Research Progresses in Microstructure Designs of Flexible Pressure Sensors

Abstract

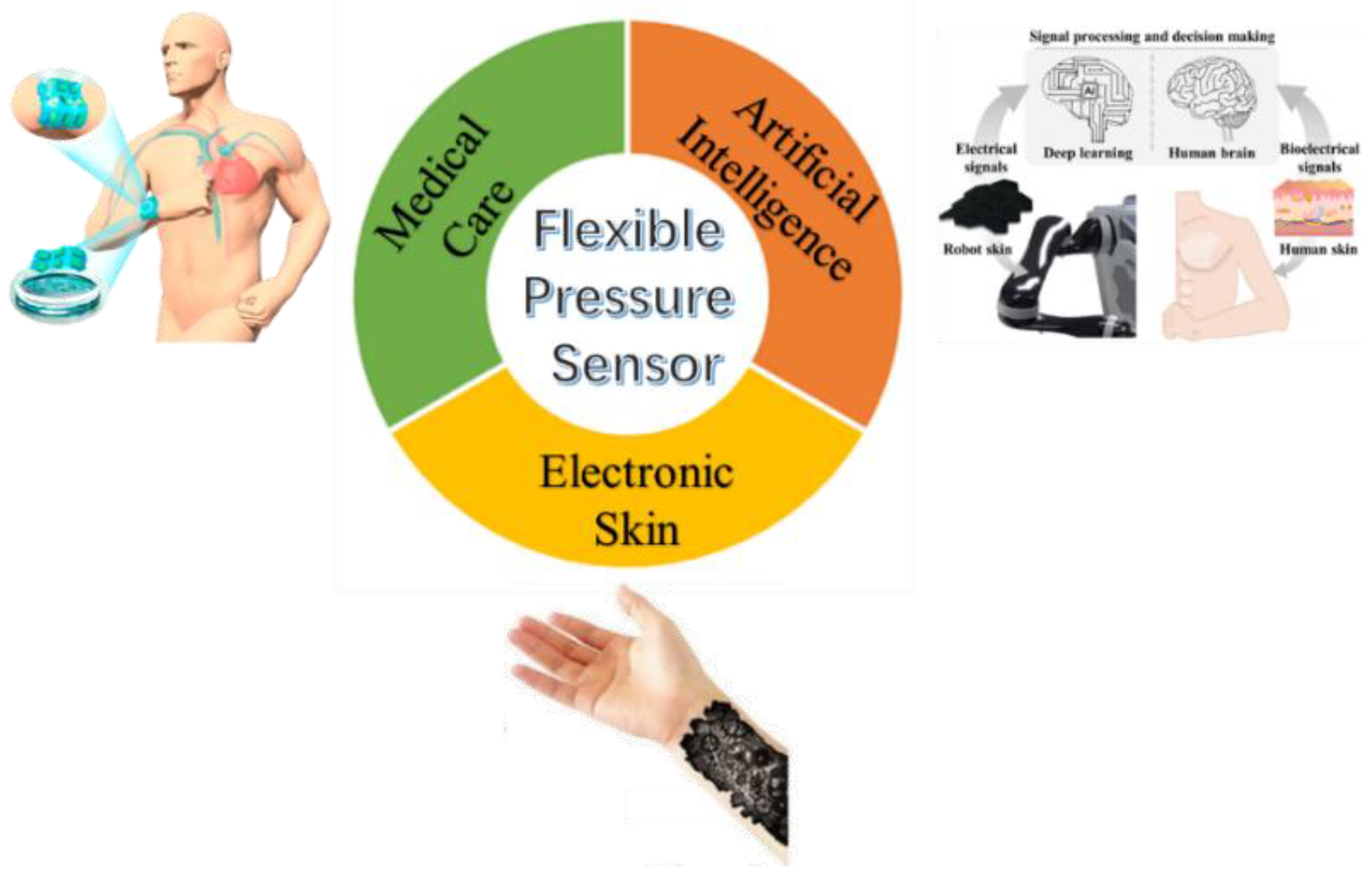

:1. Introduction

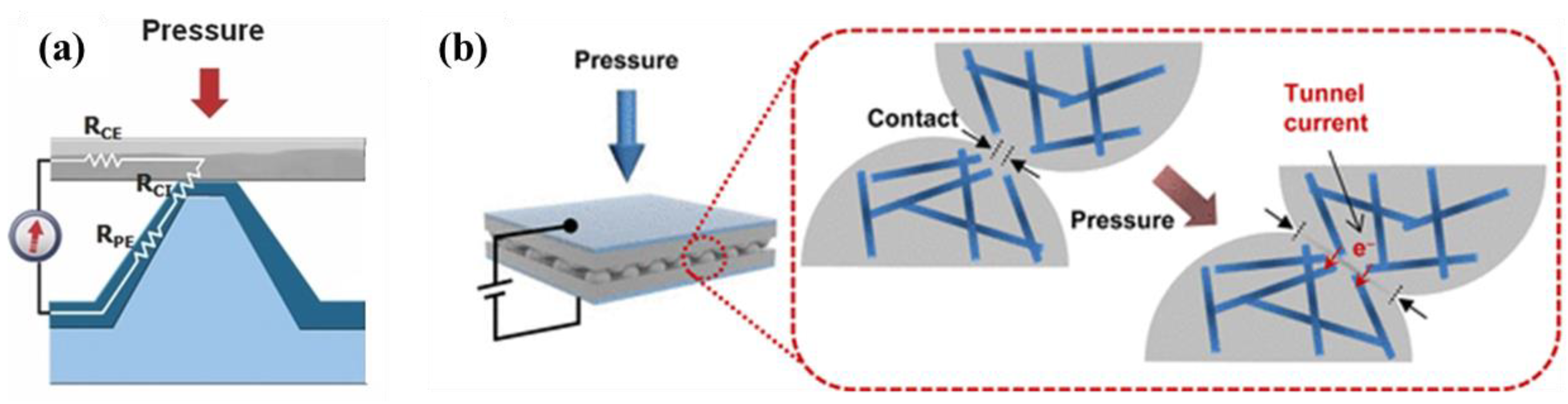

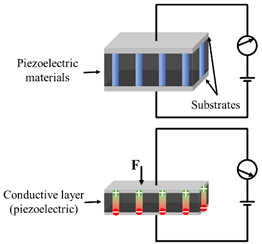

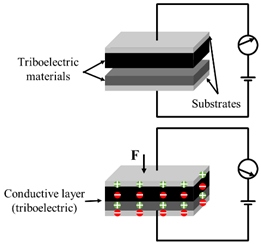

2. Sensor Types and Microstructure Mechanism

2.1. The Types of Flexible Pressure Sensor

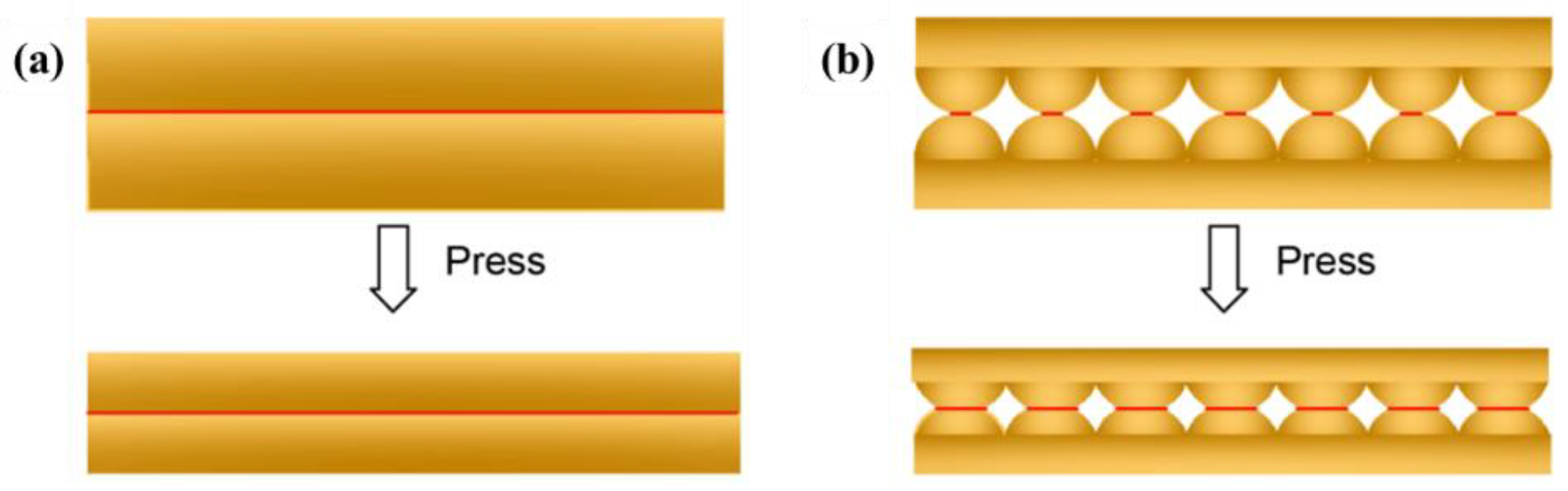

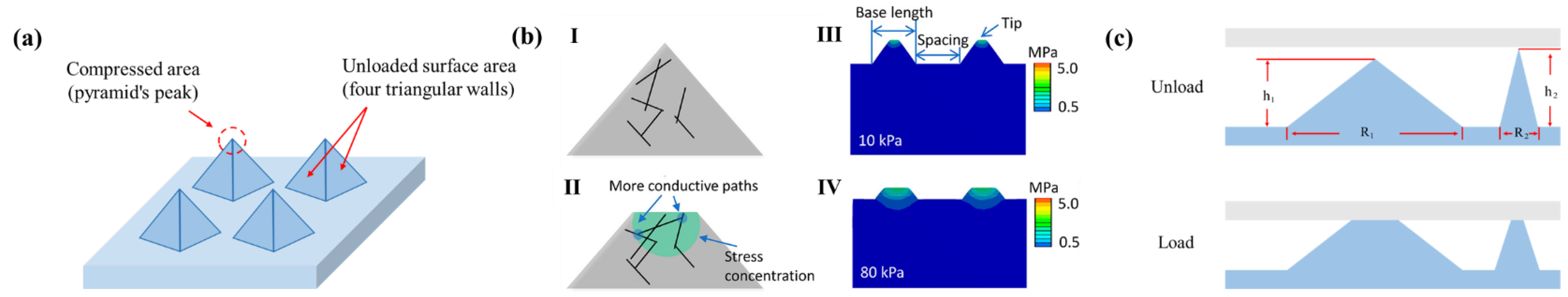

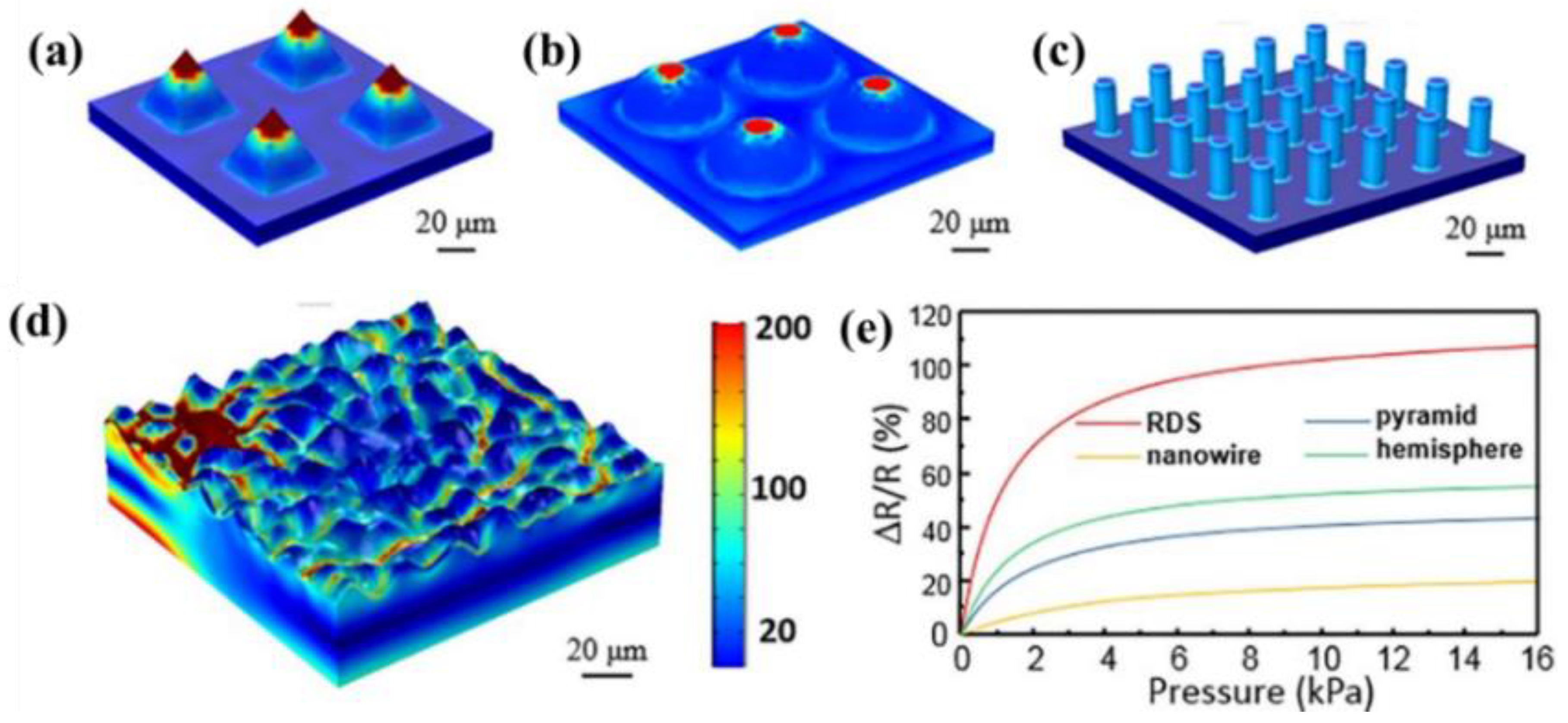

