Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review

Abstract

1. Introduction

2. Hemp Polymeric and Extract Components

3. Hemp Polymeric Fiber and Nanofiber

3.1. Preparation and Composition of Hemp Fiber

3.1.1. Biological Retting

3.1.2. Steam Explosion and Plasma Treatment

3.1.3. Alkaline Treatment

3.1.4. Acetylation Treatment

3.1.5. Silane Treatment

3.1.6. Maleic Anhydride Treatment

4. Hemp Polymeric Composites in Packaging Applications

4.1. Package Forming Technology

4.1.1. Melt Mixing

4.1.2. Solution Casting

4.1.3. Extrusion Compounding

4.1.4. Injection Molding

4.1.5. Compression Molding

4.2. Applications of Hemp Fiber

4.2.1. Paper

4.2.2. Textile

4.2.3. Composites and Plastic

5. Extraction and Composition of Hemp Extract

5.1. Solventless Extraction

5.2. Solvent-Based Extraction

5.2.1. Soxhlet Extraction

5.2.2. Dynamic Maceration (DM)

6. Application of Hemp Extracts in Packaging, Food and Textile

6.1. Polymeric Packaging

6.2. Food, Feed and Pharmaceutical Products

7. Conclusions and Challenges

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Frassinetti, S.; Moccia, E.; Caltavuturo, L.; Gabriele, M.; Longo, V.; Bellani, L.; Giorgi, G.; Giorgetti, L. Nutraceutical potential of hemp (Cannabis sativa L.) seeds and sprouts. Food Chem. 2018, 262, 56–66. [Google Scholar] [CrossRef]

- Hayase, S. Manila Hemp in World, Regional, National and Local History. J. Asia-Pac. Stud. 2018, 3, 171–181. [Google Scholar]

- Li, H.-L. An archaeological and historical account of cannabis in China. Econ. Bot. 1974, 28, 437–448. [Google Scholar] [CrossRef]

- Adesina, I.; Bhowmik, A.; Sharma, H.; Shahbazi, A. A review on the current state of knowledge of growing conditions, agronomic soil health practices and utilities of hemp in the United States. Agriculture 2020, 10, 129. [Google Scholar] [CrossRef]

- Mikulcová, V.; Kašpárková, V.; Humpolíček, P.; Buňková, L. Formulation, characterization and properties of hemp seed oil and its emulsions. Molecules 2017, 22, 700. [Google Scholar] [CrossRef] [PubMed]

- Pasqua, T.; Rocca, C.; Lupi, F.R.; Baldino, N.; Amelio, D.; Parisi, O.I.; Granieri, M.C.; De Bartolo, A.; Lauria, A.; Dattilo, M. Cardiac and metabolic impact of functional foods with antioxidant properties based on whey derived proteins enriched with hemp seed oil. Antioxidants 2020, 9, 1066. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crops Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- Shuttleworth, P.S.; Díez-Pascual, A.M.; Marco, C.; Ellis, G. Flexible bionanocomposites from epoxidized hemp seed oil thermosetting resin reinforced with halloysite nanotubes. J. Phys. Chem. B 2017, 121, 2454–2467. [Google Scholar] [CrossRef]

- Tedeschi, A.; Volpe, M.G.; Polimeno, F.; Siano, F.; Maglione, G.; Di Tommasi, P.; Vasca, E.; Magliulo, V.; Vitale, L. Soil fertilization with urea has little effect on seed quality but reduces soil N2O emissions from a hemp cultivation. Agriculture 2020, 10, 240. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Biodegradable Poly(Butylene Adipate-Co-Terephthalate) and Thermoplastic Starch-Blended TiO2 Nanocomposite Blown Films as Functional Active Packaging of Fresh Fruit. Polymers 2021, 13, 4192. [Google Scholar] [CrossRef] [PubMed]

- Wongphan, P.; Panrong, T.; Harnkarnsujarit, N. Effect of different modified starches on physical, morphological, thermomechanical, barrier and biodegradation properties of cassava starch and polybutylene adipate terephthalate blend film. Food Packag. Shelf Life 2022, 32, 100844. [Google Scholar] [CrossRef]

- Tremlová, B.; Mikulášková, H.K.; Hajduchová, K.; Jancikova, S.; Kaczorová, D.; Ćavar Zeljković, S.; Dordevic, D. Influence of technological maturity on the secondary metabolites of hemp concentrate (Cannabis sativa L.). Foods 2021, 10, 1418. [Google Scholar] [CrossRef]

- Jarman, C. Plant Fibre Processing; Small Scale Textile Series; Intermediate Technology Publications: London, UK, 1998; 64p. [Google Scholar]

- Gassan, J.; Bledzki, A. Composition of different natural fibers. Die Angew. Makromol. Chem. 1996, 236, 129–138. [Google Scholar]

- Bolton, J. The potential of plant fibres as crops for industrial use. Outlook Agric. 1995, 24, 85–89. [Google Scholar] [CrossRef]

- Dupeyre, D.; Vignon, M. Fibres from semi-retted hemp bundles by steam explosion treatment. Biomass Bioenergy 1998, 14, 251–260. [Google Scholar]

- Mougin, G. Natural-fibre composites: Problems and solutions: Natural fibres. JEC Compos. 2006, 25, 32–35. [Google Scholar]

- Kozlowski, R.; Wladyka-Przybylak, M. Uses of natural fiber reinforced plastics. In Natural Fibers, Plastics and Composites; Springer: Cham, Switzerland, 2004; pp. 249–274. [Google Scholar]

- Baltazar-y-Jimenez, A.; Bismarck, A. Wetting behaviour, moisture up-take and electrokinetic properties of lignocellulosic fibres. Cellulose 2007, 14, 115–127. [Google Scholar] [CrossRef]

- Bismarck, A.; Sarikakis, K. Green composites as panacea? Socio-economic aspects of green materials. Environ. Dev. Sustain. 2006, 8, 445–463. [Google Scholar] [CrossRef]

- Wang, B.; Sain, M.; Oksman, K. Study of structural morphology of hemp fiber from the micro to the nanoscale. Appl. Compos. Mater. 2007, 14, 89–103. [Google Scholar] [CrossRef]

- Timell, T. Some properties of native hemp, jute, and kapok celluloses. Text. Res. J. 1957, 27, 854–859. [Google Scholar] [CrossRef]

