Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification of Ground Tire Rubber

2.3. Preparation of Flexible Polyurethane/Ground Tire Rubber Composite Foams

2.4. Measurements

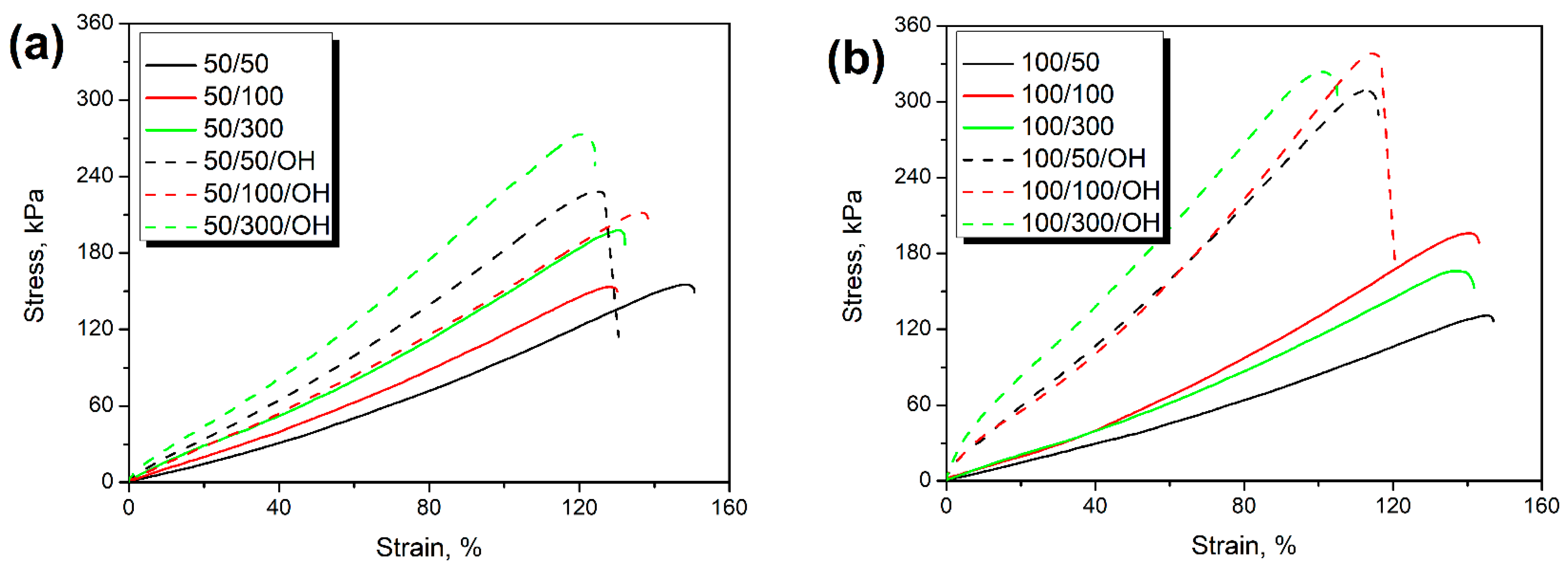

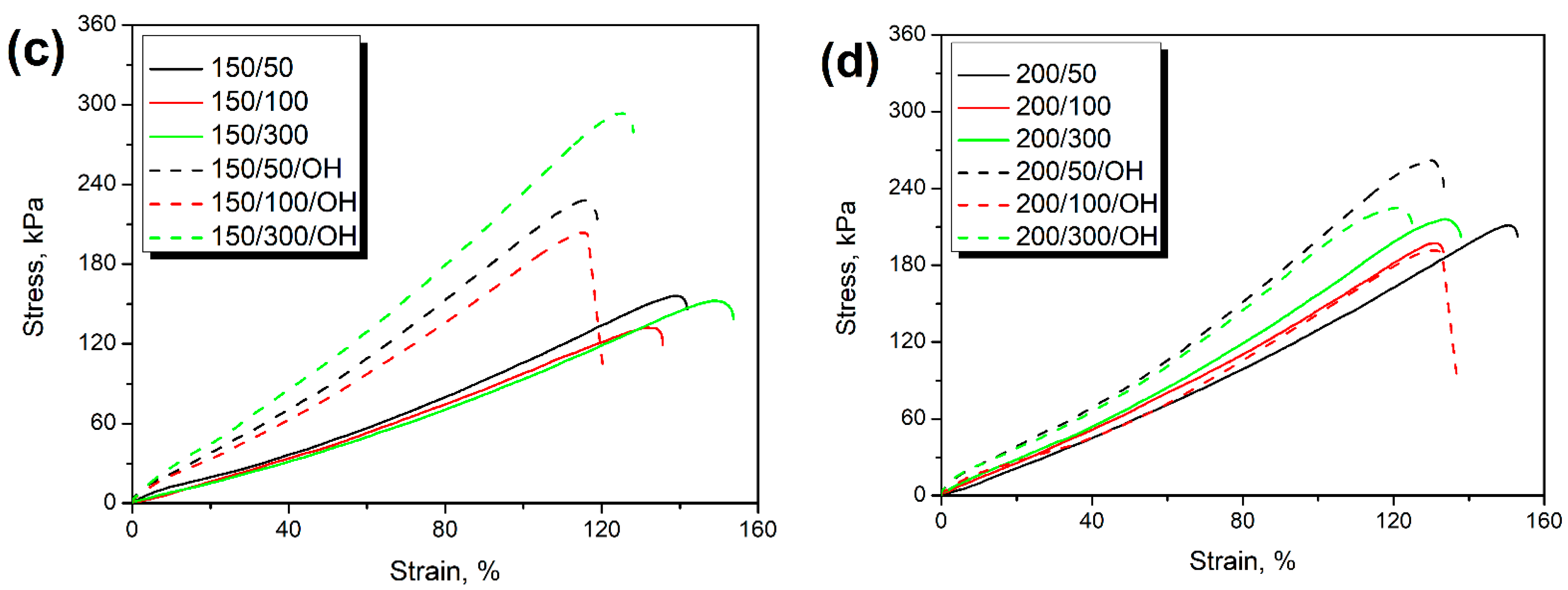

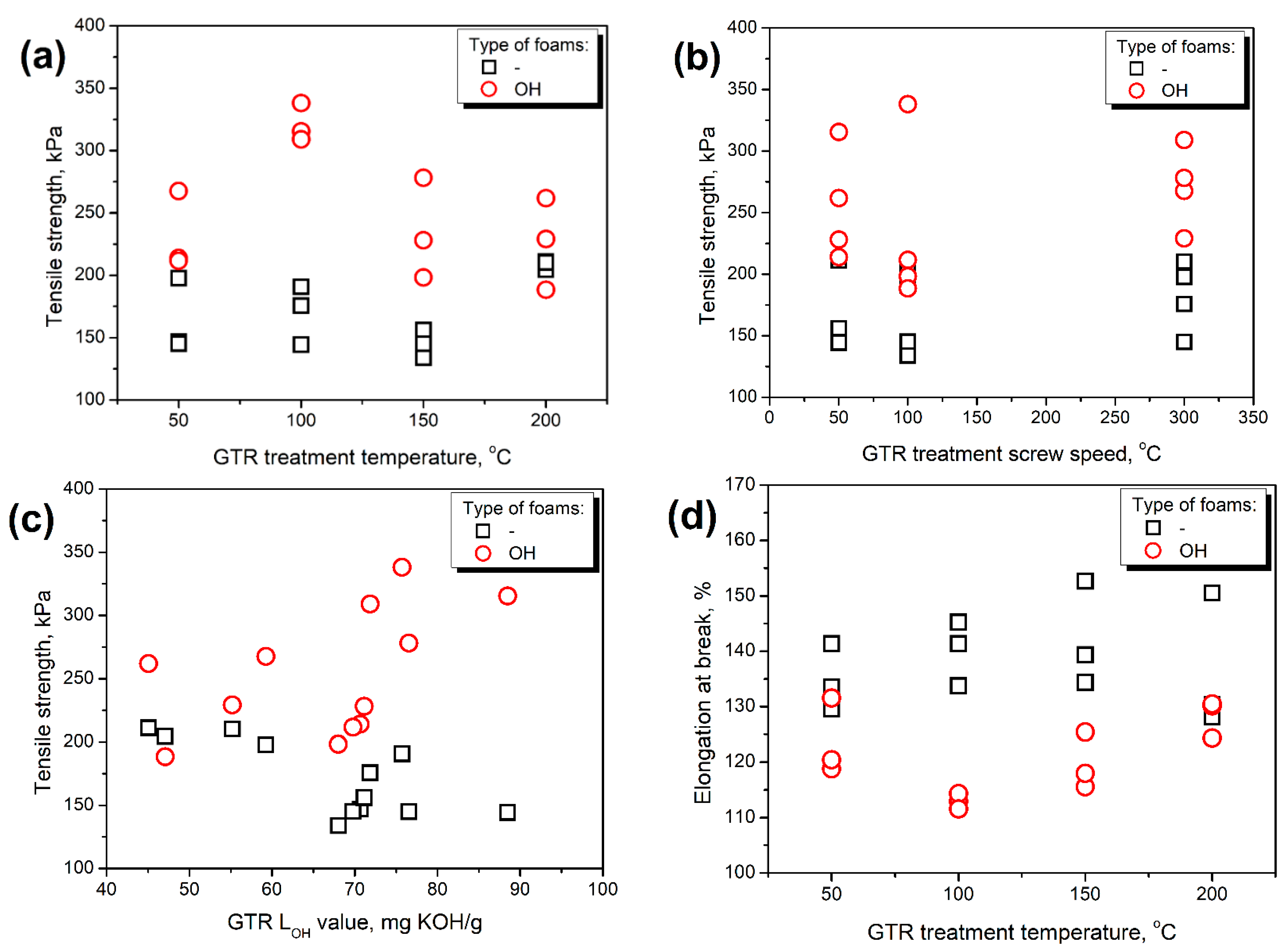

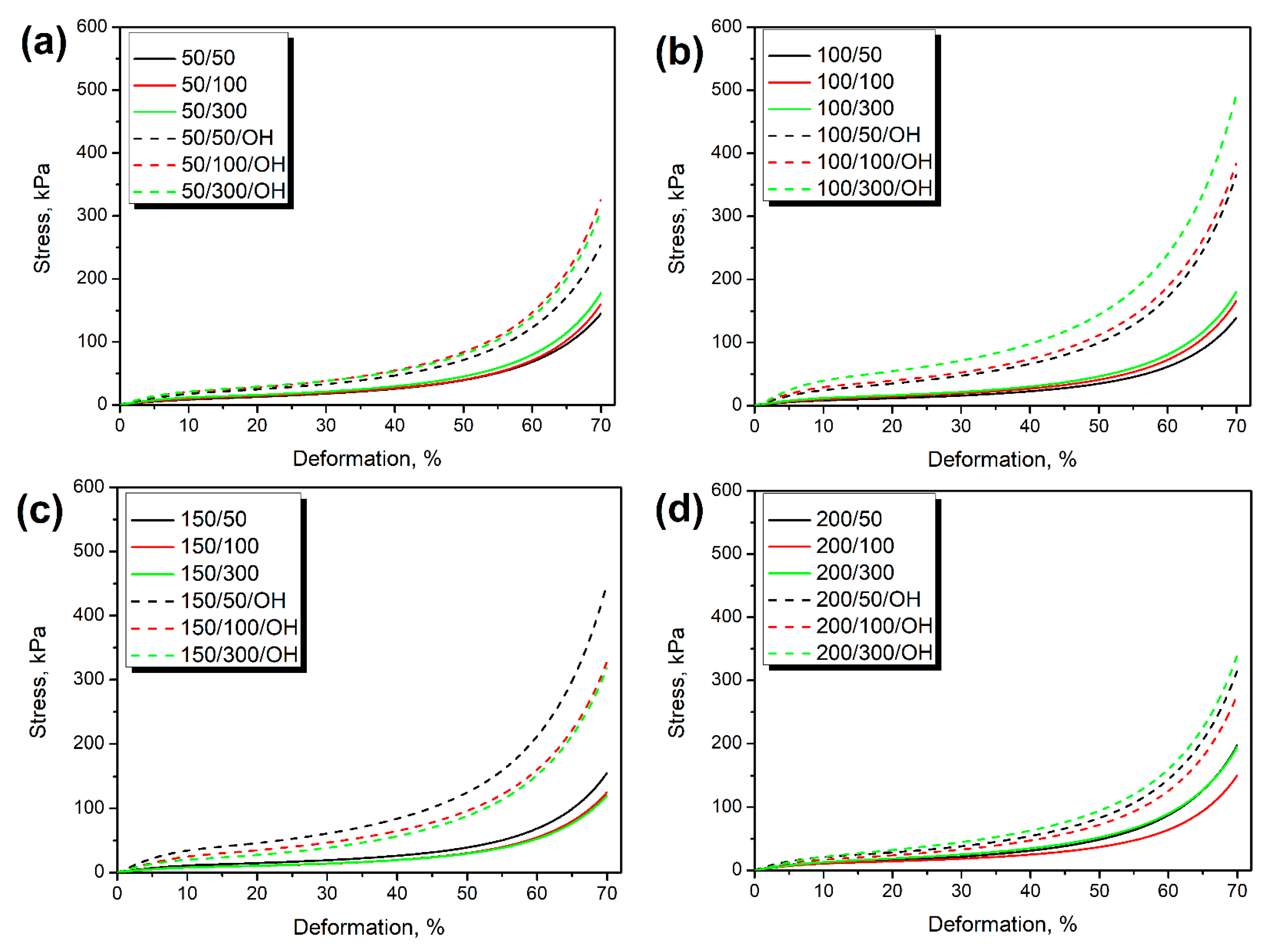

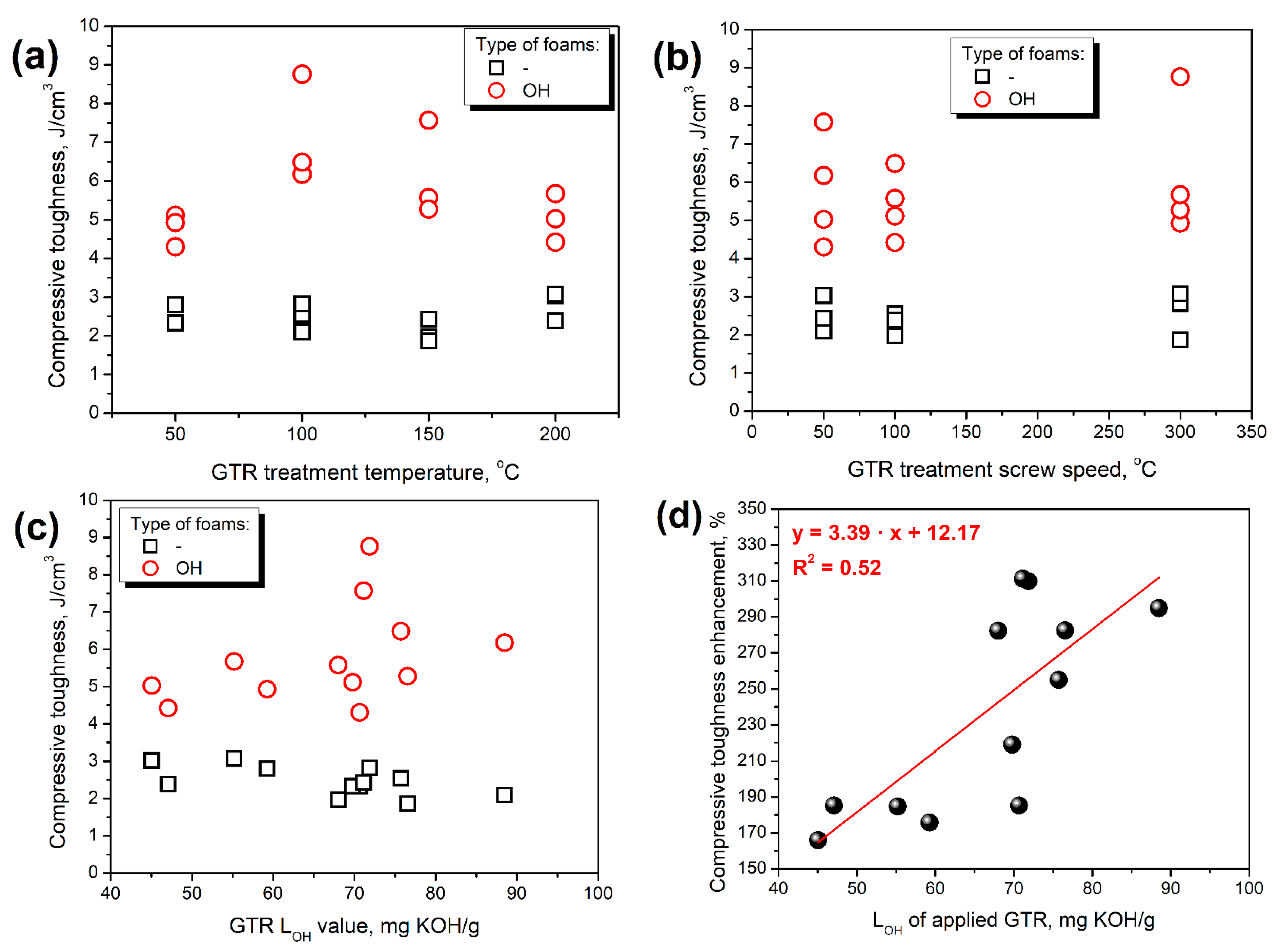

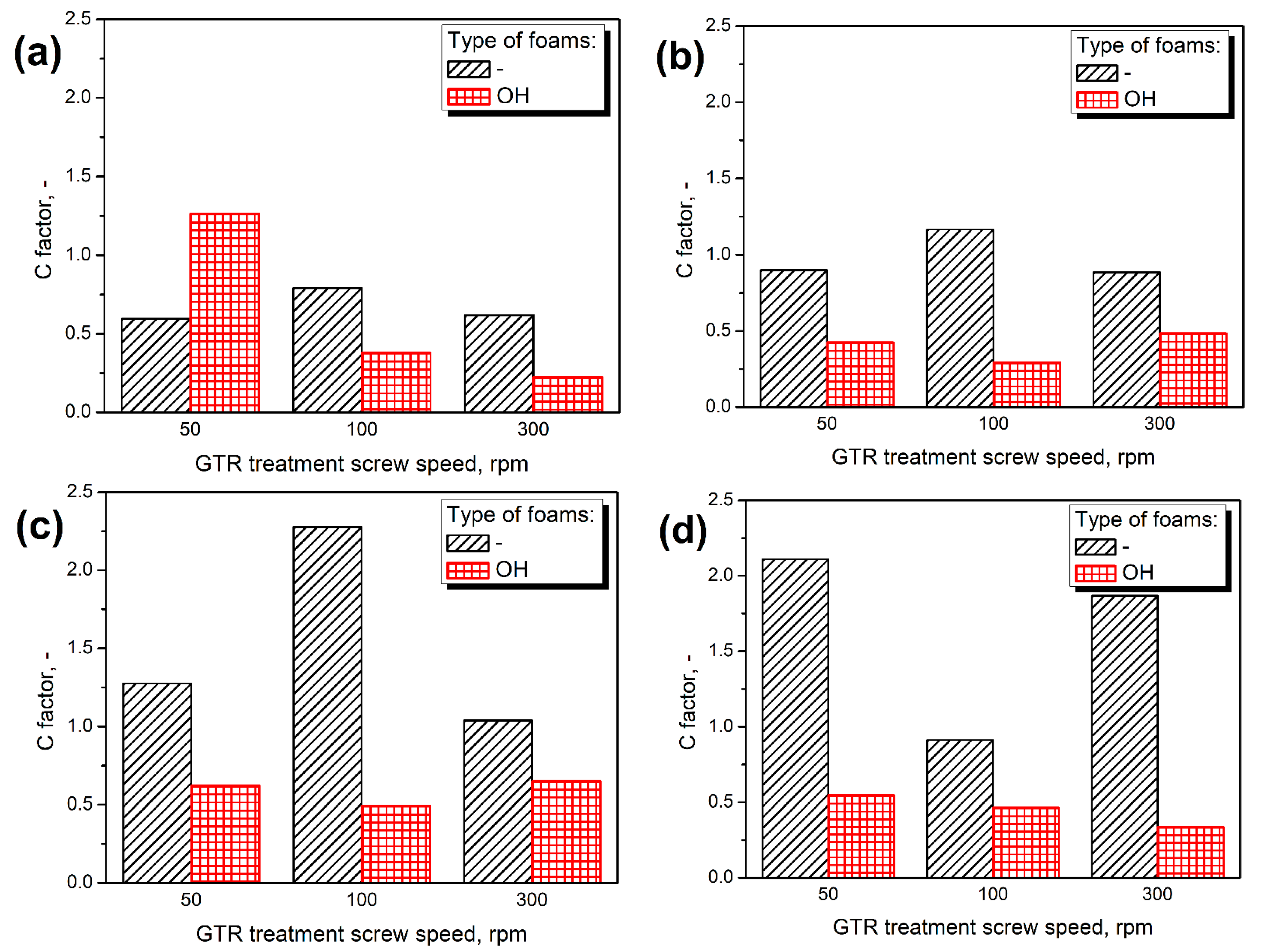

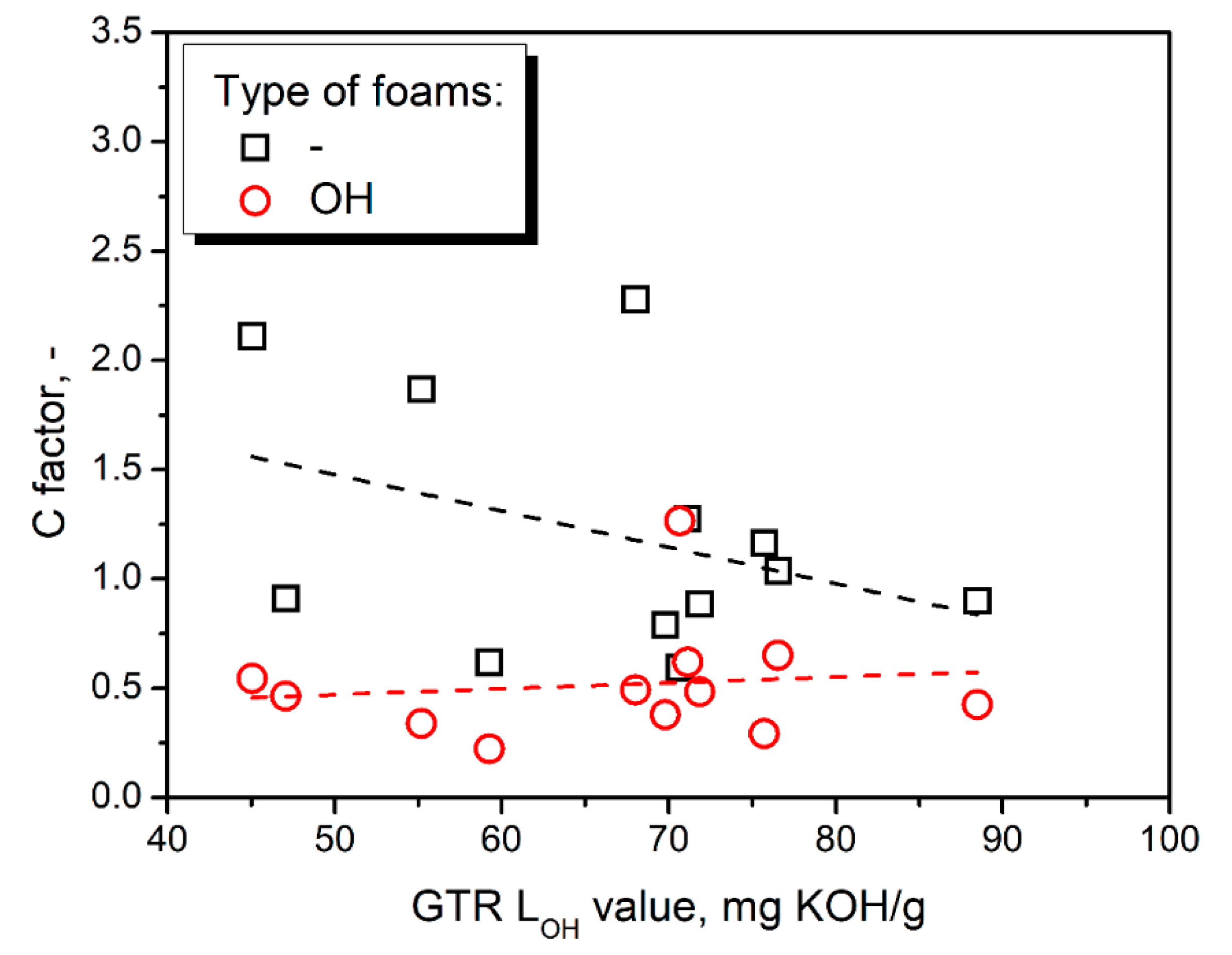

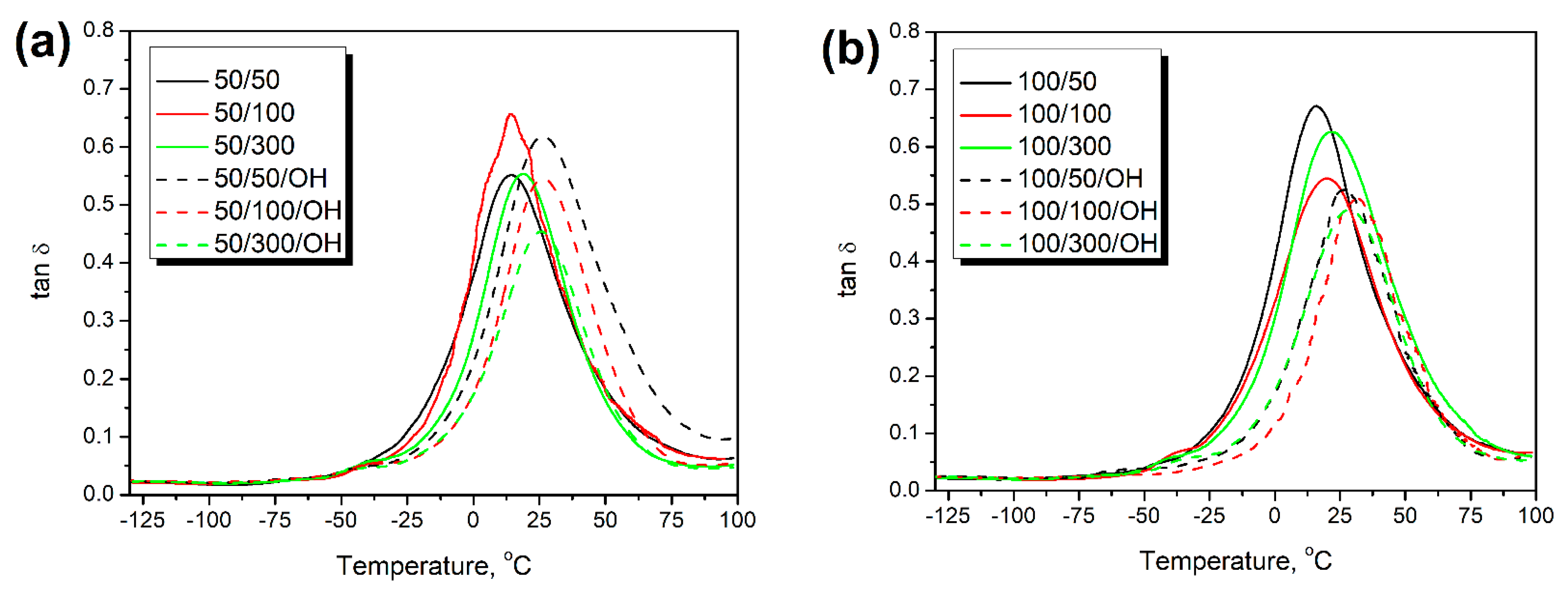

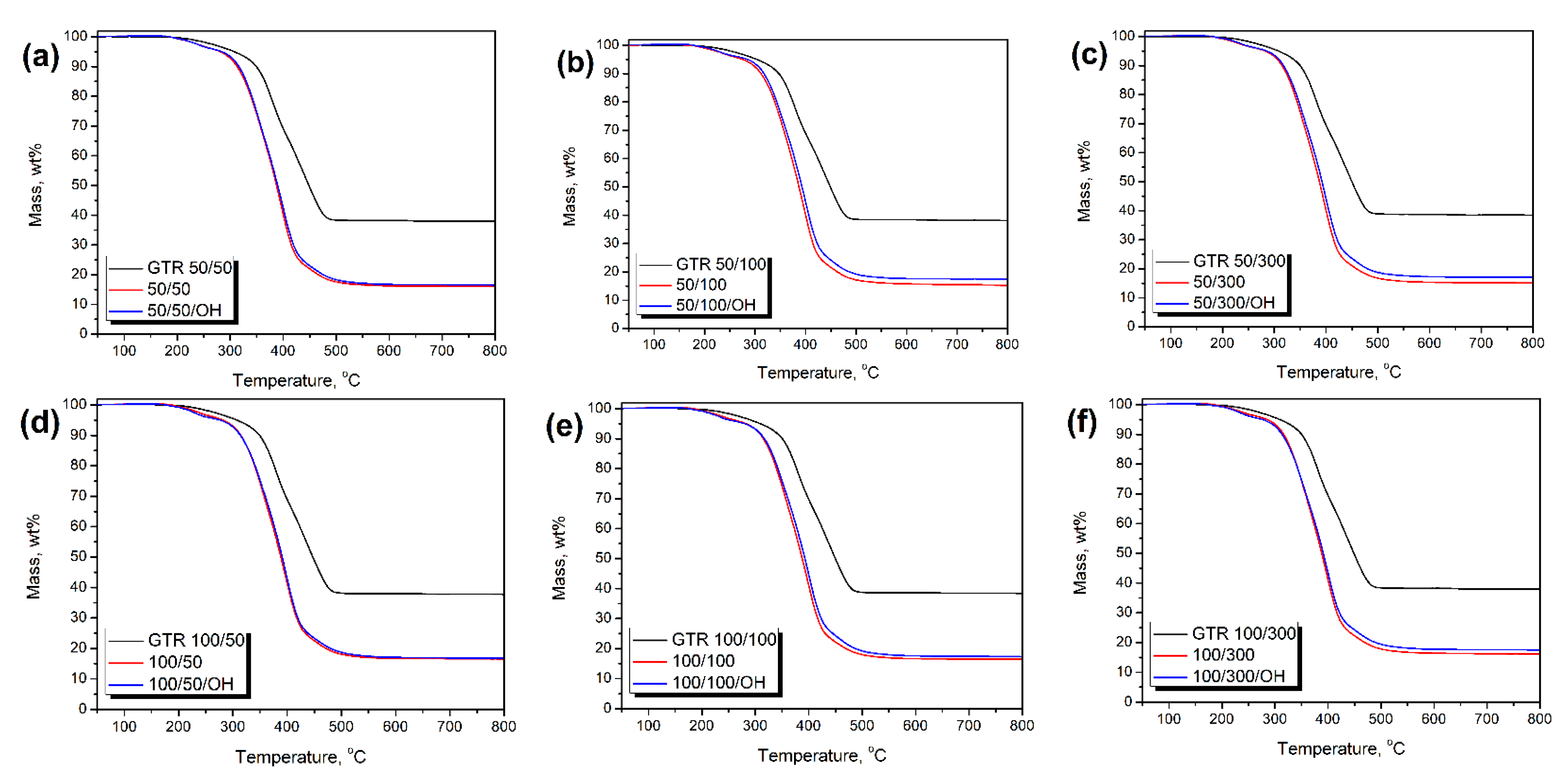

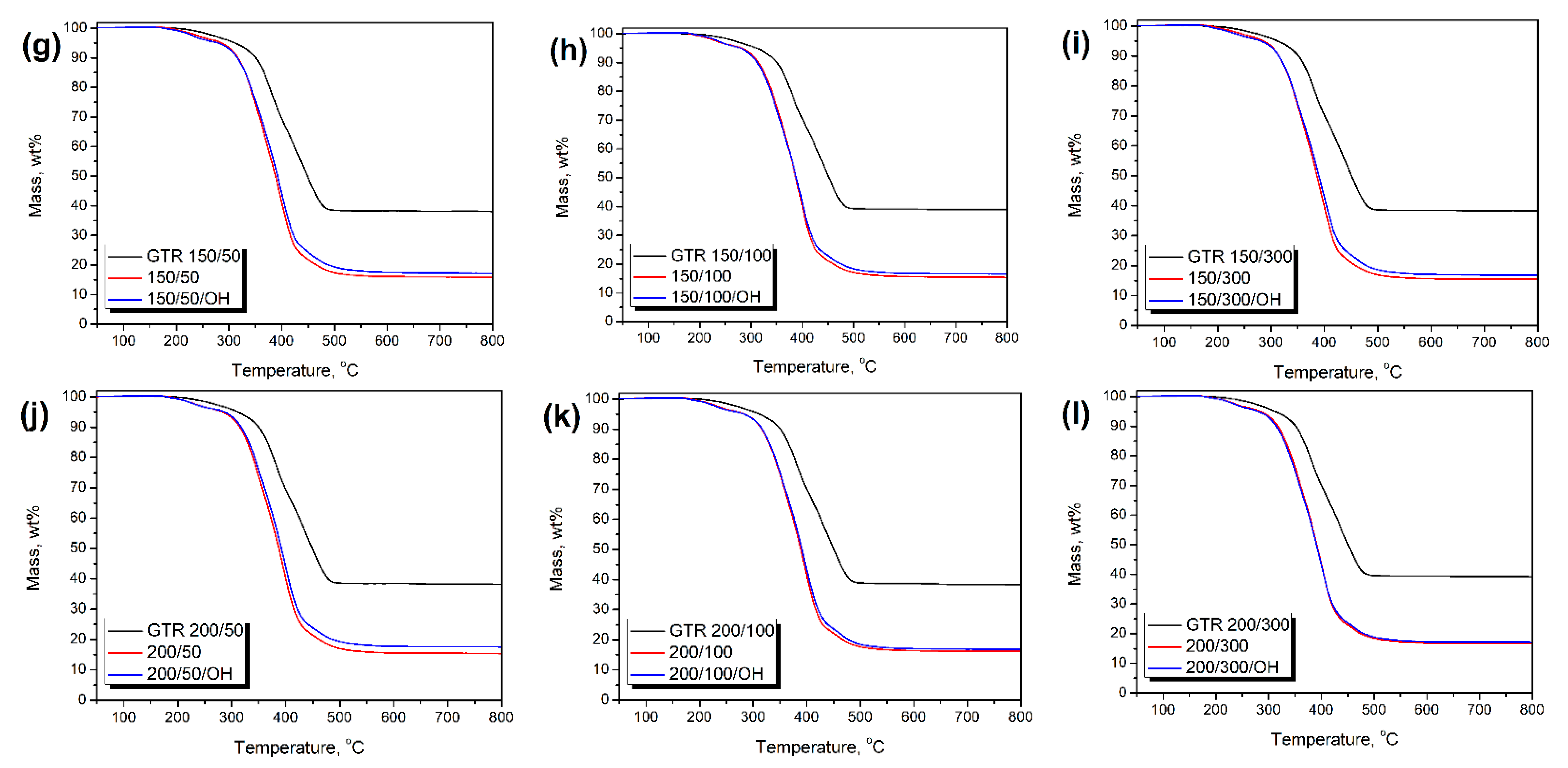

