Styrene-Free Bio-Based Thermosetting Resins with Tunable Properties Starting from Vegetable Oils and Terpenes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Thermoset Resins Characterization

3. Results and Discussion

3.1. Homopolymers with Acrylated Vegetable Oils

3.2. Heteropolymers with Acrylated Vegetale Oils and Terpenes

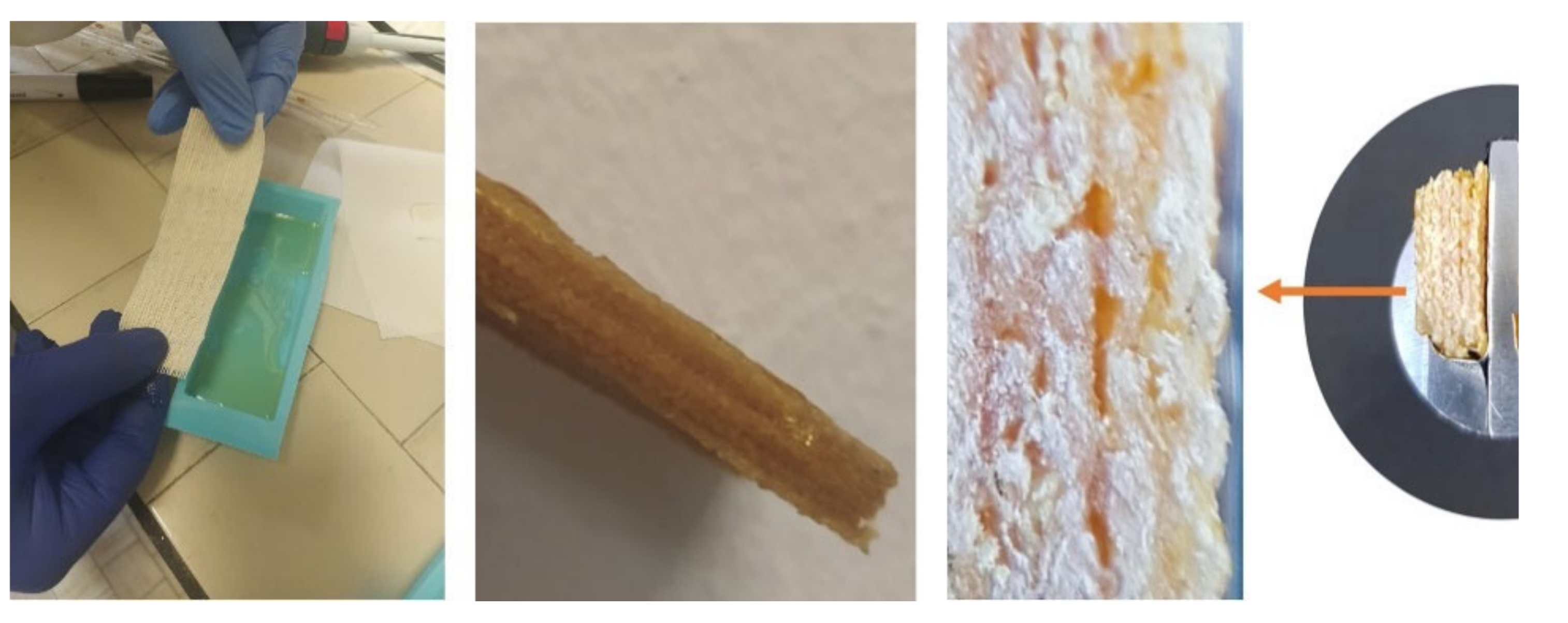

3.3. Composites with Natural Fibers

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Growth Opportunities for Thermoset Resin Market in the Global Composites Industry. Available online: https://www.reportlinker.com/p06177936/Growth-Opportunities-of-Thermoset-Resin-in-the-Global-Composites-Market.html (accessed on 5 September 2022).

