Improved Electrical Signal of Non-Poled 3D Printed Zinc Oxide-Polyvinylidene Fluoride Nanocomposites

Abstract

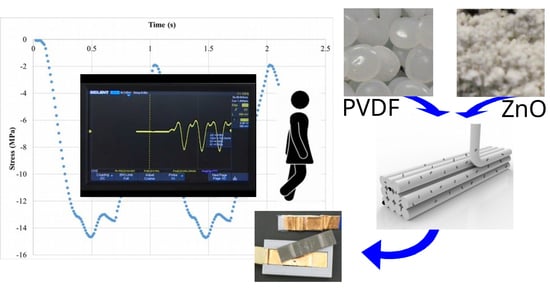

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extrusion

2.3. 3D Printing

2.4. SEM Imaging and EDS

2.5. Thermo-Gravimetric Analysis—TGA

2.6. Differential Scanning Calorimetry—DSC

2.7. Fourier Transform Infrared Spectroscopy—FTIR

2.8. Rheometry

2.9. DMA

2.10. Tensile and Flexion

2.11. Electrical Response

3. Results and Discussion

3.1. Materials Characterization

3.2. Rheological and Mechanical Properties

3.3. Electrical Response

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moore, A.L. Fluoroelastomers Handbook: The Definitive User’s Guide and Databook; William Andrew Pub: Norwich, NY, USA, 2006. [Google Scholar]

- Eun, J.H.; Sung, S.M.; Kim, M.S.; Choi, B.K.; Lee, J.S. Effect of Mwcnt Content on the Mechanical and Piezoelectric Properties of Pvdf Nanofibers. Mater. Des. 2021, 206, 109785. [Google Scholar] [CrossRef]

- He, Z.; Rault, F.; Lewandowski, M.; Mohsenzadeh, E.; Salaün, F. Electrospun Pvdf Nanofibers for Piezoelectric Applications: A Review of the Influence of Electrospinning Parameters on the β Phase and Crystallinity Enhancement. Polymers 2021, 13, 174. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, Y.; Zheng, H.; Ramakrishna, S. Piezoelectric Materials for Flexible and Wearable Electronics: A Review. Mater. Des. 2021, 211, 110164. [Google Scholar] [CrossRef]

- Santos, B.P.S.; Arias, J.J.R.; Jorge, F.E.; Értola Pereira de Deus Santos, R.; da Silva Fernandes, B.; da Silva Candido, L.; de Carvalho Peres, A.C.; Chaves, E.G.; de Fátima Vieira Marques, M. Preparation, Characterization and Permeability Evaluation of poly(vinylidene fluoride) Composites with Zno Particles for Flexible Pipelines. Polym. Test. 2021, 94, 107064. [Google Scholar] [CrossRef]

- Uchino, K. 3.24 Piezoelectro Composites. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 613–624. [Google Scholar] [CrossRef]

- Foster, F.; Harasiewicz, K.; Sherar, M. A history of medical and biological imaging with polyvinylidene fluoride (PVDF) transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 1363–1371. [Google Scholar] [CrossRef]

- Barrau, S.; Ferri, A.; Costa, A.D.; Defebvin, J.; Leroy, S.; Desfeux, R.; Lefebvre, J.M. Nanoscale Investigations of α- and γ-Crystal Phases in Pvdf-Based Nanocomposites. ACS Appl. Mater. Interfaces 2018, 10, 13092–13099. [Google Scholar] [CrossRef]

- Kashfi, M.; Fakhri, P.; Amini, B.; Yavari, N.; Rashidi, B.; Kong, L.; Bagherzadeh, R. A Novel Approach to Determining Piezoelectric Properties of Nanogenerators Based on Pvdf Nanofibers Using Iterative Finite Element Simulation for Walking Energy Harvesting. J. Ind. Text. 2020, 51, 531S–553S. [Google Scholar] [CrossRef]

- Bodkhe, S.; Turcot, G.; Gosselin, F.P.; Therriault, D. One-Step Solvent Evaporation-Assisted 3D Printing of Piezoelectric PVDF Nanocomposite Structures. ACS Appl. Mater. Interfaces 2017, 9, 20833–20842. [Google Scholar] [CrossRef]

