Development of a High-Fidelity Framework to Describe the Process-Dependent Viscoelasticity of a Fast-Curing Epoxy Matrix Resin including Testing, Modelling, Calibration and Validation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Investigations

2.2.1. Isothermal Oscillation Experiments in Parallel-Plate Geometry

2.2.2. Isothermal Relaxation Experiments in Torsion Mode

2.2.3. Continuously Heated Oscillation Experiments in Torsion Mode

2.3. Derivation of Governing Equations

- The underlying behaviour of the material in its equilibrium state. This behaviour is omnipresent and independent of loading or holding time and is discussed in more detail in Section 2.3.3.

- The strongly time- and rate-dependent behaviour observable in the conducted relaxation experiments. Since resulting stresses from this part of the material’s behaviour are overlaid with the equilibrium behaviour, they are often referred to as overstresses. This behaviour will be the focus of Section 2.3.4.

2.3.1. Reaction Kinetics

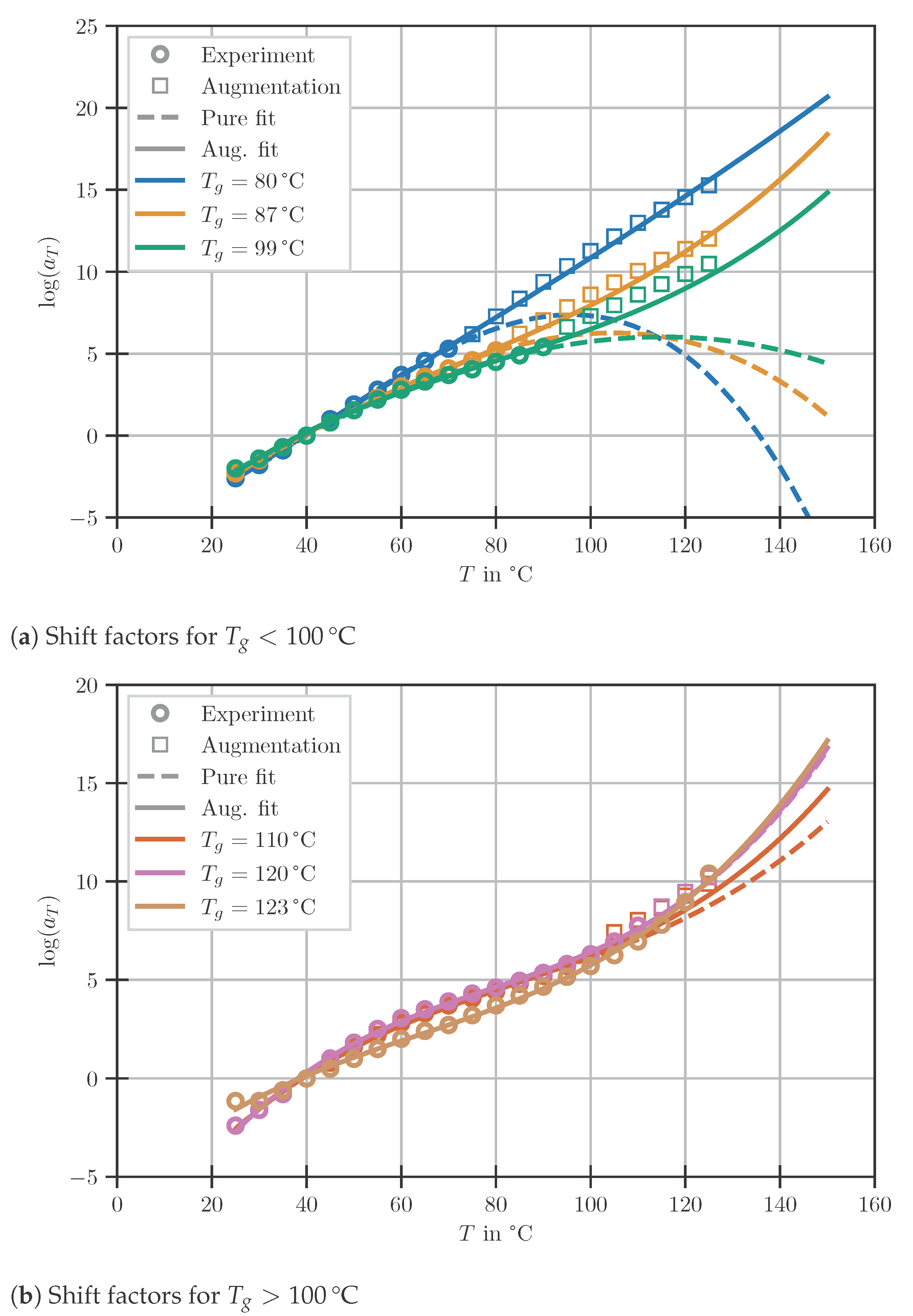

2.3.2. Time–Temperature Analogy

2.3.3. Equilibrium Behaviour—Time-Independent

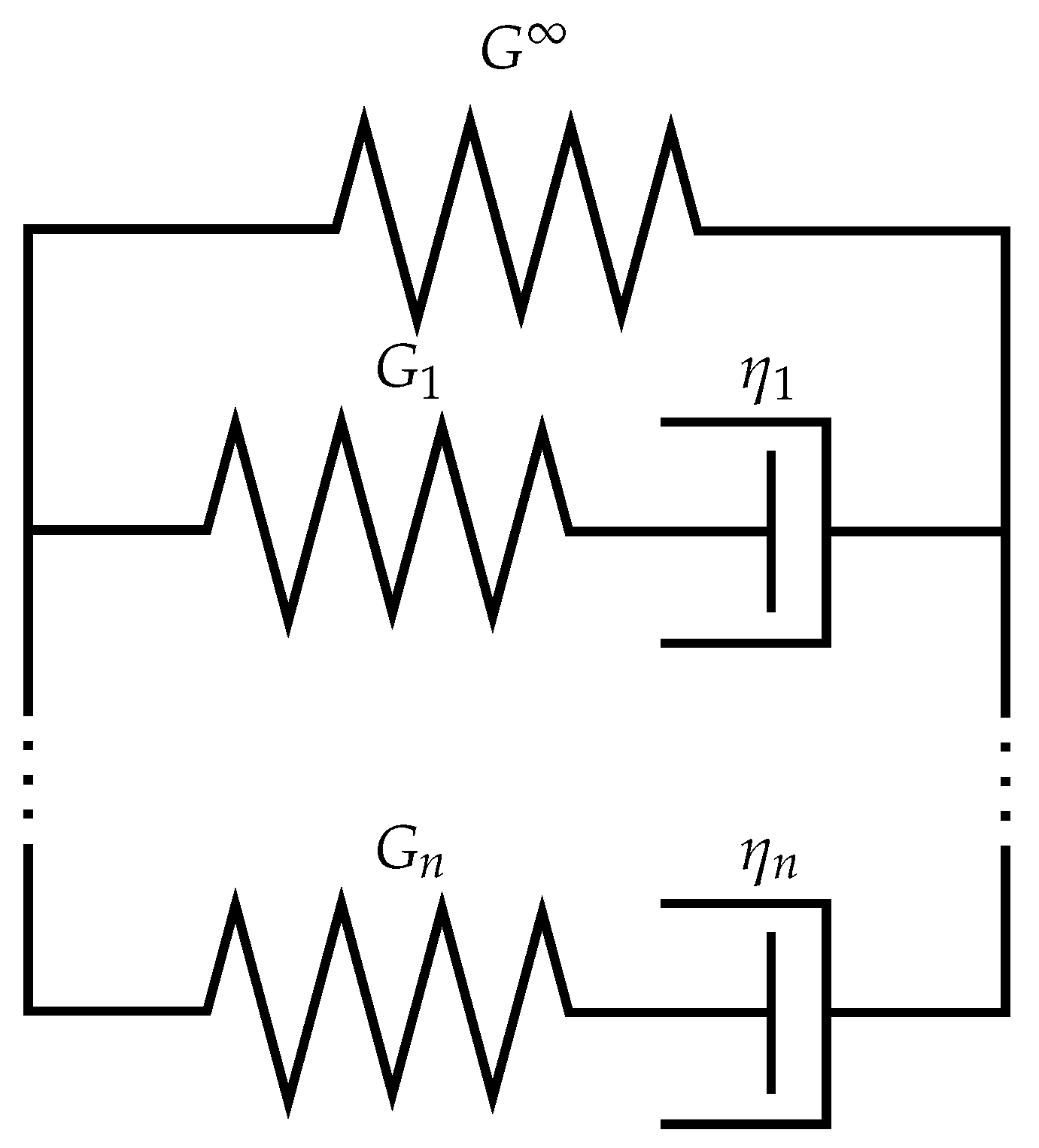

2.3.4. Disequilibrium Behaviour—Time-Dependent

2.3.5. Final Model Assembly

3. Results

3.1. Parameter Identification

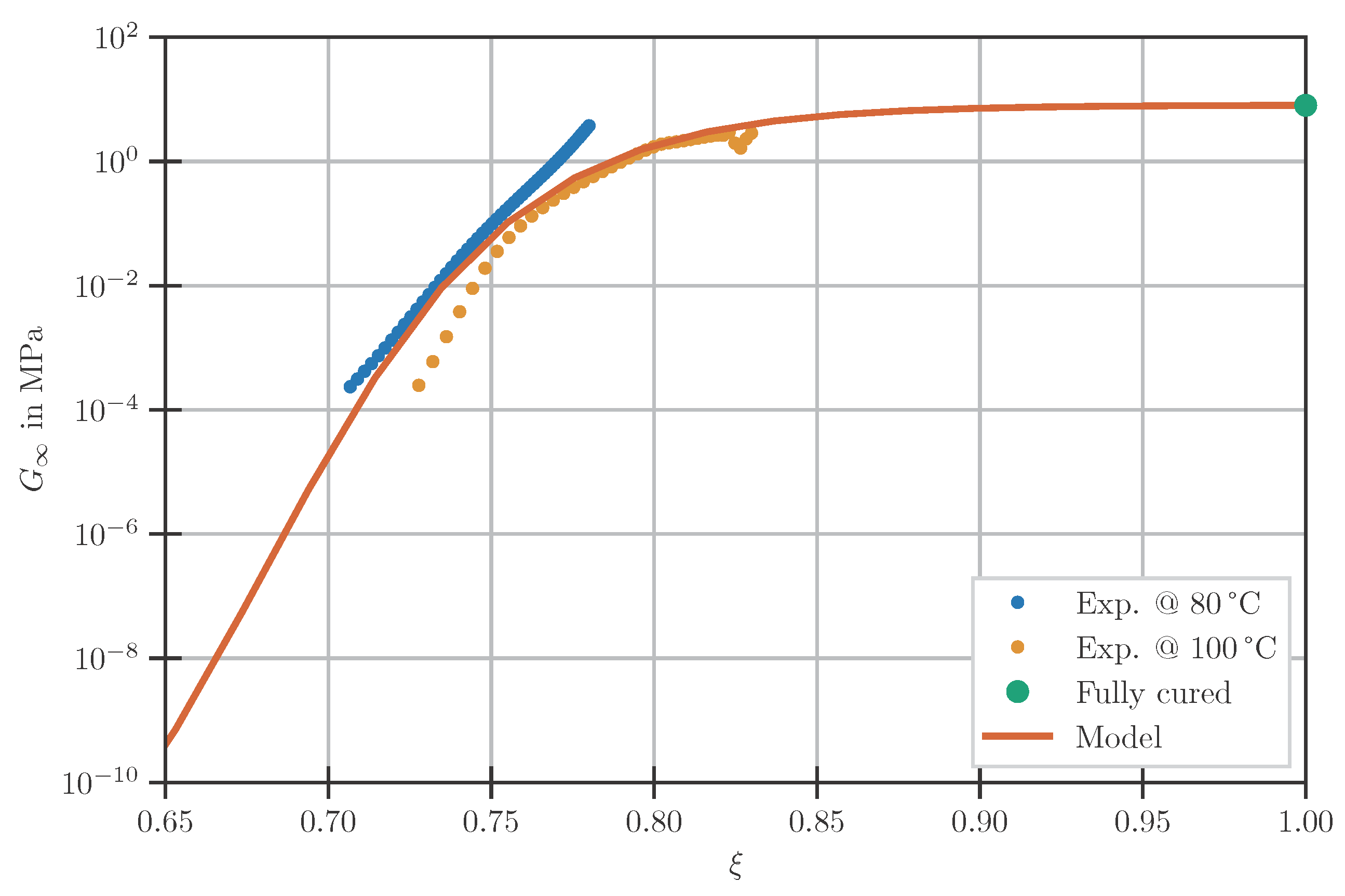

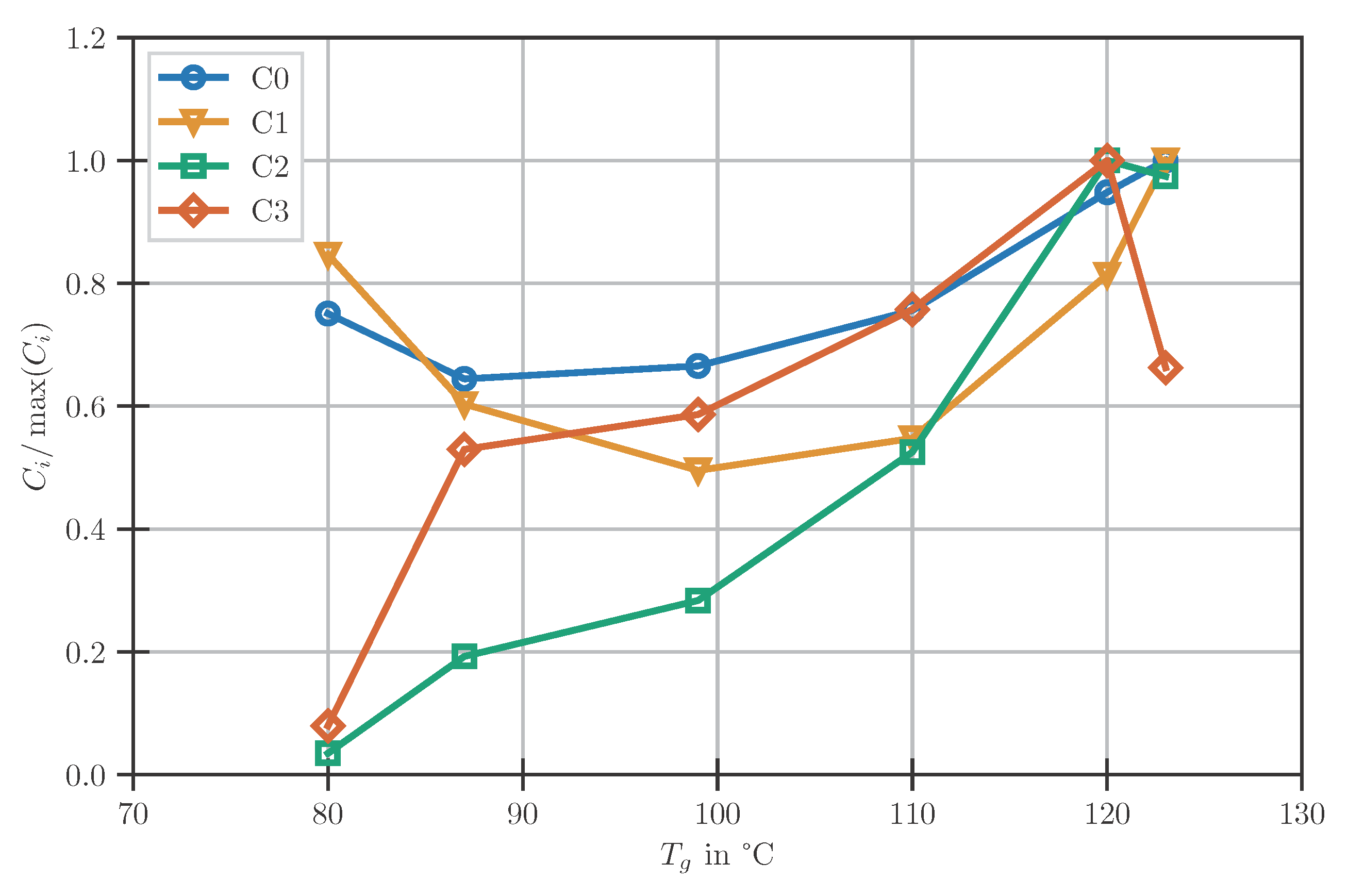

3.1.1. Determination of Fully Relaxed Modulus

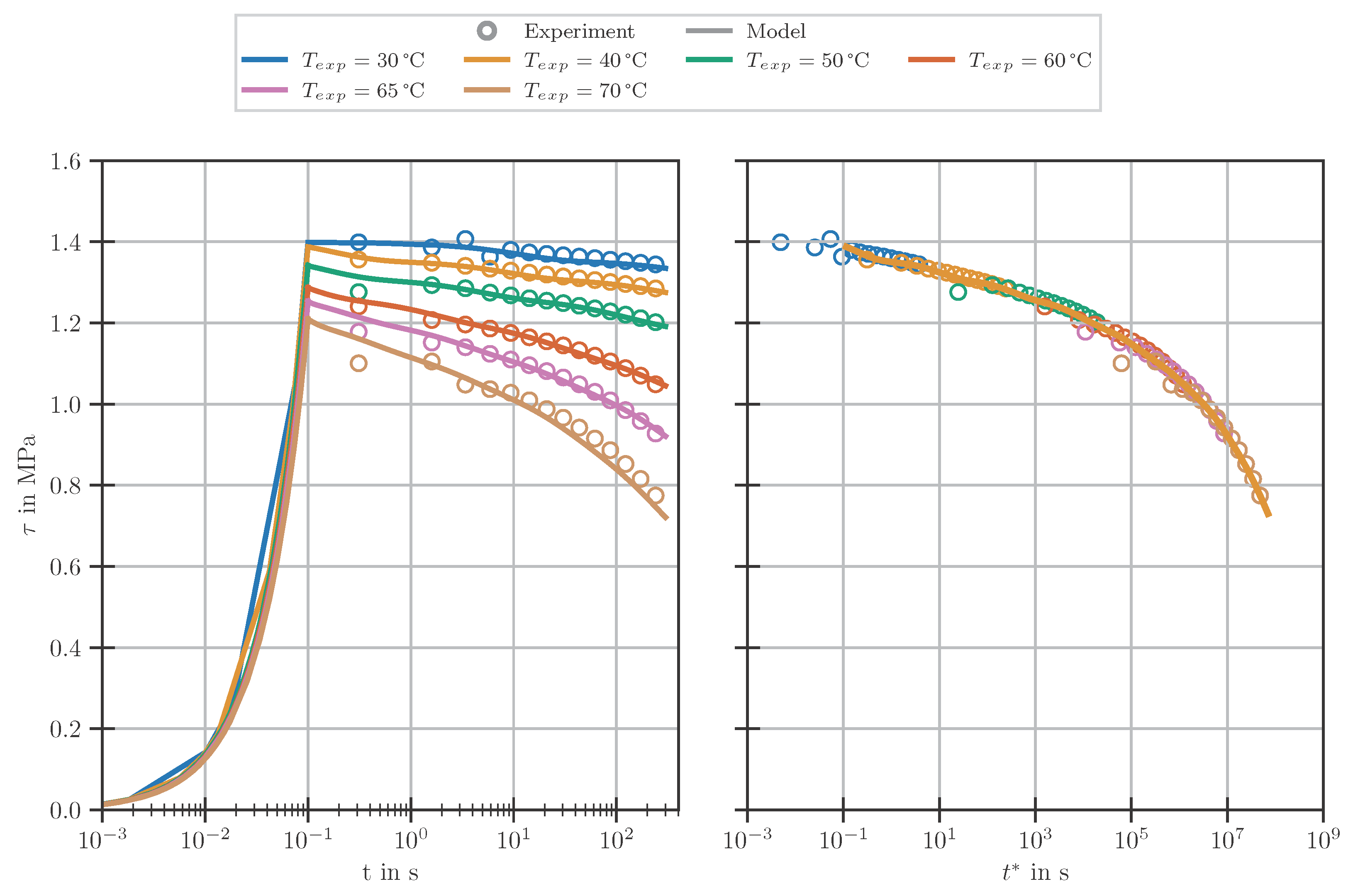

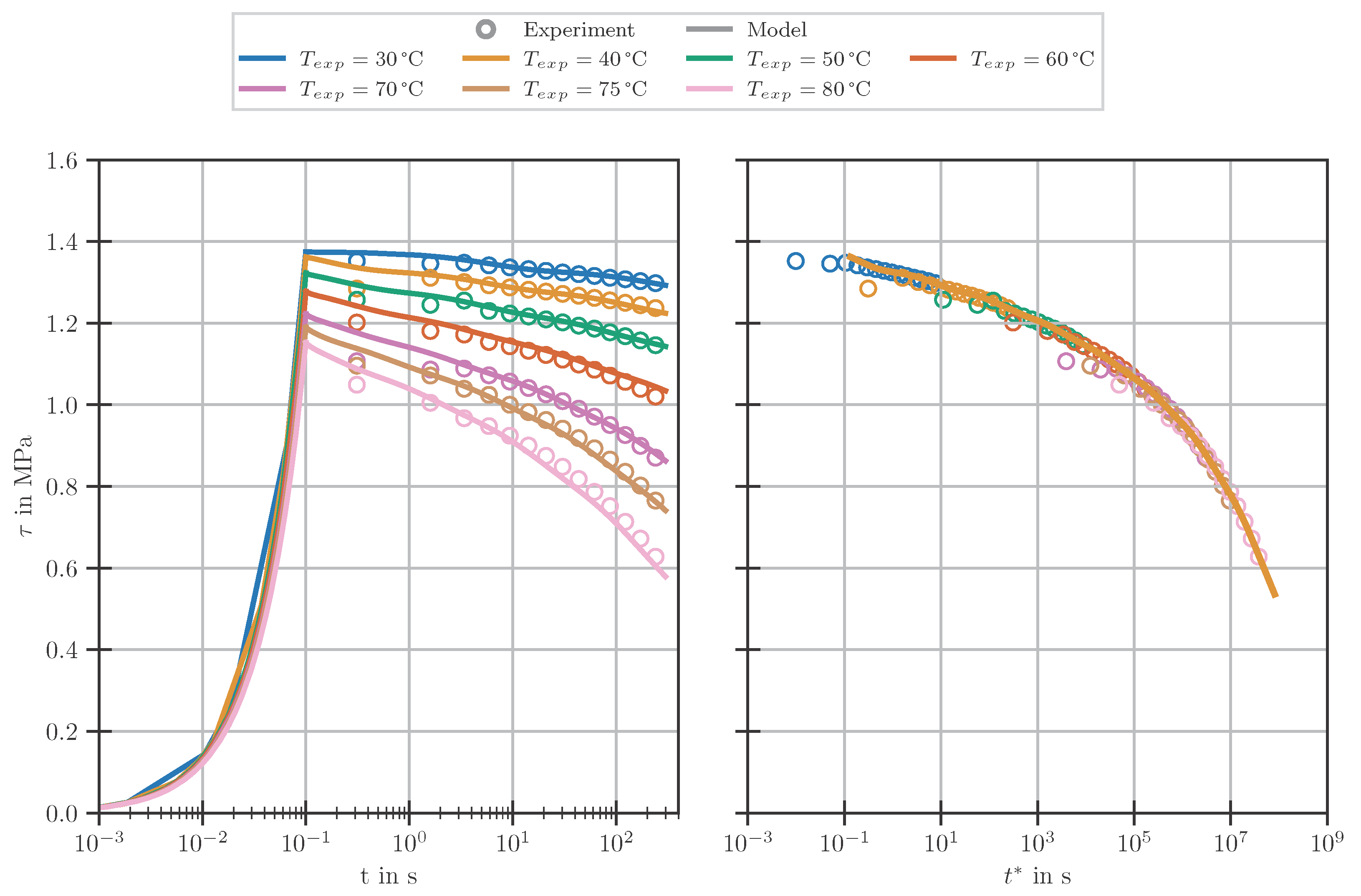

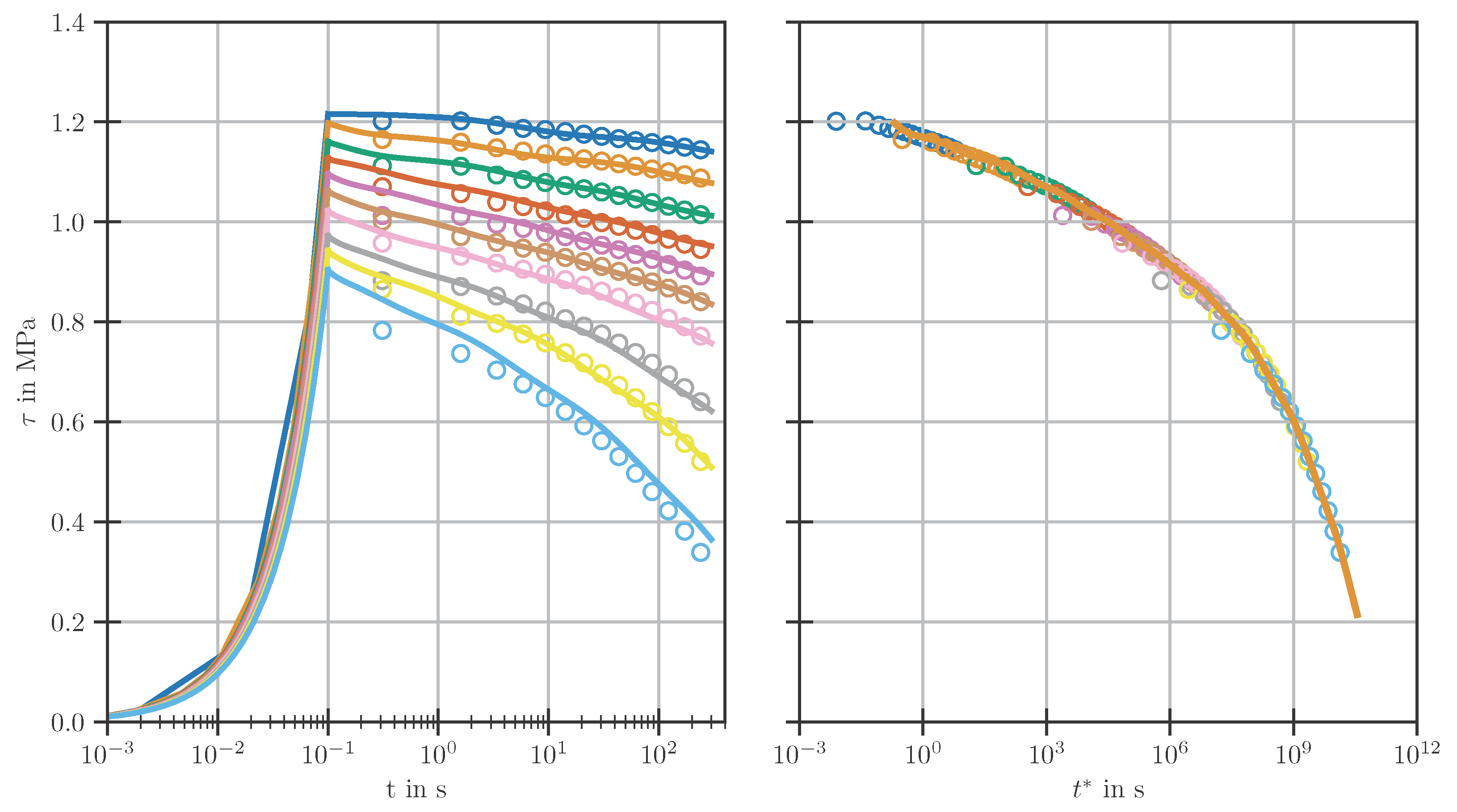

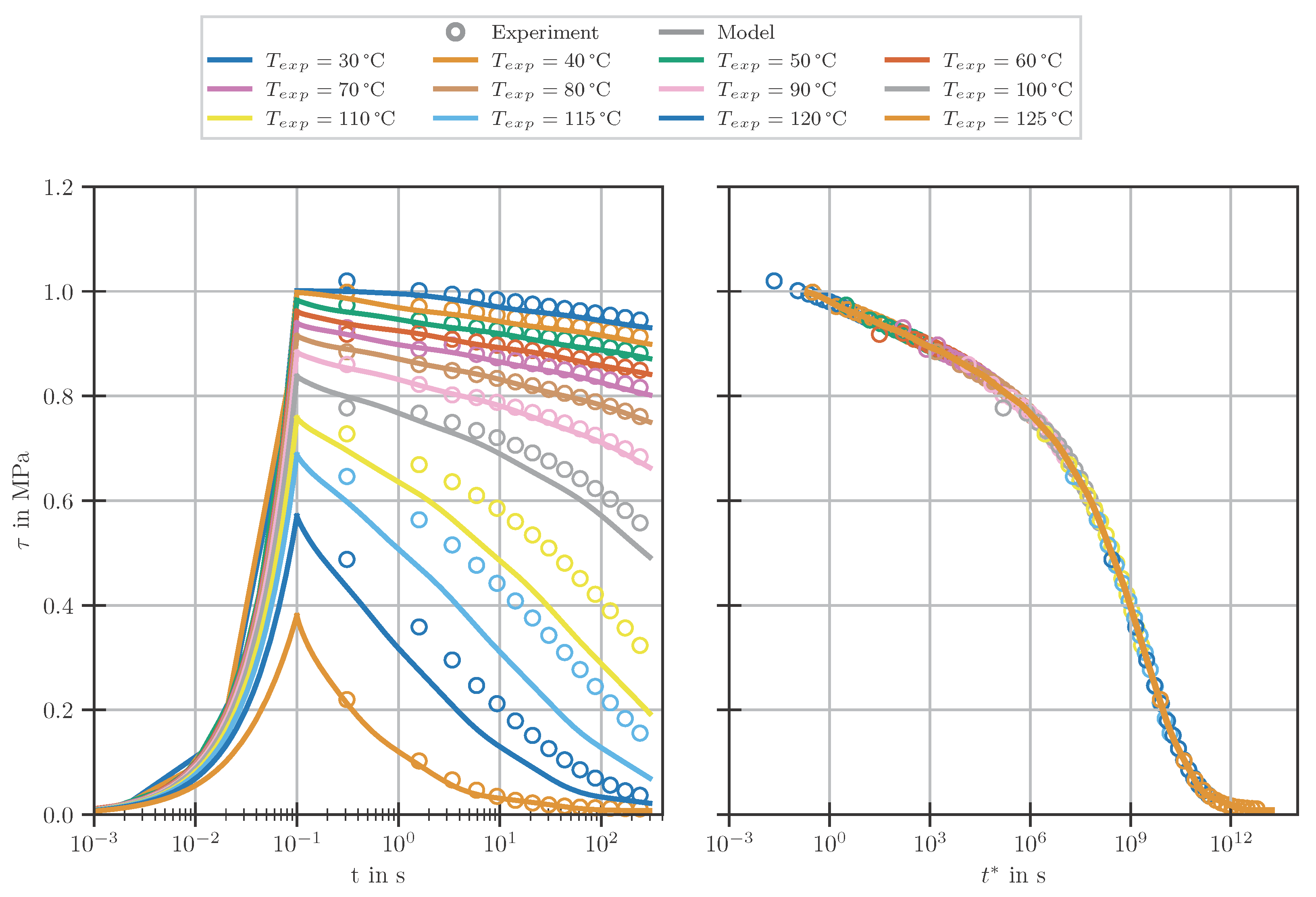

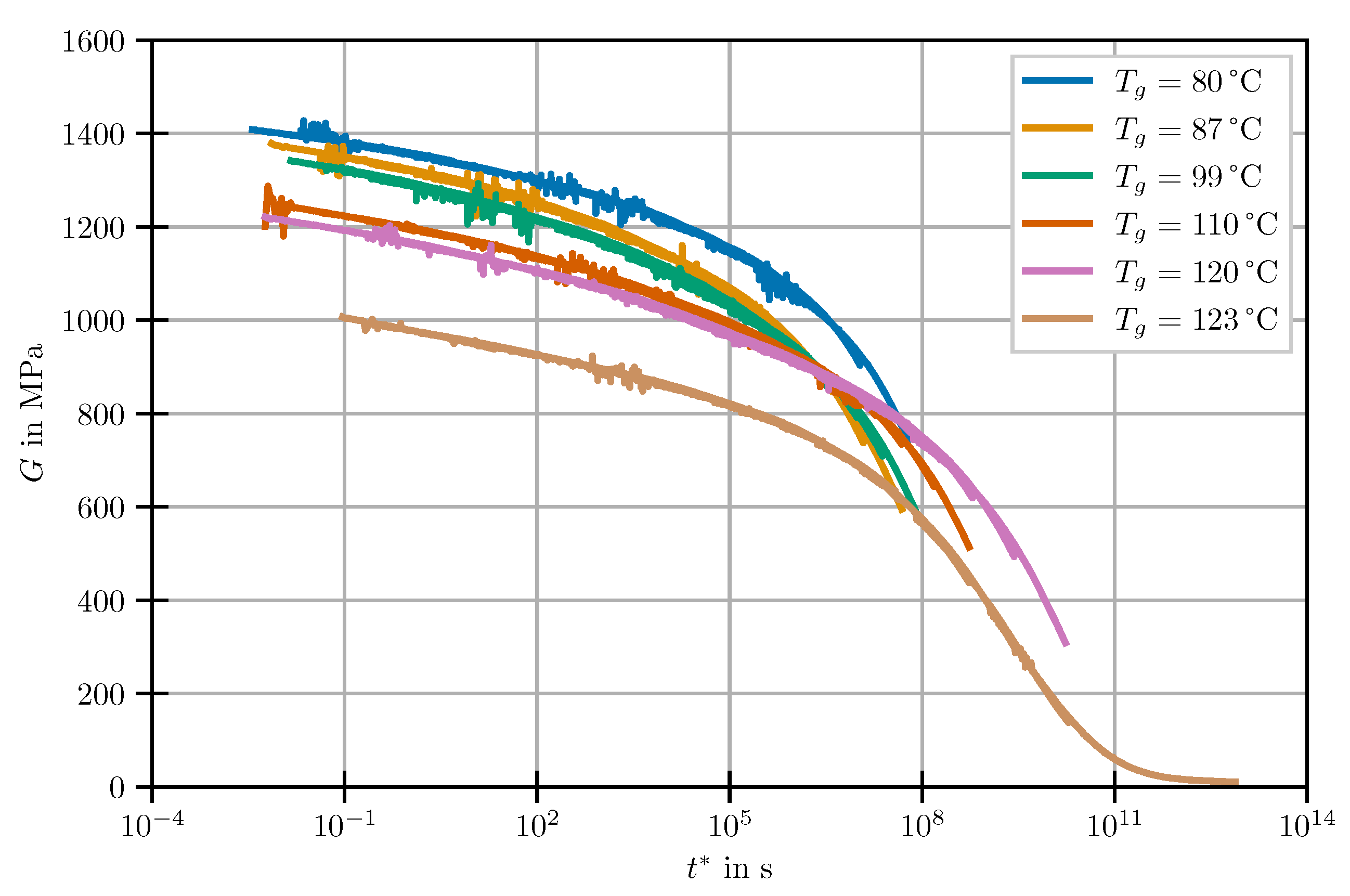

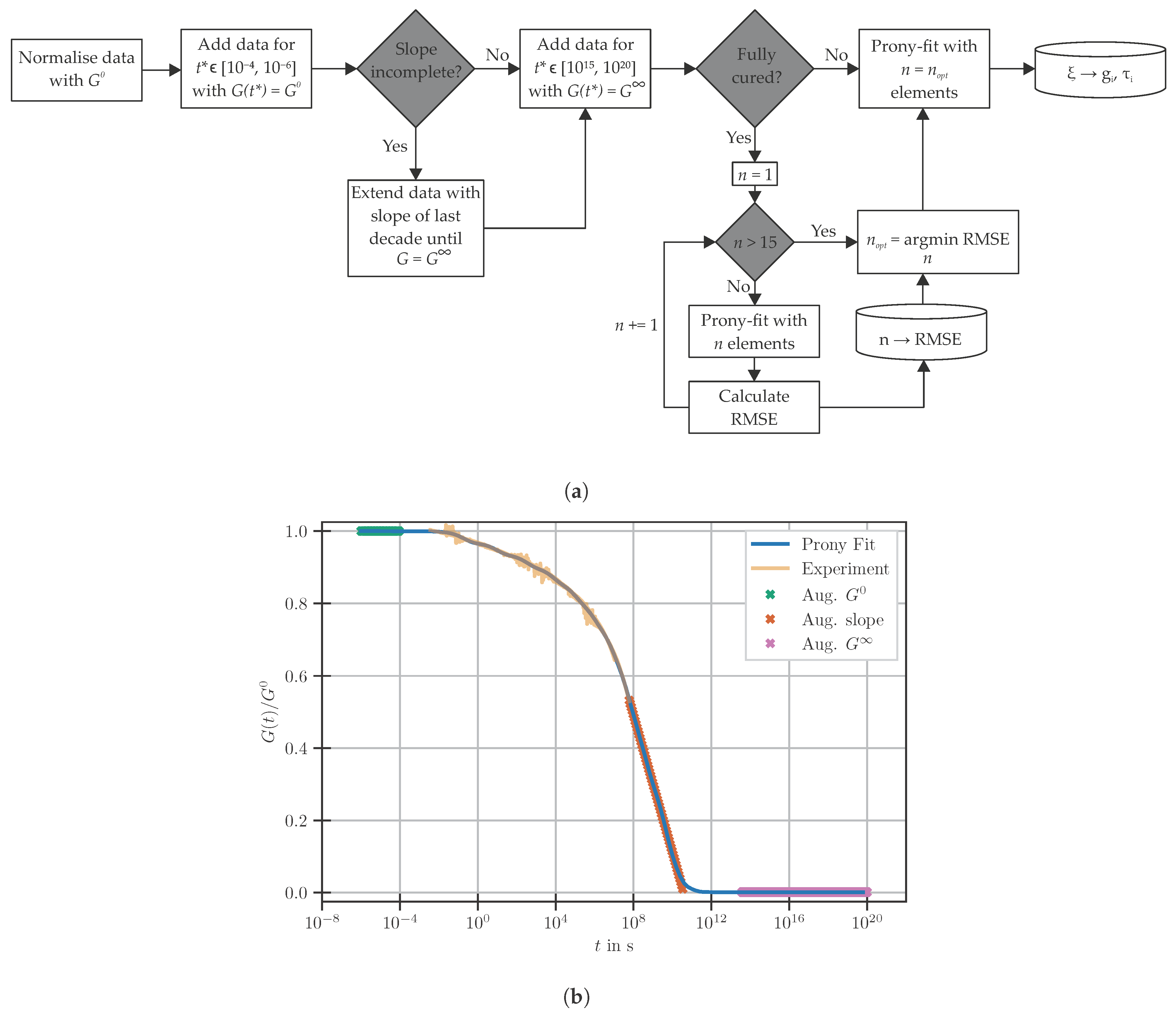

3.1.2. Analysis of Relaxation Experiments

3.2. Model Analysis

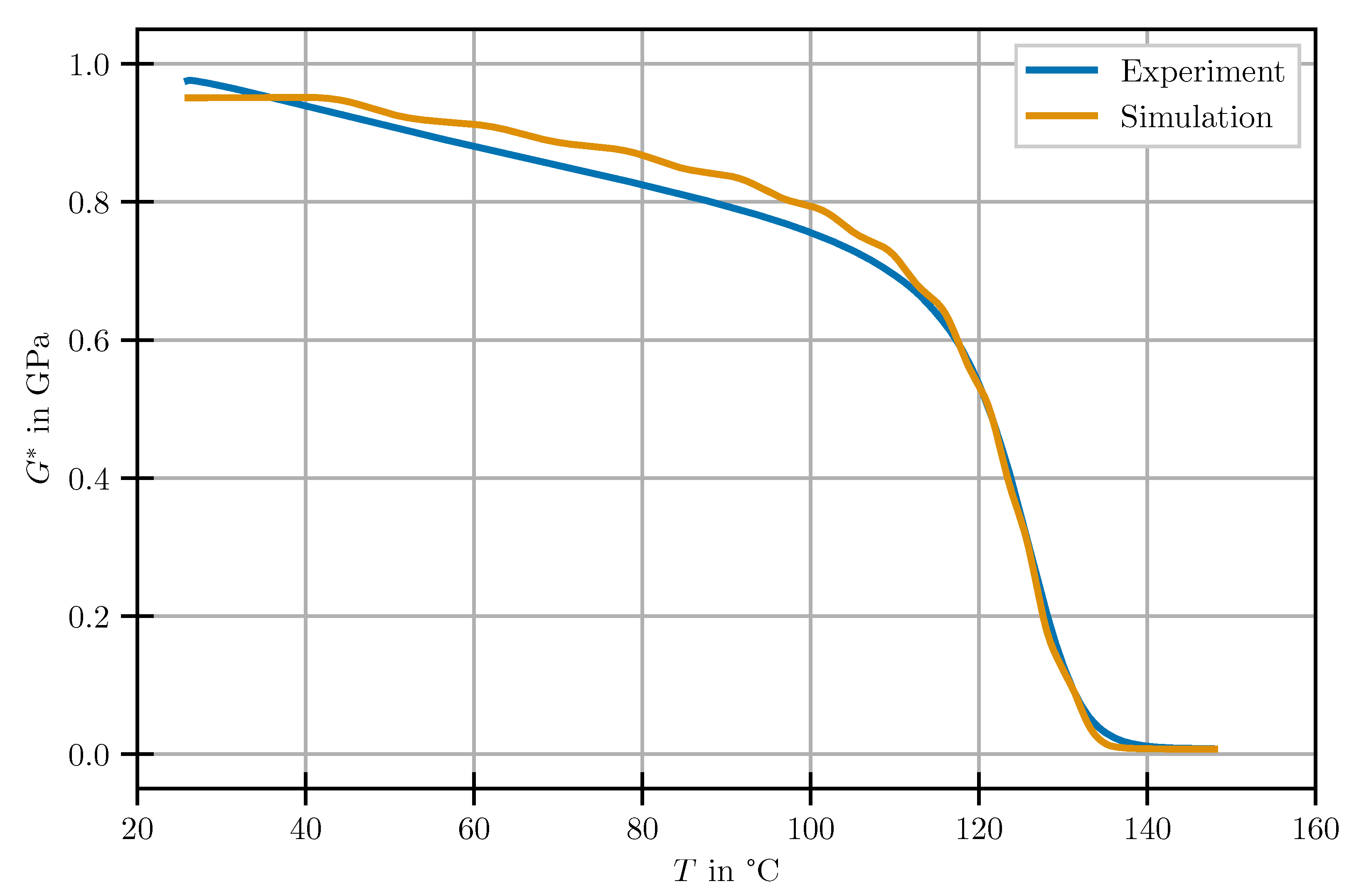

3.2.1. Calibration

3.2.2. Validation

4. Discussion

- Permanent changes of strain and strain rate even including sign changes in both quantities;

- Change of the temperature with a constant rate throughout the experiment;

