Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. PJM Technology

- High speed (HS)—with a material layer height of 32 µm, which is characterized by high-speed printing parts;

- High quality (HQ)—with a material layer height of 16 µm, which is characterized by a lower print speed and very high accuracy;

- Digital material (DM)—with a material layer height of 32 µm, which is characterized by the combination of different materials.

2.2. Material MED610

2.3. Measurement Technologies

- Mean value

- Standard deviation

- Sample cross-section

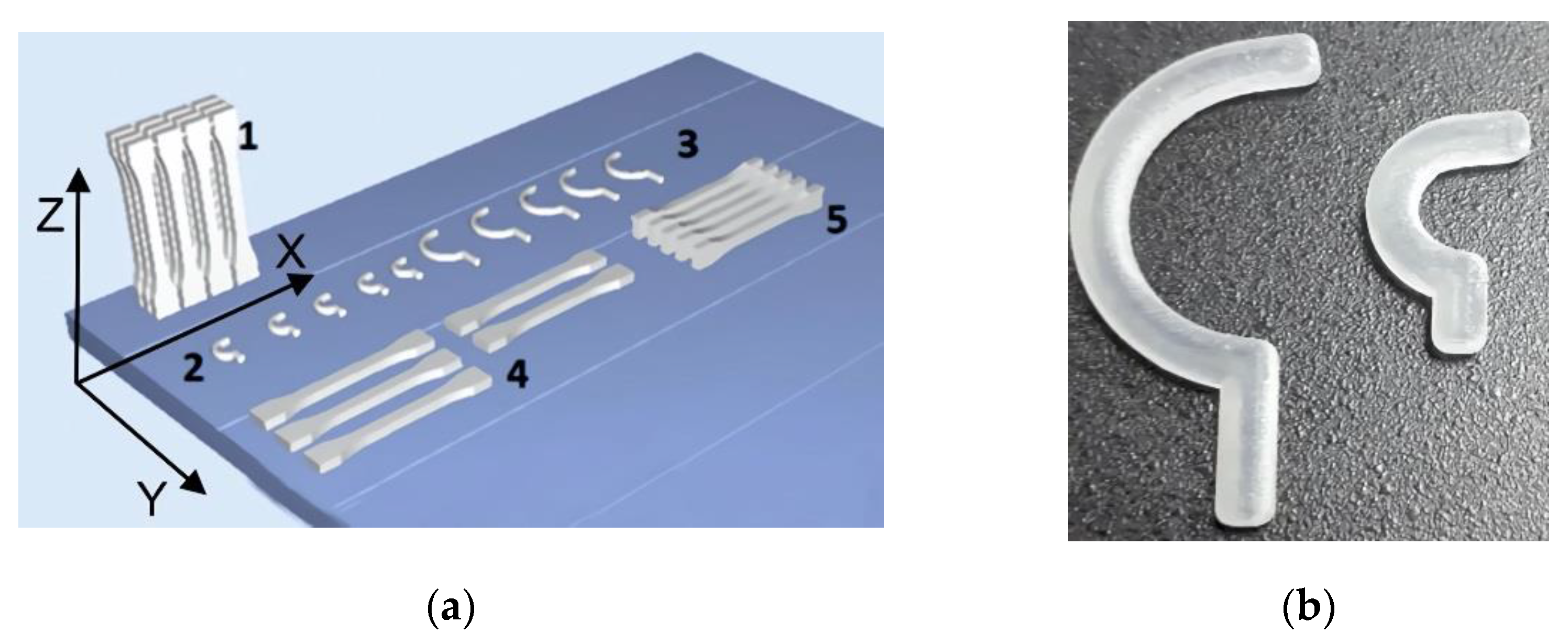

2.4. Samples Preparation

3. Results

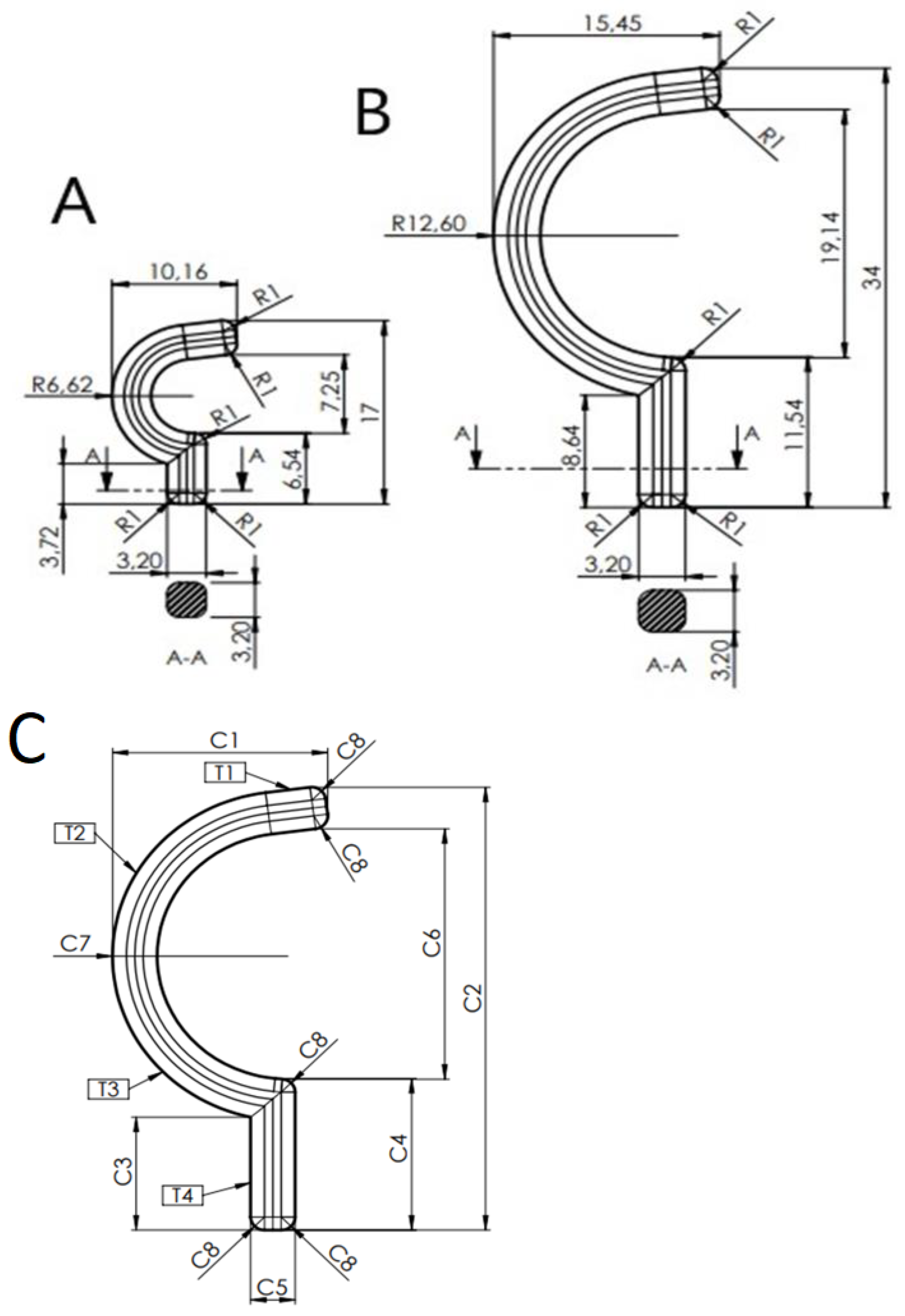

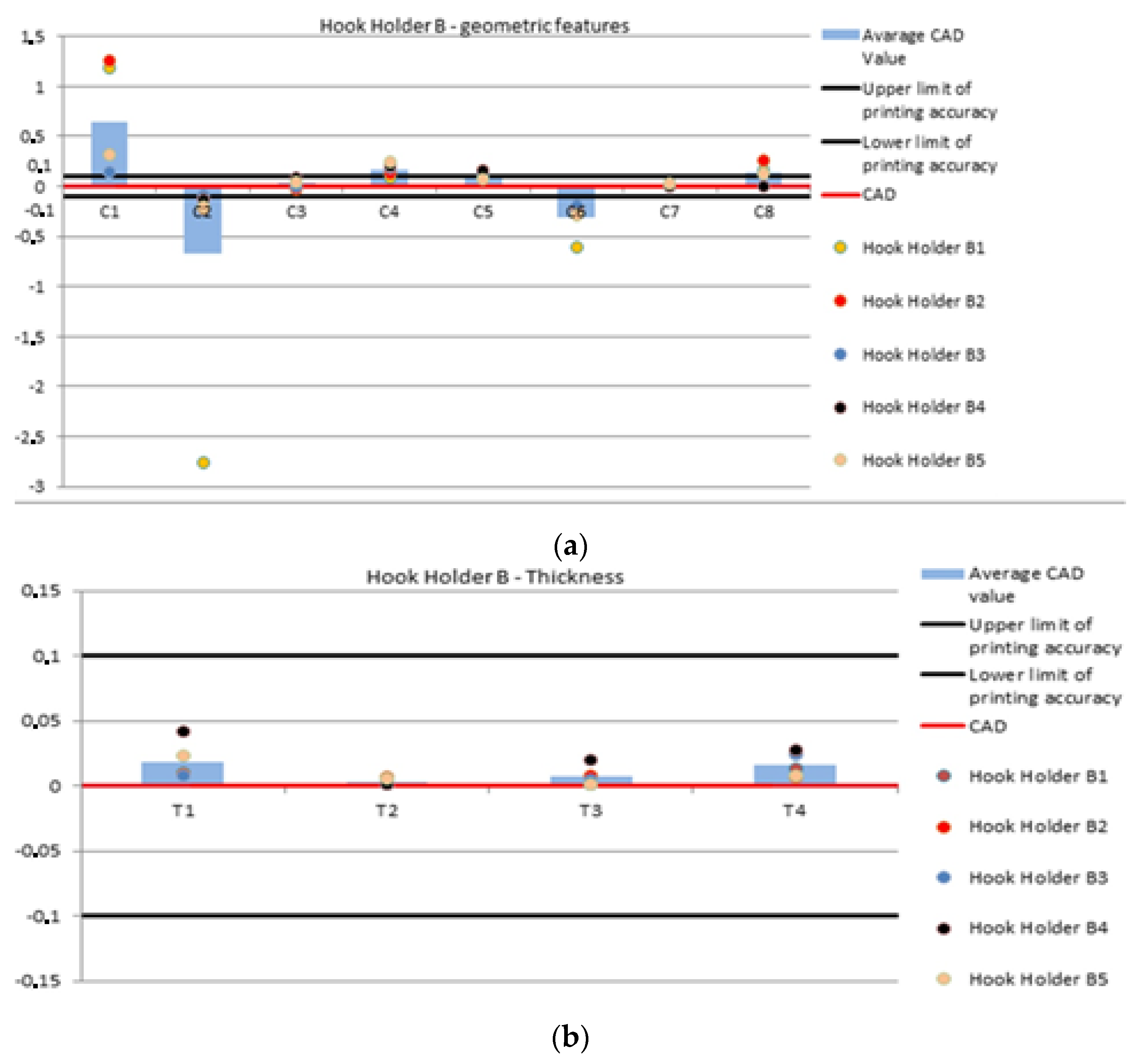

3.1. Dimensional and Shape Precision

- The red line represents the CAD form, which is the value imposed by the research team to make the holder.

- The black line named, respectively, 0.1 and −0.1 mm indicate the PolyJet printing precision, i.e., 0.1 mm.

- The average CAD value columns show the difference between the mean value and the value used in the CAD drawing, i.e.,

- Difference = average value − CAD value (4).

- Where the difference between the values will be represented as a mean value. The columns show how the mean value deviates from the given CAD dimension.

- The brown, red, blue, black and orange colored points represent the geometrical characteristics C1–C8 and T1–T4 for the measured holder.

