A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity

Abstract

1. Introduction

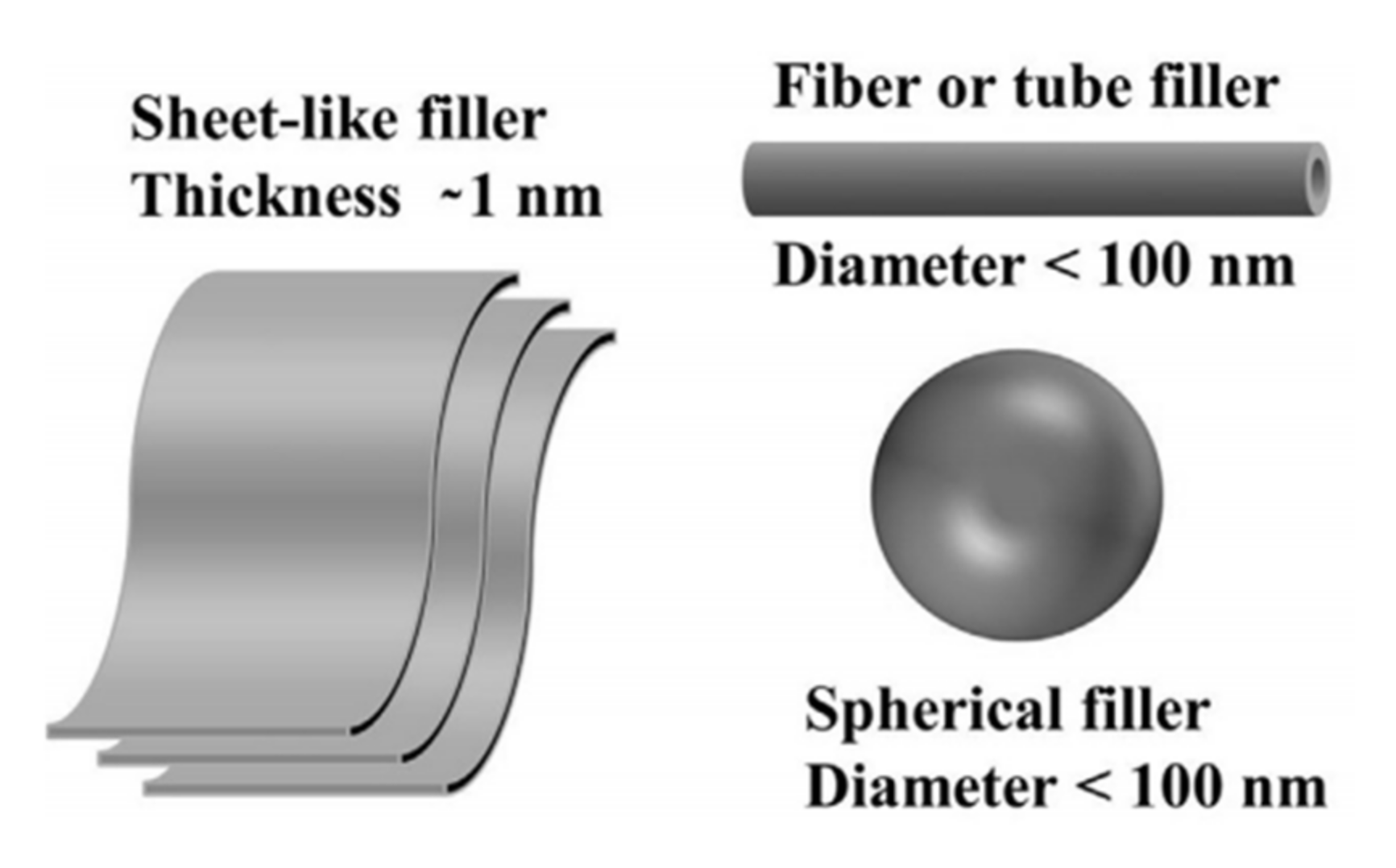

- Zero-dimensional nanofillers: all dimensions are at the nanoscale (<100 nm). 0-D nanofillers are also known as nanoparticles;

- One-dimensional nanofillers: one dimension only is not at the nanoscale. Such materials include nanotubes, nanofibers, nanowires, and nanorods, e.g., carbon and halloysite nanotubes;

- Two-dimensional nanofillers: exactly two dimensions are not at the nanoscale. These include nanofilms and nanoplates/sheets, e.g., graphene sheets and layered silicate.

