Rheological Properties and Melt Spinning Application of Controlled-Rheology Polypropylenes via Pilot-Scale Reactive Extrusion

Abstract

:1. Introduction

2. Experiment

2.1. Twin-Screw Extrusion of PP Resins

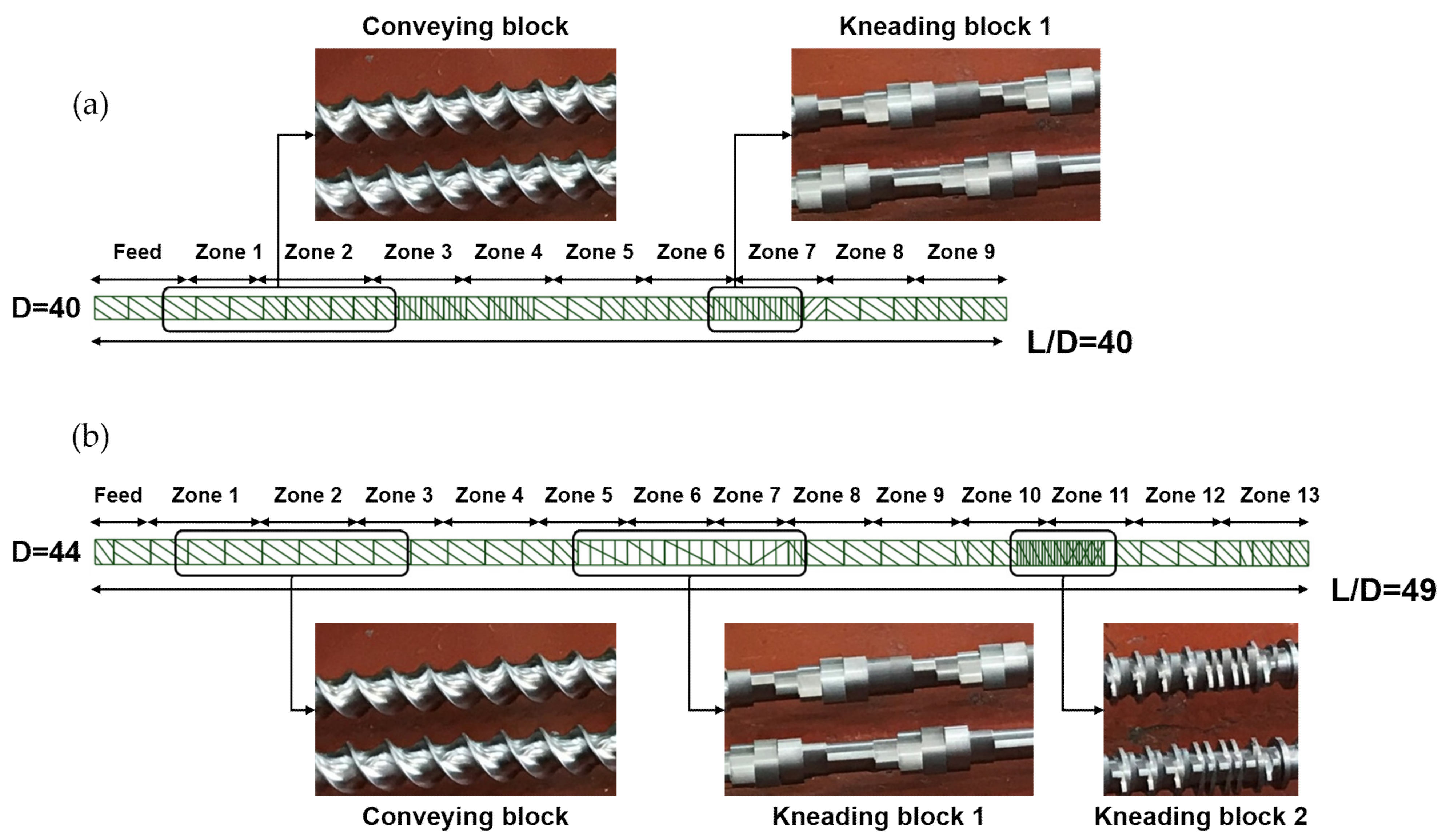

2.1.1. Twin-Screw Extruders with Different Screw Configurations

2.1.2. Materials

2.2. Characterization