- A very long period of time to be investigated coherently.

- high-fidelity, process-near testing,

- tailored material modelling and calibration with

- independent validation experiments

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BC | boundary condition |

| DE | differential equation |

| DMA | dynamic mechanical analysis |

| DOC | degree of cure |

| DSC | differential scanning calorimetry |

| EP | epoxy resin |

| PMC | polymer matrix composites |

| RTM | resin transfer moulding |

| SRF | solid rectangular fixture |

| glass transition temperature | |

| WLF | Williams–Landel–Ferry |

Appendix A

References

- Henning, F.; Kärger, L.; Dörr, D.; Schirmaier, F.J.; Seuffert, J.; Bernath, A. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 2019, 171, 261–279. [Google Scholar] [CrossRef]

- Baran, I.; Cinar, K.; Ersoy, N.; Akkerman, R.; Hattel, J.H. A Review on the mechanical modeling of composite manufacturing processes. Arch. Comput. Methods Eng. 2017, 24, 365–395. [Google Scholar] [CrossRef] [PubMed]

- Mesogitis, T.S.; Skordos, A.A.; Long, A.C. Uncertainty in the manufacturing of fibrous thermosetting composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 57, 67–75. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, G.; Xu, J.; Shi, X.P.; Wang, X. Review of curing deformation control methods for carbon fiber reinforced resin composites. Polym. Compos. 2022. [Google Scholar] [CrossRef]

- Gross, T.S.; Jafari, H.; Tsukrov, I.; Bayraktar, H.; Goering, J. Curing cycle modification for RTM6 to reduce hydrostatic residual tensile stress in 3D woven composites. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Joosten, M.W.; Agius, S.; Hilditch, T.; Wang, C. Effect of residual stress on the matrix fatigue cracking of rapidly cured epoxy/anhydride composites. Compos. Part A Appl. Sci. Manuf. 2017, 101, 521–528. [Google Scholar] [CrossRef]

- Hunt, C.; Kratz, J.; Partridge, I.K. Cure path dependency of mode I fracture toughness in thermoplastic particle interleaf toughened prepreg laminates. Compos. Part A Appl. Sci. Manuf. 2016, 87, 109–114. [Google Scholar] [CrossRef]

