Synthesis of Iron(II) Clathrochelate-Based Poly(vinylene sulfide) with Tetraphenylbenzene Bridging Units and Their Selective Oxidation into Their Corresponding Poly(vinylene sulfone) Copolymers: Promising Materials for Iodine Capture

Abstract

:1. Introduction

2. Materials

2.1. Characterization Techniques

2.2. Synthesis

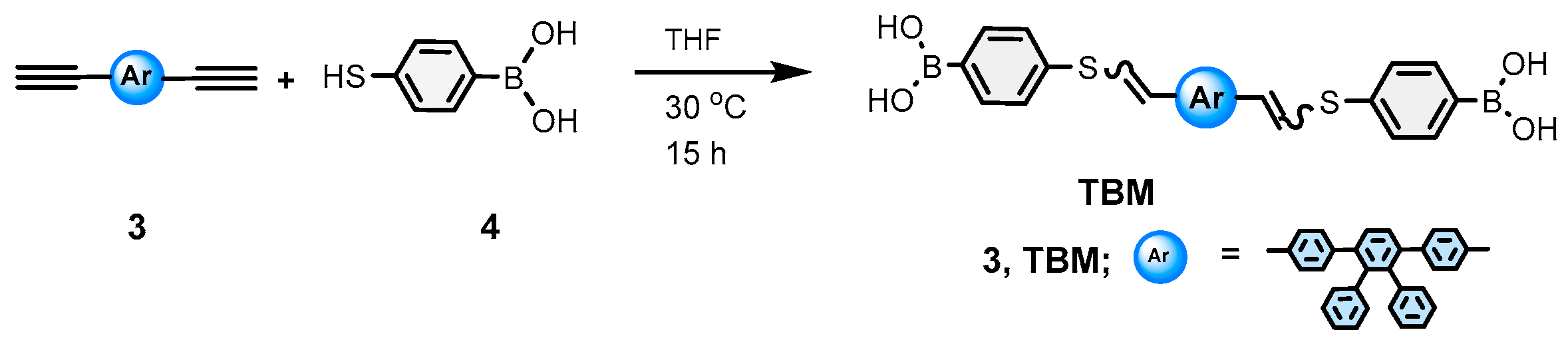

2.2.1. Synthesis of ((((2′,3′-diphenyl-[1,1′:4′,1″-terphenyl]-4,4″-diyl)bis(ethene-2,1-diyl))bis(sulfanediyl))bis(4,1-phenylene))diboronic Acid (TBM)