- Kostic, M.; Pejic, B.; Skundric, P. Quality of chemically modified hemp fibers. Bioresour. Technol. 2008, 99, 94–99. [Google Scholar] [CrossRef]

- Tyagi, P.; Gutierrez, J.N.; Nathani, V.; Lucia, L.A.; Rojas, O.J.; Hubbe, M.A.; Pal, L. Hydrothermal and mechanically generated hemp hurd nanofibers for sustainable barrier coatings/films. Ind. Crops Prod. 2021, 168, 113582. [Google Scholar] [CrossRef]

- Osong, S.H.; Norgren, S.; Engstrand, P. Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: A review. Cellulose 2016, 23, 93–123. [Google Scholar] [CrossRef]

- Van der Werf, H.M.; Turunen, L. The environmental impacts of the production of hemp and flax textile yarn. Ind. Crops Prod. 2008, 27, 1–10. [Google Scholar] [CrossRef]

- Liu, M.; Silva, D.A.S.; Fernando, D.; Meyer, A.S.; Madsen, B.; Daniel, G.; Thygesen, A. Controlled retting of hemp fibres: Effect of hydrothermal pre-treatment and enzymatic retting on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 253–262. [Google Scholar] [CrossRef]

- Vignon, M.; Dupeyre, D.; Garcia-Jaldon, C. Morphological characterization of steam-exploded hemp fibers and their utilization in polypropylene-based composites. Bioresour. Technol. 1996, 58, 203–215. [Google Scholar] [CrossRef]

- Wang, H.; Postle, R.; Kessler, R.; Kessler, W. Removing pectin and lignin during chemical processing of hemp for textile applications. Text. Res. J. 2003, 73, 664–669. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Kabir, M.; Wang, H.; Lau, K.; Cardona, F. Effects of chemical treatments on hemp fibre structure. Appl. Surf. Sci. 2013, 276, 13–23. [Google Scholar] [CrossRef]

- Islam, M.S.; Pickering, K.L.; Foreman, N. Influence of alkali fiber treatment and fiber processing on the mechanical properties of hemp/epoxy composites. J. Appl. Polym. Sci. 2011, 119, 3696–3707. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.; Williams, D.; Baillie, C.; Matthews, F. Engineering and characterisation of the interface in flax fibre/polypropylene composite materials. Part I. Development and investigation of surface treatments. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1083–1093. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, Q.; McNabb, H.S. Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood Fiber Sci. 2000, 32, 88–104. [Google Scholar]

- Hajiha, H.; Sain, M.; Mei, L. Modification and characterization of hemp and sisal fibers. J. Nat. Fibers 2014, 11, 144–168. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.; Olayo, R.; Herrera-Franco, P. Chemical modification of henequen fibers with an organosilane coupling agent. Compos. Part B Eng. 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Caulfield, D.F.; Jacobson, R.E.J.P.; Resources, C.F.A.-B. Agro-fiber thermoplastic composites. In Paper and Composites from Agro-Based Resources; CRC Press LLC: Boca Raton, FL, USA, 1997; pp. 377–401. [Google Scholar]

- Gironès, J.; López, J.; Mutjé, P.; Carvalho, A.J.F.d.; Curvelo, A.A.d.S.; Vilaseca, F. Natural fiber-reinforced thermoplastic starch composites obtained by melt processing. Compos. Sci. Technol. 2012, 72, 858–863. [Google Scholar] [CrossRef]

- Wongphan, P.; Khowthong, M.; Supatrawiporn, T.; Harnkarnsujarit, N. Novel edible starch films incorporating papain for meat tenderization. Food Packag. Shelf Life 2022, 31, 100787. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

