High-Efficiency Carbon Fiber Recovery Method and Characterization of Carbon FIBER-Reinforced Epoxy/4,4′-Diaminodiphenyl Sulfone Composites

Abstract

1. Introduction

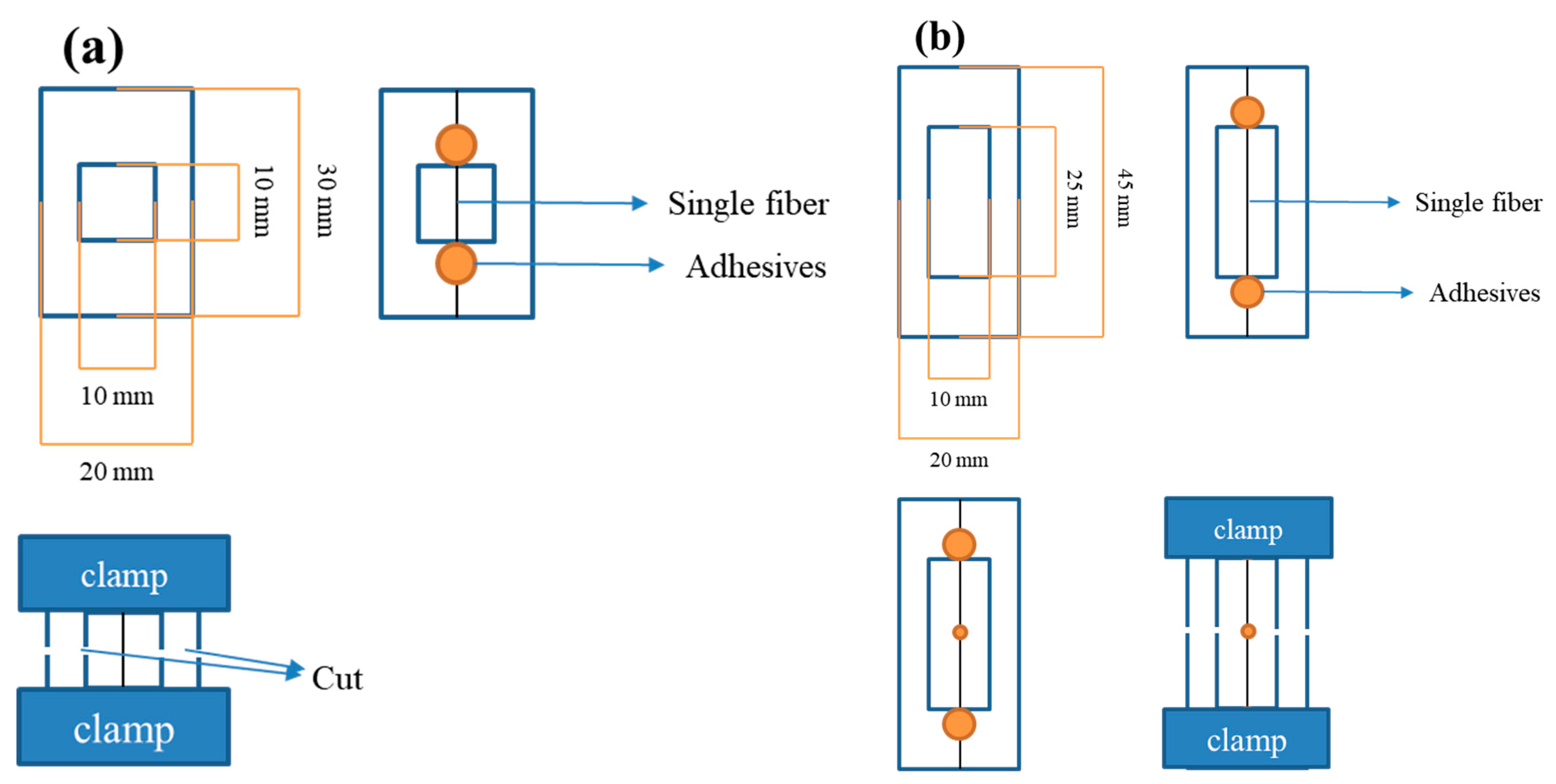

2. Materials and Methods

2.1. CFRP Pyrolysis

2.2. Fixed Pyrolysis Conditions

2.3. Physical Properties

2.4. Component Analysis

