Effect of Wet Mixing on Properties of Radial-Orientation Basalt Fiber-Reinforced Rubber Compounds

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Experimental Equipment

2.3. Preparation Experiments of Short-Fiber-Reinforced Composites

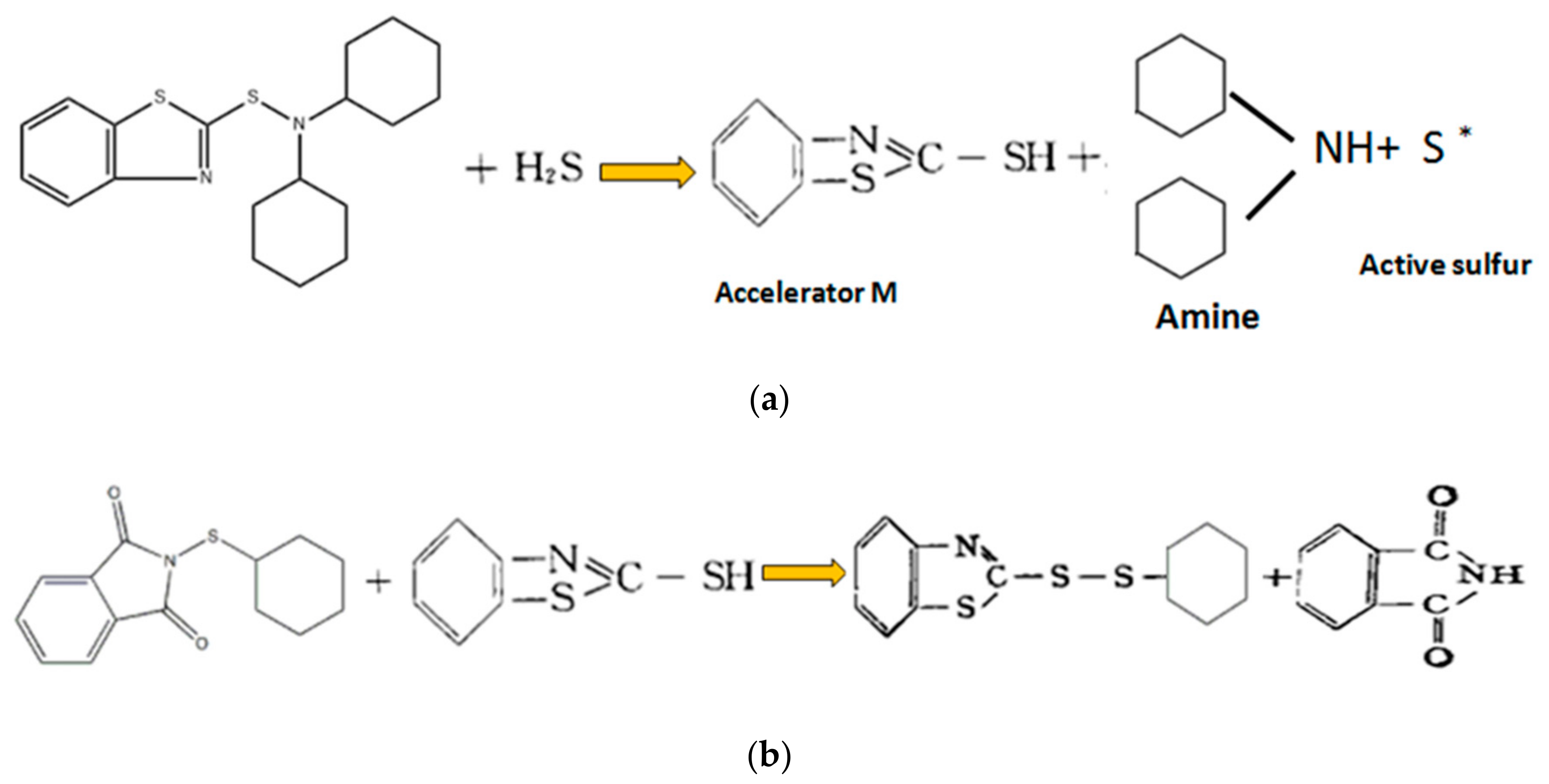

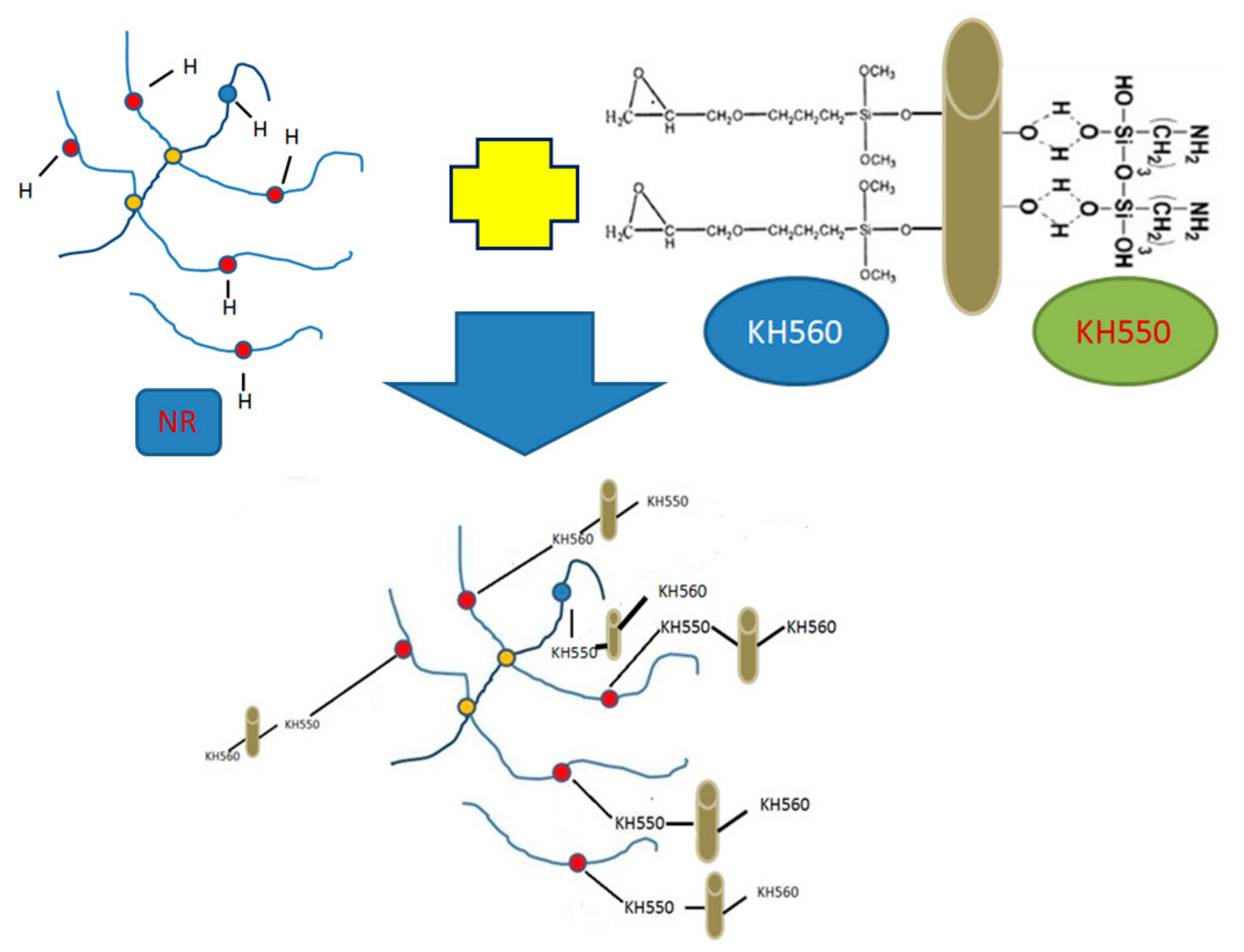

2.3.1. Preparation Experiments and Delay Formulation Mechanism of Different Types of Short-Fiber-Reinforced Composites

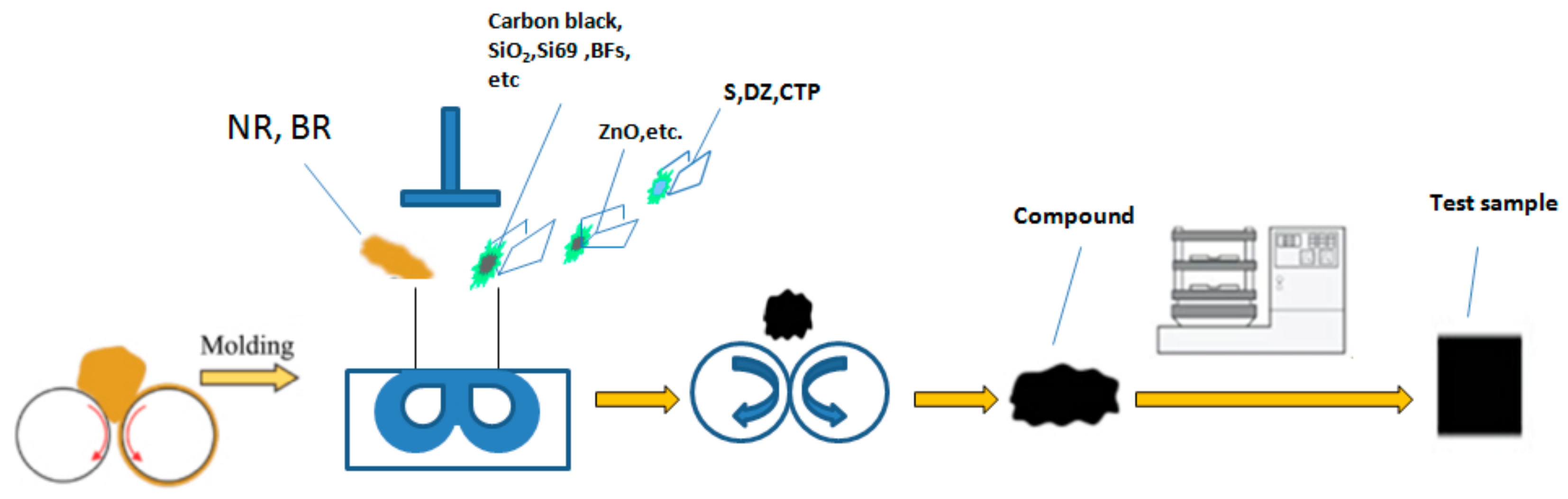

- (1)

- (a) First-stage mixing: we lifted the top bolt, put the NR cut into small pieces into the mixer from the feeding port, closed the top bolt, adjusted the rotor speed to 70 r/min, and mixed for 30 s. We then lifted the top bolt, added 8 phr silica, 22.5 phr carbon black N234, 1 phr Si 69 and 3 phr BF, closed the top bolt, and mixed for 120 s; 70 r/min.We then lifted the top bolt, added 3.5 phr ZnO, 2 phr stearic acid, 1 phr microcrystalline wax, 22.5 phr carbon black, 1.5 phr antioxidant RD, 1.5 phr 4020, 1.6 phr NS and 0.08 phr of plasticizer, closed the top bolt, adjusted the rotor speed to 40 r/min, and mixed for 4 min and 30 s.(b) Second-stage mixing: We added 1 phr sulfur to the master batch obtained in step (a), mixed for 1 min, and discharged the compound.

- (2)

- After the mixing was uniform, the sheet was opened, and the obtained rubber was calendered and oriented along the short-fiber direction. The specific method was as follows:

- (1)

- The raw materials were proportioned and weighed, and sequentially added to an internal mixer for mixing.

- (1)