2.2.1. Rheological Properties of CR-PP Samples

2.2.2. Mechanical Properties of CR-PPs

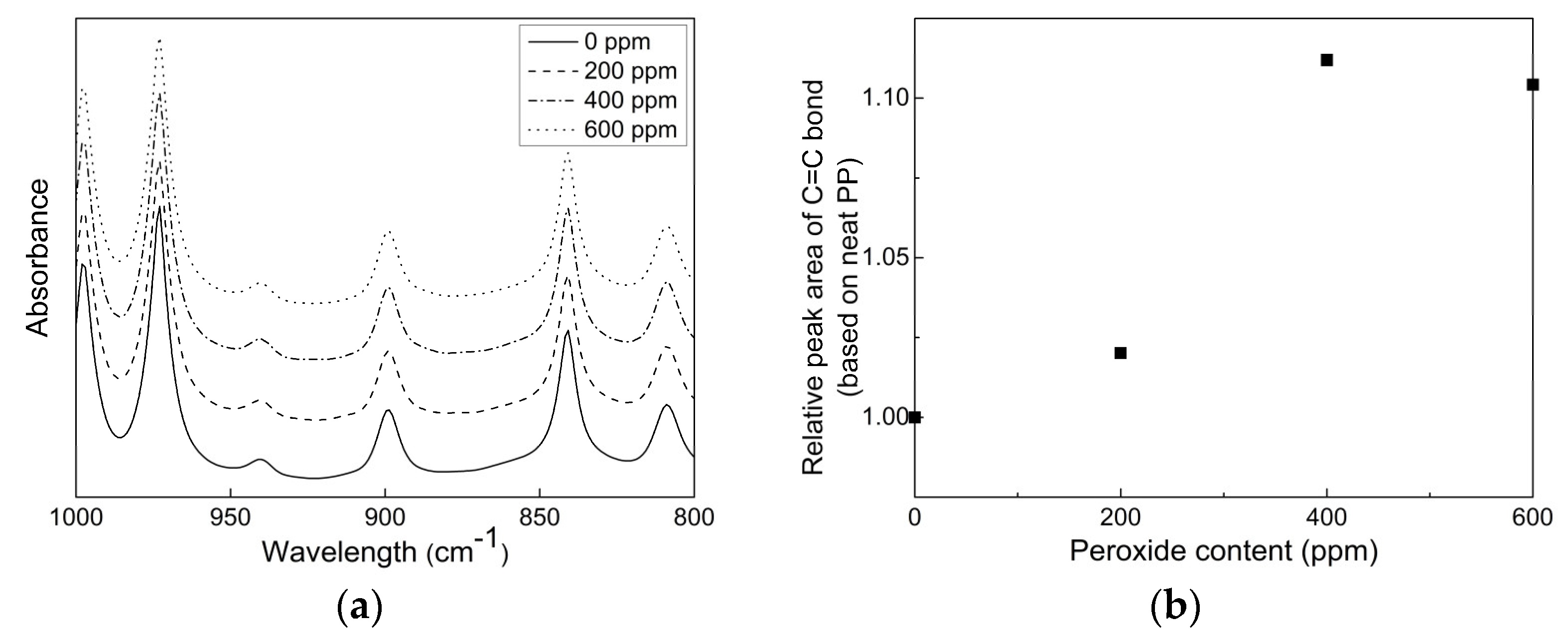

2.2.3. Fourier-Transform Infrared Spectroscopy (FT-IR)

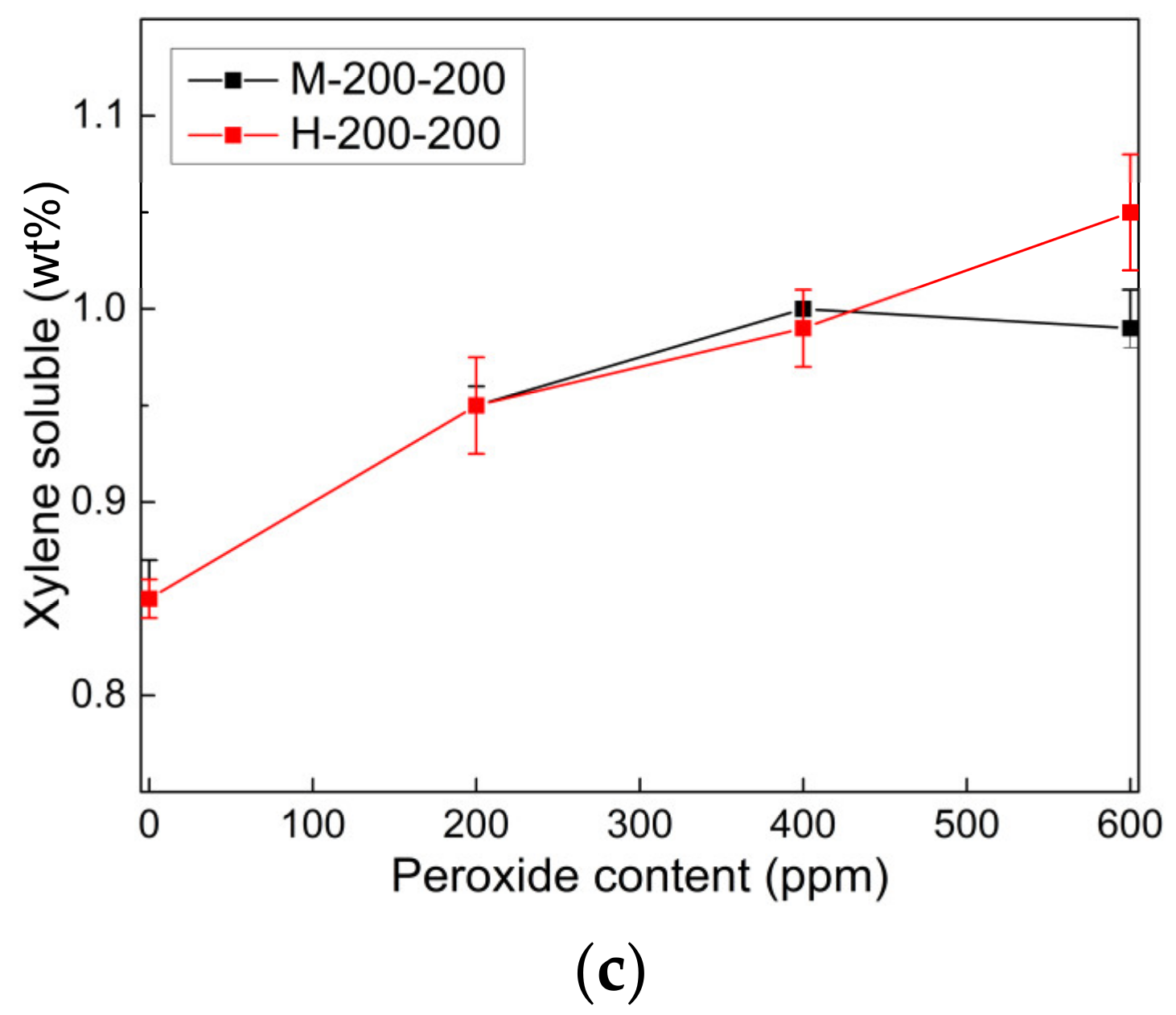

2.2.4. Cold Xylene Soluble (CXS) Property

2.2.5. Volatile Matter Measurement

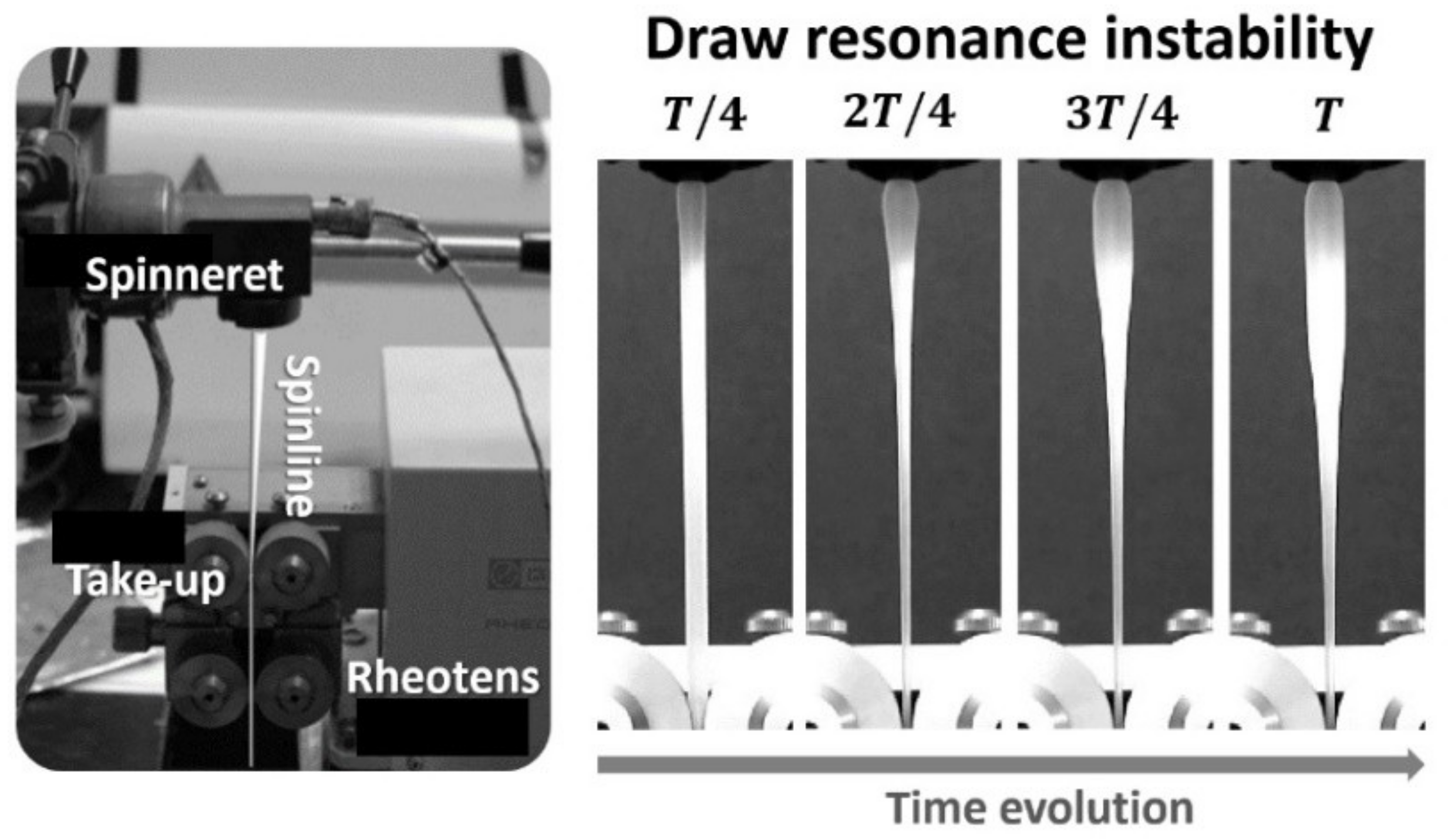