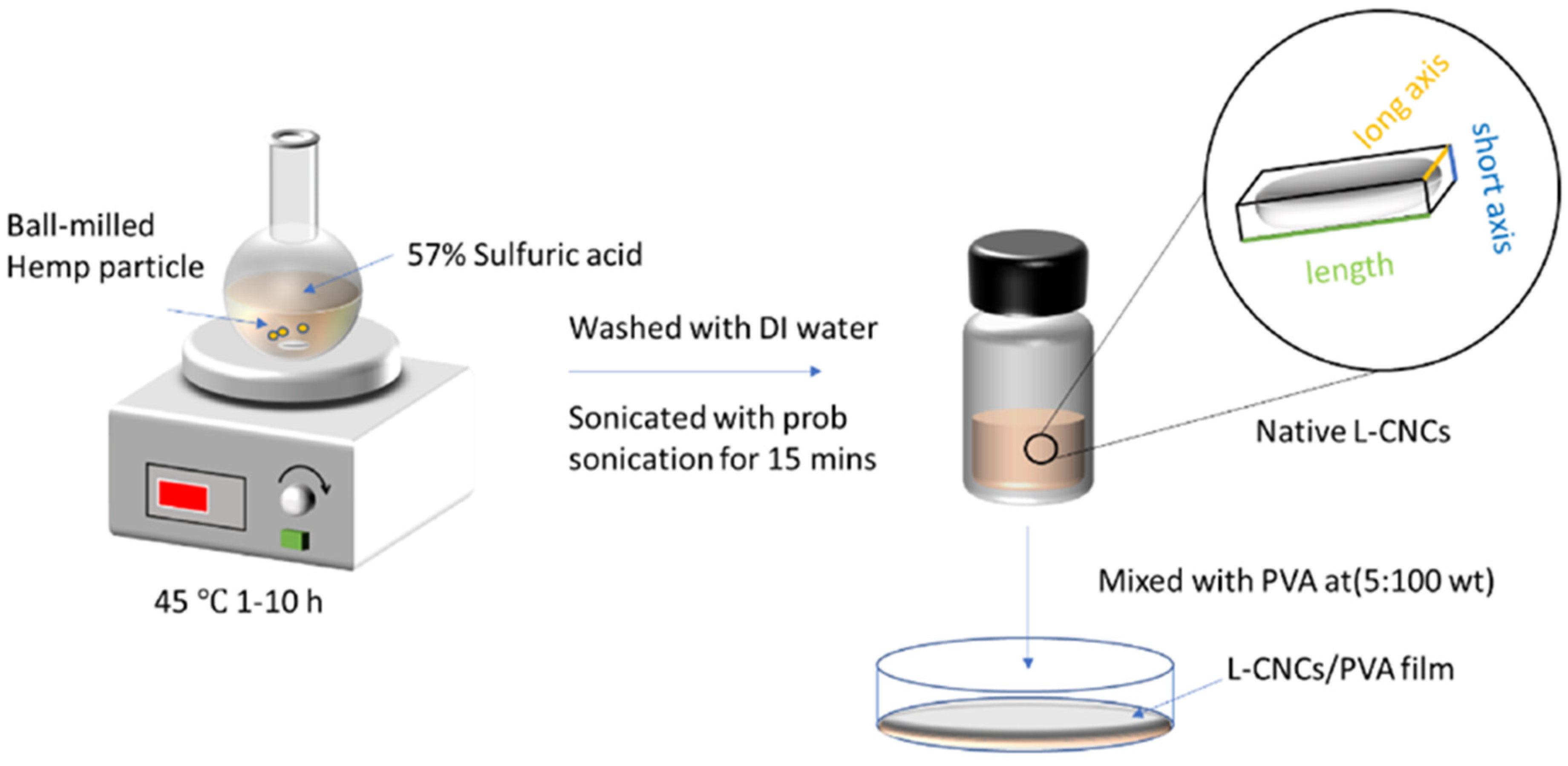

- Zhang, Y.; Remadevi, R.; Hinestroza, J.P.; Wang, X.; Naebe, M. Transparent ultraviolet (UV)-shielding films made from waste hemp hurd and polyvinyl alcohol (PVA). Polymers 2020, 12, 1190. [Google Scholar] [CrossRef]

- Zhang, Y.; Haque, A.N.M.A.; Naebe, M. Lignin–Cellulose Nanocrystals from Hemp Hurd as Light-Coloured Ultraviolet (UV) Functional Filler for Enhanced Performance of Polyvinyl Alcohol Nanocomposite Films. Nanomaterials 2021, 11, 3425. [Google Scholar] [CrossRef] [PubMed]

- Promsorn, J.; Harnkarnsujarit, N. Oxygen absorbing food packaging made by extrusion compounding of thermoplastic cassava starch with gallic acid. Food Control 2022, 142, 109273. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Harnkarnsujarit, N. Migration, aggregations and thermal degradation behaviors of TiO2 and ZnO incorporated PBAT/TPS nanocomposite blown films. Food Packag. Shelf Life 2022, 33, 100901. [Google Scholar] [CrossRef]

- Wadaugsorn, K.; Panrong, T.; Wongphan, P.; Harnkarnsujarit, N. Plasticized hydroxypropyl cassava starch blended PBAT for improved clarity blown films: Morphology and properties. Ind. Crops Prod. 2022, 176, 114311. [Google Scholar] [CrossRef]

- Phothisarattana, D.; Wongphan, P.; Promhuad, K.; Promsorn, J.; Harnkarnsujarit, N. Blown film extrusion of PBAT/TPS/ZnO nanocomposites for shelf-life extension of meat packaging. Colloids Surf. B Biointerfaces 2022, 214, 112472. [Google Scholar] [CrossRef]

- Beckermann, G.; Pickering, K.; Foreman, N. Evaluation of the mechanical properties of injection moulded hemp fibre reinforced polypropylene composites. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2007; pp. 303–306. [Google Scholar]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and study of fully biodegradable composite materials based on poly (butylene succinate) and hemp fibers or hemp shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Yan, Z.L.; Wang, H.; Lau, K.; Pather, S.; Zhang, J.; Lin, G.; Ding, Y. Reinforcement of polypropylene with hemp fibres. Compos. Part B Eng. 2013, 46, 221–226. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Bennett, N.; Reis, P. Low-velocity impact response of non-woven hemp fibre reinforced unsaturated polyester composites: Influence of impactor geometry and impact velocity. Compos. Struct. 2012, 94, 2756–2763. [Google Scholar] [CrossRef]

- Wretfors, C.; Cho, S.-W.; Hedenqvist, M.S.; Marttila, S.; Nimmermark, S.; Johansson, E. Use of industrial hemp fibers to reinforce wheat gluten plastics. J. Polym. Environ. 2009, 17, 259–266. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Xu, Y.-L.; Zegaoui, A.; Nizamani, A.A.; Wang, J.; Zhang, L.; Liu, W.-B.; Shah, A. Reinforcement of waste hemp fibres in aromatic diamine-based benzoxazine thermosets for the enhancement of mechanical and thermomechanical properties. Plast. Rubber Compos. 2017, 46, 442–449. [Google Scholar] [CrossRef]

- Dayo, A.Q.; Zegaoui, A.; Nizamani, A.A.; Kiran, S.; Wang, J.; Derradji, M.; Cai, W.-a.; Liu, W. The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: Mechanical, thermal and water absorption properties. Mater. Chem. Phys. 2018, 217, 270–277. [Google Scholar] [CrossRef]

- Dayo, A.; Ullah, S.; Kiran, S.; Wang, J.; Shah, A.; Zegaoui, A.; Arse, Y.; LIUa, W. Tensile and water absorption behaviour of polybenzoxazine/hemp fibres composites: Experimental analysis and theoretical validation. Dig. J. Nanomater. Biostruct. 2019, 14, 231–241. [Google Scholar]

- Robinson, R. The Great Book of Hemp: The Complete Guide to the Environmental, Commercial, and Medicinal Uses of the World’s Most Extraordinary Plant; Inner Traditions/Bear & Co.: Rochester, VT, USA, 1996. [Google Scholar]

- Barbash, V.A.; Yashchenko, O.; Yakymenko, O.; Zakharko, R.; Myshak, V. Preparation of hemp nanocellulose and its use to improve the properties of paper for food packaging. Cellulose 2022, 29, 8305–8317. [Google Scholar] [CrossRef]

- Cetin, M.; Aydogdu, R.; Toprakci, O.; Karahan Toprakci, H. Sustainable, Tree-Free, PLA Coated, Biodegradable, Barrier Papers from Kendir (Turkish Hemp). J. Nat. Fibers 2022, 1–13. [Google Scholar] [CrossRef]

- Amode, N.S.; Jeetah, P. Paper production from Mauritian hemp fibres. Waste Biomass Valorization 2021, 12, 1781–1802. [Google Scholar] [CrossRef]

