Fabrication Mechanisms of Lignin Nanoparticles and Their Ultraviolet Protection Ability in PVA Composite Film

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Purification of Kraft Lignin

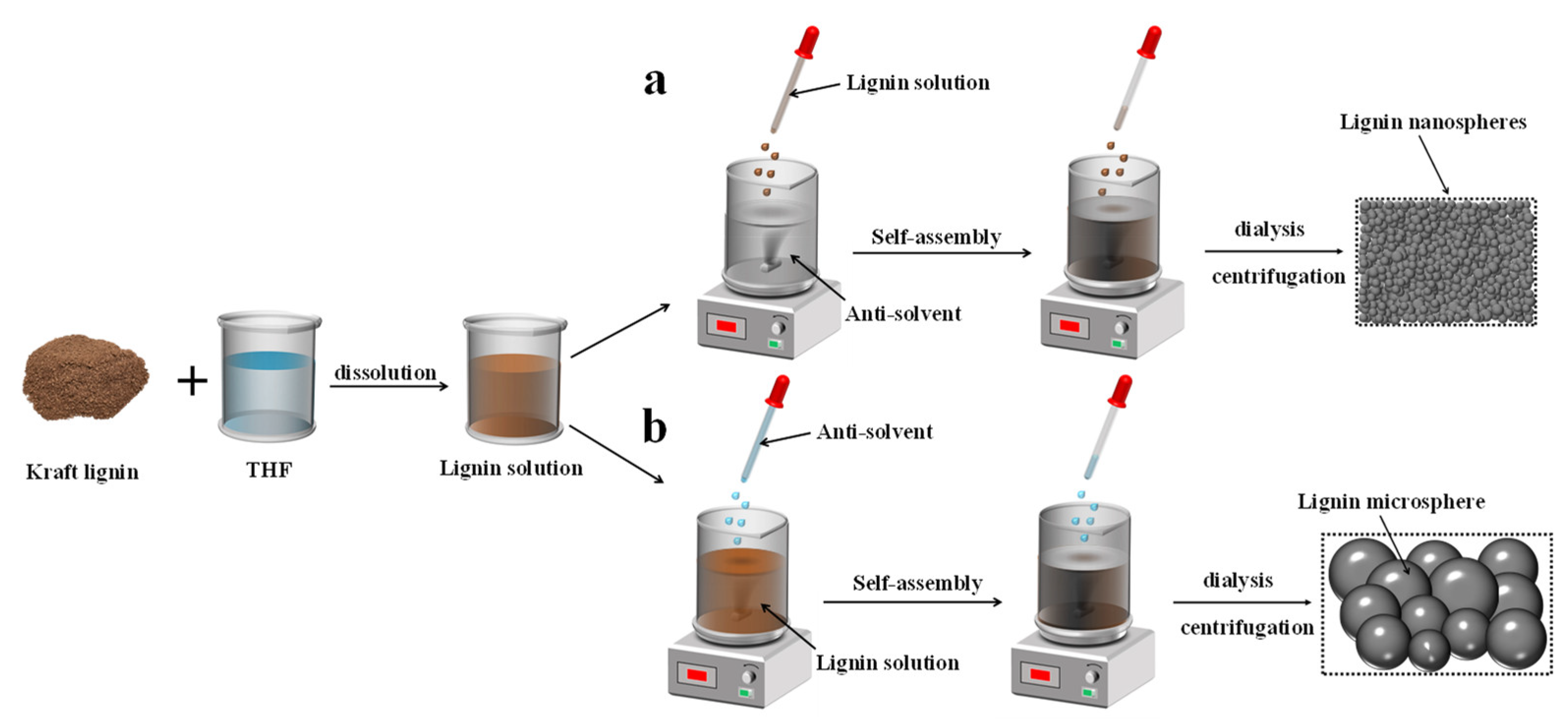

2.3. Preparation of Lignin Nanoparticles

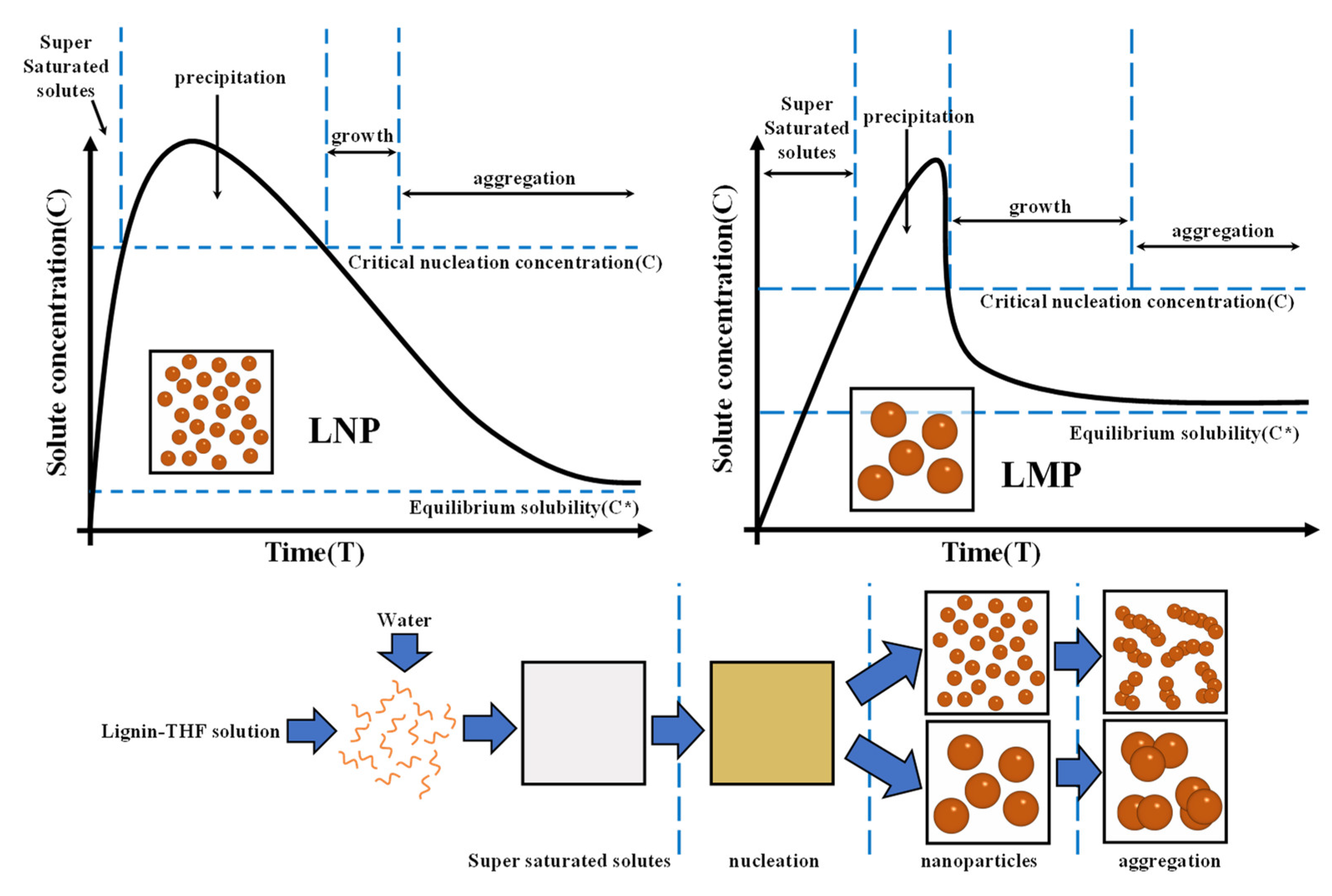

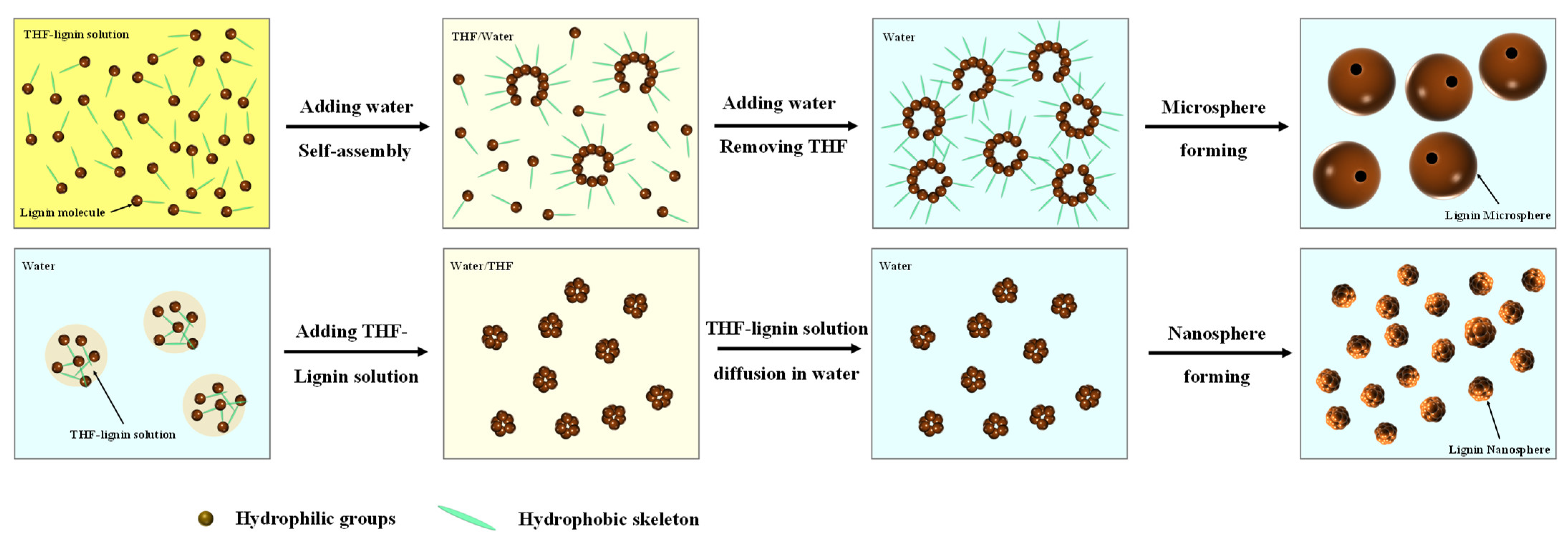