3. Results and Discussion

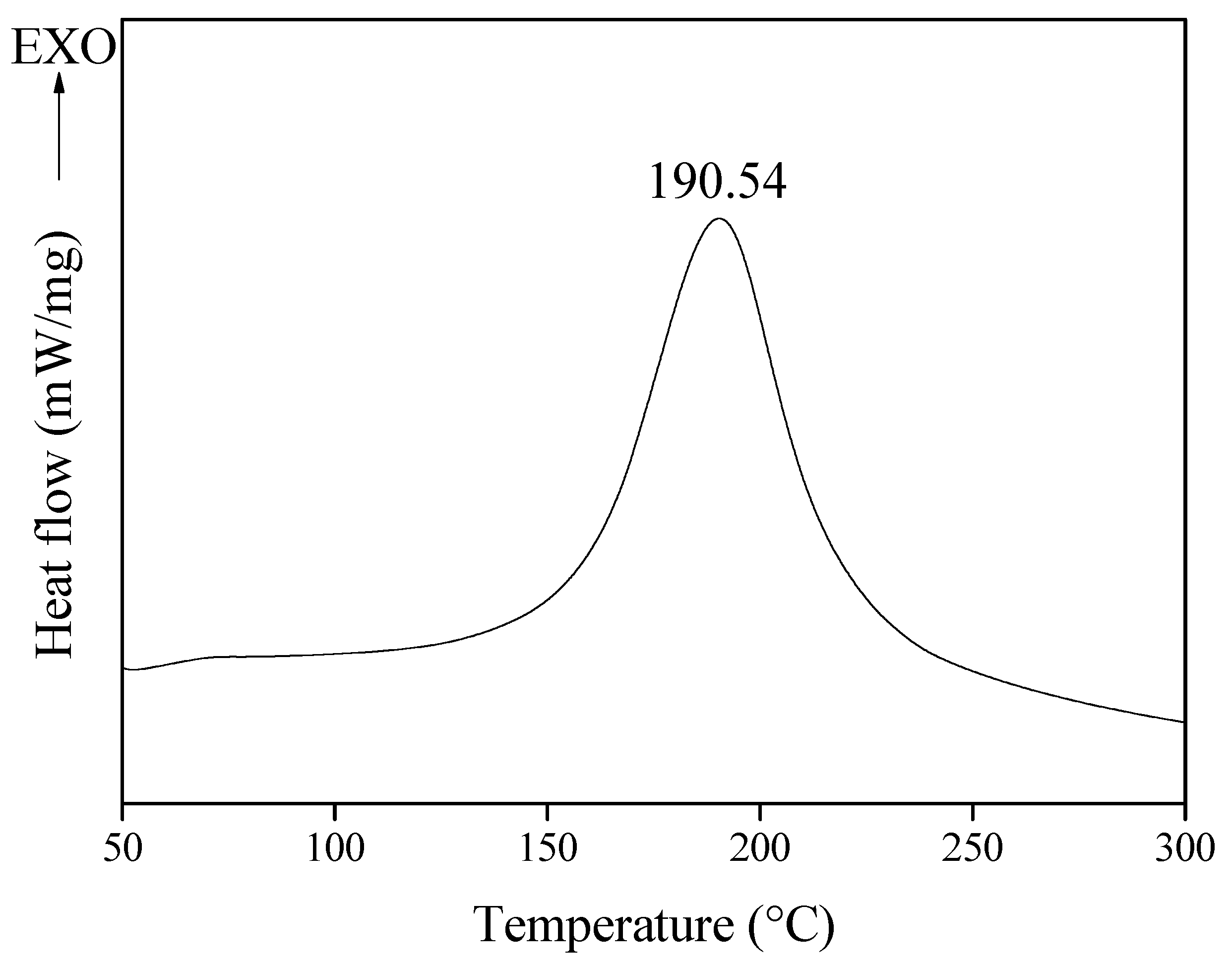

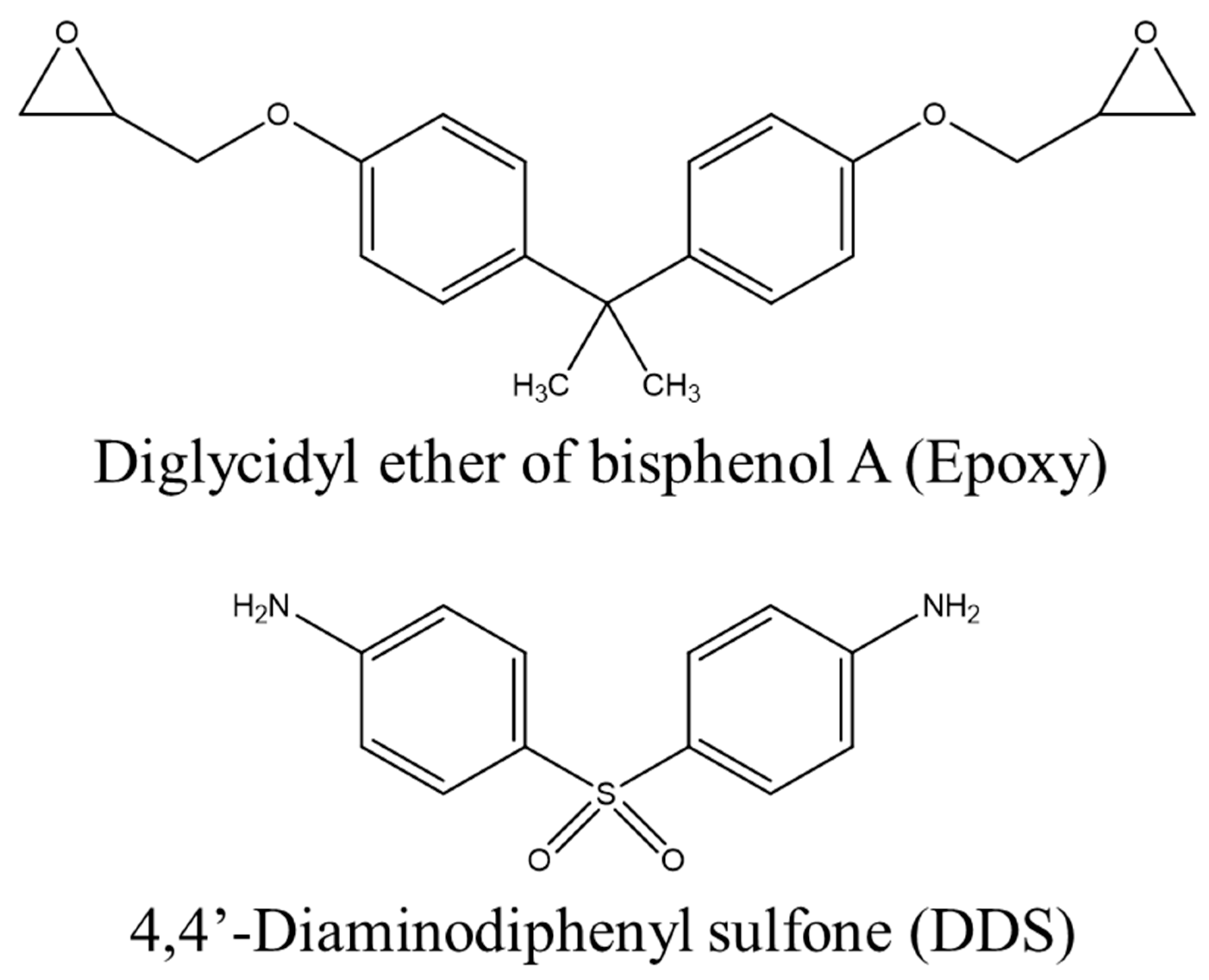

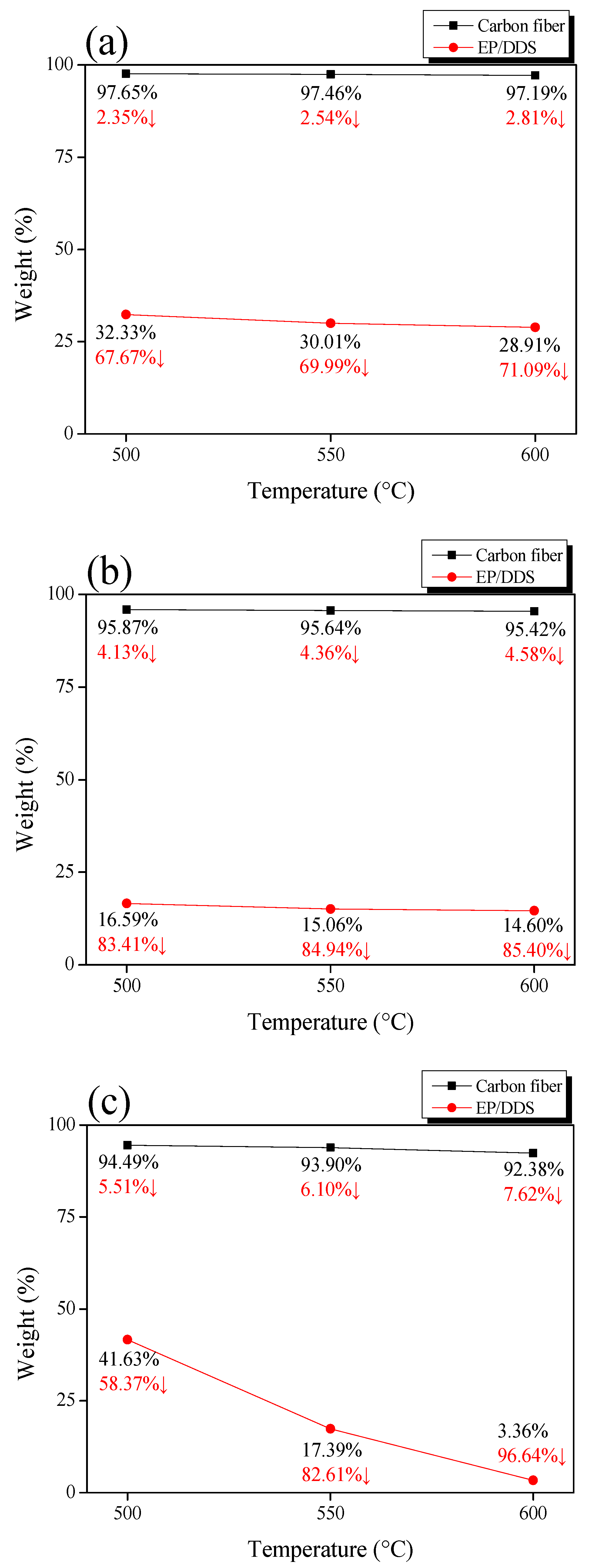

3.1. Pyrolysis Conditions of EP/DDS and Carbon Fiber

3.2. Morphology of the r-CF

3.3. Mechanical Properties of the r-CF

3.4. Functional Group of r-CF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hernandez, T.P.A.; Mills, A.R.; Yazdani Nezhad, H.Y. Shear driven deformation and damage mechanisms in High-performance carbon Fibre-reinforced thermoplastic and toughened thermoset composites subjected to high strain loading. Compos. Struct. 2021, 261, 113289. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Rao, P.S.; Hardiman, M.; O’Dowd, N.P.; Sebaey, T.A. Comparison of progressive damage between thermoset and thermoplastic CFRP composites under in-situ tensile loading. J. Compos. Mater. 2020, 55, 1473–1484. [Google Scholar] [CrossRef]

- EUR. L.Ex. 12 April 2022. Available online: eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32022D0591 (accessed on 6 April 2022).