2.2.6. Application to Melt-Spinning Process: Melt Tension and Draw Resonance Instability of PPs

3. Results and Discussion

3.1. Effect of Peroxide Content on Physical Properties of CR-PPs via Reactive Extrusion

3.1.1. MI, MWD, and CXS Properties

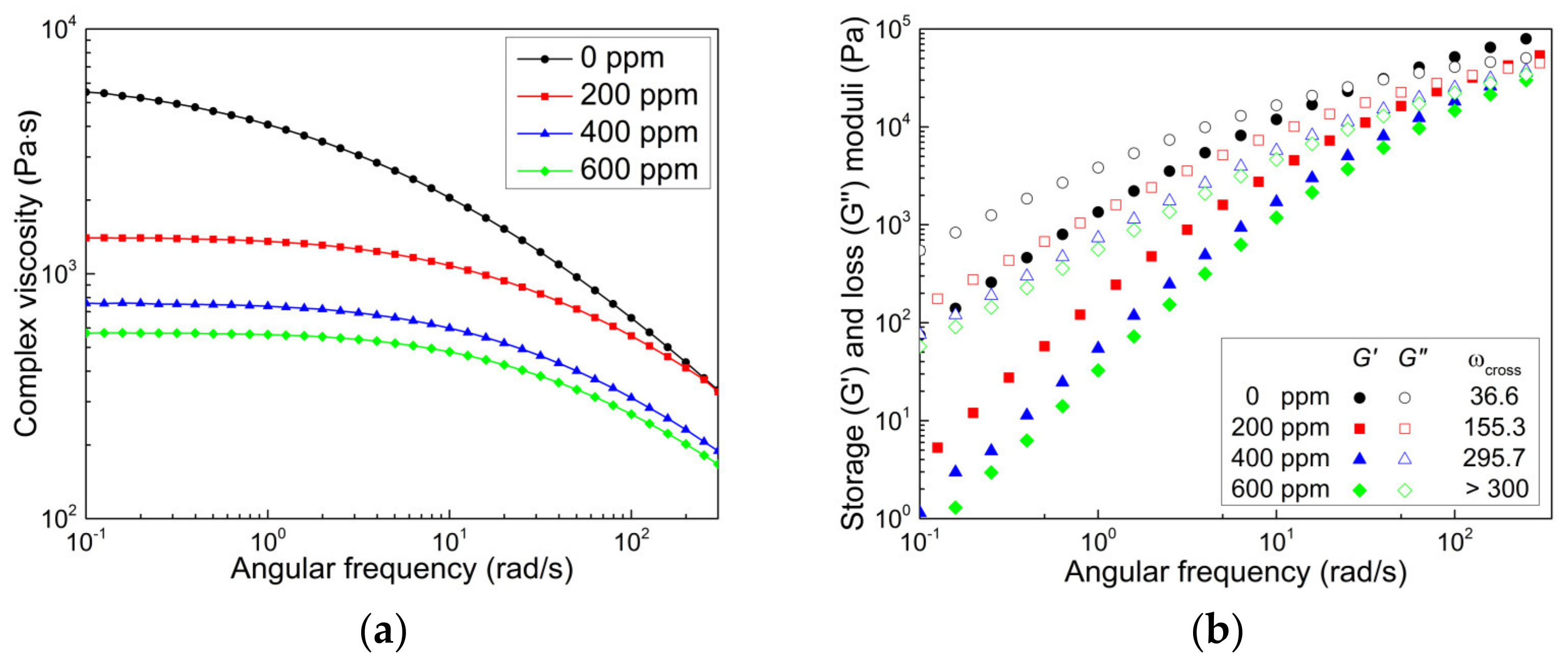

3.1.2. Rheological and Mechanical Properties

3.2. Effect of Various Extrusion Conditions on CR-PP Production

