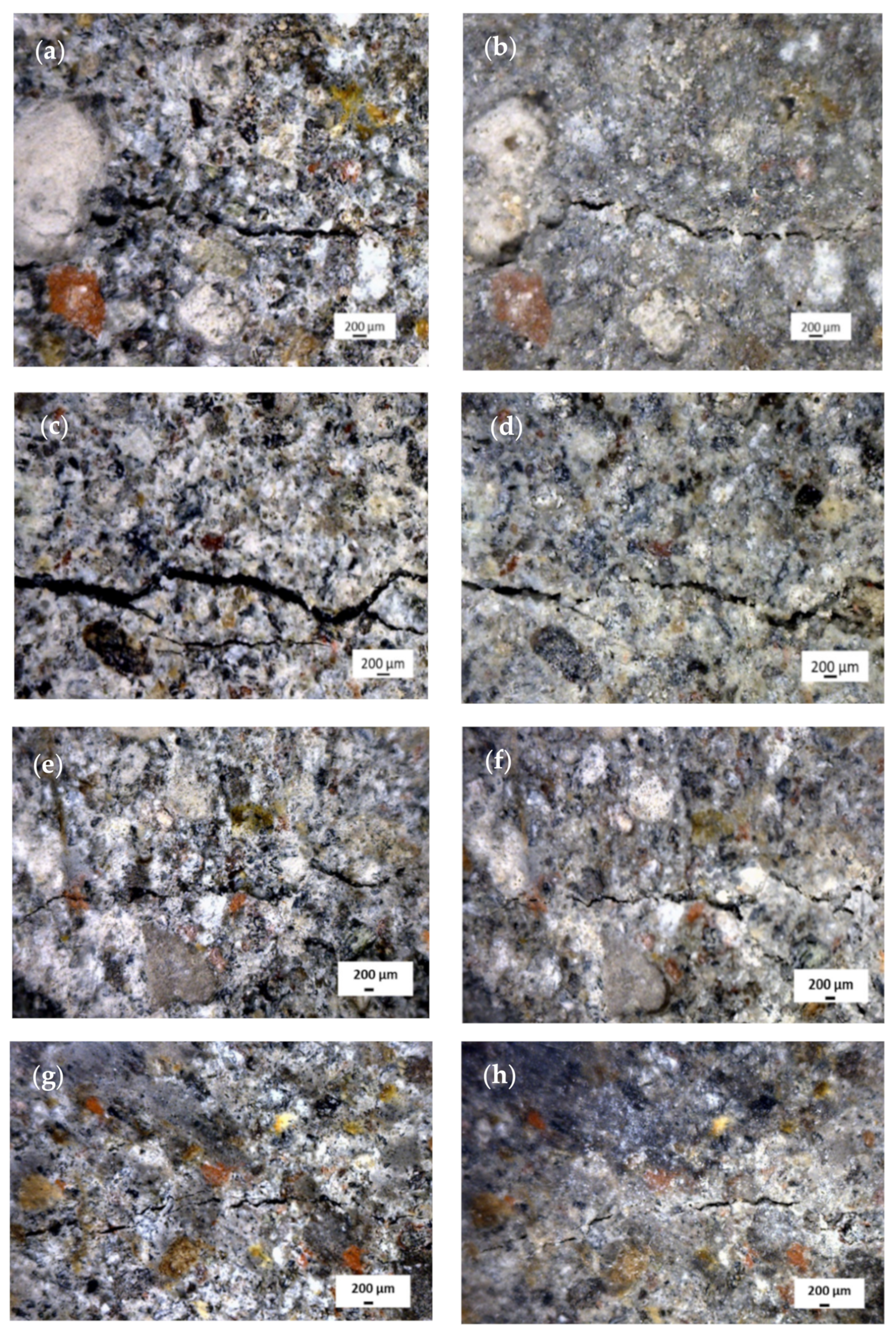

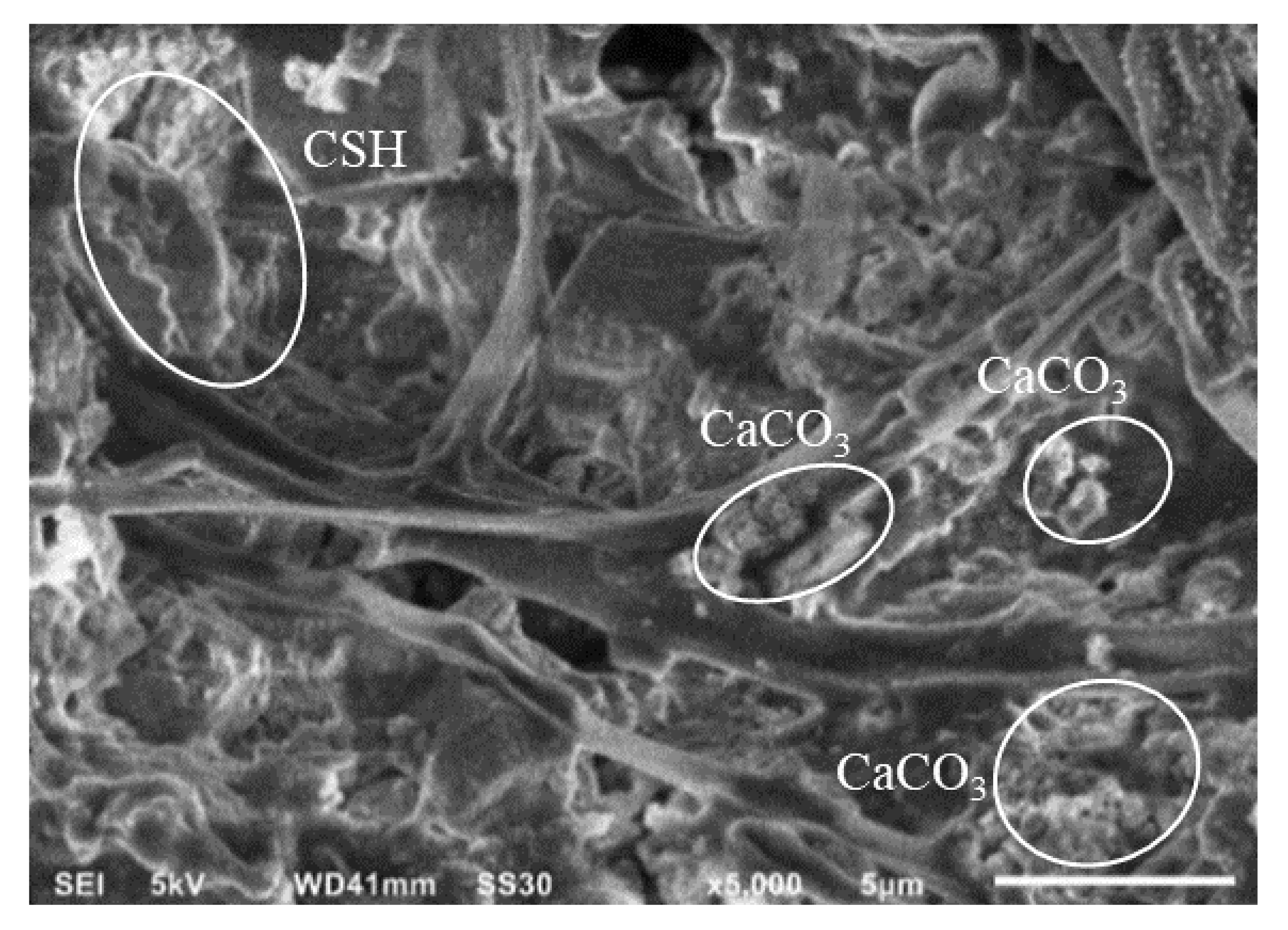

3.2.3. Crack Recovery by Wet-Dry Cycle Treatment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choi, Y.; Yuan, R.L. Experimental relationship between splitting tensile strength and compressive strength of GFRC and PFRC. Cem. Concr. Res. 2005, 35, 1587–1591. [Google Scholar] [CrossRef]