- Kirilovs, E.; Kukle, S.; Beļakova, D.; Borodiņecs, A.; Ruciņš, Ā.; Stramkale, V. Thermal conductivity of hemp based boards. In Environment. Technologies. Resources. Proceedings of the International Scientific and Practical Conference, London, UK, 25–26 January 2015; IEEE: Manhattan, NY, USA, 2015; pp. 61–66. [Google Scholar]

- Jianyong, F.; Jianchun, Z. Preparation and oil/air filtration properties of hemp paper. J. Ind. Text. 2015, 45, 3–32. [Google Scholar] [CrossRef]

- Nabels-Sneiders, M.; Platnieks, O.; Grase, L.; Gaidukovs, S. Lamination of Cast Hemp Paper with Bio-Based Plastics for Sustainable Packaging: Structure-Thermomechanical Properties Relationship and Biodegradation Studies. J. Compos. Sci. 2022, 6, 246. [Google Scholar] [CrossRef]

- Baptista, C.; Santos, N.; Rosa, M. Portuguese hemp plant as raw material for papermaking. Athens J. Sci. 2020, 7, 15–28. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Properties and fibre characterisation of bleached hemp, birch and pine pulps: A comparison. Cellulose 2017, 24, 5173–5186. [Google Scholar] [CrossRef]

- Mirski, R.; Boruszewski, P.; Trociński, A.; Dziurka, D. The possibility to use long fibres from fast growing hemp (Cannabis sativa L.) for the production of boards for the building and furniture industry. BioResources 2017, 12, 3521–3529. [Google Scholar] [CrossRef]

- Fernea, R.; Tămaș-Gavrea, D.R.; Manea, D.L.; Aciu, C. Physical and Mechanical Property Characterization of Hemp Shive Reinforced Gypsum Composite Board. In Proceedings of the Advanced Engineering Forum, Wollerau, Switzerland, 1–2 November 2017; pp. 262–271. [Google Scholar]

- Kirilovs, E.; Zotova, I.; Gendelis, S.; Jörg-Gusovius, H.; Kukle, S.; Stramkale, V. Experimental study of using micro-encapsulated phase-change material integrated into hemp shive wallboard. Buildings 2020, 10, 228. [Google Scholar] [CrossRef]

- Danielewicz, D.; Surma-Ślusarska, B. Bleached Kraft pulps from blends of wood and hemp. part i. demand for alkali, yield of pulps, their fractional composition and fibre properties. Fibres Text. East. Eur. 2019, 27, 112–117. [Google Scholar] [CrossRef]

- Kremensas, A.; Kairytė, A.; Vaitkus, S.; Vėjelis, S.; Członka, S.; Strąkowska, A. The impact of hot-water-treated fibre hemp shivs on the water resistance and thermal insulating performance of corn starch bonded biocomposite boards. Ind. Crops Prod. 2019, 137, 290–299. [Google Scholar] [CrossRef]

- Väisänen, T.; Batello, P.; Lappalainen, R.; Tomppo, L. Modification of hemp fibers (Cannabis sativa L.) for composite applications. Ind. Crops Prod. 2018, 111, 422–429. [Google Scholar] [CrossRef]

- Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of hemp hurds as bio-sourced additives in PLA-based biocomposites. Polymers 2021, 13, 3786. [Google Scholar] [CrossRef]

- Khan, B.A.; Chevali, V.S.; Na, H.; Zhu, J.; Warner, P.; Wang, H. Processing and properties of antibacterial silver nanoparticle-loaded hemp hurd/poly (lactic acid) biocomposites. Compos. Part B Eng. 2016, 100, 10–18. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; de Ballesteros, O.R.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Sergi, C.; Seghini, M.C.; Cozzarini, L.; Graupner, N. Effect of basalt fibre hybridisation and sizing removal on mechanical and thermal properties of hemp fibre reinforced HDPE composites. Compos. Struct. 2018, 188, 394–406. [Google Scholar] [CrossRef]

- Cozmuta, A.M.; Turila, A.; Apjok, R.; Ciocian, A.; Cozmuta, L.M.; Peter, A.; Nicula, C.; Galić, N.; Benković, T. Preparation and characterization of improved gelatin films incorporating hemp and sage oils. Food Hydrocoll. 2015, 49, 144–155. [Google Scholar] [CrossRef]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Pedró, J.P. Novel Molecular Tools to Uncover the Genetic Architecture of Hemp Fibre Quality; Wageningen University and Research: Wageningen, The Netherlands, 2020. [Google Scholar]

- Yan, X.; Hong, L.; Pei, S.; Hamilton, A.; Sun, H.; Yang, R.; Liu, A.; Yang, L. A natural yellow colorant from Buddleja officinalis for dyeing hemp fabric. Ind. Crops Prod. 2021, 171, 113968. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, K.; Fernando, A.; Gao, Y.; Li, G.; Jin, L.; Zhai, H.; Yi, Y.; Xu, L.; Zheng, Y. Permeable graphited hemp fabrics-based, wearing-comfortable pressure sensors for monitoring human activities. Chem. Eng. J. 2021, 403, 126191. [Google Scholar] [CrossRef]

- Tama, D.; Isler, M.; Abreu, M.J. Evaluating the thermal comfort properties of Rize’s traditional hemp fabric (Feretiko) using a thermal manikin. Mater. Today Proc. 2020, 31, S197–S200. [Google Scholar] [CrossRef]

- Corbin, A.-C.; Soulat, D.; Ferreira, M.; Labanieh, A.-R.; Gabrion, X.; Malécot, P.; Placet, V. Towards hemp fabrics for high-performance composites: Influence of weave pattern and features. Compos. Part B Eng. 2020, 181, 107582. [Google Scholar] [CrossRef]

- Misnon, M.; Islam, M.; Epaarachchi, J.; Chen, H.; Goda, K.; Khan, M. Flammability characteristics of chemical treated woven hemp fabric reinforced vinyl ester composites. Sci. Technol. Mater. 2018, 30, 174–188. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M. Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp–lyocell hybrid yarn fabrics. Compos. Part A Appl. Sci. Manuf. 2016, 81, 139–144. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Langella, A.; Carrino, L. Creep behaviour of polylactic acid reinforced by woven hemp fabric. Compos. Part A Appl. Sci. Manuf. 2017, 124, 16–22. [Google Scholar] [CrossRef]