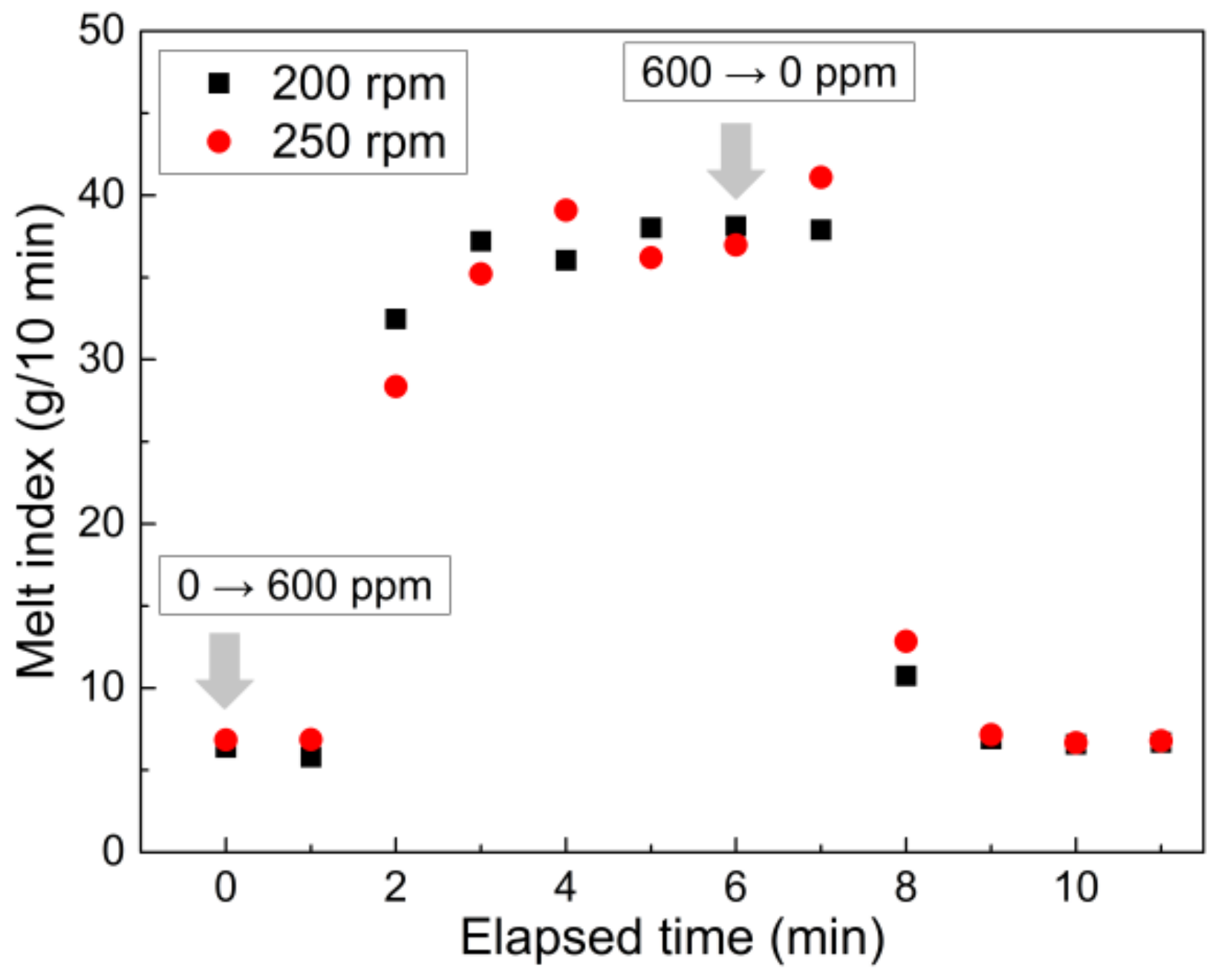

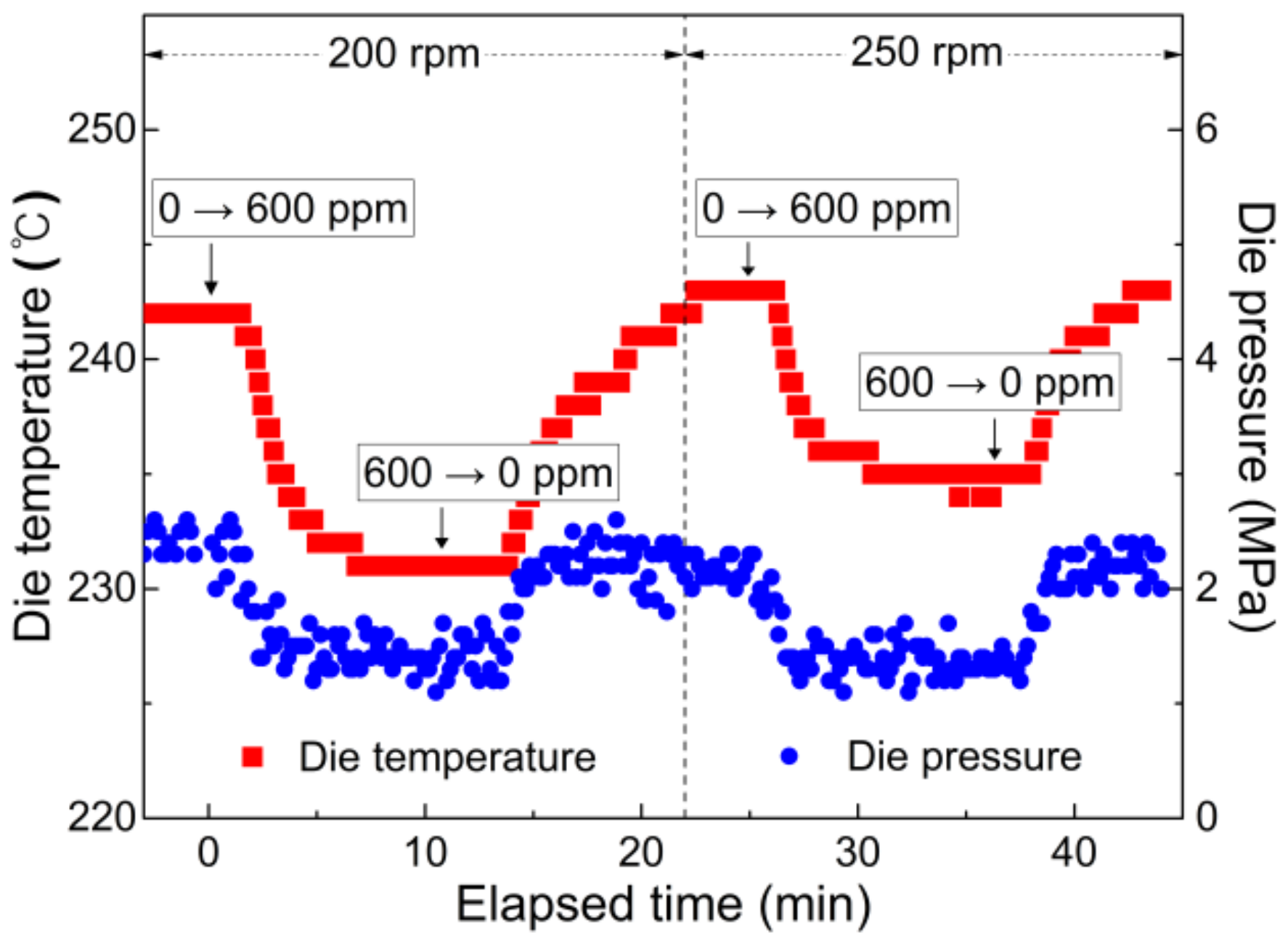

3.2.1. Change in Flow Properties inside Twin-Screw Extruder

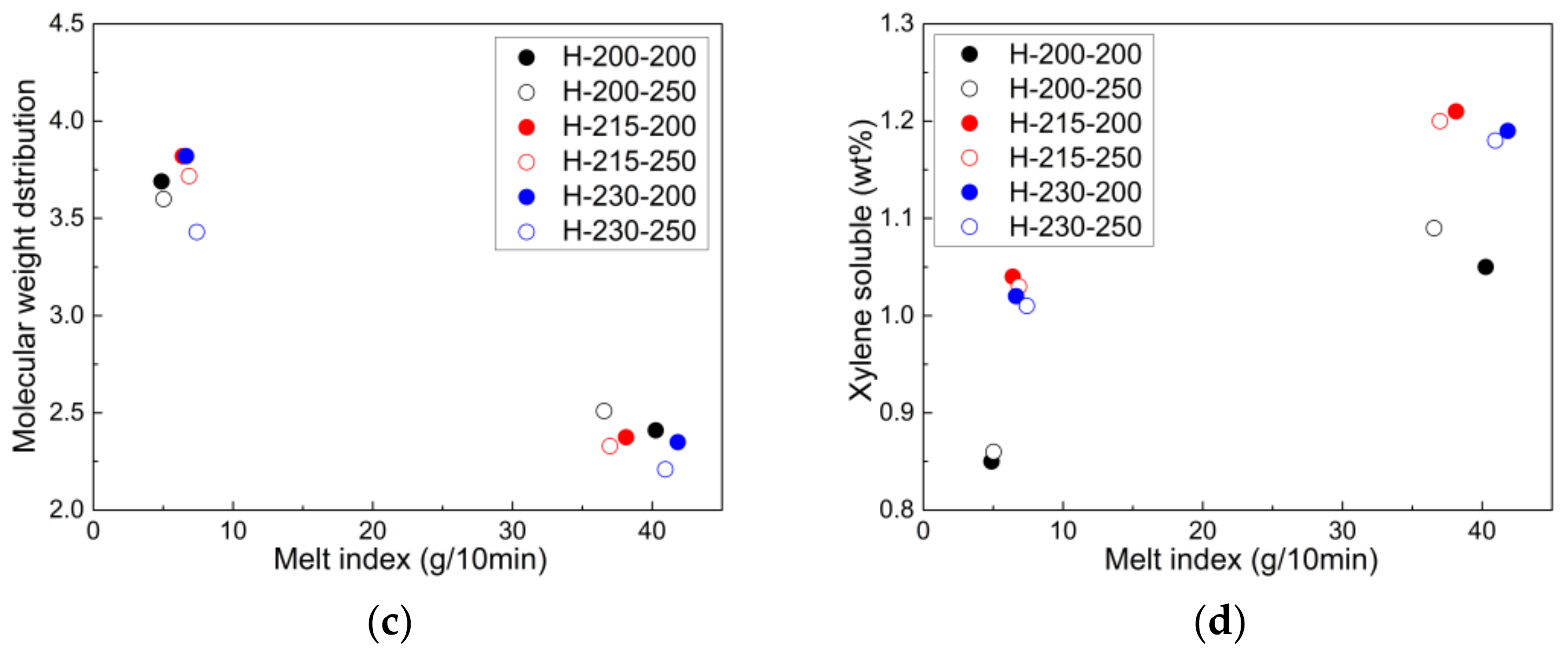

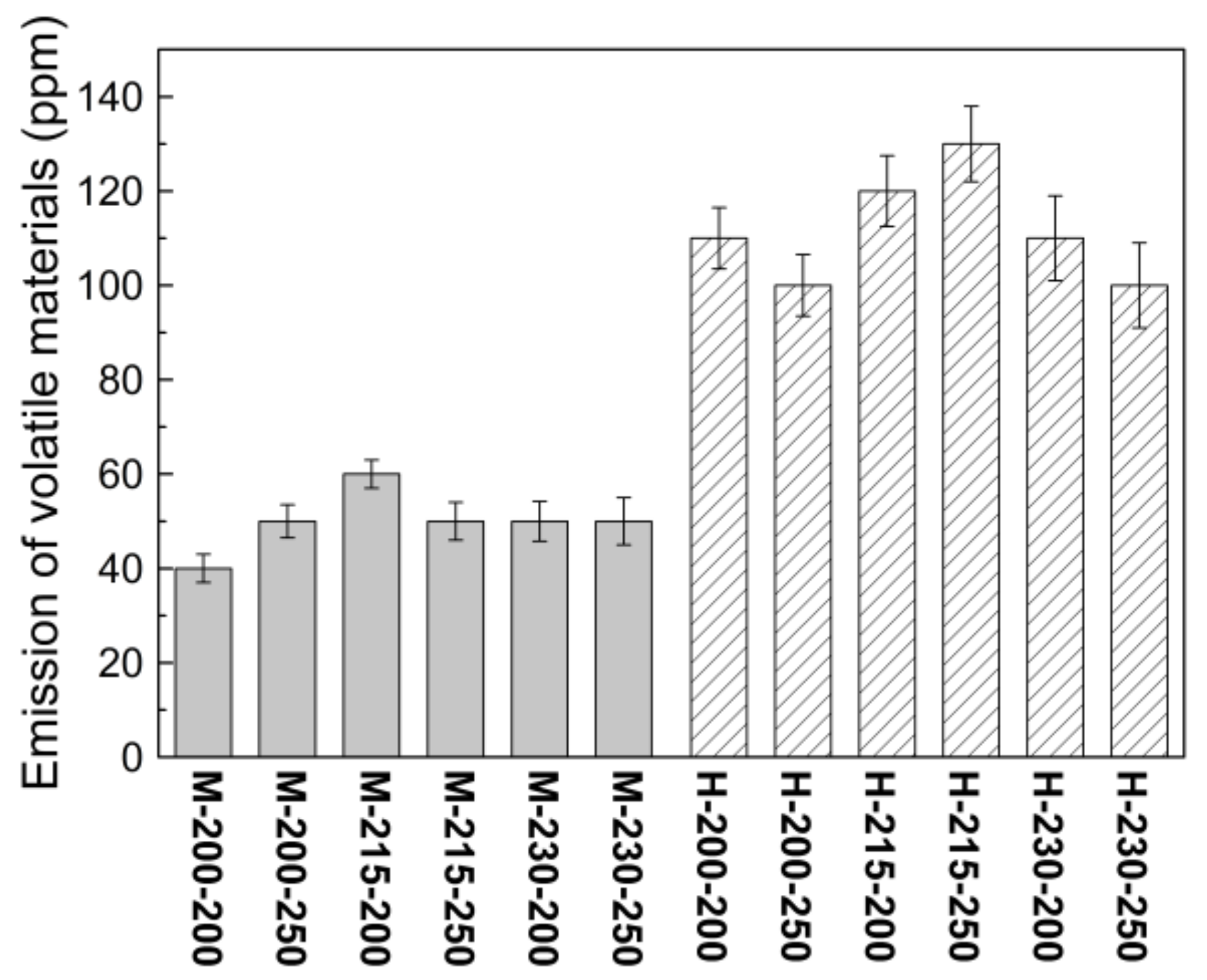

3.2.2. Change in MI, MWD, CXS, and Volatile Materials

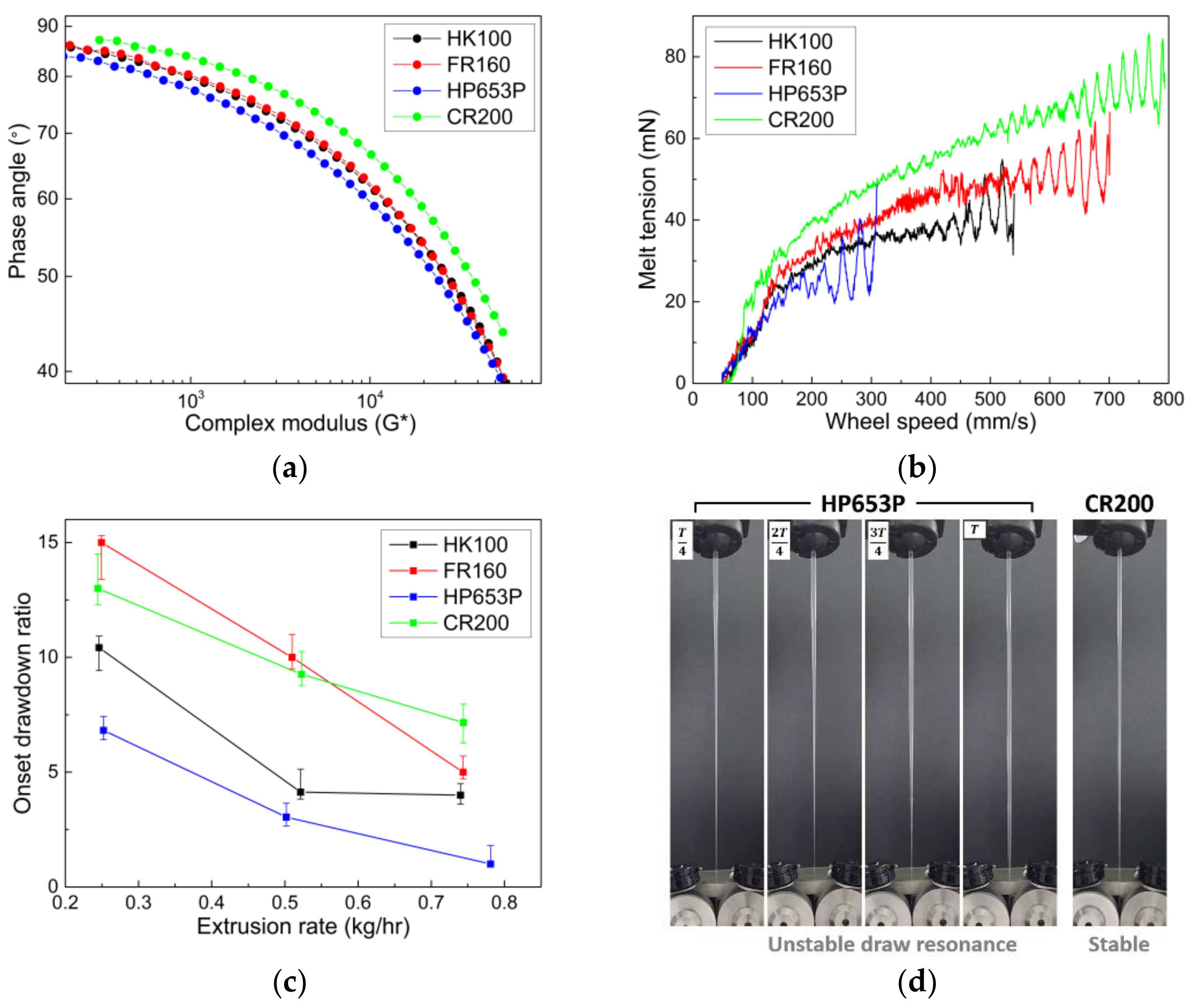

3.3. Application of CR-PP in Fiber-Spinning Process: Comparison of Melt Tension and Draw Resonance Instability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasquini, N. Polypropylene—the business. In Polypropylene Handbook, 2nd ed.; Hanser: Munich, Germany, 2005; pp. 489–571. [Google Scholar]

- Misra, S.; Lu, F.M.; Spruiell, J.; Richeson, G. Influence of molecular weight distribution on the structure and properties of melt-spun polypropylene filaments. J. Appl. Polym. Sci. 1995, 56, 1761–1779. [Google Scholar] [CrossRef]

- Triacca, V.; Gloor, P.; Zhu, S.; Hrymak, A.; Hamielec, A. Free radical degradation of polypropylene: Random chain scission. Polym. Eng. Sci. 1993, 33, 445–454. [Google Scholar] [CrossRef]

