Wear Behaviour of Multilayer Al-PVD-Coated Polymer Gears

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Coating Deposition Process

2.2.2. Coating Characterisation

2.2.3. Indentation Tests and Adhesion Analysis

2.2.4. Gear-Wear Tests

3. Results and Discussion

3.1. Coating Characterisation

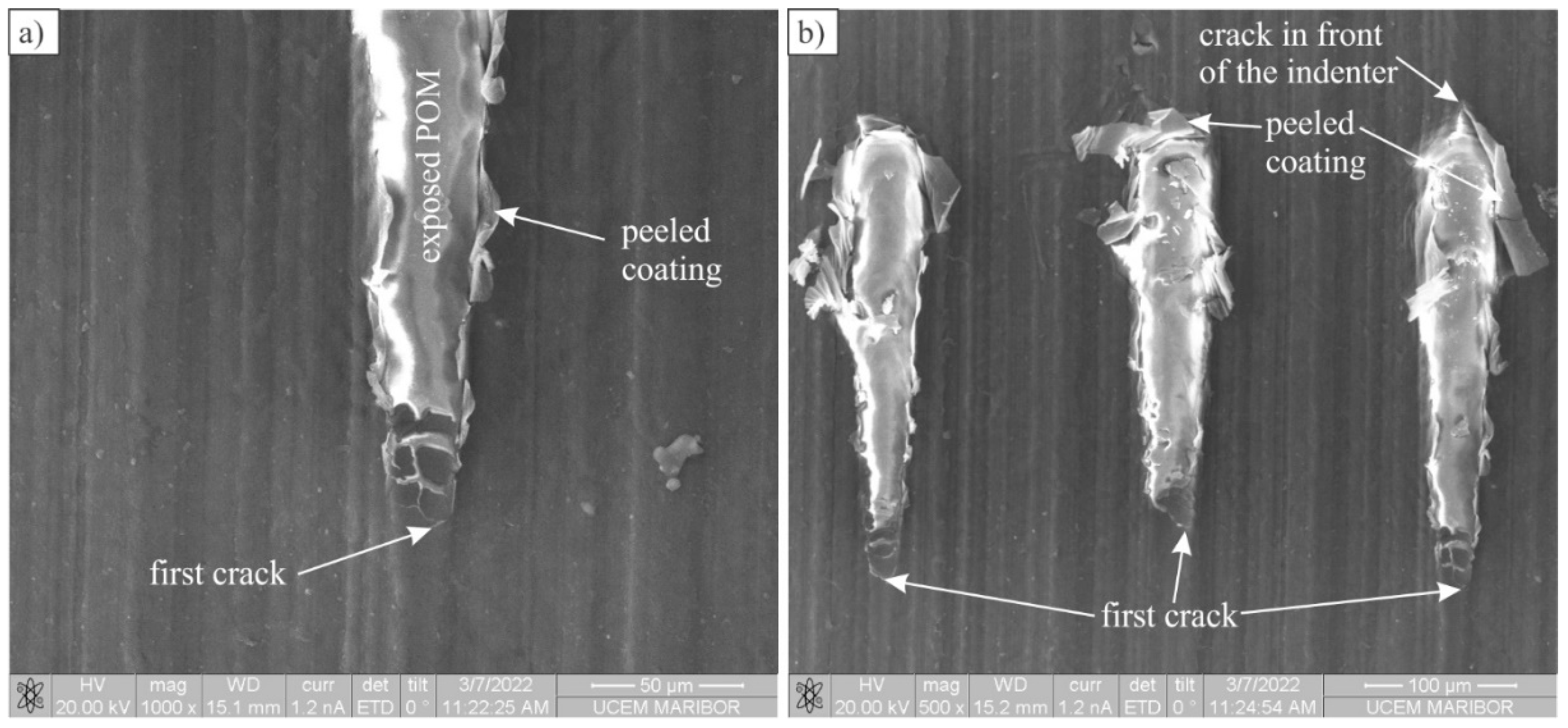

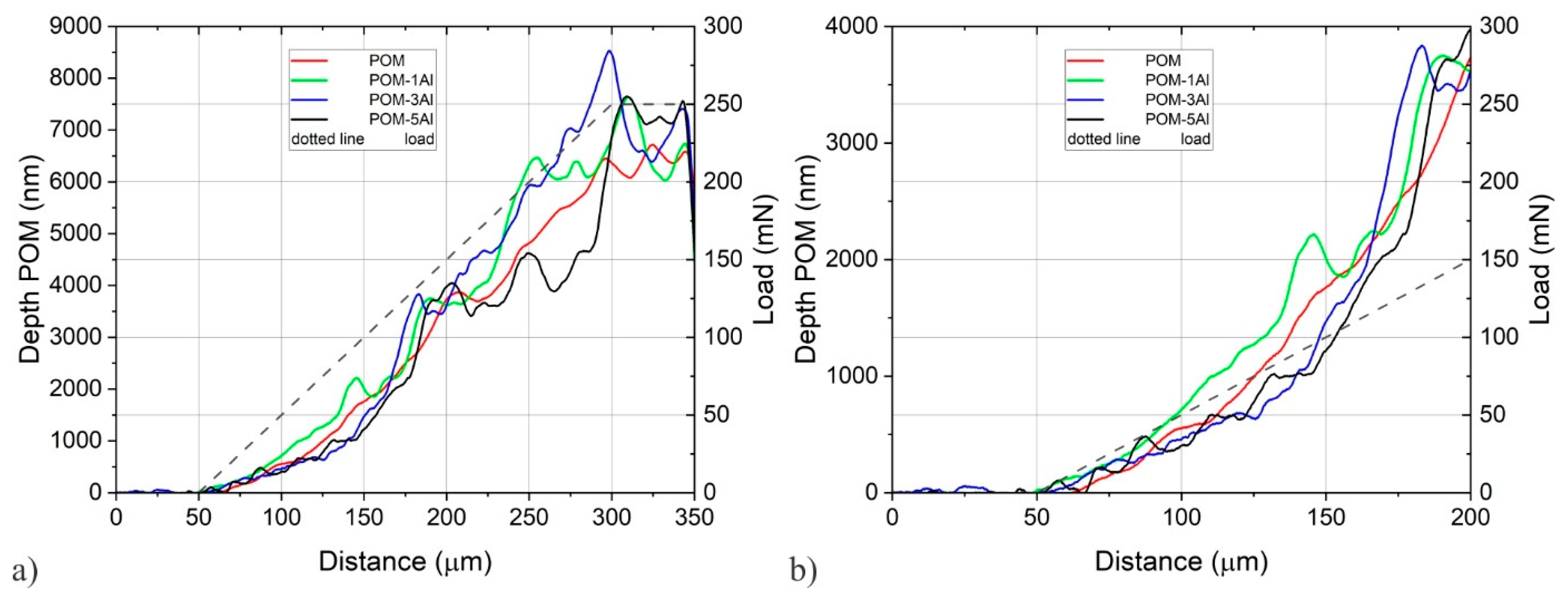

3.2. Adhesion Analysis

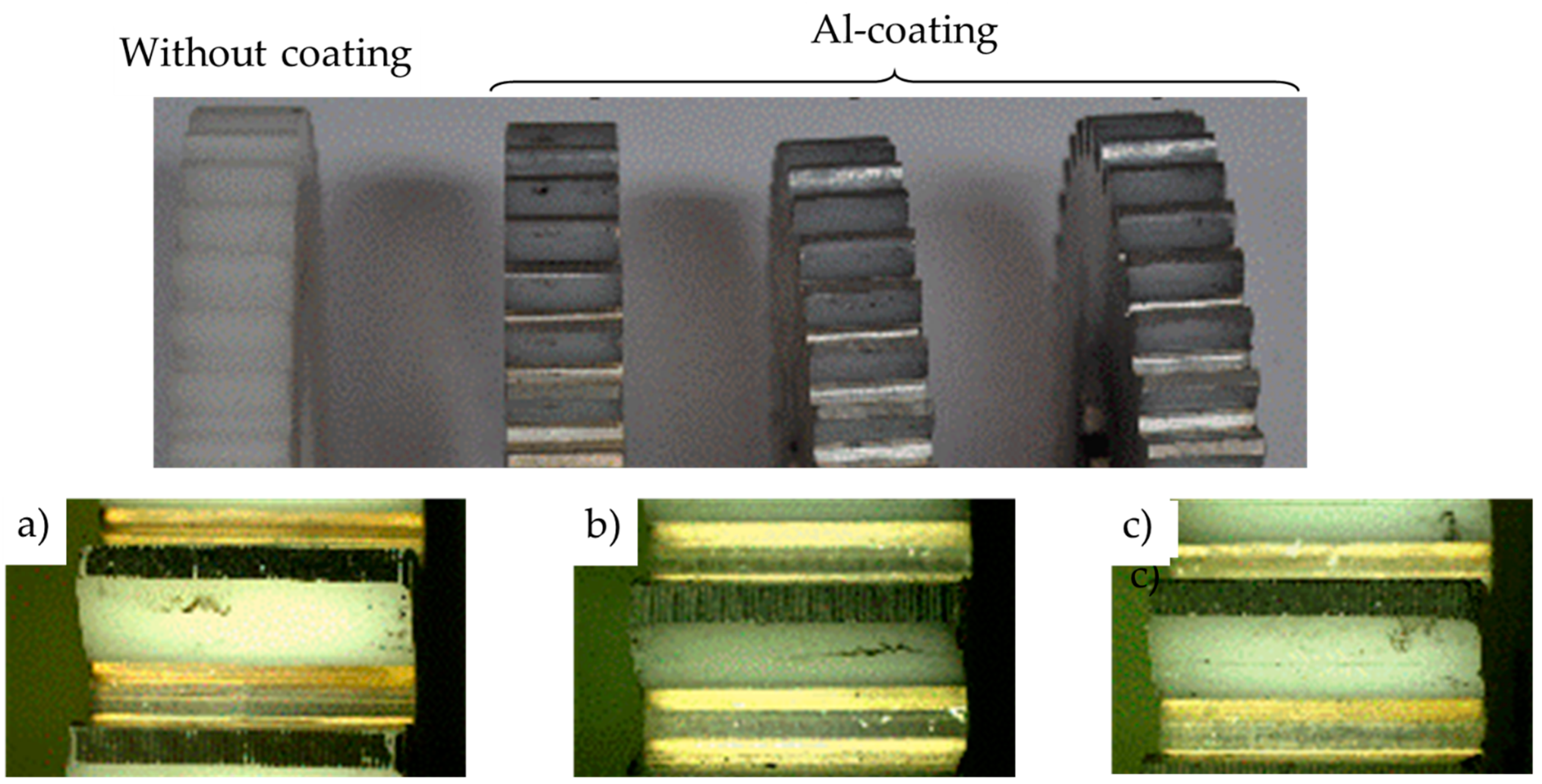

3.3. Wear Behaviour of the Analysed Gears

4. Conclusions

- The indentation tests made on both the uncoated and coated samples have shown a very small increase in indentation hardness and modulus due to the Al-coating. However, the indentation hardness and reduced modulus increased with the increasing thickness of surface coatings and were much lower than the known properties of pure aluminium.

- The SEM analysis of the coated surfaces has shown that the surface with the five Al-layers was rougher compared to surfaces with one or three coating layers. Furthermore, some porosity appeared in the surface coating with five coating layers, which probably arose during the deposition process and may have led to the separation of the individual layers.

- The comprehensive adhesion analysis has shown that the adherence between the substrate (POM) and Al coating was not sufficiently high, which may have led to the separation of the coated surface layer in a very early stage of gear operation.

- For both the uncoated and coated polymer gears, the wear increased with increasing torque. However, a negative influence of the surface coating on the wear resistance of analysed polymer gears was obtained, especially in the case of five coating layers. This phenomenon could be explained due to the fact that the surface coating was removed at a very early stage of experimental testing and then acted as an abrasive material between the meshing gear flanks.

- Based on the general findings as explained above, it can be concluded that the influence of the analysed Al coatings on the wear behaviour of POM polymer spur gears is small and does not reduce the wear of meshing gear flanks. For that reason, a systematic investigation of the complete PVD procedure is recommended in the future to improve the adhesion characteristics between a POM substrate and an Al coating. Furthermore, the other PVD coatings (Cr, CrN, etc.) may be considered in further research work related to the wear behaviour of coated polymer gears.