2.2. The Mechanism of Microstructure

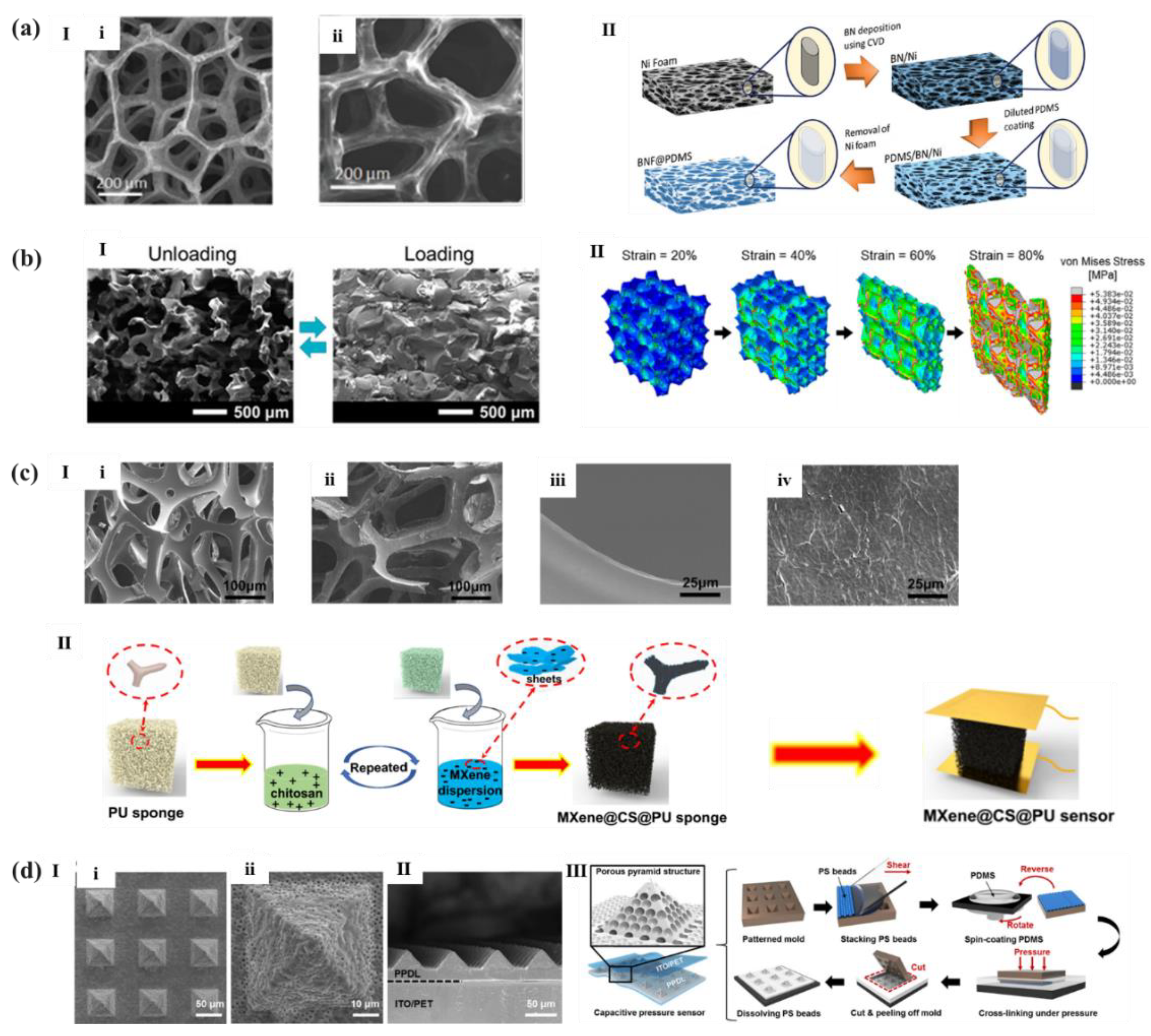

3. Microstructure Design

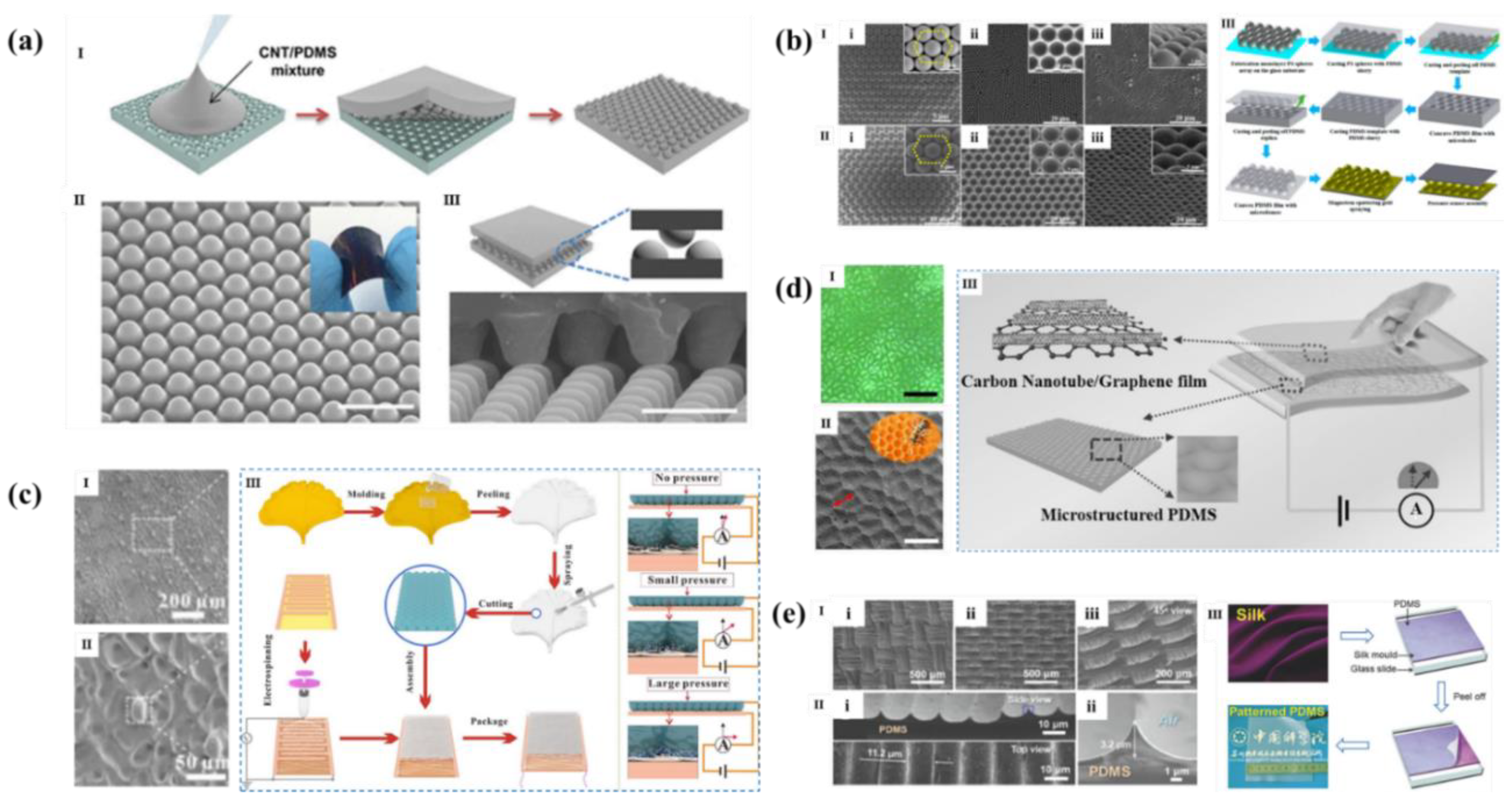

3.1. Sharp Bulge Microstructures

3.2. Micro Fluctuation Structures

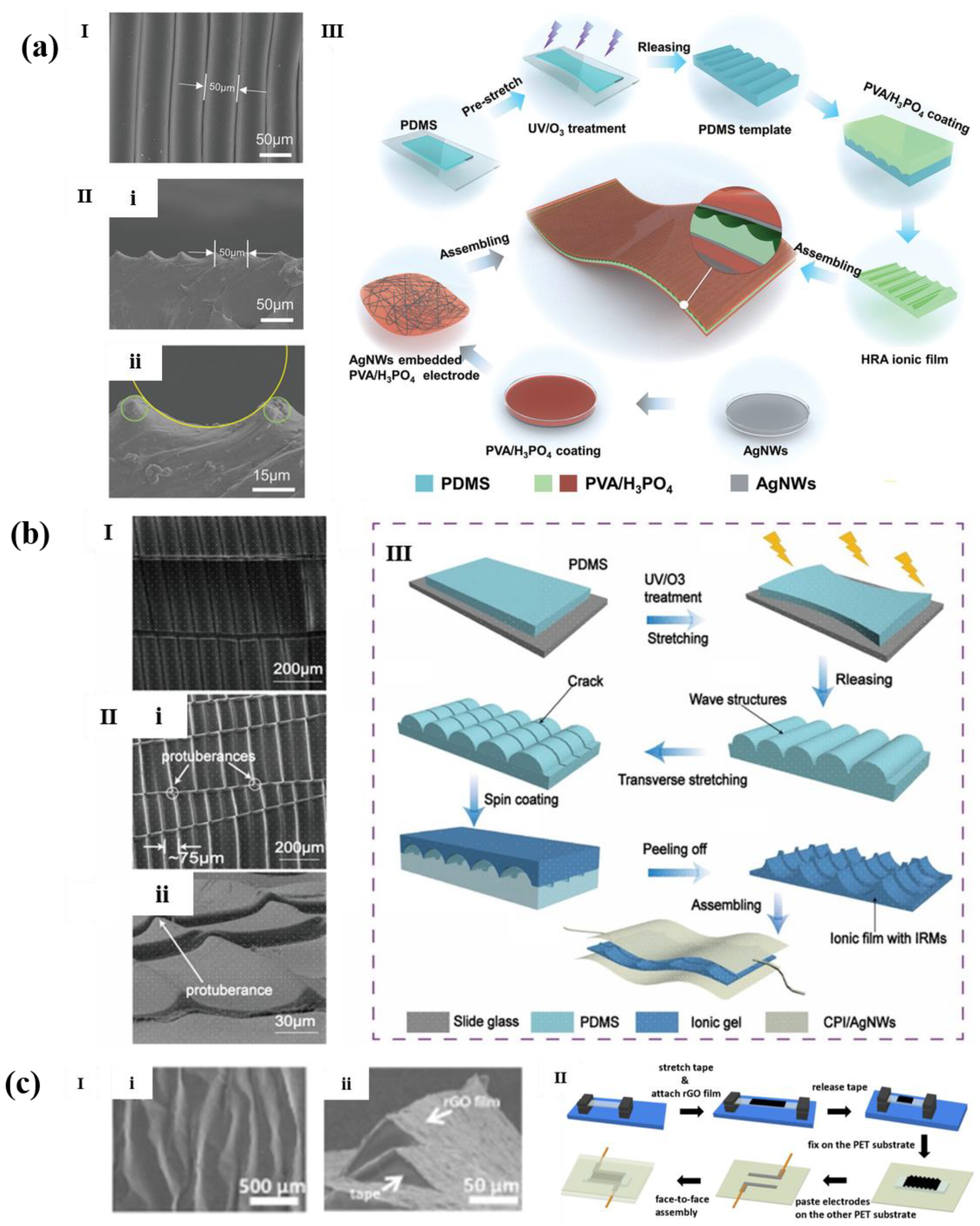

3.3. Wave/Ridge Microstructures

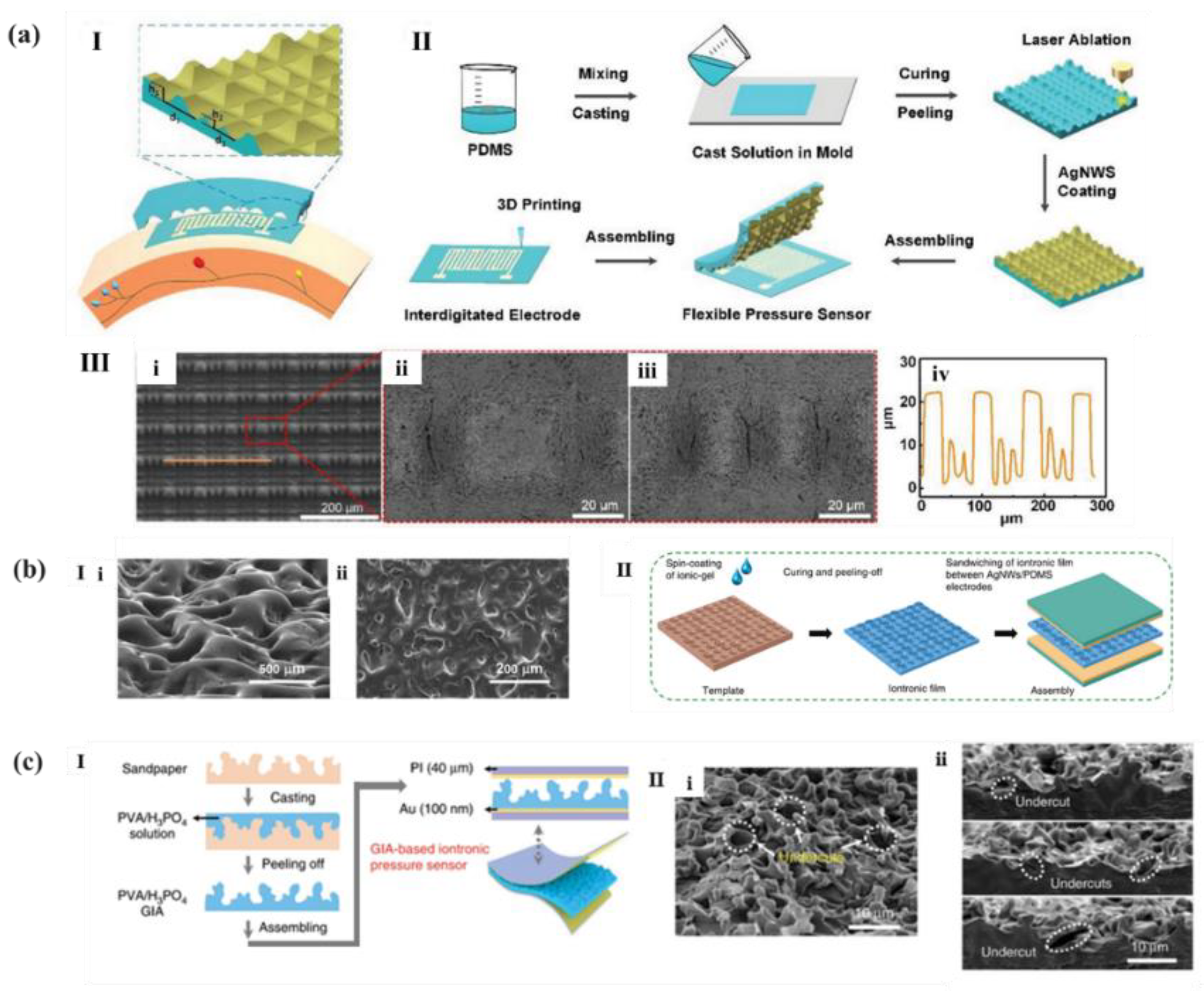

3.4. Hierarchical Microstructures

3.5. Composite Microstructures

3.6. Porous Microstructures

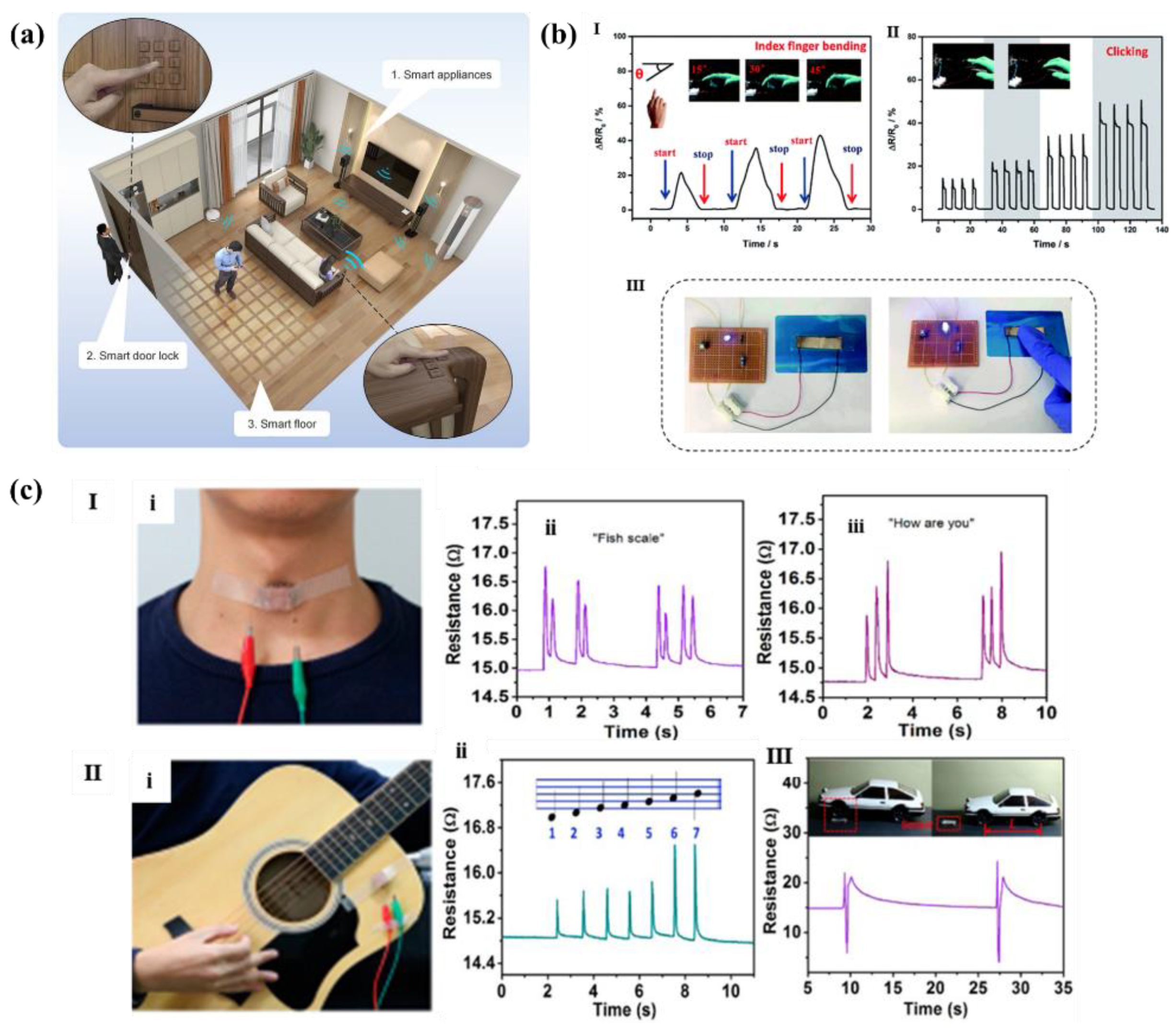

4. Applications

4.1. Sports, Health Monitoring and Wearable Devices

4.2. Tactile Perception and Electronic Skin

4.3. Other Applications

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, C.Q.; Zou, Z.N.; Lei, Z.P.; Zhu, P.C.; Zhang, W.; Xiao, J.L. Heterogeneous integration of rigid, soft, and liquid materials for self-healable, recyclable, and reconfigurable wearable electronics. Sci. Adv. 2020, 6, d202. [Google Scholar] [CrossRef] [PubMed]