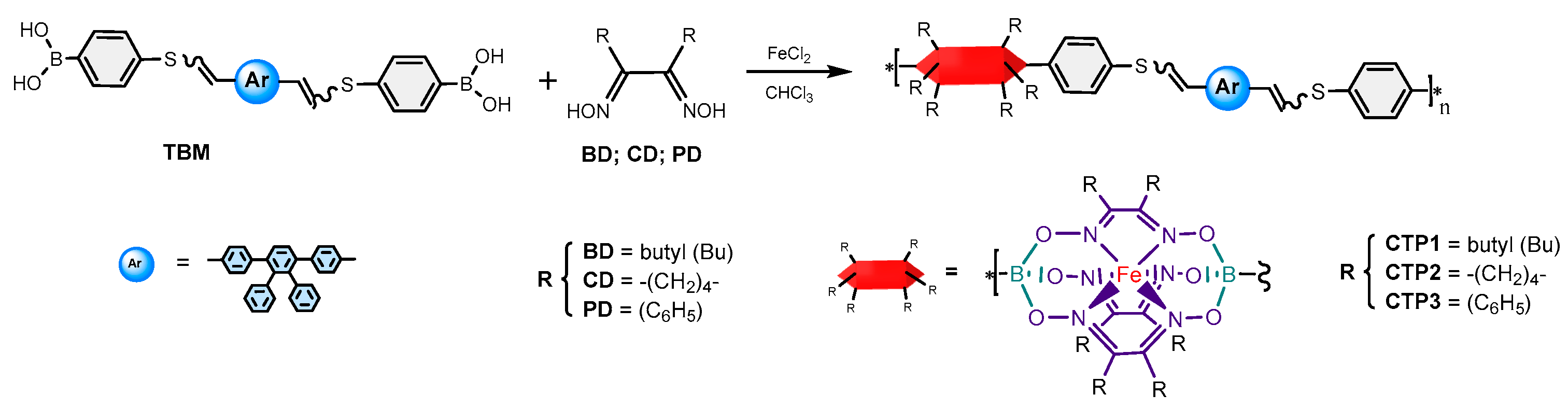

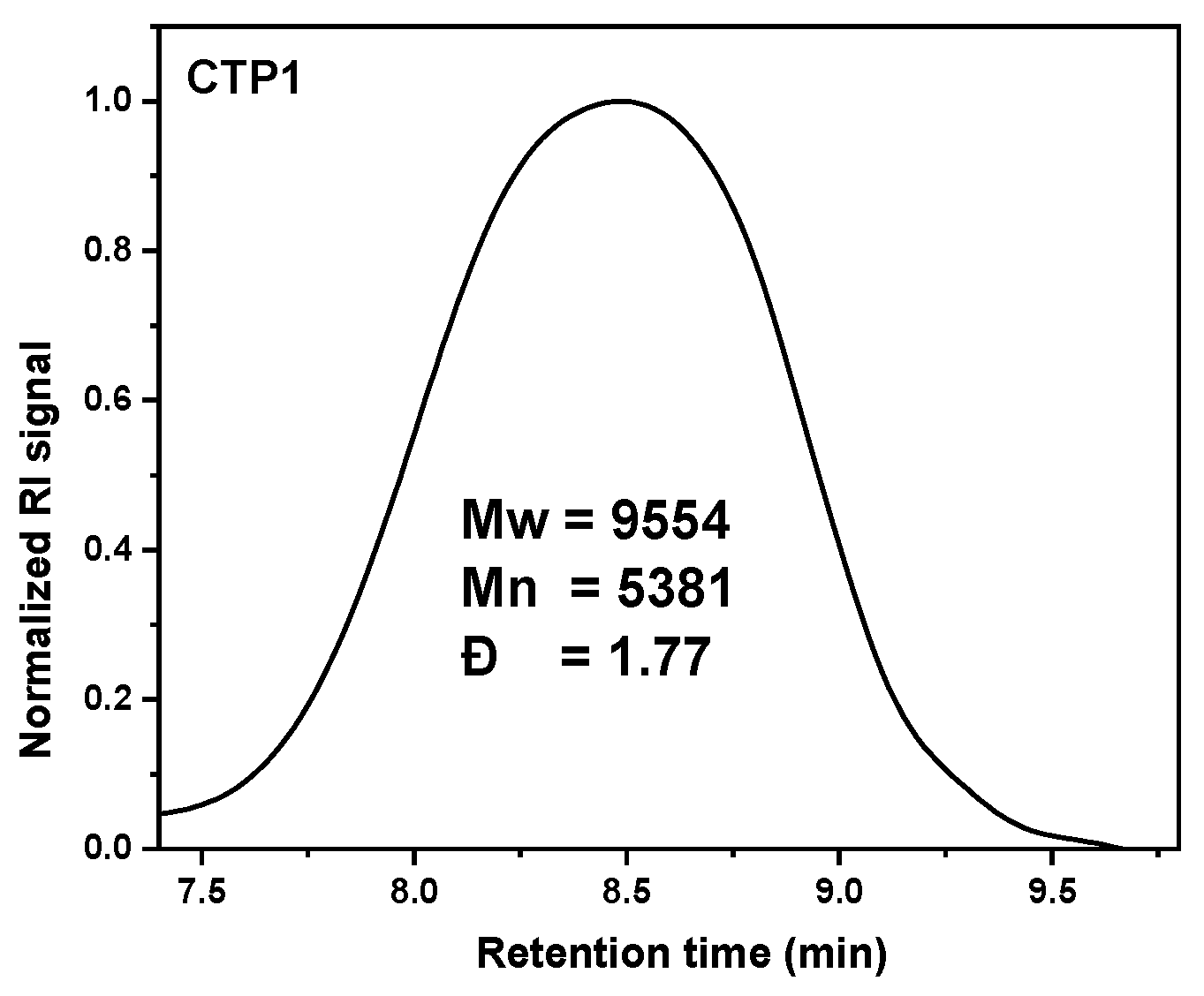

2.2.2. Synthesis of Copolymer CTP1 (Procedure A)

2.2.3. Synthesis of Copolymer CTP2

2.2.4. Synthesis of Copolymer CTP3

2.2.5. Synthesis of CTP4 (Procedure B)

2.2.6. Synthesis of CTP5

2.2.7. Synthesis of CTP6

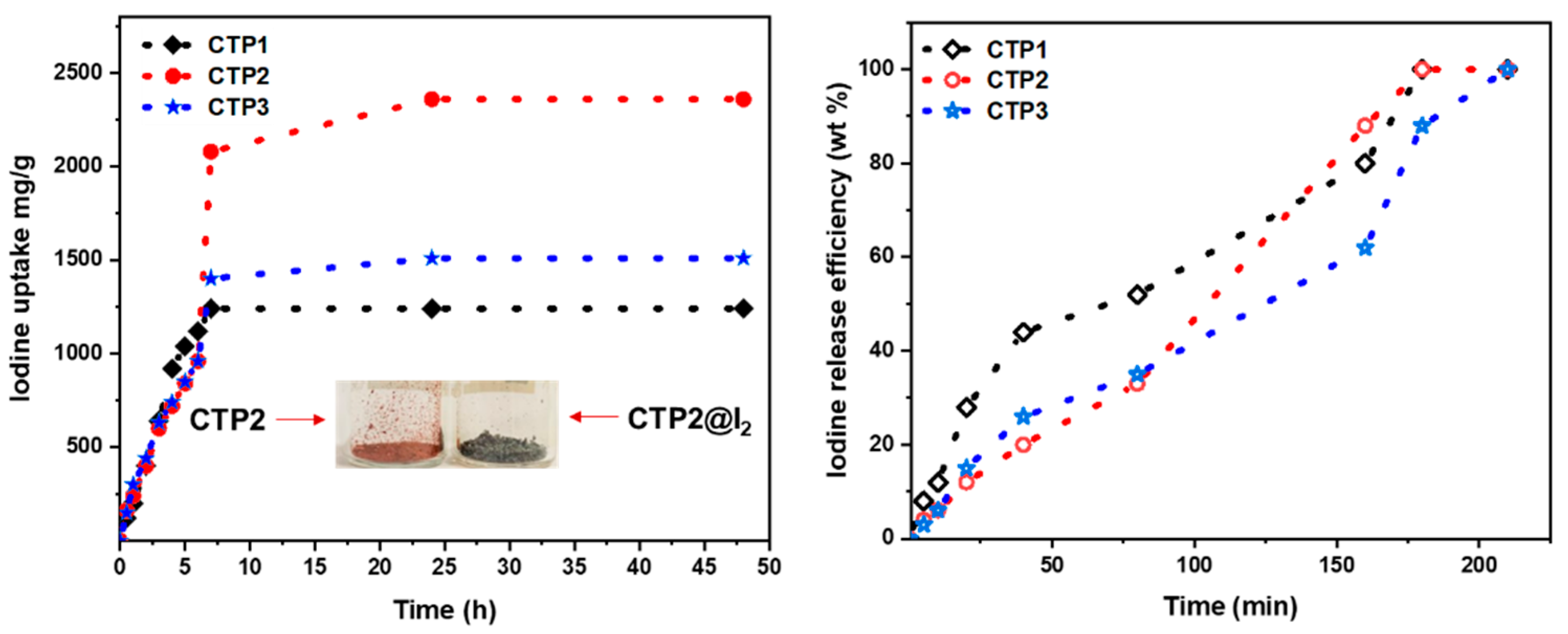

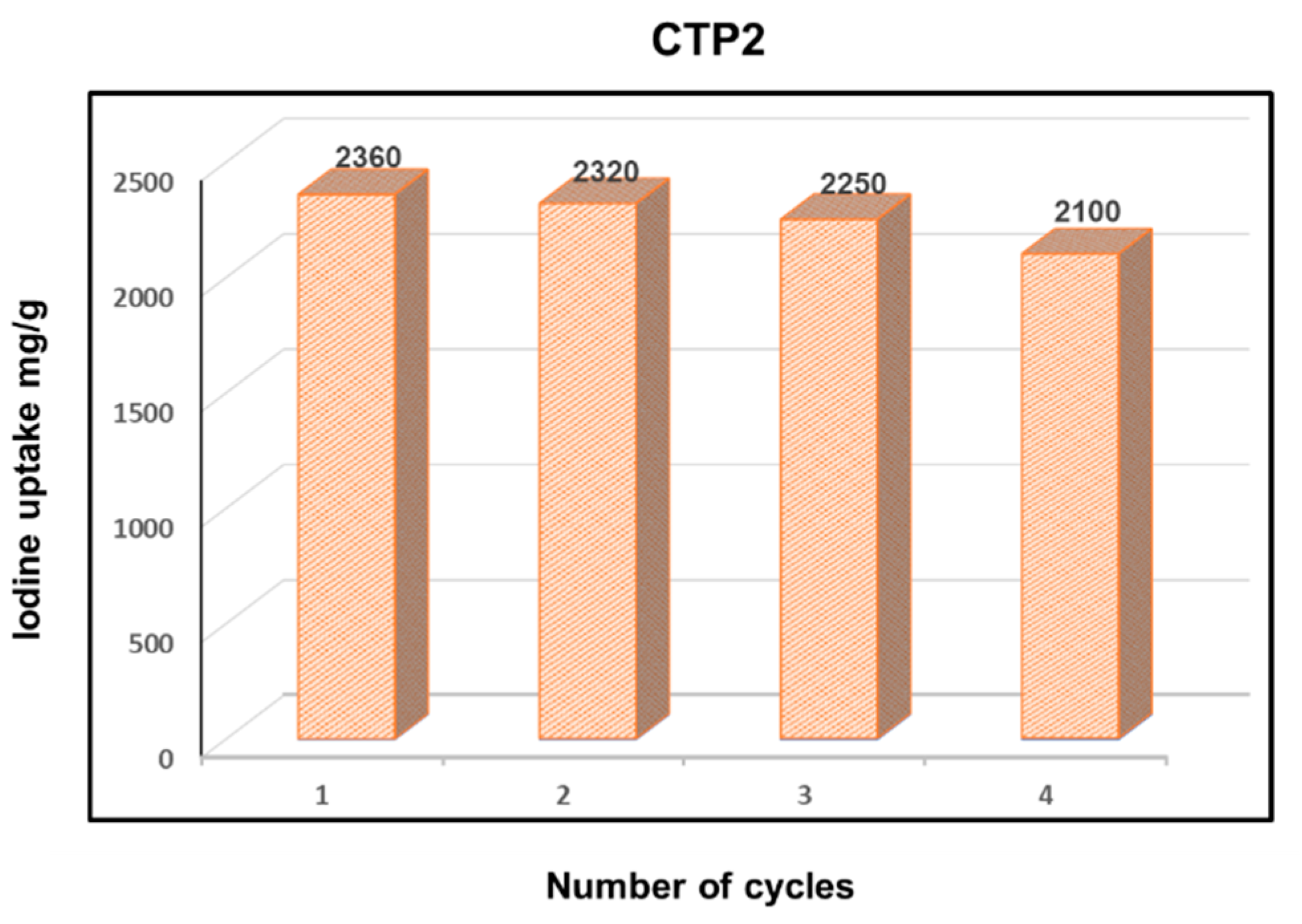

2.3. Iodine Adsorption Studies of CTP1-6

Adsorption Equilibrium and Kinetics

3. Results

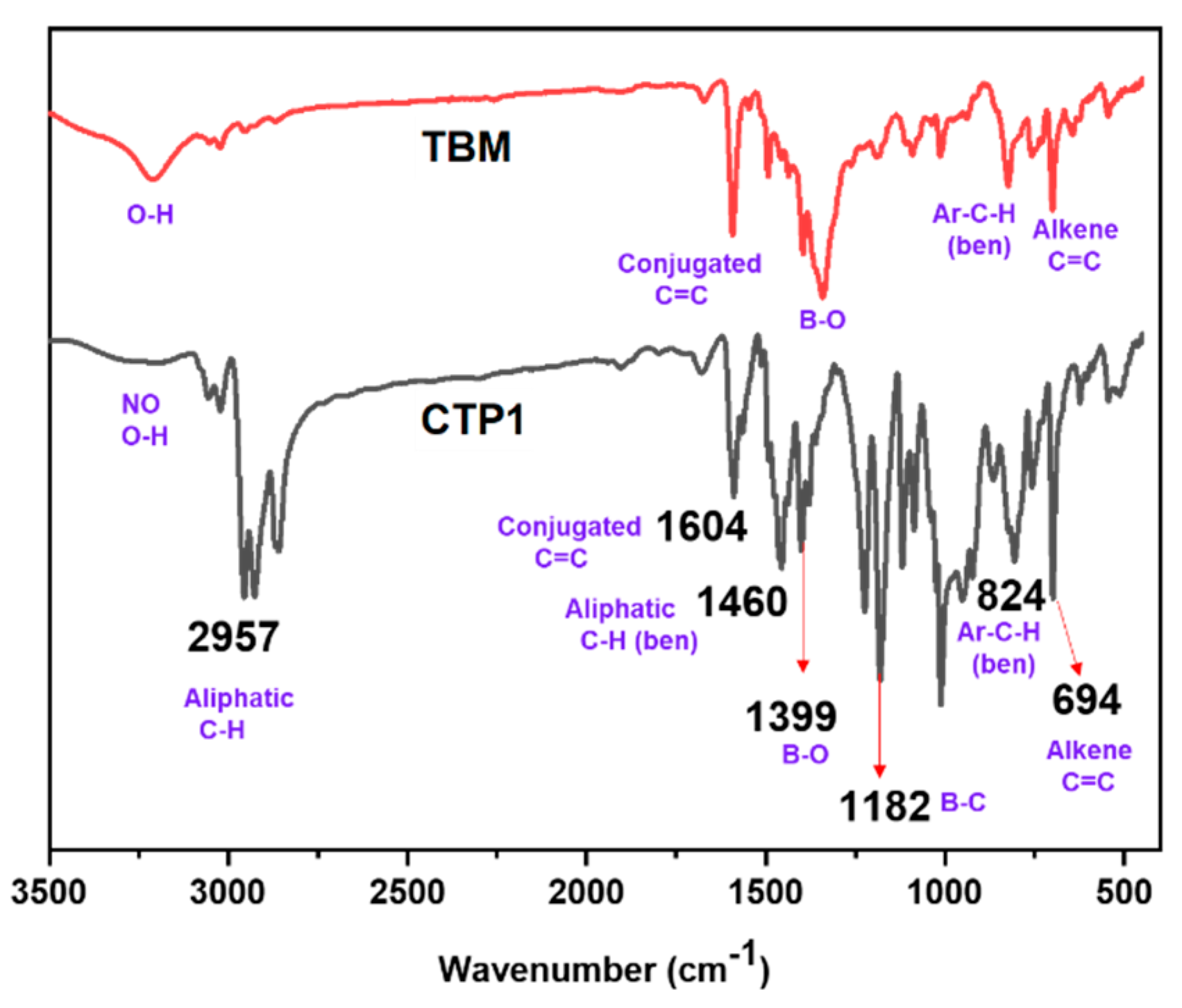

3.1. Synthesis of TBM

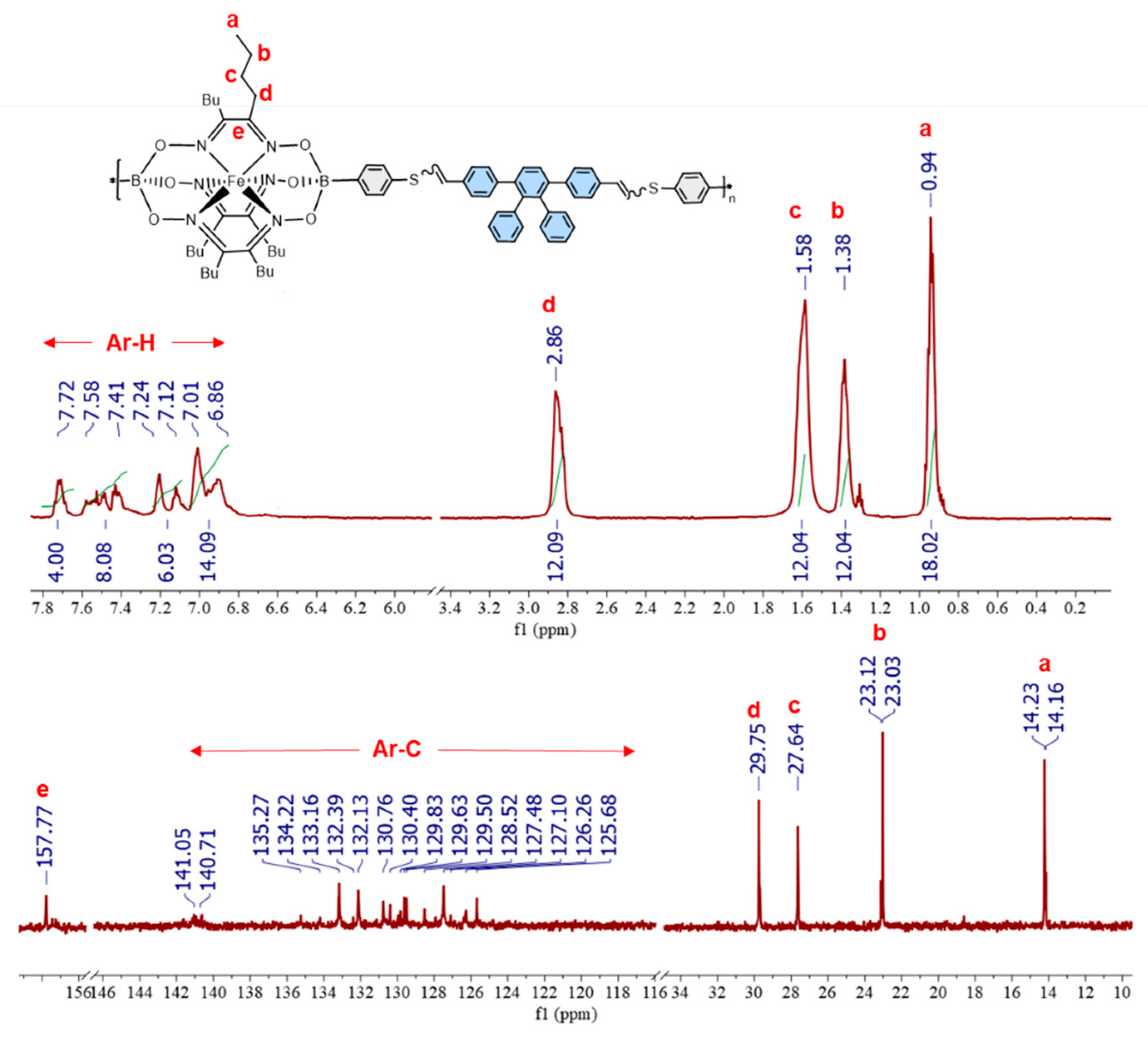

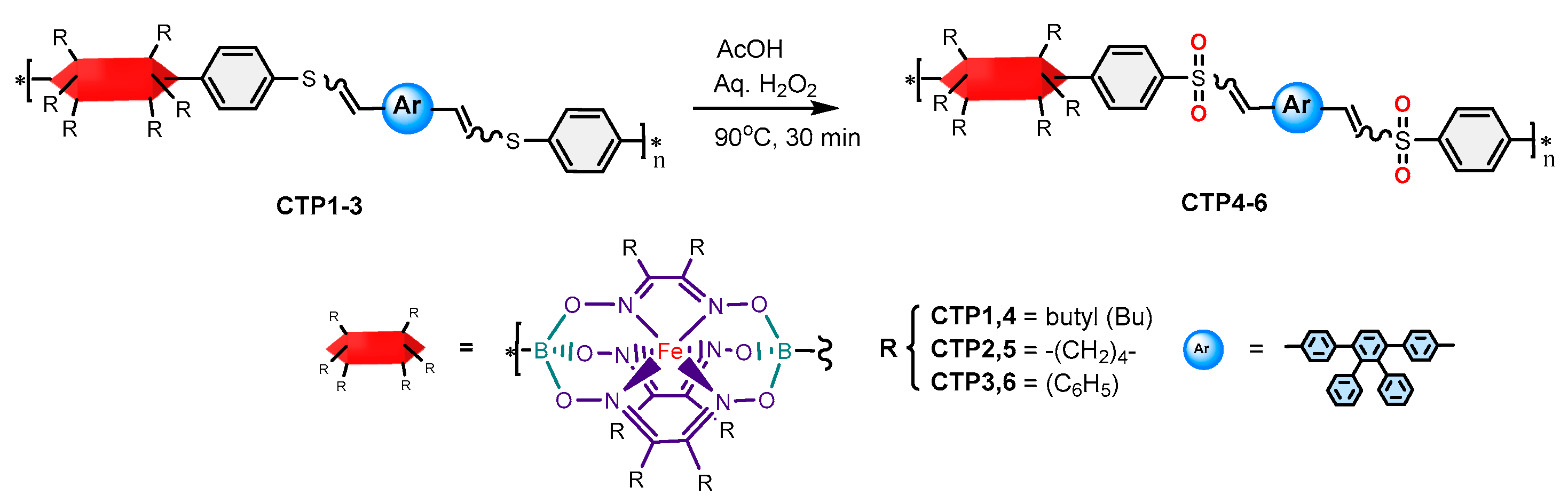

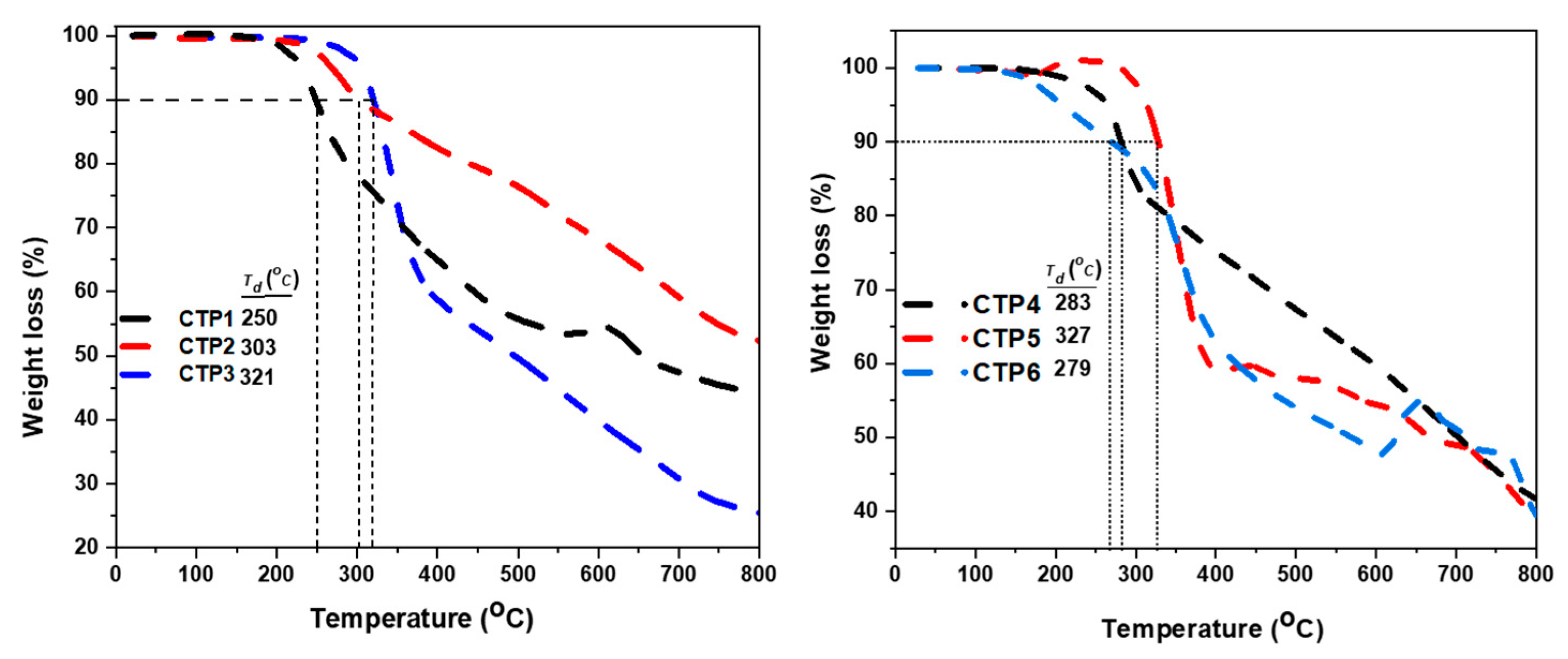

3.2. Synthesis of Copolymers CTP1-3

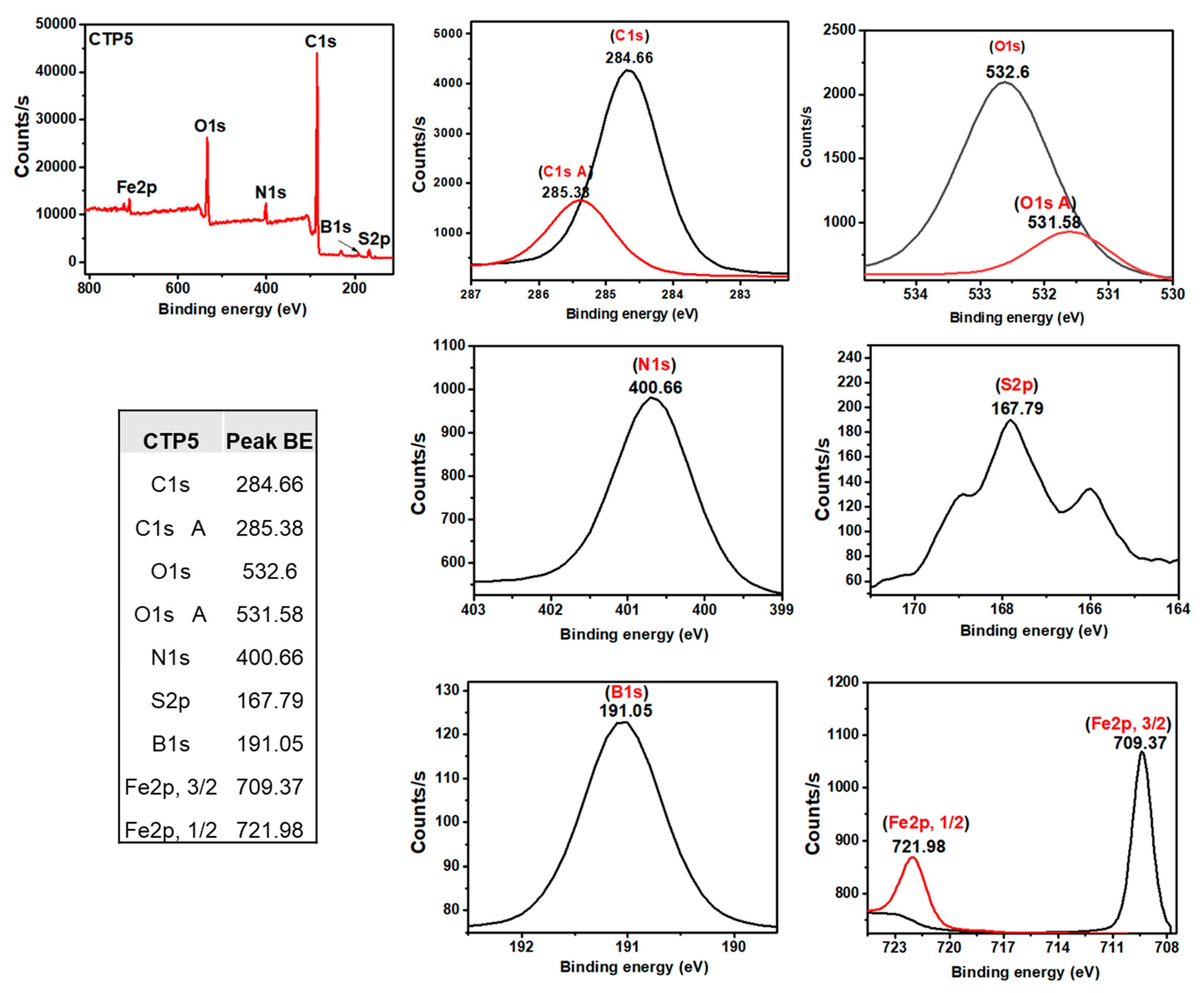