- Ramesh, D.; D’Souza, N. Experimental and Computational Investigation of PVDF-BaTiO3 Interface for Impact Sensing and Energy Harvesting Applications. SN Appl. Sci. 2020, 2, 1129. [Google Scholar] [CrossRef]

- Zandesh, G.; Gheibi, A.; Bafqi, M.S.S.; Bagherzadeh, R.; Ghoorchian, M.; Latifi, M. Piezoelectric Electrospun Nanofibrous Energy Harvesting Devices: Influence of the Electrodes Position and Finite Variation of Dimensions. J. Ind. Text. 2016, 47, 348–362. [Google Scholar] [CrossRef]

- Meng, N.; Ren, X.; Santagiuliana, G.; Ventura, L.; Zhang, H.; Wu, J.; Yan, H.; Reece, M.J.; Bilotti, E. Ultrahigh β-phase Content poly(vinylidene fluoride) with Relaxor-Like Ferroelectricity for High Energy Density Capacitors. Nat. Commun. 2019, 10, 4535. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Maurya, D.; Peddigari, M.; Kang, M.G.; Geng, L.D.; Sharpes, N.; Annapureddy, V.; Palneedi, H.; Sriramdas, R.; Yan, Y.; Song, H.C.; et al. Lead-Free Piezoelectric Materials and Composites for High Power Density Energy Harvesting. J. Mater. Res. 2018, 33, 2235–2263. [Google Scholar] [CrossRef]

- Gheibi, A.; Bagherzadeh, R.; Merati, A.A.; Latifi, M. Electrical Power Generation From Piezoelectric Electrospun Nanofibers Membranes: Electrospinning Parameters Optimization and Effect of Membranes Thickness on Output Electrical Voltage. J. Polym. Res. 2014, 21, 571. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and Applications of the β Phase Poly(vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef]

- Kawai, H. The Piezoelectricity of Poly (vinylidene Fluoride). Jpn. J. Appl. Phys. 1969, 8, 975–976. [Google Scholar] [CrossRef]

- Sencadas, V.; Moreira, M.V.; Lanceros-Méndez, S.; Pouzada, A.S.; Gregório Filho, R. α- to β Transformation on PVDF Films Obtained by Uniaxial Stretch. Mater. Sci. Forum 2006, 514–516, 872–876. [Google Scholar] [CrossRef]

- Fortunato, M.; Chandraiahgari, C.; Bellis, G.D.; Ballirano, P.; Sarto, F.; Tamburrano, A.; Sarto, M. Piezoelectric Effect and Electroactive Phase Nucleation in Self-Standing Films of Unpoled Pvdf Nanocomposite Films. Nanomaterials 2018, 8, 743. [Google Scholar] [CrossRef]

- Xiong, X.; Li, Q.; Zhang, X.C.; Wang, L.; Guo, Z.X.; Yu, J. Poly(vinylidene fluoride)/silica nanocomposite membranes by electrospinning. J. Appl. Polym. Sci. 2013, 129, 1089–1095. [Google Scholar] [CrossRef]

- Haddadi, S.A.; Ghaderi, S.; Amini, M.; Ramazani, S.A. Mechanical and piezoelectric characterizations of electrospun PVDF-nanosilica fibrous scaffolds for biomedical applications. Mater. Today Proc. 2018, 5, 15710–15716. [Google Scholar] [CrossRef]

- Dodds, J.S.; Meyers, F.N.; Loh, K.J. Piezoelectric Characterization of PVDF-TrFE Thin Films Enhanced with ZnO Nanoparticles. IEEE Sens. J. 2012, 12, 1889–1890. [Google Scholar] [CrossRef]

- Hu, Y.C.; Hsu, W.L.; Wang, Y.T.; Ho, C.T.; Chang, P.Z. Enhance the Pyroelectricity of Polyvinylidene Fluoride by Graphene-Oxide Doping. Sensors 2014, 14, 6877. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Singh, M.; Kumar, P. On Zno Nano Particle Reinforced Pvdf Composite Materials for 3d Printing of Biomedical Sensors. J. Manuf. Process 2020, 60, 268–282. [Google Scholar] [CrossRef]