- An, W.; Wang, X.; Liu, X.; Wu, G.; Xu, S.; Wang, Y.; Wang, X. Chemical Recovery of Thermosetting Unsaturated. Green Chem. 2022, 24, 701–712. [Google Scholar] [CrossRef]

- Yue, L.; Amirkhosravi, M.; Gong, X.; Gray, T.G.; Manas-Zloczower, I. Recycling Epoxy by Vitrimerization: Influence of an Initial Thermoset Chemical Structure. ACS Sustain. Chem. Eng. 2020, 8, 12706–12712. [Google Scholar] [CrossRef]

- Kuang, X.; Guo, E.; Chen, K.; Qi, H.J. Extraction of Biolubricant via Chemical Recycling of Thermosetting Polymers. ACS Sustain. Chem. Eng. 2019, 7, 6880–6888. [Google Scholar] [CrossRef]

- Mashouf Roudsari, G.; Mohanty, A.K.; Misra, M. Green Approaches to Engineer Tough Biobased Epoxies: A Review. ACS Sustain. Chem. Eng. 2017, 5, 9528–9541. [Google Scholar] [CrossRef]

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite Recycling in the Construction Industry. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1216–1222. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable Polymers from Renewable Resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Pandey, S.; Rajput, B.S.; Chikkali, S.H. Refining Plant Oils and Sugars to Platform Chemicals, Monomers, and Polymers. Green Chem. 2021, 23, 4255–4295. [Google Scholar] [CrossRef]

- Ecochard, Y.; Auvergne, R.; Boutevin, B.; Caillol, S. Linseed Oil-Based Thermosets by Aza-Michael Polymerization. Eur. J. Lipid Sci. Technol. 2020, 122, 1900145. [Google Scholar] [CrossRef]

- Zaccheria, F.; Psaro, R.; Ravasio, N. Selective Hydrogenation of Alternative Oils: A Useful Tool for the Production of Biofuels. Green Chem. 2009, 11, 462–465. [Google Scholar] [CrossRef]

- Bellini, M.; Bianchi, S.; Zaccheria, F.; Ravasio, N. Vegetable Oils as Triple Bottom Line Compliant Lubricants. Tribol. Int. 2021, 161, 107103. [Google Scholar] [CrossRef]

- Di Mauro, C.; Malburet, S.; Genua, A.; Graillot, A.; Mija, A. Sustainable Series of New Epoxidized Vegetable Oil-Based Thermosets with Chemical Recycling Properties. Biomacromolecules 2020, 21, 3923–3935. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.R.; Sharma, S. The Development and Comparison of Bio-Thermoset Plastics from Epoxidized Plant Oils. Ind. Crops Prod. 2012, 36, 485–499. [Google Scholar] [CrossRef]

- Dworakowska, S.; Bogdał, D.; Zaccheria, F.; Ravasio, N. The Role of Catalysis in the Synthesis of Polyurethane Foams Based on Renewable Raw Materials. Catal. Today 2014, 223, 148–156. [Google Scholar] [CrossRef]

- Omonov, T.S.; Patel, V.R.; Curtis, J.M. Biobased Thermosets from Epoxidized Linseed Oil and Its Methyl Esters. ACS Appl. Polym. Mater. 2022, 4, 6531–6542. [Google Scholar] [CrossRef]

- Ding, C.; Matharu, A.S. Recent Developments on Biobased Curing Agents: A Review of Their Preparation and Use. ACS Sustain. Chem. Eng. 2014, 2, 2217–2236. [Google Scholar] [CrossRef]

- Jagtap, A.R.; More, A. Developments in Reactive Diluents: A Review. Polym. Bull. 2022, 79, 5667–5708. [Google Scholar] [CrossRef]

- La Scala, J.J.; Orlicki, J.A.; Winston, C.; Robinette, E.J.; Sands, J.M.; Palmese, G.R. The Use of Bimodal Blends of Vinyl Ester Monomers to Improve Resin Processing and Toughen Polymer Properties. Polymer 2005, 46, 2908–2921. [Google Scholar] [CrossRef]

- Fei, M.; Liu, T.; Fu, T.; Zhang, J.; Wu, Y.; Qiu, R.; Liu, W. Styrene-Free Soybean Oil Thermoset Composites Reinforced by Hybrid Fibers from Recycled and Natural Resources. ACS Sustain. Chem. Eng. 2019, 7, 17808–17816. [Google Scholar] [CrossRef]

