Masterbatch of Chitosan Nanowhiskers for Preparation of Nylon 6,10 Nanocomposite by Melt Blending

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Synthesis of CSW

2.3. Preparation of Nylon/CSW Masterbatch

2.4. Preparation of Nylon/CSW Nanocomposites Using Melt Blending

2.5. Instrumental Analysis

2.5.1. Mechanical Properties

2.5.2. Thermal Properties

2.5.3. Rheological Properties

2.5.4. Fourier Transform Infrared Spectroscopy (FT-IR)

3. Results

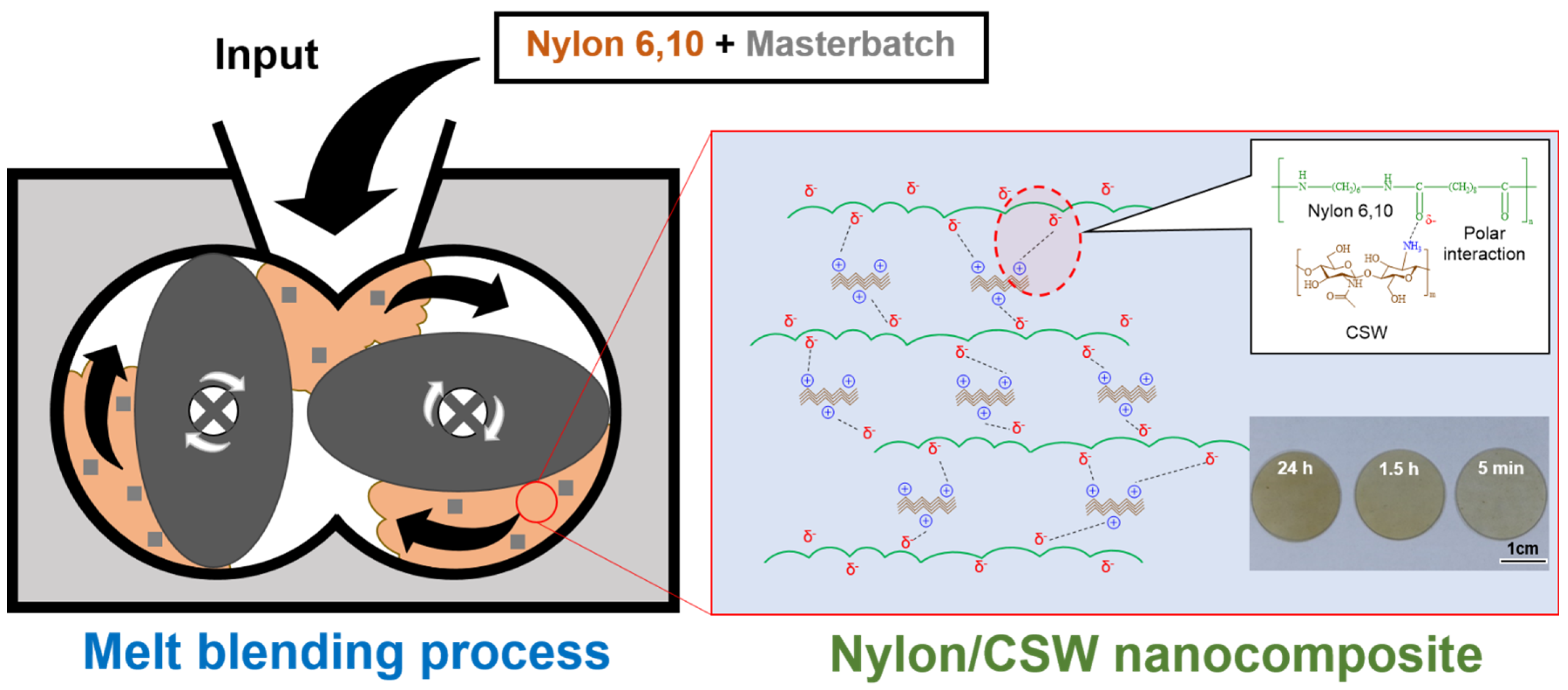

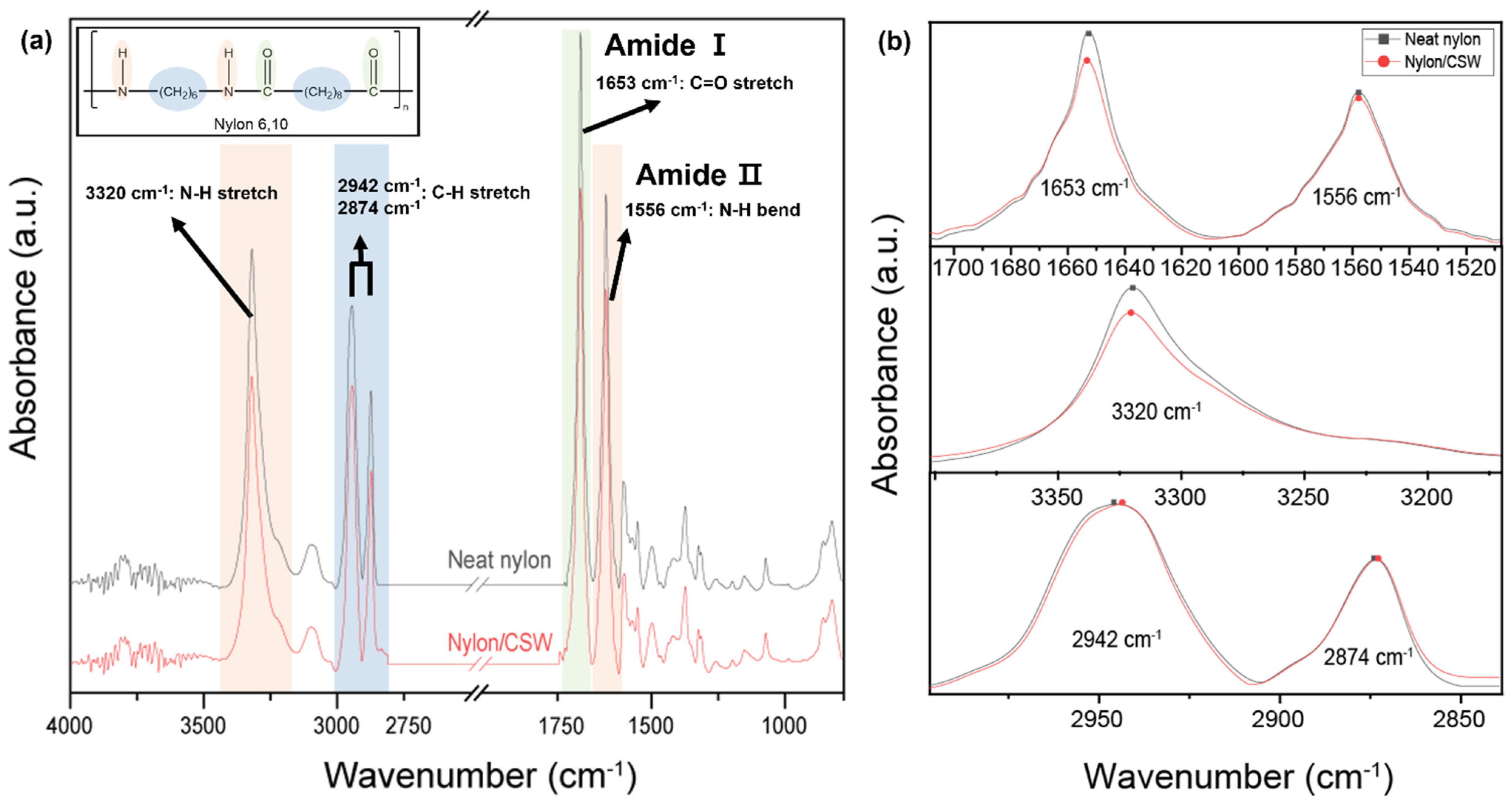

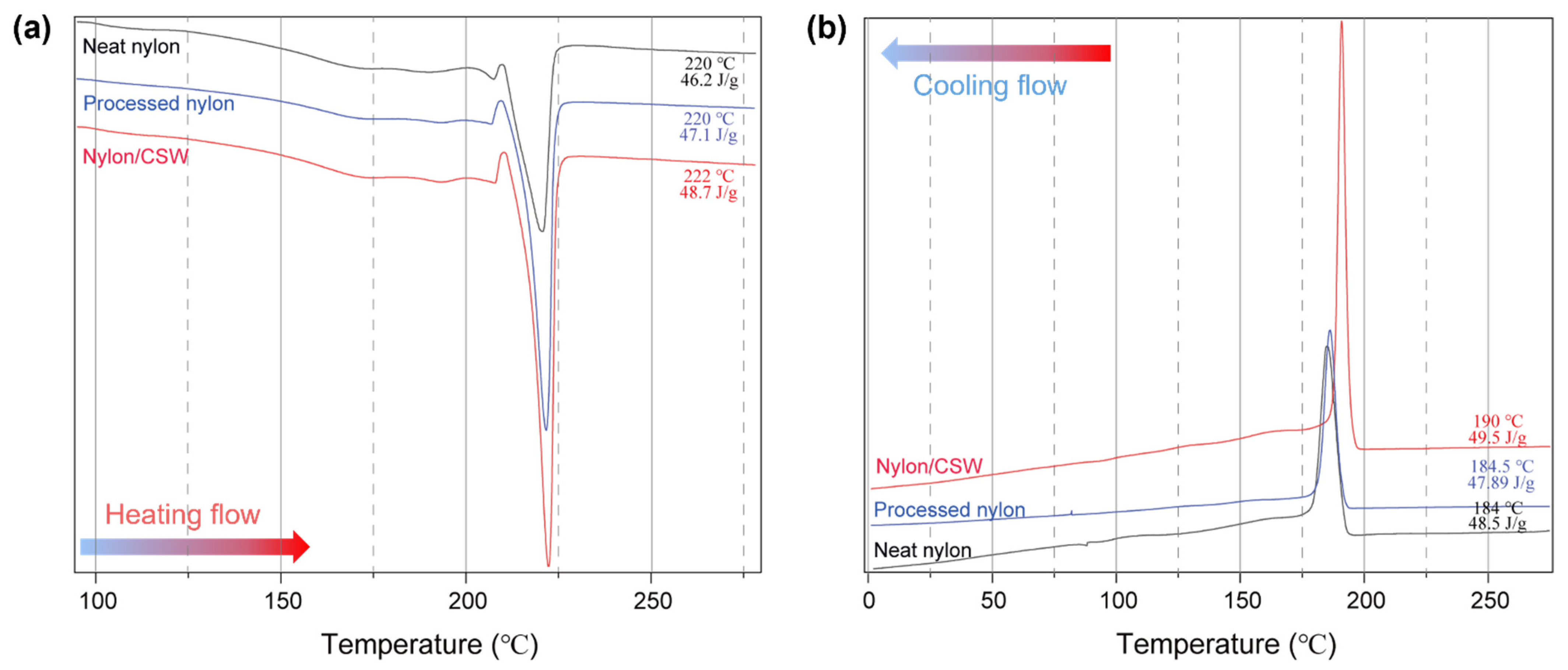

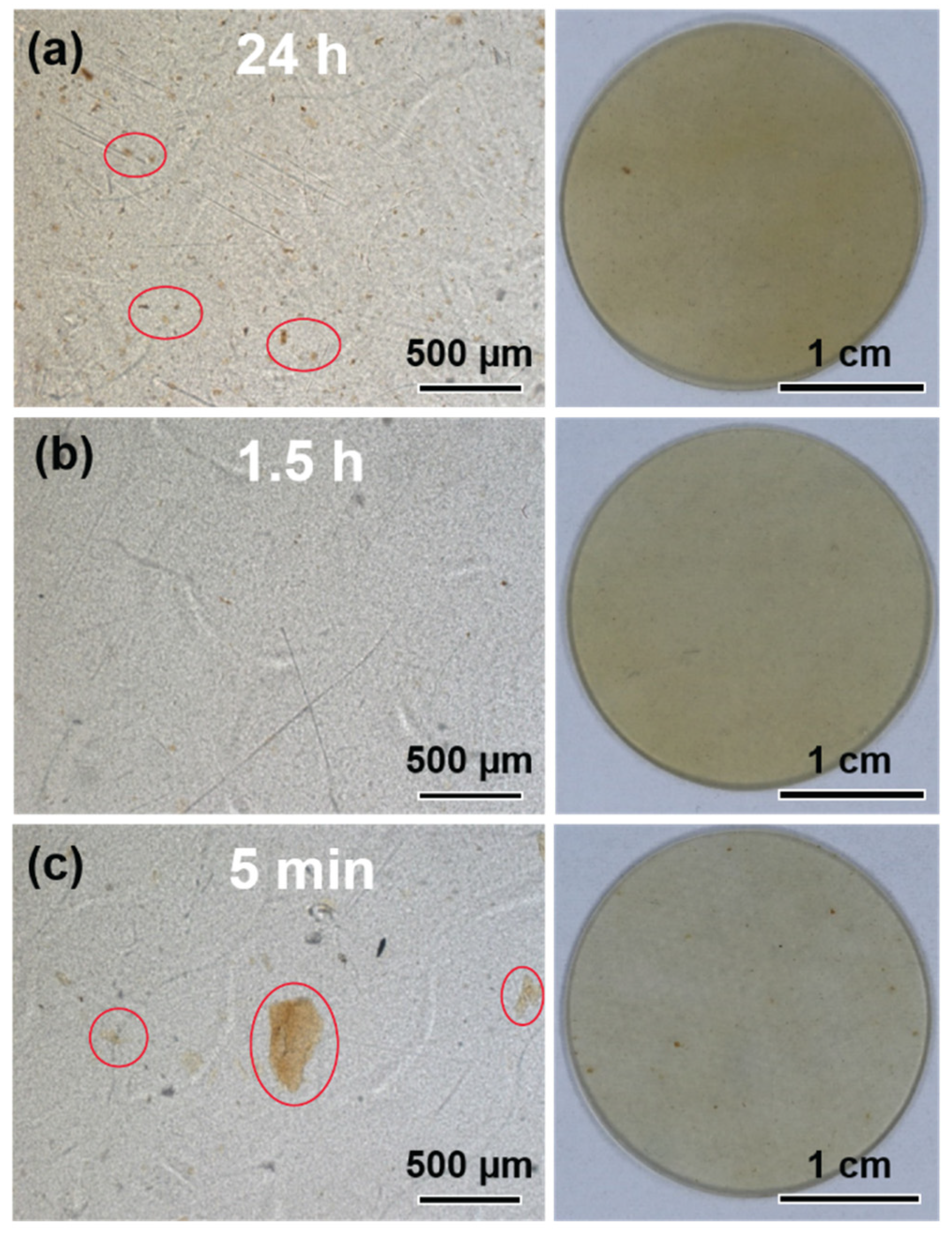

3.1. Synthesis of Nylon/CSW Nanocomposites

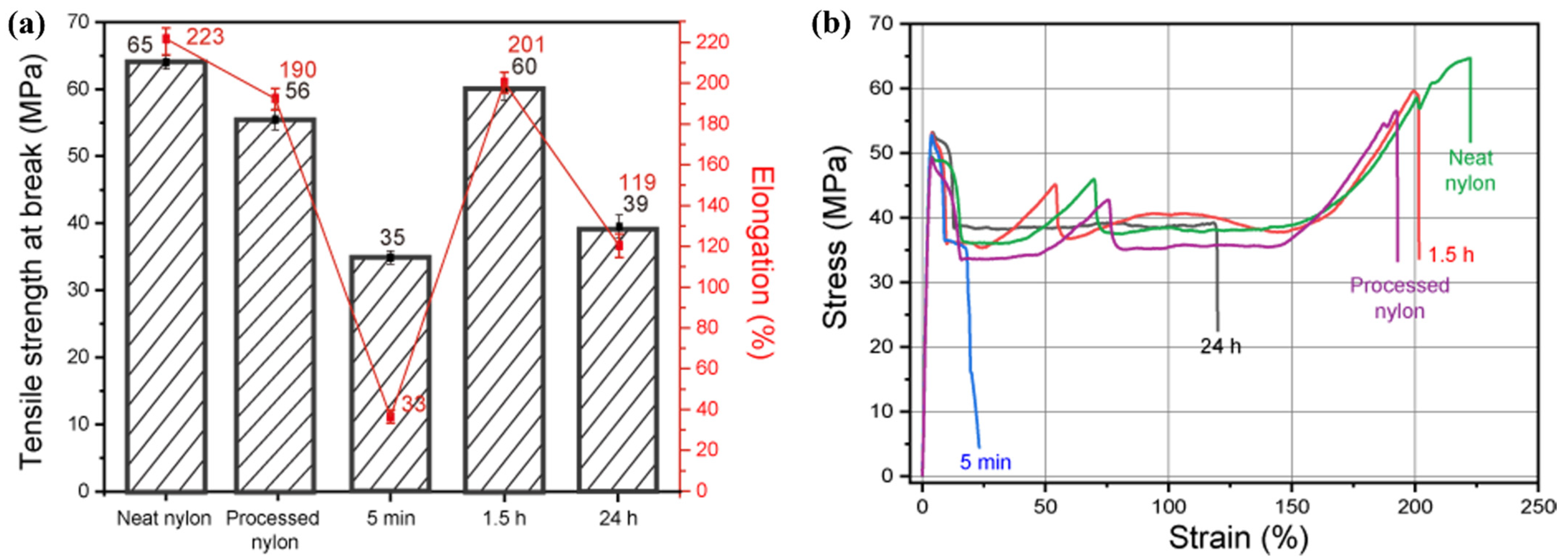

3.2. Mechanical Properties of Nylon/CSW Nanocomposites

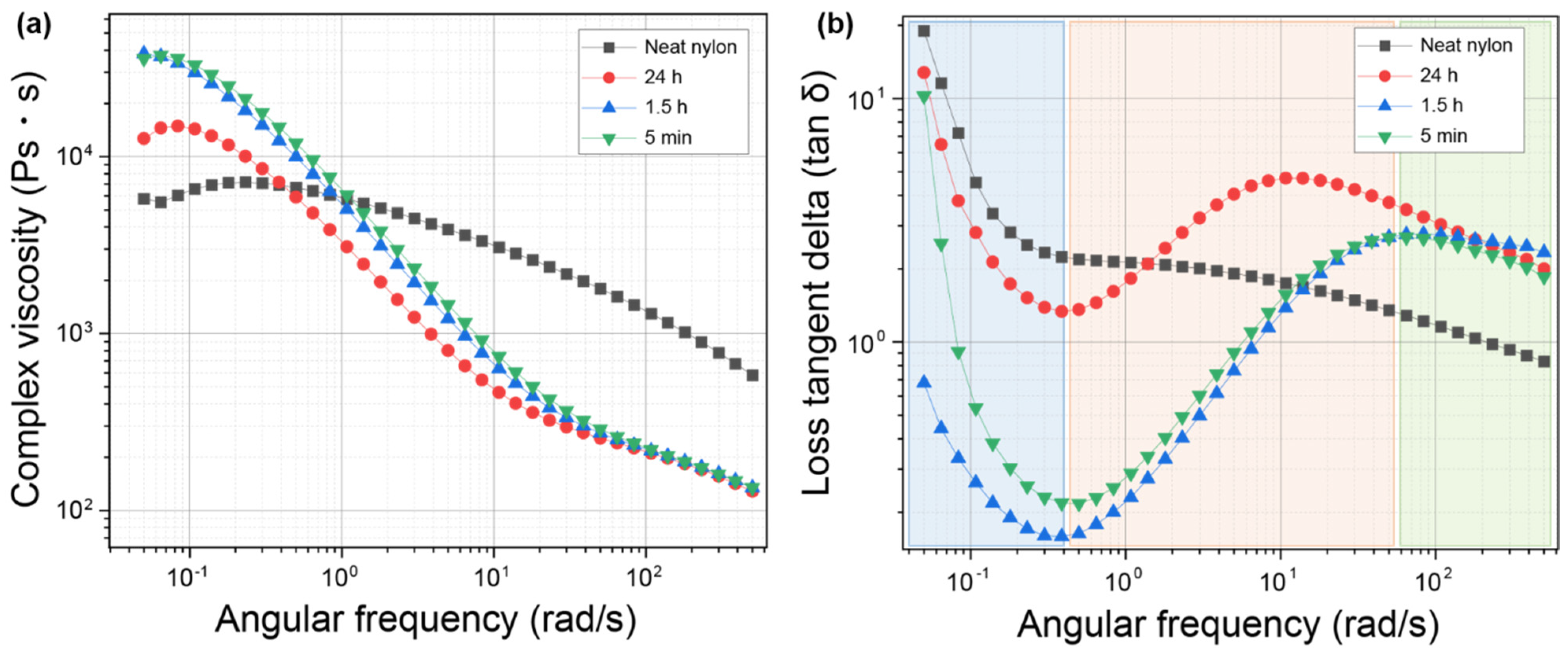