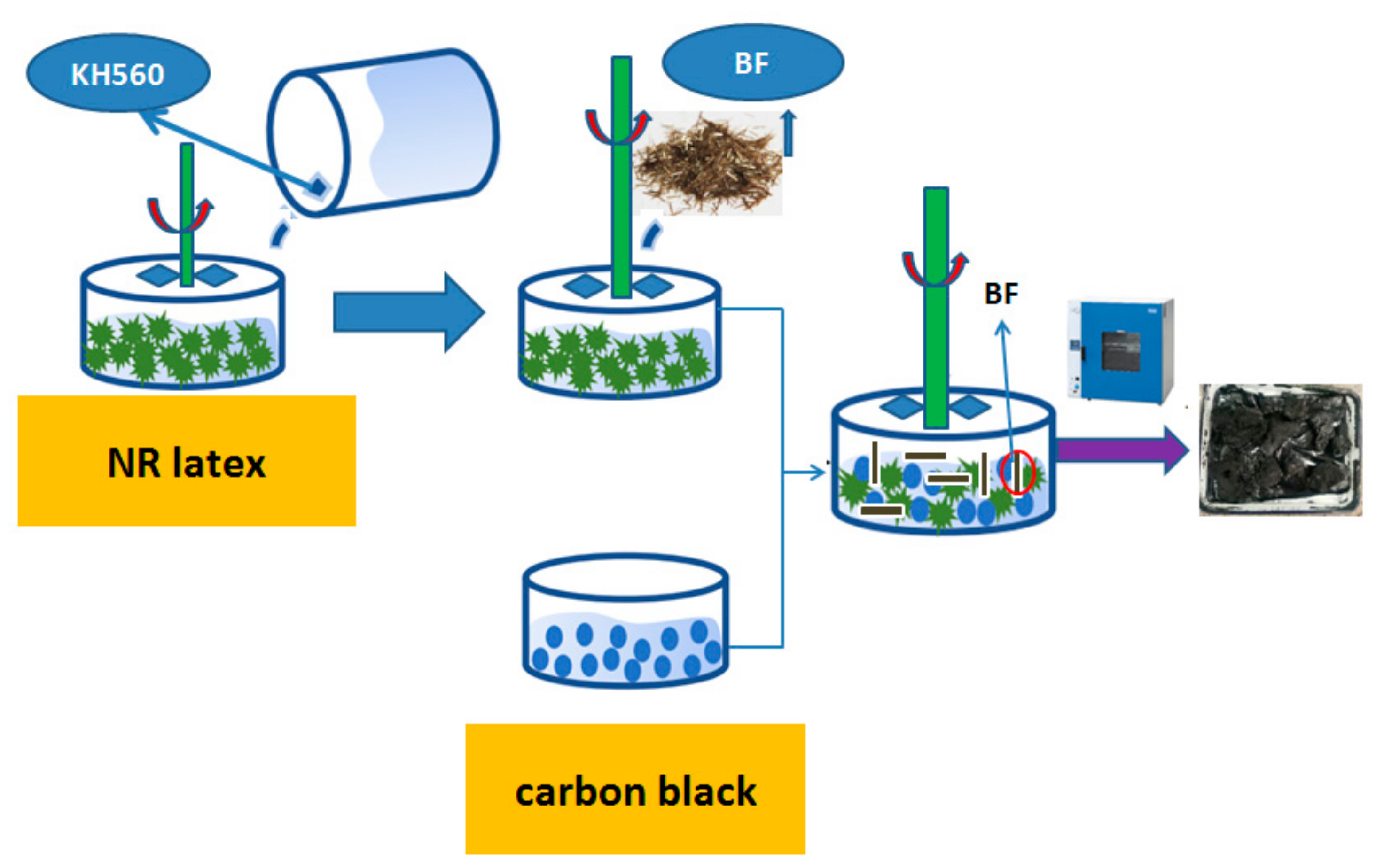

- Firstly, the natural latex was subjected to wall-breaking treatment, and 850 g natural latex (60% by mass) solution was stirred in a high-speed mixer at 1800 r/min for 8 min;

- (2)

- We took the silane coupling agent KH560, 1.5 g/L, 40 mL, and added it into a 850 g natural latex (60% by mass) solution, and stirred it at 1800 r/min in a high-speed mixer for 1 min;

- (3)

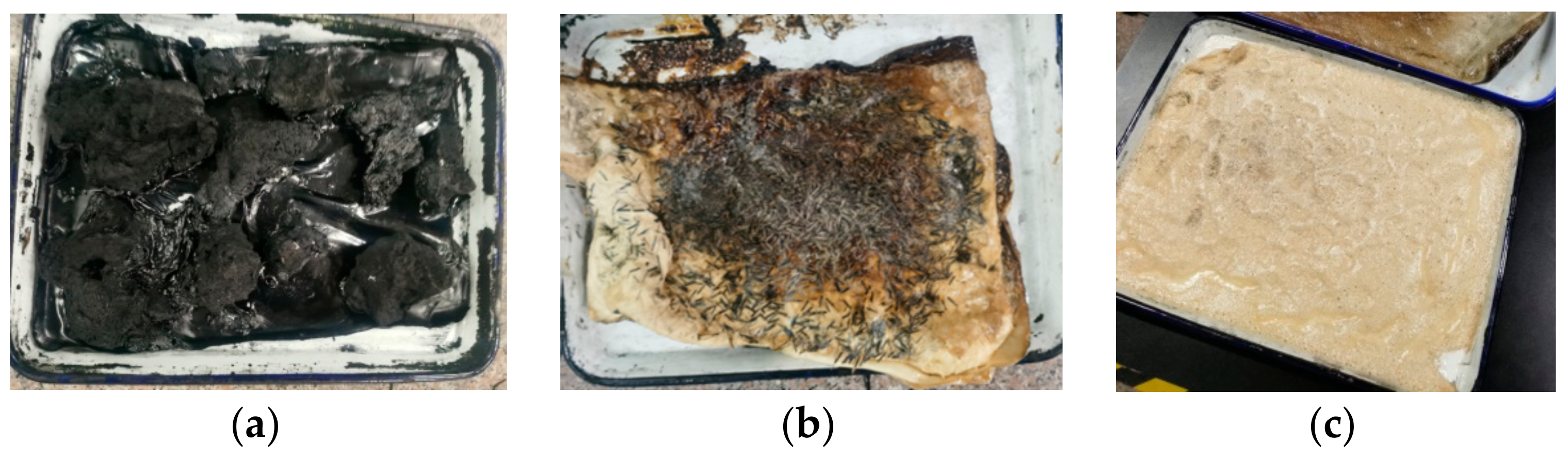

- We cleaned a proper amount of BFs with deionized water (treated with KH550), added BF to the treated natural latex after the water was clear, stirred for 1 min at 1800 r/min under normal temperature, poured it into a glass dish after completion, and dried it in an oven for 6 h; cut into small pieces, the NR/BF masterbatch was prepared.

- (1)

- Firstly, the natural latex was subjected to wall-breaking treatment, and 850 g natural latex (60% by mass) solution was stirred in a high-speed mixer at 1800 r/min for 8 min;

- (2)

- We washed 3 phr BF with deionized water (treated with KH550). After the water was clear, we put 3 phr BF into 40 mL of 1.5 g/L KH560 solution with equal concentration, and heated it in water bath for 2 h. The coupling agent KH560 was attached to the surface of the fibers; it was taken out and placed in the oven for 4 h of drying;

- (3)

- We took out the BF after BF drying, added the BF to the treated natural latex, stirred it at 1800 r/min for 1 min under normal temperature, poured it into the glass dish after completion, and dried it in the oven for 6 h; cut into small pieces, the NR/BF masterbatch was prepared.

- (1)

- Firstly, the natural latex was subjected to wall-breaking treatment, and 850 g natural latex (60% by mass) solution was stirred in a high-speed mixer at 1800 r/min for 8 min;

- (2)

- We took silane coupling agent KH560, 1.5 g/L, 40 mL, and added it to the 850 g natural latex (60% by mass) solution, and stirred it at 1800 r/min in a high-speed mixer for 1 min. We then washed a proper number of BFs with deionized water (treated with KH550), added 3 phr BF to the treated natural latex after the water was clear, and stirred at 1800 r/min for 1 min under normal temperature;

- (3)

- We weighed 258 g carbon black (N234) and put it into a beaker, then poured 800 g deionized water. Then, we stirred the carbon black aqueous solution in a stirrer with a stirring speed of 750 r/min and a stirring time of 5 min to fully dissolve the carbon black;

- (4)

- Then, the latex was poured into the carbon black aqueous solution (poured while stirring); the stirring speed was 750 r/min, and the stirring time was 1 min. After completion, it was poured into the glass dish, dried in the oven for 6 h, and then poured into the large tray to be laid and dried to prepare the NR/BF masterbatch.

- (a)

- We adjusted the bar pitch of the open mill to 1 mm, and rolled the roll 5 times along the rolling direction of the open mill. Then, we adjusted the pitch to 3 mm, and paid close attention to passing the roller 5 times along the rolling direction to obtain the short-fiber-reinforced compounds with the most fibers oriented along the rolling direction;

- (b)

- At the end of vulcanization, the performance test should be carried out, and the compounds should be stored for 24 h for standby; this is conducive to the uniformity and stability of the compounds’ properties and the relaxation of the internal stress of the rubber macromolecule.

