Effects of Fluorine-Based Modification on Triboelectric Properties of Cellulose

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Reagents

2.2. Fluoro Modification of Cellulose

2.3. Preparation of Paper and Fluorinated Paper (PDOTES-Paper)

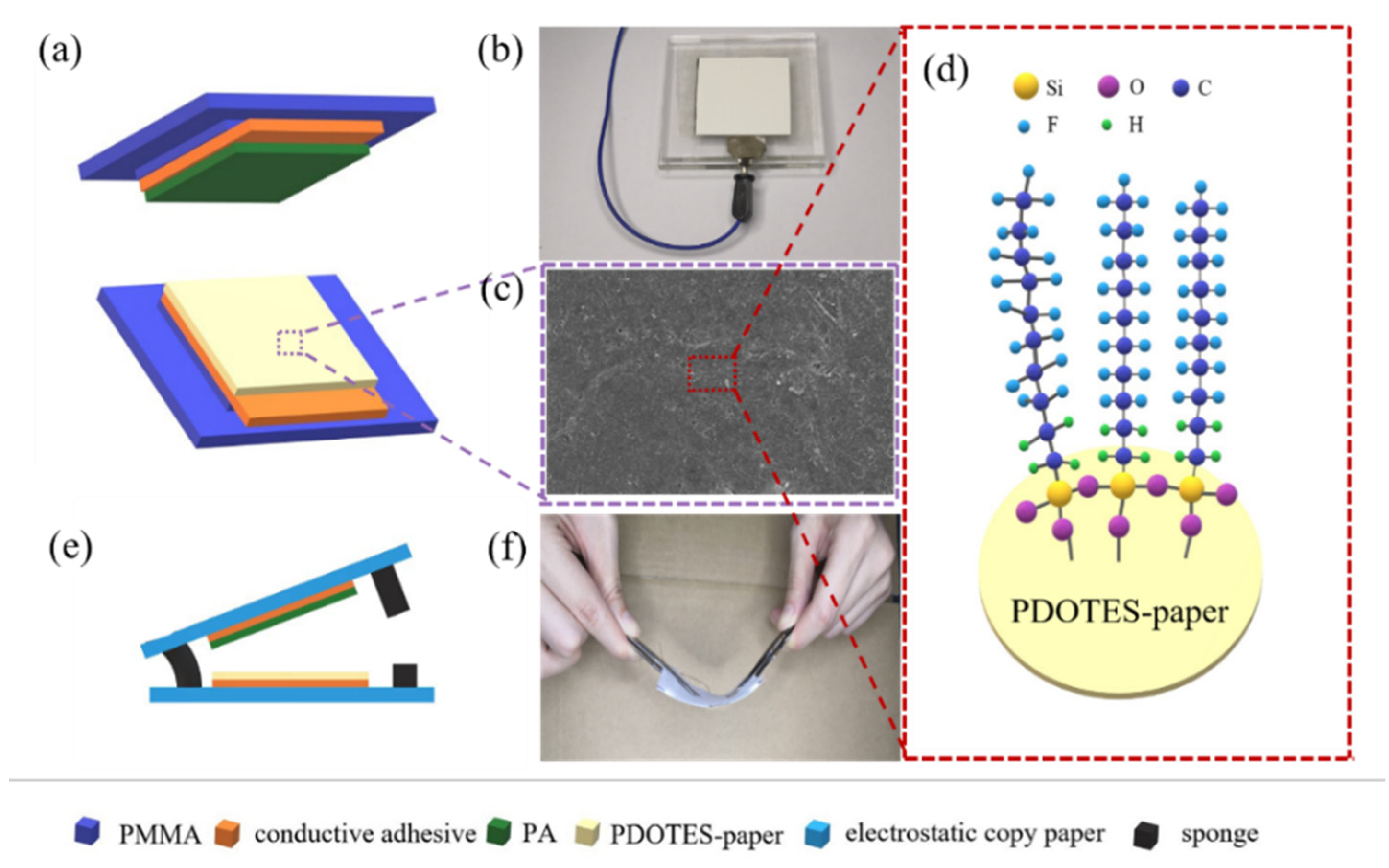

2.4. Structure of TENG and Wearable Device

2.5. Characterization

3. Results

3.1. Characterization of Cellulose