- Kupski, J.; Teixeira de Freitas, S.T.D. Design of adhesively bonded lap joints with laminated CFRP adherends: Review, challenges and new opportunities for aerospace structures. Compos. Struct. 2021, 268, 113923. [Google Scholar] [CrossRef]

- Morioka, K.; Tomita, Y.; Takigawa, K. High-temperature fracture properties of CFRP composite for aerospace applications. Mater. Sci. Eng. A 2001, 319, 675–678. [Google Scholar] [CrossRef]

- Petrakli, F.; Gkika, A.; Bonou, A.; Karayannis, P.; Koumoulos, E.P.; Semitekolos, D.; Trompeta, A.-F.; Rocha, N.; Santos, R.M.; Simmonds, G.; et al. End-of-Life Recycling Options of (Nano)Enhanced CFRP Composite Prototypes Waste—A Life Cycle perspective. Polymers 2020, 12, 2129. [Google Scholar] [CrossRef]

- Shi, J.; Bao, L. Optimum decomposition conditions for glass fiber reinforced plastic recycling by superheated steam. Jpn. J. Appl. Phys. 2011, 50, 01AJ01. [Google Scholar] [CrossRef]

- Bere, P.; Dudescu, M.; Neamțu, C.; Cocian, C. Design, manufacturing and test of CFRP front hood concepts for a light-weight vehicle. Polymers 2021, 13, 1374. [Google Scholar] [CrossRef] [PubMed]

- Fragassa, C.; Pavlovic, A.; Minak, G. On the structural behaviour of a CFRP safety cage in a solar powered electric vehicle. Compos. Struct. 2020, 252, 112698. [Google Scholar] [CrossRef]

- Jeong, J.S.; Kim, K.W.; An, K.-H.; Kim, B.-J. Fast recovery process of carbon fibers from waste carbon fibers-reinforced thermoset plastics. J. Environ. Manag. 2019, 247, 816–821. [Google Scholar] [CrossRef]

- Berger, D.; Brabandt, D.; Bakir, C.; Hornung, T.; Lanza, G.; Summa, J.; Schwarz, M.; Herrmann, H.-G.; Pohl, M.; Stommel, M. Effects of defects in series production of hybrid CFRP lightweight components—Detection and evaluation of quality critical characteristics. Measurement 2017, 95, 389–394. [Google Scholar] [CrossRef]

- Zhang, J. Zhou, P.; Guan, C.; Liu, T.Q.; Kang, W.-H.; Feng, P.; Gao, Shuoqi. An ultra-lightweight CFRP beam-string structure. Compos. Struct. 2021, 257, 113149. [Google Scholar] [CrossRef]

- Wong, D.W.Y.; Lin, L.; McGrail, P.T.; Peijs, T.; Hogg, P.J. Improved fracture toughness of carbon fibre/epoxy composite laminates using dissolvable thermoplastic fibres. Compos. A 2010, 41, 759–767. [Google Scholar] [CrossRef]

- El-Tahan, M.; Galal, K.; Hoa, V.S. New thermoplastic CFRP bendable rebars for reinforcing structural concrete elements. Compos. B Eng. 2013, 45, 1207–1215. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M.; Ichimura, J.; Hayakawa, E. Accelerated testing for long-term strength of innovative CFRP laminates for marine use. Compos. B Eng. 2008, 39, 5–12. [Google Scholar] [CrossRef]

- Alam, P.; Robert, C.; Ó Brádaigh, C.M.Ó. Tidal turbine blade composites—A review on the effects of hygrothermal aging on the properties of CFRP. Compos. B Eng. 2018, 149, 248–259. [Google Scholar] [CrossRef]