- Grégoire, M.; Barthod-Malat, B.; Labonne, L.; Evon, P.; De Luycker, E.; Ouagne, P. Investigation of the potential of hemp fibre straws harvested using a combine machine for the production of technical load-bearing textiles. Ind. Crops Prod. 2020, 145, 111988. [Google Scholar] [CrossRef]

- Muzyczek, M. The use of flax and hemp for textile applications. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 147–167. [Google Scholar]

- Zhang, J. Natural fibres in China. In Common Fund for Commodities Proceedings of the Symposium on Natural Fibres; Food and Agriculture Organization (FAO) and Common Fund for Commodities (CFC): Rome, Italy, 2008; pp. 53–61. [Google Scholar]

- Horne, M. Bast fibres: Hemp cultivation and production. In Handbook of Natural Fibres; Woodhead Publishing: Cambridge, UK, 2020; Volume 1, pp. 163–196. [Google Scholar]

- Ahmed, A.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a potential raw material toward a sustainable world: A review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Hao, X.M.; Yang, Y.; An, L.X.; Wang, J.M.; Han, L. Study on antibacterial mechanism of hemp fiber. In Advanced Materials Research; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2014; pp. 610–613. [Google Scholar]

- Song, Y.S.; Lee, J.T.; Ji, D.S.; Kim, M.W.; Lee, S.H.; Youn, J.R. Viscoelastic and thermal behavior of woven hemp fiber reinforced poly (lactic acid) composites. Compos. Part B Eng. 2012, 43, 856–860. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Di Girolamo, R.; Famiglietti, M.; Porta, R. Hemp (Cannabis sativa) seed oilcake as a promising by-product for developing protein-based films: Effect of transglutaminase-induced crosslinking. Food Packag. Shelf Life 2022, 31, 100779. [Google Scholar] [CrossRef]

- Guessasma, S.; Bassir, D.; Hedjazi, L. Influence of interphase properties on the effective behaviour of a starch-hemp composite. Mater. Des. 2015, 65, 1053–1063. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Shi, S.Q.; Cheng, J. Water-resistant hemp fiber-reinforced composites: In-situ surface protection by polyethylene film. Ind. Crops Prod. 2018, 112, 210–216. [Google Scholar] [CrossRef]

- Bledzki, A.; Fink, H.P.; Specht, K. Unidirectional hemp and flax EP-and PP-composites: Influence of defined fiber treatments. J. Appl. Polym. Sci. 2004, 93, 2150–2156. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M. Hemp fibre reinforced cashew nut shell liquid composites. Compos. Sci. Technol. 2003, 63, 1297–1305. [Google Scholar] [CrossRef]

- Rouison, D.; Sain, M.; Couturier, M. Resin transfer molding of hemp fiber composites: Optimization of the process and mechanical properties of the materials. Compos. Sci. Technol. 2006, 66, 895–906. [Google Scholar] [CrossRef]

- Surender, R.; Mahendran, A.R.; Wuzella, G.; Vijayakumar, C. Synthesis, characterization and degradation behavior of thermoplastic polyurethane from hydroxylated hemp seed oil. J. Therm. Anal. Calorim. 2016, 123, 525–533. [Google Scholar] [CrossRef]

- Dixit, S.; Mishra, G.; Yadav, V.L.J.P.B. Optimization of novel bio-composite packaging film based on alkali-treated Hemp fiber/polyethylene/polypropylene using response surface methodology approach. Polym. Bull. 2022, 79, 2559–2583. [Google Scholar] [CrossRef]

- Mu, J.; Wang, F.M.; Zhang, D.R. Preparation and Static Cushioning Property of Foaming Packaging Material with Hemp Haulm. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2012; pp. 401–405. [Google Scholar]

- Blake, A.; Nahtigal, I. The evolving landscape of cannabis edibles. Curr. Opin. Food Sci. 2019, 28, 25–31. [Google Scholar] [CrossRef]

- Vas, G. State of the art solventless sample preparation alternatives for analytical evaluation of the volatile constituents of different cannabis based products. In Comprehensive Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2020; Volume 90, pp. 105–137. [Google Scholar]

- Dussy, F.E.; Hamberg, C.; Luginbühl, M.; Schwerzmann, T.; Briellmann, T.A. Isolation of Δ9-THCA-A from hemp and analytical aspects concerning the determination of Δ9-THC in cannabis products. Forensic Sci. Int. 2005, 149, 3–10. [Google Scholar] [CrossRef]

- Lehmann, T.; Brenneisen, R.J.P.A. A new chromatographic method for the isolation of (−)-Δ9-(trans)-tetrahydrocannabinolic acid A. Phytochem. Anal. 1992, 3, 88–90. [Google Scholar] [CrossRef]

- Romano, L.L.; Hazekamp, A. Cannabis oil: Chemical evaluation of an upcoming cannabis-based medicine. Cannabinoids 2013, 1, 1–11. [Google Scholar]

- Rovetto, L.J.; Aieta, N.V. Supercritical carbon dioxide extraction of cannabinoids from Cannabis sativa L. J. Supercrit. Fluids 2017, 129, 16–27. [Google Scholar] [CrossRef]

- Raber, J.C.; Elzinga, S.; Kaplan, C. Understanding dabs: Contamination concerns of cannabis concentrates and cannabinoid transfer during the act of dabbing. J. Supercrit. Fluids 2015, 40, 797–803. [Google Scholar] [CrossRef] [PubMed]

- Azmir, J.; Zaidul, I.S.M.; Rahman, M.M.; Sharif, K.; Mohamed, A.; Sahena, F.; Jahurul, M.; Ghafoor, K.; Norulaini, N.; Omar, A. Techniques for extraction of bioactive compounds from plant materials: A review. J. Food Eng. 2013, 117, 426–436. [Google Scholar] [CrossRef]

- De Castro, M.L.; Garcıa-Ayuso, L. Soxhlet extraction of solid materials: An outdated technique with a promising innovative future. Anal. Chim. Acta 1998, 369, 1–10. [Google Scholar] [CrossRef]

- Lewis-Bakker, M.M.; Yang, Y.; Vyawahare, R.; Kotra, L. Extractions of medical cannabis cultivars and the role of decarboxylation in optimal receptor responses. Cannabis Cannabinoid Res. 2019, 4, 183–194. [Google Scholar] [CrossRef]

