Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current

Abstract

:1. Introduction

2. Samples and Experimentation

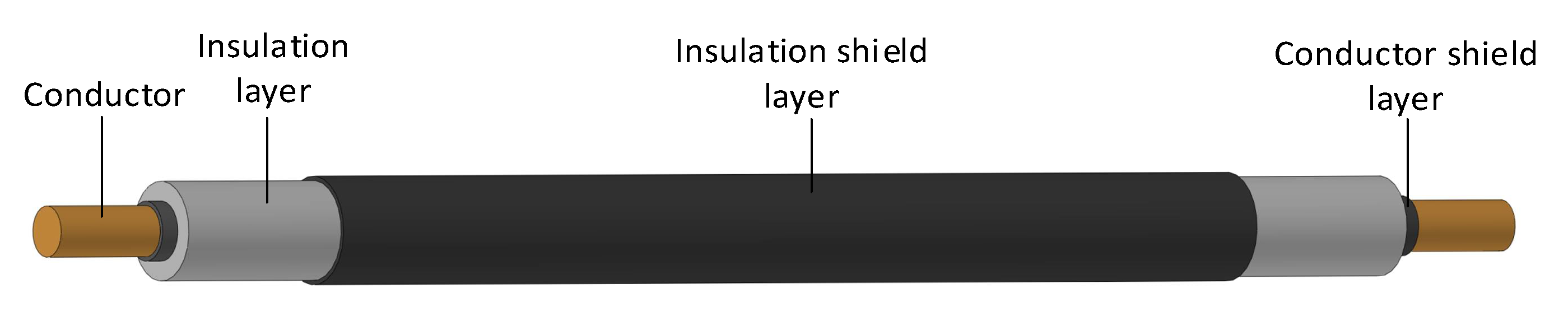

2.1. Sample Preparation

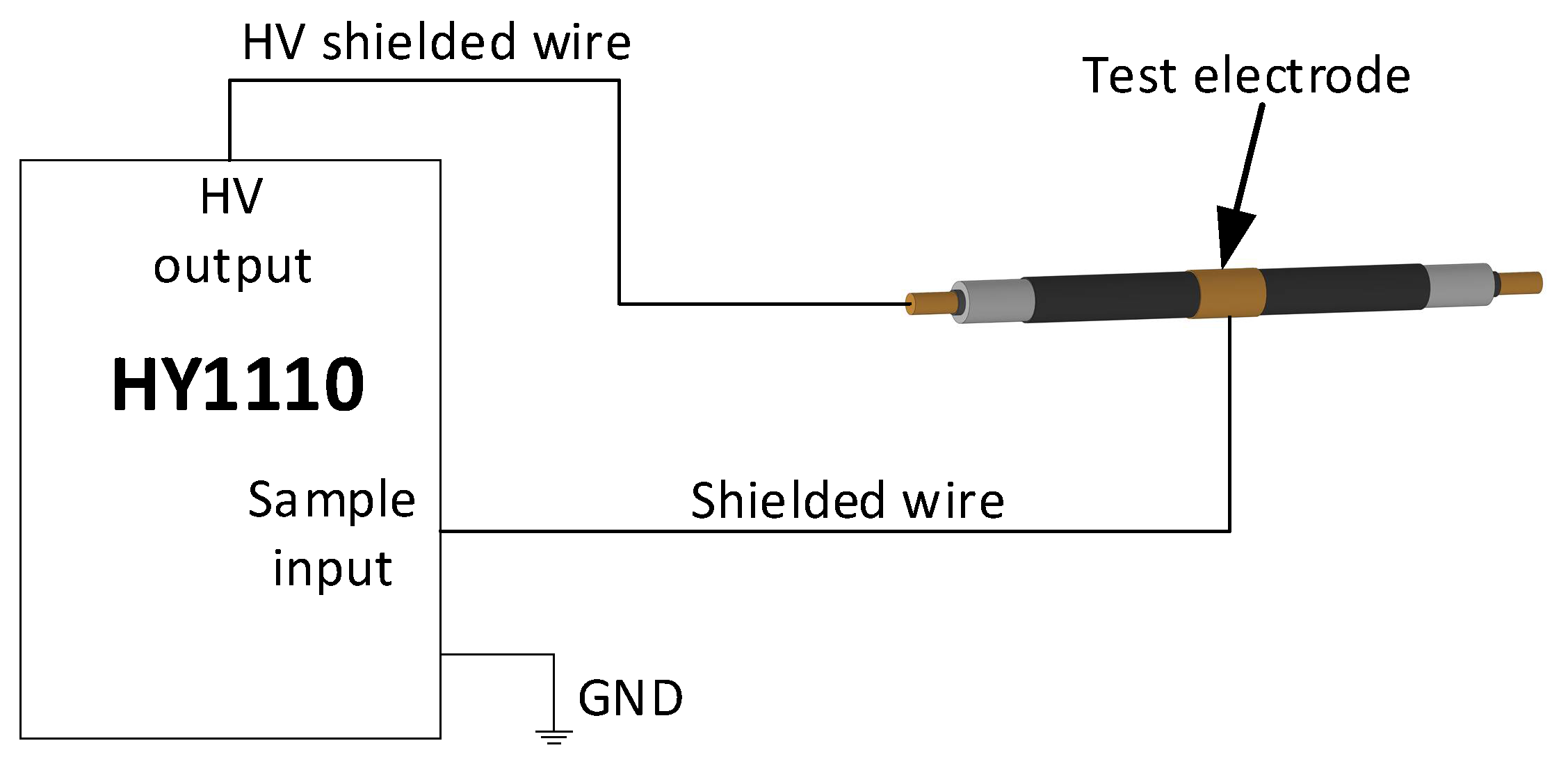

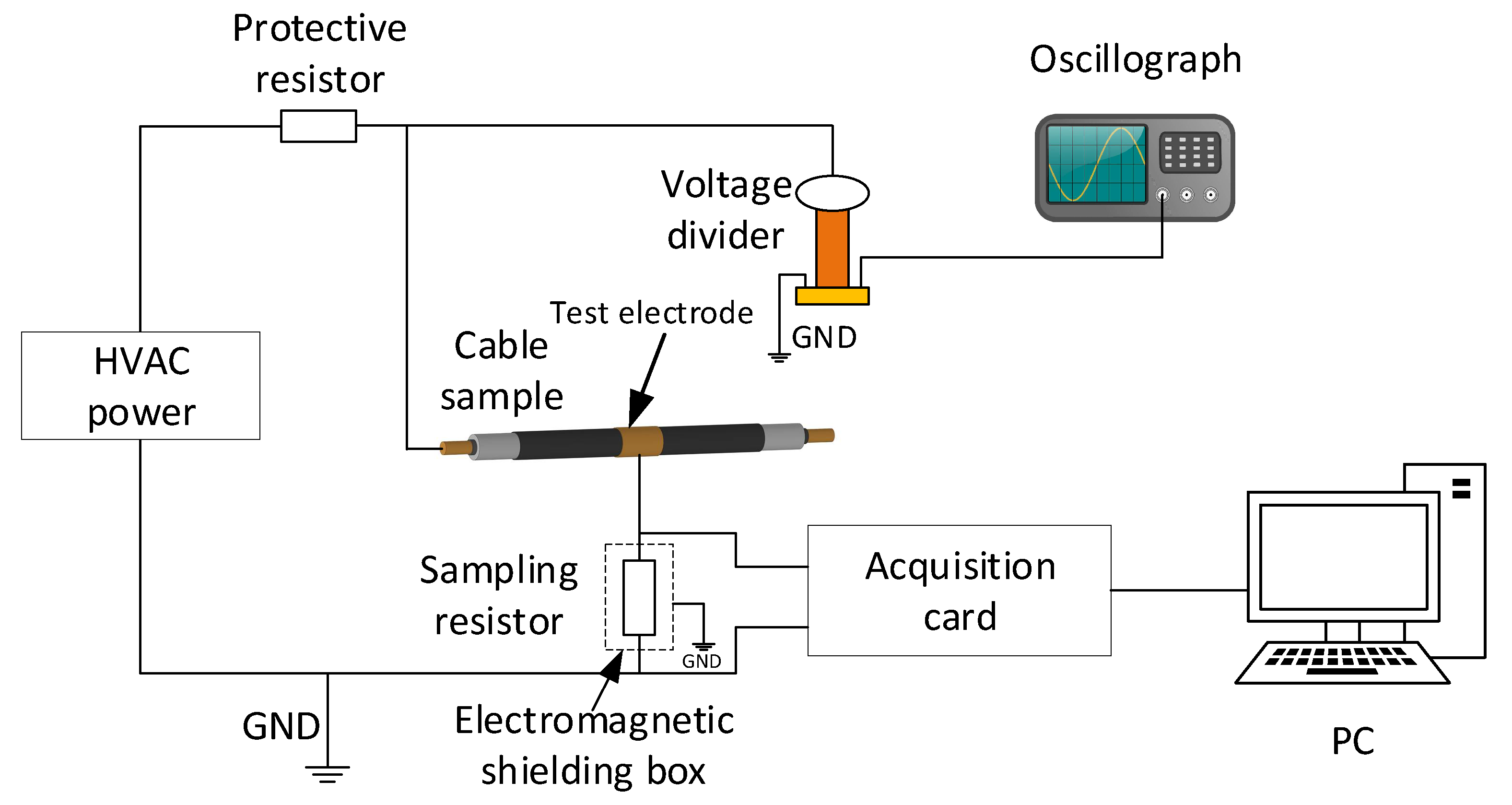