- Fei, M.; Liu, W.; Jia, A.; Ban, Y.; Qiu, R. Bamboo Fibers Composites Based on Styrene-Free Soybean-Oil Thermosets Using Methacrylates as Reactive Diluents. Compos. Part A Appl. Sci. Manuf. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, M.; Huang, X.; Zhang, H.; Shang, S.; Song, J. Synthesis and Performance of a Thermosetting Resin: Acrylated Epoxidized Soybean Oil Curing with a Rosin-Based Acrylamide. J. Appl. Polym. Sci. 2017, 134, 44545. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Shen, M.; Shang, S.; Song, J.; Jiang, J.; Song, Z. Soybean Oil-Based Thermoset Reinforced with Rosin-Based Monomer. Iran. Polym. J. 2018, 27, 405–411. [Google Scholar] [CrossRef]

- Ma, Q.; Liu, X.; Zhang, R.; Zhu, J.; Jiang, Y. Synthesis and Properties of Full Bio-Based Thermosetting Resins from Rosin Acid and Soybean Oil: The Role of Rosin Acid Derivatives. Green Chem. 2013, 15, 1300–1310. [Google Scholar] [CrossRef]

- Chen, J.; Liu, H.; Zhang, W.; Lv, L.; Liu, Z. Thermosets Resins Prepared from Soybean Oil and Lignin Derivatives with High Biocontent, Superior Thermal Properties, and Biodegradability. J. Appl. Polym. Sci. 2020, 137, 48827. [Google Scholar] [CrossRef]

- Zhang, Q.; Phillips, H.R.; Purchel, A.; Hexum, J.K.; Reineke, T.M. Sustainable and Degradable Epoxy Resins from Trehalose, Cyclodextrin, and Soybean Oil Yield Tunable Mechanical Performance and Cell Adhesion. ACS Sustain. Chem. Eng. 2018, 6, 14967–14978. [Google Scholar] [CrossRef]

- Liu, W.; Xie, T.; Qiu, R. Biobased Thermosets Prepared from Rigid Isosorbide and Flexible Soybean Oil Derivatives. ACS Sustain. Chem. Eng. 2017, 5, 774–783. [Google Scholar] [CrossRef]

- Liu, K.; Madbouly, S.A.; Kessler, M.R. Biorenewable Thermosetting Copolymer Based on Soybean Oil and Eugenol. Eur. Polym. J. 2015, 69, 16–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Wang, L.; Gao, Z.; Kessler, M.R. Synthesis and Characterization of Methacrylated Eugenol as a Sustainable Reactive Diluent for a Maleinated Acrylated Epoxidized Soybean Oil Resin. ACS Sustain. Chem. Eng. 2017, 5, 8876–8883. [Google Scholar] [CrossRef]

- Mahmoud Zaghloul, M.Y.; Yousry Zaghloul, M.M.; Yousry Zaghloul, M.M. Developments in Polyester Composite Materials—An in-Depth Review on Natural Fibres and Nano Fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Chen, T.; Su, C.; Zeng, Y.; Chen, Y.; Qiu, R.; Liu, W. Effects of Hydrogen Bonds on Soybean Oil-Based Thermosets and Their Bamboo Fibers Composites. Compos. Commun. 2022, 33, 101231. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Zlatanić, A.; Lava, C.C.; Sinadinović-Fišer, S. Epoxidation of Soybean Oil in Toluene with Peroxoacetic and Peroxoformic Acids—Kinetics and Side Reactions. Eur. J. Lipid Sci. Technol. 2002, 104, 293–299. [Google Scholar] [CrossRef]

- La Scala, J.; Wool, R.P. Property Analysis of Triglyceride-Based Thermosets. Polymer 2005, 46, 61–69. [Google Scholar] [CrossRef]

- Auvergne, R.; Caillol, S.; David, G.; Boutevin, B.; Pascault, J.P. Biobased Thermosetting Epoxy: Present and Future. Chem. Rev. 2014, 114, 1082–1115. [Google Scholar] [CrossRef] [PubMed]

- Zaccheria, F.; Psaro, R.; Ravasio, N.; Bondioli, P. Standardization of Vegetable Oils Composition to Be Used as Oleochemistry Feedstock through a Selective Hydrogenation Process. Eur. J. Lipid Sci. Technol. 2012, 114, 24–30. [Google Scholar] [CrossRef]

- Filippi, L.; Meier, M.A.R. Fully Renewable Non-Isocyanate Polyurethanes via the Lossen Rearrangement. Macromol. Rapid Commun. 2021, 42, 2000440. [Google Scholar] [CrossRef]