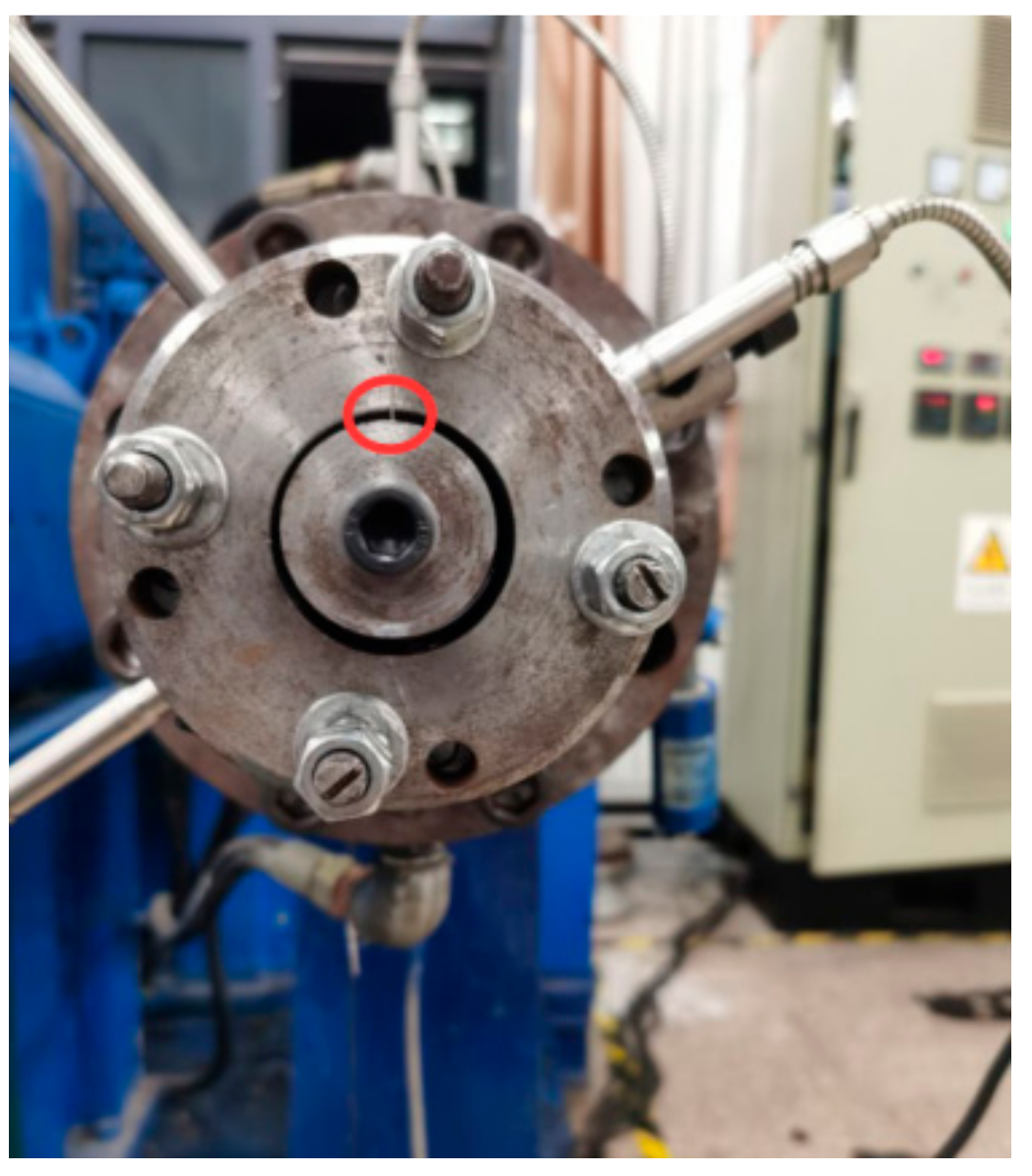

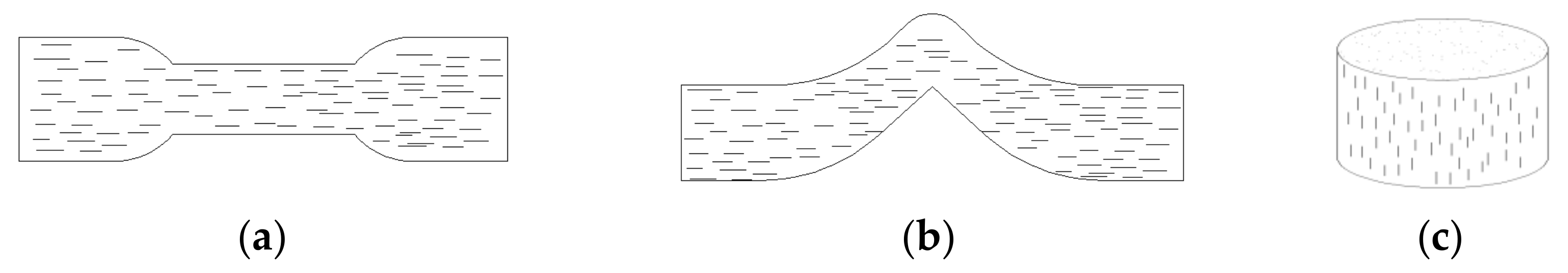

2.3.2. Extrusion Experiment of Different Compounds and 3D Physical Model of Extruder Die

2.4. Characterization

2.4.1. Physical and Mechanical Property Test and Wear Resistance

Preparation of the Test Sample

Performance Test

2.4.2. SEM Scanning Test Process

2.4.3. Payne Effect

2.4.4. Mooney Test Process

2.4.5. Dynamic Thermomechanical Analysis

2.4.6. Hardness

2.4.7. Three-Dimensional Topography Test

2.4.8. Carbon Black Dispersion Meter Test

3. Analysis and Discussion of Test Results

3.1. Vulcanizate in Filler System, Vulcanization Performance, Physical and Mechanical Properties and Dispersion Effect, SEM Analysis