2. Modeling the Mechanical Behavior of Polymers and Polymer Nanocomposites

2.1. General Modeling and Simulation Methods

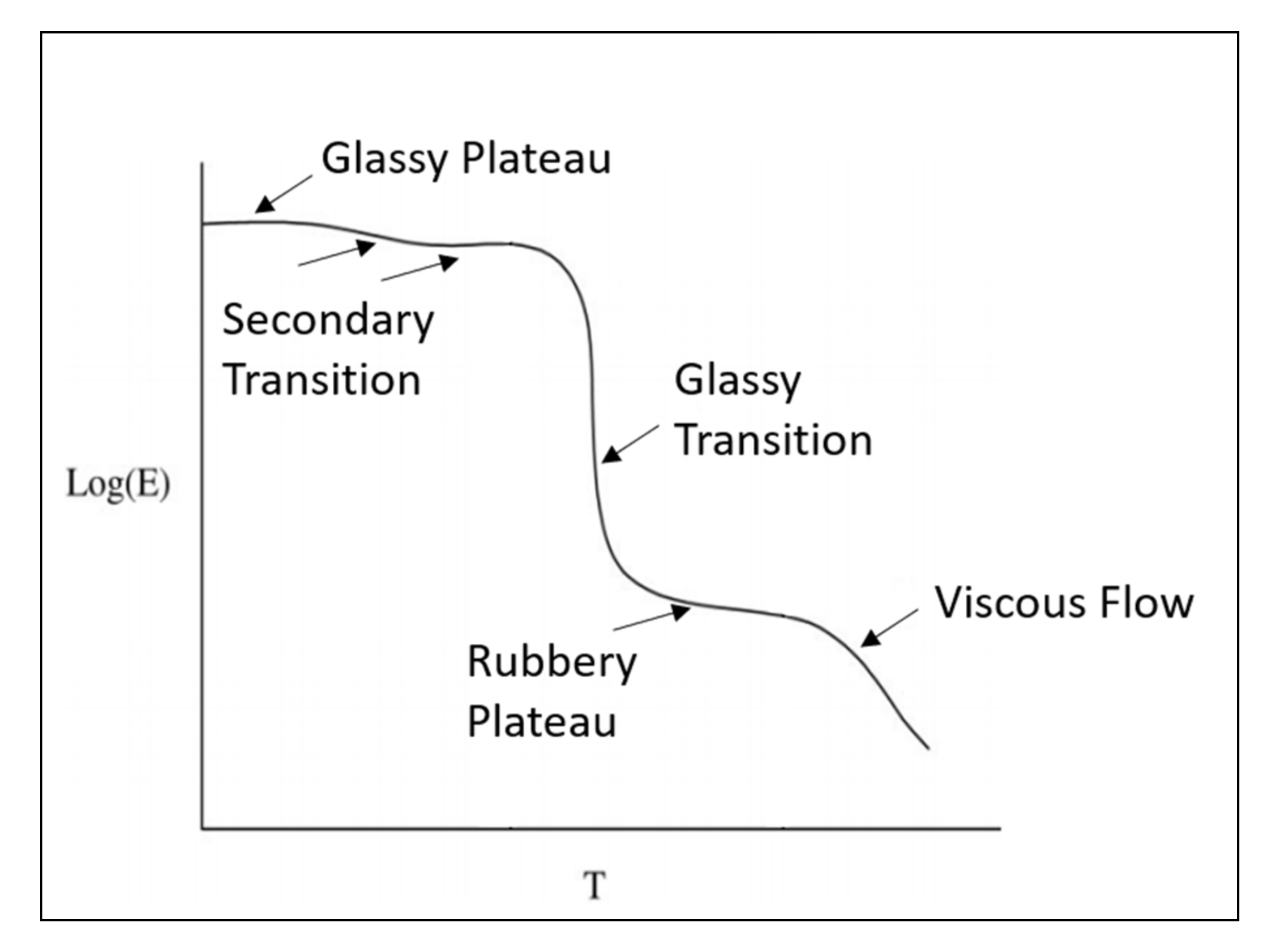

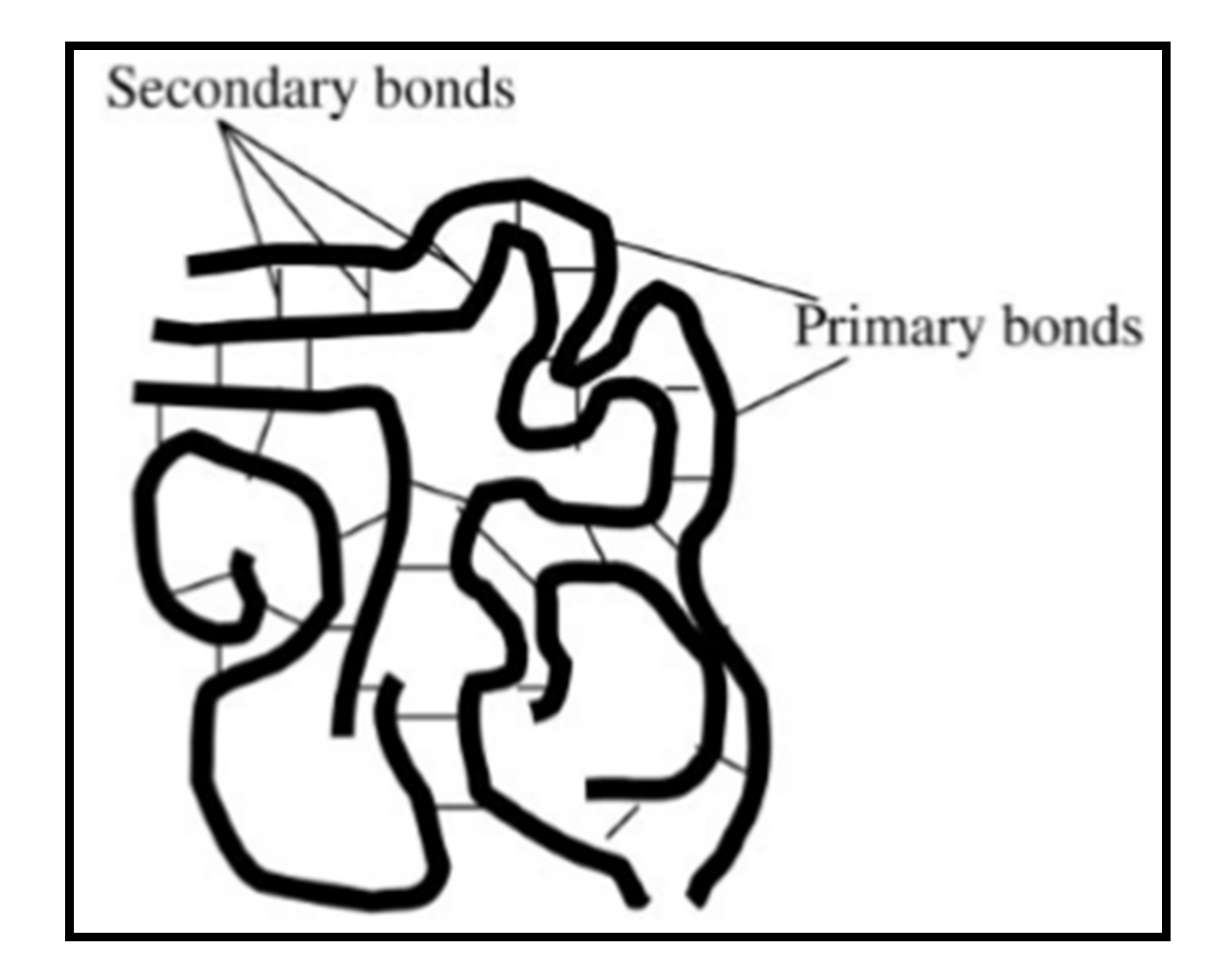

2.2. Elastic Behavior of Polymers

- (1)

- The glassy region where the modulus is high (in GPa);

- (2)

- The glass transition region where the modulus sharply goes down;

- (3)

- The rubbery region where the modulus is low (in MPa);

- (4)

- The viscous region where a polymer begins to flow;

- (5)

- Decomposition region where the chemical breakdown begins.

- (1)

- The glass region and secondary relaxation

- (2)

- The glass transition region

- (3)

- The rubbery region

- (4)

- Viscous flow region

- (5)