3.3. Synthesis of Poly(vinylene sulfone) Derivatives CTP4-6

3.4. Gravimetric Iodine Capture Studies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- British Petroleum. Statistical Review of World Energy 2022; British Petroleum Co.: London, UK, 2022; p. 60. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2022-full-report.pdf (accessed on 28 July 2022).

- U.S. Department of Energy. International Energy Outlook 2021; U.S. Department of Energy: Washington, DC, USA, 2021; p. 42. Available online: https://www.eia.gov/outlooks/ieo/pdf/IEO2021_Narrative.pdf (accessed on 28 July 2022).

- Zhao, T.; Yang, Z.; Tang, Y.; Liu, J.; Wang, F. Advances and Perspectives of Photopromoted CO2 Hydrogenation for Methane Production: Catalyst Development and Mechanism Investigations. Energy Fuels 2022, 36, 6711–6735. [Google Scholar] [CrossRef]

- Sun, Z.; Liao, Y.; Zhao, S.; Zhang, X.; Liu, Q.; Shi, X.J. Research progress in metal–organic frameworks (MOFs) in CO2 capture from post-combustion coal-fired flue gas: Characteristics, preparation, modification and applications. Mater. Chem. A 2022, 10, 5174–5211. [Google Scholar] [CrossRef]

- Zantye, M.S.; Arora, A.; Hasan, M.M.F. Renewable-integrated flexible carbon capture: A synergistic path forward to clean energy future. Energy Environ. Sci. 2021, 14, 3986–4008. [Google Scholar] [CrossRef]

- Gao, W.; Liang, S.; Wang, R.; Jiang, Q.; Zhang, Y.; Zheng, Q.; Xie, B.; Toe, C.Y.; Zhu, X.; Wang, J.; et al. Industrial carbon dioxide capture and utilization: State of the art and future challenges. Chem. Soc. Rev. 2020, 49, 8584–8686. [Google Scholar] [CrossRef]

- Niu, T.-H.; Feng, C.-C.; Yao, C.; Yang, W.-Y.; Xu, Y.-H. Bisimidazole-Based Conjugated Polymers for Excellent Iodine Capture. ACS Appl. Polym. Mater. 2021, 3, 354–361. [Google Scholar] [CrossRef]

- Huve, J.; Ryzhikov, A.; Nouali, H.; Lalia, V.; Augé, G.; Daou, T.J. Porous sorbents for the capture of radioactive iodine compounds: A review. RSC Adv. 2018, 8, 29248–29273. [Google Scholar] [CrossRef]

- Banerjee, D.; Cairns, A.J.; Liu, J.; Motkuri, R.K.; Nune, S.K.; Fernandez, C.A.; Krishna, R.; Strachan, D.M.; Thallapally, P.K. Potential of Metal–Organic Frameworks for Separation of Xenon and Krypton. Acc. Chem. Res. 2015, 48, 211–219. [Google Scholar] [CrossRef]