3.2. Metrological Analysis

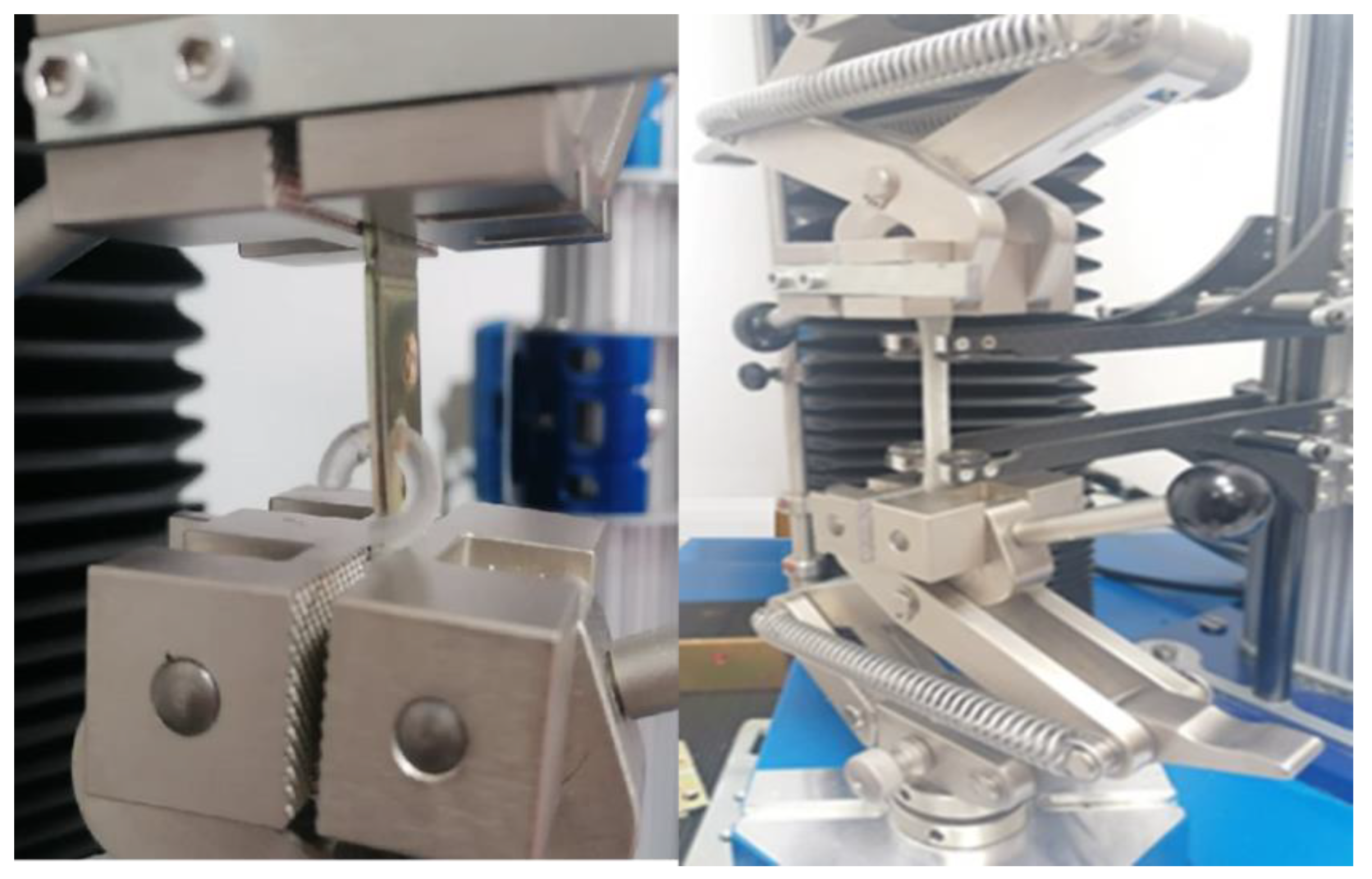

3.3. Mechanical Strength

- For the printing direction OX—1.29%,

- For the printing direction OY—2.32%,

- For the printing direction OZ—9.84%.

3.4. Solidworks Simulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Coakley, M.; Hurt, D.E. 3D Printing in the Laboratory: Maximize Time and Funds with Customized and Open-Source Labware. J. Lab. Autom. 2016, 21, 489–495. [Google Scholar] [CrossRef]

- Provaggi, E.; Leong, J.J.H.; Kalaskar, D.M. Applications of 3D printing in the management of severe spinal conditions. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017, 231, 471–486. [Google Scholar] [CrossRef]

- Saharudin, M.S.; Hajnys, J.; Kozior, T.; Gogolewski, D.; Zmarzły, P. Quality of Surface Texture and Mechanical Properties of PLA and PA-Based Material Reinforced with Carbon Fibers Manufactured by FDM and CFF 3D Printing Technologies. Polymers 2021, 13, 1671. [Google Scholar] [CrossRef]

- Bochnia, J.; Blasiak, S. Anisotrophy of mechanical properties of a material which is shaped incrementally using polyjet technology. In Proceedings of the 22nd International Conference Engineering Mechanics 2016, Svratka, Czech Republic, 9–12 May 2016. [Google Scholar]

- Kozior, T. The Influence of Selected Selective Laser Sintering Technology Process Parameters on Stress Relaxation, Mass of Models, and Their Surface Texture Quality. 3D Print. Addit. Manuf. 2020, 7, 126–138. [Google Scholar] [CrossRef]

- Pagáč, M.; Hajnyš, J.; Petrů, J.; ZLáMAL, T.; Šofer, M. The study of mechanical properties stainless steel 316L after production from metal powder with using additive technology and by method selective laser melting. In Proceedings of the METAL 2017—26th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 24–26 May 2017. [Google Scholar]

- Hanon, M.M.; Zsidai, L.; Ma, Q. Accuracy investigation of 3D printed PLA with various process parameters and different colors. Mater. Today Proc. 2021, 42, 3089–3096. [Google Scholar] [CrossRef]