- Decomposition region

2.3. Mahieux and Reifsnider Model for the Elastic Modulus

2.4. Richeton Model for the Elastic Modulus

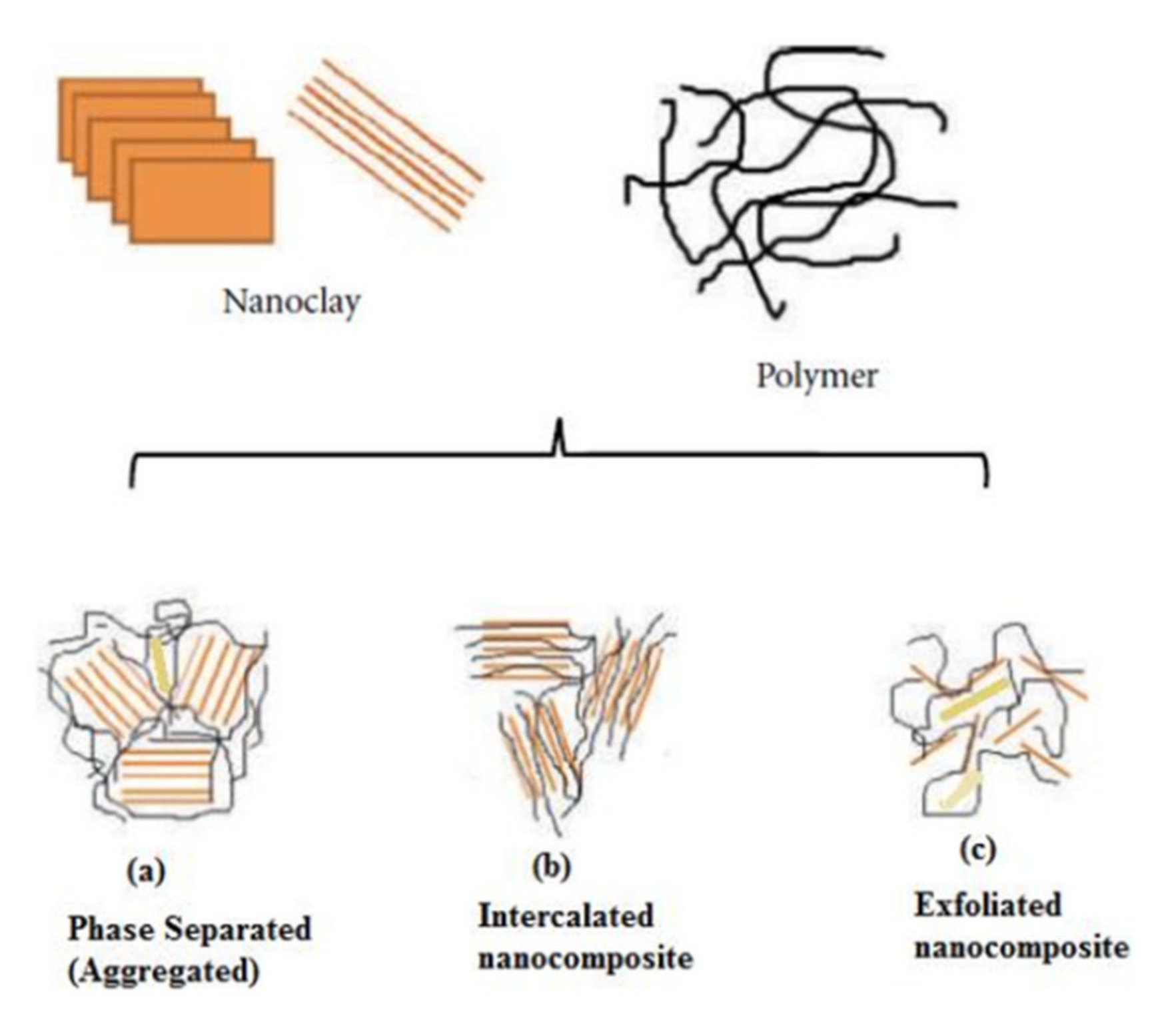

3. Elastic Behavior of Polymer Nanocomposites

3.1. Halpin-Tsai Model

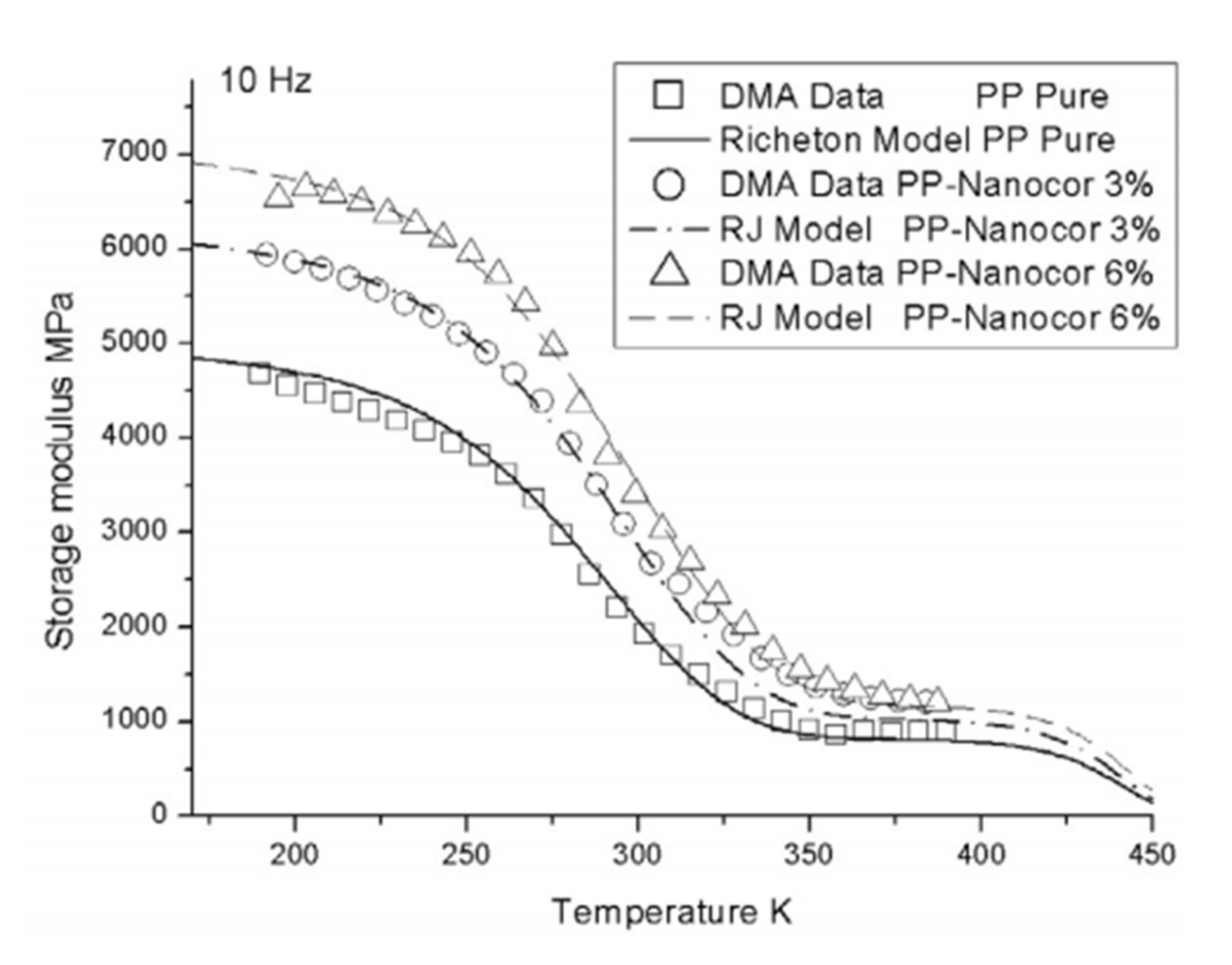

3.2. Richeton-Ji Model for the Elastic Modulus

3.3. The Richeton-Tandon-Weng Model for the Elastic Modulus

4. Yield Stress of Polymers and Polymer Nanocomposites

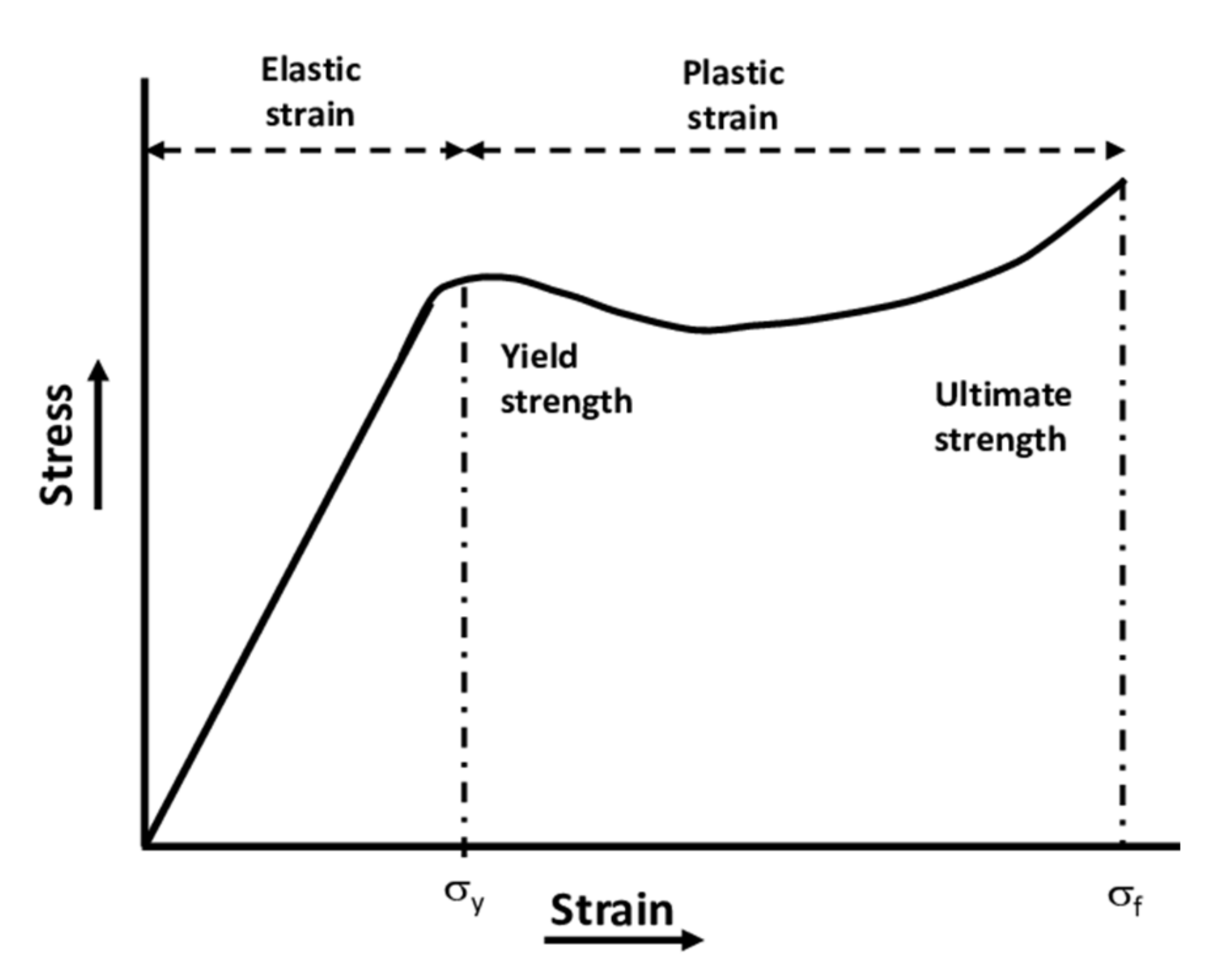

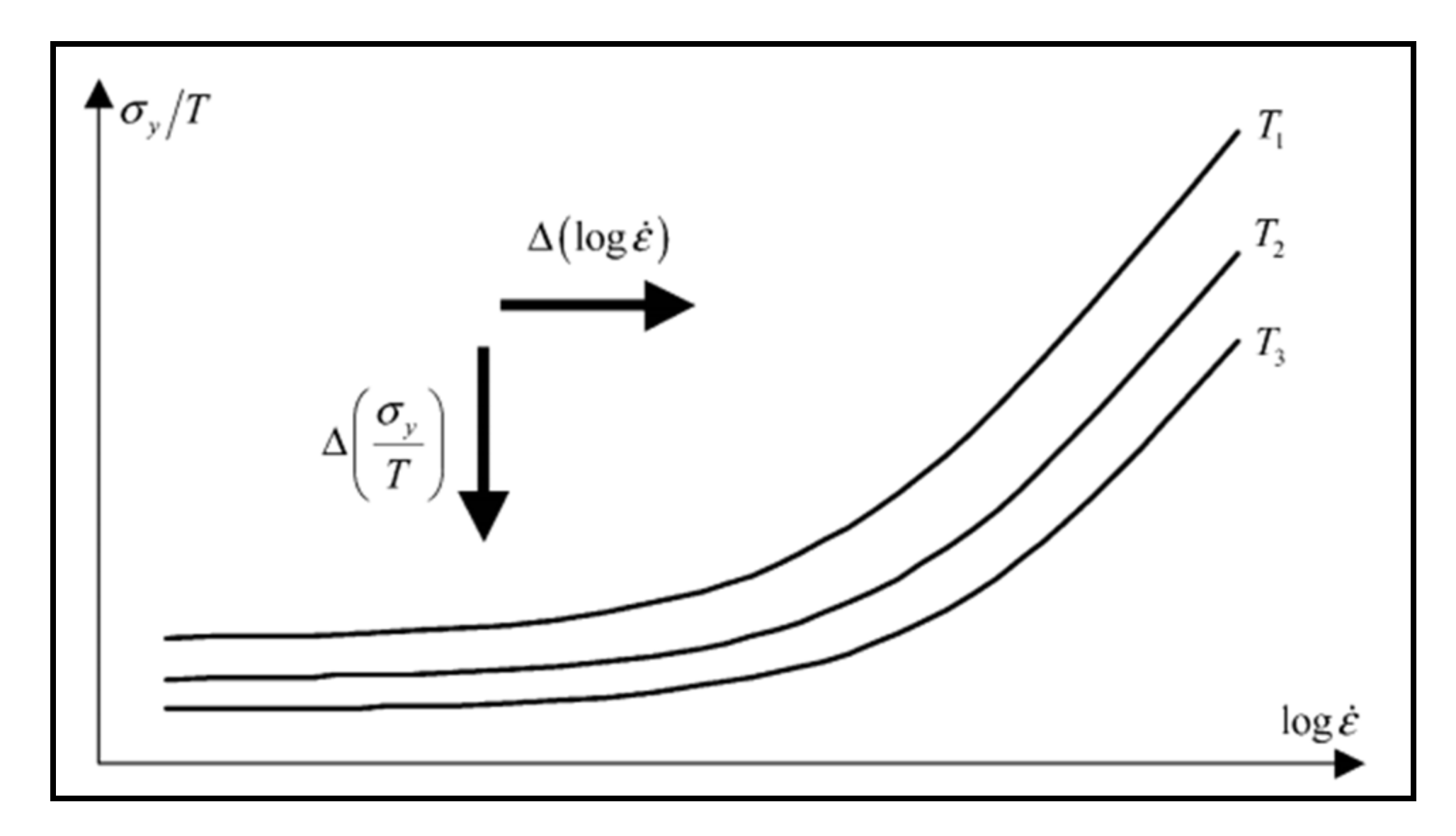

4.1. Yield Stress of Polymers

4.1.1. Eyring Model

4.1.2. Argon Model

4.1.3. The Modified Argon Model

4.1.4. The Ree-Eyring Model

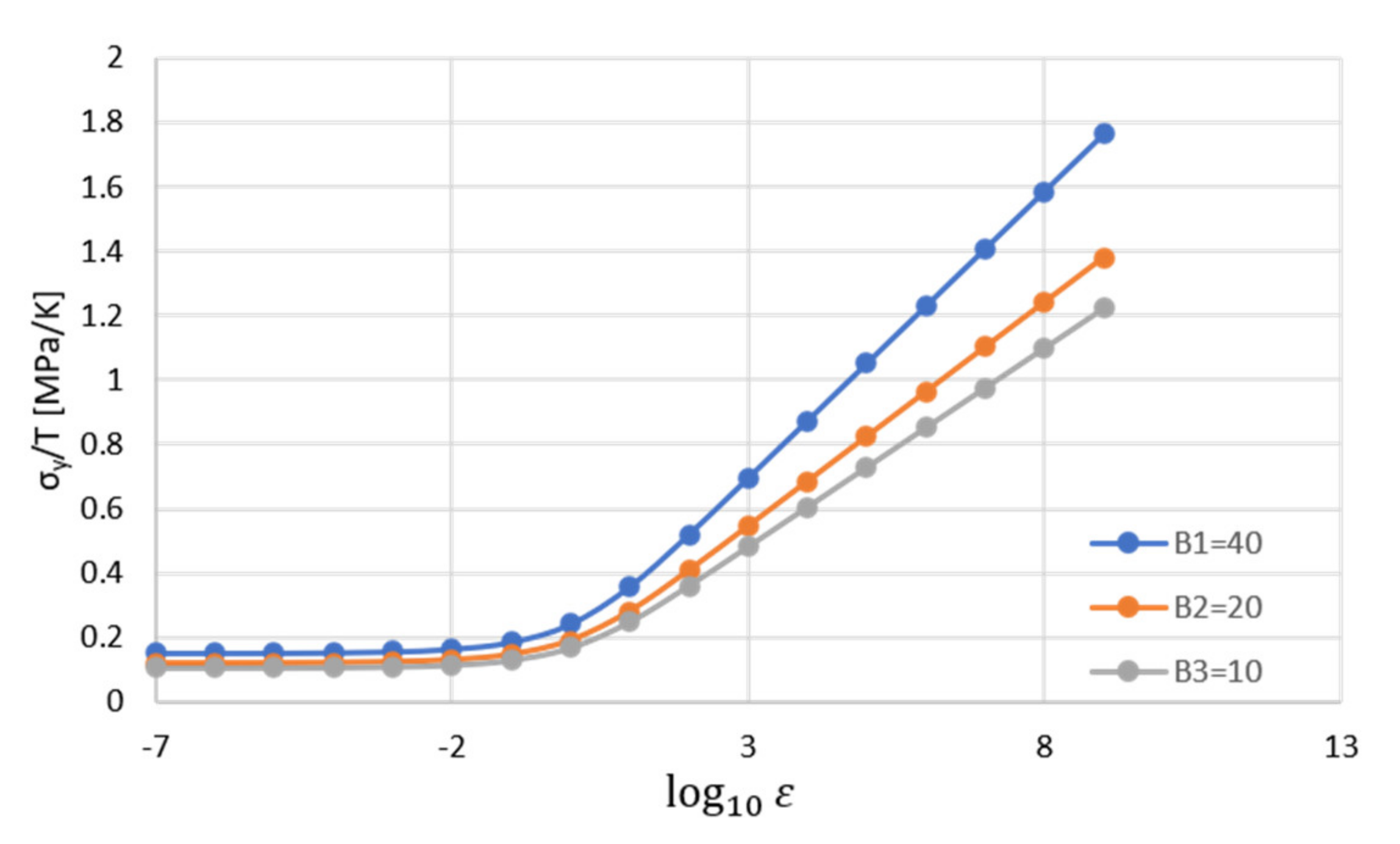

4.1.5. Cooperative Model: Governing Equations

4.1.6. Cooperative Model: Yield Stress for Semi-Crystalline Polymers

4.2. Yield Stress of Polymer Nanocomposites (Extended Cooperative Mode)

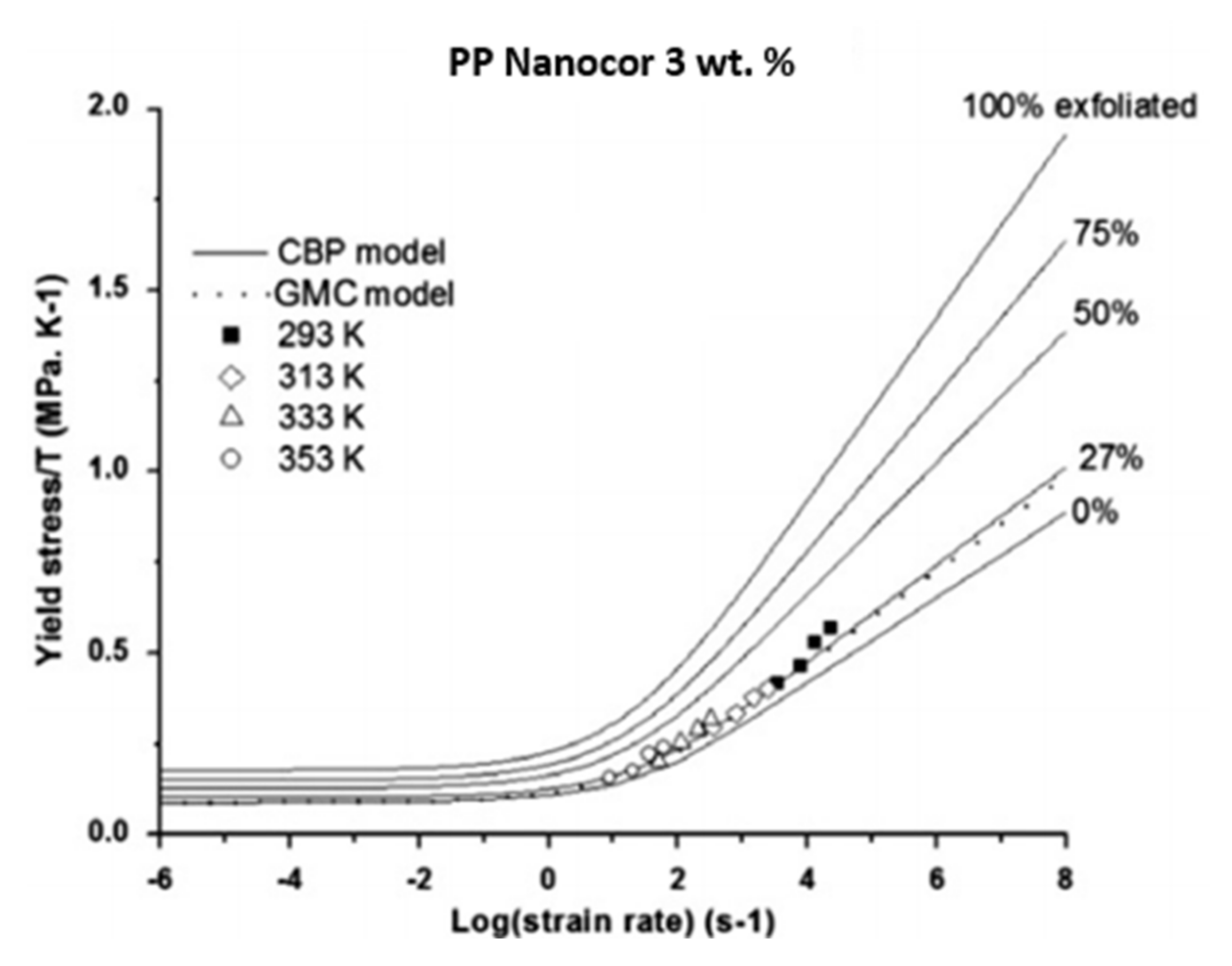