- Fathordoobady, F.; Singh, A.; Kitts, D.D.; Pratap Singh, A. Hemp (Cannabis sativa L.) extract: Anti-microbial properties, methods of extraction, and potential oral delivery. Food Rev. Int. 2019, 35, 664–684. [Google Scholar] [CrossRef]

- Devi, V.; Khanam, S. Comparative study of different extraction processes for hemp (Cannabis sativa) seed oil considering physical, chemical and industrial-scale economic aspects. J. Clean. Prod. 2019, 207, 645–657. [Google Scholar] [CrossRef]

- Mikulec, A.; Kowalski, S.; Sabat, R.; Skoczylas, Ł.; Tabaszewska, M.; Wywrocka-Gurgul, A. Hemp flour as a valuable component for enriching physicochemical and antioxidant properties of wheat bread. LWT 2019, 102, 164–172. [Google Scholar] [CrossRef]

- Deferne, J.-L.; Pate, D.W. Hemp seed oil: A source of valuable essential fatty acids. J. Int. Hemp Assoc. 1996, 3, 1–7. [Google Scholar]

- Galasso, I.; Russo, R.; Mapelli, S.; Ponzoni, E.; Brambilla, I.M.; Battelli, G.; Reggiani, R. Variability in seed traits in a collection of Cannabis sativa L. genotypes. Front. Plant Sci. 2016, 7, 688. [Google Scholar] [CrossRef]

- Aluko, O.; Gowtham, S.; Odegard, G.M. Multiscale modeling and analysis of graphene nanoplatelet/carbon fiber/epoxy hybrid composite. Compos. Part B Eng. 2017, 131, 82–90. [Google Scholar] [CrossRef]

- Ferrante, C.; Recinella, L.; Ronci, M.; Menghini, L.; Brunetti, L.; Chiavaroli, A.; Leone, S.; Di Iorio, L.; Carradori, S.; Tirillini, B. Multiple pharmacognostic characterization on hemp commercial cultivars: Focus on inflorescence water extract activity. Food Chem. Toxicol. 2019, 125, 452–461. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

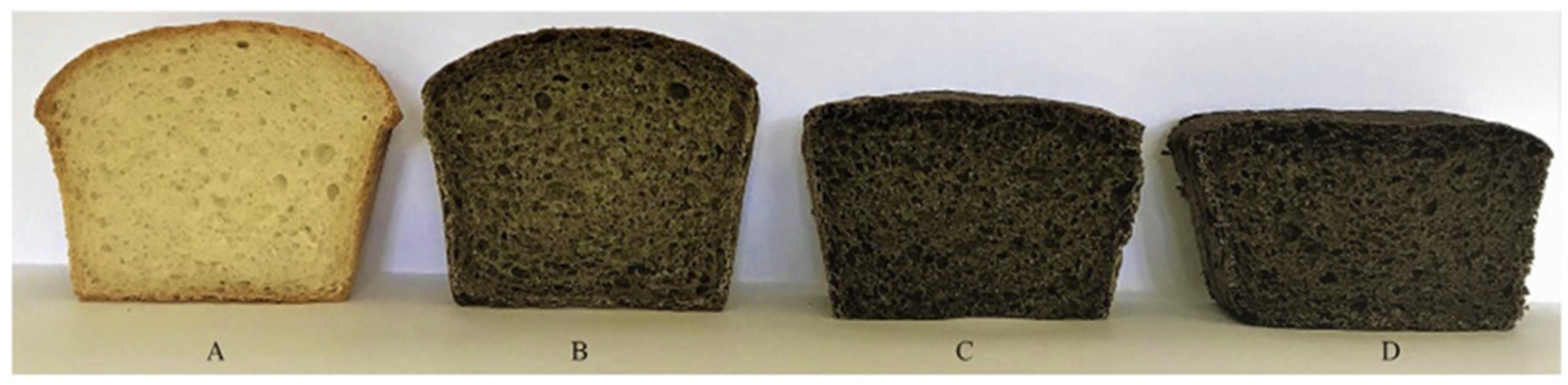

- Švec, I.; Hrušková, M. Crumb evaluation of bread with hemp products addition by means of image analysis. Acta Univ. Agric. Silvic. Mendel. Brun 2013, 61, 1867–1872. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M. Properties and nutritional value of wheat bread enriched by hemp products. Potravinarstvo 2015, 9, 304–308. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M. The Mixolab parameters of composite wheat/hemp flour and their relation to quality features. LWT 2015, 60, 623–629. [Google Scholar] [CrossRef]

- Talens, C.; Lago, M.; Simó-Boyle, L.; Odriozola-Serrano, I.; Ibargüen, M. Desirability-based optimization of bakery products containing pea, hemp and insect flours using mixture design methodology. LWT 2022, 168, 113878. [Google Scholar] [CrossRef]

- Nissen, L.; di Carlo, E.; Gianotti, A. Prebiotic potential of hemp blended drinks fermented by probiotics. Food Res. Int. 2020, 131, 109029. [Google Scholar] [CrossRef] [PubMed]

- Palade, L.M.; Habeanu, M.; Marin, D.E.; Chedea, V.S.; Pistol, G.C.; Grosu, I.A.; Gheorghe, A.; Ropota, M.; Taranu, I. Effect of dietary hemp seed on oxidative status in sows during late gestation and lactation and their offspring. Animals 2019, 9, 194. [Google Scholar] [CrossRef]

- Mourot, J.; Guillevic, M.J.O.O.; Crops, F. Effect of introducing hemp oil into feed on the nutritional quality of pig meat. OCL Oilseeds Fats Crops Lipids 2015, 22, D612. [Google Scholar] [CrossRef]

- Jing, M.; Zhao, S.; House, J. Performance and tissue fatty acid profile of broiler chickens and laying hens fed hemp oil and HempOmegaTM. Poult. Sci. 2017, 96, 1809–1819. [Google Scholar] [CrossRef] [PubMed]

- Reggiani, R.; Russo, R. Beneficial Effect of Supplementation of Flax and Hemp Seeds in the Diet of Alpine Goats on the Iron Content in Blood. J. Sci. Res. Rep. 2016, 10, 1–5. [Google Scholar] [CrossRef]

- Göhl, B.J.F. Les Aliments du Bétail sous les Tropiques; FAO, Division de Production et Santé Animale: Roma, Italy, 1982; Volume 12, 543p. [Google Scholar]