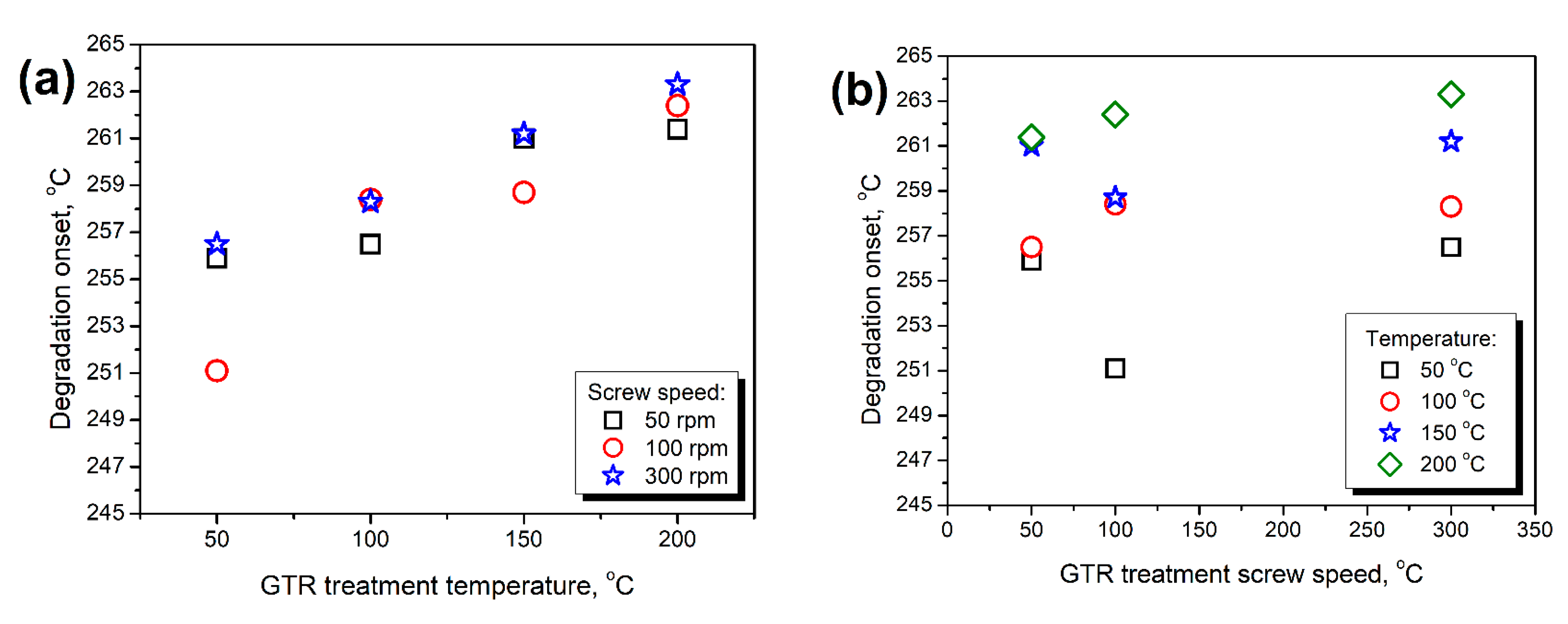

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Stachak, P.; Hebda, E.; Pielichowski, K. Foaming extrusion of thermoplastic polyurethane modified by POSS nanofillers. Compos. Theory Pract. 2019, 19, 23–29. [Google Scholar]

- Małysa, T.; Nowacki, K.; Wieczorek, J. Assessment of sound absorbing properties of polyurethane sandwich system. Compos. Theory Pract. 2016, 16, 244–248. [Google Scholar]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Plant oils as platform chemicals for polyurethane synthesis: Current state-of-the-art. Biomacromolecules 2010, 11, 2825–2835. [Google Scholar] [CrossRef]