3.3. Rheological Properties of Nylon/CSW Nanocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nishino, T.; Matsui, R.; Nakamae, K. Elastic Modulus of the Crystalline Regions of Chitin and Chitosan. J. Polym. Sci. B Polym. Phys. 1999, 37, 1191–1196. [Google Scholar] [CrossRef]

- Kozma, M.; Acharya, B.; Bissessur, R. Chitin, Chitosan, and Nanochitin: Extraction, Synthesis, and Applications. Polymers 2022, 14, 3989. [Google Scholar] [CrossRef] [PubMed]

- Kou, S.; Peters, L.M.; Mucalo, M.R. Chitosan: A review of sources and preparation methods. Int. J. Biol. Macromol. 2021, 169, 85–94. [Google Scholar] [CrossRef]

- Saharan, V.; Mehrotra, A.; Khatik, R.; Rawal, P.; Sharma, S.S.; Pal, A. Synthesis of chitosan based nanoparticles and their in vitro evaluationagainst phytopathogenic fungi. Int. J. Biol. Macromol. 2013, 62, 677–683. [Google Scholar] [CrossRef] [PubMed]

- Ifuku, S. Chitin and Chitosan Nanofibers: Preparation and Chemical Modifications. Molecules 2014, 19, 18367–18380. [Google Scholar] [CrossRef] [PubMed]

- Jayakumar, R.; Menon, D.; Manzoor, K.; Nair, S.V.; Tamura, H. Biomedical applications of chitin and chitosan based nanomaterials—A short review. Carbohydr. Polym. 2010, 82, 227–232. [Google Scholar] [CrossRef]

- Min, B.M.; Lee, S.W.; Lim, J.M.; You, Y.; Lee, T.S.; Kang, P.H.; Park, W.H. Chitin and chitosan nanofibers: Electrospinning of chitin and deacetylation of chitin nanofibers. Polymer 2004, 45, 7137–7142. [Google Scholar] [CrossRef]