2.2. Experimental Setup

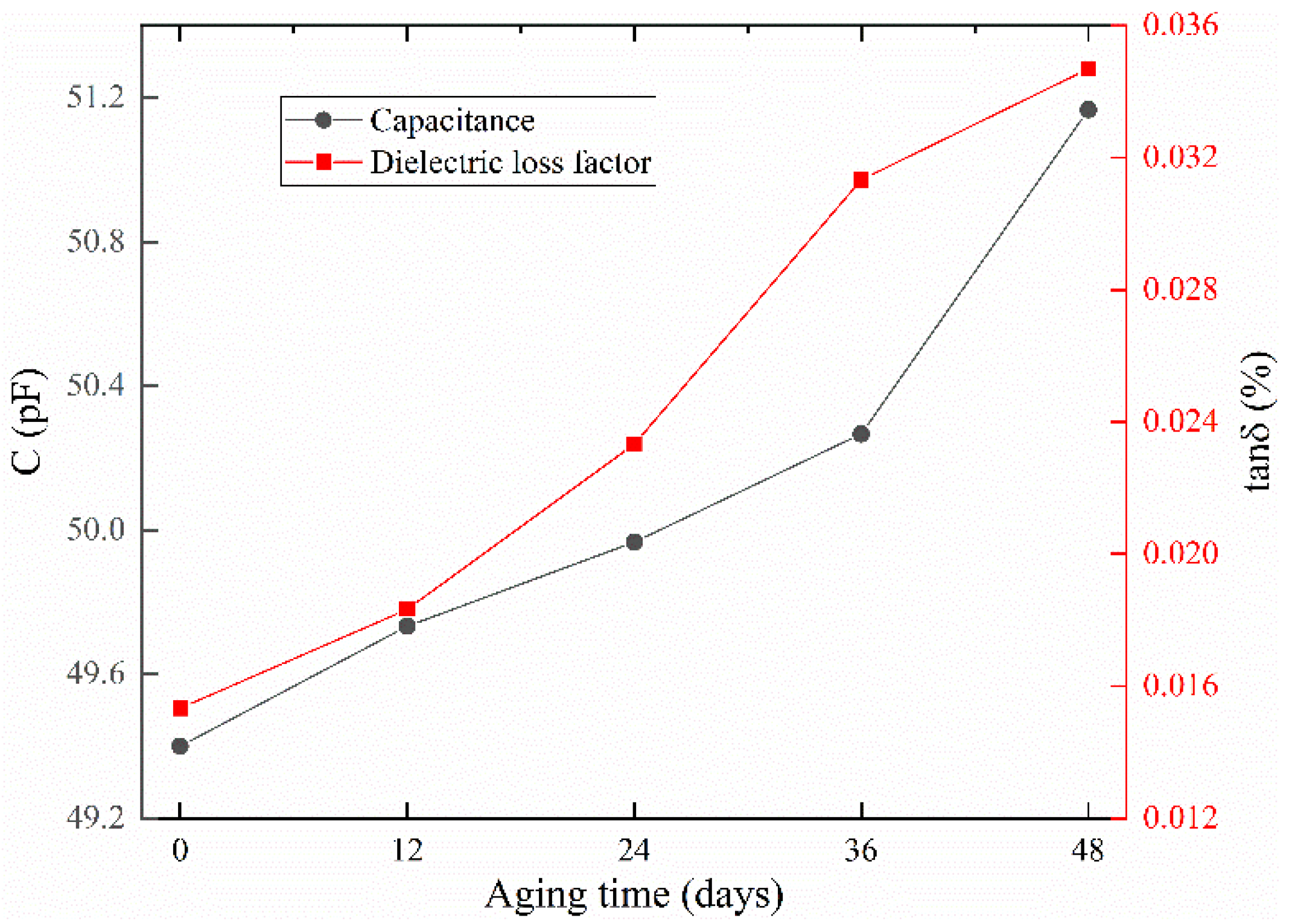

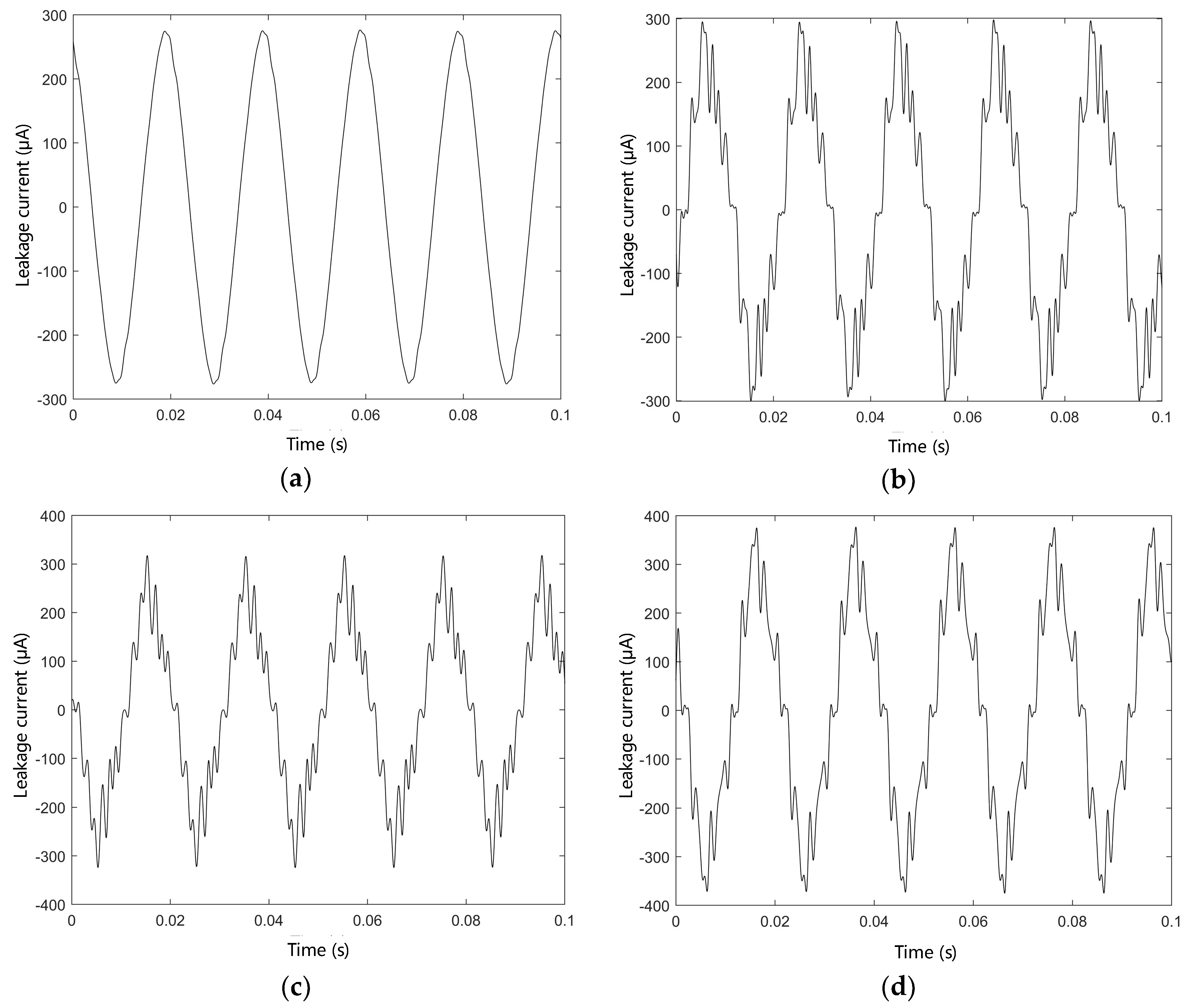

2.3. Experimental Results