- Krol, P. Synthesis methods, chemical structures and phase structures of linear polyurethanes. properties and applications of linear polyurethanes in polyurethane elastomers, copolymers and ionomers. Prog. Mater. Sci. 2007, 52, 915–1015. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Kuranska, M.; Polaczek, K.; Auguscik-Krolikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell polyurethane foams based on modified used cooking oil. Polimery 2020, 65, 216–225. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Barros-Timmons, A. Polyurethane foams: Past, present, and future. Materials 2018, 11, 1841. [Google Scholar] [CrossRef]

- Kuranska, M.; Prociak, A.; Michalowski, S.; Zawadzinska, K. The influence of blowing agents type on foaming process and properties of rigid polyurethane foams. Polimery 2018, 63, 672–678. [Google Scholar] [CrossRef]

- Lapprand, A.; Boisson, F.; Delolme, F.; Méchin, F.; Pascault, J.-P. Reactivity of isocyanates with urethanes: Conditions for allophanate formation. Polym Degrad Stab 2005, 90, 363–373. [Google Scholar] [CrossRef]

- Vilar, W.D. Química e Tecnologia Dos Poliuretanos, 2nd ed.; Vilar Consultoria Técnica Ltda: Rio de Janeiro, Brazil, 1998. [Google Scholar]

- Zieleniewska, M.; Ryszkowska, J.; Bryskiewicz, A.; Auguscik, M.; Szczepkowski, L.; Swiderski, A.; Wrzesniewska-Tosik, K. The structure and properties of viscoelastic polyurethane foams with fyrol and keratin fibers. Polimery 2017, 62, 127–135. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym Test 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Bryśkiewicz, A.; Zieleniewska, M.; Przyjemska, K.; Chojnacki, P.; Ryszkowska, J. Modification of flexible polyurethane foams by the addition of natural origin fillers. Polym. Degrad. Stab. 2016, 132, 32–40. [Google Scholar] [CrossRef]

- Dang, X.; Yang, M.; Zhang, B.; Chen, H.; Wang, Y. Recovery and utilization of collagen protein powder extracted from chromium leather scrap waste. Environ. Sci. Pollut. Res. 2019, 26, 7277–7283. [Google Scholar] [CrossRef] [PubMed]

- Barczewski, M.; Szostak, M.; Nowak, D.; Piasecki, A. Effect of wood flour addition and modification of its surface on the properties of rotationally molded polypropylene composites. Polimery 2018, 63, 772–784. [Google Scholar] [CrossRef]