4.2.1. GMC Model

4.2.2. CBP Model

5. Modeling the Porosity Effect on the Mechanical Behavior

5.1. Power Law for Modeling Porosity

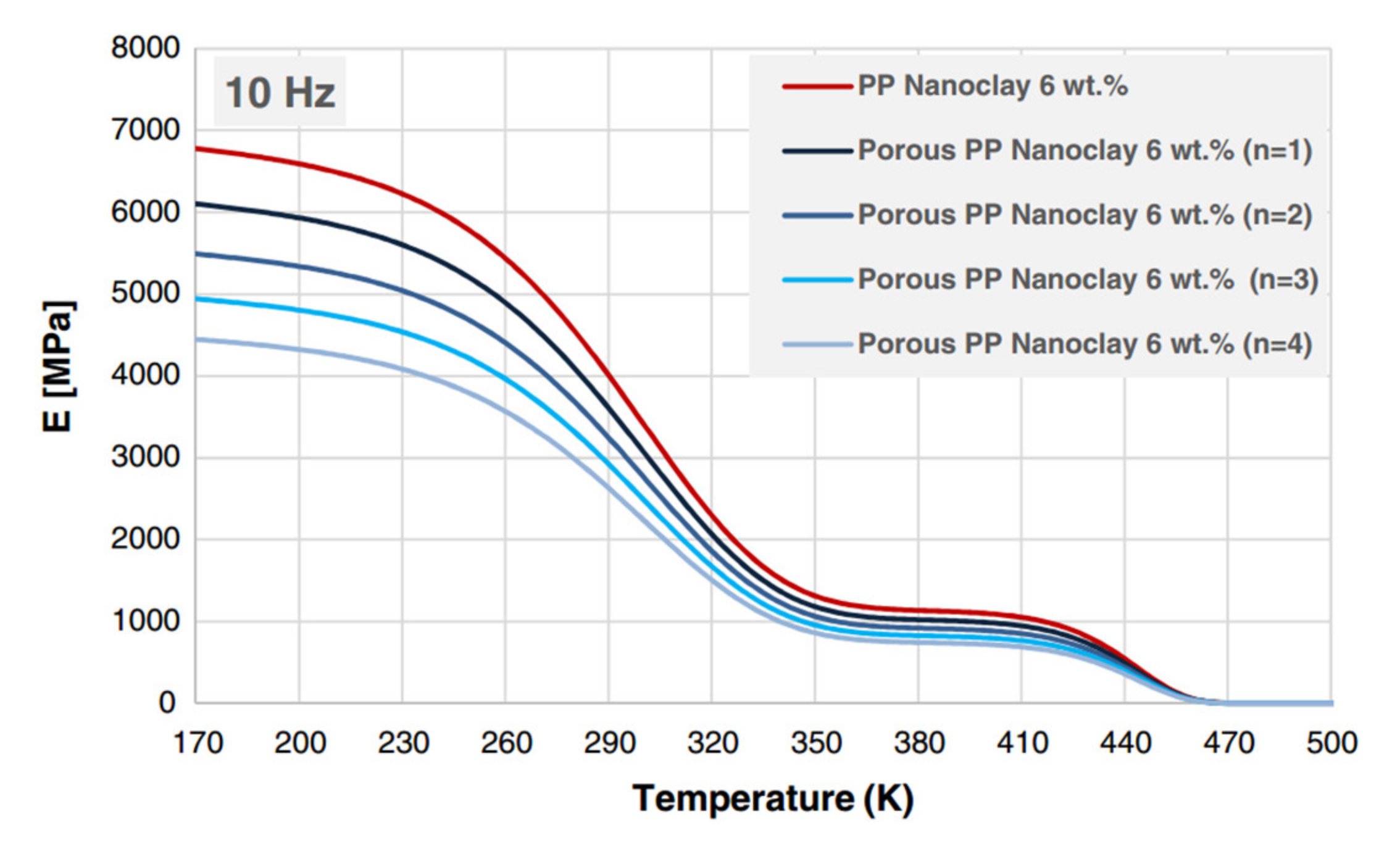

5.2. Modeling the Mechanical Behavior of Porous Polymers and Polymer Nanocomposites

5.2.1. Elastic Modulus

5.2.2. Yield Stress

6. Three Dimensional Computational Implementation to the Elastic-Plastic Stress-Strain Curve

7. Experimental Characterization of Mechanical Behavior of Polymers and Polymer Nanocomposites

8. Modeling of the Mechanical Behavior of Polymer Nanocomposites: Application Cases

9. Conclusions

- The recent models used to predict the elastic modulus and yield stress of porous polymers/polymer nanocomposites have performed a sensitivity analysis on the pore morphology factor (n). More investigation on this parameter can be helpful to determine its value depending on the microstructural features of the chosen material;