- Kireev, D.; Sel, K.; Ibrahim, B.; Kumar, N.; Akbari, A.; Jafari, R.; Akinwande, D. Continuous cuffless monitoring of arterial blood pressure via graphene bioimpedance tattoos. Nat. Nanotechnol. 2022. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wang, W.; Jiang, Y.; Wang, Y.; Wu, Y.; Lai, J.; Niu, S.; Xu, C.; Shih, C.; Wang, C.; et al. High-brightness all-polymer stretchable LED with charge-trapping dilution. Nature 2022, 603, 624–630. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.Q.; Liu, Y.; Zhong, D.; Nikzad, S.; Liu, S.; Yu, Z.; Liu, D.; Wu, H.C.; Zhu, C.; Li, J.; et al. Monolithic optical microlithography of high-density elastic circuits. Science 2021, 373, 88–94. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.; Xu, L.; Zhang, H.; Yang, Y.; Wang, Z.L. Hierarchically patterned self-powered sensors for multifunctional tactile sensing. Sci. Adv. 2020, 6, b9083. [Google Scholar] [CrossRef]

- Zhu, B.; Ma, C.; Qian, Z.; Ren, L.; Yuan, H. Highly Stretchable and Sensitive Multimodal Tactile Sensor Based on Conductive Rubber Composites to Monitor Pressure and Temperature. Polymers 2022, 14, 1294. [Google Scholar] [CrossRef]

- Hayward, J. Wearable Technology Forecasts 2021–2031; IDTechEx: Cambridge, UK, 2021. [Google Scholar]

- Kong, D.; Yang, G.; Pang, G.; Ye, Z.; Lv, H.; Yu, Z.; Wang, F.; Wang, X.V.; Xu, K.; Yang, H. Bioinspired Co-Design of Tactile Sensor and Deep Learning Algorithm for Human–Robot Interaction. Adv. Intell. Syst. 2022, 4, 2200050. [Google Scholar] [CrossRef]

- Xia, P.; Liu, P.; Wu, S.; Zhang, Q.; Wang, P.; Hu, R.; Xing, K.; Liu, C.; Song, A.; Yang, X.; et al. Highly stretchable and sensitive flexible resistive strain sensor based on waterborne polyurethane polymer for wearable electronics. Compos. Sci. Technol. 2022, 221, 109355. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, M.; Yu, H.; Abdalkarim, S.Y.H.; Ouyang, Z.; Zhu, J.; Yao, J. Multifunctional Biosensors Made with Self-Healable Silk Fibroin Imitating Skin. ACS Appl. Mater. Inter. 2021, 13, 33371–33382. [Google Scholar] [CrossRef]

- Gao, J.; Fan, Y.; Zhang, Q.; Luo, L.; Hu, X.; Li, Y.; Song, J.; Jiang, H.; Gao, X.; Zheng, L.; et al. Ultra-Robust and Extensible Fibrous Mechanical Sensors for Wearable Smart Healthcare. Adv. Mater. 2022, 34, 2107511. [Google Scholar]

- Ha, K.H.; Zhang, W.; Jang, H.; Kang, S.; Wang, L.; Tan, P.; Hwang, H.; Lu, N. Highly Sensitive Capacitive Pressure Sensors over a Wide Pressure Range Enabled by the Hybrid Responses of a Highly Porous Nanocomposite. Adv. Mater. 2021, 33, 2103320. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Gao, X.; Wang, Y.; Niu, X.; Wang, T.; Liu, Y.; Qi, F.; Jiang, Y.; Liu, H. Development of High-Sensitivity Piezoresistive Sensors Based on Highly Breathable Spacer Fabric with TPU/PPy/PDA Coating. Polymers 2022, 14, 859. [Google Scholar] [CrossRef] [PubMed]

- Tai, G.; Wei, D.; Su, M.; Li, P.; Xie, L.; Yang, J. Force-Sensitive Interface Engineering in Flexible Pressure Sensors: A Review. Sensors 2022, 22, 2652. [Google Scholar] [CrossRef] [PubMed]

- Duan, Y.; He, S.; Wu, J.; Su, B.; Wang, Y. Recent Progress in Flexible Pressure Sensor Arrays. Nanomaterials 2022, 12, 2495. [Google Scholar] [CrossRef] [PubMed]

- Chao, M.; He, L.; Gong, M.; Li, N.; Li, X.; Peng, L.; Shi, F.; Zhang, L.; Wan, P. Breathable Ti3 C2 Tx MXene/Protein Nanocomposites for Ultrasensitive Medical Pressure Sensor with Degradability in Solvents. ACS Nano 2021, 15, 9746–9758. [Google Scholar] [CrossRef]

- Long, Z.; Liu, X.; Xu, J.; Huang, Y.; Wang, Z. High-Sensitivity Flexible Piezoresistive Pressure Sensor Using PDMS/MWNTS Nanocomposite Membrane Reinforced with Isopropanol for Pulse Detection. Sensors 2022, 22, 4765. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, L.; Liu, Z. Intentional Blocking Based Photoelectric Soft Pressure Sensor with High Sensitivity and Stability. Soft Robot. 2022. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Hou, X.; Li, G.; Wang, L.; Bai, N.; Cai, M.; Zhao, L.; Wang, Y.; Zhang, J.; et al. Highly stable flexible pressure sensors with a quasi-homogeneous composition and interlinked interfaces. Nat. Commun. 2022, 13, 1317. [Google Scholar] [CrossRef]

- Zou, B.; Chen, Y.; Liu, Y.; Xie, R.; Du, Q.; Zhang, T.; Shen, Y.; Zheng, B.; Li, S.; Wu, J.; et al. Repurposed Leather with Sensing Capabilities for Multifunctional Electronic Skin. Adv. Sci. 2018, 6, 1801283. [Google Scholar] [CrossRef]

- Kang, K.; Jung, H.; An, S.; Baac, H.W.; Shin, M.; Son, D. Skin-like Transparent Polymer-Hydrogel Hybrid Pressure Sensor with Pyramid Microstructures. Polymers 2021, 13, 3272. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Yang, H.; Oh, J.H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Compos. Part B Eng. 2021, 211, 108607. [Google Scholar] [CrossRef]

- Tan, X.; Zheng, J. A Novel Porous PDMS-AgNWs-PDMS (PAP)-Sponge-Based Capacitive Pressure Sensor. Polymers 2022, 14, 1495. [Google Scholar] [CrossRef] [PubMed]

- Ariati, R.; Sales, F.; Souza, A.; Lima, R.A.; Ribeiro, J. Polydimethylsiloxane Composites Characterization and Its Applications: A Review. Polymers 2021, 13, 4258. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Qiu, Z.; Hong, Y.; Wang, Y.; Zhang, J.; Liu, Q.; Wu, Z.; Guo, C.F. A Highly Sensitive Flexible Capacitive Tactile Sensor with Sparse and High-Aspect-Ratio Microstructures. Adv. Electron. Mater. 2018, 4, 1700586. [Google Scholar] [CrossRef]

- Kim, S.J.; Mondal, S.; Min, B.K.; Choi, C. Highly Sensitive and Flexible Strain–Pressure Sensors with Cracked Paddy-Shaped MoS2/Graphene Foam/Ecoflex Hybrid Nanostructures. ACS Appl. Mater. Inter. 2018, 10, 36377–36384. [Google Scholar] [CrossRef]

- Balderrama, V.S.; Leon-Gil, J.A.; Fernandez-Benavides, D.A.; Ponce-Hernandez, J.; Bandala-Sanchez, M.; Vazquez, V.B. MEMS Piezoresistive Pressure Sensor Based on Flexible PET Thin-Film for Applications in Gaseous-Environments. IEEE Sens. J. 2022, 22, 1939–1947. [Google Scholar] [CrossRef]

- Chen, W.J.; Gui, X.C.; Liang, B.H.; Yang, R.L.; Zheng, Y.J.; Zhao, C.C.; Li, X.M.; Zhu, H.; Tang, Z.K. Structural Engineering for High Sensitivity, Ultrathin Pressure Sensors Based on Wrinkled Graphene and Anodic Aluminum Oxide Membrane. ACS Appl. Mater. Inter. 2017, 9, 24111–24117. [Google Scholar] [CrossRef]

- Kim, S.; Amjadi, M.; Lee, T.I.; Jeong, Y.; Kwon, D.; Kim, M.S.; Kim, K.; Kim, T.S.; Oh, Y.S.; Park, I. Wearable, Ultrawide-Range, and Bending-Insensitive Pressure Sensor Based on Carbon Nanotube Network-Coated Porous Elastomer Sponges for Human Interface and Healthcare Devices. ACS Appl. Mater. Inter. 2019, 11, 23639–23648. [Google Scholar] [CrossRef]

- Cui, J.; Nan, X.; Shao, G.; Sun, H. High-Sensitivity Flexible Pressure Sensor-Based 3 D CNTs Sponge for Human–Computer Interaction. Polymers 2021, 13, 3465. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H.; Yuan, W.; Li, Y.; Gao, P.; Tiwari, N.; Chen, X.; Wang, Z.; Niu, G.; Cheng, H. Wearable Pressure Sensors Based on MXene/Tissue Papers for Wireless Human Health Monitoring. ACS Appl. Mater. Inter. 2021, 13, 60531–60543. [Google Scholar] [CrossRef]

- Su, Y.; Ma, K.; Mao, X.; Liu, M.; Zhang, X. Highly Compressible and Sensitive Flexible Piezoresistive Pressure Sensor Based on MWCNTs/Ti3 C2 Tx MXene @ Melamine Foam for Human Gesture Monitoring and Recognition. Nanomaterials 2022, 12, 2225. [Google Scholar] [CrossRef] [PubMed]

- Ju, Y.H.; Han, C.J.; Kim, K.S.; Kim, J.W. UV-Curable Adhesive Tape-Assisted Patterning of Metal Nanowires for Ultrasimple Fabrication of Stretchable Pressure Sensor. Adv. Mater. Technol. 2021, 6, 2100776. [Google Scholar] [CrossRef]