- Szefer, E.; Leszczyńska, A.; Pielichowski, K. Modification of microcrystalline cellulose filler with succinic anhydride—Effect of microwave and conventional heating. Compos. Theory Pract. 2018, 18, 25–31. [Google Scholar]

- Prut, E.V.; Zhorina, L.A.; Kompaniets, L.V.; Novikov, D.D.; Gorenberg, A.Y. The role of functional polymers in rubber powder/thermoplastic composites. Polimery 2017, 62, 548–555. [Google Scholar] [CrossRef]

- Zedler, Ł.; Kosmela, P.; Olszewski, A.; Burger, P.; Formela, K.; Hejna, A. Recycling of waste rubber by thermo-mechanical treatment in a twin-screw extruder. In Proceedings of the First International Conference on “Green” Polymer Materials 2020, Basel, Switzerland, 4 November 2020; p. 10. [Google Scholar]

- Olszewski, A.; Kosmela, P.; Zedler, Ł.; Formela, K.; Hejna, A. Optimization of foamed polyurethane/ground tire rubber composites manufacturing. In Proceedings of the 2nd International Online Conference on Polymer Science, Polymers and Nanotechnology for Industry 4.0, Basel, Switzerland, 30 October 2021; p. 12. [Google Scholar]

- Formela, K.; Klein, M.; Colom, X.; Saeb, M.R. Investigating the combined impact of plasticizer and shear force on the efficiency of low temperature reclaiming of Ground Tire Rubber (GTR). Polym. Degrad. Stab. 2016, 125, 1–11. [Google Scholar] [CrossRef]

- Kosmela, P.; Olszewski, A.; Zedler, Ł.; Burger, P.; Piasecki, A.; Formela, K.; Hejna, A. Ground tire rubber filled flexible polyurethane foam—effect of waste rubber treatment on composite performance. Materials 2021, 14, 3807. [Google Scholar] [CrossRef] [PubMed]

- Kosmela, P.; Olszewski, A.; Zedler, Ł.; Hejna, A.; Burger, P.; Formela, K. Structural changes and their implications in foamed flexible polyurethane composites filled with rapeseed oil-treated Ground Tire Rubber. J. Compos. Sci. 2021, 5, 90. [Google Scholar] [CrossRef]

- Simon, D.Á.; Pirityi, D.Z.; Bárány, T. Devulcanization of Ground Tire Rubber: Microwave and thermomechanical approaches. Sci. Rep. 2020, 10, 16587. [Google Scholar] [CrossRef]

- Hejna, A.; Olszewski, A.; Zedler, Ł.; Kosmela, P.; Formela, K. The impact of Ground Tire Rubber oxidation with H2O2 and KMnO4 on the structure and performance of flexible polyurethane/Ground Tire Rubber composite foams. Materials 2021, 14, 499. [Google Scholar] [CrossRef] [PubMed]

- Yeh, A.; Hwang, S.; Guo, J. Effects of screw speed and feed rate on residence time distribution and axial mixing of wheat flour in a twin-screw extruder. J. Food Eng. 1992, 17, 1–13. [Google Scholar] [CrossRef]

- Suparno, M.; Dolan, K.D.; NG, P.K.W.; Steffe, J.F. average shear rate in a twin-screw extruder as a function of degree of fill, flow behavior index, screw speed and screw configuration. J. Food Process. Eng. 2011, 34, 961–982. [Google Scholar] [CrossRef]

- Altomare, R.E.; Ghossi, P. An analysis of residence time distribution patterns in a twin screw cooking extruder. Biotechnol. Prog. 1986, 2, 157–163. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Skórczewska, K.; Szulc, J.; Chmielnicki, B.; Korol, J.; Formela, K. Sustainable upcycling of brewers’ spent grain by thermo-mechanical treatment in twin-screw extruder. J. Clean Prod. 2021, 285, 124839. [Google Scholar] [CrossRef]

- Formela, K.; Cysewska, M.; Haponiuk, J. The influence of screw configuration and screw speed of co-rotating twin screw extruder on the properties of products obtained by thermomechanical reclaiming of Ground Tire Rubber. Polimery 2014, 59, 170–177. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of chemically treated eucalyptus fibers on mechanical, thermal and insulating properties of polyurethane composite foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef]

- Paukszta, D.; Szostak, M.; Rogacz, M. Mechanical properties of polypropylene copolymers composites filled with rapeseed straw. Polimery 2014, 59, 165–169. [Google Scholar] [CrossRef]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Prociak, A.; Malewska, E.; Bąk, S. Influence of isocyanate index on selected properties of flexible polyurethane foams modified with various bio-components. J. Renew. Mater. 2016, 4, 78–85. [Google Scholar] [CrossRef]

- Rojek, P.; Prociak, A. Effect of different rapeseed-oil-based polyols on mechanical properties of flexible polyurethane foams. J. Appl. Polym. Sci. 2012, 125, 2936–2945. [Google Scholar] [CrossRef]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed polyurethane composites with different types of ash—Morphological, mechanical and thermal behavior assessments. Cell. Polym. 2016, 35, 213–220. [Google Scholar] [CrossRef]

- Arnold, R.G.; Nelson, J.A.; Verbanc, J.J. Recent advances in isocyanate chemistry. Chem. Rev. 1957, 57, 47–76. [Google Scholar] [CrossRef]

- Bukowczan, A.; Hebda, E.; Michałowski, S.; Pielichowski, K. Modification of polyurethane viscoelastic foams by functionalized Polyhedral Oligomeric Silsesquioxanes (POSS). Compos. Theory Pract. 2018, 18, 77–81. [Google Scholar]

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crops Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Smoleń, J.; Olszowska, K.; Godzierz, M. Composites of rigid polyurethane foam and shredded car window glass particles—Structure and mechanical properties. Compos. Theory Pract. 2021, 21, 135–140. [Google Scholar]

- Caban, R. Examinations of structure and properties of polymer composite with glass fiber. Compos. Theory Pract. 2019, 19, 150–156. [Google Scholar]

- Wolska, A.; Goździkiewicz, M.; Ryszkowska, J. Thermal and mechanical behaviour of flexible polyurethane foams modified with graphite and phosphorous fillers. J. Mater. Sci. 2012, 47, 5627–5634. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. structure evaluation and mechanical performance. Compos. B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Zedler, Ł.; Kowalkowska-Zedler, D.; Colom, X.; Cañavate, J.; Saeb, M.R.; Formela, K. Reactive sintering of Ground Tire Rubber (GTR) modified by a trans-polyoctenamer rubber and curing additives. Polymers 2020, 12, 3018. [Google Scholar] [CrossRef] [PubMed]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee silverskin as a multifunctional waste filler for high-density polyethylene green composites. J. Compos. Sci. 2021, 5, 44. [Google Scholar] [CrossRef]

- Russo, P.; Acierno, D.; Corradi, A.; Leonelli, C. RETRACTED: Dynamic-mechanical behavior and morphology of polystyrene/perovskite composites: Effects of filler size. Procedia Eng. 2011, 10, 1017–1022. [Google Scholar] [CrossRef]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Hejna, A.; Haponiuk, J.; Piszczyk, Ł.; Klein, M.; Formela, K. Performance properties of rigid polyurethane-polyisocyanurate/Brewers’ spent grain foamed composites as function of isocyanate index. e-Polymers 2017, 17, 427–437. [Google Scholar] [CrossRef]