- Shah, K.W.; Huseien, G.F. Biomimetic Self-Healing Cementitious Construction Materials for Smart Buildings. Biomimetics 2020, 5, 47. [Google Scholar] [CrossRef] [PubMed]

- Mihashi, H.; Nishiwaki, T. Development of Engineered Self-Healing and Self-Repairing Concrete-State-of-the-Art Report. J. Adv. Concr. Technol. 2012, 10, 170–184. [Google Scholar] [CrossRef] [Green Version]

- Schlangen, E.; Sangadji, S. Addressing Infrastructure Durability and Sustainability by Self Healing. Procedia Eng. 2013, 54, 39–57. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, F.B.; De Belie, N.; Boon, N.; Verstraete, W. Production of non-axenic ureolytic spores for self-healing concrete applications. Constr. Build. Mater. 2015, 93, 1034–1041. [Google Scholar] [CrossRef]

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: A promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1088. [Google Scholar] [CrossRef] [Green Version]

- Lucas, S.; Moxham, C.; Tziviloglou, E.; Jonkers, H. Study of self-healing properties in concrete with bacteria encapsulated in expanded clay. Sci. Technol. Mater. 2018, 30, 93–98. [Google Scholar] [CrossRef]

- Roy, R.; Rossi, E.; Silfwerbrand, J.; Jonkers, H. Self-healing capacity of mortars with added-in bio-plastic bacteria-based agents: Characterization and quantification through micro-scale techniques. Constr. Build. Mater. 2021, 297, 123793. [Google Scholar] [CrossRef]

- Monte, F.L.; Ferrara, L. Self-healing characterization of UHPFRCC with crystalline admixture: Experimental assessment via multi-test/multi-parameter approach. Constr. Build. Mater. 2021, 283, 122579. [Google Scholar] [CrossRef]

- Dupuis, R.; Moon, J.; Jeong, Y.; Taylor, R.; Kang, S.-H.; Manzano, H.; Ayuela, A.; Monteiro, P.J.M.; Dolado, J.S. Normal and anomalous self-healing mechanism of crystalline calcium silicate hydrates. Cem. Concr. Res. 2021, 142, 106356. [Google Scholar] [CrossRef]

- Tomczak, K.; Jakubowski, J.; Kotwica, Ł. Enhanced autogenous self-healing of cement-based composites with mechanically activated fluidized-bed combustion fly ash. Constr. Build. Mater. 2021, 300, 124028. [Google Scholar] [CrossRef]

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2012, 25, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Snoeck, D.; Smetryns, P.-A.; De Belie, N. Improved multiple cracking and autogenous healing in cementitious materials by means of chemically-treated natural fibres. Biosyst. Eng. 2015, 139, 87–99. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Mechanical and self-healing properties of cementitious composites reinforced with flax and cottonised flax, and compared with polyvinyl alcohol fibres. Biosyst. Eng. 2012, 111, 325–335. [Google Scholar] [CrossRef]

- Azevedo, A.R.; Marvila, M.T.; Zanelato, E.B.; Alexandre, J.; Xavier, G.C.; Cecchin, D. Development of mortar for laying and coating with pineapple fibers. Rev. Bras. Eng. Agrícola Ambient. 2020, 24, 187–193. [Google Scholar] [CrossRef]

- De Azevedo, A.R.G.; Klyuev, S.; Marvila, M.T.; Vatin, N.; Alfimova, N.; De Lima, T.E.S.; Fediuk, R.; Olisov, A. Investigation of the Potential Use of Curauá Fiber for Reinforcing Mortars. Fibers 2020, 8, 69. [Google Scholar] [CrossRef]