2.4. Formation Mechanism of LNPs

2.5. Preparation of LNP/PVA Composite Film

2.6. Material Characterization

3. Results and Discussion

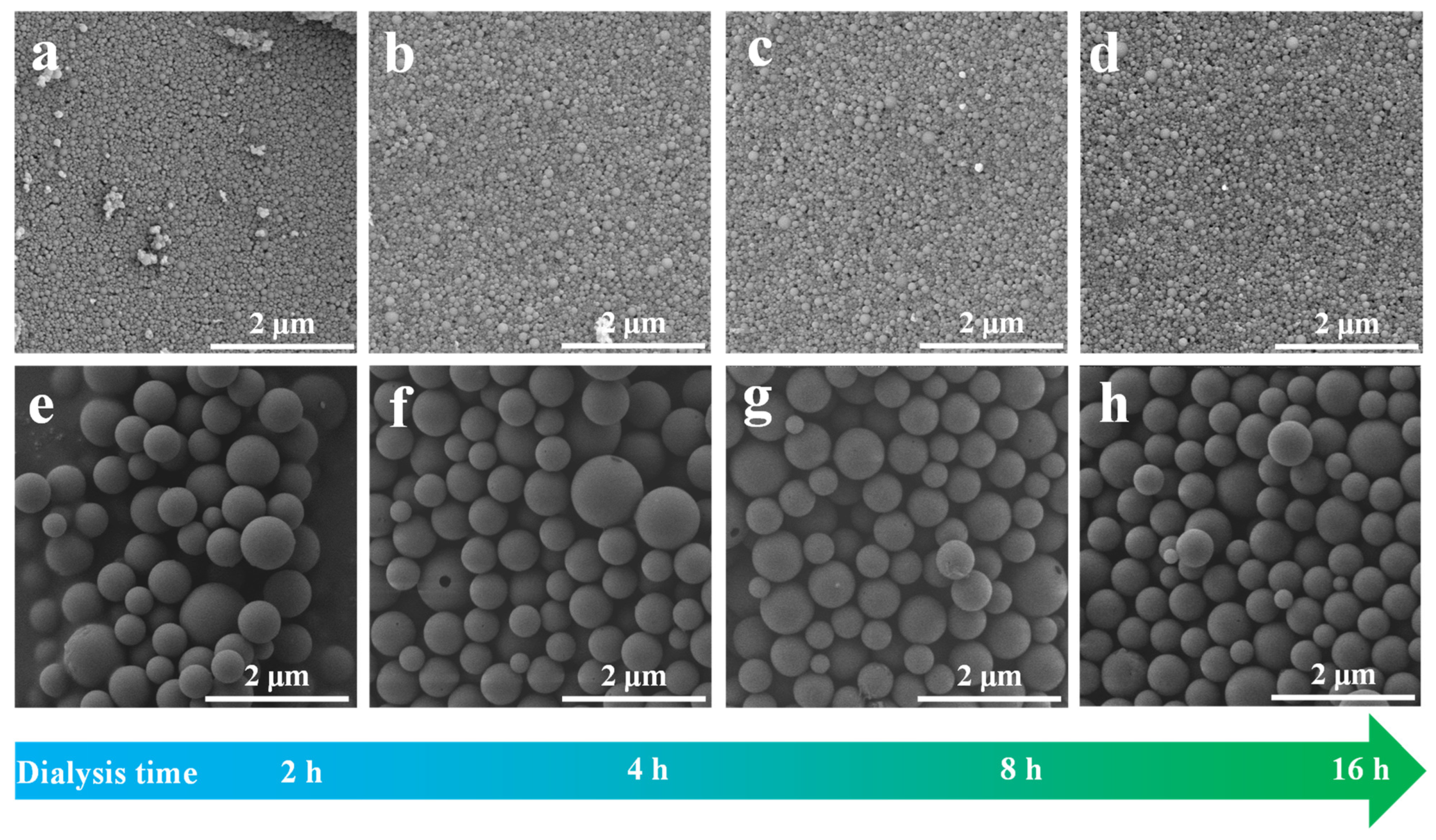

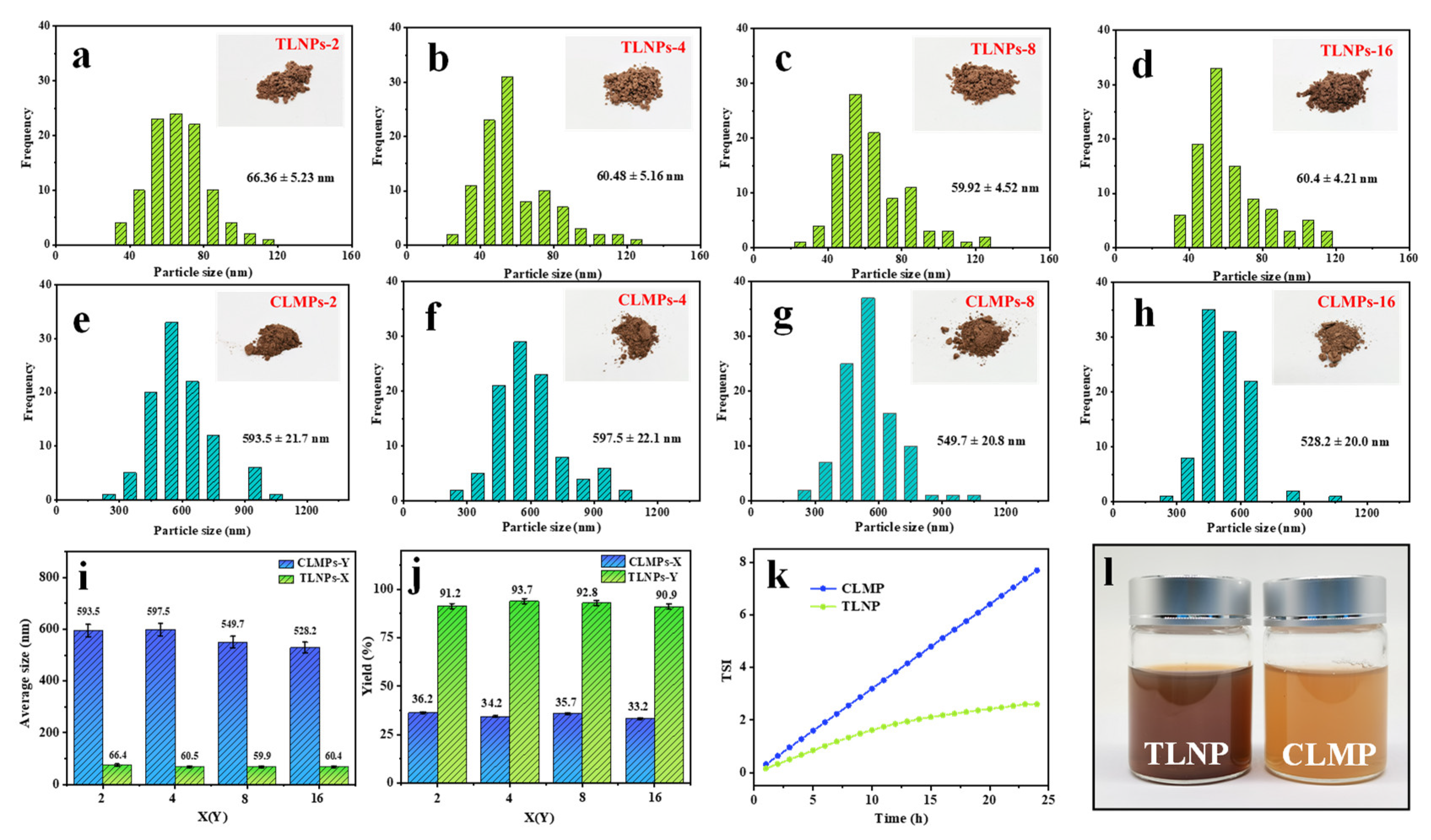

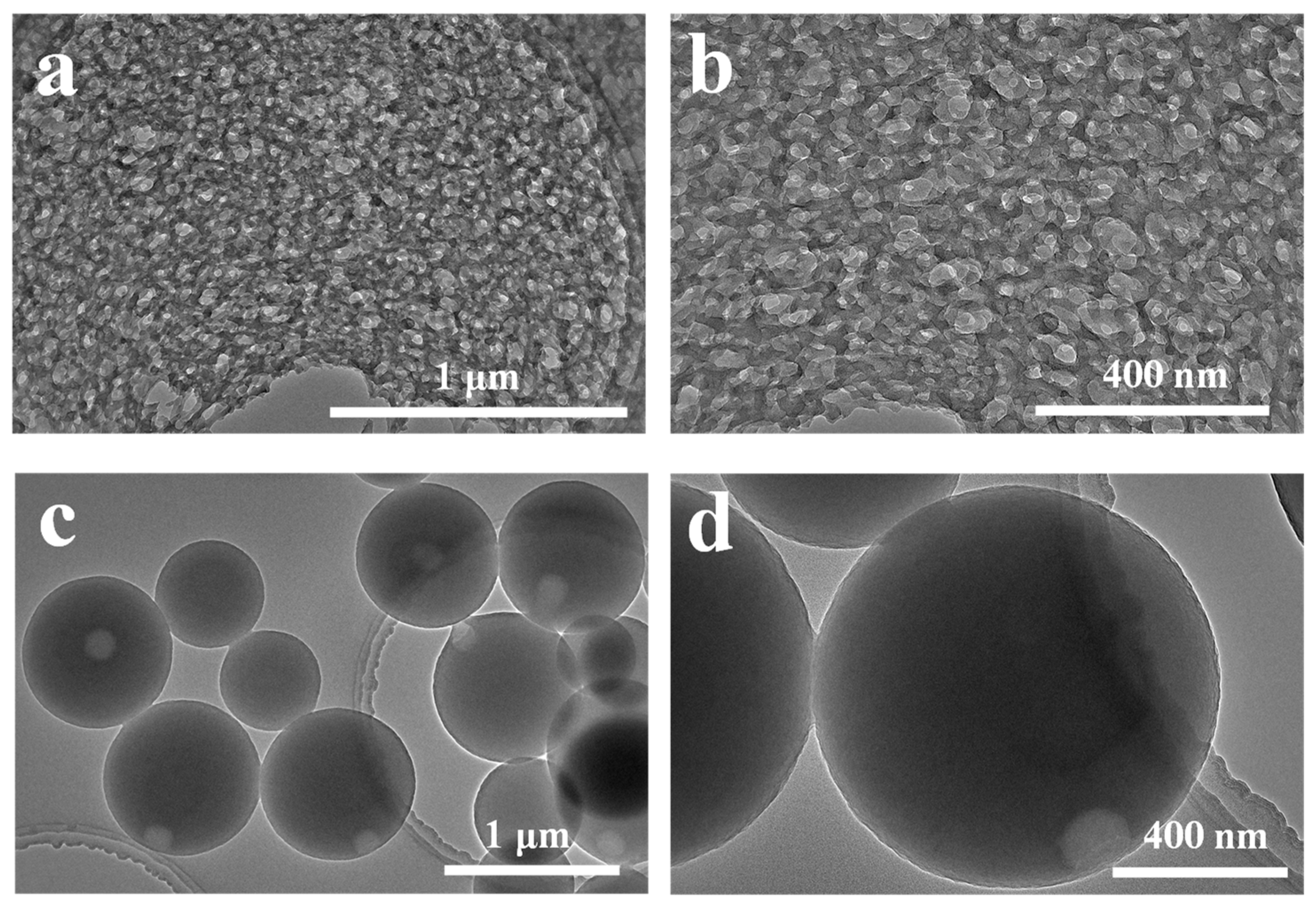

3.1. Morphologies and Characteristics of TLNPs and CLMPs

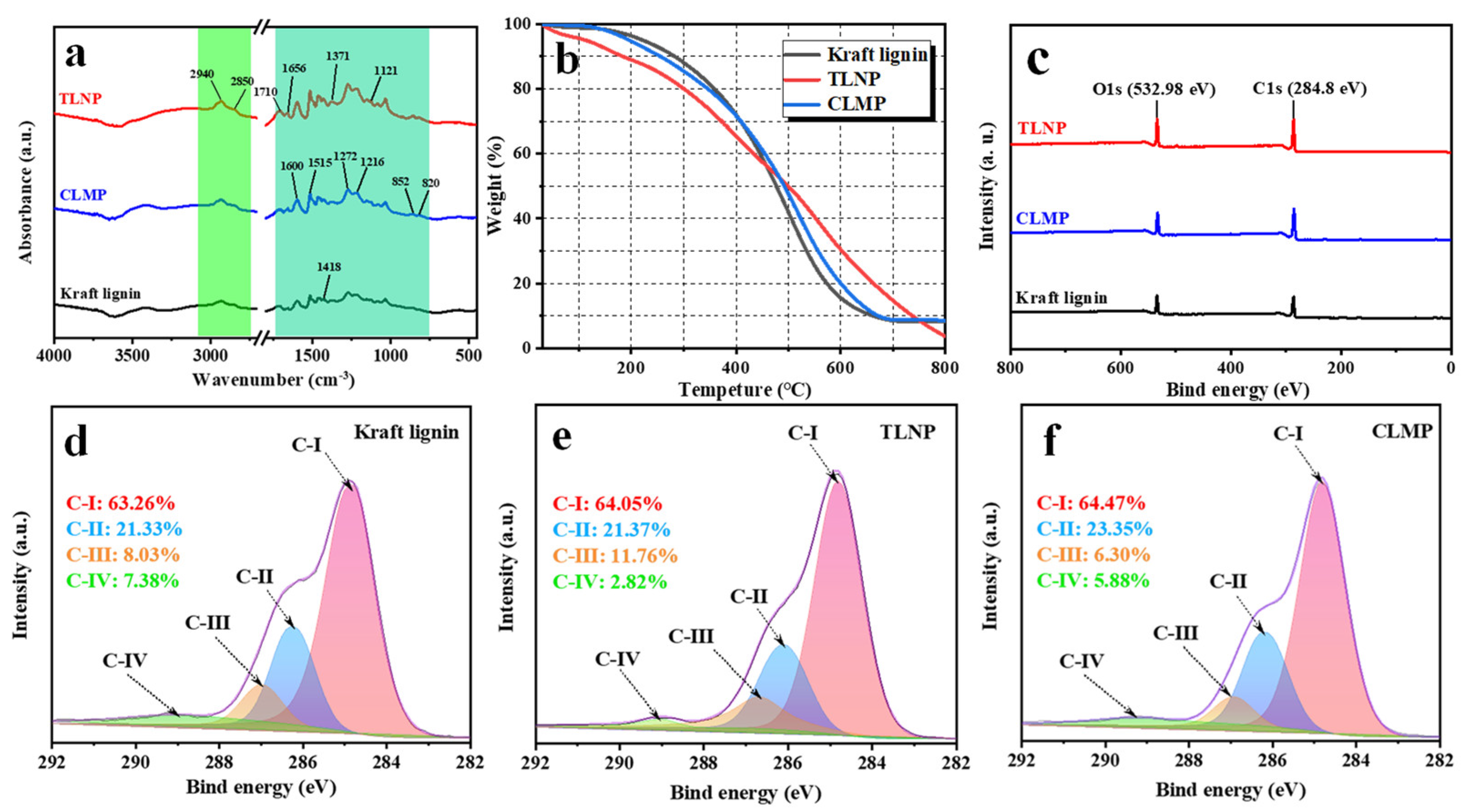