- Ivdre, A.; Abolins, A.; Sevastyanova, I.; Kirpluks, M.; Cabulis, U.; Merijs-Meri, R. Rigid polyurethane foams with various isocyanate indices based on polyols from rapeseed oil and waste PET. Polymers 2020, 12, 738. [Google Scholar] [CrossRef]

- Nadal Gisbert, A.; Crespo Amorós, J.E.; López Martínez, J.; Garcia, A.M. Study of thermal degradation kinetics of elastomeric powder (Ground Tire Rubber). Polym. Plast. Technol. Eng. 2007, 47, 36–39. [Google Scholar] [CrossRef]

- Zedler, Ł.; Kowalkowska-Zedler, D.; Vahabi, H.; Saeb, M.R.; Colom, X.; Cañavate, J.; Wang, S.; Formela, K. Preliminary investigation on auto-thermal extrusion of Ground Tire Rubber. Materials 2019, 12, 2090. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and fire-retardancy of polyurethanes—A review of the recent literature. Polym. Int. 2004, 53, 1585–1610. [Google Scholar] [CrossRef]

- Mizera, K.; Ryszkowska, J. Thermal properties of polyurethane elastomers from soybean oil-based polyol with a different isocyanate index. J. Elastomers Plast. 2019, 51, 157–174. [Google Scholar] [CrossRef]

| GTR Treatment Parameters | LOH, mg KOH/g | GTR Treatment Parameters | LOH, mg KOH/g | ||

|---|---|---|---|---|---|

| Temperature, °C | Screw Speed, rpm | Temperature, °C | Screw Speed, rpm | ||

| 50 | 50 | 70.65 ± 2.37 | 150 | 50 | 71.13 ± 1.76 |

| 100 | 69.78 ± 2.43 | 100 | 68.00 ± 1.60 | ||

| 300 | 59.26 ± 2.81 | 300 | 76.55 ± 0.85 | ||

| 100 | 50 | 88.49 ± 2.97 | 200 | 50 | 45.05 ± 2.01 |

| 100 | 75.71 ± 2.92 | 100 | 47.08 ± 1.50 | ||

| 300 | 71.85 ± 2.01 | 300 | 55.21 ± 2.85 | ||

| Component | Type of Applied GTR (Temperature of Treatment/Screw Speed) | |||||||||||

| 50/50 | 50/100 | 50/300 | 100/50 | 100/100 | 100/300 | |||||||

| - | OH | - | OH | - | OH | - | OH | - | OH | - | OH | |

| Rokopol F3000 | 26.10 | 26.38 | 26.10 | 26.37 | 26.10 | 26.27 | 26.10 | 26.03 | 26.10 | 26.33 | 26.10 | 26.13 |

| Rokopol V700 | 26.10 | 26.38 | 26.10 | 26.37 | 26.10 | 26.27 | 26.10 | 26.03 | 26.10 | 26.33 | 26.10 | 26.13 |

| Glycerol | 0.60 | 0.63 | 0.60 | 0.63 | 0.60 | 0.63 | 0.60 | 0.63 | 0.60 | 0.63 | 0.60 | 0.63 |

| DBTDL | 0.50 | 0.48 | 0.50 | 0.48 | 0.50 | 0.48 | 0.50 | 0.47 | 0.50 | 0.48 | 0.50 | 0.47 |

| 33LV | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.31 | 0.30 | 0.32 | 0.30 | 0.32 |

| TKA30 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.31 | 0.30 | 0.32 | 0.30 | 0.32 |

| Water | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 |

| GTR | 20.00 | 16.18 | 20.00 | 16.18 | 20.00 | 16.90 | 20.00 | 16.90 | 20.00 | 16.15 | 20.00 | 16.90 |

| pMDI | 25.80 | 29.05 | 25.80 | 29.06 | 25.80 | 28.54 | 25.80 | 29.05 | 25.80 | 29.18 | 25.80 | 28.84 |

| Component | Type of Applied GTR (Temperature of Treatment/Screw Speed) | |||||||||||

| 150/50 | 150/100 | 150/300 | 200/50 | 200/100 | 200/300 | |||||||

| - | OH | - | OH | - | OH | - | OH | - | OH | - | OH | |

| Rokopol F3000 | 26.10 | 26.08 | 26.10 | 26.41 | 26.10 | 26.04 | 26.10 | 26.72 | 26.10 | 26.71 | 26.10 | 26.59 |

| Rokopol V700 | 26.10 | 26.08 | 26.10 | 26.41 | 26.10 | 26.04 | 26.10 | 26.72 | 26.10 | 26.71 | 26.10 | 26.59 |

| Glycerol | 0.60 | 0.63 | 0.60 | 0.64 | 0.60 | 0.63 | 0.60 | 0.64 | 0.60 | 0.64 | 0.60 | 0.64 |

| DBTDL | 0.50 | 0.47 | 0.50 | 0.48 | 0.50 | 0.47 | 0.50 | 0.48 | 0.50 | 0.48 | 0.50 | 0.48 |

| 33LV | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.31 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.32 |

| TKA30 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.31 | 0.30 | 0.32 | 0.30 | 0.32 | 0.30 | 0.32 |

| Water | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 | 0.30 | 0.27 |

| GTR | 20.00 | 16.90 | 20.00 | 16.20 | 20.00 | 16.90 | 20.00 | 16.39 | 20.00 | 16.39 | 20.00 | 16.32 |

| pMDI | 25.80 | 28.94 | 25.80 | 28.97 | 25.80 | 29.04 | 25.80 | 28.12 | 25.80 | 28.14 | 25.80 | 28.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszewski, A.; Kosmela, P.; Żukowska, W.; Wojtasz, P.; Szczepański, M.; Barczewski, M.; Zedler, Ł.; Formela, K.; Hejna, A. Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites. Polymers 2022, 14, 3838. https://doi.org/10.3390/polym14183838

Olszewski A, Kosmela P, Żukowska W, Wojtasz P, Szczepański M, Barczewski M, Zedler Ł, Formela K, Hejna A. Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites. Polymers. 2022; 14(18):3838. https://doi.org/10.3390/polym14183838

Chicago/Turabian StyleOlszewski, Adam, Paulina Kosmela, Wiktoria Żukowska, Paweł Wojtasz, Mariusz Szczepański, Mateusz Barczewski, Łukasz Zedler, Krzysztof Formela, and Aleksander Hejna. 2022. "Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites" Polymers 14, no. 18: 3838. https://doi.org/10.3390/polym14183838

APA StyleOlszewski, A., Kosmela, P., Żukowska, W., Wojtasz, P., Szczepański, M., Barczewski, M., Zedler, Ł., Formela, K., & Hejna, A. (2022). Insights into Stoichiometry Adjustments Governing the Performance of Flexible Foamed Polyurethane/Ground Tire Rubber Composites. Polymers, 14(18), 3838. https://doi.org/10.3390/polym14183838