- Gogolewski, D.; Bartkowiak, T.; Kozior, T.; Zmarzły, P. Multiscale analysis of surface texture quality of models manufactured by laser powder-bed fusion technology and machining from 316l steel. Materials 2021, 14, 2794. [Google Scholar] [CrossRef] [PubMed]

- Adamczak, S.; Zmarzly, P.; Kozior, T.; Gogolewski, D. Assessment of Roundness and Waviness Deviations of Elements Produced By Selective Laser Sintering Technology. Eng. Mech. 2017, 2017, 70–73. [Google Scholar]

- Paszkiewicz, A.; Bolanowski, M.; Budzik, G.; Przeszłowski, Ł.; Oleksy, M. Process of creating an integrated design and manufacturing environment as part of the structure of industry 4.0. Processes. 2020, 8, 1019. [Google Scholar] [CrossRef]

- Fina, F.; Madla, C.M.; Goyanes, A.; Zhang, J.; Gaisford, S.; Basit, A.W. Fabricating 3D printed orally disintegrating printlets using selective laser sintering. Int. J. Pharm. 2018, 541, 101–107. [Google Scholar] [CrossRef]

- Taormina, G.; Sciancalepore, C.; Messori, M.; Bondioli, F. 3D printing processes for photocurable polymeric materials: Technologies, materials, and future trends. J. Appl. Biomater. Funct. Mater. 2018, 16, 151–160. [Google Scholar] [CrossRef]

- Rimann, M.; Bono, E.; Annaheim, H.; Bleisch, M.; Graf-Hausner, U. Standardized 3D Bioprinting of Soft Tissue Models with Human Primary Cells. J. Lab. Autom. 2016, 21, 496–509. [Google Scholar] [CrossRef] [PubMed]

- Zmarzły, P. Technological heredity of the turning process. Teh. Vjesn. 2020, 27, 1194–1203. [Google Scholar] [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Wortmann, M.; Sabantina, L.; Ehrmann, A. Electrospinning on 3D printed polymers for mechanically stabilized filter composites. Polymers 2019, 11, 2034. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, A. 3D printed MEMS technology-recent developments and applications. Micromachines 2020, 11, 434. [Google Scholar] [CrossRef]

- Hanon, M.M.; Alshammas, Y.; Zsidai, L. Effect of print orientation and bronze existence on tribological and mechanical properties of 3D-printed bronze/PLA composite. Int. J. Adv. Manuf. Technol. 2020, 108, 553–570. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. The Road to Improved Fiber-Reinforced 3D Printing Technology. Technologies 2020, 8, 51. [Google Scholar] [CrossRef]

- Barclift, M.W.; Williams, C.B. Examining variability in the mechanical properties of parts manufactured via polyjet direct 3D printing. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2012, Austin, TX, USA, 6–8 August 2012. [Google Scholar]

- Bandyopadhyay, A.; Bose, S.; Das, S. 3D printing of biomaterials. MRS Bull. 2015, 40, 108–115. [Google Scholar] [CrossRef]

- Zmarzły, P.; Gogolewski, D.; Kozior, T. Design guidelines for plastic casting using 3D printing. J. Eng. Fiber. Fabr. 2020, 15, 1–10. [Google Scholar] [CrossRef]

- Dziubek, T.; Sobolewski, B.; Filip, M. Development and evaluation of correction factors which increase the accuracy of models of research carried out in the form of geometric primitives for additive manufacturing methods PolyJet. Mechanik 2016. [Google Scholar] [CrossRef][Green Version]

- Šercer, M.; Rezic, T.; Godec, D.; Oros, D.; Pilipovic, A.; Ivušic, F.; Rezic, I.; Andlar, M.; Ludwig, R.; Šantek, B. Microreactor production by PolyJet Matrix 3D-printing technology: Hydrodynamic characterization. Food Technol. Biotechnol. 2019. [Google Scholar] [CrossRef] [PubMed]

- Intuitive Da Vinci X/Xi Instrument & Accessory Catalog November 2020. Available online: https://www.intuitive.com/en-us/-/media/Project/Intuitive-surgical/files/pdf/xi-x-ina-catalog-no-pricing-us-1052082.pdf?la=en&hash=189164507BDFEC40E9DAB44BA10731A5 (accessed on 19 January 2022).

- Morley, T.A.; Baron, D.S.; Wallace, D.T. Minimally Invasive Surgical Hook Apparatus. Available online: https://patentimages.storage.googleapis.com/bf/b0/07/357cb15148483d/US7276065B2.pdf (accessed on 21 December 2021).