- Wijesena, R.N.; Tissera, N.; Kannangara, Y.Y.; Lin, Y.; Amaratunga, G.A.J.; de Silva, K.M.N. A method for top down preparation of chitosan nanoparticles and nanofibers. Carbohydr. Polym. 2015, 117, 731–738. [Google Scholar] [CrossRef]

- Esabee, M.Z.; Naguib, H.F.; Morsi, R.E. Chitosan based nanofibers, review. Mater. Sci. Eng. C 2012, 32, 1711–1726. [Google Scholar] [CrossRef]

- Tran, T.H.; Nguyen, H.L.; Hwang, D.S.; Lee, J.Y.; Cha, H.G.; Koo, J.M.; Hwang, S.Y.; Park, J.; Oh, D.X. Five different chitin nanomaterials from identical source with different advantageous functions and performances. Carbohydr. Polym. 2019, 205, 392–400. [Google Scholar] [CrossRef]

- Madihally, S.V.; Matthew, H.W.T. Porous chitosan scaffolds for tissue engineering. Biomaterials 1999, 20, 1133–1142. [Google Scholar] [CrossRef] [PubMed]

- Tanabe, T.; Okitsu, N.; Tachibana, A.; Yamauchi, K. Preparation and characterization of keratin–chitosan composite film. Biomaterials 2002, 23, 817–825. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.T.; Eom, Y.H.; Tran, T.H.; Koo, J.M.; Jegal, J.; Hwang, S.Y.; Oh, D.X.; Park, J. Rediscovery of nylon upgraded by interactive biorenewable nano-fillers. Nanoscale 2020, 20, 2393. [Google Scholar] [CrossRef] [PubMed]

- Chakrabarty, A.; Teramoto, Y. Recent Advances in Nanocellulose Composites with Polymers: A Guide for Choosing Partners and How to Incorporate Them. Polymers 2018, 10, 517. [Google Scholar] [CrossRef]

- Youssef, A.M.; Yousef, H.A.; El-Sayed, S.M.; Kamel, S. Mechanical and antibacterial properties of novel high performancechitosan/nanocomposite films. Int. J. Biol. Macromol. 2015, 76, 25–32. [Google Scholar] [CrossRef]