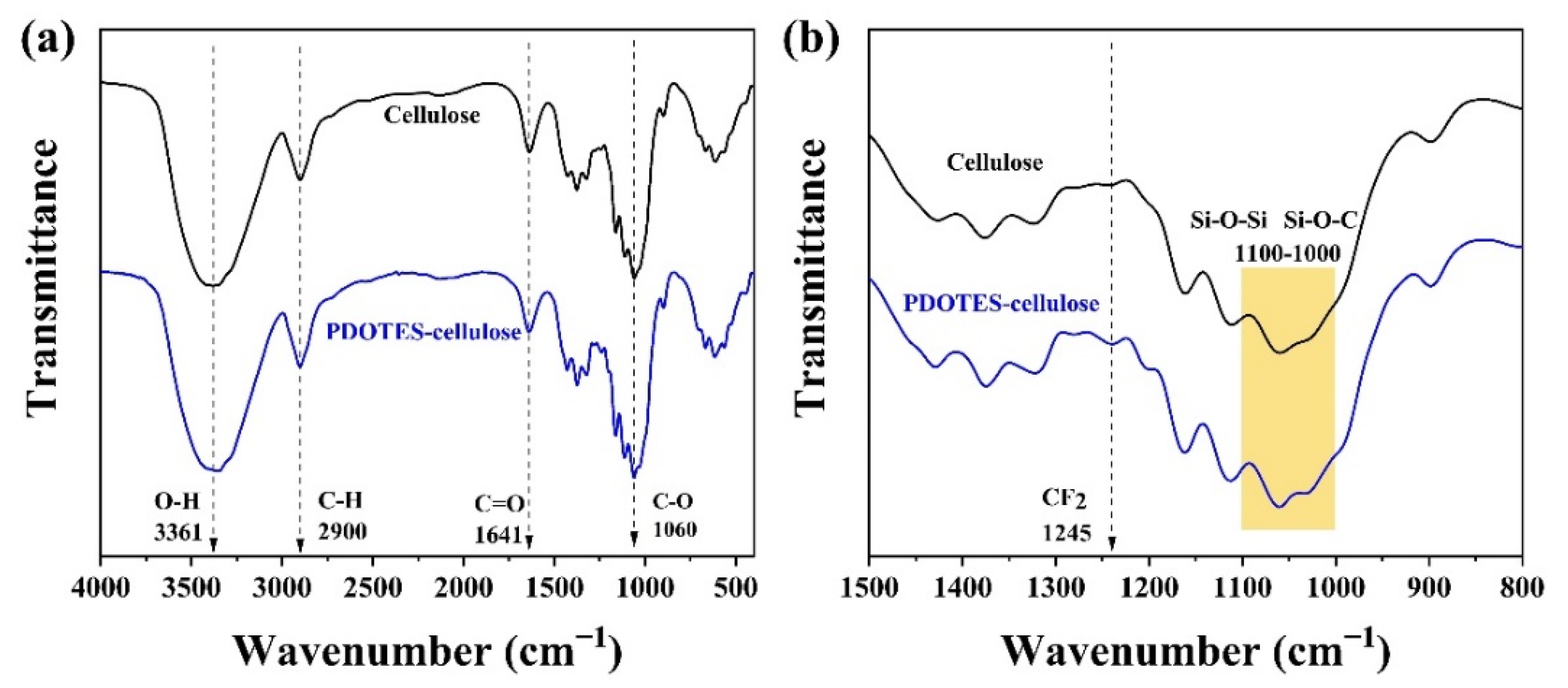

3.1.1. FTIR Analysis

3.1.2. XRD Analysis

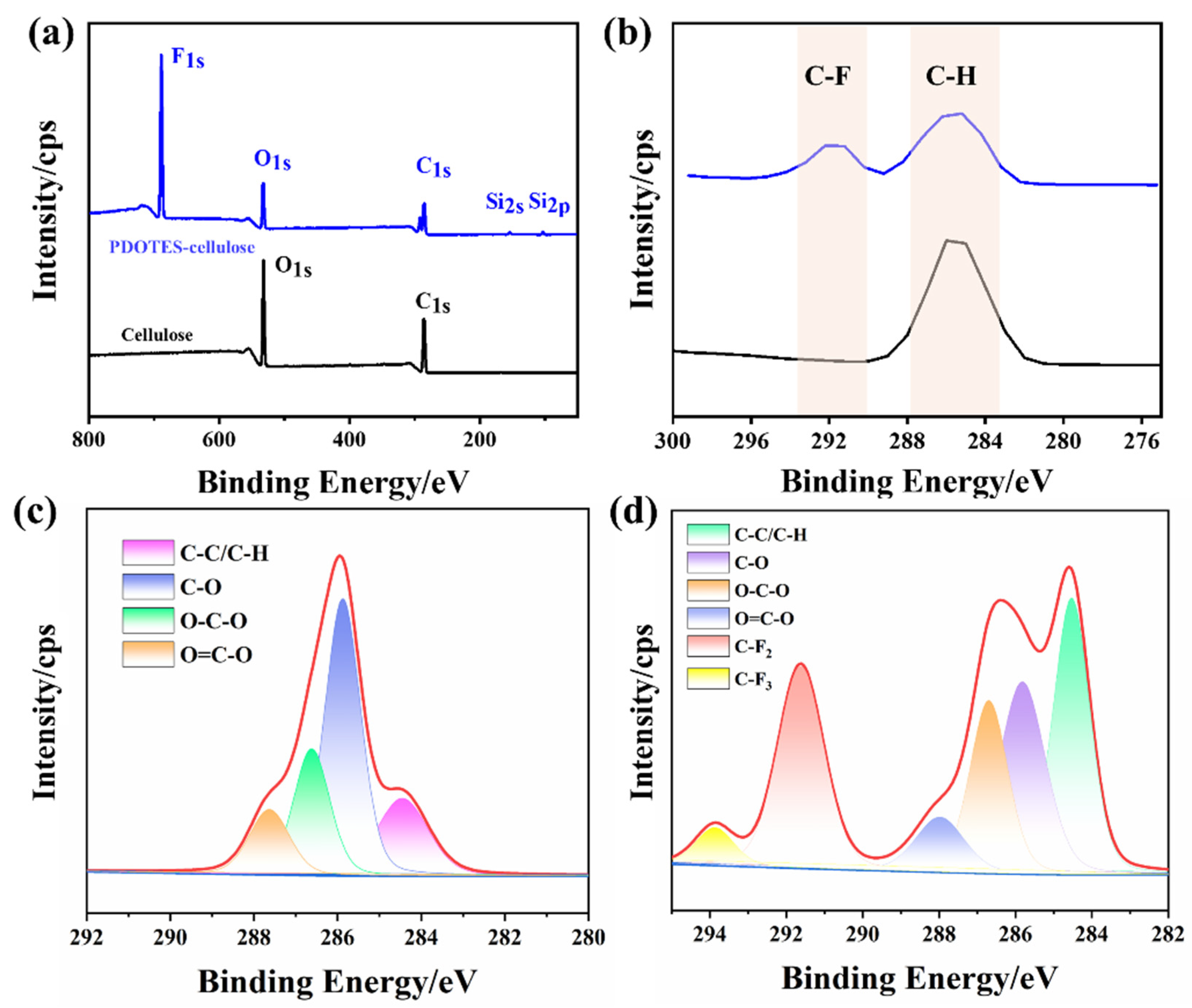

3.1.3. XPS Analysis

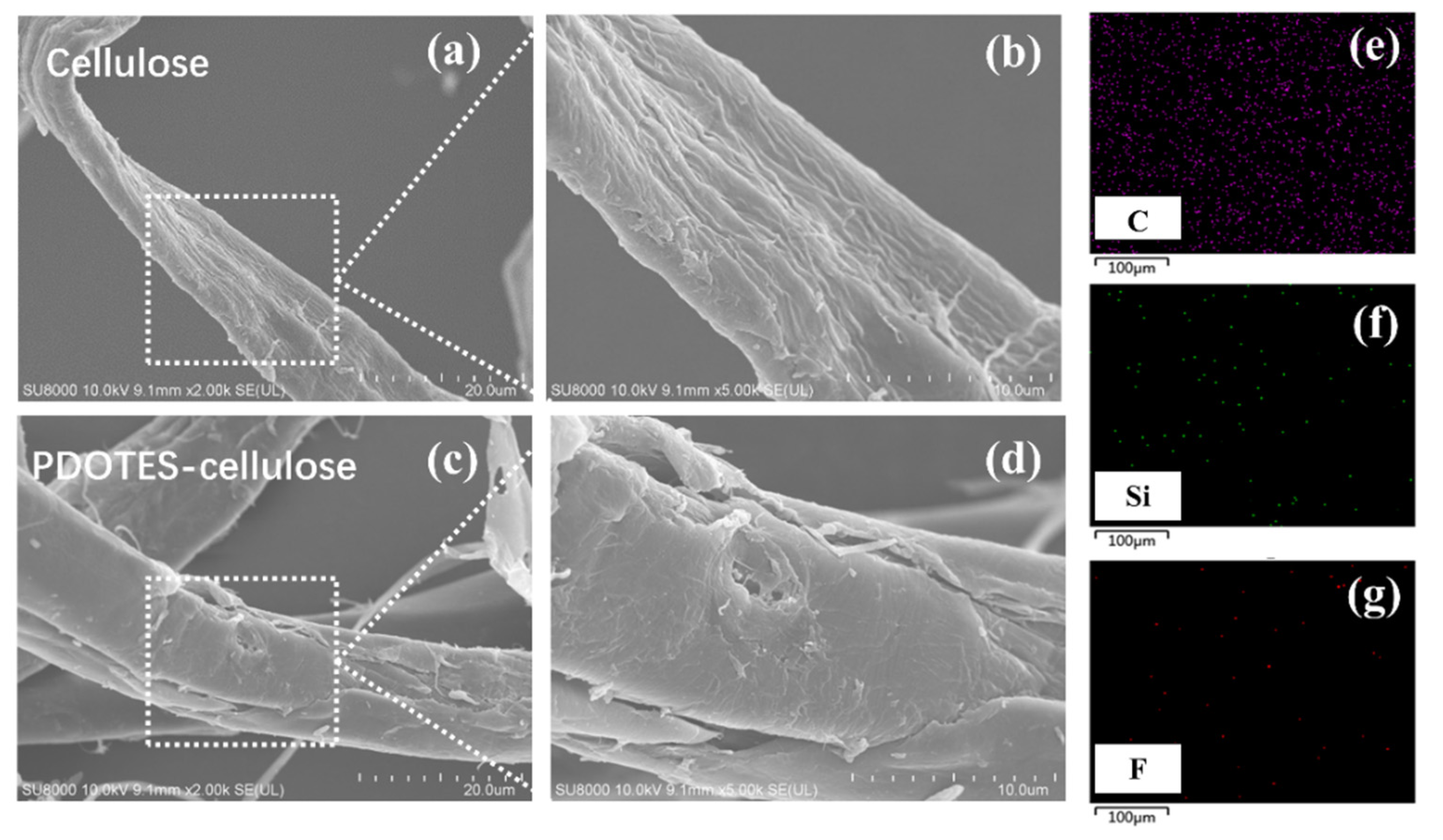