- For better adhesion of aluminium to polymer samples, it would be reasonable to optimize the plasma activation process. Parameters that could possibly improve adhesion are a higher power, longer process step, use of argon instead of air, etc. Finer surface treatment of the polymer samples and degreasing the samples before the sputtering process might also help to improve adhesion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trobentar, B.; Kulovec, S.; Hlebanja, G.; Glodež, S. Experimental Failure Analysis of S-Polymer Gears. Eng. Fail. Anal. 2020, 111, 104496. [Google Scholar] [CrossRef]

- Matkovič, S.; Pogačnik, A.; Kalin, M. Wear-Coefficient Analyses for Polymer-Gear Life-Time Predictions: A Critical Appraisal of Methodologies. Wear 2021, 480–481, 203944. [Google Scholar] [CrossRef]

- Zorko, D.; Demšar, I.; Tavčar, J. An Investigation on the Potential of Bio-Based Polymers for Use in Polymer Gear Transmissions. Polym. Test. 2021, 93, 106994. [Google Scholar] [CrossRef]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Gear Fatigue Life and Thermomechanical Behavior of Novel Green and Bio-Composite Materials vs. High-Performance Thermoplastics. Polym. Test. 2018, 66, 403–414. [Google Scholar] [CrossRef]

- Gnatowski, A.; Gołębski, R.; Sikora, P. Analysis of the Impact of Changes in Thermomechanical Properties of Polymer Materials on the Machining Process of Gears. Polymers 2020, 13, 28. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Wu, W. A Practical Numerical Approach to Characterising Non-Linear Shrinkage and Optimising Dimensional Deviation of Injection-Molded Small Module Plastic Gears. Polymers 2021, 13, 2092. [Google Scholar] [CrossRef] [PubMed]

- Senthilvelan, S.; Gnanamoorthy, R. Damping Characteristics of Unreinforced, Glass and Carbon Fiber Reinforced Nylon 6/6 Spur Gears. Polym. Test. 2006, 25, 56–62. [Google Scholar] [CrossRef]

- Singh, A.K.; Siddhartha; Singh, P.K. Polymer Spur Gears Behaviors under Different Loading Conditions: A Review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 210–228. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer Composites for Tribological Applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Zorko, D.; Kulovec, S.; Duhovnik, J.; Tavčar, J. Durability and Design Parameters of a Steel/PEEK Gear Pair. Mech. Mach. Theory 2019, 140, 825–846. [Google Scholar] [CrossRef]

- Hribersek, M.; Erjavec, M.; Hlebanja, G.; Kulovec, S. Durability Testing and Characterization of POM Gears. Eng. Fail. Anal. 2021, 124, 105377. [Google Scholar] [CrossRef]

- Mao, K. A Numerical Method for Polymer Composite Gear Flash Temperature Prediction. Wear 2007, 262, 1321–1329. [Google Scholar] [CrossRef]

- Evans, S.M.; Keogh, P.S. Efficiency and Running Temperature of a Polymer–Steel Spur Gear Pair from Slip/Roll Ratio Fundamentals. Tribol. Int. 2016, 97, 379–389. [Google Scholar] [CrossRef]

- Md Ghazali, W.; Daing Idris, D.M.N.; Sofian, A.H.; Siregar, J.P.; Abdul Aziz, I.A. A Review on Failure Characteristics of Polymer Gear. MATEC Web Conf. 2017, 90, 01029. [Google Scholar] [CrossRef]

- Pogačnik, A.; Tavčar, J. An Accelerated Multilevel Test and Design Procedure for Polymer Gears. Mater. Des. 2015, 65, 961–973. [Google Scholar] [CrossRef]

- Mao, K.; Chetwynd, D.G.; Millson, M. A New Method for Testing Polymer Gear Wear Rate and Performance. Polym. Test. 2020, 82, 106323. [Google Scholar] [CrossRef]

- Düzcükoğlu, H. Study on Development of Polyamide Gears for Improvement of Load-Carrying Capacity. Tribol. Int. 2009, 42, 1146–1153. [Google Scholar] [CrossRef]

- ISO 6336; Calculation of Load Capacity of Spur and Helical Gears. ISO: Geneva, Switzerland, 2019.

- VDI 2736; Thermoplastic Gear Wheels, German Standard. VDI: Düsseldorf, Germany, 2019.