3.2. Structural Characterization of LNPs: FTIR, TG, and XPS Analysis

3.3. Formation Mechanism of LNPs

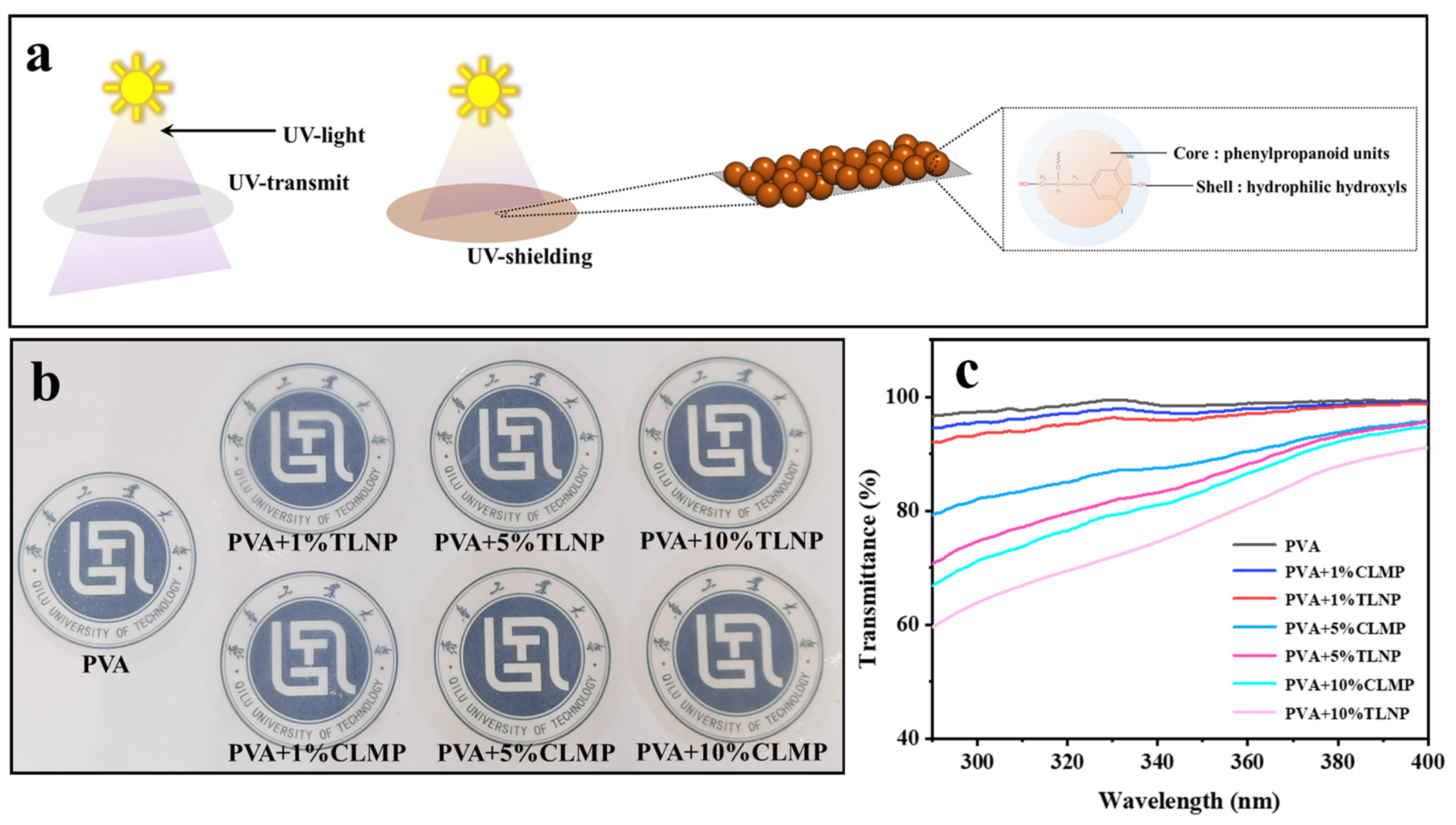

3.4. Anti-UV Performance of Lignin–PVA Composite Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable polymers from biomass: Bridging chemistry with materials and processing. Prog. Polym. Sci. 2020, 101, 101197. [Google Scholar] [CrossRef]

- Anderson, E.M.; Stone, M.L.; Katahira, R.; Reed, M.; Muchero, W.; Ramirez, K.J.; Beckham, G.T.; Roman-Leshkov, Y. Differences in S/G ratio in natural poplar variants do not predict catalytic depolymerization monomer yields. Nat. Commun. 2019, 10, 2033. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Vanholme, R.; Demedts, B.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin biosynthesis and structure. Plant Physiol. 2010, 153, 895–905. [Google Scholar] [CrossRef] [PubMed]

- Akinosho, H.O.; Yoo, C.G.; Dumitrache, A.; Natzke, J.; Muchero, W.; Brown, S.D.; Ragauskas, A.J. Elucidating the structural changes to populus lignin during consolidated bioprocessing with clostridium thermocellum. ACS Sustain. Chem. Eng. 2017, 5, 7486–7491. [Google Scholar] [CrossRef]