- Yoo, J.I.; Kim, S.H.; Ko, H.C. Stick-and-play system based on interfacial adhesion control enhanced by micro/nanostructures. Nano Res. 2021, 14, 3143–3158. [Google Scholar] [CrossRef]

- Dos Santos, A.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Transduction Mechanisms, Micro-Structuring Techniques, and Applications of Electronic Skin Pressure Sensors: A Review of Recent Advances. Sensors 2020, 20, 4407. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, S.; Yue, W.; Zhang, C.; Li, Y. Anodized Aluminum Oxide-Assisted Low-Cost Flexible Capacitive Pressure Sensors Based on Double-Sided Nanopillars by a Facile Fabrication Method. ACS Appl. Mater. Interfaces 2019, 11, 48594–48603. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Li, C.; Xie, K.; Zhu, P.; Shao, B.; Zhang, J.; Yang, J.; Zhang, J.; Wang, Q.; et al. Highly Transparent and Flexible Iontronic Pressure Sensors Based on an Opaque to Transparent Transition. Adv. Sci. 2020, 7, 2000348. [Google Scholar]

- Choong, C.; Shim, M.; Lee, B.; Jeon, S.; Ko, D.; Kang, T.; Bae, J.; Lee, S.H.; Byun, K.; Im, J.; et al. Highly Stretchable Resistive Pressure Sensors Using a Conductive Elastomeric Composite on a Micropyramid Array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef]

- Chen, L.; Chen, G.H.; Lu, L. Piezoresistive Behavior Study on Finger-Sensing Silicone Rubber/Graphite Nanosheet Nanocomposites. Adv. Funct. Mater. 2007, 17, 898–904. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Ha, M.; Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Giant Tunneling Piezoresistance of Composite Elastomers with Interlocked Microdome Arrays for Ultrasensitive and Multimodal Electronic Skins. ACS Nano 2014, 8, 4689–4697. [Google Scholar] [CrossRef]

- Cui, X.H.; Huang, F.L.; Zhang, X.C.; Song, P.A.; Zheng, H.; Chevali, V.; Wang, H.; Xu, Z.G. Flexible pressure sensors via engineering microstructures for wearable human-machine interaction and health monitoring applications. iScience 2022, 25, 104148. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Xu, D.; Huang, Y.; Wang, P.; Huang, J.; Zhou, J.; Liu, W.; Li, S.; Huang, Y.; Duan, X. Robust Flexible Pressure Sensors Made from Conductive Micropyramids for Manipulation Tasks. ACS Nano 2020, 14, 12866–12876. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Nie, P.; Wang, R.; Sun, J. Piezoresistive electronic skin based on diverse bionic microstructure. Sens. Actuators A Phys. 2021, 318, 112532. [Google Scholar] [CrossRef]

- Zhu, B.; Niu, Z.; Wang, H.; Leow, W.R.; Wang, H.; Li, Y.; Zheng, L.; Wei, J.; Huo, F.; Chen, X. Microstructured Graphene Arrays for Highly Sensitive Flexible Tactile Sensors. Small 2014, 10, 3625–3631. [Google Scholar] [CrossRef]

- Huang, Z.; Gao, M.; Yan, Z.; Pan, T.; Khan, S.A.; Zhang, Y.; Zhang, H.; Lin, Y. Pyramid microstructure with single walled carbon nanotubes for flexible and transparent micro-pressure sensor with ultra-high sensitivity. Sens. Actuators A Phys. 2017, 266, 345–351. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Song, R.; Fang, C.; Wang, Z.; Wang, C.; Huang, Y. Freestanding silver/polypyrrole composite film for multifunctional sensor with biomimetic micropattern for physiological signals monitoring. Chem. Eng. J. 2021, 404, 126940. [Google Scholar] [CrossRef]

- Yao, G.; Xu, L.; Cheng, X.; Li, Y.; Huang, X.; Guo, W.; Liu, S.; Wang, Z.L.; Wu, H. Bioinspired Triboelectric Nanogenerators as Self-Powered Electronic Skin for Robotic Tactile Sensing. Adv. Funct. Mater. 2019, 30, 1907312. [Google Scholar] [CrossRef]

- Yu, S.; Li, L.; Wang, J.; Liu, E.; Zhao, J.; Xu, F.; Cao, Y.; Lu, C. Light-Boosting Highly Sensitive Pressure Sensors Based on Bioinspired Multiscale Surface Structures. Adv. Funct. Mater. 2020, 30, 1907091. [Google Scholar] [CrossRef]

- Fan, Z.; Chen, J.; Zou, J.; Bullen, D.; Liu, C.; Delcomyn, F. Design and fabrication of artificial lateral line flow sensors. J. Micromech. Microeng. 2002, 12, 655–661. [Google Scholar] [CrossRef]

- Alfadhel, A.; Kosel, J. Magnetic Nanocomposite Cilia Tactile Sensor. Adv. Mater. 2015, 27, 7888–7892. [Google Scholar] [CrossRef]

- Lin, M.; Cheng, C.; Yang, C.; Hsiao, W.; Yang, C. A wearable and highly sensitive capacitive pressure sensor integrated a dual-layer dielectric layer of PDMS microcylinder array and PVDF electrospun fiber. Org. Electron. 2021, 98, 106290. [Google Scholar] [CrossRef]

- Li, X.; Huang, W.; Yao, G.; Gao, M.; Wei, X.; Liu, Z.; Zhang, H.; Gong, T.; Yu, B. Highly sensitive flexible tactile sensors based on microstructured multiwall carbon nanotube arrays. Scr. Mater. 2017, 129, 61–64. [Google Scholar] [CrossRef]

- Li, H.; Wu, K.; Xu, Z.; Wang, Z.; Meng, Y.; Li, L. Ultrahigh-Sensitivity Piezoresistive Pressure Sensors for Detection of Tiny Pressure. ACS Appl. Mater. Inter. 2018, 10, 20826–20834. [Google Scholar] [CrossRef]

- Zhu, B.; Ling, Y.; Yap, L.W.; Yang, M.; Lin, F.; Gong, S.; Wang, Y.; An, T.; Zhao, Y.; Cheng, W. Hierarchically Structured Vertical Gold Nanowire Array-Based Wearable Pressure Sensors for Wireless Health Monitoring. ACS Appl. Mater. Inter. 2019, 11, 29014–29021. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. Piezoresistive E-Skin Sensors Produced with Laser Engraved Molds. Adv. Electron. Mater. 2018, 4, 1800182. [Google Scholar] [CrossRef]

- Nie, K.; Wang, Z.; Zhou, H.; Tang, R.; Shen, X.; Sun, Q. Improved dielectricity of anisotropic wood slices and bioinspired micropatterned film electrodes for highly sensitive flexible electronic sensors. J. Mater. Chem. C Mater. Opt. Electron. Devices 2020, 8, 11612–16113. [Google Scholar] [CrossRef]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible Capacitive Tactile Sensor Based on Micropatterned Dielectric Layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, S.; Lin, Y.; Yang, Z.; Liu, L. Cu–Ag core–shell nanowires for electronic skin with a petal molded microstructure. J. Mater. Chem. C 2015, 3, 9594–9602. [Google Scholar] [CrossRef]

- Yang, T.; Deng, W.; Chu, X.; Wang, X.; Hu, Y.; Fan, X.; Song, J.; Gao, Y.; Zhang, B.; Tian, G.; et al. Hierarchically Microstructure-Bioinspired Flexible Piezoresistive Bioelectronics. ACS Nano 2021, 15, 11555–11563. [Google Scholar] [CrossRef]

- Mahata, C.; Algadi, H.; Lee, J.; Kim, S.; Lee, T. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications. Measurement 2020, 151, 107095. [Google Scholar] [CrossRef]

- Qiu, Z.; Wan, Y.; Zhou, W.; Yang, J.; Yang, J.; Huang, J.; Zhang, J.; Liu, Q.; Huang, S.; Bai, N.; et al. Ionic Skin with Biomimetic Dielectric Layer Templated fromCalathea Zebrine Leaf. Adv. Funct. Mater. 2018, 28, 1802343. [Google Scholar] [CrossRef]

- Liu, Y.F.; Fu, Y.F.; Li, Y.Q.; Huang, P.; Xu, C.H.; Hu, N.; Fu, S.Y. Bio-inspired highly flexible dual-mode electronic cilia. J. Mater. Chem. B 2018, 6, 896–902. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Zhu, P.; Han, F.; Zhu, Y.; Sun, R.; Wong, C. Flexible and Highly Sensitive Pressure Sensor Based on Microdome-Patterned PDMS Forming with Assistance of Colloid Self-Assembly and Replica Technique for Wearable Electronics. ACS Appl. Mater. Inter. 2017, 9, 35968–35976. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Ma, Y.; Jia, G.; Zhao, S.; Yue, Y.; Cheng, F.; Zhang, C.; Cao, M.; Xiong, Y.; Shen, P.; et al. Bionic MXene based hybrid film design for an ultrasensitive piezoresistive pressure sensor. Chem. Eng. J. 2022, 431, 133458. [Google Scholar] [CrossRef]

- Jian, M.; Xia, K.; Wang, Q.; Yin, Z.; Wang, H.; Wang, C.; Xie, H.; Zhang, M.; Zhang, Y. Flexible and Highly Sensitive Pressure Sensors Based on Bionic Hierarchical Structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-Molded Flexible, Ultrasensitive, and Highly Stable Electronic Skin for Monitoring Human Physiological Signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, A.; Pinela, N.; Alves, P.; Santos, R.; Farinha, R.; Fortunato, E.; Martins, R.; Águas, H.; Igreja, R. E-Skin Bimodal Sensors for Robotics and Prosthesis Using PDMS Molds Engraved by Laser. Sensors 2019, 19, 899. [Google Scholar] [CrossRef]

- Gao, Y.; Lu, C.; Guohui, Y.; Sha, J.; Tan, J.; Xuan, F. Laser micro-structured pressure sensor with modulated sensitivity for electronic skins. Nanotechnology 2019, 30, 325502. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, L.; Liu, J.; Jiang, H.; Li, C. Flexible hemispheric microarrays of highly pressure-sensitive sensors based on breath figure method. Nanoscale 2018, 10, 10691–10698. [Google Scholar] [CrossRef]

- Jung, Y.; Choi, J.; Lee, W.; Ko, J.S.; Park, I.; Cho, H. Irregular Microdome Structure-Based Sensitive Pressure Sensor Using Internal Popping of Microspheres. Adv. Funct. Mater. 2022, 2201147. [Google Scholar] [CrossRef]

- Zhou, Q.; Ji, B.; Chen, G.; Ding, Y.; Wu, J.; She, J.; Wang, S.; Zhou, B. Lithography-Free Formation of Controllable Microdomes via Droplet Templates for Robust, Ultrasensitive, and Flexible Pressure Sensors. ACS Appl. Nano Mater. 2019, 2, 7178–7187. [Google Scholar] [CrossRef]