- There is a need to conduct experiments on different porous polymeric materials or polymeric nanocomposite materials. This will help in increasing the validity of the models for the prediction of the elastic modulus and yield stress of porous polymers/polymer nanocomposites. Future experiments can include DMA tests as well as uniaxial compression/tension tests;

- The model given by Equation (45) for the yield stress prediction can be further modified by considering the three parameters of B presented in Equation (36). A study can be done to investigate how this modification can improve the prediction of the agglomeration for nanofillers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashby, M.F.; Schodek, D.L.; Ferreira, P. Nanomaterials: Classes and fundamentals. In Nanomaterials, Nanotechnologies and Design: An Introduction for Engineers and Architects; Elsiever: Amsterdam, The Netherlands, 2009; pp. 177–197. [Google Scholar]

- Fu, S.-Y.; Sun, Z.; Huang, P.; Li, Y.-Q.; Hu, N. Some basic aspects of polymer nanocomposites: A critical review. Nano Mater. Sci. 2019, 1, 2–30. [Google Scholar] [CrossRef]

- Harito, C.; Bavykin, D.V.; Yuliarto, B.; Dipojono, H.; Walsh, F.C. Polymer nanocomposites having a high filler content: Synthesis, structures, properties, and applications. Nanoscale 2019, 11, 4653–4682. [Google Scholar] [CrossRef]

- De Oliveira, A.D.; Beatrice, C.A.G. Polymer Nanocomposites with Different Types of Nanofiller. In Nanocomposites-Recent Evolutions; Intech Open: London, UK, 2018; pp. 103–128. [Google Scholar]

- Khan, W.S.; Hamadneh, N.N.; Khan, W.A. Polymer nanocomposites—Synthesis techniques, classification and properties. In Science and Applications of Tailored Nanostructures; Di Sia, P., Ed.; One Central Press (OCP): Cheshire, UK, 2017; pp. 50–67. [Google Scholar]

- Cho, J.; Paul, D. Nylon 6 nanocomposites by melt compounding. Polymer 2001, 42, 1083–1094. [Google Scholar] [CrossRef]

- Liu, L.; Qi, Z.; Zhu, X. Studies on Nylon 6/Clay Nanocomposites by Melt-Intercalation Process. J. Appl. Polym. Sci. 1999, 71, 1133–1138. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, S.; Qi, Z. Synthesis and Characterization of Elastomeric Polyurethane/Clay Nanocomposites. J. Appl. Polym. Sci. 2001, 82, 1444–1448. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Mahmoodi, M.J. Micromechanics-based characterization of elastic properties of shape memory polymer nanocomposites containing SiO2 nanoparticles. J. Intell. Mater. Syst. Struct. 2018, 29, 2392–2405. [Google Scholar] [CrossRef]

- Xie, S.; Harkin-Jones, E.; Shen, Y.; Hornsby, P.; McAfee, M.; McNally, T.; Patel, R.; Benkreira, H.; Coates, P. Quantitative characterization of clay dispersion in polypropylene-clay nanocomposites by combined transmission electron microscopy and optical microscopy. Mater. Lett. 2010, 64, 185–188. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M. Prediction of electrical conductivity of carbon fiber-carbon nanotube-reinforced polymer hybrid composites. Compos. Part B Eng. 2019, 167, 728–735. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. The effect of nanoparticle conglomeration on the overall conductivity of nanocomposites. Int. J. Eng. Sci. 2020, 157, 103392. [Google Scholar] [CrossRef]

- Haghgoo, M.; Ansari, R.; Hassanzadeh-Aghdam, M. Predicting effective electrical resistivity and conductivity of carbon nanotube/carbon black-filled polymer matrix hybrid nanocomposites. J. Phys. Chem. Solids 2021, 161, 110444. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.; Ansari, R. Thermal conductivity of shape memory polymer nanocomposites containing carbon nanotubes: A micromechanical approach. Compos. Part B Eng. 2018, 162, 167–177. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K. Evaluating the effective creep properties of graphene-reinforced polymer nanocomposites by a homogenization approach. Compos. Sci. Technol. 2021, 209, 108791. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Mahmoodi, M.J.; Ansari, R. Creep performance of CNT polymer nanocomposites—An emphasis on viscoelastic interphase and CNT agglomeration. Compos. Part B Eng. 2018, 168, 274–281. [Google Scholar] [CrossRef]

- Shi, D.-L.; Feng, X.-Q.; Huang, Y.Y.; Hwang, K.-C.; Gao, H. The Effect of Nanotube Waviness and Agglomeration on the Elastic Property of Carbon Nanotube-Reinforced Composites. J. Eng. Mater. Technol. 2004, 126, 250–257. [Google Scholar] [CrossRef]

- Ji, X.-Y.; Cao, Y.-P.; Feng, X.-Q. Micromechanics prediction of the effective elastic moduli of graphene sheet-reinforced polymer nanocomposites. Model. Simul. Mater. Sci. Eng. 2010, 18, 045005. [Google Scholar] [CrossRef]

- Kundalwal, S.; Ray, M. Effective properties of a novel composite reinforced with short carbon fibers and radially aligned carbon nanotubes. Mech. Mater. 2012, 53, 47–60. [Google Scholar] [CrossRef]

- Snipes, J.; Robinson, C.; Baxter, S. Effects of scale and interface on the three-dimensional micromechanics of polymer nanocomposites. J. Compos. Mater. 2011, 45, 2537–2546. [Google Scholar] [CrossRef]

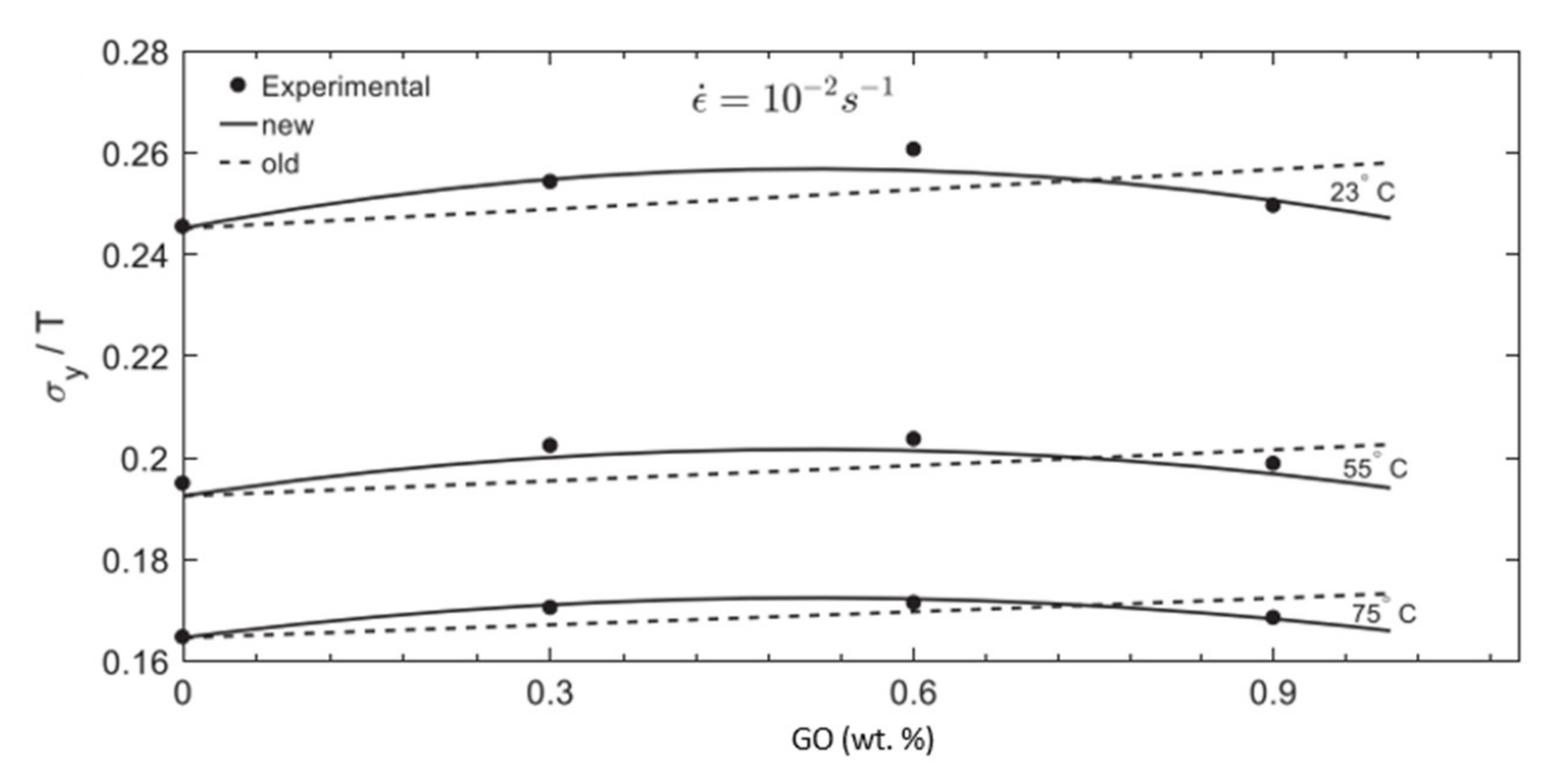

- Wang, K.; Ahzi, S.; Boumbimba, R.M.; Bahlouli, N.; Addiego, F.; Remond, Y. Micromechanical modeling of the elastic behavior of polypropylene based organoclay nanocomposites under a wide range of temperatures and strain rates/frequencies. Mech. Mater. 2013, 64, 56–68. [Google Scholar] [CrossRef]