- Mishra, S.K.; Kannan, S. Development, mechanical evaluation and surface characteristics of chitosan/polyvinyl alcohol based polymer composite coatings on titanium metal. J. Mech. Behav. Biomed. Mater. 2014, 40, 314–324. [Google Scholar] [CrossRef]

- Miri, N.E.; Abdelouahdi, K.; Zahouily, M.; Fihri, A.; Barakat, A.; Solhy, A.; Achaby, M.E. Bio-nanocomposite films based on cellulose nanocrystals filled polyvinyl alcohol/chitosan polymer blend. J. Appl. Polym. Sci. 2015, 132, 42004. [Google Scholar] [CrossRef]

- Ju, J.; Kim, J.; Choi, Y.; Jin, S.; Kim, S.; Son, D.; Shin, M. Punicalagin-Loaded Alginate/Chitosan-Gallol Hydrogels for Efficient Wound Repair and Hemostasis. Polymers 2022, 14, 3248. [Google Scholar] [CrossRef]

- Choo, K.; Ching, Y.C.; Chuah, C.H.; Julai, S.; Liou, N.-S. Preparation and Characterization of Polyvinyl Alcohol-Chitosan Composite Films Reinforced with Cellulose Nanofiber. Materials 2016, 9, 644. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Raj, S.A.; Kandasamy, J.; Baghdadi, M.A.; Shahzad, M.A. Chitosan: A Sustainable Material for Multifarious Applications. Polymers 2022, 14, 2335. [Google Scholar] [CrossRef]

- Schnurch, A.B.; Dunnhaupt, S. Chitosan-based drug delivery systems. Eur. J. Pharm. Biopharm. 2012, 81, 463–469. [Google Scholar] [CrossRef] [PubMed]

- Popat, A.; Liu, J.; Lu, G.Q.; Qiao, S.Z. A pH-responsive drug delivery system based on chitosan coated mesoporous silica nanoparticles. J. Mater. Chem. 2012, 22, 11173. [Google Scholar] [CrossRef]

- Hao, L.T.; Park, S.H.; Choy, S.H.; Kim, Y.M.; Lee, S.W.; Ok, Y.S.; Koo, J.M.; Hwang, S.Y.; Hwang, D.S.; Park, J.; et al. Strong, Multifaceted Guanidinium-Based Adhesion of Bioorganic Nanoparticles to Wet Biological Tissue. JACS Au 2021, 1, 1399–1411. [Google Scholar] [CrossRef] [PubMed]

- Park, E.; Lee, J.; Huh, K.M.; Lee, S.H.; Lee, H. Toxicity-Attenuated Glycol Chitosan Adhesive Inspired by Mussel Adhesion Mechanisms. Adv. Healthc. Mater. 2019, 8, 1900275. [Google Scholar] [CrossRef] [PubMed]

- Patel, A.K.; Michaud, P.; Petit, E.; Baynast, H.D.; Grediac, M.; Mathias, J.D. Development of a Chitosan-Based Adhesive. Application to Wood Bonding. J. Appl. Polym. Sci. 2013, 6, 127. [Google Scholar] [CrossRef]

- Thuy, V.T.T.; Hao, L.H.; Jeon, H.; Koo, J.M.; Park, J.; Lee, E.S.; Hwang, S.Y.; Choi, S.; Park, J.; Oh, D.X. Sustainable, self-cleaning, transparent, and moisture/oxygen-barrier coating films for food packaging. Green Chem. 2021, 23, 2658. [Google Scholar] [CrossRef]

- Laufer, G.; Kirkland, C.; Cain, A.A.; Grunlan, J.C. Clay−Chitosan Nanobrick Walls: Completely Renewable Gas Barrier and Flame-Retardant Nanocoatings. ACS Appl. Mater. Interfaces 2012, 4, 1643–1649. [Google Scholar] [CrossRef]

- Choi, S.; Jeon, H.; Jang, M.; Kim, H.; Shin, G.; Koo, J.M.; Lee, M.; Sung, H.K.; Eom, Y.; Yang, H.; et al. Biodegradable, Efficient, and Breathable Multi-Use Face Mask Filter. Adv. Sci. 2021, 8, 2003155. [Google Scholar] [CrossRef]

- Shakiba, M.; Ghomi, E.R.; Khosravi, F.; Jouybar, S.; Bigham, A.; Zare, M.; Abdouss, M.; Moaref, R.; Ramakrishna, S. Nylon—A material introduction and overview for biomedical applications. Polym. Adv. Technol. 2021, 32, 3368–3383. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Aparna, S.; Purnima, D.; Adusumalli, R.B. Review on Various Compatibilizers and its Effect on Mechanical Properties of Compatibilized Nylon Blends. Polym. Plast. Technol. Eng. 2017, 56, 617–634. [Google Scholar] [CrossRef]

- Kumar, K.S.; Reddy, A.C. Study on Reinforcement Materials for Nylon Matrix Composites—A Review. Int. J. Sci. Eng. Res. 2016, 7, 156–160. [Google Scholar]