- Leizer, C.; Ribnicky, D.; Poulev, A.; Dushenkov, S.; Raskin, I. The composition of hemp seed oil and its potential as an important source of nutrition. J. Nutraceuticals Funct. Med. Foods 2000, 2, 35–53. [Google Scholar] [CrossRef]

- Zuardi, A.W. History of cannabis as a medicine: A review. Braz. J. Psychiatry 2006, 28, 153–157. [Google Scholar] [CrossRef]

- Maiolo, S.A.; Fan, P.; Bobrovskaya, L. Bioactive constituents from cinnamon, hemp seed and polygonum cuspidatum protect against H2O2 but not rotenone toxicity in a cellular model of Parkinson’s disease. J. Tradit. Complement. Med. 2018, 8, 420–427. [Google Scholar] [CrossRef]

- Fiorini, D.; Molle, A.; Nabissi, M.; Santini, G.; Benelli, G.; Maggi, F. Valorizing industrial hemp (Cannabis sativa L.) by-products: Cannabidiol enrichment in the inflorescence essential oil optimizing sample pre-treatment prior to distillation. Ind. Crops Prod. 2019, 128, 581–589. [Google Scholar] [CrossRef]

- Hilderbrand, R.J. Hemp & cannabidiol: What is a medicine? Mo. Med. 2018, 115, 306. [Google Scholar]

| Cellulose (%) | Hemicellulose (%) | Pectin (%) | Lignin (%) | Other (%) | Reference |

|---|---|---|---|---|---|

| 67.0 | 16.1 | 0.8 | 3.3 | 2.8 | [14] |

| 74.4 | 17.9 | 0.9 | 3.7 | 0.8 | [15] |

| 74.0 | 18.0 | 1.0 | 4.0 | [16] | |

| 55.0 | 16.0 | 18.0 | 4.0 | 7.0 | [17] |

| 76.0 | 11.5 | 1.3 | 3.2 | [18] | |

| 57.0–77.0 | 9.0–13.0 | [19] | |||

| 75.1 | <2.0 | 0.8 | [20] | ||

| 70.0–74.0 | 17.9–22.4 | 0.9 | 3.7–5.7 | 0.8 | [21] |

| 75.6 | 10.7 | 6.6 | [22] | ||

| 78.3 | 2.9 | [23] | |||

| 76.1 | 12.3 | 1.6 | 5.7 | 3.3 | [24] |

| Main Material | Type of Material | Application | Reference |

|---|---|---|---|

| Composite | Hemp fiber and epoxy resin | Reinforcements | [70] |

| Hemp hurds and PLA | Reinforcements packaging | [71] | |

| Hemp hurd powder and PLA | Food packaging | [72] | |

| Hemp fiber and PLA | Reinforcements | [73] | |

| Hemp fiber and high-density polyethylene | Reinforcements | [74] | |

| Hemp fibers and polybenzoxazine | Green composite | [54] | |

| Hemp fibers and polybenzoxazine | Reinforcements | [55] | |

| Hemp hurd and polyvinyl alcohol solution | UV-shielding | [42] | |

| Hemp hurd and polyvinyl alcohol solution | UV-shielding | [43] | |

| Hemp seed oil and gelatin | Active packaging | [75] | |

| Paper | Hemp fiber | Insulation material | [60] |

| Root bast section of waste hemps | Air and oil filtration | [61] | |

| hemp stalks, PHA, PLA, PBS and PBSA | Food packaging | [62] | |

| Hemp pulp and eucalyptus pulp | Raw materials for papermaking | [63] | |

| Hemp pulp, birch pulp and pine pulps | Raw materials for papermaking | [64] | |

| Hemp fiber | Reinforced gypsum composite board | [66] | |

| Hemp shive | Phase change materials (PCMs) | [67] | |

| Hemp stalks, hemp-woody core, birch and pine | Raw materials for papermaking | [68] | |

| Hemp fiber and corn starch | Insulation material | [69] | |

| Hemp fiber | Furniture | [65] |

| Types/Additive/Composite Material | Processing Technology | Fabric Characteristic | Reference |

|---|---|---|---|

| Yellow colorant (Buddleja officinalis) | traditional techniques of dyeing from communities of Yunnan, China equipped with natural mordant treatment | Optimum dying achieved at pH 5, 60 °C for 90 min. Natural mordant treatment improved the yellowness and color fastness was maintained, indicating a good combination process between natural mordant treatment and natural yellow dyeing. | [78] |

| Graphited knitting hemp fabric (GKHF). | Furnace filled with a nitrogen atmosphere, heating at 800 °C | GKHF showed a great air permeability, water vapor and moisture, as well as remarkable static stability in the range of 0.5 to 480 KPa.GHKF detected a variety of static pressure and physiological signals for health monitoring, rehabilitation, and convenience sport stuff. | [79] |

| Feretiko hemp fiber (woven) | Thermal comfort evaluated by thermal manikin | Clothing insulation of Feretiko was 0.20, very close to ASHRAE standard 55-2013 for clothing insulation of a long-sleeve (0.25 clo). The air permeability was also high (2600 L/m2 s). | [80] |

| Hemp fabric and epoxy resin composite | Composite technology: plate and Impregnated Fiber Bundle Test (IFBT) | The pores of composite are low observed in tomography with the similar fiber volume for all the composite. Untwisting reduced the tenacity at break of the rovings. Low-twisted rovings of composite resulting in similar tensile strength of best flax in the range of 150–200 MPa. | [81] |

| Hemp fabric and vinyl ester composite | Chemical treated woven hemp fabric: NaOH and fire retardant (FR) | The treatment increase weight, thickness, density and yarn crimp, while decreased mechanical properties of woven fabric due elimination of hemicellulose and lignin by NaOH and hydrolyzation of cellulose by FR.The treatment increased thermal stability and limiting oxygen index values indicating fire retardant properties was improved. | [82] |

| Hemp fiber, Lyocell and PLA composite | Wrap spinning process | Lyocell addition improve tensile strength of hemp/PLA composite-based fabric and lesser fiber pull-outs appears, but did not affect on water absorption. | [83] |

| PLA | Compression molding technique | Reinforcement improved flexural and charpy detected for fibre volume fraction of 20 and 30%, and decreased at 40%. The impact strength increased by increasing reinforcement content. 30% reinforcement showed the best creep behavior | [84] |