3.2. Surface Morphology and Elemental Distribution

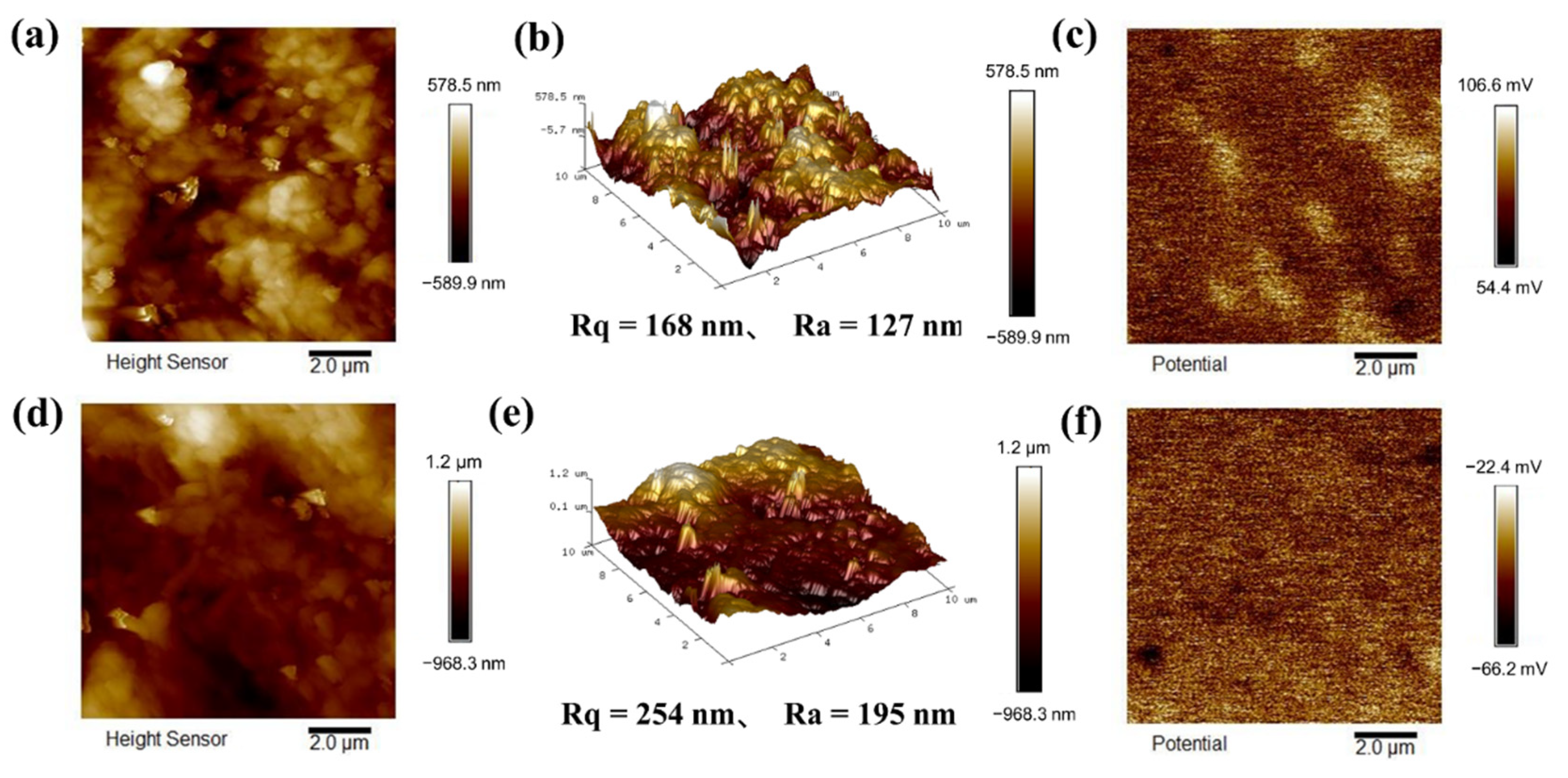

3.3. Surface Roughness and Surface Potential Distribution