- Marvila, M.T.; De Azevedo, A.R.G.; Alexandre, J.; Colorado, H.; Antunes, M.L.P.; Vieira, C.M.F. Circular economy in cementitious ceramics: Replacement of hydrated lime with a stoichiometric balanced combination of clay and marble waste. Int. J. Appl. Ceram. Technol. 2020, 18, 192–202. [Google Scholar] [CrossRef]

- Neuba, L.D.M.; Junio, R.F.P.; Ribeiro, P.M.; Souza, A.T.; Lima, E.S.; Filho, F.C.G.; Figueiredo, A.B.S.; Braga, F.O.; Azevedo, A.R.G.; Monteiro, S.N. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef]

- Ahmad, S.; Khushnood, R.A.; Jagdale, P.; Tulliani, J.-M.; Ferro, G.A. High performance self-consolidating cementitious composites by using micro carbonized bamboo particles. Mater. Des. 2015, 76, 223–229. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Ferro, G.A.; Restuccia, L.; Tulliani, J.M.; Jagdale, P. Modified fracture properties of cement composites with nano/micro carbonized bagasse fibers. Frat. Integrita Strutt. 2015, 9, 534–542. [Google Scholar] [CrossRef]

- Horgnies, M.; Dubois-Brugger, I.; Gartner, E.M. NOx de-pollution by hardened concrete and the influence of activated charcoal additions. Cem. Concr. Res. 2012, 42, 1348–1355. [Google Scholar] [CrossRef]

- Krou, N.J.; Batonneau-Gener, I.; Belin, T.; Mignard, S.; Javierre, I.; Dubois-Brugger, I.; Horgnies, M. Reactivity of volatile organic compounds with hydrated cement paste containing activated carbon. Build. Environ. 2015, 87, 102–107. [Google Scholar] [CrossRef]

- Hambali, E.; Rivai, M. The Potential of Palm Oil Waste Biomass in Indonesia in 2020 and 2030. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012050. [Google Scholar] [CrossRef]

- Kaliwon, J.; Ahmad, S.S.; Abdul Aziz, A. Performance of Oil Palm EFB Fibre Reinforced Concrete Roof Slates. In Proceedings of the 2010 International Conference on Science and Social Research (CSSR 2010), Kuala Lumpur, Malaysia, 5–7 December 2010; pp. 528–531. [Google Scholar] [CrossRef]

- Omoniyi, T.E. Potential of Oil Palm (Elaeisguineensis) Empty Fruit Bunch Fibres Cement Composites for Building Applications. AgriEngineering 2019, 1, 153–163. [Google Scholar] [CrossRef] [Green Version]

- Namdar, A.; Yahaya, F.M. Oil Palm Shell Ash-Cement Mortar Mixture and Modification of Mechanical Properties. Int. J. Civ. Environ. Eng. 2014, 8, 173–175. [Google Scholar]

- Tonnayopas, D.; Laopreechakul, S. Utilization of Oil Palm Shell Ash as Mineral Admixture in Portland Cement Mortar. In Proceedings of the 1st International Conference Hazardous Waste Management for a Sustainable Future, Bangkok, Thailand, 1995; pp. 1–7. [Google Scholar] [CrossRef]

- Byrne, C.E.; Nagle, D.C. Carbonization of wood for advanced materials applications. Carbon 1997, 35, 259–266. [Google Scholar] [CrossRef]

- SNI 06-3730-1995; Arang Aktif Teknis. Indonesian National Standard Bureau: Jakarta, Indonesia, 1995.