- Wang, W.-X.; Matsubara, T.; Hu, J.; Odahara, S.; Nagai, T.; Karasutani, T.; Ohya, Y. Experimental investigation into the influence of the flanged diffuser on the dynamic behavior of CFRP blade of a shrouded wind turbine. Renew. Energy 2015, 78, 386–397. [Google Scholar] [CrossRef]

- Taniguchi, N.; Nishiwaki, T.; Kawada, H. Tensile strength of unidirectional CFRP laminate under high strain rate. Adv. Compos. Mater. 2007, 16, 167–180. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Michel, A.; Liebscher, M.; Schneider, K.; Großmann, C. Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: Material and automation perspectives. Autom. Constr. 2020, 110, 103002. [Google Scholar] [CrossRef]

- Firmo, J.P.; Roquette, M.G.; Correia, J.R.; Azevedo, A.S. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications. Int. J. Adhes. Adhes. 2019, 93, 102333. [Google Scholar] [CrossRef]

- Danilov, A.I. Some aspects of CFRP steel structures reinforcement in civil engineering. Procedia Eng. 2016, 153, 124–130. [Google Scholar] [CrossRef][Green Version]

- Kim, K.W.; Lee, H.M.; An, J.H.; Chung, D.C.; An, K.-H.; Kim, B.-J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef] [PubMed]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Liu, W.; Huang, H.; Zhu, L.; Liu, Z. Integrating carbon fiber reclamation and additive manufacturing for recycling CFRP waste. Compos. B Eng. 2021, 215, 108808. [Google Scholar] [CrossRef]

- EUR. L.Ex. 21 October 2000. Available online: eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex%3A32000L0053 (accessed on 18 September 2000).

- Maaß, S. Aircraft Recycling—A Literature Review; Hamburg University of Applied Sciences: Hamburg, Germany, 2020; pp. 8–23. [Google Scholar]

- Gopalraj, S.K. Impacts of Recycled Carbon Fibre and Glass Fibre as Sustainable Raw Materials for Thermosetting Composites. Ph.D. Thesis, Acta Universitatis Lappeenrantensis, Lappeenranta, Finland, 2022; pp. 15–17. [Google Scholar]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. A 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Khalil, Y.F. Comparative environmental and human health evaluations of thermolysis and solvolysis recycling technologies of carbon fiber reinforced polymer waste. Waste Manag. 2018, 76, 767–778. [Google Scholar] [CrossRef]

- Tapper, R.J.; Longana, M.L.; Hamerton, I.; Potter, K.D. A closed-loop recycling process for discontinuous carbon fibre polyamide 6 composites. Compos. B Eng. 2019, 179, 107418. [Google Scholar] [CrossRef]

- Thomas, C.; Borges, P.H.R.; Panzera, T.H.; Cimentada, A.; Lombillo, I. Epoxy composites containing CFRP powder wastes. Compos. B Eng. 2014, 59, 260–268. [Google Scholar] [CrossRef]

- Obunai, K.; Fukuta, T.; Ozaki, K. Carbon fiber extraction from waste CFRP by microwave irradiation. Compos. A 2015, 78, 160–165. [Google Scholar] [CrossRef]

- Zhao, Q.; An, L.; Li, C.; Zhang, L.; Jiang, J.; Li, Y. Environment-friendly recycling of CFRP composites via gentle solvent system at atmospheric pressure. Compos. Sci. Technol. 2022, 224, 109461. [Google Scholar] [CrossRef]

- Hanaoka, T.; Arao, Y.; Kayaki, Y.; Kuwata, S.; Kubouchi, M. Analysis of nitric acid decomposition of epoxy resin network structures for chemical recycling. Polym. Degrad. Stab. 2021, 186, 109537. [Google Scholar] [CrossRef]

- Hanaoka, T.; Ikematsu, H.; Takahashi, S.; Ito, N.; Ijuin, N.; Kawada, H.; Arao, Y.; Kubouchi, M. Recovery of carbon fiber from prepreg using nitric acid and evaluation of recycled CFRP. Compos. B. Eng. 2022, 231, 109560. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Xu, P.; Li, J.; Ding, J. Chemical recycling of carbon fibre/epoxy composites in a mixed solution of peroxide hydrogen and N,N-dimethylformamide. Compos. Sci. Technol. 2013, 82, 54–59. [Google Scholar] [CrossRef]

