Novel In Situ Modification for Thermoplastic Starch Preparation based on Arenga pinnata Palm Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Thermoplastic Starch (TPS)

2.3. Fourier-Transform Infrared (FTIR)

2.4. Density Measurements

2.5. Scanning Electron Microscopy (SEM)

2.6. X-ray Diffraction (XRD)

2.7. Mechanical Properties

2.8. Rheological Properties

2.9. Differential Scanning Calorimeter (DSC)

2.10. Thermogravimetric Analysis (TGA)

3. Results and Discussions

3.1. FTIR Analysis

3.2. Physical Properties

3.3. Morphology

3.4. Crystallinity

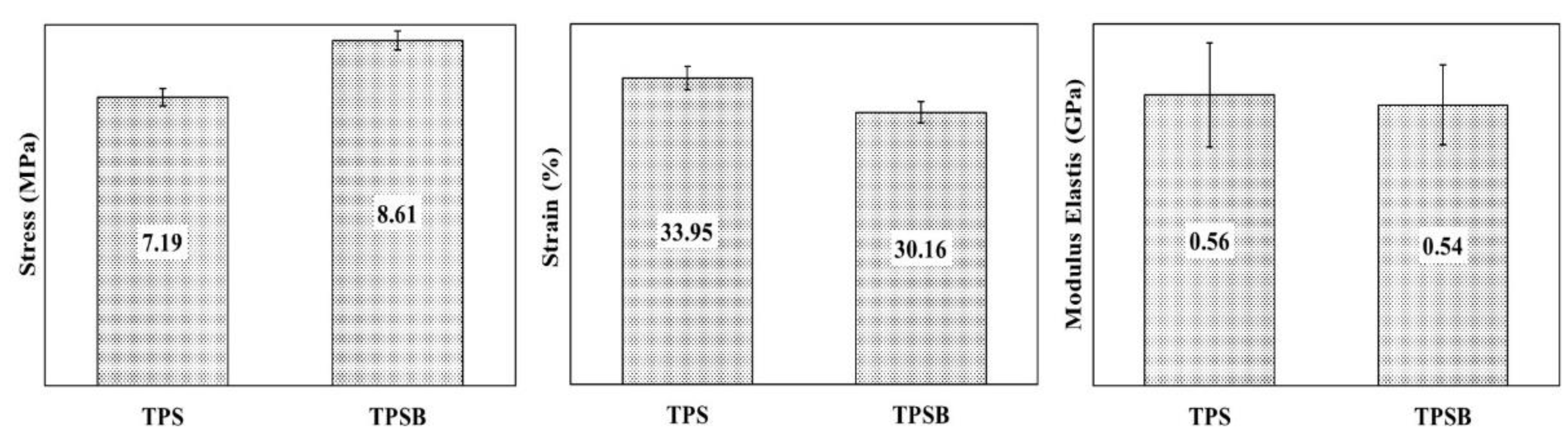

3.5. Mechanical Properties

3.6. Rheological Properties

3.7. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nessi, V.; Falourd, X.; Maigret, J.-H.; Cahier, K.; D’Orlando, A.; Descamps, N.; Gaucher, V.; Chevigny, C.; Lourdin, D. Cellulose nanocrystals-starch nanocomposites produced by extrusion: Structure and behavior in physiological conditions. Carbohydr. Polym. 2019, 225, 115123. [Google Scholar] [CrossRef] [PubMed]

- Lendvai, L.; Karger-Kocsis, J.; Kmetty, Á.; Drakopoulos, S.X. Production and characterization of microfibrillated cellulose-reinforced thermoplastic starch composites. J. Appl. Polym. Sci. 2016, 133, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Recent developments in sugar palm (Arenga pinnata) based biocomposites and their potential industrial applications: A review. Renew. Sustain. Energy Rev. 2016, 54, 533–549. [Google Scholar] [CrossRef]

- Kringel, D.H.; Dias, A.R.G.; Zavareze, E.R.; Gandra, E.A. Fruit Wastes as Promising Sources of Starch: Extraction, Properties, and Applications. Starch/Staerke 2020, 72, 3–4. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N.; Nurazzi, N.M.; Atiqah, A.; Ansari, M.N.M.; et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Adawiyah, D.R.; Sasaki, T.; Kohyama, K. Characterization of arenga starch in comparison with sago starch. Carbohydr. Polym. 2013, 92, 2306–2313. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ebadi, S.; Azrina, A.; Razman, M.R. Mechanical properties of sugar palm lignocellulosic fibre reinforced polymer composites: A review. Cellulose 2022, 29, 6493–6516. [Google Scholar] [CrossRef]