- Ginting, A.; Satiyajati, A.N. Compressive Strength of Concrete Based on SNI-DT-91-0008-2007 on Various Aggregate Water Content. J. Tek. 2013, 3, 1–10. [Google Scholar]

- Santoso, A.; Pari, G. The Effect of Active Charcoal in Mixed Raw Materials on the Characteristics of The ParticleBoard. J. Penelit. Has. Hutan 2012, 3, 235–242. [Google Scholar]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Filho, R.D.T.; Joseph, K.; Ghavami, K.; England, G.L. The use of sisal fibre as reinforcement in cement based composites. Rev. Bras. Eng. Agrícola Ambient. 1999, 3, 245–256. [Google Scholar] [CrossRef] [Green Version]

- Alizadeh, R.; Raki, L.; Makar, J.M.; Beaudoin, J.J.; Moudrakovski, I. Hydration of tricalcium silicate in the presence of synthetic calcium–silicate–hydrate. J. Mater. Chem. 2009, 19, 7937–7946. [Google Scholar] [CrossRef] [Green Version]

| Sample | Characteristics | EFB Hydrochar | OPS-Activated Charcoal |

|---|---|---|---|

| 1 | Water content (%) | 4.00 ± 0.10 | 2.46 ± 0.04 |

| 2 | Ash content (%) | 2.50 ± 0.04 | 6.52 ± 0.16 |

| 3 | Volatile matter content (%) | 49.00 ± 1.96 | 20 ± 0.70 |

| 4 | Fixed carbon (%) | 46.50 ± 1.86 | 73.48 ± 2.94 |

| 5 | Surface area (m2/g) | 4.41 ± 0.09 | 421.25 ± 12.64 |

| Sample | Mortar Type | Density (g/cm3) | Compressive Strength (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|---|---|

| 1 | Mortar + 0% AC | 1.962 ± 0.067 | 15.64 ± 0.89 | 4.161 ± 0.138 | 1236 ± 54 |

| 2 | Mortar + 1% AC | 1.930 ± 0.021 | 9.86 ± 2.80 | 4.207 ± 0.088 | 1352 ± 82 |

| 3 | Mortar + 2% AC | 1.931 ± 0.027 | 9.58 ± 0.24 | 4.217 ± 0.070 | 1328 ± 60 |

| 4 | Mortar + 3% AC | 1.937 ± 0.070 | 20.22 ± 2.87 | 4.517 ± 0.119 | 1875 ± 114 |

| Sample | Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 11.81 + 1.345 X | 1.2 |

| 2 | Quadratic | Y = 15.91 − 10.97 X + 4.104 X2 | 82.5 |

| 3 | Cubic | Y = 16.07 − 12.70 X + 4.685 X2 + 0.0688 X3 | 82.6 |

| Sample | Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 4.114 + 0.1078 X | 48.0 |

| 2 | Quadratic | Y = 4.178 − 0.08368 X + 0.06384 X2 | 60.3 |

| 3 | Cubic | Y = 4.161 − 0.1718 X − 0.1808 X2 − 0.05436 X3 | 62.0 |

| Sample | Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 1164 + 189.4 X | 63.5 |

| 2 | Quadratic | Y = 1271 − 133.8 X + 107.7 X2 | 80.6 |

| 3 | Cubic | Y = 1236 + 421.5 X − 423.9 X2 + 118.1 X3 | 91.0 |

| Sample | Mortar Type | Adsorption (%) | |||

|---|---|---|---|---|---|

| Benzene | Formaldehyde | Ammonium | Chloroform | ||

| 1 | Mortar + 0% AC | 2.398 ± 0.021 | 1.478 ± 0.016 | 1.829 ± 0.055 | 1.714 ± 0.041 |

| 2 | Mortar + 1% AC | 2.449 ± 0.020 | 1.517 ± 0.017 | 1.880 ± 0.058 | 2.150 ± 0.110 |

| 3 | Mortar + 2% AC | 2.912 ± 0.048 | 1.609 ± 0.012 | 1.955 ± 0.081 | 2.225 ± 0.113 |

| 4 | Mortar + 3% AC | 2.918 ± 0.057 | 1.697 ± 0.018 | 1.958 ± 0.099 | 2.367 ± 0.128 |