3. Time–Frequency Domain Analysis and Multidimensional Characteristic Parameter Extraction of Leakage Current

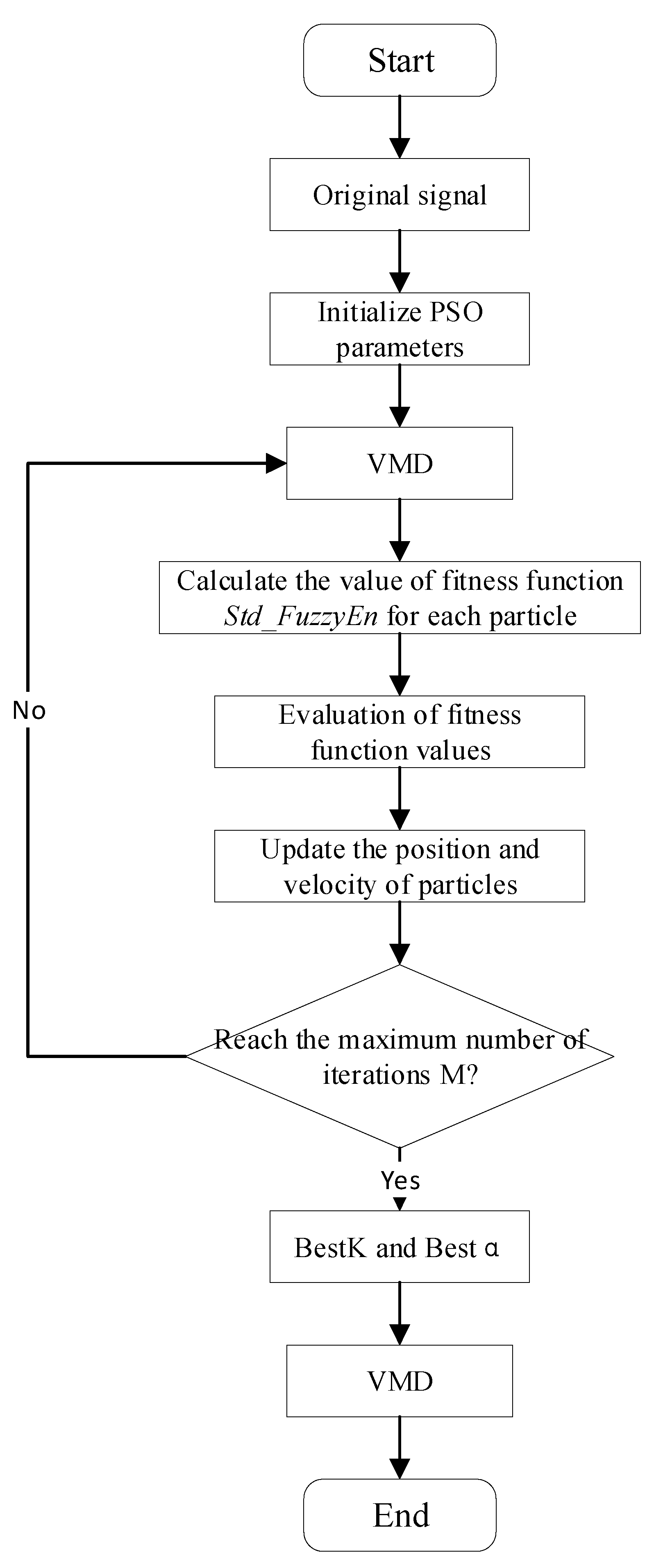