- Tian, Y.; Zhu, G. Porous Aromatic Frameworks (PAFs). Chem. Rev. 2020, 120, 8934–8986. [Google Scholar] [CrossRef]

- Janeta, M.; Bury, W.; Szafert, S. Porous Silsesquioxane–Imine Frameworks as Highly Efficient Adsorbents for Cooperative Iodine Capture. ACS Appl. Mater. Interfaces 2018, 10, 19964–19973. [Google Scholar] [CrossRef]

- Xu, X.-H.; Li, Y.-X.; Zhou, L.; Liu, N.; Wu, Z.-Q. Precise fabrication of porous polymer frameworks using rigid polyisocyanides as building blocks: From structural regulation to efficient iodine capture. Chem. Sci. 2022, 13, 1111–1118. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Q.; Li, T.; Lan, T.; Bai, P.; Liu, F.; Yuan, Z.; Zheng, W.; Yan, W.; Yan, T. Porous Copper-Loaded Zeolites for High-Efficiency Capture of Iodine from Spent Fuel Reprocessing Off-Gas. Inorg. Chem. 2022, 61, 7746–7753. [Google Scholar] [CrossRef] [PubMed]

- Riley, B.J.; Vienna, J.D.; Strachan, D.M.; McCloy, J.S.; Jerden, J.L. Materials and processes for the effective capture and immobilization of radioiodine: A review. J. Nucl. Mater. 2016, 470, 307–326. [Google Scholar] [CrossRef]

- Song, S.; Shi, Y.; Liu, N.; Liu, F. Theoretical Screening and Experimental Synthesis of Ultrahigh-Iodine Capture Covalent Organic Frameworks. ACS Appl. Mater. Interfaces 2021, 13, 10513–10523. [Google Scholar] [CrossRef] [PubMed]

- Ojovan, M.I.; Lee, W.E. An Introduction to Nuclear Waste Immobilisation, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- de Rooij, D.G.; van de Kant, H.J.G.; Dol, R.; Wagemaker, G.; van Buul, P.P.W.; van Duijn-Goedhart, A.; de Jong, F.H.; Broerse, J.J. Long-Term Effects of Irradiation Before Adulthood on Reproductive Function in the Male Rhesus Monkey1. Biol. Reprod. 2002, 66, 486–494. [Google Scholar] [CrossRef] [PubMed]

- Toki, H.; Wada, T.; Manabe, Y.; Hirota, S.; Higuchi, T.; Tanihata, I.; Satoh, K.; Bando, M. Relationship between environmental radiation and radioactivity and childhood thyroid cancer found in Fukushima health management survey. Sci. Rep. 2020, 10, 4074. [Google Scholar] [CrossRef]

- Yamamoto, H.; Hayashi, K.; Scherb, H. Association between the detection rate of thyroid cancer and the external radiation dose-rate after the nuclear power plant accidents in Fukushima, Japan. Medicine 2019, 98, e17165. [Google Scholar] [CrossRef]

- Yasuda, S.; Kyozuka, H.; Nomura, Y.; Fujimori, K.; Goto, A.; Yasumura, S.; Hata, K.; Ohira, T.; Abe, M.J. Influence of the Great East Japan Earthquake and the Fukushima Daiichi nuclear disaster on the birth weight of newborns in Fukushima Prefecture: Fukushima Health Management Survey. Matern. Fetal Neonatal Med. 2017, 30, 2900–2904. [Google Scholar] [CrossRef]

- Hayama, S.I.; Tsuchiya, M.; Ochiai, K.; Nakiri, S.; Nakanishi, S.; Ishii, N.; Kato, T.; Tanaka, A.; Konno, F.; Kawamoto, Y.; et al. Small head size and delayed body weight growth in wild Japanese monkey fetuses after the Fukushima Daiichi nuclear disaster. Sci. Rep. 2017, 7, 3528. [Google Scholar] [CrossRef]

- Kojima, Y.; Yokoya, S.; Kurita, N.; Idaka, T.; Ishikawa, T.; Tanaka, H.; Ezawa, Y.; Ohto, H. Cryptorchidism after the Fukushima Daiichi Nuclear Power Plant accident:causation or coincidence? Fukushima J. Med. Sci. 2019, 65, 76–98. [Google Scholar] [CrossRef] [Green Version]

- Khlifi, S.; Marrot, J.; Haouas, M.; Shepard, W.E.; Falaise, C.; Cadot, E. Chaotropic Effect as an Assembly Motif to Construct Supramolecular Cyclodextrin–Polyoxometalate-Based Frameworks. J. Am. Chem. Soc. 2022, 144, 4469–4477. [Google Scholar] [CrossRef]

- Feng, Y.; Zou, M.-Y.; Hu, H.-C.; Li, W.-H.; Cai, S.-L.; Zhang, W.-G.; Zheng, S.-R. Amorphous metal–organic frameworks obtained from a crystalline precursor for the capture of iodine with high capacities. Chem. Commun. 2022, 58, 5013–5016. [Google Scholar] [CrossRef]

- Gamal Mohamed, M.; Tsai, M.-Y.; Wang, C.-F.; Huang, C.-F.; Danko, M.; Dai, L.; Chen, T.; Kuo, S.-W. Multifunctional Polyhedral Oligomeric Silsesquioxane (POSS) Based Hybrid Porous Materials for CO2 Uptake and Iodine Adsorption. Polymers 2021, 13, 221. [Google Scholar] [CrossRef] [PubMed]

- Riley, B.J.; Chong, S.; Schmid, J.; Marcial, J.; Nienhuis, E.T.; Bera, M.K.; Lee, S.; Canfield, N.L.; Kim, S.; Derewinski, M.A.; et al. Role of Zeolite Structural Properties toward Iodine Capture: A Head-to-head Evaluation of Framework Type and Chemical Composition. ACS Appl. Mater. Interfaces 2022, 14, 18439–18452. [Google Scholar] [CrossRef]

- Ayadi, T.; Badawi, M.; Cantrel, L.; Lebègue, S. Rational approach for an optimized formulation of silver-exchanged zeolites for iodine capture from first-principles calculations. Mol. Syst. Des. Eng. 2022, 7, 422–433. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Pasha, S.S.; Pramanik, S.K.; Alameddine, B. Copolymer networks with contorted units and highly polar groups for ultra-fast selective cationic dye adsorption and iodine uptake. Polymer 2022, 239, 124467. [Google Scholar] [CrossRef]

- Hassan, A.; Alam, A.; Chandra, S.; Prince; Das, N. Triptycene-based and imine linked porous uniform microspheres for efficient and reversible scavenging of iodine from various media: A systematic study. Environ. Sci. Adv. 2022, 1, 320. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Alameddine, B. Conjugated microporous polymers using a copper-catalyzed [4 + 2] cyclobenzannulation reaction: Promising materials for iodine and dye adsorption. Polym. Chem. 2021, 12, 2282–2292. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Alameddine, B. Synthesis of conjugated polymers via cyclopentannulation reaction: Promising materials for iodine adsorption. Polym. Chem. 2020, 11, 3066–3074. [Google Scholar] [CrossRef]