| Sample | Pollutant Type | Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|---|

| 1 | Benzene | Linear | Y = 2.366 + 0.2022 X | 80.4% |

| Quadratic | Y = 2.355 + 0.236 X − 0.01127 X2 | 76.7% | ||

| Cubic | Y = 2.398 − 0.4435 X + 0.6394 X2 − 0.1446 X3 | 97.7% | ||

| 2 | Formaldehyde | Linear | Y = 1.463 + 0.0748 X | 94.9% |

| Quadratic | Y = 1.476 + 0.03764 X + 0.01239 X2 | 96.8% | ||

| Cubic | Y = 1.478 − 0.00531 X + 0.05351 X2 − 0.009139 X3 | 96.9% | ||

| 3 | Chloroform | Linear | Y = 1.809 + 0.2036 X | 76.5% |

| Quadratic | Y = 1.735 + 0.4239 X − 0.07345 X2 | 83.4% | ||

| Cubic | Y = 1.714 + 0.7614 X − 0.3965 X2 + 0.0718 X3 | 85.5% |

| Sample | Mortar Type | Density (g/cm3) | Compressive Strength (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|---|---|

| 1 | Mortar + 3% AC + 0% hydrochar | 1.937 ± 0.070 | 20.22 ± 2.87 | 4.517 ± 0.119 | 1875 ± 114 |

| 2 | Mortar + 3% AC + 1% hydrochar | 1.932 ± 0.009 | 30.63 ± 1.58 | 5.195 ± 0.135 | 2642 ± 129 |

| 3 | Mortar + 3% AC + 2% hydrochar | 1.913 ± 0.055 | 26.75 ± 0.84 | 4.873 ± 0.174 | 1617 ± 70 |

| 4 | Mortar + 3% AC + 3% hydrochar | 1.900 ± 0.011 | 21.81 ± 2.44 | 4.036 ± 0.185 | 1529 ± 90 |

| Sample | Type of Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 24.72 + 0.091 X | 0.0 |

| 2 | Quadratic | Y = 20.88 + 11.61 X − 3.839 X2 | 68.7 |

| 3 | Cubic | Y = 20.22 + 21.97 X − 13.76 X2 + 2.204 X3 | 79.9 |

| Sample | Type of Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 4.920 − 0.1767 X | 11.3 |

| 2 | Quadratic | Y = 4.542 + 0.9588 X − 0.3785 X2 | 88.4 |

| 3 | Cubic | Y = 4.517 + 1.339 X − 0.7421 X2 + 0.08081 X3 | 89.0 |

| Sample | Type of Regression Model | Regression Equation | R2 adj (%) |

|---|---|---|---|

| 1 | Linear | Y = 2225 − 206.4 X | 19.4 |

| 2 | Quadratic | Y = 2011 + 434.6 X − 213.7 X2 | 38.5 |

| 3 | Cubic | Y = 1875 + 2571 X − 2259 X2 + 454.6 X3 | 95.1 |

| Sample | Mortar Type | Adsorption (%) | |||

|---|---|---|---|---|---|

| Benzene | Formaldehyde | Ammonium | Chloroform | ||

| 1 | Mortar + 3% AC + 0% hydrochar | 2.918 ± 0.057 | 1.697 ± 0.018 | 1.958 ± 0.099 | 2.367 ± 0.128 |

| 2 | Mortar + 3% AC + 1% hydrochar | 2.936 ± 0.070 | 1.699 ± 0.039 | 1.846 ± 0.087 | 2.326 ± 0.114 |

| 3 | Mortar + 3% AC + 2% hydrochar | 3.391 ± 0.239 | 1.780 ± 0.049 | 2.118 ± 0.105 | 2.666 ± 0.138 |

| 4 | Mortar + 3% AC + 3% hydrochar | 3.351 ± 0.188 | 1.843 ± 0.058 | 2.183 ± 0.131 | 2.478 ± 0.103 |