3.1.1. Vulcanization Performance Analysis

3.1.2. Physical and Mechanical Properties

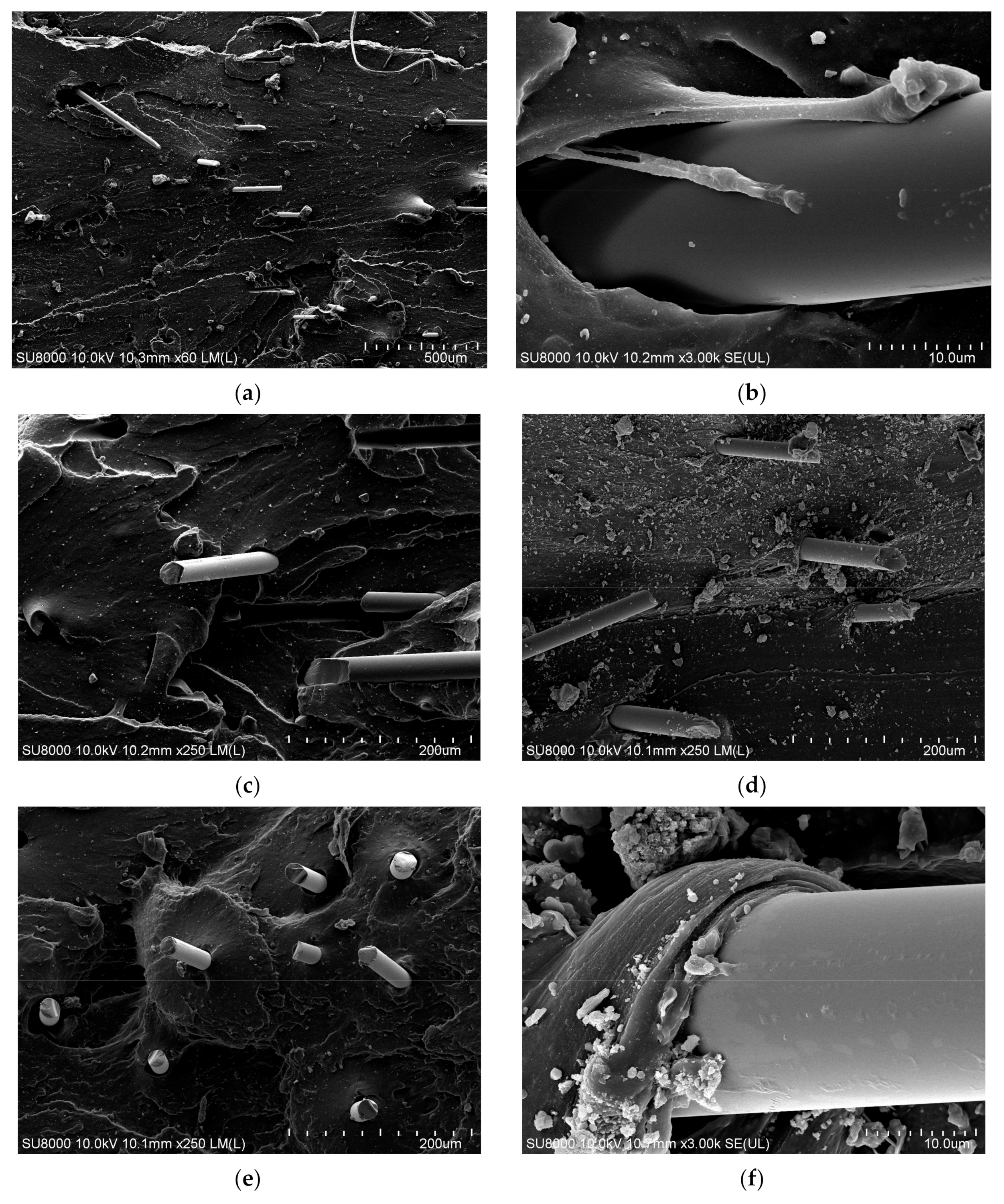

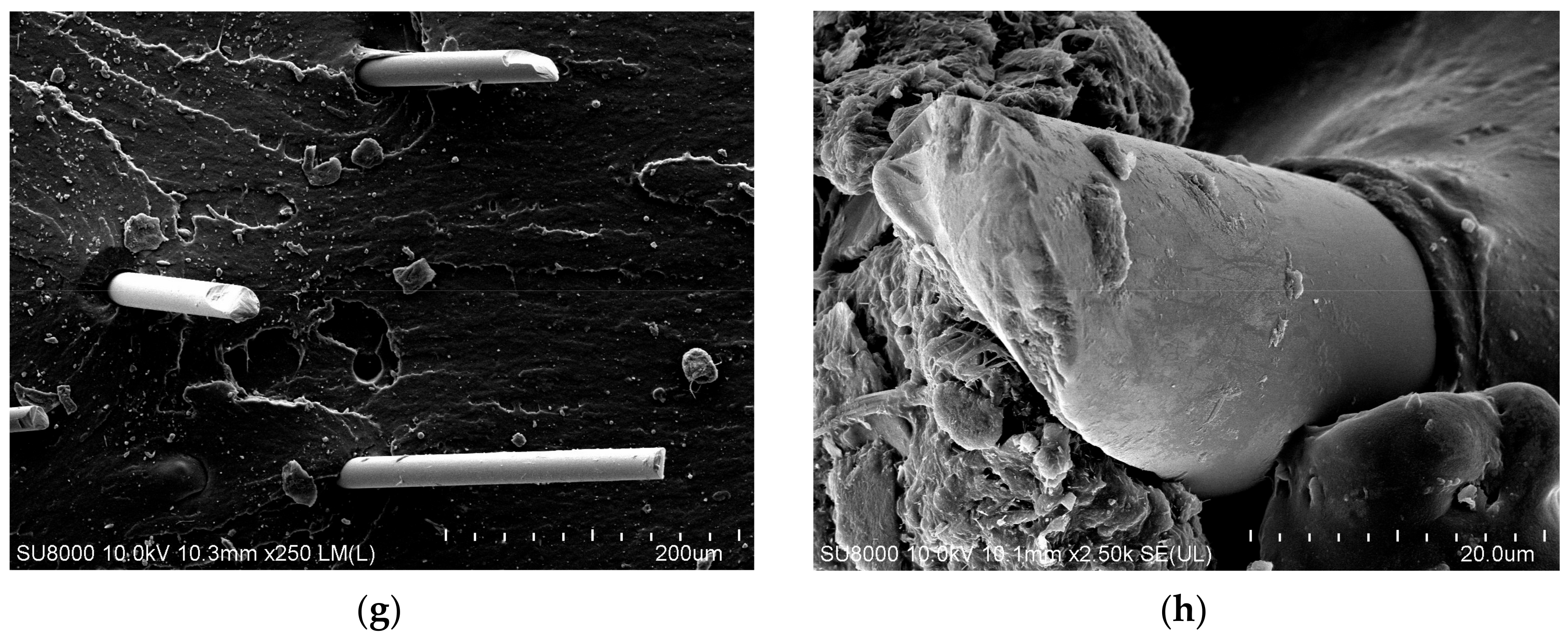

3.1.3. SEM Analysis

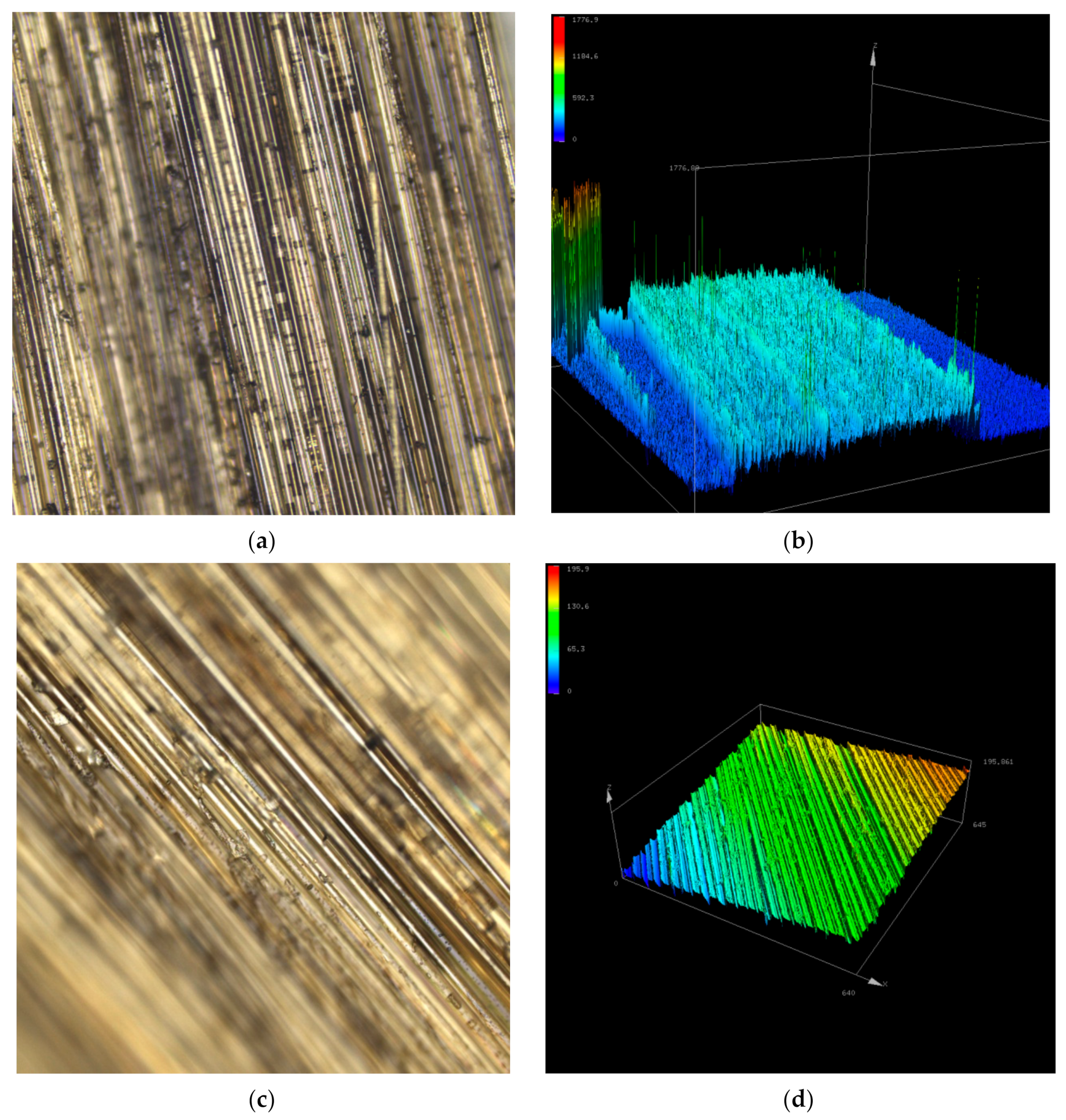

3.1.4. Three-Dimensional Topography Test

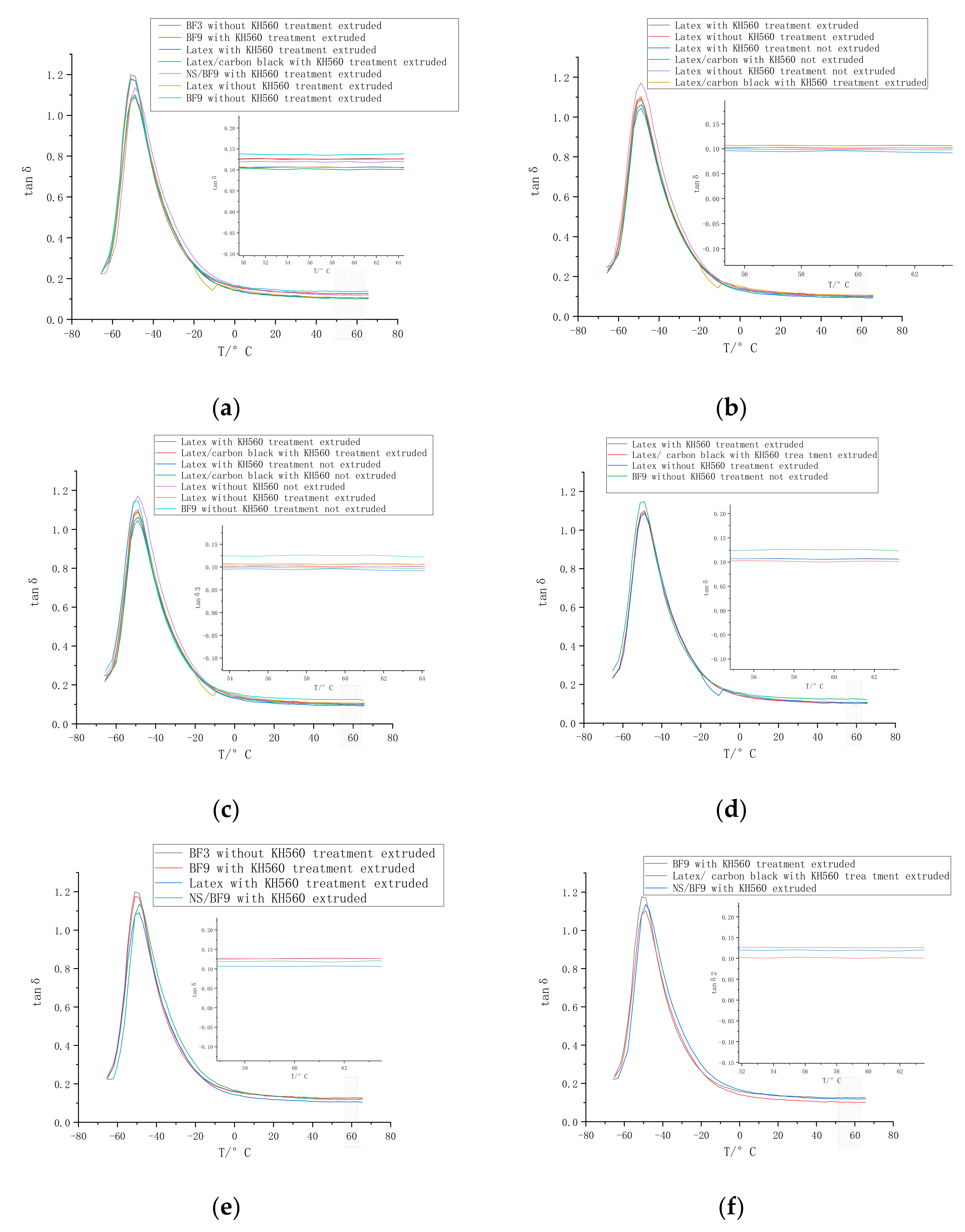

3.1.5. BF on Dynamic Viscoelasticity of Composites

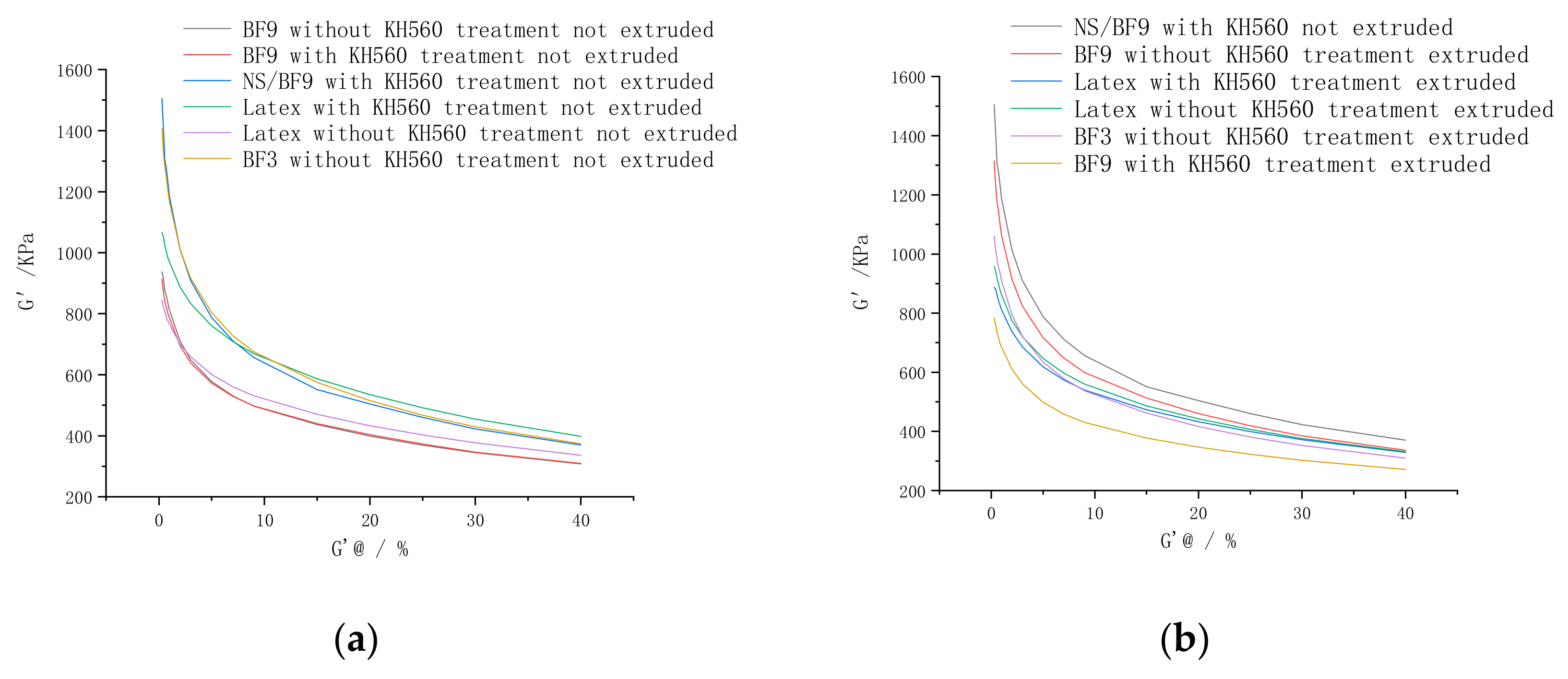

3.1.6. BF on Payne Effect of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.S.; Zhang, D.W.; Liu, H.Q.; Shen, B.; Li, S.M.; Bian, H.G. Effects of fibers orientation on properties of the rubber composites. Spec. Purp. Rubber Prod. 2014, 35, 32. (In Chinese) [Google Scholar] [CrossRef]

- Günzel, S.; Hickmann, S.; Wittemeyer, C.; Trappe, V. Effects of Fiber Orientation and Moisture on the Crack Growth in Short Glass Fiber Reinforced Polyamide. Adv. Eng. Mater. 2012, 14, 557–563. [Google Scholar] [CrossRef]

- Gao, G.X.; Zhang, Z.C.; Zheng, Y.S.; Jin, Z.H. Effect of fiber orientation angle on thermal degradation and ablative properties of short-fiber reinforced EPDM/NBR rubber composites. Polym. Compos. 2010, 31, 1127–1133. [Google Scholar] [CrossRef]

- Pramila Devi, D.S.; Nair, A.B.; Jabin, T.; Kutty, S.K. Mechanical, thermal, and microwave properties of conducting composites of polypyrrole/polypyrrole-coated short nylon fibers with acrylonitrile butadiene rubber. J. Appl. Polym. Sci. 2012, 126, 1965–1976. [Google Scholar] [CrossRef]