- Xiong, Y.; Shen, Y.; Tian, L.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Yu, Y.; Zhu, P.; Song, Q.; Deng, Y. High-Sensitivity Flexible Pressure Sensor with Low Working Voltage Based on Sphenoid Microstructure. IEEE Sens. J. 2020, 20, 7354–7361. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, J.; Li, Y.; Huang, L. Flexible and high sensitive capacitive pressure sensor with microstructured electrode inspired by ginkgo leaf. J. Phys. D Appl. Phys. 2021, 54, 465401. [Google Scholar] [CrossRef]

- Su, B.; Gong, S.; Ma, Z.; Yap, L.W.; Cheng, W. Mimosa-Inspired Design of a Flexible Pressure Sensor with Touch Sensitivity. Small 2015, 11, 1886–1891. [Google Scholar] [CrossRef]

- Zhao, T.; Li, T.; Chen, L.; Yuan, L.; Li, X.; Zhang, J. Highly Sensitive Flexible Piezoresistive Pressure Sensor Developed Using Biomimetically Textured Porous Materials. ACS Appl. Mater. Inter. 2019, 11, 29466–29473. [Google Scholar] [CrossRef]

- Xia, K.; Wang, C.; Jian, M.; Wang, Q.; Zhang, Y. CVD growth of fingerprint-like patterned 3 D graphene film for an ultrasensitive pressure sensor. Nano Res. 2018, 11, 1124–1134. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Zheng, A.; Xia, Q. Bioinspired Design of Hill-Ridge Architecture-Based Iontronic Sensor with High Sensibility and Piecewise Linearity. Adv. Mater. Technol. 2022, 7, 2100510. [Google Scholar] [CrossRef]

- Zou, Q.; Li, S.; Xue, T.; Ma, Z.; Lei, Z.; Su, Q. Highly sensitive ionic pressure sensor with broad sensing range based on interlaced ridge-like microstructure. Sens. Actuators A Phys. 2020, 313, 112173. [Google Scholar] [CrossRef]

- Weng, M.; Sun, L.; Qu, S.; Chen, L. Fingerprint-inspired graphene pressure sensor with wrinkled structure. Extrem. Mech. Lett. 2020, 37, 100714. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Li, C.; Lai, X.; Zeng, X. Conductive and room-temperature self-healable polydimethylsiloxane-based elastomer film with ridge-like microstructure for piezoresistive pressure sensor. Chem. Eng. J. 2022, 430, 133103. [Google Scholar] [CrossRef]

- Ma, L.; Shuai, X.; Hu, Y.; Liang, X.; Zhu, P.; Sun, R.; Wong, C. A highly sensitive and flexible capacitive pressure sensor based on a micro-arrayed polydimethylsiloxane dielectric layer. J. Mater. Chem. C Mater. Opt. Electron. Devices 2018, 6, 13232–13240. [Google Scholar] [CrossRef]

- Du, Q.; Liu, L.; Tang, R.; Ai, J.; Wang, Z.; Fu, Q.; Li, C.; Chen, Y.; Feng, X. High-Performance Flexible Pressure Sensor Based on Controllable Hierarchical Microstructures by Laser Scribing for Wearable Electronics. Adv. Mater. Technol. 2021, 6, 2100122. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis Microstructure Inspired Graphene Pressure Sensor with Random Distributed Spinosum for High Sensitivity and Large Linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef] [PubMed]

- Chhetry, A.; Kim, J.; Yoon, H.; Park, J.Y. Ultrasensitive Interfacial Capacitive Pressure Sensor Based on a Randomly Distributed Microstructured Iontronic Film for Wearable Applications. ACS Appl. Mater. Inter. 2019, 11, 3438–3449. [Google Scholar] [CrossRef] [PubMed]

- Bai, N.; Wang, L.; Wang, Q.; Deng, J.; Wang, Y.; Lu, P.; Huang, J.; Li, G.; Zhang, Y.; Yang, J.; et al. Graded intrafillable architecture-based iontronic pressure sensor with ultra-broad-range high sensitivity. Nat. Commun. 2020, 11, 209. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, B.; Li, K.; Zhang, T.; Yang, X. A wide linearity range and high sensitivity flexible pressure sensor with hierarchical microstructures via laser marking. J. Mater. Chem. C 2020, 8, 3088–3096. [Google Scholar] [CrossRef]

- Ji, B.; Zhou, Q.; Lei, M.; Ding, S.; Song, Q.; Gao, Y.; Li, S.; Xu, Y.; Zhou, Y.; Zhou, B. Gradient Architecture-Enabled Capacitive Tactile Sensor with High Sensitivity and Ultrabroad Linearity Range. Small 2021, 17, 2103312. [Google Scholar] [CrossRef]

- Tang, X.; Wu, C.; Gan, L.; Zhang, T.; Zhou, T.; Huang, J.; Wang, H.; Xie, C.; Zeng, D. Multilevel Microstructured Flexible Pressure Sensors with Ultrahigh Sensitivity and Ultrawide Pressure Range for Versatile Electronic Skins. Small 2019, 15, 1804559. [Google Scholar] [CrossRef]

- Jia, J.; Huang, G.; Deng, J.; Pan, K. Skin-inspired flexible and high-sensitivity pressure sensors based on rGO films with continuous-gradient wrinkles. Nanoscale 2019, 11, 4258–4266. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, S.; Zeng, J.; Ren, X.; Chee, A.J.Y.; Yiu, B.Y.S.; Chung, W.C.; Yang, Y.; Yu, A.C.H.; Roberts, R.C.; et al. High Sensitivity, Wearable, Piezoresistive Pressure Sensors Based on Irregular Microhump Structures and Its Applications in Body Motion Sensing. Small 2016, 12, 3827–3836. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Chen, L.; Yang, X.; Chen, X.; Zhang, Z.; Zhao, T.; Li, X.; Zhang, J. A flexible pressure sensor based on an MXene–textile network structure. J. Mater. Chem. C Mater. Opt. Electron. Devices 2019, 7, 1022–1027. [Google Scholar] [CrossRef]

- Lu, W.; Yu, P.; Jian, M.; Wang, H.; Wang, H.; Liang, X.; Zhang, Y. Molybdenum Disulfide Nanosheets Aligned Vertically on Carbonized Silk Fabric as Smart Textile for Wearable Pressure-Sensing and Energy Devices. ACS Appl. Mater. Inter. 2020, 12, 11825–11832. [Google Scholar] [CrossRef]

- Yang, C.; Li, L.; Zhao, J.; Wang, J.; Xie, J.; Cao, Y.; Xue, M.; Lu, C. Highly Sensitive Wearable Pressure Sensors Based on Three-Scale Nested Wrinkling Microstructures of Polypyrrole Films. ACS Appl. Mater. Inter. 2018, 10, 25811–25818. [Google Scholar] [CrossRef] [PubMed]

- Yoon, S.G.; Park, B.J.; Chang, S.T. Highly Sensitive Piezocapacitive Sensor for Detecting Static and Dynamic Pressure Using Ion-Gel Thin Films and Conductive Elastomeric Composites. ACS Appl. Mater. Inter. 2017, 9, 36206–36219. [Google Scholar] [CrossRef] [PubMed]

- Archard, J.F. Elastic deformation and the laws of friction. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1957, 243, 190–205. [Google Scholar]

- Zhang, C.; Chen, R.; Xiao, C.; Zhao, H.; Wang, Y.; Geng, D.; Chen, S.; Luo, T.; Zhou, W. Laser Direct Writing of Highly Ordered Two-Level Hierarchical Microstructures for Flexible Piezoresistive Sensor with Enhanced Sensitivity. Adv. Mater. Interfaces 2022, 9, 2101596. [Google Scholar] [CrossRef]

- Boutry, C.M.; Negre, M.; Jorda, M.; Vardoulis, O.; Chortos, A.; Khatib, O.; Bao, Z. A hierarchically patterned, bioinspired e-skin able to detect the direction of applied pressure for robotics. Sci Robot 2018, 3, u6914. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Han, D.; Zhang, Y.; Sun, H. Versatile Electronic Skins with Biomimetic Micronanostructures Fabricated Using Natural Reed Leaves as Templates. ACS Appl. Mater. Inter. 2019, 11, 38084–38091. [Google Scholar] [CrossRef]

- Zhao, T.; Yuan, L.; Li, T.; Chen, L.; Li, X.; Zhang, J. Pollen-Shaped Hierarchical Structure for Pressure Sensors with High Sensitivity in an Ultrabroad Linear Response Range. ACS Appl. Mater. Inter. 2020, 12, 55362–55371. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, T.; Xin, Y.; Huang, J.; Liang, J.; He, X.; Zhang, C.; Yang, W.; He, X. Natural bamboo leaves as dielectric layers for flexible capacitive pressure sensors with adjustable sensitivity and a broad detection range. RSC Adv. 2021, 11, 17291–17300. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.; Park, J.; Choi, B. Flexible piezoresistive pulse sensor using biomimetic PDMS mold replicated negatively from shark skin and PEDOT:PSS thin film. Sens. Actuators A Phys. 2019, 286, 107–114. [Google Scholar] [CrossRef]

- Li, W.; Jin, X.; Han, X.; Li, Y.; Wang, W.; Lin, T.; Zhu, Z. Synergy of Porous Structure and Microstructure in Piezoresistive Material for High-Performance and Flexible Pressure Sensors. ACS Appl. Mater. Inter. 2021, 13, 19211–19220. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Qiu, Z.; Huang, J.; Yang, J.; Wang, Q.; Lu, P.; Yang, J.; Zhang, J.; Huang, S.; Wu, Z.; et al. Natural Plant Materials as Dielectric Layer for Highly Sensitive Flexible Electronic Skin. Small 2018, 14, 1801657. [Google Scholar] [CrossRef] [PubMed]

- Bae, G.Y.; Han, J.T.; Lee, G.; Lee, S.; Kim, S.W.; Park, S.; Kwon, J.; Jung, S.; Cho, K. Pressure/Temperature Sensing Bimodal Electronic Skin with Stimulus Discriminability and Linear Sensitivity. Adv. Mater. 2018, 30, 1803388. [Google Scholar] [CrossRef]

- Tay, R.Y.; Li, H.; Lin, J.; Wang, H.; Lim, J.S.K.; Chen, S.; Leong, W.L.; Tsang, S.H.; Teo, E.H.T. Lightweight, Superelastic Boron Nitride/Polydimethylsiloxane Foam as Air Dielectric Substitute for Multifunctional Capacitive Sensor Applications. Adv. Funct. Mater. 2020, 30, 1909604. [Google Scholar] [CrossRef]