| Sample | Mortar Types | Before Wet-Dry Cycle | After Wet-Dry Cycle | ||

|---|---|---|---|---|---|

| Width (µm) | Length (µm) | Width (µm) | Length (µm) | ||

| 1 | Mortar + 3% AC + 0% EFB hydrochar | 28.6–171.4 | 171.4–1028.6 | 0.0–71.4 | 0.0–714 |

| 2 | Mortar + 3% AC + 1% EFB hydrochar | 42.9–228.6 | 257.1–3143 | 0.0–128.6 | 0.0–1429 |

| 3 | Mortar + 3% AC + 2% EFB hydrochar | 48.0–120.0 | 240.0–2140 | 20.0–26.0 | 40.0–1000 |

| 4 | Mortar + 3% AC + 3% EFB hydrochar | 40.0–280.0 | 240.0–1300 | 0.0–80.0 | 0.0–700.0 |

| Sample | Mortar Type | Crack Area with Width <50 (µm2) | Crack Area with Width >50 (µm2) | Total Crack Area (µm2) | Crack Recovery with Width <50 µm (%) | Crack Recovery with Width >50 µm (%) | Total Crack Recovery (%) |

|---|---|---|---|---|---|---|---|

| 1 | Mortar + 3% AC + 0% EFB hydrochar | 21,026 | 399,184 | 420,204 | 88.3 | 68.5 | 69.5 |

| 2 | Mortar + 3% AC + 1% EFB hydrochar | 47,747 | 1,397,956 | 1,445,703 | 100.0 | 75.5 | 76.3 |

| 3 | Mortar + 3% AC + 2% EFB hydrochar | 32,160 | 632,000 | 664,160 | 89.4 | 69.1 | 70.1 |

| 4 | Mortar + 3% AC + 3% EFB hydrochar | 39,200 | 519,840 | 559,040 | 69.4 | 69.7 | 69.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hermawan, D.; Budiman, I.; Febrianto, F.; Subyakto, S.; Pari, G.; Ghozali, M.; Bahtiar, E.T.; Sutiawan, J.; Azevedo, A.R.G.d. Enhancement of the Mechanical, Self-Healing and Pollutant Adsorption Properties of Mortar Reinforced with Empty Fruit Bunches and Shell Chars of Oil Palm. Polymers 2022, 14, 410. https://doi.org/10.3390/polym14030410

Hermawan D, Budiman I, Febrianto F, Subyakto S, Pari G, Ghozali M, Bahtiar ET, Sutiawan J, Azevedo ARGd. Enhancement of the Mechanical, Self-Healing and Pollutant Adsorption Properties of Mortar Reinforced with Empty Fruit Bunches and Shell Chars of Oil Palm. Polymers. 2022; 14(3):410. https://doi.org/10.3390/polym14030410

Chicago/Turabian StyleHermawan, Dede, Ismail Budiman, Fauzi Febrianto, Subyakto Subyakto, Gustan Pari, Muhammad Ghozali, Effendi Tri Bahtiar, Jajang Sutiawan, and Afonso R. G. de Azevedo. 2022. "Enhancement of the Mechanical, Self-Healing and Pollutant Adsorption Properties of Mortar Reinforced with Empty Fruit Bunches and Shell Chars of Oil Palm" Polymers 14, no. 3: 410. https://doi.org/10.3390/polym14030410

APA StyleHermawan, D., Budiman, I., Febrianto, F., Subyakto, S., Pari, G., Ghozali, M., Bahtiar, E. T., Sutiawan, J., & Azevedo, A. R. G. d. (2022). Enhancement of the Mechanical, Self-Healing and Pollutant Adsorption Properties of Mortar Reinforced with Empty Fruit Bunches and Shell Chars of Oil Palm. Polymers, 14(3), 410. https://doi.org/10.3390/polym14030410