- ElKhoury, L.; Berg, J.C. The effect of curing schedules on fiber-matrix adhesion in carbon fiber–epoxy resin composites. J. Compos. Mater. 2021, 002199832110604. [Google Scholar] [CrossRef]

- Prussak, R.; Stefaniak, D.; Kappel, E.; Hühne, C.; Sinapius, M. Smart cure cycles for fiber metal laminates using embedded fiber Bragg grating sensors. Compos. Struct. 2019, 213, 252–260. [Google Scholar] [CrossRef]

- Zobeiry, N.; Forghani, A.; Li, C.; Gordnian, K.; Thorpe, R.; Vaziri, R.; Fernlund, G.; Poursartip, A. Multiscale characterization and representation of composite materials during processing. Philos. Trans. Ser. A Math. Phys. Eng. Sci. 2016, 374, 20150278. [Google Scholar] [CrossRef]

- Ding, A.; Li, S.; Sun, J.; Wang, J.; Zu, L. A comparison of process-induced residual stresses and distortions in composite structures with different constitutive laws. J. Reinf. Plast. Compos. 2016, 35, 807–823. [Google Scholar] [CrossRef]

- Müller-Pabel, M.; Rodríguez Agudo, J.A.; Gude, M. Measuring and understanding cure-dependent viscoelastic properties of epoxy resin: A review. Polym. Test. 2022, 114, 107701. [Google Scholar] [CrossRef]

- Lorenz, N.; Müller-Pabel, M.; Gerritzen, J.; Müller, J.; Gröger, B.; Schneider, D.; Fischer, K.; Gude, M.; Hopmann, C. Characterization and modeling cure- and pressure-dependent thermo-mechanical and shrinkage behavior of fast curing epoxy resins. Polym. Test. 2022, 108, 107498. [Google Scholar] [CrossRef]

- Svanberg, J. Predictions of Manufacturing Induced Shape Distortions: High Performance Thermoset Composites. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2002. [Google Scholar]

- Brauner, C.; Block, T.B.; Purol, H.; Herrmann, A.S. Microlevel manufacturing process simulation of carbon fiber/epoxy composites to analyze the effect of chemical and thermal induced residual stresses. J. Compos. Mater. 2012, 46, 2123–2143. [Google Scholar] [CrossRef]