- Tzoganakis, C.; Tang, Y.; Vlachopoulos, J.; Hamielec, A. Controlled degradation of polypropylene: A comprehensive experimental and theoretical investigation. Polym. Plast. Technol. Eng. 1989, 28, 319–350. [Google Scholar] [CrossRef]

- Bertin, D.; Leblanc, M.; Marque, S.R.; Siri, D. Polypropylene degradation: Theoretical and experimental investigations. Polym. Degrad. Stab. 2010, 95, 782–791. [Google Scholar] [CrossRef]

- Fritz, H.-G.; Stöhrer, B. Polymer compounding process for controlled peroxide-degradation of PP. Int. Polym. Process. 1986, 1, 31–41. [Google Scholar] [CrossRef]

- Suwanda, D.; Lew, R.; Balke, S. Reactive extrusion of polypropylene I: Controlled degradation. J. Appl. Polym. Sci. 1988, 35, 1019–1032. [Google Scholar] [CrossRef]

- Decker, C.; Mayo, F.R.; Richardson, H. Aging and degradation of polyolefins. III. Polyethylene and ethylene–propylene copolymers. J. Polym. Sci. Polym. Chem. Ed. 1973, 11, 2879–2898. [Google Scholar] [CrossRef]

- Krell, M.; Brandolin, A.; Vallés, E. Controlled rheology polypropylenes. An improved model with experimental validation for the single screw extruder process. Polym. React. Eng. 1994, 2, 389–408. [Google Scholar] [CrossRef]

- Pabedinskas, A.; Cluett, W.; Balke, S. Modeling of polypropylene degradation during reactive extrusion with implications for process control. Polym. Eng. Sci. 1994, 34, 598–612. [Google Scholar] [CrossRef]

- Ebner, K.; White, J. Peroxide induced and thermal degradation of polypropylene. Int. Polym. Process. 1994, 9, 233–239. [Google Scholar] [CrossRef]

- Lambla, M. Reactive Extrusion. In Rheological Fundamentals of Polymer Processing; Springer: Strasbourg, France, 1995; pp. 437–454. [Google Scholar]

- Scorah, M.J.; Zhu, S.; Psarreas, A.; McManus, N.T.; Dhib, R.; Tzoganakis, C.; Penlidis, A. Peroxide-controlled degradation of polypropylene using a tetra-functional initiator. Polym. Eng. Sci. 2009, 49, 1760–1766. [Google Scholar] [CrossRef]

- Lazár, M.; Hrčková, L.u.; Borsig, E.; Marcinčin, A.; Reichelt, N.; Rätzsch, M. Course of degradation and build-up reactions in isotactic polypropylene during peroxide decomposition. J. Appl. Polym. Sci. 2000, 78, 886–893. [Google Scholar] [CrossRef]

- Moad, G.; Dagley, I.J.; Habsuda, J.; Garvey, C.J.; Li, G.; Nichols, L.; Simon, G.P.; Nobile, M.R. Aqueous hydrogen peroxide-induced degradation of polyolefins: A greener process for controlled-rheology polypropylene. Polym. Degrad. Stab. 2015, 117, 97–108. [Google Scholar] [CrossRef]

- Rocha, M.C.; Coutinho, F.M.; Balke, S.T. A study of polypropylene peroxide promoted degradation. Polym. Test. 1995, 14, 369–380. [Google Scholar] [CrossRef]

- Azizi, H.; Ghasemi, I. Reactive extrusion of polypropylene: Production of controlled-rheology polypropylene (CRPP) by peroxide-promoted degradation. Polym. Test. 2004, 23, 137–143. [Google Scholar] [CrossRef]

- Azizi, H.; Ghasemi, I.; Karrabi, M. Controlled-peroxide degradation of polypropylene: Rheological properties and prediction of MWD from rheological data. Polym. Test. 2008, 27, 548–554. [Google Scholar] [CrossRef]

- Tzoganakis, C.; Vlachopoulos, J.; Hamielec, A. Production of controlled-rheology polypropylene resins by peroxide promoted degradation during extrusion. Polym. Eng. Sci. 1988, 28, 170–180. [Google Scholar] [CrossRef]

- Baik, J.J.; Tzoganakis, C. A study of extrudate distortion in controlled-rheology polypropylenes. Polym. Eng. Sci. 1998, 38, 274–281. [Google Scholar] [CrossRef]

- Cao, J.; Lü, Q.-F. Crystalline structure, morphology and mechanical properties of β-nucleated controlled-rheology polypropylene random copolymers. Polym. Test. 2011, 30, 899–906. [Google Scholar] [CrossRef]

- Stanic, S.; Koch, T.; Schmid, K.; Knaus, S.; Archodoulaki, V.M. Upcycling of polypropylene with various concentrations of peroxydicarbonate and dilauroyl peroxide and two processing steps. J. Appl. Polym. Sci. 2021, 138, 50659. [Google Scholar] [CrossRef]

- Ryu, S.; Gogos, C.; Xanthos, M. Parameters affecting process efficiency of peroxide-initiated controlled degradation of polypropylene. Adv. Polym. Technol. J. Polym. Process. Inst. 1991, 11, 121–131. [Google Scholar] [CrossRef]

- Machado, A.; Maia, J.; Canevarolo, S.; Covas, J. Evolution of peroxide-induced thermomechanical degradation of polypropylene along the extruder. J. Appl. Polym. Sci. 2004, 91, 2711–2720. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B.; Canevarolo, S.; Machado, A.; Covas, J. Evolution of the peroxide-induced degradation of polypropylene along a twin-screw extruder: Experimental data and theoretical predictions. J. Appl. Polym. Sci. 2006, 99, 2082–2090. [Google Scholar] [CrossRef]

- Tzoganakis, C.; Tang, Y.; Vlachopoulos, J.; Hamielec, A. Measurements of residence time distribution for the peroxide degradation of polypropylene in a single-screw plasticating extruder. J. Appl. Polym. Sci. 1989, 37, 681–693. [Google Scholar] [CrossRef]

- Iedema, P.; Remerie, K.; Van der Ham, M.; Biemond, E.; Tacx, J. Controlled peroxide-induced degradation of polypropylene in a twin-screw extruder: Change of molecular weight distribution under conditions controlled by micromixing. Chem. Eng. Sci. 2011, 66, 5474–5486. [Google Scholar] [CrossRef]