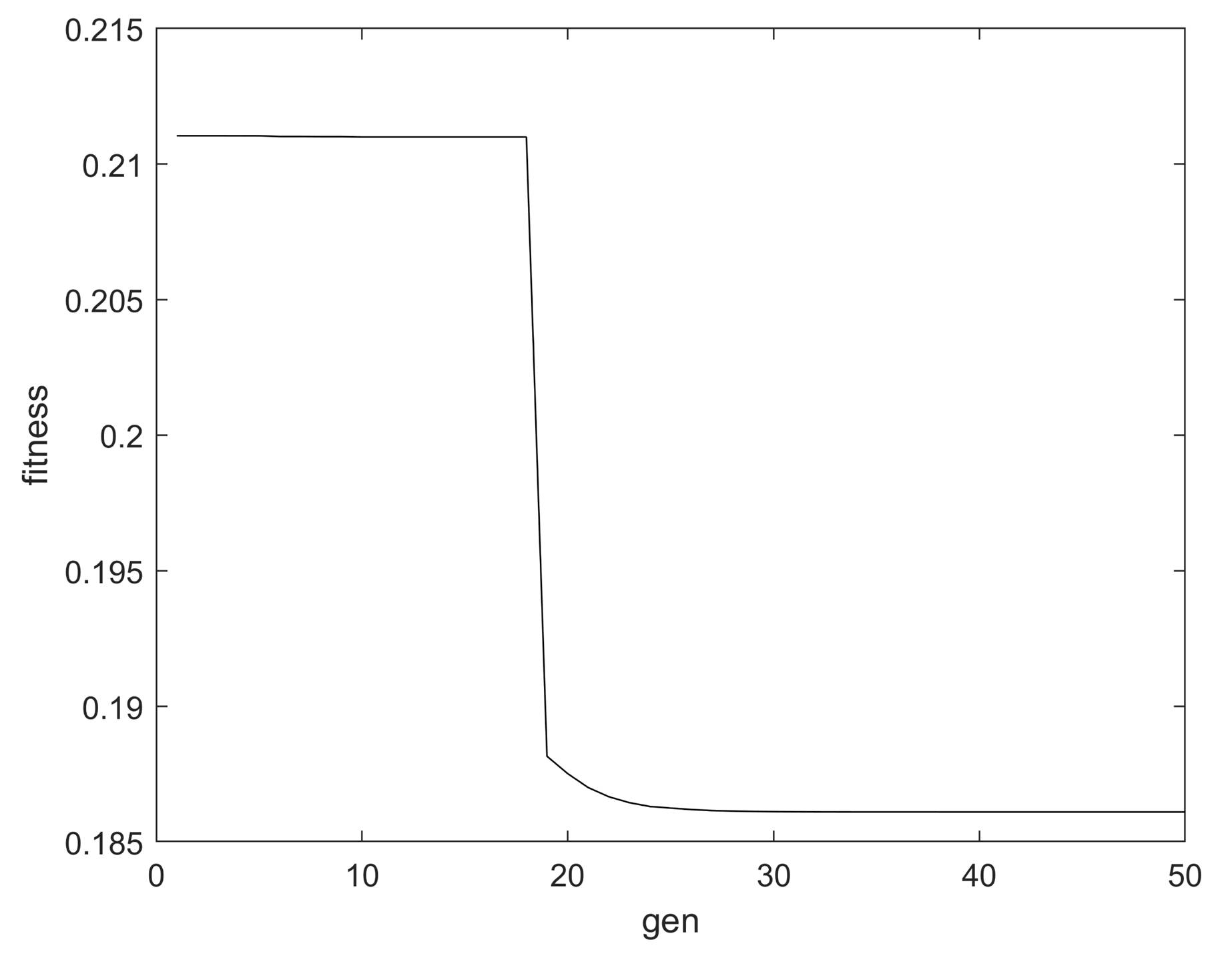

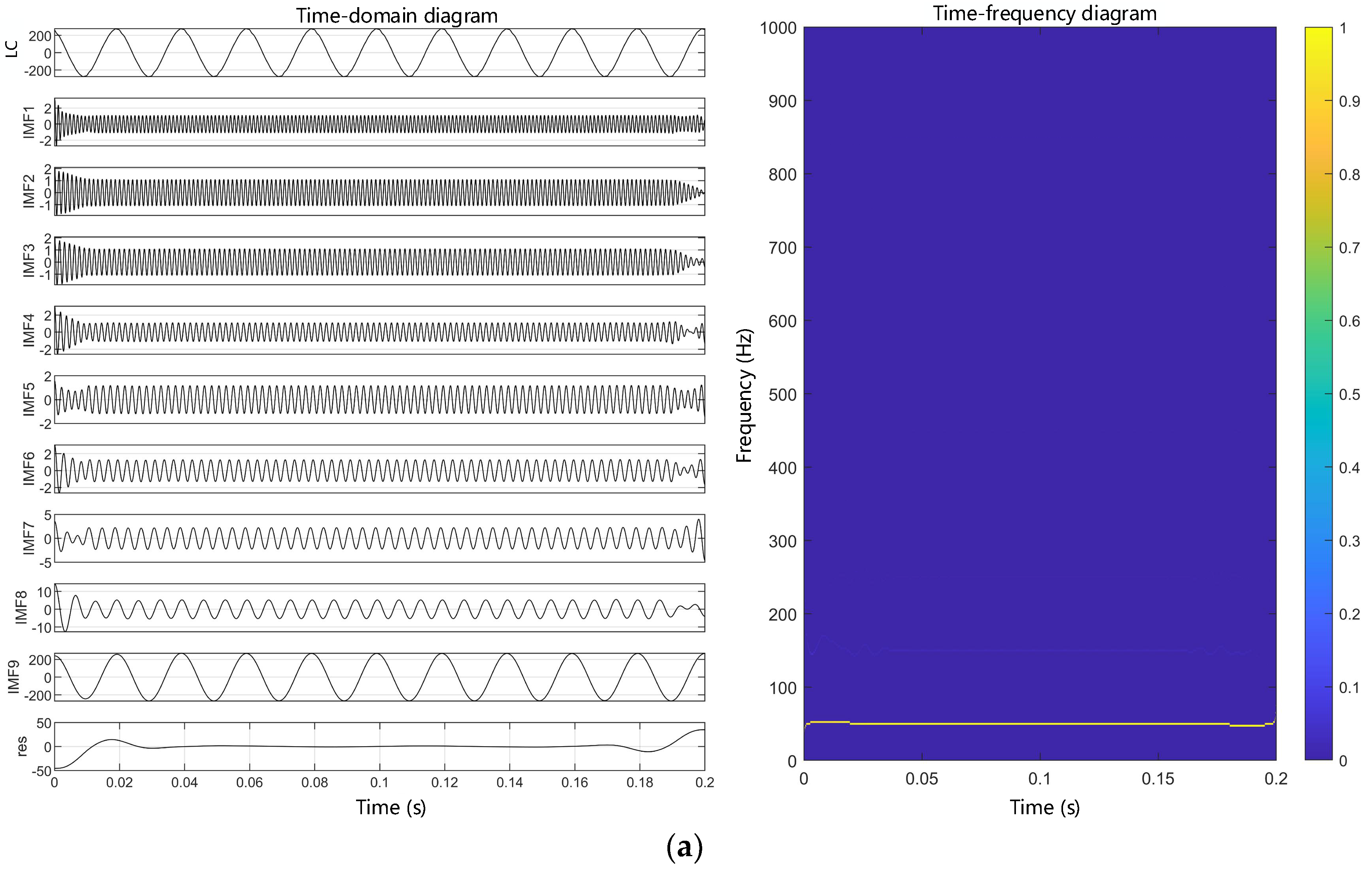

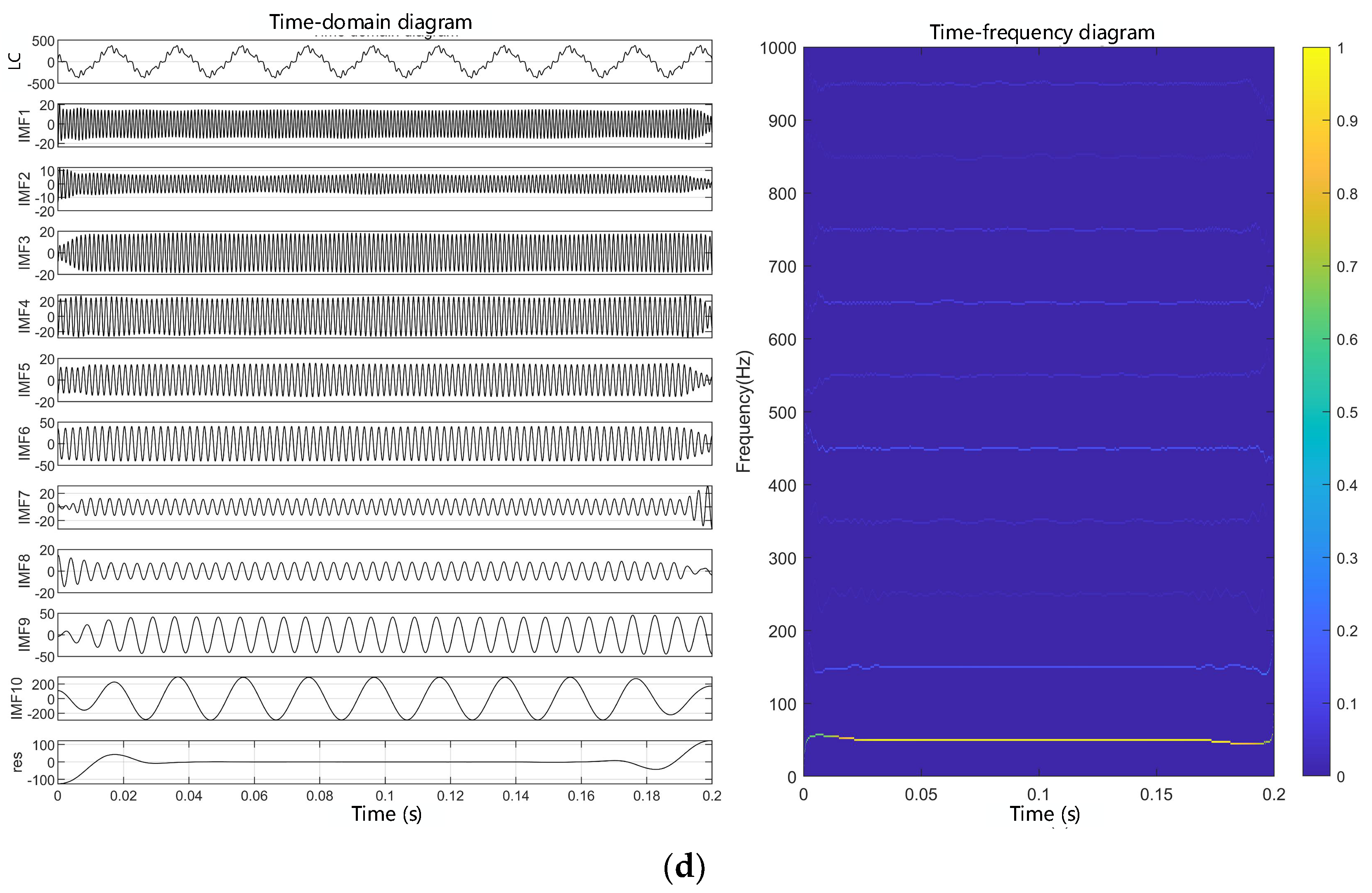