- Zarrelli, M.; Skordos, A.A.; Partridge, I.K. Toward a constitutive model for cure-dependent modulus of a high temperature epoxy during the cure. Eur. Polym. J. 2010, 46, 1705–1712. [Google Scholar] [CrossRef]

- Eom, Y.; Boogh, L.; Michaud, V.; Sunderland, P.; Månson, J.A. Time-cure-temperature superposition for the prediction of instantaneous viscoelastic properties during cure. Polym. Eng. Sci. 2000, 40, 1281–1292. [Google Scholar] [CrossRef]

- Simon, S.L.; Mckenna, G.B.; Sindt, O. Modeling the evolution of the dynamic mechanical properties of a commercial epoxy during cure after gelation. J. Appl. Polym. Sci. 2000, 76, 495–508. [Google Scholar] [CrossRef]

- Prasatya, P.; Mckenna, G.B.; Simon, S.L. A Viscoelastic Model for Predicting Isotropic Residual Stresses in Thermosetting Materials: Effects of Processing Parameters. J. Compos. Mater. 2001, 35, 826–848. [Google Scholar] [CrossRef]

- Kim, Y.K.; White, S.R. Stress relaxation behavior of 3501–6 epoxy resin during cure. Polym. Eng. Sci. 1996, 36, 2852–2862. [Google Scholar] [CrossRef]