- Wang, C.S.; Zhang, D.W.; Bian, H.G.; Wang, X.B.; Guo, L. Experimental Study of Screw Speed Effects on Quality of Short Fiber-Rubber Composite Material. Adv. Mater. Res. 2011, 1159, 369–372. [Google Scholar] [CrossRef]

- Cazan, C.; Cosnita, M.; Duta, A. Effect of PET functionalization in composites of. rubber–PET–HDPE type. Arab. J. Chem. 2017, 10, 300–312. [Google Scholar] [CrossRef]

- Franciszczak, P.; Bledzki, A.K. Tailoring of dual-interface in high tenacity PP composites—Toughening with positive hybrid effect. Compos. Part A 2016, 83, 185–192. [Google Scholar] [CrossRef]

- Mortazavian, S.; Fatemi, A. Fatigue of short fiber thermoplastic composites: A review of recent experimental results and analysis. Int. J. Fatigue 2017, 102, 171–183. [Google Scholar] [CrossRef]

- Kumar, V.; Sinha, S.K.; Agarwal, A.K. Tribological studies of epoxy composites with solid and liquid fillers. Tribol. Int. 2017, 105, 27–36. [Google Scholar] [CrossRef]

- Yang, X.; Finne-Wistrand, A.; Hakkarainen, M. Improved dispersion of grafted starch granules leads to lower water resistance for starch-g-PLA/PLA composites. Compos. Sci. Technol. 2013, 86, 149–156. [Google Scholar] [CrossRef]

- Obande, W.; Ray, D.; Brádaigh, C.M.Ó. Viscoelastic and Drop-Weight Impact Properties of an Acrylic Resin Matrix Composite and a Conventional Thermoset Composite—A Comparative Study. Mater. Lett. 2018, 238, 38–41. [Google Scholar] [CrossRef]

- Jia, X.L.; Zhang, Q.; Huang, J.Q.; Zheng, C.; Qian, W.Z.; Wei, F. The direct dispersion of granular agglomerated carbon nanotubes in bismaleimide by high pressure homogenization for the production of strong composites. Powder Technol. 2012, 217, 477–481. [Google Scholar] [CrossRef]