- Qu, G.; Han, Y.; Qi, J.; Xing, X.; Hou, M.; Sun, Y.; Wang, X.; Sun, G. Rapid iodine capture from radioactive wastewater by green and low-cost biomass waste derived porous silicon–carbon composite. RSC Adv. 2021, 11, 5268–5275. [Google Scholar] [CrossRef]

- Liu, S.; Wang, N.; Zhang, Y.; Li, Y.; Han, Z.; Na, P.J. Efficient removal of radioactive iodide ions from water by three-dimensional Ag2O-Ag/TiO2 composites under visible light irradiation. Hazard. Mater. 2015, 284, 171–181. [Google Scholar] [CrossRef]

- Zhang, X.; Maddock, J.; Nenoff, T.M.; Denecke, M.A.; Yang, S.; Schröder, M. Adsorption of iodine in metal–organic framework materials. Chem. Soc. Rev. 2022, 51, 3243–3262. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.-F.; Hu, H.-C.; Deng, S.-Q.; Cai, S.-L.; Fan, J.; Zhang, W.-G.; Zheng, S.-R. Ni(ii) metal–organic framework with helical channels for the capture of iodine via guest exchange induced amorphization. New J. Chem. 2022, 46, 7144–7152. [Google Scholar] [CrossRef]

- Song, Q.; Jiang, S.; Hasell, T.; Liu, M.; Sun, S.; Cheetham, A.K.; Sivaniah, E.; Cooper, A.I. Porous Organic Cage Thin Films and Molecular-Sieving Membranes. Adv. Mater. 2016, 28, 2629–2637. [Google Scholar] [CrossRef]

- Chen, Z.; Idrees, K.B.; Shetty, S.; Xie, H.; Wasson, M.C.; Gong, W.; Zhang, X.; Alameddine, B.; Farha, O.K. Regulation of Catenation in Metal–Organic Frameworks with Tunable Clathrochelate-Based Building Blocks. Cryst. Growth Des. 2021, 21, 6665–6670. [Google Scholar] [CrossRef]

- Selin, R.O.; Klemt, I.; Chernii, V.Y.; Losytskyy, M.Y.; Chernii, S.; Mular, A.; Gumienna-Kontecka, E.; Kovalska, V.B.; Voloshin, Y.Z.; Vologzhanina, A.V.; et al. Synthesis and spectral characterization of the first fluorescein-tagged iron(ii) clathrochelates, their supramolecular interactions with globular proteins, and cellular uptake. RSC Adv. 2021, 11, 8163–8177. [Google Scholar] [CrossRef] [PubMed]

- Planes, O.M.; Jansze, S.M.; Scopelliti, R.; Fadaei-Tirani, F.; Severin, K. Two-Step Synthesis of Linear and Bent Dicarboxylic Acid Metalloligands with Lengths of up to 3 nm. Inorg. Chem. 2020, 59, 14544–14548. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Synthesis of secondary arylamine copolymers with Iron(II) clathrochelate units and their functionalization into tertiary Polyarylamines via Buchwald-Hartwig cross-coupling reaction. Polymer 2019, 178, 121606. [Google Scholar] [CrossRef]

- Alameddine, B.; Shetty, S.; Anju, R.S.; Al-Sagheer, F.; Al-Mousawi, S. Highly soluble metal-organic polymers based on iron(II) clathrochelates and their gelation induced by sonication. Eur. Polym. J. 2017, 95, 566–574. [Google Scholar] [CrossRef]

- Cecot, G.; Alameddine, B.; Prior, S.; Zorzi, R.D.; Geremia, S.; Scopelliti, R.; Fadaei, F.T.; Solari, E.; Severin, K. Large heterometallic coordination cages with gyrobifastigium-like geometry. Chem. Commun. 2016, 52, 11243–11246. [Google Scholar] [CrossRef]

- Gong, W.; Xie, Y.; Pham, T.D.; Shetty, S.; Son, F.A.; Idrees, K.B.; Chen, Z.; Xie, H.; Liu, Y.; Snurr, R.Q.; et al. Creating Optimal Pockets in a Clathrochelate-Based Metal–Organic Framework for Gas Adsorption and Separation: Experimental and Computational Studies. J. Am. Chem. Soc. 2022, 144, 3737–3745. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Al-Mousawi, S.; Alameddine, B. Removal of anionic and cationic dyes using porous copolymer networks made from a Sonogashira cross-coupling reaction of diethynyl iron (II) clathrochelate with various arylamines. J. Appl. Polym. Sci. 2022, e52966. [Google Scholar] [CrossRef]

- Denisov, G.; Novikov, V.V.; Belova, S.A.; Belov, A.; Melnikova, E.; Aysin, R.; Voloshin, Y.Z.; Nelyubina, Y.V. First Iron(II) Clathrochelate with a Temperature-Induced Spin Crossover to an Elusive High-Spin State. Cryst. Growth Des. 2021, 21, 4594–4606. [Google Scholar] [CrossRef]

- Shetty, S.; Baig, N.; Hassan, A.; Al-Mousawi, S.; Das, N.; Alameddine, B. Fluorinated Iron(ii) clathrochelate units in metalorganic based copolymers: Improved porosity, iodine uptake, and dye adsorption properties. RSC Adv. 2021, 11, 14986–14995. [Google Scholar] [CrossRef] [PubMed]

- Alameddine, B.; Shetty, S.; Baig, N.; Al-Mousawi, S.; Al-Sagheer, F. Synthesis and characterization of metalorganic polymers of intrinsic microporosity based on iron(II) clathrochelate. Polymer 2017, 122, 200–207. [Google Scholar] [CrossRef]

- Alameddine, B.; Baig, N.; Shetty, S.; Al-Sagheer, F.; Al-Mousawi, S. Microwave-Assisted [4+2] Diels–Alder Cycloaddition of 1,4-Diethynyl Triptycene with Various Cyclopentadienone Derivatives: Promising Building Blocks for Polymer Networks. Asian J. Org. Chem. 2018, 7, 378–382. [Google Scholar] [CrossRef]

- Alameddine, B.; Sobhana Anju, R.; Shetty, S.; Baig, N.; Al-Mousawi, S.; Al-Sagheer, F. Direct synthesis of polyaromatic chains of tribenzopentaphene copolymers through cyclodehydrogenation of their poly-tetraphenylbenzene precursors. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 3565–3572. [Google Scholar] [CrossRef]

- Zhou, B.; Chen, Z.; Feng, S.; Wang, D.; Liu, H. Engineering Functionality in Organic Porous Networks by Multicomponent Polymerization. Macromolecules 2021, 54, 7642–7652. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Synthesis of triptycene-derived covalent organic polymer networks and their subsequent in-situ functionalization with 1,2-dicarbonyl substituents. React. Funct. Polym. 2019, 139, 153–161. [Google Scholar] [CrossRef]

- Alameddine, B.; Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F. Tuning the optical properties of ethynylene triptycene-based copolymers via oxidation of their alkyne groups into α-diketones. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 931–937. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Moustafa, M.S.; Al-Mousawi, S.; Alameddine, B. Selective removal of toxic organic dyes using Trӧger base-containing sulfone copolymers made from a metal-free thiol-yne click reaction followed by oxidation. RSC Adv. 2021, 11, 21170–21178. [Google Scholar] [CrossRef]