- Braun, D.; Richter, S.; Hellmann, G.; Rätzsch, M. Peroxy-initiated chain degradation, crosslinking, and grafting in PP–PE blends. J. Appl. Polym. Sci. 1998, 68, 2019–2028. [Google Scholar] [CrossRef]

- Graebling, D.; Lambla, M.; Wautier, H. PP/PE blends by reactive extrusion: PP rheological behavior changes. J. Appl. Polym. Sci. 1997, 66, 809–819. [Google Scholar] [CrossRef]

- Andreopoulos, A.; Tarantili, P.; Anastassakis, P. Properties of low density polyethylene/polypropylene blends. J. Macromol. Sci. Part A Pure Appl. Chem. 1998, 35, 751–761. [Google Scholar] [CrossRef]

- Berzin, F.; Vergnes, B.; Delamare, L. Rheological behavior of controlled-rheology polypropylenes obtained by peroxide-promoted degradation during extrusion: Comparison between homopolymer and copolymer. J. Appl. Polym. Sci. 2001, 80, 1243–1252. [Google Scholar] [CrossRef]

- Brostow, W.; Datashvili, T.; Hackenberg, K.P. Effect of different types of peroxides on properties of vulcanized EPDM+ PP blends. Polym. Compos. 2010, 31, 1678–1691. [Google Scholar] [CrossRef]

- Şirin, K.; Balcan, M. Mechanical properties and thermal analysis of low-density polyethylene+ polypropylene blends with dialkyl peroxide. Polym. Adv. Technol. 2010, 21, 250–255. [Google Scholar]

- Gu, J.; Xu, H.; Wu, C. The Effect of PP and Peroxide on the Properties and Morphology of HDPE and HDPE/PP Blends. Adv. Polym. Technol. 2013, 32, 21326. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Riasat, S.; Lewucha, C. Reactive antioxidants for peroxide crosslinked polyethylene. Polym. Degrad. Stab. 2017, 145, 11–24. [Google Scholar] [CrossRef] [Green Version]

- Wagner, M.; Schulze, V.; Göttfert, A. Rheotens-mastercurves and drawability of polymer melts. Polym. Eng. Sci. 1996, 36, 925–935. [Google Scholar] [CrossRef]

- Jung, H.W. Fiber spinning and film blowing instabilities. In Polymer Processing Instabilities: Control and Understanding, 1st ed.; Hatzikiriakos, S.G., Migler, K.B., Eds.; Marcel Dekker: New York, NY, USA, 2005; pp. 321–381. [Google Scholar]

- Jung, H.W.; Hyun, J.C. Instabilities in extensional deformation polymer processing. In Rheology Reviews; Binding, D.M., Walters, K., Eds.; The British Society of Rheology: Aberystwyth, UK, 2006; pp. 131–164. [Google Scholar]

- Qu, M.; Qin, Y.; Zhu, K.; Schubert, D.W.; Lu, D.; Wu, S.; Xie, Z.; Han, L.; Gao, Q.; Bier, A. Study on the spinnability and mechanical properties of aspirator aided melt-spun binary blends polypropylene fibers. Polym. Adv. Technol. 2021, 32, 4840–4850. [Google Scholar] [CrossRef]

- Amer, I. Molecular weight effects on crystallization of polypropylene. Ph.D. Thesis, University of Stellenbosch, Stellenbosch, South Africa, 2011. [Google Scholar]

- Myasnikova, Y.V.; Popov, A.; Shibryaeva, L. Crystallization of oxidized isotactic polypropylene. Polym. Sci. Ser. B 2006, 48, 229–232. [Google Scholar] [CrossRef]

- Steffl, T. Rheological and Film Blowing Properties of Various Low Density Polyethylenes and Their Blends. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Erlangen, Germany, 2003. [Google Scholar]

| Mild Extrusion | Harsh Extrusion | |||||

|---|---|---|---|---|---|---|

| Set Temp. (°C) | 200 | 215 | 230 | 200 | 215 | 230 |

| Zone 1 | 160 | 160 | 160 | 160 | 160 | 160 |

| Zone 2 | 175 | 175 | 175 | 175 | 175 | 175 |

| Zone 3 | 190 | 190 | 190 | 190 | 190 | 190 |

| Zone 4 | 190 | 200 | 210 | 190 | 190 | 200 |

| Zone 5 | 200 | 200 | 210 | 190 | 200 | 210 |

| Zone 6 | 200 | 215 | 230 | 190 | 200 | 210 |

| Zone 7 | 200 | 215 | 230 | 200 | 215 | 230 |

| Zone 8 | 200 | 215 | 230 | 200 | 215 | 230 |

| Zone 9 | 200 | 215 | 230 | 200 | 215 | 230 |

| Zone 10 | - | 200 | 215 | 230 | ||

| Zone 11 | 200 | 215 | 230 | |||

| Zone 12 | 200 | 215 | 230 | |||

| Zone 13 | 200 | 215 | 230 | |||

| Peroxide Content (ppm) | Flexural Modulus (MPa) | Tensile Strength (MPa) | Izod Impact Strength (J/m) |

|---|---|---|---|

| 0 | 1520 ± 10 | 34.3 ± 0.5 | 13.3 ± 0.7 |

| 200 | 1516 ± 4 | 33.6 ± 0.1 | 15.2 ± 1.0 |

| 400 | 1509 ± 10 | 33.4 ± 1.0 | 15.7 ± 0.7 |

| 600 | 1500 ± 10 | 33.3 ± 0.2 | 16.3 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, H.S.; Park, G.; Jung, H.W. Rheological Properties and Melt Spinning Application of Controlled-Rheology Polypropylenes via Pilot-Scale Reactive Extrusion. Polymers 2022, 14, 3226. https://doi.org/10.3390/polym14153226

Ji HS, Park G, Jung HW. Rheological Properties and Melt Spinning Application of Controlled-Rheology Polypropylenes via Pilot-Scale Reactive Extrusion. Polymers. 2022; 14(15):3226. https://doi.org/10.3390/polym14153226

Chicago/Turabian StyleJi, Ho Suk, Geunyeop Park, and Hyun Wook Jung. 2022. "Rheological Properties and Melt Spinning Application of Controlled-Rheology Polypropylenes via Pilot-Scale Reactive Extrusion" Polymers 14, no. 15: 3226. https://doi.org/10.3390/polym14153226

APA StyleJi, H. S., Park, G., & Jung, H. W. (2022). Rheological Properties and Melt Spinning Application of Controlled-Rheology Polypropylenes via Pilot-Scale Reactive Extrusion. Polymers, 14(15), 3226. https://doi.org/10.3390/polym14153226