- Boumbimba, R.M.; Wang, K.; Bahlouli, N.; Ahzi, S.; Rémond, Y.; Addiego, F. Experimental investigation and micromechanical modeling of high strain rate compressive yield stress of a melt mixing polypropylene organoclay nanocomposites. Mech. Mater. 2012, 52, 58–68. [Google Scholar] [CrossRef]

- Liu, Y.; Stein, O.; Campbell, J.H.; Jiang, L.; Petta, N.; Lu, Y. Three-dimensional printing and deformation behavior of low-density target structures by two-photon polymerization. In Proceedings of the Nanoengineering: Fabrication, Properties, Optics, and Devices XIV, San Diego, CA, USA, 9–10 August 2017; pp. 1–18. [Google Scholar] [CrossRef]

- Balani, K.; Verma, V.; Agarwal, A.; Narayan, R. Physical, Thermal, and Mechanical Properties of Polymers. In Biosurfaces: A Materials Science and Engineering Perspective; Wiley: Hoboken, NJ, USA, 2015; pp. 329–344. [Google Scholar]

- Malyarenko, A.; Ostoja-Starzewski, M. A Random Field Formulation of Hooke’s Law in All Elasticity Classes. J. Elast. 2016, 127, 269–302. [Google Scholar] [CrossRef]

- William, D.C.J.; Rethwisch, D.G. Mechanical Properties. In Fundamentals of Materials Science and Engineering: An Integrated Approach; Wiley: Hoboken, NJ, USA, 2018; pp. 190–241. [Google Scholar]

- Singh, K. Material Characterization, Constitutive Modeling and Finite Element Simulation of Polymethyl Methacrylate (PMMA) for Applications in Hot Embossing. Doctoral Dissertation, The Ohio State University, Columbus, OH, USA, 2011. [Google Scholar]

- Meyers, M.A.; Chawla, K.K. Materials: Structure, properties, and performance. In Mechanical Behavior of Materials; Cambridge University Press: Cambridge, UK, 2008; pp. 1–70. [Google Scholar]

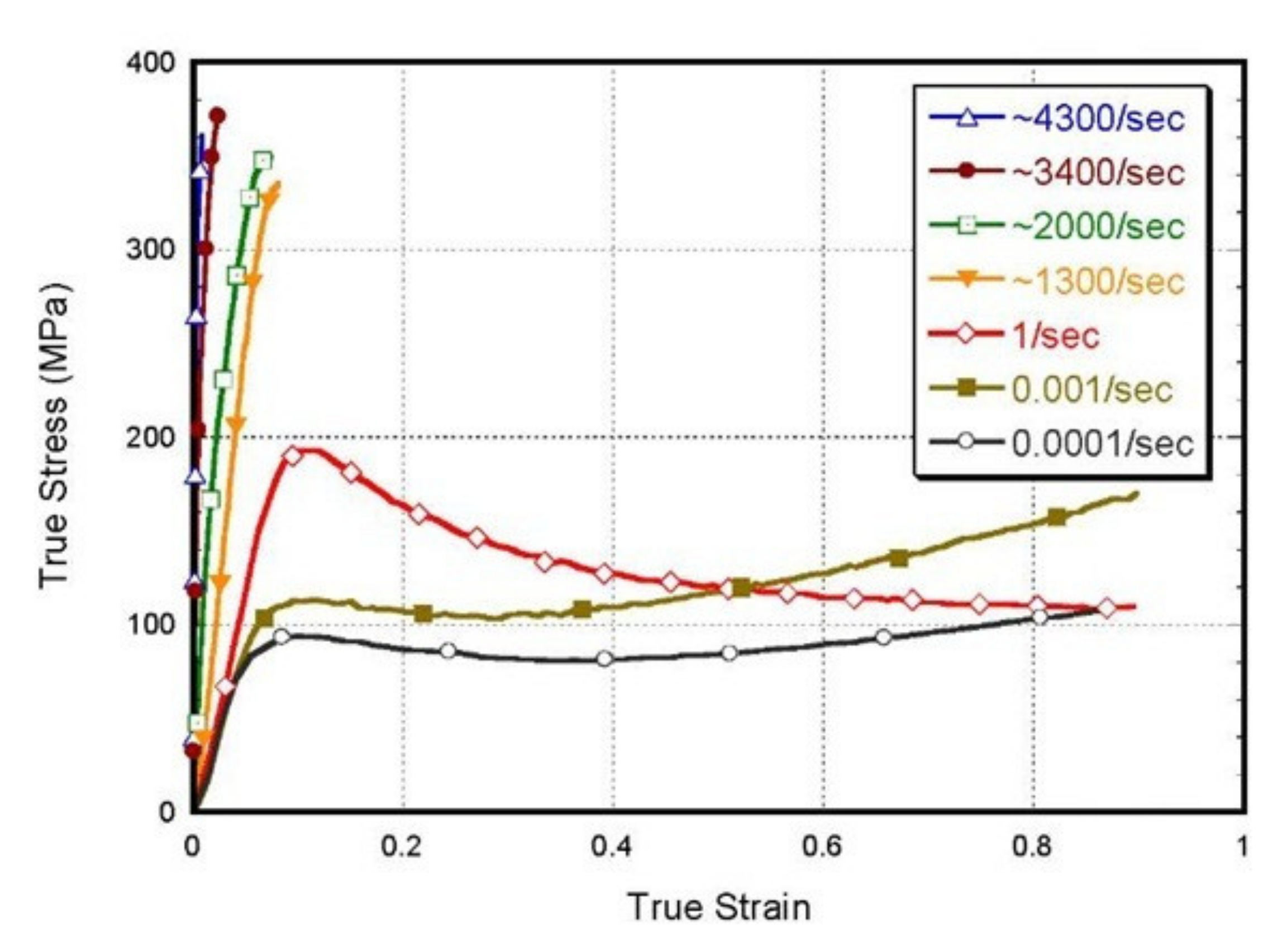

- Siviour, C.R. High strain rate characterization of polymers. In AIP Conference Proceedings; AIP Publishing: Bydgoszcz, Poland, 2017; Volume 1793. [Google Scholar] [CrossRef]

- Moy, P.; Gunnarsson, C.A.; Weerasooriya, T.; Chen, W. Stress-strain response of PMMA as a function of strain-rate and temperature. In Dynamic Behavior of Materials; Proceedings of the Society for Experimental Mechanics Series; Springer: New York, NY, USA, 2011; Volume 1, pp. 125–133. [Google Scholar] [CrossRef]

- Curiel-Sosa, J.L.; Brighenti, R.; Moreno, M.C.S.; Barbieri, E. Computational techniques for simulation of damage and failure in composite materials. In Structural Integrity and Durability of Advanced Composites: Innovative Modelling Methods and Intelligent Design; Woodhead Publishing: Thorston, UK, 2015; pp. 199–219. [Google Scholar]

- Gates, T.; Hinkley, J. Computational Materials: Modeling and Simulation of Nanostructured Materials and Systems. In Proceedings of the 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Norfolk, VA, USA, 7–10 April 2003. [Google Scholar] [CrossRef]

- Valavala, P.K.; Odegard, G.M. Modeling techniques for determination of mechanical properties of polymer nanocomposites. Rev. Adv. Mater. Sci. 2005, 9, 34–44. [Google Scholar]

- Steinhauser, M.O.; Hiermaier, S. A Review of Computational Methods in Materials Science: Examples from Shock-Wave and Polymer Physics. Int. J. Mol. Sci. 2009, 10, 5135–5216. [Google Scholar] [CrossRef]

- Richeton, J.; Schlatter, G.; Vecchio, K.; Remond, Y.; Ahzi, S. A unified model for stiffness modulus of amorphous polymers across transition temperatures and strain rates. Polymer 2005, 46, 8194–8201. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.; Jiang, F.; Adharapurapu, R. Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 2006, 43, 2318–2335. [Google Scholar] [CrossRef]

- Acar, A.; Colak, O.; Correia, J.; Ahzi, S. Cooperative-VBO model for polymer/graphene nanocomposites. Mech. Mater. 2018, 125, 1–13. [Google Scholar] [CrossRef]

- Mahieux, C.; Reifsnider, K. Property modeling across transition temperatures in polymers: A robust stiffness–temperature model. Polymer 2001, 42, 3281–3291. [Google Scholar] [CrossRef]

- Mahieux, C.A.; Reifsnider, K.L. Property modeling across transition temperatures in polymers: Application to thermoplastic systems. J. Mater. Sci. 2002, 37, 911–920. [Google Scholar] [CrossRef]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures, Processing and Design, 3rd ed.; Elsevier: Oxford, UK, 2006. [Google Scholar]

- Mercier, J.P.; Zambelli, G.; Kurz, W. Factors influencing mechanical properties. In Introduction to Materials Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2002; pp. 279–320. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Çolak, Ö.Ü.; Çakir, Y. Genetic Algorithm Optimization Method for Parameter Estimation in the Modeling of Storage Modulus of Thermoplastics. Sigma J. Eng. Nat. Sci. 2019, 37, 981–988. [Google Scholar]

- Colak, O.U.; Cakir, Y. Material model parameter estimation with genetic algorithm optimization method and modeling of strain and temperature dependent behavior of epoxy resin with cooperative-VBO model. Mech. Mater. 2019, 135, 57–66. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar]

- Hablot, E.; Matadi, R.; Ahzi, S.; Avérous, L. Renewable biocomposites of dimer fatty acid-based polyamides with cellulose fibres: Thermal, physical and mechanical properties. Compos. Sci. Technol. 2010, 70, 504–509. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Jamali, J. A new form of a Halpin–Tsai micromechanical model for characterizing the mechanical properties of carbon nanotube-reinforced polymer nanocomposites. Bull. Mater. Sci. 2019, 42, 117. [Google Scholar] [CrossRef]