3.4. Working Principle of Triboelectric Nanogenerator

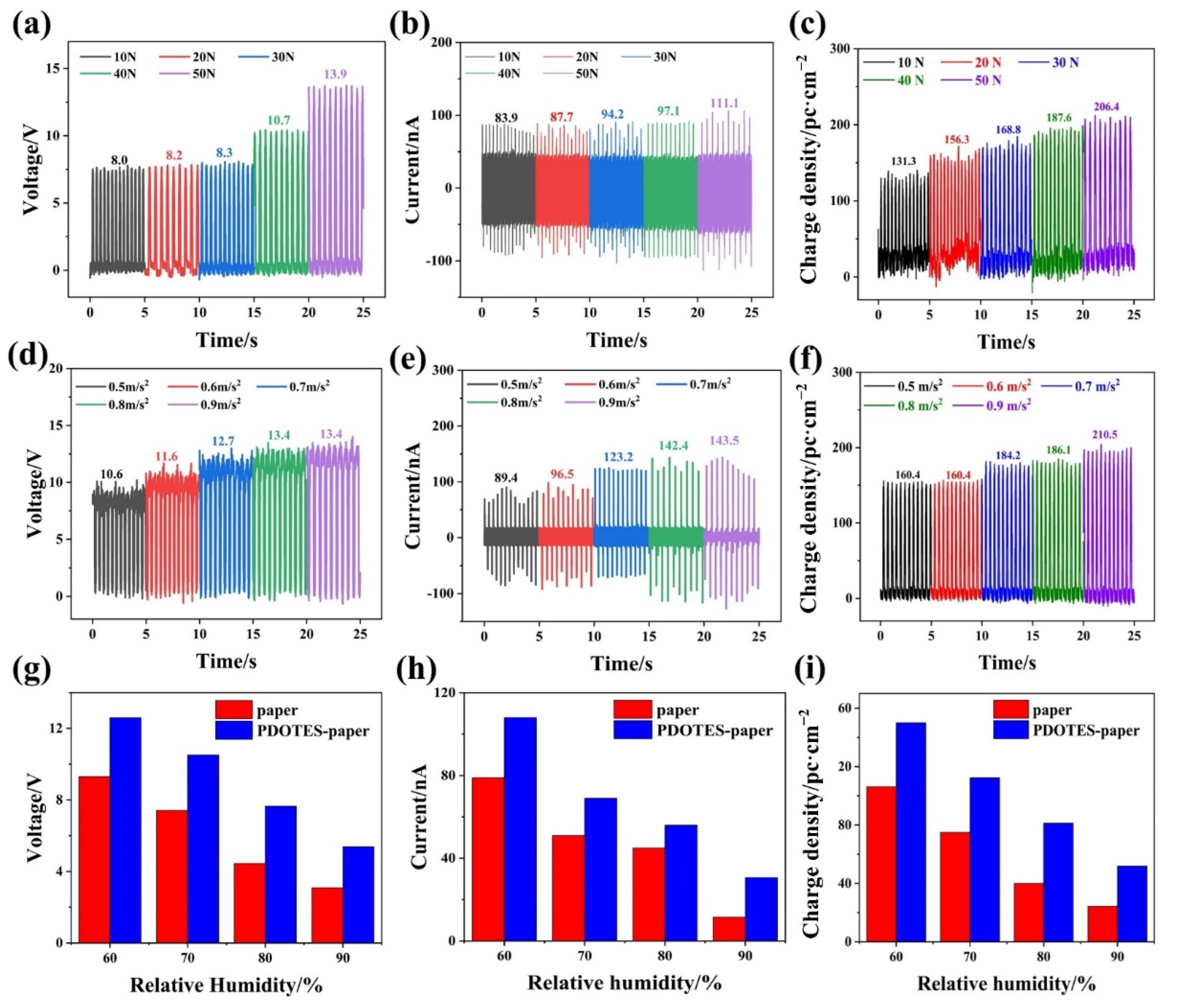

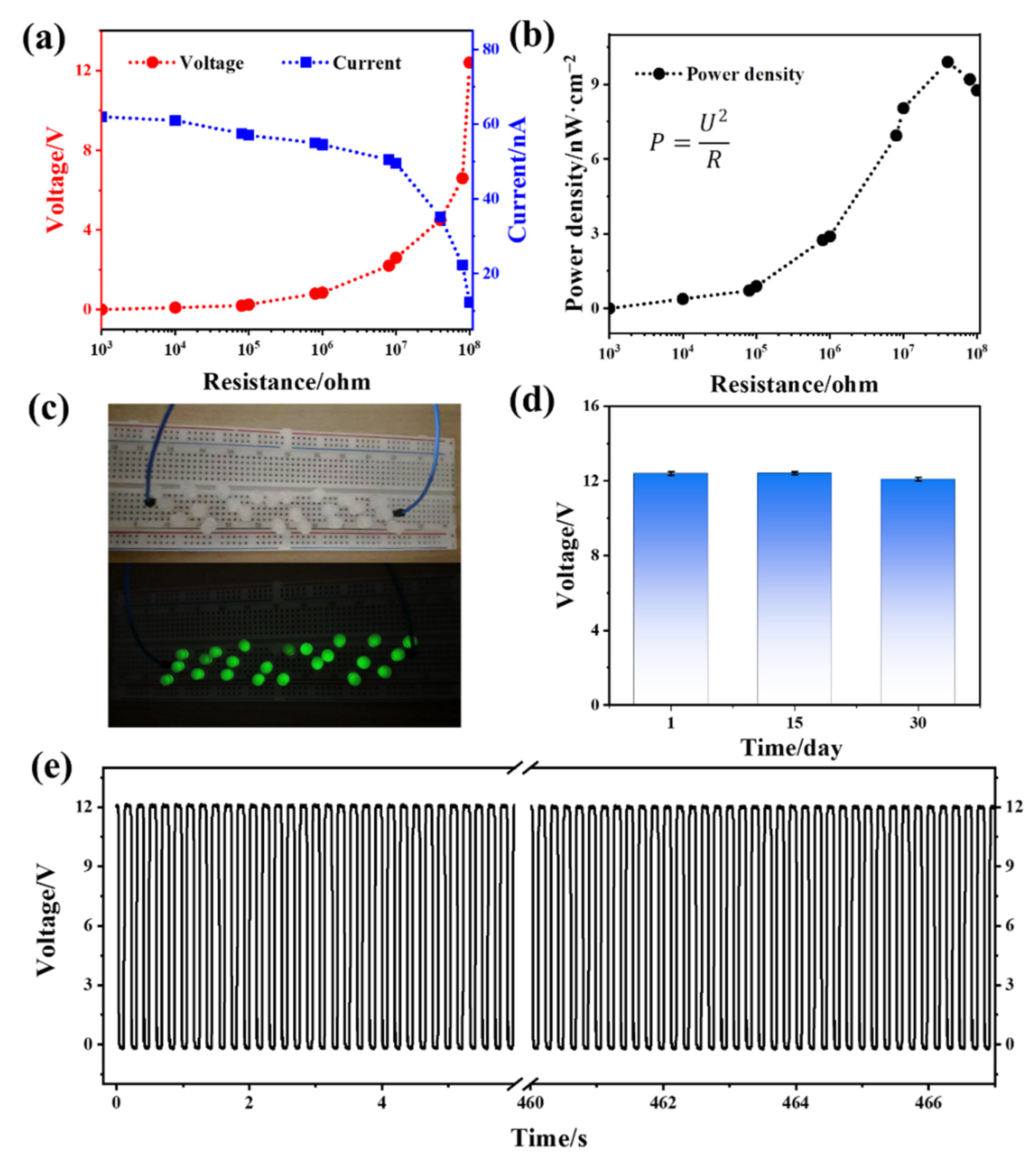

3.5. Output Performance of Triboelectric Nanogenerator

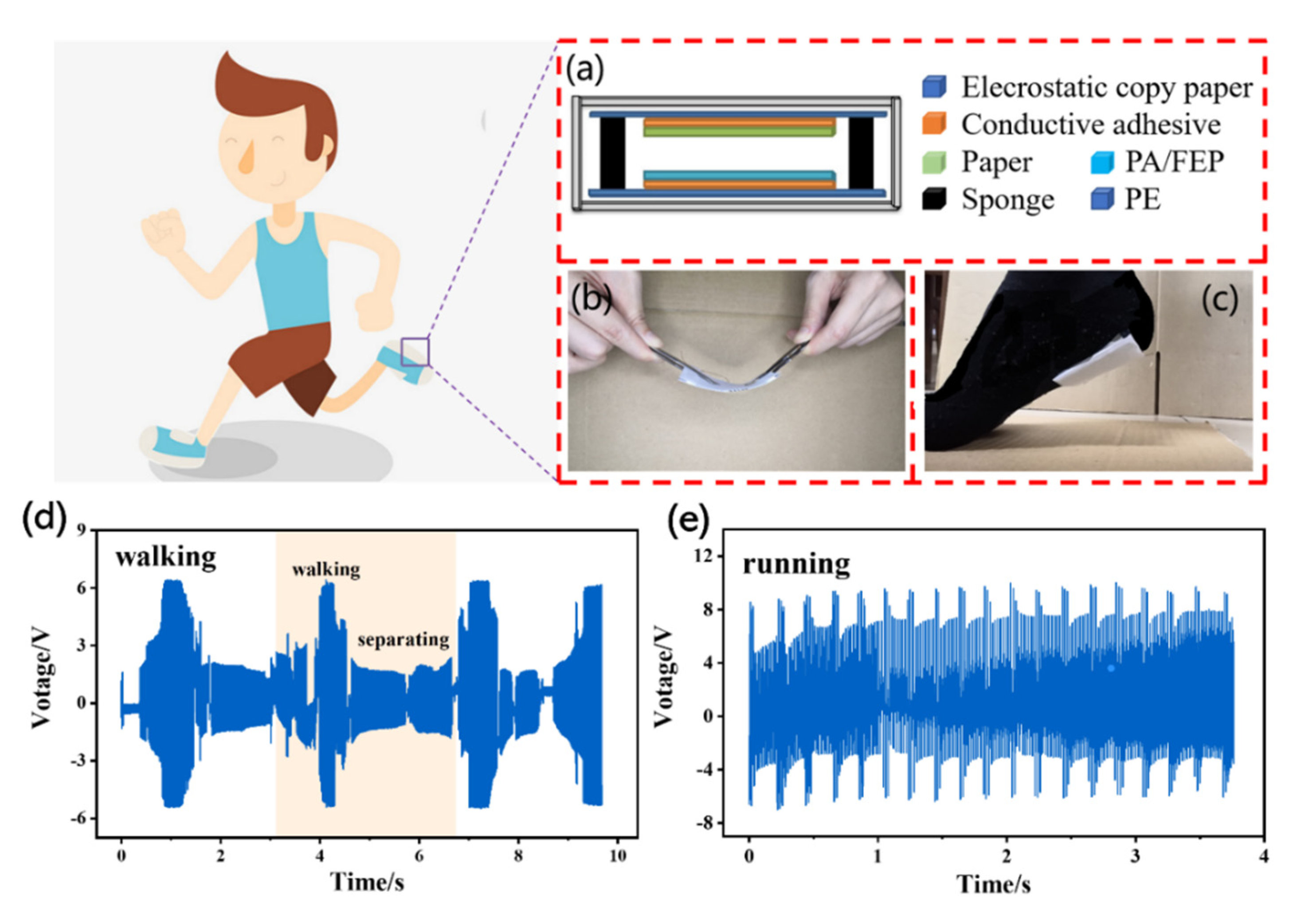

3.6. Applications of FG-TENGs in Self-Powered Sensing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PDOTES | 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane |

| TENG | Triboelectric nanogenerator |

| CNFs | Cellulose nanofibers |

| PMMA | Polymethyl methacrylate |

| PA | Nylon |

References

- Wei, X.; Zhao, Z.; Zhang, C.; Yuan, W.; Wu, Z.; Wang, J.; Wang, Z.L. All-Weather Droplet-Based Triboelectric Nanogenerator for Wave Energy Harvesting. ACS Nano 2021, 15, 13200–13208. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wu, W. Nanotechnology-Enabled Energy Harvesting for Self-Powered Micro-/Nanosystems. Angew. Chem. Int. Ed. 2012, 51, 11700–11721. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Chen, C.; Chen, L.; Wu, Z.; Guo, H.; Yu, W.; Du, Z.; Wang, Z.L. 3D double-faced interlock fabric triboelectric nanogenerator for bio-motion energy harvesting and as self-powered stretching and 3D tactile sensors. Mater. Today 2020, 32, 84–93. [Google Scholar] [CrossRef]

- Chandrasekhar, A.; Vivekananthan, V.; Khandelwal, G.; Kim, S.J. A fully packed water-proof, humidity resistant triboelectric nanogenerator for transmitting Morse code. Nano Energy 2019, 60, 850–856. [Google Scholar] [CrossRef]

- Rajabi-Abhari, A.; Lee, J.; Tabassian, R.; Kim, J.; Lee, H.; Oh, I. Antagonistically Functionalized Diatom Biosilica for Bio-Triboelectric Generators. Small 2022, 18, 2107638. [Google Scholar] [CrossRef]

- Yao, L.; Zhou, Z.; Zhang, Z.; Du, X.; Zhang, Q.-L.; Yang, H. Dyeing-Inspired Sustainable and Low-Cost Modified Cellulose-Based TENG for Energy Harvesting and Sensing. ACS Sustain. Chem. Eng. 2022, 10, 3909–3919. [Google Scholar] [CrossRef]

- Shi, K.; Zou, H.; Sun, B.; Jiang, P.; He, J.; Huang, X. Dielectric Modulated Cellulose Paper/PDMS-Based Triboelectric Nanogenerators for Wireless Transmission and Electro polymerization Applications. Adv. Funct. Mater. 2019, 30, 1904536. [Google Scholar] [CrossRef]

- Kim, I.; Roh, H.; Choi, W.; Kim, D. Air-gap embedded triboelectric nanogenerator via surface modification of non-contact layer using sandpapers. Nanoscale 2021, 13, 8837–8847. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Yu, J.S. High-performance and cost-effective triboelectric nanogenerators by sandpaper-assisted micropatterned polytetrafluoroethylene. Energy 2018, 165, 677–684. [Google Scholar] [CrossRef]

- Zhao, D.; Zhu, Y.; Cheng, W.; Chen, W.; Wu, Y.; Yu, H. Cellulose-Based Flexible Functional Materials for Emerging Intelligent Electronics. Adv. Mater. 2021, 33, 2000619. [Google Scholar] [CrossRef]

- Zhang, R.; Dahlstrom, C.; Zou, H.; Jonzon, J.; Hummelgard, M.; Ortegren, J.; Blomquist, N.; Yang, Y.; Andersson, H.; Olsen, M.; et al. Cellulose-Based Fully Green Triboelectric Nanogenerators with Output Power Density of 300 W m−2. Adv. Mater. 2020, 32, 2002824. [Google Scholar] [CrossRef]

- Qin, Y.; Mo, J.; Liu, Y.; Zhang, S.; Wang, J.; Fu, Q.; Wang, S.; Nie, S. Stretchable Triboelectric Self-Powered Sweat Sensor Fabricated from Self-Healing Nanocellulose Hydrogels. Adv. Funct. Mater. 2022, 32, 2201846. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Ye, E.; Li, Z.; Wang, D. Control methods and applications of interface contact electrification of triboelectric nanogenerators: A review. Mater. Res. Lett. 2022, 10, 97–123. [Google Scholar] [CrossRef]

- Yao, C.; Yin, X.; Yu, Y.; Cai, Z.; Wang, X. Chemically Functionalized Natural Cellulose Materials for Effective Triboelectric Nanogenerator Development. Adv. Funct. Mater. 2017, 27, 1700794. [Google Scholar] [CrossRef]

- Roy, S.; Ko, H.-U.; Maji, P.K.; Van Hai, L.; Kim, J. Large amplification of triboelectric property by allicin to develop high performance cellulosic triboelectric nanogenerator. Chem. Eng. J. 2019, 385, 123723. [Google Scholar] [CrossRef]

- Nie, S.; Cai, C.; Lin, X.; Zhang, C.; Lu, Y.; Mo, J.; Wang, S. Chemically Functionalized Cellulose Nanofibrils for Improving Triboelectric Charge Density of a Triboelectric Nanogenerator. ACS Sustain. Chem. Eng. 2020, 8, 18678–18685. [Google Scholar] [CrossRef]

- Tabaght, F.E.; El Idrissi, A.; Aqil, M.; Elbachiri, A.; Tahani, A.; Maaroufi, A. Grafting method of fluorinated compounds to cellulose and cellulose acetate: Characterization and biodegradation stund. Cellul. Chem. Technol. 2021, 55, 511–528. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced performance of a cellulose nanofibrils-based triboelectric nanogenerator by tuning the surface polarizability and hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Kaynak, B.; Alpan, C.; Kratzer, M.; Ganser, C.; Teichert, C.; Kern, W. Anti-adhesive layers on stainless steel using thermally stable dipodal perfluoroalkyl silanes. Appl. Surf. Sci. 2017, 416, 824–833. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Xu, S.; Wu, L.; Lu, S.; Wu, H.; Huang, L.; Chen, L. Preparation and Characterization of Cellulose-g-PFOEMA. J. Cellul. Sci. Technol. 2016, 24, 7–11. [Google Scholar]