- Bravo, A.; Koffi, D.; Toubal, L.; Erchiqui, F. Life and Damage Mode Modeling Applied to Plastic Gears. Eng. Fail. Anal. 2015, 58, 113–133. [Google Scholar] [CrossRef]

- Dearn, K.D.; Hoskins, T.J.; Andrei, L.; Walton, D. Lubrication Regimes in High-Performance Polymer Spur Gears. Adv. Tribol. 2013, 2013, 987251. [Google Scholar] [CrossRef]

- Yu, G.; Liu, H.; Mao, K.; Zhu, C.; Lu, Z. Examination on the Wear Process of Polyformaldehyde Gears under Dry and Lubricated Conditions. Friction 2021, 9, 538–550. [Google Scholar] [CrossRef]

- Singh, P.K.; Siddhartha; Singh, A.K. An Investigation on the Thermal and Wear Behavior of Polymer Based Spur Gears. Tribol. Int. 2018, 118, 264–272. [Google Scholar] [CrossRef]

- Li, W.; Wood, A.; Weidig, R.; Mao, K. An Investigation on the Wear Behaviour of Dissimilar Polymer Gear Engagements. Wear 2011, 271, 2176–2183. [Google Scholar] [CrossRef]

- Evans, S.M.; Keogh, P.S. Wear Mechanisms in Polyoxymethylene Spur Gears. Wear 2019, 428–429, 356–365. [Google Scholar] [CrossRef]

- Lin, A.-D.; Kuang, J.-H. Dynamic Interaction between Contact Loads and Tooth Wear of Engaged Plastic Gear Pairs. Int. J. Mech. Sci. 2008, 50, 205–213. [Google Scholar] [CrossRef]

- Mao, K.; Langlois, P.; Hu, Z.; Alharbi, K.; Xu, X.; Milson, M.; Li, W.; Hooke, C.J.; Chetwynd, D. The Wear and Thermal Mechanical Contact Behaviour of Machine Cut Polymer Gears. Wear 2015, 332–333, 822–826. [Google Scholar] [CrossRef]

- Gürgen, S.; Sert, A.; Kuşhan, M.C. An Investigation on Wear Behavior of UHMWPE/Carbide Composites at Elevated Temperatures. J. Appl. Polym. Sci. 2021, 138, 50245. [Google Scholar] [CrossRef]

- Gürgen, S. Wear Behavior of UHMWPE Composites under Oxidative Effect. Polym. Degrad. Stab. 2022, 199, 109912. [Google Scholar] [CrossRef]

- Hoskins, T.J.; Dearn, K.D.; Chen, Y.K.; Kukureka, S.N. The Wear of PEEK in Rolling–Sliding Contact–Simulation of Polymer Gear Applications. Wear 2014, 309, 35–42. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhu, C.; Wei, P.; Tang, J. Tribological Behavior of Coated Spur Gear Pairs with Tooth Surface Roughness. Friction 2019, 7, 117–128. [Google Scholar] [CrossRef]

- Dearn, K.D.; Hoskins, T.J.; Petrov, D.G.; Reynolds, S.C.; Banks, R. Applications of Dry Film Lubricants for Polymer Gears. Wear 2013, 298–299, 99–108. [Google Scholar] [CrossRef]

- Alam, K.I.; Baratz, A.; Burris, D. Leveraging Trace Nanofillers to Engineer Ultra-Low Wear Polymer Surfaces. Wear 2021, 482–483, 203965. [Google Scholar] [CrossRef]

- Alam, K.I.; Burris, D.L. Ultralow Wear Poly(Tetrafluoroethylene): A Virtuous Cycle of Wear Reduction and Tribochemical Accumulation. J. Phys. Chem. C 2021, 125, 19417–19427. [Google Scholar] [CrossRef]

- Bae, S.-M.; Seo, K.-J.; Kim, D.-E. Effect of Friction on the Contact Stress of a Coated Polymer Gear. Friction 2020, 8, 1169–1177. [Google Scholar] [CrossRef]

- Trobentar, B.; Glodež, S.; Flašker, J.; Zafošnik, B. The Influence of Surface Coatings on the Tooth Tip Deflection of Polymer Gears. Mater. Tehnol. 2016, 50, 517–522. [Google Scholar] [CrossRef]

- Baptista, A.; Silva, F.; Porteiro, J.; Míguez, J.; Pinto, G. Sputtering Physical Vapour Deposition (PVD) Coatings: A Critical Review on Process Improvement and Market Trend Demands. Coatings 2018, 8, 402. [Google Scholar] [CrossRef]

- Baptista, A.; Pinto, G.; Silva, F.J.G.; Ferreira, A.A.; Pinto, A.G.; Sousa, V.F.C. Wear Characterization of Chromium PVD Coatings on Polymeric Substrate for Automotive Optical Components. Coatings 2021, 11, 555. [Google Scholar] [CrossRef]

- Ferreira, A.A.; Silva, F.J.G.; Pinto, A.G.; Sousa, V.F.C. Characterization of Thin Chromium Coatings Produced by PVD Sputtering for Optical Applications. Coatings 2021, 11, 215. [Google Scholar] [CrossRef]