- An, N.; Liu, H.; Ding, Y.; Zhang, M.; Tang, Y. Preparation and electroactive properties of a PVDF/nano-TiO2 composite film. Appl. Surf. Sci. 2011, 257, 3831–3835. [Google Scholar] [CrossRef]

- Castanet, E.; Thamish, M.A.; Hameed, N.; Krajewski, A.; Dumée, L.F.; Magniez, K. Zinc Oxide PVDF Nano-Composites-Tuning Interfaces toward Enhanced Mechanical Properties and UV Protection: Zinc Oxide PVDF Nano-Composites. Adv. Eng. Mater. 2017, 19, 1600611. [Google Scholar] [CrossRef]

- Muralidhar, C.; Pillai, P.K.C. Dielectric behaviour of barium titanate (BaTiO3)/polyvinylidene fluoride (PVDF) composite. J. Mater. Sci. Lett. 1987, 6, 346–348. [Google Scholar] [CrossRef]

- Kalani, S.; Kohandani, R.; Bagherzadeh, R. Flexible Electrospun Pvdf-Batio3 Hybrid Structure Pressure Sensor With Enhanced Efficiency. RSC Adv. 2020, 10, 35090–35098. [Google Scholar] [CrossRef]

- Wu, L.; Jing, M.; Liu, Y.; Ning, H.; Liu, X.; Liu, S.; Lin, L.; Hu, N.; Liu, L. Power generation by PVDF-TrFE/graphene nanocomposite films. Compos. Part Eng. 2019, 164, 703–709. [Google Scholar] [CrossRef]

- Li, Y.; Feng, W.; Meng, L.; Tse, K.M.; Li, Z.; Huang, L.; Su, Z.; Guo, S. Investigation on In-Situ Sprayed, Annealed and Corona Poled Pvdf-Trfe Coatings for Guided Wave-Based Structural Health Monitoring: From Crystallization To Piezoelectricity. Mater. Des. 2021, 199, 109415. [Google Scholar] [CrossRef]

- Kim, Y.J.; Ahn, C.H.; Choi, M.O. Effect of thermal treatment on the characteristics of electrospun PVDF-silica composite nanofibrous membrane. Eur. Polym. J. 2010, 46, 1957–1965. [Google Scholar] [CrossRef]

- Kim, H.; Fernando, T.; Li, M.; Lin, Y.; Tseng, T.L.B. Fabrication and characterization of 3D printed BaTiO3/PVDF nanocomposites. J. Compos. Mater. 2018, 52, 197–206. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Wu, Y.; Villagran, D.; Lin, Y.; Tseng, T.L. Integrated 3D printing and corona poling process of PVDF piezoelectric films for pressure sensor application. Smart Mater. Struct. 2017, 26, 085027. [Google Scholar] [CrossRef]

- Kennedy, Z.C.; Christ, J.F.; Evans, K.A.; Arey, B.W.; Sweet, L.E.; Warner, M.G.; Erikson, R.L.; Barrett, C.A. 3D-printed poly(vinylidene fluoride)/carbon nanotube composites as a tunable, low-cost chemical vapour sensing platform. Nanoscale 2017, 9, 5458–5466. [Google Scholar] [CrossRef]

- Porter, D.A.; Hoang, T.V.; Berfield, T.A. Effects of in situ poling and process parameters on fused filament fabrication printed PVDF sheet mechanical and electrical properties. Addit. Manuf. 2017, 13, 81–92. [Google Scholar] [CrossRef]

- Tu, R.; Sprague, E.; Sodano, H.A. Precipitation-Printed High-β Phase Poly(vinylidene fluoride) for Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 58072–58081. [Google Scholar] [CrossRef]

- Elsheikh, A. Bistable Morphing Composites for Energy-Harvesting Applications. Polymers 2022, 14, 1893. [Google Scholar] [CrossRef]

- D20 Committee. ASTM D638—14 Test Method for Tensile Properties of Plastics; Technical report; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar] [CrossRef]

- D20 Committee. ASTM D790—17 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; Technical report; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Institute, J.W. Orthoload Loading of Orthopaedic Implant. Available online: https://orthoload.com/ (accessed on 5 September 2020).