- Ralph, J.; Lundquist, K.; Brunow, G.; Lu, F.; Kim, H.; Schatz, P.F.; Marita, J.M.; Hatfield, R.D.; Ralph, S.A.; Christensen, J.H.; et al. Lignins: Natural polymers from oxidative coupling of 4-hydroxyphenyl-propanoids. Phytochem. Rev. 2004, 3, 29–60. [Google Scholar] [CrossRef]

- Andeme Ela, R.C.; Spahn, L.; Safaie, N.; Ferrier, R.C., Jr.; Ong, R.G. Understanding the effect of precipitation process variables on hardwood lignin characteristics and recovery from black liquor. ACS Sustain. Chem. Eng. 2020, 8, 13997–14005. [Google Scholar] [CrossRef]

- Magdeldin, M.; Jarvinen, M. Supercritical water gasification of kraft black liquor: Process design, analysis, pulp mill inte-gration and economic evaluation. Appl. Energy 2020, 262, 114558. [Google Scholar] [CrossRef]

- Giummarella, N.; Linden, P.A.; Areskogh, D.; Lawoko, M. Fractional profiling of kraft lignin structure: Unravelling insights on lignin reaction mechanisms. ACS Sustain. Chem. Eng. 2020, 8, 1112–1120. [Google Scholar] [CrossRef]

- Giummarella, N.; Pylypchuk, L.V.; Sevastyanova, O.; Lawoko, M. New structures in eucalyptus kraft lignin with complex mechanistic implications. ACS Sustain. Chem. Eng. 2020, 8, 10983–10994. [Google Scholar] [CrossRef]

- Zhang, H.N.; Ren, H.; Zhai, H.M. Analysis of phenolation potential of spruce kraft lignin and construction of its molecular structure model. Ind. Crops Prod. 2021, 167, 113506. [Google Scholar] [CrossRef]

- Kollman, M.; Jiang, X.; Thompson, S.J.; Mante, O.; Dayton, D.C.; Chang, H.M.; Jameel, H. Improved understanding of technical lignin functionalization through comprehensive structural characterization of fractionated pine kraft lignins modified by the Mannich reaction. Green Chem. 2021, 23, 7122–7136. [Google Scholar] [CrossRef]

- Kamran, A.; Asif, M. Plant biomass conversion. Crop Sci. 2012, 52, 988–989. [Google Scholar] [CrossRef]

- De Assis, C.A.; Greca, L.G.; Ago, M.; Balakshin, M.Y.; Jameel, H.; Gonzalez, R.; Rojas, O.J. Techno-economic assessment, scalability, and applications of aerosol lignin micro- and nanoparticles. ACS Sustain. Chem. Eng. 2018, 6, 11853–11868. [Google Scholar] [CrossRef]

- Zhang, Z.; Terrasson, V.; Guénin, E. Lignin nanoparticles and their nanocomposites. Nanomaterials 2021, 11, 1336. [Google Scholar] [CrossRef]

- Mishra, P.K.; Ekielski, A. The self-assembly of lignin and its application in nanoparticle synthesis: A short review. Nanomaterials 2019, 9, 243. [Google Scholar] [CrossRef]

- Grossman, A.; Vermerris, W. Lignin-based polymers and nanomaterials. Curr. Opin. Biotechnol. 2019, 56, 112–120. [Google Scholar] [CrossRef]

- Sameni, J.; Jaffer, S.A.; Tjong, J.; Sain, M. Advanced applications for lignin micro- and nano-based materials. Curr. For. Rep. 2020, 6, 159–171. [Google Scholar] [CrossRef]

- Figueiredo, P.; Lintinen, K.; Hirvonen, J.T.; Kostiainen, M.A.; Santos, H.A. Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog. Mater. Sci. 2018, 93, 233–269. [Google Scholar] [CrossRef]

- Tian, D.; Hu, J.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C. Lignin valorization: Lignin nanoparticles as high-value bio-additive for multifunctional nanocomposites. Biotechnol. Biofuels 2017, 10, 192. [Google Scholar] [CrossRef]

- Lizundia, E.; Sipponen, M.H.; Greca, L.G.; Balakshin, M.; Tardy, B.L.; Rojas, O.J.; Puglia, D. Multifunctional lignin-based nanocomposites and nanohybrids. Green Chem. 2021, 23, 6698–6760. [Google Scholar] [CrossRef]

- Yan, Z.; Song, B.; Fang, G.; Wu, T.; Chen, N.; Zhao, M.; Zou, X.; Liao, G. Bringing material concepts into conventional biorefineries: Considerations of sources, preparations, and applications of lignin nanomaterials. ACS Sustain. Chem. Eng. 2021, 9, 10403–10423. [Google Scholar] [CrossRef]

- Yuan, Z.; Shang, X.; Fang, J.; Li, H. A simple method for preparation of lignin/TiO2 nanocomposites by sulfonation degree regulation and their application in polyurethane films. Int. J. Biol. Macromol. 2022, 198, 18–25. [Google Scholar] [CrossRef]

- Parvathy, G.; Sethulekshmi, A.S.; Jayan, J.S.; Raman, A.; Saritha, A. Lignin based nano-composites: Synthesis and appli-cations. Process Saf. Environ. Prot. 2021, 145, 395–410. [Google Scholar]

- Mubarak, N.; Rehman, F.; Ihsan-Ul-Haq, M.; Xu, M.; Li, Y.; Zhao, Y.; Luo, Z.; Huang, B.; Kim, J.K. Highly sodiophilic, defect-rich, lignin-derived skeletal carbon nanofiber host for sodium metal batteries. Adv. Energy Mater. 2022, 12, 2103904. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, S.; Wu, C.; Liu, Y.; Yang, G.; Ni, Y. Super-stable, solvent-resistant and uniform lignin nanorods and nano-spheres with a high yield in a mild and facile process. Green Chem. 2020, 22, 8734–8744. [Google Scholar] [CrossRef]

- Wang, J.; Chen, W.; Yang, D.; Fang, Z.; Liu, W.; Xiang, T.; Qiu, X. Monodispersed lignin colloidal spheres with tailorable sizes for bio-photonic materials. Small 2022, 18, 2200671. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Hou, Y. A simple environment-friendly process for preparing high-concentration alkali lignin nanospheres. Eur. Polym. J. 2019, 112, 15–23. [Google Scholar] [CrossRef]