- Abuhav, I. ISO 13485: A Complete Guide to Quality Management in the Medical Device Industry; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Bochnia, J.; Blasiak, M.; Kozior, T. Tensile strength analysis of thin-walled polymer glass fiber reinforced samples manufactured by 3d printing technology. Polymers 2020, 12, 2783. [Google Scholar] [CrossRef]

- Bochnia, J.; Blasiak, M.; Kozior, T. A Comparative Study of the Mechanical Properties of FDM 3D Prints Made of PLA and Carbon Fiber-Reinforced PLA for Thin-Walled Applications. Materials 2021, 14, 7062. [Google Scholar] [CrossRef] [PubMed]

- Kitamori, H.; Sumida, I.; Tsujimoto, T.; Shimamoto, H.; Murakami, S.; Ohki, M. Evaluation of mouthpiece fixation devices for head and neck radiotherapy patients fabricated in PolyJet photopolymer by a 3D printer. Phys. Med. 2019. [Google Scholar] [CrossRef] [PubMed]

- EN ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity; ISO: Geneva, Switzerland, 2009.

- EN ISO 10993-10:2013; Biological Evaluation of Medical Devices—Part 10: Tests for Irritation and Skin Sensitization; ISO: Geneva, Switzerland, 2013.

- EN ISO 10993-3:2014; Biological Evaluation of Medical Devices—Part 3: Tests for Genotoxicity, Carcinogenicity and Reproductive Toxicit; ISO: Geneva, Switzerland, 2014.

- EN ISO 10993-18:2009; Biological Evaluation of Medical Devices—Part 18: Chemical Characterization of Materials; ISO: Geneva, Switzerland, 2009.

- Stratasys MSDS Clear Bio-Compatible MED610. Available online: https://www.sys-uk.com/wp-content/uploads/2016/01/MSDS-Clear-Bio-Compatible-MED610-English-US-1.pdf (accessed on 21 December 2021).

- Stratasys Biocompatible Clear MED610. Available online: https://cadxpert.pl/wp-content/uploads/2019/03/spec_PolyJet_MED610_MED620.pdf (accessed on 21 December 2021).

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T.G. Waviness of Freeform Surface Characterizations from Austenitic Stainless Steel (316L) Manufactured by 3D Printing-Selective Laser Melting (SLM) Technology. Materials 2020, 13, 4372. [Google Scholar] [CrossRef] [PubMed]

- Doitrand, A.; Martin, E.; Leguillon, D. Numerical implementation of the coupled criterion: Matched asymptotic and full finite element approaches. Finite Elem. Anal. Des. 2020, 168, 103344. [Google Scholar] [CrossRef]

| Properties | |||

|---|---|---|---|

| Property | Standard | Value | |

| Tensile strength | D-638-03 | 50–65 MPa | |

| Ultimate elongation | D-638-05 | 10–25% | |

| Young’s modulus | D-638-04 | 2000–3000 MPa | |

| Bending strength | D-790-03 | 75–110 MPa | |

| Modulus of elasticity in bending | D-790-04 | 2200–3200 MPa | |

| Poisson ratio * | ASTM D638-10 | 0.41 | |

| Deflection temperature (under load of 0.46 MPa) | D-648-06 | 45–50 °C | |

| Water absorption | D-570-98 24HR | 1.1–1.5% | |

| Shore hardness | D Scale | 83–85 D | |

| Rockwell hardness | M Scale | 73–76 M | |

| Biocompatibility | PN-EN ISO 10993-1:2017 | Skin contact: - more than 30 days Contact with mucous membrane: - up to 24 h | |

| Chemical composition | |||

| Component | % of weights | ||

| Isbornyl acrylate | 15–30 | ||

| Acrylic monomer | 15–30 | ||

| Urethane acrylate | 10–30 | ||

| Acrylic monomer | 5–10; 10–15 | ||

| Epoxy acrylate | 5–10; 10–15 | ||

| Arylate oligomer | 5–10; 10–15 | ||

| Photoinitiator | 0.1–1; 1–2 | ||

| Geometric Characteristic and Thickness (mm) | CAD Dimensional | Samples | Average | SD | Hook Holder | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||||