- Indolia, A.P.; Gaur, M.S. Investigation of structural and thermal characteristics of PVDF/ZnO nanocomposites. J. Therm. Anal. Calorim. 2013, 113, 821–830. [Google Scholar] [CrossRef]

- Buckley, J.; Cebe, P.; Cherdack, D.; Crawford, J.; Ince, B.S.; Jenkins, M.; Pan, J.J.; Reveley, M.; Washington, N.; Wolchover, N. Nanocomposites of poly(vinylidene fluoride) with organically modified silicate. Polymer 2006, 47, 2411–2422. [Google Scholar] [CrossRef]

- Bafqi, M.S.S.; Bagherzadeh, R.; Latifi, M. Nanofiber Alignment Tuning: An Engineering Design Tool in Fabricating Wearable Power Harvesting Devices. J. Ind. Text. 2016, 47, 535–550. [Google Scholar] [CrossRef]

- Bafqi, M.S.S.; Bagherzadeh, R.; Latifi, M. Fabrication of Composite Pvdf-Zno Nanofiber Mats By Electrospinning for Energy Scavenging Application with Enhanced Efficiency. J. Polym. Res. 2015, 22, 130. [Google Scholar] [CrossRef]

- Zanrosso, C.D.; Piazza, D.; Lansarin, M.A. Pvdf/zno Composite Films for Photocatalysis: A Comparative Study of Solution Mixing and Melt Blending Methods. Polym. Eng. Sci. 2020, 60, 1146–1157. [Google Scholar] [CrossRef]

- Tsonos, C.; Zois, H.; Kanapitsas, A.; Soin, N.; Siores, E.; Peppas, G.; Pyrgioti, E.; Sanida, A.; Stavropoulos, S.; Psarras, G. Polyvinylidene Fluoride/magnetite Nanocomposites: Dielectric and Thermal Response. J. Phys. Chem. Solids 2019, 129, 378–386. [Google Scholar] [CrossRef]

- Sencadas, V.; Lanceros-Méndez, S.; Mano, J. Characterization of poled and non-poled β-PVDF films using thermal analysis techniques. Thermochim. Acta 2004, 424, 201–207. [Google Scholar] [CrossRef]

- Harstad, S.; D’Souza, N.; Soin, N.; El-Gendy, A.A.; Gupta, S.; Pecharsky, V.K.; Shah, T.; Siores, E.; Hadimani, R.L. Enhancement of β-phase in PVDF films embedded with ferromagnetic Gd5Si4 nanoparticles for piezoelectric energy harvesting. AIP Adv. 2017, 7, 056411. [Google Scholar] [CrossRef]

- Soin, N.; Boyer, D.; Prashanthi, K.; Sharma, S.; Narasimulu, A.A.; Luo, J.; Shah, T.H.; Siores, E.; Thundat, T. Exclusive self-aligned β-phase PVDF films with abnormal piezoelectric coefficient prepared via phase inversion. Chem. Commun. 2015, 51, 8257–8260. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.; Lanceros-Mendez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Fakhri, P.; Amini, B.; Bagherzadeh, R.; Kashfi, M.; Latifi, M.; Yavari, N.; Kani, S.A.; Kong, L. Flexible Hybrid Structure Piezoelectric Nanogenerator Based on Zno Nanorod/pvdf Nanofibers With Improved Output. RSC Adv. 2019, 9, 10117–10123. [Google Scholar] [CrossRef]

- Khaliq, M.H.; Gomes, R.; Fernandes, C.; Nóbrega, J.; Carneiro, O.S.; Ferrás, L.L. On the Use of High Viscosity Polymers in the Fused Filament Fabrication Process. Rapid Prototyp. J. 2017, 23, 727–735. [Google Scholar] [CrossRef]

- Sanchez, L.C.; Beatrice, C.A.G.; Lotti, C.; Marini, J.; Bettini, S.H.P.; Costa, L.C. Rheological Approach for an Additive Manufacturing Printer Based on Material Extrusion. Int. J. Adv. Manuf. Technol. 2019, 105, 2403–2414. [Google Scholar] [CrossRef]