- Pan, Q.; Shim, E.; Pourdeyhimi, B.; Gao, W. Nylon-Graphene Composite Nonwovens as Monolithic Conductive or Capacitive Fabrics. ACS Appl. Mater. Interfaces 2017, 9, 8308–8316. [Google Scholar] [CrossRef] [PubMed]

- Sucharitpong, T.; Lam, N.T.; Sukyai, P. Production of Nylon-6/Cellulose Nanocrystal Composite Films Using Solvent Dissolution. Sugar Tech 2020, 22, 328–339. [Google Scholar] [CrossRef]

- Ou, Y.; Yang, F.; Yu, Z.Z. A New Conception on the Toughness of Nylon 6/Silica Nanocomposite Prepared via In Situ Polymerization. J. Polym. Sci. B Polym. Phys. 1998, 36, 789–795. [Google Scholar] [CrossRef]

- Liang, J.-Z. Toughening and reinforcing in rigid inorganic particulate filled poly(propylene): A review. J. Appl. Polym. Sci. 2002, 83, 1547–1555. [Google Scholar] [CrossRef]

- Li, Y.-F.; Tsai, T.-H.; Yang, T.-H. A Novel Strengthening Method for Damaged Pipeline under High Temperature Using Inorganic Insulation Material and Carbon Fiber Reinforced Plastic Composite Material. Materials 2019, 12, 3484. [Google Scholar] [CrossRef]

- Ju, S.; Yoon, J.; Sung, D.; Pyo, S. Mechanical Properties of Coal Ash Particle-Reinforced Recycled Plastic-Based Composites for Sustainable Railway Sleepers. Polymers 2020, 12, 2287. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Muhammad, B. Epoxy Resin Composite Reinforced with Carbon Fiber and Inorganic Filler: Overview on Preparation and Properties. Polym. Plast. Technol. 2016, 55, 1653–1672. [Google Scholar] [CrossRef]

- Park, S.; Eom, Y.; Jeon, H.; Koo, J.M.; Kim, T.; Jeon, J.; Park, J.M.; Hwang, S.Y.; Kim, B.; Oh, D.X.; et al. Aramid Nanofiber Templated In Situ SNAr Polymerization for Maximizing the Performance of All-Organic Nanocomposites. ACS Macro Lett. 2020, 9, 558–564. [Google Scholar] [CrossRef]

- Kim, T.; Jeon, H.; Jegal, J.; Kim, J.H.; Yang, H.; Park, J.; Oh, D.X.; Hwang, S.Y. Trans crystallization behavior and strong reinforcement effect of cellulose nanocrystals on reinforced poly(butylene succinate) nanocomposites. RSC Adv. 2018, 8, 15389. [Google Scholar] [CrossRef] [PubMed]

- Utracki, L.A. Melt Flow of Polymer Blends. Polym. Eng. Sci. 1983, 23, 602–609. [Google Scholar] [CrossRef]

- Rahimi, S.K.; Otaigbe, J.U. Polyamide 6 Nanocomposites Incorporating Cellulose Nanocrystals Prepared by In Situ Ring-Opening Polymerization: Viscoelasticity, Creep Behavior, and Melt Rheological Properties. Polym. Eng. Sci. 2016, 56, 1045–1060. [Google Scholar] [CrossRef]

- Nair, K.G.; Dufresne, A. Crab Shell Chitin Whisker Reinforced Natural Rubber Nanocomposites. 1. Processing and Swelling Behavior. Biomacromolecules 2003, 4, 657–665. [Google Scholar] [CrossRef]

- Zeng, J.; He, Y.; Li, S.; Wang, Y. Chitin Whiskers: An Overview. Biomacromolecules 2012, 13, 1–11. [Google Scholar] [CrossRef]

- Fan, Y.; Saito, T.; Isogai, A. Individual chitin nano-whiskers prepared from partially deacetylated α-chitin by fibril surface cationization. Carbohydr. Polym. 2010, 79, 1046–1051. [Google Scholar] [CrossRef]

- Preira, A.G.B.; Muniz, E.C.; Hsieh, Y. Chitosan-sheath and chitin-core nanowhiskers. Carbohydr. Polym. 2014, 107, 158–166. [Google Scholar] [CrossRef]

- Ndesendo, V.M.K.; Choonara, Y.E.; Meyer, L.C.R.; Kumar, P.; Tomar, L.K.; Tyagi, C.; du Toit, L.C.; Pillay, V. In Vivo evaluation of a mucoadhesive polymeric caplet for intravaginal anti-HIV-1 delivery and development of a molecular mechanistic model for thermochemical characterization. Drug. Dev. Ind. Pharm. 2015, 41, 1274–1289. [Google Scholar] [CrossRef]

- Roberts, M.F.; Jenekhe, S.A. Site-Specific Reversible Scission of Hydrogen Bonds in Polymers. An Investigation of Polyamides and Their Lewis Acid-Base Complexes by Infrared Spectroscopy. Macromolecules 1991, 24, 3142–3146. [Google Scholar] [CrossRef]

- Xie, K.; He, Y.; Cai, J.; Hu, W. Thermal conductivity of Nylon 46, Nylon 66 and Nylon 610 characterized by Flash DSC measurement. Thermochim. Acta 2020, 683, 178445. [Google Scholar] [CrossRef]