| C1 | 10.16 | 8.333 | 9.956 | 10.767 | 11.052 | 10.663 | 10.1542 | 1.095 | A |

| C2 | 17 | 16.945 | 17.325 | 14.766 | 13.706 | 14.637 | 15.476 | 1.575 | |

| C3 | 3.72 | 3.795 | 3.642 | 3.799 | 3.893 | 3.807 | 3.787 | 0.091 | |

| C4 | 6.54 | 6.684 | 6.773 | 6.671 | 6.883 | 6.737 | 6.75 | 0.085 | |

| C5 | 3.2 | 3.305 | 3.223 | 3.302 | 3.356 | 3.26 | 3.289 | 0.05 | |

| C6 | 7.25 | 6.912 | 7.33 | 7.193 | 6.924 | 6.966 | 7.065 | 0.187 | |

| C7 | 6.62 | 6.666 | 6.642 | 6.607 | 6.580 | 6.494 | 6.598 | 0.066 | |

| C8 | 1 | 0.949 | 1.279 | 1.205 | 1.1741 | 1.125 | 1.147 | 0.111 | |

| T1 | 3.2 | 3.221 | 3.226 | 3.243 | 3.201 | 3.221 | 3.222 | 0.015 | |

| T2 | 3.2 | 3.215 | 3.227 | 3.226 | 3.216 | 3.218 | 3.220 | 0.006 | |

| T3 | 3.2 | 3.218 | 3.276 | 3.216 | 3.208 | 3.202 | 3.224 | 0.03 | |

| T4 | 3.2 | 3.205 | 3.275 | 3.217 | 3.206 | 3.221 | 3.225 | 0.029 | |

| C1 | 15.45 | 16.631 | 16.709 | 15.601 | 15.775 | 15.771 | 16.097 | 0.528 | B |

| C2 | 34 | 31.241 | 33.79 | 33.921 | 33.876 | 33.804 | 33.326 | 1.167 | |

| C3 | 8.64 | 8.701 | 8.616 | 8.646 | 8.733 | 8.679 | 8.675 | 0.046 | |

| C4 | 11.54 | 11.627 | 11.665 | 11.734 | 11.74 | 11.79 | 11.711 | 0.067 | |

| C5 | 3.2 | 3.298 | 3.361 | 3.35 | 3.365 | 3.28 | 3.331 | 0.039 | |

| C6 | 19.14 | 18.529 | 18.93 | 18.955 | 18.87 | 18.856 | 18.828 | 0.528 | |

| C7 | 12.6 | 12.595 | 12.628 | 12.626 | 12.608 | 12.628 | 12.617 | 0.172 | |

| C8 | 1 | 1.159 | 1.255 | 1.129 | 0.998 | 1.125 | 1.133 | 0.092 | |

| T1 | 3.2 | 3.21 | 3.209 | 3.208 | 3.242 | 3.223 | 3.218 | 0.015 | |

| T2 | 3.2 | 3.201 | 3.207 | 3.203 | 3.201 | 3.206 | 3.204 | 0.003 | |

| T3 | 3.2 | 3.202 | 3.208 | 3.205 | 3.22 | 3.201 | 3.207 | 0.008 | |

| T4 | 3.2 | 3.214 | 3.207 | 3.224 | 3.228 | 3.208 | 3.216 | 0.009 | |

| Hook Holder A | ||||||||

| C1 (mm) | C2 (mm) | C3 (mm) | C4 (mm) | C5 (mm) | C6 (mm) | C7 (mm) | C8 (mm) | |

| A1 | −1.827 | −0.055 | 0.075 | 0.144 | 0.105 | −0.338 | 0.046 | −0.051 |

| A2 | −0.204 | 0.325 | −0.078 | 0.233 | 0.023 | 0.08 | 0.022 | 0.279 |

| A3 | 0.607 | −2.234 | 0.079 | 0.131 | 0.102 | −0.057 | −0.013 | 0.205 |

| A4 | 0.892 | −3.294 | 0.173 | 0.343 | 0.156 | −0.326 | −0.04 | 0.174 |

| A5 | 0.503 | −2.363 | 0.087 | 0.197 | 0.06 | −0.284 | −0.126 | 0.125 |

| Difference (mean value) | −0.006 | −1.524 | 0.067 | 0.21 | 0.089 | −0.185 | −0.022 | 0.147 |

| Hook Holder B | ||||||||

| C1 (mm) | C2 (mm) | C3 (mm) | C4 (mm) | C5 (mm) | C6 (mm) | C7 (mm) | C8 (mm) | |

| B1 | 1.181 | −2.759 | 0.061 | 0.087 | 0.098 | −0.611 | −0.005 | 0.159 |

| B2 | 1.259 | −0.21 | −0.024 | 0.125 | 0.161 | −0.21 | 0.028 | 0.255 |

| B3 | 0.151 | −0.079 | 0.006 | 0.194 | 0.15 | −0.185 | 0.026 | 0.129 |

| B4 | 0.325 | −0.124 | 0.093 | 0.2 | 0.165 | −0.27 | 0.0078 | −0.002 |

| B5 | 0.321 | −0.196 | 0.039 | 0.25 | 0.08 | −0.284 | 0.028 | 0.125 |

| Difference (mean value) | 0.647 | −0.674 | 0.035 | 0.171 | 0.131 | −0.312 | 0.017 | 0.133 |