| Main Material | Packaging Technology | Material | Method of Hemp Fiber/Hemp Seed Oil | Packaging Properties | Reference |

|---|---|---|---|---|---|

| Hemp fiber | Internal mixerRoll mixerInjection molding machine | Hemp fiber and polypropylene | - |

| [50] |

| Twin-screw extruderInjection molding machine | Hemp fiber and polypropylene | Alkaline treatment |

| [48] | |

| Rapid-Kothen machine | Hemp fiber | Alkaline treatment |

| [57] | |

| Solvent casting | Hemp fiber, poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) | - |

| [41] | |

| Compression molding process | Polyester and hemp fiber | - |

| [51] | |

| Laminated in a sandwich-like structure | Poly (lactic acid)Hemp (Cannabis sativa L.) | - |

| [91] | |

| Twin-screw extruderInjection molding machine | Poly (lactic acid) and hemp fiber | - |

| [7] | |

| Single-screw extruder | Potato starch and hemp fiber | - |

| [93] | |

| Compression | Hemp fiber and polyethylene | - |

| [94] | |

| Solvent casting | Hemp hurd and polyvinyl alcohol solution (PVA) | Steam explosion treatment |

| [42] | |

| Laminates | Hemp fibers or flax fibers and epoxy resins (EP) or polypropylene (PP) | Alkaline treatment |

| [95] | |

| Solvent casting | Hemp hurd and polyvinyl alcohol solution (PVA) | - |

| [43] | |

| Compression molding | Hemp fiberWheat gluten | - |

| [52] | |

| Solvent casting | Hemp (Cannabis sativa L.) seed oilcake | - |

| [92] | |

| Compression molding | Hemp fibers and cashew nut shell liquid matrix | Alkaline treatment |

| [96] | |

| Compression molding | Hemp fibers and polybenzoxazine | Alkaline treatment |

| [55] | |

| Melt processing | Hemp fibers and corn starch | - |

| [39] | |

| Resin transfer molding | Hemp fiber and unsaturated polyester | - |

| [97] | |

| Compression molding | Hemp fibers and polybenzoxazine | Alkaline and silane treatment |

| [54] | |

| Hydraulic hot-press | Hemp fibers and polybenzoxazine | Alkaline treatment |

| [53] | |

| Hemp seed oil | Planetary centrifugal mixer | 4-dimethylaminopyridine (DMAP) and hemp seed oil | Cold-pressed hemp oil |

| [9] |

| Hydrolyzed hemp seed oil | Hemp seed oil | Cold-pressed hemp oil |

| [98] | |

| Film-forming solutions | Hemp seed oil and gelatin | Cold-pressed hemp oil |

| [75] |

| Product Type | Product Form | Mixed Ingredient | Technology | Observation Result | Reference |

|---|---|---|---|---|---|

| Food | Wheat bread | Hemp and heat flour | single-phase method in a fast rotating spiral mixer | Wheat bread containing hemp flour had higher protein content (13.38–19.29 g/100 g d.m) compared to white bread (11.02 g/100 g d.m), but reduce sensory characteristic. Moreover, bread stalling is reduced indicating hardness changing inhibition, increased browning index from 29.69 to 46.26 and phenolic content. | [113] |

| Gluten free bread | Hemp flour, corn starch, potato starch, | Baking using convection oven | Hemp flour weakened starch-based gluten free bread structure, while 20% reinforced the structure. Hemp flour improved dietary fiber content and prevent the hardening, but reduced the lightness. | [118] | |

| Bread | Hemp and wheat flour | Baking | Hemp flour improved the shelf-life of wheat bread, while reduced dough consistency up to 82%. | [121] | |

| Sponge cake | Hemp, pea, and insect protein | Baking using electric oven | Combination of 3.75% pea, 3.75% hemp, and 7.5% insect was possible to obtain egg-free sponge cake. | [122] | |

| Beverage | Fermented plant-based drink | Fermentation: Lactobacillus fermentum, Lb. plantarum, and Bifidobacterium bifidum. | Hemp seed based probiotic drink showed a strong prebiotic activity and bioactive compound improvementAcetate, propionate, and butyrate contained in hemp seed functioned to select the growth of beneficial microbes. | [123] | |

| Feed | Dietary hemp seed diet rich in ω-6 polyunsaturated fatty acid (PUFA) for sows | Hemp diet positively influence the activities of antioxidant enzymes and nitric oxide production level in sows plasma, indicating the reducing of lipid oxidation. It improved antioxidant status of lactating sows and their progeny. | [124] | ||

| Hemp oil for pig | The hemp oil improved alpha linoleic acid in the pork | [125] | |||

| Hemp oil and hemp omega for chicken broiler and laying hens | Chicken broiler and laying hens feed with hemp oil and hemp omega had greather total n-3 polyunsaturated fatty acid | [126] | |||

| Hemp seed for alpine goats | Hemp seed increased the iron content in alpine goat blood from 33 to 67%, confirmed by high phytate content in hemp seed. | [127] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Promhuad, K.; Srisa, A.; San, H.; Laorenza, Y.; Wongphan, P.; Sodsai, J.; Tansin, K.; Phromphen, P.; Chartvivatpornchai, N.; Ngoenchai, P.; et al. Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers 2022, 14, 4274. https://doi.org/10.3390/polym14204274

Promhuad K, Srisa A, San H, Laorenza Y, Wongphan P, Sodsai J, Tansin K, Phromphen P, Chartvivatpornchai N, Ngoenchai P, et al. Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers. 2022; 14(20):4274. https://doi.org/10.3390/polym14204274

Chicago/Turabian StylePromhuad, Khwanchat, Atcharawan Srisa, Horman San, Yeyen Laorenza, Phanwipa Wongphan, Janenutch Sodsai, Kittichai Tansin, Phannaphat Phromphen, Nawarat Chartvivatpornchai, Phurit Ngoenchai, and et al. 2022. "Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review" Polymers 14, no. 20: 4274. https://doi.org/10.3390/polym14204274

APA StylePromhuad, K., Srisa, A., San, H., Laorenza, Y., Wongphan, P., Sodsai, J., Tansin, K., Phromphen, P., Chartvivatpornchai, N., Ngoenchai, P., & Harnkarnsujarit, N. (2022). Applications of Hemp Polymers and Extracts in Food, Textile and Packaging: A Review. Polymers, 14(20), 4274. https://doi.org/10.3390/polym14204274