- Parrino, F.; Fidalgo, A.; Palmisano, L.; Ilharco, L.M.; Pagliaro, M.; Ciriminna, R. Polymers of Limonene Oxide and Carbon Dioxide: Polycarbonates of the Solar Economy. ACS Omega 2018, 3, 4884–4890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mija, A.; Louisy, E.; Lachegur, S.; Khodyrieva, V.; Martinaux, P.; Olivero, S.; Michelet, V. Limonene Dioxide as a Building Block for 100% Bio-Based Thermosets. Green Chem. 2021, 23, 9855–9859. [Google Scholar] [CrossRef]

- Schutz, L.; Kazemi, F.; Mackenzie, E.; Bergeron, J.Y.; Gagnon, E.; Claverie, J.P. Trans-Limonene Dioxide, a Promising Bio-Based Epoxy Monomer. J. Polym. Sci. 2021, 59, 321–328. [Google Scholar] [CrossRef]

- Sahu, P.; Bhowmick, A.K.; Kali, G. Terpene Based Elastomers: Synthesis, Properties, and Applications. Processes 2020, 8, 553. [Google Scholar] [CrossRef]

- Sarkar, P.; Bhowmick, A.K. Sustainable rubbers and rubber additives. J. Appl. Polym. Sci. 2018, 135, 45701. [Google Scholar] [CrossRef] [Green Version]

- Lebedevaite, M.; Ostrauskaite, J.; Skliutas, E.; Malinauskas, M. Photocross-Linked Polymers Based on Plant-Derived Monomers for Potential Application in Optical 3D Printing. J. Appl. Polym. Sci. 2020, 137, 48708. [Google Scholar] [CrossRef]

- Sibaja, B.; Sargent, J.; Auad, M.L. Renewable Thermoset Copolymers from Tung Oil and Natural Terpenes. J. Appl. Polym. Sci. 2014, 131, 41155. [Google Scholar] [CrossRef]

- Wu, Y.; Fei, M.; Qiu, R.; Liu, W.; Qiu, J. A Review on Styrene Substitutes in Thermosets and Their Composites. Polymers 2019, 11, 1815. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Norton, G.A.; Devlin, S.L. Determining the Modern Carbon Content of Biobased Products Using Radiocarbon Analysis. Bioresour. Technol. 2006, 97, 2084–2090. [Google Scholar] [CrossRef]

- Pan, X.; Sengupta, P.; Webster, D.C. High Biobased Content Epoxy-Anhydride Thermosets from Epoxidized Sucrose Esters of Fatty Acids. Biomacromolecules 2011, 12, 2416–2428. [Google Scholar] [CrossRef]

- Bhagwat, S.S.; Li, Y.; Cortés-Peña, Y.R.; Brace, E.C.; Martin, T.A.; Zhao, H.; Guest, J.S. Sustainable Production of Acrylic Acid via 3-Hydroxypropionic Acid from Lignocellulosic Biomass. ACS Sustain. Chem. Eng. 2021, 9, 16659–16669. [Google Scholar] [CrossRef]

- Mosiewicki, M.; Aranguren, M.I.; Borrajo, J. Mechanical Properties of Linseed Oil Monoglyceride Maleate/Styrene Copolymers. J. Appl. Polym. Sci. 2005, 97, 825–836. [Google Scholar] [CrossRef]

- Meiorin, C.; Aranguren, M.I.; Mosiewicki, M.A. Polymeric Networks Based on Tung Oil: Reaction and Modification with Green Oil Monomers. Eur. Polym. J. 2015, 67, 551–560. [Google Scholar] [CrossRef]

- Mangeon, C.; Thevenieau, F.; Renard, E.; Langlois, V. Straightforward Route to Design Biorenewable Networks Based on Terpenes and Sunflower Oil. ACS Sustain. Chem. Eng. 2017, 5, 6707–6715. [Google Scholar] [CrossRef]

- Dinu, R.; Briand, N.; Mija, A. Influence of Keratin on Epoxidized Linseed Oil Curing and Thermoset Performances. ACS Sustain. Chem. Eng. 2021, 9, 15641–15652. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Ozbakkaloglu, T. Lignocellulosic Fiber Reinforced Composites: Progress, Performance, Properties, Applications, and Future Perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Jariwala, H.; Jain, P. A Review on Mechanical Behavior of Natural Fiber Reinforced Polymer Composites and Its Applications. J. Reinf. Plast. Compos. 2019, 38, 441–453. [Google Scholar] [CrossRef]