| Hook Holder A | ||||

| T1 (mm) | T2 (mm) | T3 (mm) | T4 (mm) | |

| A1 | 0.021 | 0.015 | 0.018 | 0.005 |

| A2 | 0.026 | 0.027 | 0.076 | 0.075 |

| A3 | 0.043 | 0.026 | 0.016 | 0.017 |

| A4 | 0.001 | 0.016 | 0.008 | 0.006 |

| A5 | 0.021 | 0.018 | 0.002 | 0.021 |

| Difference (mean value) | 0.023 | 0.02 | 0.024 | 0.025 |

| Hook Holder B | ||||

| T1 (mm) | T2 (mm) | T3 (mm) | T4 (mm) | |

| B1 | 0.01 | 0.001 | 0.002 | 0.014 |

| B2 | 0.009 | 0.007 | 0.008 | 0.007 |

| B3 | 0.008 | 0.003 | 0.005 | 0.024 |

| B4 | 0.042 | 0.001 | 0.02 | 0.028 |

| B5 | 0.023 | 0.006 | 0.001 | 0.008 |

| Difference (mean value) | 0.018 | 0.004 | 0.007 | 0.016 |

| Test Number | Cross-Section (mm) | Maximum Load | Hook Holder |

|---|---|---|---|

| 1 | 10.24 | 36.8 | A |

| 2 | 45.7 | ||

| 3 | 27.3 | ||

| 4 | 46.3 | ||

| 5 | 49.1 | ||

| 41.1 | |||

| 8.95 | |||

| 1 | 10.24 | 46.3 | B |

| 2 | 48.9 | ||

| 3 | 43.8 | ||

| 4 | 30.2 | ||

| 5 | 40.0 | ||

| 41.8 | |||

| 7.3 | |||

| Test Number | Cross Section of Sample S(mm2) | Axis | ||

|---|---|---|---|---|

| 1 | 20.0694 | 1045.7 | 52.11 | OX |

| 2 | 1051.7 | 52.40 | ||

| 3 | 1061.4 | 52.89 | ||

| 4 | 1025.2 | 51.08 | ||

| 5 | 1051.4 | 52.39 | ||

| 1047.08 | 52.17 | |||

| 13.48 | 0.67 | |||

| 1 | 19.9796 | 967.0 | 48.40 | OY |

| 2 | 1008.5 | 50.48 | ||

| 3 | 1014.3 | 50.77 | ||

| 4 | 964.6 | 48.28 | ||

| 5 | 988.2 | 49.46 | ||

| 988.51 | 49.48 | |||

| 22.90 | 1.15 | |||

| 1 | 21.3725 | 372.8 | 17.4 | OZ |

| 2 | 320.3 | 15.0 | ||

| 3 | 384.4 | 18.0 | ||

| 4 | 314.3 | 14.7 | ||

| 5 | 318.4 | 14.9 | ||

| 342.04 | 16.00 | |||

| 33.68 | 1.58 | |||

| Hook A (Numbers of Nodes) | Hook A (Numbers of Triangles) | Hook B (Numbers of Nodes) | Hook B (Numbers of Triangles) | |

|---|---|---|---|---|

| Mesh (not densified) | 75,912 | 52,073 | 106,484 | 73,162 |

| Mesh densified | 107,395 | 74,441 | 150,692 | 104,287 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozior, T.; Bochnia, J.; Gogolewski, D.; Zmarzły, P.; Rudnik, M.; Szot, W.; Szczygieł, P.; Musiałek, M. Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications. Polymers 2022, 14, 408. https://doi.org/10.3390/polym14030408

Kozior T, Bochnia J, Gogolewski D, Zmarzły P, Rudnik M, Szot W, Szczygieł P, Musiałek M. Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications. Polymers. 2022; 14(3):408. https://doi.org/10.3390/polym14030408

Chicago/Turabian StyleKozior, Tomasz, Jerzy Bochnia, Damian Gogolewski, Paweł Zmarzły, Mateusz Rudnik, Wiktor Szot, Paweł Szczygieł, and Mateusz Musiałek. 2022. "Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications" Polymers 14, no. 3: 408. https://doi.org/10.3390/polym14030408

APA StyleKozior, T., Bochnia, J., Gogolewski, D., Zmarzły, P., Rudnik, M., Szot, W., Szczygieł, P., & Musiałek, M. (2022). Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications. Polymers, 14(3), 408. https://doi.org/10.3390/polym14030408