- Trevisan, H.; Rezende, C.A. Pure, stable and highly antioxidant lignin nanoparticles from elephant grass. Ind. Crops Prod. 2020, 145, 112105. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, Y.; Tian, D.; Hu, J.; He, J.; Yang, G.; Luo, L.; Xiao, Y.; Deng, S.; Deng, O.; et al. Fabrication of spherical lignin nanoparticles using acid-catalyzed condensed lignins. Int. J. Biol. Macromol. 2020, 164, 3038–3047. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Pang, T.; Chen, S.; Sui, W.; Si, C.; Ni, Y. Fabrication of lignin nanospheres by emulsification in a binary γ-valerolactone/glycerol system and their application as a bifunctional reducer and carrier for Pd nanoparticles with enhanced catalytic activity. Green Chem. 2020, 22, 8594–8603. [Google Scholar] [CrossRef]

- Sameni, J.; Krigstin, S.; Jaffer, S.A.; Sain, M. Preparation and characterization of biobased microspheres from lignin sources. Ind. Crops Prod. 2018, 117, 58–65. [Google Scholar] [CrossRef]

- Li, R.; Huang, D.; Chen, S.; Lei, L.; Chen, Y.; Tao, J.; Zhou, W.; Wang, G. From residue to resource: New insights into the synthesis of functionalized lignin micro/nanospheres by self-assembly technology for waste resource utilization. Nanoscale 2022, 14, 10299–10320. [Google Scholar] [CrossRef]

- Cha, Y.L.; Alam, A.M.; Park, S.M.; Moon, Y.H.; Kim, K.S.; Lee, J.E.; Kwon, D.E.; Kang, Y.G. Hydrothermal-process-based direct extraction of polydisperse lignin microspheres from black liquor and their physicochemical characterization. Bioresour. Technol. 2020, 297, 122399. [Google Scholar] [CrossRef]

- Ma, M.; Dai, L.; Si, C.; Hui, L.; Liu, Z.; Ni, Y. A Facile preparation of super long-term stable lignin nanoparticles from black liquor. ChemSusChem 2019, 12, 5239–5245. [Google Scholar] [CrossRef]

- Bahi, A.; Shao, J.; Mohseni, M.; Ko, F.K. Membranes based on electrospun lignin-zeolite composite nanofibers. Sep. Purif. Technol. 2017, 187, 207–213. [Google Scholar] [CrossRef]

- Camire, A.; Espinasse, J.; Chabot, B.; Lajeunesse, A. Development of electrospun lignin nanofibers for the adsorption of pharmaceutical contaminants in wastewater. Environ. Sci. Pollut. Res. 2020, 27, 3560–3573. [Google Scholar] [CrossRef]

- Mousavi, S.N.; Nazarnezhad, N.; Asadpour, G.; Ramamoorthy, S.K.; Zamani, A. Ultrafine friction grinding of lignin for development of starch biocomposite films. Polymers 2021, 13, 2024. [Google Scholar] [CrossRef]

- Chen, Y.; Gong, X.; Yang, G.; Li, Q.; Zhou, N. Preparation and characterization of a nanolignin phenol formaldehyde resin by replacing phenol partially with lignin nanoparticles. RSC Adv. 2019, 9, 29255–29262. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, B.; Lv, Y.; Ye, X.; Lin, C.; Liu, M. Insight into the performance of lignin-containing cellulose nanofibers (LCNFs) via lignin content regulation by p-toluenesulfonic acid delignification. Cellulose 2022, 29, 2273–2287. [Google Scholar] [CrossRef]

- He, T.; Chen, F.; Zhu, W.; Yan, N. Functionalized lignin nanoparticles for producing mechanically strong and tough flame-retardant polyurethane elastomers. Int. J. Biol. Macromol. 2022, 209, 1339–1351. [Google Scholar] [CrossRef]

- Taverna, M.E.; Busatto, C.A.; Lescano, M.R.; Nicolau, V.V.; Zalazar, C.S.; Meira, G.R.; Estenoz, D.A. Microparticles based on ionic and organosolv lignins for the controlled release of atrazine. J. Hazard. Mater. 2018, 359, 139–147. [Google Scholar] [CrossRef]

- Agustin, M.B.; Penttila, P.A.; Lahtinen, M.; Mikkonen, K.S. Rapid and direct Preparation of lignin nanoparticles from alkaline pulping liquor by mild ultrasonication. ACS Sustain. Chem. Eng. 2019, 7, 19925–19934. [Google Scholar] [CrossRef]

- Jiang, X.; Tian, Z.; Ji, X.; Ma, H.; Yang, G.; He, M.; Dai, L.; Xu, T.; Si, C. Alkylation modification for lignin color reduction and molecular weight adjustment. Int. J. Biol. Macromol. 2022, 201, 400–410. [Google Scholar] [CrossRef]

- Tao, J.S.; Chow, S.F.; Zheng, Y. Application of Flash Nanoprecipitation to Fabricate Poorly Water-soluble Drug Nanoparticles. Acta Pharm. Sin. B 2019, 9, 4–18. [Google Scholar] [CrossRef]

- Mun, J.S.; Pe, J.A.; Mun, S.P. Chemical characterization of kraft lignin prepared from mixed hardwoods. Molecules 2021, 26, 4861. [Google Scholar] [CrossRef]

- Kim, J.Y.; Shin, E.J.; Eom, I.Y.; Won, K.; Kim, Y.H.; Choi, D.; Choi, I.G.; Choi, J.W. Structural features of lignin macro-molecules extracted with ionic liquid from poplar wood. Bioresour. Technol. 2011, 102, 9020–9025. [Google Scholar] [CrossRef]

- Rashid, T.; Kait, C.F.; Regupathi, I.; Murugesan, T. Dissolution of kraft lignin using protic ionic liquids and characterization. Ind. Crops Prod. 2016, 84, 284–293. [Google Scholar] [CrossRef]

- Watkins, D.; Hosur, M.; Tcherbi-Narteh, A.; Jeelani, S. Extraction and characterization of lignin from different biomass resources. J. Mater. Res. Technol. 2015, 4, 26–32. [Google Scholar] [CrossRef]

- Kang, S.; Xiao, L.; Meng, L.; Zhang, X.; Sun, R. Isolation and structural characterization of lignin from cotton stalk treated in an ammonia hydrothermal system. Int. J. Mol. Sci. 2012, 13, 15209–15226. [Google Scholar] [CrossRef]