- Ewoldt, R.H.; Johnston, M.T.; Caretta, L.M. Experimental challenges of shear rheology: How to avoid bad data. In Complex Fluids in Biological Systems; Spagnolie, S., Ed.; Biological and Medical Physics, Biomedical Engineering; Springer: Berlin/Heidelberg, Germany, 2014; pp. 207–241. [Google Scholar] [CrossRef]

- O’Brien, D.J.; Mather, P.T.; White, S.R. Viscoelastic properties of an epoxy resin during cure. J. Compos. Mater. 2001, 35, 883–904. [Google Scholar] [CrossRef]

- Saseendran, S.; Wysocki, M.; Varna, J. Evolution of viscoelastic behavior of a curing LY5052 epoxy resin in the glassy state. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 74–82. [Google Scholar] [CrossRef]

- Liu, C.Y.; Yao, M.; Garritano, R.G.; Franck, A.J.; Bailly, C. Instrument compliance effects revisited: Linear viscoelastic measurements. Rheol. Acta 2011, 50, 537–546. [Google Scholar] [CrossRef]

- Courtois, A.; Hirsekorn, M.; Benavente, M.; Jaillon, A.; Marcin, L.; Ruiz, E.; Lévesque, M. Viscoelastic behavior of an epoxy resin during cure below the glass transition temperature: Characterization and modeling. J. Compos. Mater. 2019, 53, 155–171. [Google Scholar] [CrossRef]

- EPIKOTE™ TRAC 06150 Product Description: Datasheet. Hexion Inc.: Columbus, OH, USA. 2022. Available online: https://www.hexion.com/CustomServices/PDFDownloader.aspx?type=recipe&pid=8d7ec73d-5814-6fe3-ae8a-ff0300fcd525 (accessed on 29 August 2022).

- Wang, Z.; Lauter, C.; Sanitther, B.; Camberg, A.; Tröster, T. Manufacturing and investigation of steel-CFRP hybrid pillar structures for automotive applications by intrinsic resin transfer moulding technology. Int. J. Automot. Compos. 2016, 229–243. [Google Scholar] [CrossRef]

- Winter, H.H. Can the gel point of a cross-linking polymer be detected by theG? -G? crossover? Polym. Eng. Sci. 1987, 27, 1698–1702. [Google Scholar] [CrossRef]

- Flammersheim, H.J.; Opfermann, J. Formal kinetic evaluation of reactions with partial diffusion control. Thermochim. Acta 1999, 337, 141–148. [Google Scholar] [CrossRef]

- Hernández, W.P.; Castello, D.A.; Roitman, N.; Magluta, C. Thermorheologically simple materials: A bayesian framework for model calibration and validation. J. Sound Vib. 2017, 402, 14–30. [Google Scholar] [CrossRef]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cournapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J.; et al. SciPy 1.0: Fundamental algorithms for scientific computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef]

- Venditti, R.A.; Gillham, J.K.; Jean, Y.C.; Lou, Y. Free volume after cure vs. fractional conversion for a high-Tg epoxy/amine thermosetting system. J. Appl. Polym. Sci. 1995, 56, 1207–1220. [Google Scholar] [CrossRef]

- Detwiler, A.T.; Lesser, A.J. Aspects of network formation in glassy thermosets. J. Appl. Polym. Sci. 2010, 117, 1021–1034. [Google Scholar] [CrossRef]

- Marks, M.J.; Snelgrove, R.V. Effect of conversion on the structure-property relationships of amine-cured epoxy thermosets. ACS Appl. Mater. Interfaces 2009, 1, 921–926. [Google Scholar] [CrossRef]

- Müller, M.; Winkler, A.; Gude, M.; Jäger, H. Aspects of reproducibility and stability for partial cure of epoxy matrix resin. J. Appl. Polym. Sci. 2020, 137, 48342. [Google Scholar] [CrossRef]

- Smith, M. ABAQUS/Standard User’s Manual, Version 6.9; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2009. [Google Scholar]

| Post-Cure Temperature in | Post-Cure Dwell-Time in min | Resulting in |

|---|---|---|

| - | - | 80.5 |

| 75 | 10 | 87.1 |

| 85 | 10 | 99.6 |

| 95 | 10 | 109.7 |

| 105 | 10 | 120.8 |

| 130 | 10 | 123 |

| m | in log() | in | in log() | in | ||

|---|---|---|---|---|---|---|

| 1.47 | 1.41 | 1.43 | 26.18 | 0.62 | 6.99 | 67.65 |

| in | in log() | in log() | ||||

| 12 | 50 | −3 | −5.5 | |||

| in | in | |

|---|---|---|

| −14.160 | 15.067 | 0.0386 |

| in °C | ||||||

|---|---|---|---|---|---|---|

| 80 | 87 | 99 | 110 | 120 | 123 | |

| 7.2 | 6.2 | 6.4 | 7.3 | 9.1 | 9.6 | |

| 0.18 | 0.13 | 0.11 | 0.12 | 0.17 | 0.21 | |

| 7.8 × 10−5 | 4.3 × 10−4 | 6.4 × 10−4 | 1.2 × 10−3 | 2.2 × 10−3 | 2.2 × 10−3 | |

| 1.4 × 10−6 | 9.7 × 10−6 | 1.1 × 10−5 | 1.4 × 10−5 | 1.8 × 10−5 | 1.2 × 10−5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gerritzen, J.; Müller-Pabel, M.; Müller, J.; Gröger, B.; Lorenz, N.; Hopmann, C.; Gude, M. Development of a High-Fidelity Framework to Describe the Process-Dependent Viscoelasticity of a Fast-Curing Epoxy Matrix Resin including Testing, Modelling, Calibration and Validation. Polymers 2022, 14, 3647. https://doi.org/10.3390/polym14173647

Gerritzen J, Müller-Pabel M, Müller J, Gröger B, Lorenz N, Hopmann C, Gude M. Development of a High-Fidelity Framework to Describe the Process-Dependent Viscoelasticity of a Fast-Curing Epoxy Matrix Resin including Testing, Modelling, Calibration and Validation. Polymers. 2022; 14(17):3647. https://doi.org/10.3390/polym14173647

Chicago/Turabian StyleGerritzen, Johannes, Michael Müller-Pabel, Jonas Müller, Benjamin Gröger, Niklas Lorenz, Christian Hopmann, and Maik Gude. 2022. "Development of a High-Fidelity Framework to Describe the Process-Dependent Viscoelasticity of a Fast-Curing Epoxy Matrix Resin including Testing, Modelling, Calibration and Validation" Polymers 14, no. 17: 3647. https://doi.org/10.3390/polym14173647

APA StyleGerritzen, J., Müller-Pabel, M., Müller, J., Gröger, B., Lorenz, N., Hopmann, C., & Gude, M. (2022). Development of a High-Fidelity Framework to Describe the Process-Dependent Viscoelasticity of a Fast-Curing Epoxy Matrix Resin including Testing, Modelling, Calibration and Validation. Polymers, 14(17), 3647. https://doi.org/10.3390/polym14173647