3.1. Time–Frequency Domain Analysis of Leakage Current

3.2. Harmonic Selection and Signal Reconstruction

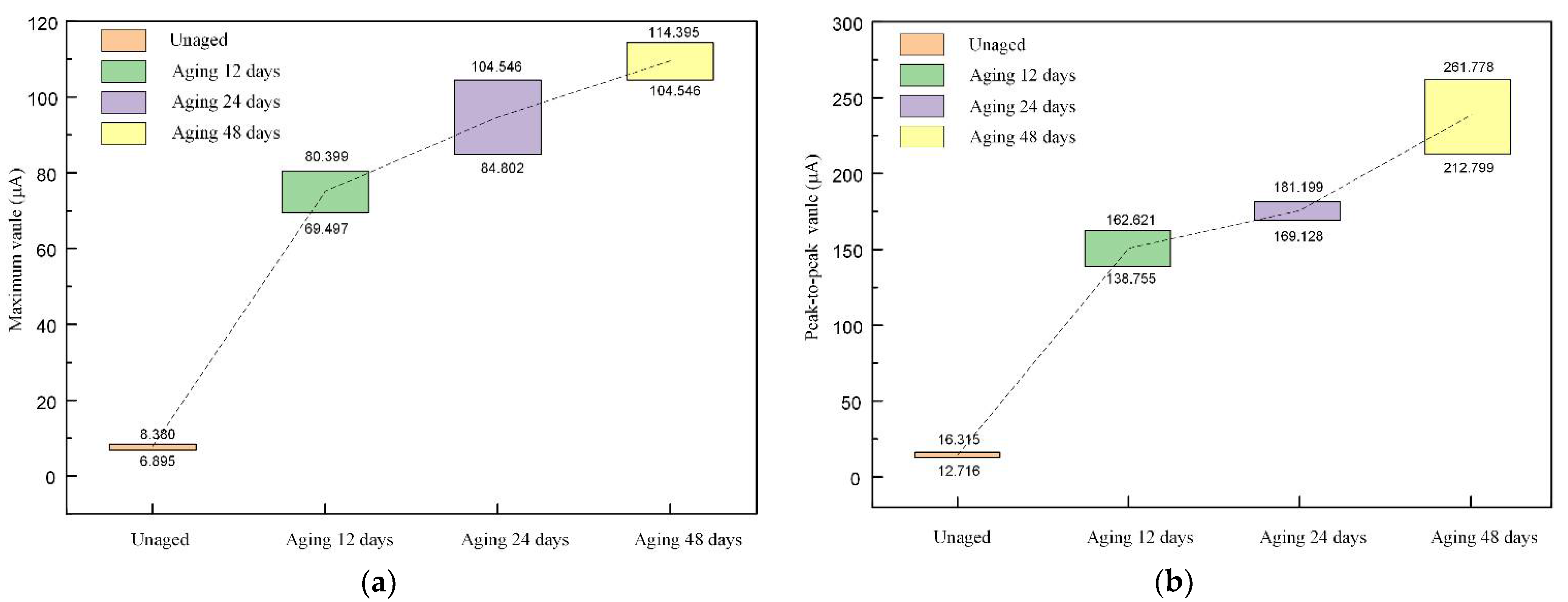