- Goudar, N.; Vanjeri, V.N.; Dixit, S.; Hiremani, V.; Sataraddi, S.; Gasti, T.; Vootla, S.K.; Masti, S.P.; Chougale, R.B. Evaluation of multifunctional properties of gallic acid crosslinked Poly (vinyl alcohol)/Tragacanth Gum blend films for food packaging applications. Int. J. Biol. Macromol. 2020, 158, 139–149. [Google Scholar] [CrossRef]

- Dong, C.H.; Li, T.; Zhang, Y.M.; Liu, J.P. Damage process and performance of PVA fiber-reinforced alkali-activated slag mortar plate under bending. J. Southeast Univ. 2018, 34, 229–236. [Google Scholar]

- Niaki, M.H.; Fereidoon, A.; Ahangari, M.G. Experimental study on the mechanical and thermal properties of basalt fiber and nanoclay reinforced polymer concrete. Compos. Struct. 2018, 191, 231–238. [Google Scholar] [CrossRef]

- Arumugam, V.; Karthikeyan, S.V.; Sridhar, B.T.N.; Stanley, A.J. Characterization of Failure Modes in Composite Laminates Under Flexural Loading Using Time–Frequency Analysis. Arab. J. Sci. Eng. 2013, 38, 1471–1480. [Google Scholar] [CrossRef]

- Wang, S.F.; Zeng, X.H.; Zhou, Y.; Wang, P.; Ma, J.N.; Zhou, H.; Li, J.H.; Pan, G.Y. Effect of PVA and basalt fiber on mechanical properties of cement-based composites. Funct. Mater. 2020, 51, 4072–4076. [Google Scholar]

- Glaskova-Kuzmina, T.; Zotti, A.; Borriello, A.; Zarrelli, M.; Aniskevich, A. Basalt Fibre Composite with Carbon Nanomodified Epoxy Matrix under Hydrothermal Ageing. Polymers 2021, 13, 532. [Google Scholar] [CrossRef]