- Guo, N.; Li, M.; Sun, X.; Wang, F.; Yang, R. Enzymatic hydrolysis lignin derived hierarchical porous carbon for superca-pacitors in ionic liquids with high power and energy densities. Green Chem. 2017, 19, 2595–2602. [Google Scholar] [CrossRef]

- Lamer, V.K.; Dinegar, R.H. Theory, production and mechanism of formation of monodispersed hydrosols. J. Am. Chem. Soc. 1950, 72, 4847–4854. [Google Scholar] [CrossRef]

- Myint, A.A.; Lee, H.W.; Seo, B.; Son, W.S.; Yoon, J.; Yoon, T.J.; Park, H.J.; Yu, J.; Yoon, J.; Lee, Y.W. One pot synthesis of environmentally friendly lignin nanoparticles with compressed liquid carbon dioxide as an antisolvent. Green Chem. 2016, 18, 2129–2146. [Google Scholar] [CrossRef]

- Wang, J.; Qian, Y.; Li, L.; Qiu, X. Atomic force microscopy and molecular dynamics simulations for study of lignin solution self-assembly mechanisms in organic–aqueous solvent mixtures. ChemSusChem 2020, 13, 4420–4427. [Google Scholar] [CrossRef]

- Liu, Z.H.; Hao, N.; Shinde, S.; Pu, Y.; Kang, X.; Ragauskas, A.J.; Yuan, J.S. Defining lignin nanoparticle properties through tailored lignin reactivity by sequential organosolv fragmentation approach (SOFA). Green Chem. 2019, 21, 245–260. [Google Scholar] [CrossRef]

- Xiong, F.; Han, Y.; Wang, S.; Li, G.; Qin, T.; Chen, Y.; Chu, F. Preparation and formation mechanism of renewable lignin hollow nanospheres with a single hole by self-assembly. ACS Sustain. Chem. Eng. 2017, 5, 2273–2281. [Google Scholar] [CrossRef]

- Norato, M.; Tavlarides, L.; Tsouris, C. Phase inversion studies in liquid-liquid dispersions. Can. J. Chem. Eng. 1998, 76, 486–494. [Google Scholar] [CrossRef]

- Xiong, F.; Wang, H.; Xu, H.; Qing, Y.; Wu, Z.; Wu, Y. Self-assembled lignin nanospheres with solid and hollow tunable struc tures. Ind. Crops Prod. 2020, 144, 112063. [Google Scholar] [CrossRef]

- Vural, D.; Smith, J.; Petridis, L. Polymer principles behind solubilizing lignin with organic cosolvents for bioenergy. Green Chem. 2020, 22, 4331–4340. [Google Scholar] [CrossRef]

- Pylypchuk, L.V.; Riazanova, A.; Lindstrom, M.E.; Sevastyanova, O. Structural and molecular-weight-dependency in the for mation of lignin nanoparticles from fractionated soft-and hardwood lignins. Green Chem. 2021, 23, 3061–3072. [Google Scholar] [CrossRef]

- Sipponen, M.H.; Lange, H.; Ago, M.; Crestini, C. Understanding lignin aggregation processes. A case study: Budesonide entrapment and stimuli controlled release from lignin nanoparticles. ACS Sustain. Chem. Eng. 2018, 6, 9342–9351. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Huang, D.; Chen, S.; Lei, L.; Chen, Y.; Tao, J.; Zhou, W.; Wang, G. Insight into the self-assembly process of bamboo lignin purified by solvent fractionation to form uniform nanospheres with excellent UV resistance. Colloids Surf. A 2022, 642, 128652. [Google Scholar] [CrossRef]

- Tagami, A.; Gioia, C.; Lauberts, M.; Budnyak, T.; Moriana, R.; Lindstrom, M.E.; Sevastyanova, O. Solvent fractionation of softwood and hardwood kraft lignins for more efficient uses: Compositional, structural, thermal, antioxidant and adsorption properties. Ind. Crops Prod. 2019, 129, 123–134. [Google Scholar] [CrossRef]

- Guerlain, C.; Pioge, S.; Detrembleur, C.; Fustin, C.A.; Gohy, J.F. Self-assembly of a triblock terpolymer mediated by hydrogen-bonded complexes. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 459–467. [Google Scholar] [CrossRef]

- Wu, Z.; Liu, J.; Li, Y.; Cheng, Z.; Li, T.; Zhang, H.; Lu, Z.; Yang, B. Self-assembly of nanoclusters into mono-, few-, and multilayered sheets via dipole-induced asymmetric van der Waals attraction. ACS Nano 2015, 9, 6315–6323. [Google Scholar] [CrossRef]

- Zheng, Y.; Rosa, L.; Thai, T.; Ng, S.H.; Gomez, D.E.; Ohshima, H.; Bach, U. Asymmetric gold nanodimer arrays: Electrostatic self-assembly and SERS activity. J. Mater. Chem. A 2015, 3, 240–249. [Google Scholar] [CrossRef]

- Wang, F.; Akimov, Y.A.; Khoo, E.H.; He, C. π–π interactions mediated self-assembly of gold nanoparticles into single crystalline superlattices in solution. RSC Adv. 2015, 5, 90766–90771. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Tian, Z.; Ji, X.; Zhang, F. Fabrication Mechanisms of Lignin Nanoparticles and Their Ultraviolet Protection Ability in PVA Composite Film. Polymers 2022, 14, 4196. https://doi.org/10.3390/polym14194196

Zhang J, Tian Z, Ji X, Zhang F. Fabrication Mechanisms of Lignin Nanoparticles and Their Ultraviolet Protection Ability in PVA Composite Film. Polymers. 2022; 14(19):4196. https://doi.org/10.3390/polym14194196

Chicago/Turabian StyleZhang, Jiawei, Zhongjian Tian, Xingxiang Ji, and Fengshan Zhang. 2022. "Fabrication Mechanisms of Lignin Nanoparticles and Their Ultraviolet Protection Ability in PVA Composite Film" Polymers 14, no. 19: 4196. https://doi.org/10.3390/polym14194196

APA StyleZhang, J., Tian, Z., Ji, X., & Zhang, F. (2022). Fabrication Mechanisms of Lignin Nanoparticles and Their Ultraviolet Protection Ability in PVA Composite Film. Polymers, 14(19), 4196. https://doi.org/10.3390/polym14194196