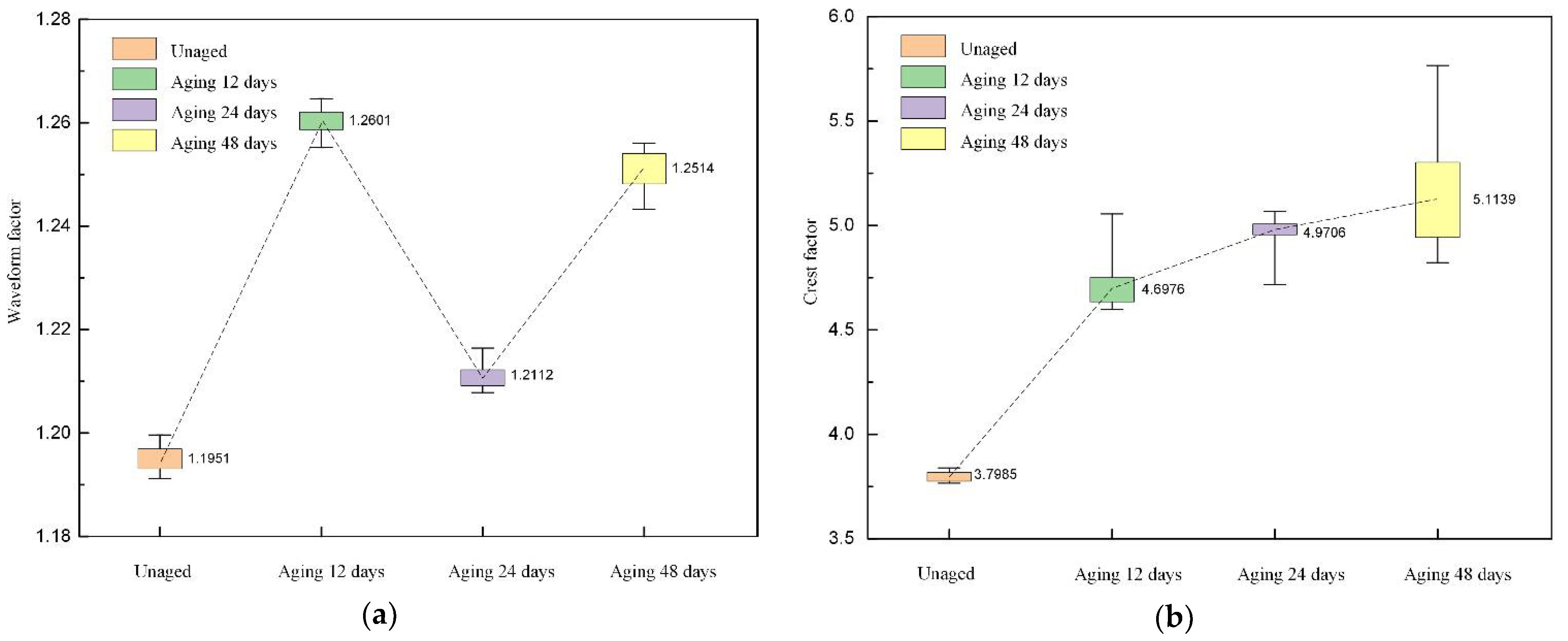

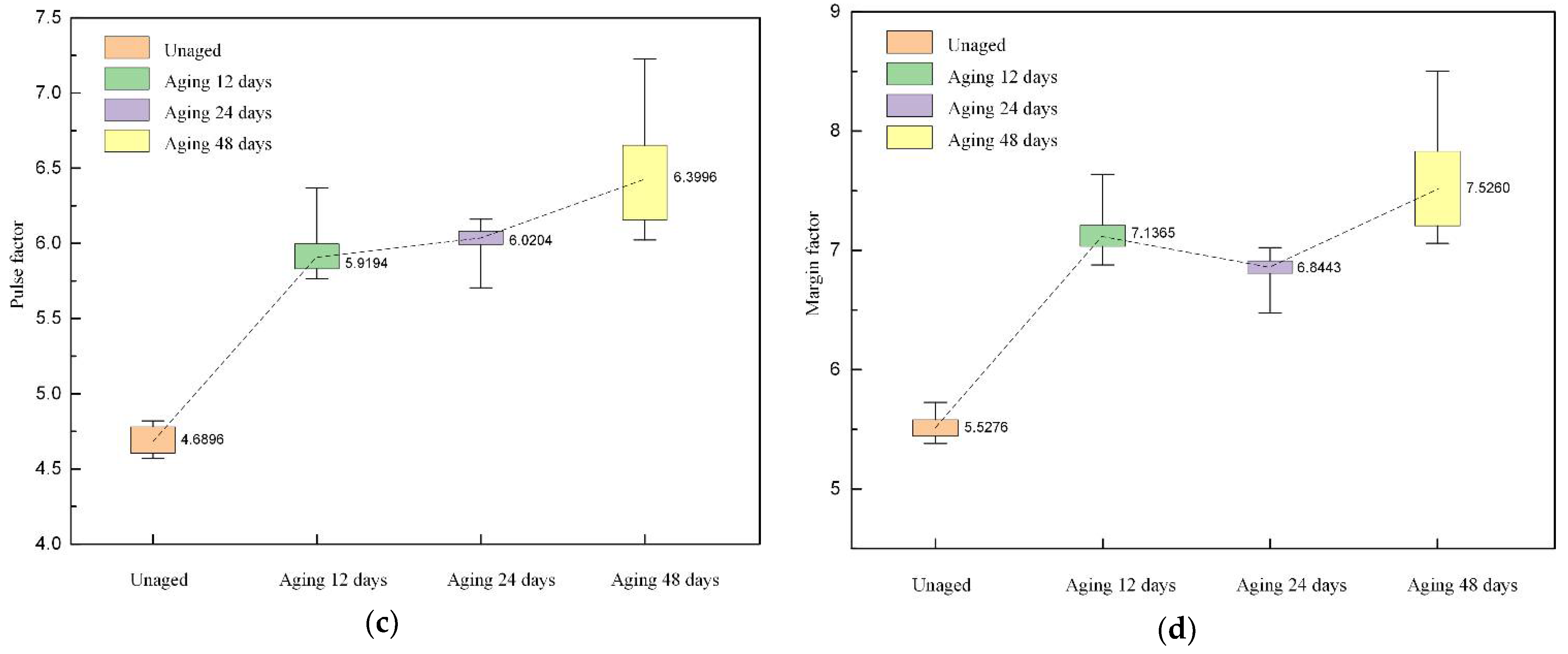

3.3. Multidimensional Characteristic Parameter Extraction

- (1)