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561. [Google Scholar] [CrossRef]

- Kairn, T.; Daivis, P.J.; Ivanov, I.; Bhattacharya, S.N. Molecular-Dynamics Simulation of Model Polymer Nanocomposite Rheology and Comparison with Experiment. J. Chem. Phys. 2005, 123, 194905. [Google Scholar] [CrossRef]

- Cao, Y.; Deng, Q.; Liu, Z.; Shen, D.; Wang, T.; Huang, Q.; Du, S.; Jiang, N.; Lin, C.T.; Yu, J. Enhanced thermal properties of poly(vinylidene fluoride) composites with ultrathin nanosheets of MXene. RSC Adv. 2017, 7, 20494–20501. [Google Scholar] [CrossRef]

- Flyagina, I.S.; Mahdi, E.M.; Titov, K.; Tan, J.C. Thermo-mechanical properties of mixed-matrix membranes encompassing zeolitic imidazolate framework-90 and polyvinylidine difluoride: ZIF-90/PVDF nanocomposites. APL Mater. 2017, 5, 086104. [Google Scholar] [CrossRef]

- Suresh, G.; Jatav, S.; Mallikarjunachari, G.; Rao, M.S.R.; Ghosh, P.; Satapathy, D.K. Influence of Microstructure on the Nanomechanical Properties of Polymorphic Phases of Poly(vinylidene fluoride). J. Phys. Chem. B 2018, 122, 8591–8600. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Li, C.; Jiang, H. Dye-Sensitized Solar Cell With Energy Storage Function Through PVDF/ZnO Nanocomposite Counter Electrode. Adv. Mater. 2013, 25, 4093–4096. [Google Scholar] [CrossRef]

- Damm, P.; Kutzner, I.; Bergmann, G.; Rohlmann, A.; Schmidt, H. Comparison of in Vivo Measured Loads in Knee, Hip and Spinal Implants During Level Walking. J. Biomech. 2017, 51, 128–132. [Google Scholar] [CrossRef]

| Parameter | Units | LCR | HCR |

|---|---|---|---|

| Initial layer height | mm | 0.27 | 0.27 |

| Layer height | mm | 0.1 | 0.1 |

| Line width | mm | 0.35 | 0.35 |

| Infill direction | ° | [0, 0] & [45, 135] | |

| Infill percentage | % | 100 | 100 |

| Printing temperature | °C | 250 | 225 |

| Build plate temperature | °C | 100 | 50 |

| Printing speed | mm s−1 | 20 | 20 |

| Cooling fan | % | 0 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joshi, S.; Gazmin, E.; Glover, J.; Weeks, N.; Khan, F.; Iacono, S.; Corti, G. Improved Electrical Signal of Non-Poled 3D Printed Zinc Oxide-Polyvinylidene Fluoride Nanocomposites. Polymers 2022, 14, 4312. https://doi.org/10.3390/polym14204312

Joshi S, Gazmin E, Glover J, Weeks N, Khan F, Iacono S, Corti G. Improved Electrical Signal of Non-Poled 3D Printed Zinc Oxide-Polyvinylidene Fluoride Nanocomposites. Polymers. 2022; 14(20):4312. https://doi.org/10.3390/polym14204312

Chicago/Turabian StyleJoshi, Sharmad, Enrique Gazmin, Jayden Glover, Nathan Weeks, Fazeel Khan, Scott Iacono, and Giancarlo Corti. 2022. "Improved Electrical Signal of Non-Poled 3D Printed Zinc Oxide-Polyvinylidene Fluoride Nanocomposites" Polymers 14, no. 20: 4312. https://doi.org/10.3390/polym14204312

APA StyleJoshi, S., Gazmin, E., Glover, J., Weeks, N., Khan, F., Iacono, S., & Corti, G. (2022). Improved Electrical Signal of Non-Poled 3D Printed Zinc Oxide-Polyvinylidene Fluoride Nanocomposites. Polymers, 14(20), 4312. https://doi.org/10.3390/polym14204312