- Zhang, L.; Mei, J.Y.; Ren, M.H.; Fu, Z. Optimization of enzyme-assisted preparation and characterization of Arenga pinnata resistant starch. Food Struct. 2020, 25, 100149. [Google Scholar] [CrossRef]

- Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Rahman, M.Z.A.; Anwar, U.M.K.; Siregar, J.P. Sugar palm (Arenga pinnata): Its fibres, polymers and composites. Carbohydr. Polym. 2013, 91, 699–710. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. Thermo-mechanical behaviors of thermoplastic starch derived from sugar palm tree (Arenga pinnata). Carbohydr. Polym. 2013, 92, 1711–1716. [Google Scholar] [CrossRef]

- Sahari, J.; Sapuan, S.M.; Zainudin, E.S.; Maleque, M.A. A New Approach to Use Arenga pinnata as Sustainable Biopolymer: Effects of Plasticizers on Physical Properties. Procedia Chem. 2012, 4, 254–259. [Google Scholar] [CrossRef] [Green Version]

- Kampangkaew, S.; Thongpin, C.; Santawtee, O. The synthesis of cellulose nanofibers from Sesbania Javanica for filler in thermoplastic starch. Energy Procedia 2014, 56, 318–325. [Google Scholar] [CrossRef] [Green Version]

- Ghanbari, A.; Tabarsa, T.; Ashori, A.; Shakeri, A.; Mashkour, M. Preparation and characterization of thermoplastic starch and cellulose nanofibers as green nanocomposites: Extrusion processing. Int. J. Biol. Macromol. 2018, 112, 442–447. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, E.M.; Curvelo, A.A.S.; Corrêa, A.C.; Marconcini, J.M.; Glenn, G.M.; Mattoso, L.H.C. Properties of thermoplastic starch from cassava bagasse and cassava starch and their blends with poly (lactic acid). Ind. Crops Prod. 2012, 37, 61–68. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Z.; Liu, J.; Dai, B.; Hu, S.; Hong, R.; Xie, H.; Li, Z.; Chen, Y.; Zeng, G. Preparation, reinforcement and properties of thermoplastic starch film by film blowing. Food Hydrocoll. 2020, 108, 106006. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Siqueira, L.V.; Augusto, P.E.D.; Tadini, C.C. Casting and extrusion processes to produce bio-based plastics using cassava starch modified by the dry heat treatment (DHT). Innov. Food Sci. Emerg. Technol. 2022, 75, 102906. [Google Scholar] [CrossRef]

- Gilfillan, N.W.; Moghaddam, L.; Bartley, J.; Doherty, W.O.S. Thermal extrusion of starch film with alcohol. J. Food Eng. 2016, 170, 92–99. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Wang, X.; Long, Z.; Wang, S.; Zhang, J.; Wang, L. Preparation and performance of thermoplastic starch and microcrystalline cellulose for packaging composites: Extrusion and hot pressing. Int. J. Biol. Macromol. 2020, 165, 2295–2302. [Google Scholar] [CrossRef]

- Hietala, M.; Mathew, A.P.; Kristiina, O. Bionanocomposites of thermoplastic starch and cellulose nanofibers manufactured using twin-screw extrusion. Eur. Polym. J. 2013, 49, 950–956. [Google Scholar] [CrossRef]

- Fourati, Y.; Magnin, A.; Putaux, J.L.; Boufi, S. One-step processing of plasticized starch/cellulose nanofibrils nanocomposites via twin-screw extrusion of starch and cellulose fibers. Carbohydr. Polym. 2020, 229, 115554. [Google Scholar] [CrossRef]

- Bangar, S.P.; Whiteside, W.S.; Ashogbon, A.O.; Kumar, M. Recent advances in thermoplastic starches for food packaging: A review. Food Packag. Shelf Life 2021, 30, 100743. [Google Scholar] [CrossRef]

- Ekielski, A.; Żelaziński, T.; Mishra, P.K.; Skudlarski, J. Properties of biocomposites produced with thermoplastic starch and digestate: Physicochemical and mechanical characteristics. Materials 2021, 14, 6092. [Google Scholar] [CrossRef] [PubMed]