- Alameddine, B.; Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F. Triptycene-containing Poly(vinylene sulfone) derivatives from a metal-free thiol-yne click polymerization followed by a mild oxidation reaction. Polymer 2018, 154, 233–240. [Google Scholar] [CrossRef]

- Mondal, S.; Banthia, A.K. Low-temperature synthetic route for boron carbide. J. Eur. Ceram. Soc. 2005, 25, 287–291. [Google Scholar] [CrossRef]

- Louette, P.; Bodino, F.; Pireaux, J.-J. Poly(sulfone resin) XPS Reference Core Level and Energy Loss Spectra. Surf. Sci. Spectra 2005, 12, 100–105. [Google Scholar] [CrossRef]

- Castner, D.G.; Hinds, K.; Grainger, D.W. X-ray Photoelectron Spectroscopy Sulfur 2p Study of Organic Thiol and Disulfide Binding Interactions with Gold Surfaces. Langmuir 1996, 12, 5083–5086. [Google Scholar] [CrossRef]

- Baig, N.; Shetty, S.; Al-Mousawi, S.; Al-Sagheer, F.; Alameddine, B. Influence of size and nature of the aryl diborate spacer on the intrinsic microporosity of Iron(II) clathrochelate polymers. Polymer 2018, 151, 164–170. [Google Scholar] [CrossRef]

- Hastings, A.M.; Ray, D.; Hanna, S.L.; Jeong, W.; Chen, Z.; Oliver, A.G.; Gagliardi, L.; Farha, O.K.; Hixon, A.E. Leveraging Nitrogen Linkages in the Formation of a Porous Thorium–Organic Nanotube Suitable for Iodine Capture. Inorg. Chem. 2022, 61, 9480–9492. [Google Scholar] [CrossRef] [PubMed]

- Tang, P.-H.; So, P.B.; Lee, K.-R.; Lai, Y.-L.; Lee, C.-S.; Lin, C.-H. Metal Organic Framework-Polyethersulfone Composite Membrane for Iodine Capture. Polymers 2020, 12, 2309. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Liang, D.; Liu, D.; Liu, Q. Preparation and characterization of three-dimensional hierarchical porous carbon from low-rank coal by hydrothermal carbonization for efficient iodine removal. RSC Adv. 2022, 12, 3062–3072. [Google Scholar] [CrossRef]

- He, L.; Chen, L.; Dong, X.; Zhang, S.; Zhang, M.; Dai, X.; Liu, X.; Lin, P.; Li, K.; Chen, C.; et al. A nitrogen-rich covalent organic framework for simultaneous dynamic capture of iodine and methyl iodide. Chem 2021, 7, 699–714. [Google Scholar] [CrossRef]

- Yadollahi, M.; Hamadi, H.; Nobakht, V. Capture of iodine in solution and vapor phases by newly synthesized and characterized encapsulated Cu2O nanoparticles into the TMU-17-NH2 MOF. J. Hazard. Mater. 2020, 399, 122872. [Google Scholar] [CrossRef]

- Sahoo, T.R.; Prelot, B. Nanomaterials for the Detection and Removal of Wastewater Pollutants; Bonelli, B., Freyria, F.S., Rossetti, I., Sethi, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 161–222. [Google Scholar] [CrossRef]

- Liao, Y.; Weber, J.; Mills, B.M.; Ren, Z.; Faul, C.F.J. Highly Efficient and Reversible Iodine Capture in Hexaphenylbenzene-Based Conjugated Microporous Polymers. Macromolecules 2016, 49, 6322–6363. [Google Scholar] [CrossRef] [Green Version]

| Entry | Product | Time in Days | CM a [M] | Yield (%) | Mn g mol−1 | Mw g mol−1 | Đ |

|---|---|---|---|---|---|---|---|

| 1 | CTP1 | 1 | 5.0 | 67 | 3672 | 10,115 | 2.8 |

| 2 | CTP1 | 2 | 5.0 | 30 | 8827 | 40,396 | 4.6 |

| 3 | CTP1 | 3 | 2.5 | 45 | 3524 | 10,026 | 2.8 |

| 4 | CTP1 | 3 | 1.0 | 52 | 4989 | 9682 | 1.9 |

| 5 | CTP1 | 5 | 2.5 | 91 | 5381 | 9554 | 1.8 |

| 6 | CTP2 | 5 | 2.5 | 93 | insoluble | - | - |

| 7 | CTP3 | 5 | 2.5 | 90 | insoluble | - | - |

| Entry | Copolymer | T (°C) | Time (min) | Oxidized Copolymer | Yield % |

|---|---|---|---|---|---|

| 1 | CTP1 | 30 | 60 | No reaction | - |

| 2 | CTP1 | 50 | 60 | No reaction | - |

| 3 | CTP1 | 100 | 60 | Decomposed | - |

| 4 | CTP1 | 90 | 10 | CTP4 | 93 |

| 5 | CTP2 | 90 | 30 | CTP5 | 98 |

| 6 | CTP3 | 90 | 30 | CTP6 | 97 |

| Entry | Copolymer | I2 Adsorption (mg g−1) after 24 h |

|---|---|---|

| 1 | CTP1 | 1240 |

| 2 | CTP2 | 2360 |

| 3 | CTP3 | 1510 |

| 4 | CTP4 | 1140 a |

| 5 | CTP5 | 1380 b |

| 6 | CTP6 | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baig, N.; Shetty, S.; Habib, S.S.; Husain, A.A.; Al-Mousawi, S.; Alameddine, B. Synthesis of Iron(II) Clathrochelate-Based Poly(vinylene sulfide) with Tetraphenylbenzene Bridging Units and Their Selective Oxidation into Their Corresponding Poly(vinylene sulfone) Copolymers: Promising Materials for Iodine Capture. Polymers 2022, 14, 3727. https://doi.org/10.3390/polym14183727

Baig N, Shetty S, Habib SS, Husain AA, Al-Mousawi S, Alameddine B. Synthesis of Iron(II) Clathrochelate-Based Poly(vinylene sulfide) with Tetraphenylbenzene Bridging Units and Their Selective Oxidation into Their Corresponding Poly(vinylene sulfone) Copolymers: Promising Materials for Iodine Capture. Polymers. 2022; 14(18):3727. https://doi.org/10.3390/polym14183727

Chicago/Turabian StyleBaig, Noorullah, Suchetha Shetty, Sameh S. Habib, Ali A. Husain, Saleh Al-Mousawi, and Bassam Alameddine. 2022. "Synthesis of Iron(II) Clathrochelate-Based Poly(vinylene sulfide) with Tetraphenylbenzene Bridging Units and Their Selective Oxidation into Their Corresponding Poly(vinylene sulfone) Copolymers: Promising Materials for Iodine Capture" Polymers 14, no. 18: 3727. https://doi.org/10.3390/polym14183727

APA StyleBaig, N., Shetty, S., Habib, S. S., Husain, A. A., Al-Mousawi, S., & Alameddine, B. (2022). Synthesis of Iron(II) Clathrochelate-Based Poly(vinylene sulfide) with Tetraphenylbenzene Bridging Units and Their Selective Oxidation into Their Corresponding Poly(vinylene sulfone) Copolymers: Promising Materials for Iodine Capture. Polymers, 14(18), 3727. https://doi.org/10.3390/polym14183727