- Zarka, M.; Dikici, B.; Niinomi, M.; Ezirmik, K.V.; Nakai, M.; Yilmazer, H. A Systematic Study of β-Type Ti-Based PVD Coatings on Magnesium for Biomedical Application. Vacuum 2021, 183, 109850. [Google Scholar] [CrossRef]

- Geyao, L.; Yang, D.; Wanglin, C.; Chengyong, W. Development and Application of Physical Vapor Deposited Coatings for Medical Devices: A Review. Procedia CIRP 2020, 89, 250–262. [Google Scholar] [CrossRef]

- Pradhan, S.K.; Nouveau, C.; Vasin, A.; Djouadi, M.-A. Deposition of CrN Coatings by PVD Methods for Mechanical Application. Surf. Coatings Technol. 2005, 200, 141–145. [Google Scholar] [CrossRef]

- Bello, M.; Shanmugan, S. Achievements in Mid and High-Temperature Selective Absorber Coatings by Physical Vapor Deposition (PVD) for Solar Thermal Application-A Review. J. Alloys Compd. 2020, 839, 155510. [Google Scholar] [CrossRef]

- Duminica, F.-D.; Belchi, R.; Libralesso, L.; Mercier, D. Investigation of Cr(N)/DLC Multilayer Coatings Elaborated by PVD for High Wear Resistance and Low Friction Applications. Surf. Coatings Technol. 2018, 337, 396–403. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G. Recent Advances on Coated Milling Tool Technology—A Comprehensive Review. Coatings 2020, 10, 235. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G. Recent Advances in Turning Processes Using Coated Tools—A Comprehensive Review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Da Silva, F.J.G.; Pinto, G.F.; Baptista, A.; Alexandre, R. Characteristics and Wear Mechanisms of TiAlN-Based Coatings for Machining Applications: A Comprehensive Review. Metals 2021, 11, 260. [Google Scholar] [CrossRef]

- Bin Abdullah, M.Z.; Ahmad, M.A.; Abdullah, A.N.; Othman, M.H.; Hussain, P.; Zainuddin, A. Metal Release of Multilayer Coatings by Physical Vapour Deposition (PVD). Procedia Eng. 2016, 148, 254–260. [Google Scholar] [CrossRef]

- Maurer, C.; Schulz, U. Erosion Resistant Titanium Based PVD Coatings on CFRP. Wear 2013, 302, 937–945. [Google Scholar] [CrossRef]

- Coto, B.; Mendizabal, L.; Pagano, F.; Kling, H.; Azpitarte, I.; Barriga, J.; Selegård, L. Role of Surface Finishing and Interfacial Lacquer Layer on Particle Erosion Mechanisms of Ti/TiN Multilayer PVD Coatings for Carbon Fibre Reinforced Polymer Substrates Protection. Mater. Lett. 2021, 285, 129187. [Google Scholar] [CrossRef]

- Qian, X.; Pang, X.; Gao, K.; Yang, H.; Jin, J.; Volinsky, A.A. Adhesion of Sputtered Nickel Films on Polycarbonate Substrates. J. Mater. Eng. Perform. 2014, 23, 786–790. [Google Scholar] [CrossRef]

- Polanec, B.; Zupanič, F.; Bončina, T.; Tašner, F.; Glodež, S. Experimental Investigation of the Wear Behaviour of Coated Polymer Gears. Polymers 2021, 13, 3588. [Google Scholar] [CrossRef]

- Faigle Material Datasheet, Material: PAS-L. Available online: https://www.faigle.com/en/materials?material=pas-l&pdf (accessed on 1 October 2022).

- ASTM C1624; Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2022.