- Takayanagi, M. Viscoelastic properties of crystalline polymers. Mem. Fac. Eng. Kyushu Univ. 1963, 13. [Google Scholar]

- Ji, X.L.; Jing, J.K.; Jiang, W.; Jiang, B.Z. Tensile modulus of polymer nanocomposites. Polym. Eng. Sci. 2002, 42, 983–993. [Google Scholar] [CrossRef]

- Tandon, G.P.; Weng, G.J. The effect of aspect ratio of inclusions on the elastic properties of unidirectionally aligned composites. Polym. Compos. 1984, 5, 327–333. [Google Scholar] [CrossRef]

- Mori, T.; Tanaka, K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Met. 1973, 21, 571–574. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Lond. 1957, 241, 376–396. [Google Scholar]

- Bernard, C.A.; Correia, J.P.M.; Ahzi, S.; Bahlouli, N. Numerical implementation of an elastic-viscoplastic constitutive model to simulate the mechanical behaviour of amorphous polymers. Int. J. Mater. Form. 2016, 10, 607–621. [Google Scholar] [CrossRef]

- Eyring, H. Viscosity, Plasticity, and Diffusion as Examples of Absolute Reaction Rates. J. Chem. Phys. 1936, 4, 283–291. [Google Scholar] [CrossRef]

- Argon, A.S. A theory for the low-temperature plastic deformation of glassy polymers. Philos. Mag. 1973, 28, 839–865. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Draidon, L.; Remond, Y. Modeling of strain rates and temperature effects on the yield behavior of amorphous polymers. J. Phys. IV 2003, 110, 39–44. [Google Scholar] [CrossRef]

- Gueguen, O.; Richeton, J.; Ahzi, S.; Makradi, A. Micromechanically based formulation of the cooperative model for the yield behavior of semi-crystalline polymers. Acta Mater. 2008, 56, 1650–1655. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.; Jiang, F.; Makradi, A. Modeling and validation of the large deformation inelastic response of amorphous polymers over a wide range of temperatures and strain rates. Int. J. Solids Struct. 2007, 44, 7938–7954. [Google Scholar] [CrossRef]

- Bernard, C.; Correia, J.; Ahzi, S. A thermodynamic analysis of Argon’s yield stress model: Extended influence of strain rate and temperature. Mech. Mater. 2019, 130, 20–28. [Google Scholar] [CrossRef]

- Bauwens, J.C. Relation between the compression yield stress and the mechanical loss peak of bisphenol-A-polycarbonate in the β transition range. J. Mater. Sci. 1972, 7, 577–584. [Google Scholar] [CrossRef]

- Bauwens, J.C.; Bauwens-Crowet, C.; Homès, G. Tensile yield-stress behavior of poly(vinyl chloride) and polycarbonate in the glass transition region. J. Polym. Sci. Part A-2 Polym. Phys. 1969, 7, 1745–1754. [Google Scholar] [CrossRef]

- Bauwens-Crowet, C. The compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates. J. Mater. Sci. 1973, 8, 968–979. [Google Scholar] [CrossRef]

- Bauwens-Crowet, C.; Bauwens, J.C.; Homès, G. Tensile yield-stress behavior of glassy polymers. J. Polym. Sci. Part A-2 Polym. Phys. 1969, 7, 735–742. [Google Scholar] [CrossRef]

- Bauwens-Crowet, C.; Bauwens, J.C.; Homès, G. The temperature dependence of yield of polycarbonate in uniaxial compression and tensile tests. J. Mater. Sci. 1972, 7, 176–183. [Google Scholar] [CrossRef]

- Ree, T.; Eyring, H. Theory of non-Newtonian flow. I. solid plastic system. J. Appl. Phys. 1955, 26, 793–800. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Daridon, L.; Remond, Y. A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 2005, 46, 6035–6043. [Google Scholar] [CrossRef]

- Duckett, R.A.; Rabinowitz, S.; Ward, I.M. The strain-rate, temperature and pressure dependence of yield of isotropic poly(methylmethacrylate) and poly(ethylene terephthalate). J. Mater. Sci. 1970, 5, 909–915. [Google Scholar] [CrossRef]

- Truss, R.W.; Clarke, P.L.; Duckett, R.A.; Ward, I.M. The dependence of yield behavior on temperature, pressure, and strain rate for linear polyethylenes of different molecular weight and morphology. J. Polym. Sci. Polym. Phys. Ed. 1984, 22, 191–209. [Google Scholar] [CrossRef]

- Robertson, R.E. Theory for the Plasticity of Glassy Polymers. J. Chem. Phys. 1966, 44, 3950–3956. [Google Scholar] [CrossRef]

- Fotheringham, D.D.; Cherry, B.W.; Bauwens-Crowet, C. Comment on ”the compression yield behaviour of polymethyl methacrylate over a wide range of temperatures and strain-rates”. J. Mater. Sci. 1976, 11, 1368–1371. [Google Scholar] [CrossRef]

- Fotheringham, D.G.; Cherry, B.W. The role of recovery forces in the deformation of linear polyethylene. J. Mater. Sci. 1978, 13, 951–964. [Google Scholar] [CrossRef]

- Povolo, F.; Hermida, B. Phenomenological description of strain rate and temperature-dependent yield stress of PMMA. J. Appl. Polym. Sci. 1995, 58, 55–68. [Google Scholar] [CrossRef]

- Povolo, F.; Schwartz, G.; Hermida, B. Temperature and strain rate dependence of the tensile yield stress of PVC. J. Appl. Polym. Sci. 1996, 61, 109–117. [Google Scholar] [CrossRef]

- Brooks, N.W.J.; Duckett, R.A.; Ward, I.M. Modeling of double yield points in polyethylene: Temperature and strain-rate dependence. J. Rheol. 1995, 39, 425–436. [Google Scholar] [CrossRef]

- Takayanagi, M.; Imada, K.; Kajiyyama, T. Mechanical properties and fine structure of drawn polymers. J. Polym. Sci. Polym. Symp. 1966, 15. [Google Scholar] [CrossRef]

- Matadi, R.; Gueguen, O.; Ahzi, S.; Gracio, J.; Muller, R.; Ruch, D. Investigation of the stiffness and yield behaviour of melt-intercalated poly(methyl methacrylate)/organoclay nanocomposites: Characterisation and modelling. J. Nanosci. Nanotechnol. 2010, 10, 2956–2961. [Google Scholar] [CrossRef] [PubMed]

- Takayanagi, M.; Imada, K.; Kajiyama, T. Mechanical properties and fine structure of drawn polymers. J. Polym. Sci. Part C Polym. Symp. 1967, 15, 263–281. [Google Scholar] [CrossRef]

- Turcsányi, B.; Pukánszky, B.; Tüdõs, F. Composition dependence of tensile yield stress in filled polymers. J. Mater. Sci. Lett. 1988, 7, 160–162. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Malek-Mohammadi, H.; Payandehpeyman, J. A new cooperative model for the prediction of compressive yield stress of polycarbonate nanocomposites considering strain rate, temperature, and agglomeration. J. Compos. Mater. 2019, 53, 3567–3575. [Google Scholar] [CrossRef]

- Blaker, J.J.; Maquet, V.; Jérôme, R.; Boccaccini, A.R.; Nazhat, S.N. Mechanical properties of highly porous PDLLA/Bioglass® composite foams as scaffolds for bone tissue engineering. Acta Biomater. 2005, 1, 643–652. [Google Scholar] [CrossRef]

- Tan, X.; Rodrigue, D. A review on porous polymeric membrane preparation. Part I: Production techniques with polysulfone and poly(vinyldiene fluoride). Polymers 2019, 11, 1160. [Google Scholar] [CrossRef]

- Abbasgholipourghadim, M.; Mailah, M.B.; Zaurah, I.; Ismail, A.F.; Dashtarzhandi, M.R.; Abbasgholipourghadim, M. Membrane Surface Porosity and Pore Area Distribution Incorporating Digital Image Processing. In Recent Advances in Mechanics and Mechanical Engineering; Springer: Berlin, Germany, 2016; Volume 10, pp. 118–123. [Google Scholar]

- Wong, P.-Z.; Koplik, J.; Tomanic, J.P. Conductivity and permeability of rocks. Phys. Rev. B 1984, 30, 6606–6614. [Google Scholar] [CrossRef]

- Wagh, A.S.; Poeppel, R.B.; Singh, J.P. Open pore description of mechanical properties of ceramics. J. Mater. Sci. 1991, 26, 3862–3868. [Google Scholar] [CrossRef]

- Roberts, A.; Garboczi, E. Elastic moduli of model random three-dimensional closed-cell cellular solids. Acta Mater. 2001, 49, 189–197. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. The mechanics of three-dimensional cellular materials. Proc. R. Soc. Lond. 1982, 382, 43–59. [Google Scholar]

- Ashby, M.F.; Medalist, R.F.M. The mechanical properties of cellular solids. Met. Mater. Trans. A 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Bruno, G.; Efremov, A.M.; Levandovskyi, A.N.; Clausen, B. Connecting the macro- and microstrain responses in technical porous ceramics: Modeling and experimental validations. J. Mater. Sci. 2010, 46, 161–173. [Google Scholar] [CrossRef]

- Alasfar, R.; Ahzi, S.; Wang, K.; Barth, N. Modeling the mechanical response of polymers and nano-filled polymers: Effects of porosity and fillers content. J. Appl. Polym. Sci. 2020, 137, 49545. [Google Scholar] [CrossRef]

- Boyce, M.C.; Parks, D.M.; Argon, A.S. Large inelastic deformation of glassy polymers. Part I: Rate dependent constitutive model. Mech. Mater. 1988, 7, 15–33. [Google Scholar] [CrossRef]

- Arruda, E.M.; Boyce, M.C.; Jayachandran, R. Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech. Mater. 1995, 19, 193–212. [Google Scholar] [CrossRef]

- Boyce, M.C.; Arruda, E.M.; Jayachandran, R. The large strain compression, tension, and simple shear of polycarbonate. Polym. Eng. Sci. 1994, 34, 716–725. [Google Scholar] [CrossRef]