- Jing-qiang, Z.; Lu, L.I.N.; Bei-hai, H.E.; Shi-jie, L.; Ping-kai, O. X-Ray Photoelectron Spectroscopic Analysis of Celluloses with Different Crystallization Index. Chem. Ind. For. Prod. 2009, 29, 30–34. [Google Scholar]

- Levdanskya, V.A.; Kondracenkoa, A.S.; Levdanskya, A.V.; Kuznetsova, B.N.; Djakovitchc, L.; Pinelc, C. Sulfation of Microcrystalline Cellulose with Sulfamic Acid in N, N-Dimethylformamide and Diglyme. J. Sib. Fed. Univ. 2014, 7, 162–167. [Google Scholar]

- Mi, H.Y.; Jing, X.; Zheng, Q.; Fang, L.; Huang, H.-X.; Turng, L.-S.; Gong, S. High-performance flexible triboelectric nanogenerator based on porous aerogels and electrospun nanofibers for energy harvesting and sensitive self-powered sensing. Nano Energy 2018, 48, 327–336. [Google Scholar] [CrossRef]

- Xu, Y.; Min, G.; Gadegaard, N.; Dahiya, R.; Mulvihill, D.M. A unified contact force-dependent model for triboelectric nanogenerators accounting for surface roughness. Nano Energy 2020, 76, 105067. [Google Scholar] [CrossRef]

- Wen, R.; Guo, J.; Yu, A.; Zhai, J.; Wang, Z.L. Humidity-Resistive Triboelectric Nanogenerator Fabricated Using Metal Organic Framework Composite. Adv. Funct. Mater. 2019, 29, 1807655. [Google Scholar] [CrossRef]

- Wang, N.; Zheng, Y.; Feng, Y.; Zhou, F.; Wang, D. Biofilm material based triboelectric nanogenerator with high output performance in 95% humidity environment. Nano Energy 2020, 77, 105088. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, G.; Lin, Z.-H.; Yang, J.; Lin, L.; Wang, Z.L. Single-electrode-based rotationary triboelectric nanogenerator and its applications as self-powered contact area and eccentric angle sensors. Nano Energy 2015, 11, 323–332. [Google Scholar] [CrossRef]

- Mule, A.R.; Dudem, B.; Patnam, H.; Graham, S.A.; Yu, J.S. Wearable Single-Electrode-Mode Triboelectric Nanogenerator via Conductive Polymer-Coated Textiles for Self-Power Electronics. ACS Sustain. Chem. Eng. 2019, 7, 16450–16458. [Google Scholar] [CrossRef]

- Wu, J.; Xi, Y.; Shi, Y. Toward wear-resistive, highly durable and high performance triboelectric nanogenerator through interface liquid lubrication. Nano Energy 2020, 72, 104659. [Google Scholar] [CrossRef]

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A Hierarchically Nanostructured Cellulose Fiber-Based Triboelectric Nanogenerator for Self-Powered Healthcare Products. Adv. Funct. Mater. 2018, 28, 1805540. [Google Scholar] [CrossRef]

- Sriphan, S.; Charoonsuk, T.; Maluangnont, T.; Pakawanit, P.; Rojviriya, C.; Vittayakorn, N. Multifunctional Nanomaterials Modification of Cellulose Paper for Efficient Triboelectric Nanogenerators. Adv. Mater. Technol. 2020, 5, 2000001. [Google Scholar] [CrossRef]

| Samples | C1s (%) | O1s (%) | F1s (%) | O/C (%) |

|---|---|---|---|---|

| Cellulose | 55.72 | 44.28 | - | 79.47 |

| PDOTES-cellulose | 43.77 | 18.59 | 37.64 | 42.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Wang, T.; Sun, X.; Wei, Y.; Zhang, S.; Wang, X.; Luo, L. Effects of Fluorine-Based Modification on Triboelectric Properties of Cellulose. Polymers 2022, 14, 3536. https://doi.org/10.3390/polym14173536

Zhu Q, Wang T, Sun X, Wei Y, Zhang S, Wang X, Luo L. Effects of Fluorine-Based Modification on Triboelectric Properties of Cellulose. Polymers. 2022; 14(17):3536. https://doi.org/10.3390/polym14173536

Chicago/Turabian StyleZhu, Qiuxiao, Tingting Wang, Xiaoping Sun, Yuhe Wei, Sheng Zhang, Xuchong Wang, and Lianxin Luo. 2022. "Effects of Fluorine-Based Modification on Triboelectric Properties of Cellulose" Polymers 14, no. 17: 3536. https://doi.org/10.3390/polym14173536

APA StyleZhu, Q., Wang, T., Sun, X., Wei, Y., Zhang, S., Wang, X., & Luo, L. (2022). Effects of Fluorine-Based Modification on Triboelectric Properties of Cellulose. Polymers, 14(17), 3536. https://doi.org/10.3390/polym14173536