- EN ISO 20502; Determination of Adhesion of Ceramic Coatings by Scratch Testing (ISO 20502:2005 Including Cor 1:2009). European Standards: Brussels, Belgium, 2016.

| Mechanical Characteristics | Standard | Unit | Value |

|---|---|---|---|

| Yield stress (+23 °C, dry) | ISO 527-1/-2 | MPa (N/mm2) | 67 |

| DIN 53455 | |||

| ASTM D 638 | |||

| Tensile strength (+23 °C, dry) | ISO 527-1/-2 | MPa (N/mm2) | 66 |

| DIN 53455 | |||

| ASTM D 638 | |||

| Elongation at break (+23 °C, dry) | ISO 527-1/-2 | % | 40 |

| DIN 53455 | |||

| ASTM D 638 | |||

| Tensile E-modulus (+23 °C, dry) | ISO 527-1/-2 | MPa (N/mm2) | 2800 |

| DIN 53455 | |||

| ASTM D 638 | |||

| Charpy notched impact strength (+23 °C, dry) | ISO 179 | kJ/m2 | 6 |

| DIN 53453 | |||

| Ball indentation hardness (dry) | ISO 2039-1 | MPa (N/mm2) | 130 |

| Thermal characteristics | Standard | Unit | Value |

| min. operating temperature (continuous) | - | °C | −50 |

| max. service temperature (continuous) | - | °C | 100 |

| max. service temperature (short-term) | - | °C | 140 |

| Thermal conductivity (+23 °C) | DIN 52612 | W/(m × K) | 0.31 |

| Physical characteristics | Standard | Unit | Value |

| Density | ISO 1183 | g/cm3 | 1.41 |

| DIN 53479 | |||

| ASTM D 792 | |||

| Moisture absorption at saturation (23 °C/50% r.h.) | ISO 62 ISO 1110 | % | 0.20 |

| Process | Pumping Time (s) | Starting Pressure (mbar) | Mass Flow Contr. MFC (sccm) | Regulation Pressure (mbar) | Process Time (s) | Regulation Energy (kWs) | T (°C) | |

|---|---|---|---|---|---|---|---|---|

| min | max | |||||||

| Plasma activation | 10 | 5·10−3 | 800 | 3·10−2 | 18 | 198 | 500 | 5000 |

| Magnetron sputtering | 150 | 4·10−4 | 500 | 2.2·10−3 | 62 | 10500 | 30 | 90 |

| Plasma polymerisation | 1 | 1.5·10−2 | 300 | 2·10−2 | 50 | 582 | 500 | 5000 |

| Parameter | Tested Gear | Supported Gear |

|---|---|---|

| Material | POM | Steel (16MnCr5) |

| Normal module m | 2.5 mm | 2.5 mm |

| Pressure angle αn | 20° | |

| Helix angle β | 0° | |

| Number of teeth z | 36 | 36 |

| Tooth width b | 14 mm | 14 mm |

| Profile shift coefficient x | 0 | |

| Centre distance a | 90 mm | |

| Basic rack profile | ISO 53 | |

| Lubrication | Dry (not lubricated) | |

| Surface Layer | Indentation Hardness (MPa) | Indentation Reduced Modulus (GPa) |

|---|---|---|

| Al 99.99 | 376.5 ± 13.2 | 69.16 ± 3.1 |

| POM | 100.0 ± 0.2 | 3.16 ± 0.20 |

| POM-1 layer Al | 172.1 ± 33.3 | 5.23 ± 0.61 |

| POM-3 layers Al | 214.4 ± 26.0 | 5.15 ± 1.08 |

| POM- 5 layers Al | 318.1 ± 62.6 | 5.96 ± 1.21 |

| Sample | Distance/µm | Critical Load/mN |

|---|---|---|

| One coating layer | 94.2 ± 12.03 | 44.2 ± 12.0 |

| Three coating layers | 155.8 ± 12.7 | 102.8 ± 12.7 |

| Five coating layers | 186.8 ± 21.3 | 136.8 ± 21.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bončina, T.; Polanec, B.; Zupanič, F.; Glodež, S. Wear Behaviour of Multilayer Al-PVD-Coated Polymer Gears. Polymers 2022, 14, 4751. https://doi.org/10.3390/polym14214751

Bončina T, Polanec B, Zupanič F, Glodež S. Wear Behaviour of Multilayer Al-PVD-Coated Polymer Gears. Polymers. 2022; 14(21):4751. https://doi.org/10.3390/polym14214751

Chicago/Turabian StyleBončina, Tonica, Brigita Polanec, Franc Zupanič, and Srečko Glodež. 2022. "Wear Behaviour of Multilayer Al-PVD-Coated Polymer Gears" Polymers 14, no. 21: 4751. https://doi.org/10.3390/polym14214751

APA StyleBončina, T., Polanec, B., Zupanič, F., & Glodež, S. (2022). Wear Behaviour of Multilayer Al-PVD-Coated Polymer Gears. Polymers, 14(21), 4751. https://doi.org/10.3390/polym14214751