- Kwon, D.; Lee, T.; Shim, J.; Ryu, S.; Kim, M.S.; Kim, S.; Kim, T.; Park, I. Highly Sensitive, Flexible, and Wearable Pressure Sensor Based on a Giant Piezocapacitive Effect of Three-Dimensional Microporous Elastomeric Dielectric Layer. ACS Appl. Mater. Inter. 2016, 8, 16922–16931. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Li, X.; Song, D.; Min, P.; Hu, C.; Zhang, H.; Koratkar, N.; Yu, Z. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interf. Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Yang, J.C.; Kim, J.; Oh, J.; Kwon, S.Y.; Sim, J.Y.; Kim, D.W.; Choi, H.B.; Park, S. Microstructured Porous Pyramid-Based Ultrahigh Sensitive Pressure Sensor Insensitive to Strain and Temperature. ACS Appl. Mater. Inter. 2019, 11, 19472–19480. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Chen, D.; Sun, M.; Liang, N.; Cheng, Q.; Ji, Y.; Gao, H.; Guo, Z.; Li, Y.; et al. Fabrication of a Sensitive Strain and Pressure Sensor from Gold Nanoparticle-Assembled 3 D-Interconnected Graphene Microchannel-Embedded PDMS. ACS Appl. Mater. Inter. 2020, 12, 51854–51863. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, H.; Chen, S.; Dong, X.; Wang, P.; Liu, S.; Lin, Y.; Wei, Y.; Liu, L. Channel Crack-Designed Gold@PU Sponge for Highly Elastic Piezoresistive Sensor with Excellent Detectability. ACS Appl. Mater. Inter. 2017, 9, 20098–20105. [Google Scholar] [CrossRef] [PubMed]

- Lei, X.; Ma, L.; Li, Y.; Cheng, Y.; Cheng, G.J.; Liu, F. Highly sensitive and wide-range flexible pressure sensor based on carbon nanotubes-coated polydimethylsiloxane foam. Mater. Lett. 2022, 308, 131151. [Google Scholar] [CrossRef]

- Lü, X.; Yu, T.; Meng, F.; Bao, W. Wide-Range and High-Stability Flexible Conductive Graphene/Thermoplastic Polyurethane Foam for Piezoresistive Sensor Applications. Adv. Mater. Technol. 2021, 6, 2100248. [Google Scholar] [CrossRef]

- Wang, J.; Suzuki, R.; Shao, M.; Gillot, F.; Shiratori, S. Capacitive Pressure Sensor with Wide-Range, Bendable, and High Sensitivity Based on the Bionic Komochi Konbu Structure and Cu/Ni Nanofiber Network. ACS Appl. Mater. Inter. 2019, 11, 11928–11935. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Dong, K.; Li, R.; Huang, X.; Chen, T.; Xiao, X. Capacitive pressure sensor inlaid a porous dielectric layer of superelastic polydimethylsiloxane in conductive fabrics for detection of human motions. Sens. Actuators A Phys. 2020, 312, 112106. [Google Scholar] [CrossRef]

- Zhao, S.; Zhu, R. High Sensitivity and Broad Range Flexible Pressure Sensor Using Multilayered Porous PDMS/AgNP Sponge. Adv. Mater. Technol. 2019, 4, 1900414. [Google Scholar] [CrossRef]

- Sun, K.; Ko, H.; Park, H.; Seong, M.; Lee, S.; Yi, H.; Park, H.W.; Kim, T.; Pang, C.; Jeong, H.E. Hybrid Architectures of Heterogeneous Carbon Nanotube Composite Microstructures Enable Multiaxial Strain Perception with High Sensitivity and Ultrabroad Sensing Range. Small 2018, 14, 1803411. [Google Scholar] [CrossRef]

- Ding, X.; Zhong, W.; Jiang, H.; Li, M.; Chen, Y.; Lu, Y.; Ma, J.; Yadav, A.; Yang, L.; Wang, D. Highly Accurate Wearable Piezoresistive Sensors without Tension Disturbance Based on Weaved Conductive Yarn. ACS Appl. Mater. Inter. 2020, 12, 35638–35646. [Google Scholar] [CrossRef]

- Elsayes, A.; Sharma, V.; Yiannacou, K.; Koivikko, A.; Rasheed, A.; Sariola, V. Plant-Based Biodegradable Capacitive Tactile Pressure Sensor Using Flexible and Transparent Leaf Skeletons as Electrodes and Flower Petal as Dielectric Layer. Adv. Sustain. Syst. 2020, 4, 2000056. [Google Scholar] [CrossRef]

- Shi, X.; Luo, J.; Luo, J.; Li, X.; Han, K.; Li, D.; Cao, X.; Wang, Z.L. Flexible Wood-Based Triboelectric Self-Powered Smart Home System. ACS Nano 2022, 16, 3341–3350. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, T.; Liu, L.; Niu, S.; Wang, K.; Song, H.; Han, Q.; Han, Z.; Ren, L.; Lin, Q. Flexible and highly sensitive pressure sensors based on microcrack arrays inspired by scorpions. RSC Adv. 2019, 9, 22740–22748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Type | Schematic Diagram | Sensing Principle | Characteristics |

|---|---|---|---|

| Piezoresistive |  | When under pressure, the resistance of the sensor will change based on the piezoresistive mechanism | High sensitivity Wide sensing range Simple structure and manufacturing technology Low cost Poor stability Lag effect |

| Capacitive |  | When under pressure, the dielectric constant or physical size of the dielectric layer changes, so that the capacitance of the sensor changes | High sensitivity Stable to temperature Mature manufacturing technology Low power consumption Highly susceptible to parasitic effects and electromagnetic interference |

| Piezoelectric |  | When under pressure, the piezoelectric material generates charge based on the inverse piezoelectric effect. This is due to the inherent dipole moment of piezoelectric materials. Pressure will deform the oriented non centrosymmetric crystal structure, resulting in the separation of electric dipole moment and voltage | High sensitivity Good dynamic response Self-power supply capacity Not suitable for static sensing Drift of sensor output over time |

| Triboelectric |  | When under pressure, two materials with different friction polarities contact each other, and opposite charges are induced on both sides of the surface based on the triboelectric effect | High sensitivity Wide detection range Self-power supply capacity Simple manufacturing process Low cost Not suitable for static sensing |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Pyramid | PDMS/rGO | Piezoresistive | 5.53 kPa−1 (<0.1 kPa) 0.1 kPa−1 (0.1–1.4 kPa) | 2 Pa | 0.2 ms | [45] |

| PDMS/poly(3,4–ethylenedioxythiophene–poly(styrenesulfonate) (PEDOT:PSS)/polyurethane dispersion(PUD) | 4.88 kPa−1 (0.37–5.9 kPa) | 37 Pa | 0.2 ms | [39] | ||

| PDMS/multiwalled carbon nanotubes (MWCNT)/Au/Ti/PET | 9.95 kPa−1 (<0.1 kPa) | <200 ms | [53] | |||

| PDMS/SWCNT | 2760 kPa−1 (<0.4 kPa) 8655.6 kPa−1 (0.4–0.9 kPa) 1874.5 kPa−1 (>0.9 kPa) | 7.3 Pa | <4 ms | [46] | ||

| PDMS/PPy/Au | 1907.2 kPa−1 (<0.1 kPa) 461.5 kPa−1 (0.1~1 kPa) 230.1 kPa−1 (1~1.9 kPa) | 0.075 Pa | 0.05 ms | [54] | ||

| PDMS/vertical gold nanowire (v-AuNWs) | 23 kPa−1 (<0.6 kPa) 0.7 kPa−1 (>0.6 kPa) | 10 ms | [55] | |||

| Micro cone | PDMS/poly(methylmethacrylate)(PMMA) | Piezoresistive | 2.5 kPa−1 (0–0.16 kPa) 0.2 kPa−1 (0.16–0.5 kPa) | 15 Pa | 20 ms | [56] |

| Lotus leaf-like sharp bulge | PPy/Ag | Piezoresistive | 0.58 kPa−1 (0.3–0.4 kPa) | [47] | ||

| PDMS/1–ethyl−3-methylimidazolium bis-(trifluoromethylsulfonyl)imide ([EMIM][NTF2])/AgNWs | Capacitive | 2.09 kPa−1 (<80 kPa) | [57] | |||

| PDMS/polystyrene (PS)/Au | 0.815 kPa−1 (0–50 N) | 17.5 Pa | 38 ms | [58] | ||

| PDMS/AgNWs/PI | 1.2 k Pa−1 (<2 kPa) | 0.8 Pa | 36 ms 58 ms | [25] | ||

| Rose-like sharp bulge | PDMS/Cu–AgNWs | Piezoresistive | 1.35 kPa−1 (<2 kPa) 0.1 kPa−1 (2–5 kPa) | 2 Pa | 36 ms 30 ms | [59] |

| PDMS/PPy | 70 kPa−1 (<0.5 kPa) 19 kPa−1 (0.5–2 kPa) | 0.88 Pa | 30 ms | [49] | ||

| PDMS/polyvinylidene fluoride (PVDF)/polyaniline (PANI) fibers/Au | 53 kPa−1 (58.4–960 Pa) 1.03 kPa−1 (0.96–5 kPa) | 58.4 Pa | 38 ms | [60] | ||

| PDMS/indium tin oxide (ITO)/PET | Capacitive | 0.055 kPa−1 (0.5–10 kPa) | <200 ms | [61] | ||

| Calathea Zebrine-like sharp bulge | colorless polymide (CPI)/AgNWs | Capacitive | 54.31 kPa−1 (<0.5 kPa) 30.11 kPa−1 (0.5–10 kPa) 8.42 kPa−1 (10–40 kPa) 1.03 kPa−1 (40–115 kPa) | 29 ms | [62] | |

| PDMS/polytetrafluoroethylene (PTFE)/AgNWs | Triboelectric | 127.22 mV kPa−1 (<50 kPa) | [48] | |||

| Cilia | PDMS/Graphene/polyvinyl chloride (PVC) | Piezoresistive | 4 kPa−1 (0–0.1 kPa) 0.25 kPa−1 (0.1–1 k Pa) | 0.9 Pa | [63] | |

| PDMS/PVDF fiber | Capacitive | 0.6 kPa−1 (0–7 kPa) 0.51 kPa−1 (7–15 kPa) 0.03 kPa−1 (15–50 kPa) | 0.065 Pa | 25 ms | [52] |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Micro dome | PDMS/Au | Piezoresistive | 15 kPa−1 (<100 Pa) 2 kPa−1 (100–400 Pa) | 4 Pa | 100 ms | [64] |

| PDMS/PMMA | 0.64 kPa−1 (<400 Pa) | 79 Pa | 28 ms | [68] | ||

| PDMS/CNT | 1.82 kPa−1 (<2 kPa) | 1 Pa | 36 ms | [69] | ||

| PDMS/Au | 196 kPa−1 (<10 kPa) 12.8 kPa−1 (10–100 kPa) | 0.5 Pa | 25 ms | [70] | ||

| PDMS/Graphene/PI | 50.45 kPa−1 (<0.05 kPa) 4.35 kPa−1 (0.05~0.4 kPa) | 0.209 Pa | 39 ms | [71] | ||

| PDMS/Carbon powder | 124 kPa−1 (0–200 Pa) 0.39 kPa−1 (0.2–5 kPa) | 2 Pa | [72] | |||

| PDMS/Au | Capacitive | 30.2 kPa−1 (<130 Pa) 0.47 kPa−1 (130 Pa–10 kPa) | 0.7 Pa | 25 ms | [73] | |

| Ginkgo biloba leaf-like micro fluctuation | PDMS/Ag | Piezoresistive | 5.9 kPa−1 (0–15 kPa) | 42 ms 53 ms | [74] | |