- Okajima, I.; Sako, T. Recycling of carbon fiber-reinforced plastic using supercritical and subcritical fluids. J. Mater. Cycles Waste Manag. 2017, 19, 15–20. [Google Scholar] [CrossRef]

- Okajima, I.; Hiramatsu, M.; Shimamura, Y.; Awaya, T.; Sako, T. Chemical recycling of carbon fiber reinforced plastic using supercritical methanol. J. Supercrit. Fluids 2014, 91, 68–76. [Google Scholar] [CrossRef]

- Okajima, I.; Sako, T. Recycling fiber-reinforced plastic using supercritical acetone. Polym. Degrad. Stab. 2019, 163, 1–6. [Google Scholar] [CrossRef]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-recycling following a pyrolysis route: Process optimization and potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Deng, Z.; Xu, L.; Zhang, L.; Peng, J.; Guo, S.; Liu, J.; Koppala, S. Recycling of Carbon Fibers from CFRP Waste by Microwave Thermolysis. Processes 2019, 7, 207. [Google Scholar] [CrossRef]

- Deng, Z.; Yue, J.; Huang, Z. Solvothermal degradation and reuse of carbon fiber reinforced boron phenolic resin composites. Compos. B. Eng. 2021, 221, 109011. [Google Scholar] [CrossRef]

- Huang, Z.; Deng, Z.; Dong, C.; Fan, C.; Ren, Y. A close-loop recycling process for carbon fiber reinforced vinyl ester resin composite. Chem. Eng. J. 2022, 446, 137254. [Google Scholar] [CrossRef]

| Sample | Step 1 | Step 2 | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | Heating Rate (°C/min) | Hold Time (min) | Steam (cc/min) | Temperature (°C) | Heating Rate (°C/min) | Hold Time (min) | Air (cc/min) | |

| Ar-CF | - | - | - | - | - | - | - | - |

| 50 | 500 | 10 | 180 | 5 | - | - | - | - |

| 55 | 550 | |||||||

| 60 | 600 | |||||||

| 50-50-10 | 500 | 10 | 180 | 5 | 500 | 10 | 10 | 200 |

| 50-55-10 | 550 | |||||||

| 50-60-10 | 600 | |||||||

| 55-60-10 | 550 | 10 | 180 | 5 | 600 | 10 | 10 | 200 |

| 60-60-10 | 600 | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.-M.; Kim, K.-W.; Kim, B.-J. High-Efficiency Carbon Fiber Recovery Method and Characterization of Carbon FIBER-Reinforced Epoxy/4,4′-Diaminodiphenyl Sulfone Composites. Polymers 2022, 14, 5304. https://doi.org/10.3390/polym14235304

Lee Y-M, Kim K-W, Kim B-J. High-Efficiency Carbon Fiber Recovery Method and Characterization of Carbon FIBER-Reinforced Epoxy/4,4′-Diaminodiphenyl Sulfone Composites. Polymers. 2022; 14(23):5304. https://doi.org/10.3390/polym14235304

Chicago/Turabian StyleLee, Yong-Min, Kwan-Woo Kim, and Byung-Joo Kim. 2022. "High-Efficiency Carbon Fiber Recovery Method and Characterization of Carbon FIBER-Reinforced Epoxy/4,4′-Diaminodiphenyl Sulfone Composites" Polymers 14, no. 23: 5304. https://doi.org/10.3390/polym14235304

APA StyleLee, Y.-M., Kim, K.-W., & Kim, B.-J. (2022). High-Efficiency Carbon Fiber Recovery Method and Characterization of Carbon FIBER-Reinforced Epoxy/4,4′-Diaminodiphenyl Sulfone Composites. Polymers, 14(23), 5304. https://doi.org/10.3390/polym14235304