- Wu, Z.; Ahzi, S.; Arruda, E.M.; Makradi, A. Modeling the large inelastic deformation response of non-filled and silica filled SL5170 cured resin. J. Mater. Sci. 2005, 40, 4605–4612. [Google Scholar] [CrossRef][Green Version]

- Mulliken, A.; Boyce, M. Mechanics of the rate-dependent elastic–plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- Parks, D.M.; Argon, A.S.; Bagepalli, B. Large elastic-plastic deformation of glassy polymers. In MIT Program in Polymer Science and Technology Report; Massachusetts Institute of Technology (MIT): Cambridge, MA, USA, 1984. [Google Scholar]

- Arruda, E.M.; Boyce, M.C. A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 1993, 41, 389–412. [Google Scholar] [CrossRef]

- Bernard, C.; George, D.; Ahzi, S.; Rémond, Y. A generalized mechanical model using stress–strain duality at large strain for amorphous polymers. Math. Mech. Solids 2020, 26, 386–400. [Google Scholar] [CrossRef]

- Çolak, O.U.; Ahzi, S.; Remond, Y. Cooperative viscoplasticity theory based on the overstress approach for modeling large deformation behavior of amorphous polymers. Polym. Int. 2013, 62, 1560–1565. [Google Scholar] [CrossRef]

- Boutaleb, S.; Zaïri, F.; Mesbah, A.; Abdelaziz, M.N.; Gloaguen, J.; Boukharouba, T.; Lefebvre, J. Micromechanics-based modelling of stiffness and yield stress for silica/polymer nanocomposites. Int. J. Solids Struct. 2009, 46, 1716–1726. [Google Scholar] [CrossRef]

- Ayoub, G.; Zaïri, F.; Naït-Abdelaziz, M.N.; Gloaguen, J.M. Modelling large deformation behaviour under loading–unloading of semicrystalline polymers: Application to a high density polyethylene. Int. J. Plast. 2010, 26, 329–347. [Google Scholar] [CrossRef]

- Bjerke, T.; Li, Z.; Lambros, J. Role of plasticity in heat generation during high rate deformation and fracture of polycarbonate. Int. J. Plast. 2002, 18, 549–567. [Google Scholar] [CrossRef]

- Bjerke, T.; Lambros, J. Heating during shearing and opening dominated dynamic fracture of polymers. Exp. Mech. 2002, 42, 107–114. [Google Scholar] [CrossRef]

- Boyce, M.C.; Montagut, E.L.; Argon, A.S. The effects of thermomechanical coupling on the cold drawing process of glassy polymers. Polym. Eng. Sci. 1992, 32, 1073–1085. [Google Scholar] [CrossRef]

- Wang, K.; Abdala, A.; Hilal, N.; Khraisheh, M. Mechanical Characterization of Membranes. In Membrane Characterization; Elsevier: Amsterdam, The Netherlands, 2017; pp. 259–306. [Google Scholar] [CrossRef]

- Wang, K.; Abdalla, A.A.; Khaleel, M.A.; Hilal, N.; Khraisheh, M.K. Mechanical properties of water desalination and wastewater treatment membranes. Desalination 2016, 401, 190–205. [Google Scholar] [CrossRef]

- Menard, K.P.; Menard, N.R. Dynamic Mechanical Analysis in the Analysis of Polymers and Rubbers. Encycl. Polym. Sci. Technol. 2015, 1–33. [Google Scholar] [CrossRef]

- De Nardo, L.; Farè, S. Dynamico-mechanical characterization of polymer biomaterials. In Characterization of Polymeric Biomaterials; Woodhead Publishing: Thorston, UK, 2017; pp. 203–232. [Google Scholar] [CrossRef]

- Ghasemi, F.A.; Ghorbani, A.; Ghasemi, I. Mechanical, Thermal and Dynamic Mechanical Properties of PP/GF/xGnP Nanocomposites. Mech. Compos. Mater. 2017, 53, 131–138. [Google Scholar] [CrossRef]

- Reiter, M.; Major, Z. Determination of Tensile Properties of Polymers at High Strain Rates. EPJ Web Conf. 2010, 6, 39008. [Google Scholar] [CrossRef][Green Version]

- Zhang, C.Y.; Zhang, Y.W.; Zeng, K.Y.; Shen, L. Characterization of mechanical properties of polymers by nanoindentation tests. Philos. Mag. 2006, 86, 4487–4506. [Google Scholar] [CrossRef]

- Oyen, M.; Toivola, Y.A.; Cook, R. Load-Displacement Behavior During Sharp Indentation of Viscous-Elastic-Plastic Materials. MRS Proc. 2003, 18, 139–150. [Google Scholar] [CrossRef]

- Wang, N.; Ji, S.; Zhang, G.; Li, J.; Wang, L. Self-assembly of graphene oxide and polyelectrolyte complex nanohybrid membranes for nanofiltration and pervaporation. Chem. Eng. J. 2012, 213, 318–329. [Google Scholar] [CrossRef]

- Purkait, M.K.; Sinha, M.K.; Mondal, P.; Singh, R. Introduction to membranes. In Stimuli Responsive Polymeric Membranes; Elsiever: Amsterdam, The Netherlands, 2018; Volume 25, pp. 1–37. [Google Scholar]

- Zhong, L.; Ding, Z.; Li, B.; Zhang, L. Preparation and Characterization of Polysulfone/Sulfonated Polysulfone/Cellulose Nanofibers Ternary Blend Membranes. BioResources 2015, 10, 2936–2948. [Google Scholar] [CrossRef][Green Version]

- Zhang, W.; Zhong, L.; Wang, T.; Jiang, Z.; Gao, X.; Zhang, L. Surface modification of cellulose nanofibers and their effects on the morphology and properties of polysulfone membranes. IOP Conf. Series: Mater. Sci. Eng. 2018, 397, 012016. [Google Scholar] [CrossRef]

- Kamal, N.; Kochkodan, V.; Zekri, A.; Ahzi, S. Polysulfone Membranes Embedded with Halloysites Nanotubes: Preparation and Properties. Membranes 2019, 10, 2. [Google Scholar] [CrossRef] [PubMed]

- Manawi, Y.M.; Wang, K.; Kochkodan, V.; Johnson, D.J.; Atieh, M.A.; Khraisheh, M.K. Engineering the Surface and Mechanical Properties of Water Desalination Membranes Using Ultralong Carbon Nanotubes. Membranes 2018, 8, 106. [Google Scholar] [CrossRef]

- Han, Q.F.; Wang, Z.W.; Tang, C.Y.; Chen, L.; Tsui, C.P.; Law, W.C. Hyper-elastic modeling and mechanical behavior investigation of porous poly-d-l-lactide/nano-hydroxyapatite scaffold material. J. Mech. Behav. Biomed. Mater. 2017, 71, 262–270. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Wang, J.X.; Tang, C.Y.; Chen, D.Z.; Law, W.C. Shape memory effect of thermal-responsive nano-hydroxyapatite reinforced poly-d-l-lactide composites with porous structure. Compos. Part B Eng. 2016, 107, 67–74. [Google Scholar] [CrossRef]

- Zheng, X.; Zhou, S.; Li, X.; Weng, J. Shape memory properties of poly(D,L-lactide)/hydroxyapatite composites. Biomaterials 2006, 27, 4288–4295. [Google Scholar] [CrossRef] [PubMed]

- Meskinfam, M. Polymer scaffolds for bone regeneration. In Characterization of Polymeric Biomaterials; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 441–475. [Google Scholar]

| Models | Equations | Parameters * | Use | Effect of |

|---|---|---|---|---|

| Mahieux and Reifsnider model | Equation (1) | Polymers | Account for the effect of | |

| Richeton model | Equation (2) for storage modulus Equation (3) for Young’s modulus | Polymers | Account for the effects of | |

| Halpin-Tsai model | Equation (9) | Polymer nanocomposites | Doesn’t account for the effects of | |

| RJ model | Equation (15) | Polymer nanocomposites | Account for the effects of | |

| RTW model | Equation (17) | Polymer nanocomposites | Account for the effects of | |

| Alasfar and co-workers’ model | Equation (43) Equation (44) | in addition to parameters of the Richeton and RJ models | Porous polymers Porous polymer nanocomposites | Account for the effects of |

| Models | Equations | Parameters * | Use | Remarks |

|---|---|---|---|---|

| Eyring model | Equation (19) | Polymers | ||

| Argon model | Equation (20) | Polymers | ||

| Modified Argon model | Equation (21) | Polymers | ||

| Ree-Eyring model | Equation (22) | Polymers | ||

| Cooperative model | : Equation (29) | Polymers | Compared to previous models, this model is the most accurate model for yield stress prediction | |

| Extended cooperative model | GMC: Equation (33) | Polymer nanocomposites | Two-phase | |

| CBP: Equation (35) | Three-phase (the third phase is the interphase between matrix and fillers) | |||

| Alasfar and co-workers’ model | Equation (45) | in addition to parameters of the extended cooperative model (CBP) | Porous polymer nanocomposites | Three-phase (the third phase is the interphase between matrix and fillers) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alasfar, R.H.; Ahzi, S.; Barth, N.; Kochkodan, V.; Khraisheh, M.; Koç, M. A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity. Polymers 2022, 14, 360. https://doi.org/10.3390/polym14030360

Alasfar RH, Ahzi S, Barth N, Kochkodan V, Khraisheh M, Koç M. A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity. Polymers. 2022; 14(3):360. https://doi.org/10.3390/polym14030360

Chicago/Turabian StyleAlasfar, Reema H., Said Ahzi, Nicolas Barth, Viktor Kochkodan, Marwan Khraisheh, and Muammer Koç. 2022. "A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity" Polymers 14, no. 3: 360. https://doi.org/10.3390/polym14030360

APA StyleAlasfar, R. H., Ahzi, S., Barth, N., Kochkodan, V., Khraisheh, M., & Koç, M. (2022). A Review on the Modeling of the Elastic Modulus and Yield Stress of Polymers and Polymer Nanocomposites: Effect of Temperature, Loading Rate and Porosity. Polymers, 14(3), 360. https://doi.org/10.3390/polym14030360