- Fernandes, F.C.; Kirwan, K.; Wilson, P.R.; Coles, S.R. Sustainable Alternative Composites Using Waste Vegetable Oil Based Resins. J. Polym. Environ. 2019, 27, 2464–2477. [Google Scholar] [CrossRef] [Green Version]

- Di Mauro, C.; Genua, A.; Rymarczyk, M.; Dobbels, C.; Malburet, S.; Graillot, A.; Mija, A. Chemical and Mechanical Reprocessed Resins and Bio-Composites Based on Five Epoxidized Vegetable Oils Thermosets Reinforced with Flax Fibers or PLA Woven. Compos. Sci. Technol. 2021, 205, 108678. [Google Scholar] [CrossRef]

- Touchaleaume, F.; Tessier, R.; Auvergne, R.; Caillol, S.; Hoppe, S.; Angellier-Coussy, H. Polyhydroxybutyrate/Hemp Biocomposite: Tuning Performances by Process and Compatibilisation. Green Mater. 2019, 7, 194–204. [Google Scholar] [CrossRef]

- Tanasă, F.; Zănoagă, M.; Teacă, C.A.; Nechifor, M.; Shahzad, A. Modified Hemp Fibers Intended for Fiber-Reinforced Polymer Composites Used in Structural Applications—A Review. I. Methods of Modification. Polym. Compos. 2020, 41, 5–31. [Google Scholar] [CrossRef]

| Oil | C16:0 %mol | C18:0 %mol | C18:1 %mol | C18:2 %mol | C18:3 %mol | IV |

|---|---|---|---|---|---|---|

| Soybean oil | 14.0 | 5.4 | 26.8 | 44.0 | 8.0 | 130 |

| Hempseed oil | 6.4 | 2.8 | 14.2 | 57.0 | 17.3 | 164 |

| Linseed oil | 5.4 | 3.4 | 16.3 | 16.7 | 58.2 | 186 |

| sample | Td,5% a (°C) | Tg b (°C) | E′−30 °C c (MPa) | E′100 °C c (MPa) |

|---|---|---|---|---|

| AESO | 336 | 49 | 1432 | 9 |

| AESO-Li | 340 | 51 | 1489 | 7 |

| AESO-My | 328 | 41 | 1498 | 9 |

| AESO-Pi | 340 | 44 | 1347 | 10 |

| AESO-St | 348 | 65 | 1892 | 13 |

| AEHO | 332 | 60 | 1635 | 7 |

| AEHO-Li | 335 | 66 | 1578 | 7 |

| AEHO-My | 330 | 63 | 1779 | 10 |

| AEHO-Pi | 332 | 59 | 1533 | 15 |

| AELO | 326 | 74 | 2339 | 95 |

| AELO-Li | 320 | 79 | 2172 | 26 |

| AELO-My | 310 | 70 | 2323 | 104 |

| AELO-Pi | 318 | 76 | 2102 | 38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bertini, F.; Vignali, A.; Marelli, M.; Ravasio, N.; Zaccheria, F. Styrene-Free Bio-Based Thermosetting Resins with Tunable Properties Starting from Vegetable Oils and Terpenes. Polymers 2022, 14, 4185. https://doi.org/10.3390/polym14194185

Bertini F, Vignali A, Marelli M, Ravasio N, Zaccheria F. Styrene-Free Bio-Based Thermosetting Resins with Tunable Properties Starting from Vegetable Oils and Terpenes. Polymers. 2022; 14(19):4185. https://doi.org/10.3390/polym14194185

Chicago/Turabian StyleBertini, Fabio, Adriano Vignali, Marcello Marelli, Nicoletta Ravasio, and Federica Zaccheria. 2022. "Styrene-Free Bio-Based Thermosetting Resins with Tunable Properties Starting from Vegetable Oils and Terpenes" Polymers 14, no. 19: 4185. https://doi.org/10.3390/polym14194185

APA StyleBertini, F., Vignali, A., Marelli, M., Ravasio, N., & Zaccheria, F. (2022). Styrene-Free Bio-Based Thermosetting Resins with Tunable Properties Starting from Vegetable Oils and Terpenes. Polymers, 14(19), 4185. https://doi.org/10.3390/polym14194185