- Maulana, M.I.; Lubis, M.A.R.; Febrianto, F.; Hua, L.S.; Iswanto, A.H.; Antov, P.; Kristak, L.; Mardawati, E.; Sari, R.K.; Zaini, L.H.; et al. Environmentally Friendly Starch-Based Adhesives for Bonding High-Performance Wood Composites: A Review. Forests 2022, 13, 1614. [Google Scholar] [CrossRef]

- Vanier, N.L.; El Halal, S.L.M.; Dias, A.R.G.; Zavareze, E.R. Molecular structure, functionality and applications of oxidized starches: A review. Food Chem. 2017, 221, 1546–1559. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, X.; Zhao, G.; Wang, Y. Influence of oxidized starch on the properties of thermoplastic starch. Carbohydr. Polym. 2013, 96, 358–364. [Google Scholar] [CrossRef] [PubMed]

- Herniou-Julien, C.; Mendieta, J.R.; Gutiérrez, T.J. Characterization of biodegradable/non-compostable films made from cellulose acetate/corn starch blends processed under reactive extrusion conditions. Food Hydrocoll. 2018, 89, 67–79. [Google Scholar] [CrossRef]

- Jariyasakoolroj, P.; Supthanyakul, R.; Laobuthee, A.; Lertworasirikul, A.; Yoksan, R.; Phongtamrug, S.; Chirachanchai, S. Structure and properties of in situ reactive blend of polylactide and thermoplastic starch. Int. J. Biol. Macromol. 2021, 182, 1238–1247. [Google Scholar] [CrossRef]

- Raabe, J.; Fonseca, A.S.; Bufalino, L.; Ribeiro, C.; Martins, M.A.; Marconcini, J.M.; Mendes, L.M.; Tonoli, G.H.D. Biocomposite of cassava starch reinforced with cellulose pulp fibers modified with deposition of silica (SiO2) nanoparticles. J. Nanomater. 2015, 2015, 6. [Google Scholar] [CrossRef] [Green Version]

- Teixeira, E.M.; Lotti, C.; Correa, A.C.; Teodoro, K.B.R.; Marconcini, J.M.; Mattoso, L.H.C.M. Thermoplastic Corn Starch Reinforced with Cotton Cellulose Nanofibers. J. Appl. Polym. Sci. 2011, 120, 2428–2433. [Google Scholar] [CrossRef]

- Yan, Q.; Hou, H.; Guo, P.; Dong, H. Effects of extrusion and glycerol content on properties of oxidized and acetylated corn starch-based films. Carbohydr. Polym. 2012, 87, 707–712. [Google Scholar] [CrossRef]

- Yusoff, N.H.; Pal, K.; Narayanan, T.; de Souza, F.G. Recent trends on bioplastics synthesis and characterizations: Polylactic acid (PLA) incorporated with tapioca starch for packaging applications. J. Mol. Struct. 2021, 1232, 129954. [Google Scholar] [CrossRef]

- Özeren, H.D.; Olsson, R.T.; Nilsson, F.; Hedenqvist, M.S. Prediction of plasticization in a real biopolymer system (starch) using molecular dynamics simulations. Mater. Des. 2020, 187, 108387. [Google Scholar] [CrossRef]

| Sample | APPS | TPS | TPSB |

|---|---|---|---|

| Gelatinization temperature (°C) | 70 | - | - |

| Glass transition temperature (°C) | - | 65 | 52 |

| Residual mass at 600 °C (%) | 9.36 | 5.47 | 5.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghozali, M.; Meliana, Y.; Chalid, M. Novel In Situ Modification for Thermoplastic Starch Preparation based on Arenga pinnata Palm Starch. Polymers 2022, 14, 4813. https://doi.org/10.3390/polym14224813

Ghozali M, Meliana Y, Chalid M. Novel In Situ Modification for Thermoplastic Starch Preparation based on Arenga pinnata Palm Starch. Polymers. 2022; 14(22):4813. https://doi.org/10.3390/polym14224813

Chicago/Turabian StyleGhozali, Muhammad, Yenny Meliana, and Mochamad Chalid. 2022. "Novel In Situ Modification for Thermoplastic Starch Preparation based on Arenga pinnata Palm Starch" Polymers 14, no. 22: 4813. https://doi.org/10.3390/polym14224813

APA StyleGhozali, M., Meliana, Y., & Chalid, M. (2022). Novel In Situ Modification for Thermoplastic Starch Preparation based on Arenga pinnata Palm Starch. Polymers, 14(22), 4813. https://doi.org/10.3390/polym14224813