| PDMS/MXene/PVA | 164.93 kPa−1 (0~10 kPa) 403.46 kPa−1 (10~18 kPa) | 0.88 Pa | 99.3 ms | [65] | ||

| thermoplastic polyurethane (TPU)/carbon black (CB) | Capacitive | 1.194 kPa−1 (<1 kPa) | 6.53 Pa | 80 ms | [75] | |

| Mimosa-like micro fluctuation | PDMS/Au | Piezoresistive | 50.17 kPa−1 (0–0.07 kPa) 1.38 kPa−1 (0.2–1.5 kPa) | 20 ms | [76] | |

| Epipremnum aureum leaf-like micro fluctuation | PDMS/CNT/Graphene | Piezoresistive | 19.8 kPa−1 (<0.3 kPa) 0.27 kPa−1 (0.3–6 kPa) | 0.6 Pa | [66] | |

| PDMS/MWCNT | 83.9 kPa−1 (<0.14 kPa) 0.4 kPa−1 (0.14–10 kPa) | 0.5 Pa | 90 ms 130 ms | [77] | ||

| PDMS/Graphene | 110 kPa−1 (<0.2 kPa) 3 kPa−1 (0.2–15 kPa) 0.26 kPa−1 (15–75 kPa) | 0.2 Pa | <30 ms | [78] | ||

| Oleander-like micro fluctuation | PDMS/Ag | Piezoresistive | 8.5 kPa−1 (<0.8 kPa) 0.2 kPa−1 (0.8–8.8 kPa) | 1 Pa | 40 ms | [44] |

| Silk-like micro fluctuation | PDMS/SWNTs | Piezoresistive | 1.80 kPa−1 (<0.3 kPa) | 0.6 Pa | <10 ms | [67] |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Ridge | PDMS-polyurea (PUa)-1,3,5-triformylbenzene (TFB) 0.1 | Piezoresistive | 8.7 kPa−1 (<6.1 kPa) 0.9 kPa−1 (6.1–29.1 kPa) | 50 Pa | 40 ms | [82] |

| PDMS/PVA/H3 PO4 | Capacitive | 37.78 kPa−1 (<4 kPa) 16.81 kPa−1 (4–100 kPa) 4.69 kPa−1 (100–350 kPa) | 0.32 Pa | 23 ms | [79] | |

| PDMS/Ionic gel | 92 kPa−1 (<0.4 kPa) 45.04 kPa−1 (0.4–20 kPa) 8.5 kPa−1 (20–100 kPa) 1.25 kPa−1 (100–300 kPa) | 1 Pa | 45 ms | [80] | ||

| Wave | PET/rGO/tape | Piezoresistive | 5.77 kPa−1 (<0.49 kPa) 0.25 kPa−1 (0.49–9.8 Pa) | 3 Pa | 97 ms 98 ms | [81] |

| PDMS/AgNWs | Capacitive | 2.04 kPa−1 (<2 kPa) 0.57 kPa−1 (2–9 kPa) | 7 Pa | 100 ms | [83] |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Hierarchical sharp bulge | PDMS/AgNWs/PET | Piezoresistive | 4.48 kPa−1 (<22 kPa) 0.86 kPa−1 (27–65 kPa) | 3 Pa | 7 ms | [84] |

| Hierarchical micro dome | PDMS/acrylonitrile butadiene styrene (ABS) | Piezoresistive | 15.4 kPa−1 (<200 kPa) | 16 Pa | 20 ms | [88] |

| PDMS/CNT | Capacitive | 0.065 kPa−1 (<1700 kPa) | 100 ms | [89] | ||

| Fold | PDMS/rGO | Piezoresistive | 2.5 kPa−1 (10 Pa−1 kPa) 12.0 kPa−1 (1–50 kPa) 1051 kPa−1 (50–200 kPa) 470 kPa−1 (200–400 kPa) | 10 Pa | 150 ms | [90] |

| PDMS/MWCNT | 6.67 kPa−1 (0–20 kPa) 1.91 kPa−1 (20–100 kPa) 0.74 kPa−1 (100–270 kPa) | 2 Pa | 24 ms 30 ms | [91] | ||

| PDMS/PEDOT:PSS | 851 kPa−1 (<20 kPa) | 34 Pa | 0.15 ms | [92] | ||

| PI/Mxene/Mo | 3.844 kPa−1 (0–29 kPa) 12.095 kPa−1 (29–40 kPa) | 26 ms | [93] | |||

| Carbonized Silk/MoS | 11.6 kPa−1 (0–0.25 kPa) 4.6 kPa−1 (0.25–3 kPa) 0.6 kPa−1 (3–20 kPa) | <70 Pa | [94] | |||

| PDMS/PPy | 19.32 kPa−1 (<0.8 kPa) 0.51 kPa−1 (>0.8 kPa) | 1 Pa | 20 ms | [95] | ||

| PVA/H3 PO4 | Capacitive | 3302.9 kPa−1 (<10 kPa) 671.7 kPa−1 (10–100 kPa) 229.9 kPa−1 (100–360 kPa) | 0.08 Pa | 9 ms | [87] | |

| P(VDF-HFP)/[EMIM] [TFSI]/AgNWs | 131.5 kPa−1 (<1.5 kPa) 11.73 kPa−1 (5–27.7 kPa) | 1.12 Pa | 43 ms | [86] | ||

| PDMS/CNTs | 9.55 kPa−1 | <5 Pa | 52 ms | [96] |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Micro dome/grid | PDMS/MWCNT | Piezoresistive | 0.90 kPa−1 (<600 Pa); 11.06 kPa−1 (600 Pa–10 kPa) 4.5 kPa−1 (10–300 kPa) | [98] | ||

| Micro dome/cone | PDMS/MWCNT | 3.5 kPa−1 (0–218 kPa) | 31 ms 52 ms | [101] | ||

| Micro groove/ridge | PDMS/PEDOT:PSS/Cu/Ag | 62.56 kPa−1 (<0.7 kPa) 8.32 kPa−1 (0.7~6 kPa) | [103] | |||

| Micro elliptic cylinder/porous | PDMS/MWCNTs | 10.805 kPa−1 (1 Pa−1 kPa); 2.015 kPa−1 (1–10 kPa) | 1 Pa | [104] | ||

| Micro groove/sharp bulge | PDMS/MXene/AgNWs | Capacitive | 2.08 kPa−1 (<1 kPa) 0.16 kPa−1 (1~100 kPa) 0.01 kPa−1 (100~600 kPa) | 36 ms | [102] | |

| Micro sharp bulge/porous | CPI/AgNWs | 1.54 kPa−1 (<1 kPa) 0.014 kPa−1 (1~40 kPa) 0.068 kPa−1 (40~115 kPa) | 0.6 Pa | [105] | ||

| Micro dome/pyramid | PDMS/CNT/PU | 0.19 ± 0.07 kPa−1 (<1 kPa) 0.10 ± 0.01 kPa−1 (1~10 kPa) 0.04 ± 0.001 kPa−1 (10–20 kPa) | [99] | |||

| Micro pyramid/fold | PDMS/SWNT | 0.7 kPa−1 (<25 kPa) | 100 ms | [106] | ||

| Micro groove/sharp bulge | PDMS/Au | 0.6 kPa−1 (<1 kPa) Maximum detection pressure is 40 kPa | 4.5 Pa | 180 ms 120 ms | [100] |

| Structure | Materials | Type | Sensitivity/Working Range | Detection Limit | Response Time | Reference |

|---|---|---|---|---|---|---|

| Porous | 3 D graphene microchannels (GMC)-PDMS/Au nanoparticles (AuNPs) | Piezoresistive | 5.37 kPa−1 (<1 kPa) 1.56 kPa−1 (1–10 kPa) 0.5 kPa−1 (10–50 kPa) | 4.4 Pa | 20 ms | [111] |

| PU/Au Sponge | 0.059 kPa−1 (0–4.7 kPa) 0.096 kPa−1 (4.7 kPa–10.2 kPa) 0.122 KPa−1 (10.2 kPa–14.2 kPa) | 0.568 Pa | 9 ms | [112] | ||

| PU/CS/MXene Sponge | 0.014 kPa−1 (<6.5 kPa) −0.015 kPa−1 (6.5–85.1 kPa) −0.001 kPa−1 (>85.1 kPa) | 9 Pa | 19 ms | [109] | ||

| PDMS/CNT Sponge | 290.45 kPa−1 (0–25 kPa) 67.02 kPa−1 (25–270 kPa) | 95 ms | [113] | |||

| TPU/rGO Foam | 0.0152 kPa−1 (20–500 kPa) 0.0007 kPa−1 (500~1940 kPa) | 166 ms | [114] | |||

| PDMS/Cu/Ni Nanofiber | Capacitive | 0.171 kPa−1 (<5 kPa) | 162 ms | [115] | ||

| PDMS/BNF | 0.854 kPa−1 (<0.5 kPa) 0.29 kPa−1 (0.5–2.1 kPa) | <1 Pa | 50 ms | [107] | ||

| PDMS/Cu/Ni | 0.023 kPa−1 (<20 kPa) | 155 ms | [116] | |||

| Ecoflex/CNT | 0.601 kPa−1 (<5 kPa) 0.077 kPa−1 (30–130 kPa) | 0.1 Pa | [108] | |||

| PDMS/ITO/PET | 44.5 kPa−1 (<100 Pa) | 0.14 Pa | 50 ms | [110] | ||

| PDMS/Ag nanoparticle (AgNP) Sponge | Piezoelectric | 50 mV kPa−1 (<4 kPa) 1.8 mV kPa−1 (4~110 kPa) 0.8 mV kPa−1 (110–200 kPa) | 4.1 Pa | [117] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, H.; Zhong, J.; Ye, Y.; Wu, R.; Luo, B.; Ning, H.; Qiu, T.; Luo, D.; Yao, R.; Peng, J. Research Progresses in Microstructure Designs of Flexible Pressure Sensors. Polymers 2022, 14, 3670. https://doi.org/10.3390/polym14173670

Huang H, Zhong J, Ye Y, Wu R, Luo B, Ning H, Qiu T, Luo D, Yao R, Peng J. Research Progresses in Microstructure Designs of Flexible Pressure Sensors. Polymers. 2022; 14(17):3670. https://doi.org/10.3390/polym14173670

Chicago/Turabian StyleHuang, Hao, Jinyao Zhong, Yongliang Ye, Renxu Wu, Bin Luo, Honglong Ning, Tian Qiu, Dongxiang Luo, Rihui Yao, and Junbiao Peng. 2022. "Research Progresses in Microstructure Designs of Flexible Pressure Sensors" Polymers 14, no. 17: 3670. https://doi.org/10.3390/polym14173670

APA StyleHuang, H., Zhong, J., Ye, Y., Wu, R., Luo, B., Ning, H., Qiu, T., Luo, D., Yao, R., & Peng, J. (2022). Research Progresses in Microstructure Designs of Flexible Pressure Sensors. Polymers, 14(17), 3670. https://doi.org/10.3390/polym14173670