- Correlo, V.M.; Boesel, L.F.; Bhattacharya, M.; Mano, J.F.; Neves, N.M.; Reis, R.L. Properties of melt processed chitosan and aliphatic polyester blends. Mater. Sci. Eng. A 2005, 403, 57–68. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Yuan, M.; Turng, L.S. Microstructure and mechanical properties of microcellular injection molded polyamide-6 nanocom-posites. Polymer 2005, 46, 7273–7292. [Google Scholar] [CrossRef]

- Afzal, S.; Maswal, M.; Dar, A.A. Rheological behavior of pH responsive composite hydrogels of chitosan and alginate: Characterization and its use in encapsulation of citral. Colloids Surf. B Biointerfaces 2018, 169, 99–106. [Google Scholar] [CrossRef]

- Pavoni, J.M.F.; Luchese, C.L.; Tessaro, I.C. Impact of acid type for chitosan dissolution on the characteristics and biodegradability of cornstarch/chitosan based films. Int. J. Biol. Macromol. 2019, 138, 693–703. [Google Scholar] [CrossRef] [PubMed]

- Jozwiak, T.; Filipkowska, U.; Szymczyk, P.; Rodziewicz, J.; Mielarek, A. Effect of ionic and covalent crosslinking agents on properties of chitosan beads and sorption effectiveness of Reactive Black 5 dye. React. Funct. Polym. 2017, 114, 58–74. [Google Scholar] [CrossRef]

- Li, D.; Kaner, R.B. Shape and Aggregation Control of Nanoparticles: Not Shaken, Not Stirred. J. Am. Chem. Soc. 2005, 128, 968–975. [Google Scholar] [CrossRef] [PubMed]

- Ghorbani, F.M.; Kaffashi, B.; Shokrollahi, P.; Akhlaghi, S.; Hedenqvist, M.S. Effect of hydroxyapatite nano-particles on morphology, rheology and thermal behavior of poly(caprolactone)/chitosan blends. Mater. Sci. Eng. Mater. C 2016, 59, 980–989. [Google Scholar] [CrossRef]

- Correa, A.C.; Teixeira, E.D.M.; Carmona, V.B.; Teodoro, K.B.R.; Ribeiro, C.; Mattoso, L.H.C.; Marconcini, J.M. Obtaining nanocomposites of polyamide 6 and cellulose whiskers via extrusion and injection molding. Cellulose 2014, 21, 311–322. [Google Scholar] [CrossRef]

- Arias, A.; Heuzey, M.C.; Huneault, M.A.; Ausias, G.; Bendahou, A. Enhanced dispersion of cellulose nanocrystals in melt-processed polylactide-based nanocomposites. Cellulose 2015, 22, 483–498. [Google Scholar] [CrossRef]

- Aitha, S.; Vasanthan, N. Effect of cellulose nanocrystals on crystallization, morphology and phase transition of polyamide 6. Compos. Interfaces 2020, 27, 371–384. [Google Scholar] [CrossRef]

- Zheng, T.; Pilla, S. Melt Processing of Cellulose Nanocrystal-Filled Composites: Toward Reinforcement and Foam Nucleation. Ind. Eng. Chem. Res. 2020, 59, 8511–8531. [Google Scholar] [CrossRef]

- Li, T.; Meng, F.; Chi, W.; Xu, S.; Wang, L. An Edible and Quick-Dissolving Film from Cassia Gum and Ethyl Cellulose with Improved Moisture Barrier for Packaging Dried Vegetables. Polymers 2022, 14, 4035. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, S.B.; Hao, L.T.; Hwang, S.Y.; Oh, D.X.; Koo, J.M.; Jeon, H.; Park, S.B.; Park, J. Masterbatch of Chitosan Nanowhiskers for Preparation of Nylon 6,10 Nanocomposite by Melt Blending. Polymers 2022, 14, 5488. https://doi.org/10.3390/polym14245488

Jin SB, Hao LT, Hwang SY, Oh DX, Koo JM, Jeon H, Park SB, Park J. Masterbatch of Chitosan Nanowhiskers for Preparation of Nylon 6,10 Nanocomposite by Melt Blending. Polymers. 2022; 14(24):5488. https://doi.org/10.3390/polym14245488

Chicago/Turabian StyleJin, Se Bin, Lam Tan Hao, Sung Yeon Hwang, Dongyeop X. Oh, Jun Mo Koo, Hyeonyeol Jeon, Sung Bae Park, and Jeyoung Park. 2022. "Masterbatch of Chitosan Nanowhiskers for Preparation of Nylon 6,10 Nanocomposite by Melt Blending" Polymers 14, no. 24: 5488. https://doi.org/10.3390/polym14245488

APA StyleJin, S. B., Hao, L. T., Hwang, S. Y., Oh, D. X., Koo, J. M., Jeon, H., Park, S. B., & Park, J. (2022). Masterbatch of Chitosan Nanowhiskers for Preparation of Nylon 6,10 Nanocomposite by Melt Blending. Polymers, 14(24), 5488. https://doi.org/10.3390/polym14245488