- Manas-Zloczower, I.; Nir, A.; Tadmor, Z. Dispersive mixing in internal mixers: A theoretical model based on ag-glomerate rupture. Rubber Chem. Technol. 1982, 55, 1250–1285. [Google Scholar] [CrossRef]

- Shiga, S.; Furuta, M. Processability of EPR in an internal ates during mixing. Rubber Chem. Technol. 1985, 58, 1–20. [Google Scholar] [CrossRef]

- Manas, Z.I.; Feke, D.L. Observation of carbon black ag-glomerate dispersion in simple shear flows. Polym. Eng. Sci. 1990, 30, 701–706. [Google Scholar]

- Zhang, L.; Wang, Y.; Wang, Y.; Sui, Y.; Yu, D. Morphology and mechanical properties of elay/styrene-butadiene rubber nano-composites. J. Appl. Polym. Sci. 2000, 78, 1873–1878. [Google Scholar] [CrossRef]

- Li, H.T. Preparation Mechanism and Experimental Study of Carbon Fiber Reinforced Natural Latex Composite; Qingdao University of Science and Technology: Qingdao, China, 2018. [Google Scholar]

- Xu, J.X. Effect of anti scorching agent in natural rubber blends. Spec. Purp. Rubber Prod. 1995, 6–10. [Google Scholar] [CrossRef]

| Delayed Formula | Formulation (phr) | All-Steel Tire Formula | Formulation (phr) |

|---|---|---|---|

| NR | 85 | NR | 100 |

| BR | 15 | Plasticizer | 0.08 |

| Carbon black N234 | 43 | Carbon black N234 | 45 |

| ZnO | 4 | ZnO | 3.5 |

| SAD | 2 | SAD | 2 |

| 4020 | 2 | 4020 | 1.5 |

| Microcrystalline wax | 1 | Microcrystalline wax | 1 |

| S | 1 | S | 1 |

| DZ | 1.8 | NS | 1.6 |

| CTP | 0.3 | RD | 1.5 |

| RD | 1 | Si69 | 1 |

| Si69SiO2 | 0.55 | SiO2 | 8 |

| Items | 1# | 2# | 3# | 4# | 5# | 6# | 7# |

|---|---|---|---|---|---|---|---|

| t10/min | 2.34 | 5.42 | 6.31 | 5.73 | 4.34 | 4.09 | 3.00 |

| t90/min | 7.99 | 16.61 | 16.41 | 15.23 | 13.09 | 13.33 | 10.67 |

| ML/(dN·m) | 3.50 | 3.08 | 3.33 | 2.91 | 3.88 | 4.19 | 3.09 |

| MH/(dN·m) | 15.81 | 14.51 | 12.88 | 12.37 | 16.24 | 16.69 | 13.31 |

| (MH-ML)/(dN·m) | 12.31 | 11.43 | 9.55 | 9.46 | 12.36 | 12.5 | 10.22 |

| Mooney ML (1 + 4) | 76.25 | 76.73 | 78.65 | 74.43 | 87.57 | 97.09 | 77.99 |

| Items | 1# | 2# | 3# | 4# | 5# | 6# | 7# |

|---|---|---|---|---|---|---|---|

| t10/min | 1.87 | 3.55 | 4.55 | 3.70 | 3.92 | 4.31 | 0.93 |

| t90/min | 6.95 | 13.71 | 13.92 | 13.42 | 11.24 | 12.55 | 7.59 |

| ML/(dN·m) | 2.79 | 2.40 | 2.63 | 2.18 | 3.16 | 3.31 | 2.59 |

| MH/(dN·m) | 14.42 | 12.82 | 12.55 | 12.92 | 15.12 | 15.48 | 10.65 |

| (MH-ML)/(dN·m) | 11.63 | 10.42 | 9.92 | 10.74 | 11.96 | 11.17 | 8.06 |

| Mooney ML (1 + 4) | 73.14 | 73.95 | 74.43 | 66.52 | 85.28 | 94.11 | 74.96 |

| Items | 1# | 2# | 3# | 4# | 5# | 6# | 7# |

|---|---|---|---|---|---|---|---|

| Hardness | 62 | 67 | 65 | 67.5 | 68.5 | 67.5 | 66 |

| σ1 | 2.43 | 1.41 | 1.28 | 0.87 | 1.49 | 2.60 | 1.41 |

| σ2 | 19.05 | 19.41 | 19.72 | 19.82 | 21.42 | 20.70 | 21.61 |

| εt | 460.8 | 570.4 | 604.6 | 543.0 | 634.3 | 468.9 | 615.7 |

| τt | 92 | 81 | 71 | 83 | 88 | 84 | 85 |

| △V | 153.68 | 161.51 | 132.92 | 119.70 | 111.38 | 116.51 | 106.83 |

| Mooney | 76.25 | 76.73 | 78.65 | 74.43 | 87.57 | 97.09 | 81.68 |

| Carbon black dispersion | 5.43 | 6.25 | 6.12 | 6.83 | 6.20 | 6.36 | 6.91 |

| Items | 1# | 2# | 3# | 4# | 5# | 6# | 7# |

|---|---|---|---|---|---|---|---|

| Hardness | 66 | 62.5 | 64 | 62.5 | 67 | 67 | 64 |

| σ1 | 2.35 | 1.25 | 1.56 | 1.63 | 3.01 | 1.81 | 1.41 |

| σ2 | 20.99 | 18.59 | 19.75 | 20.58 | 22.32 | 21.09 | 22.79 |

| εt | 511.6 | 555.8 | 545.5 | 543.0 | 520.7 | 508.4 | 538.8 |

| τt | 90 | 84 | 79 | 87 | 83 | 86 | 86 |

| △V | 141.62 | 156.55 | 127.90 | 112.74 | 101.26 | 106.93 | 97.77 |

| Mooney | 73.14 | 73.95 | 74.43 | 66.52 | 85.28 | 94.11 | 77.99 |

| Carbon black dispersion | 7.51 | 7.36 | 7.50 | 7.97 | 7.00 | 7.25 | 7.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, B.; Wang, J.; Wang, K.; Han, D.; Ren, J.; Zhang, D.; Wang, C. Effect of Wet Mixing on Properties of Radial-Orientation Basalt Fiber-Reinforced Rubber Compounds. Polymers 2022, 14, 4422. https://doi.org/10.3390/polym14204422

Yu B, Wang J, Wang K, Han D, Ren J, Zhang D, Wang C. Effect of Wet Mixing on Properties of Radial-Orientation Basalt Fiber-Reinforced Rubber Compounds. Polymers. 2022; 14(20):4422. https://doi.org/10.3390/polym14204422

Chicago/Turabian StyleYu, Benhui, Jing Wang, Kongshuo Wang, Deshang Han, Jianbin Ren, Dewei Zhang, and Chuansheng Wang. 2022. "Effect of Wet Mixing on Properties of Radial-Orientation Basalt Fiber-Reinforced Rubber Compounds" Polymers 14, no. 20: 4422. https://doi.org/10.3390/polym14204422

APA StyleYu, B., Wang, J., Wang, K., Han, D., Ren, J., Zhang, D., & Wang, C. (2022). Effect of Wet Mixing on Properties of Radial-Orientation Basalt Fiber-Reinforced Rubber Compounds. Polymers, 14(20), 4422. https://doi.org/10.3390/polym14204422