- Time-domain characteristic parameters

- (2)

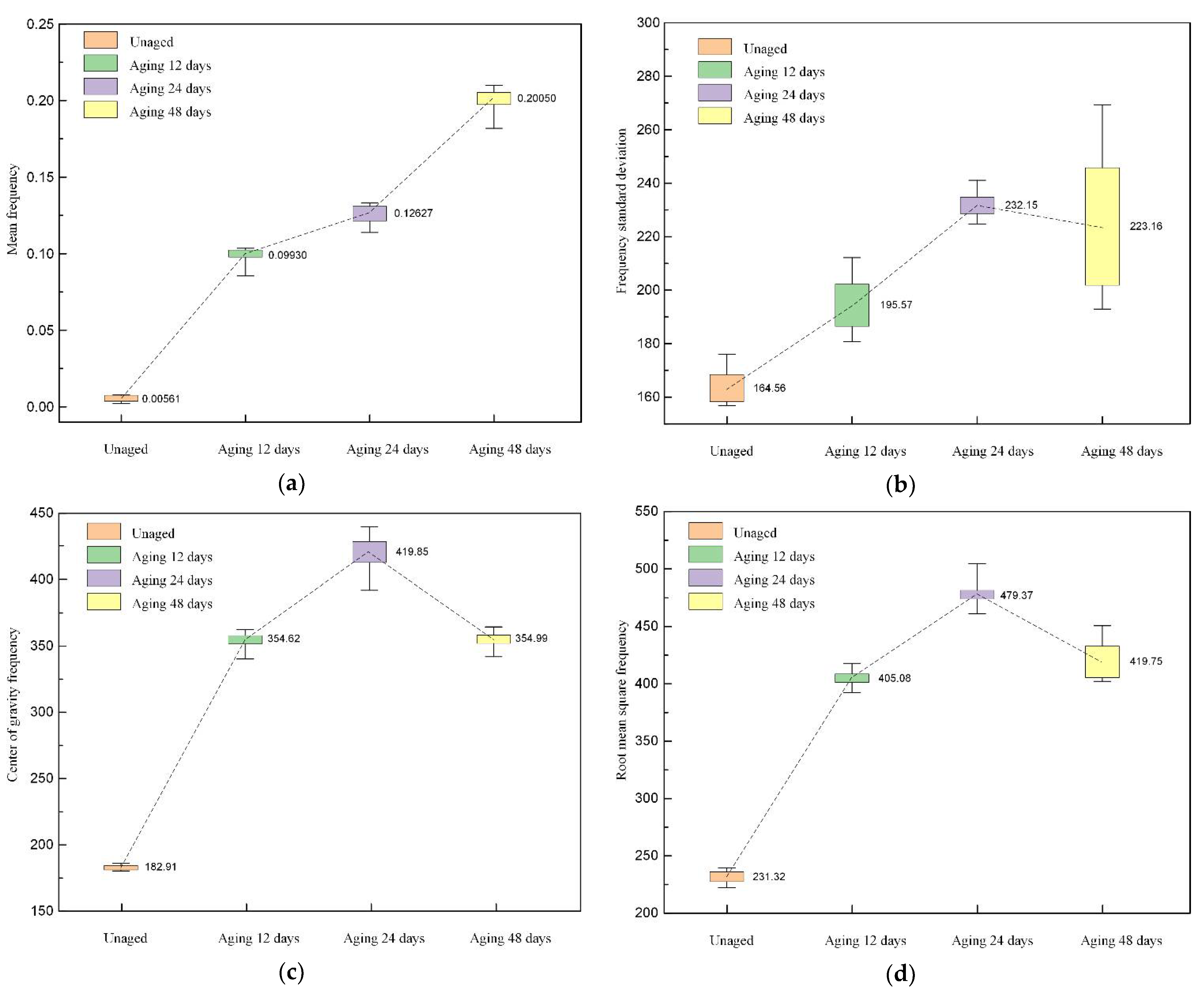

- Frequency-domain characteristic parameters

- (3)

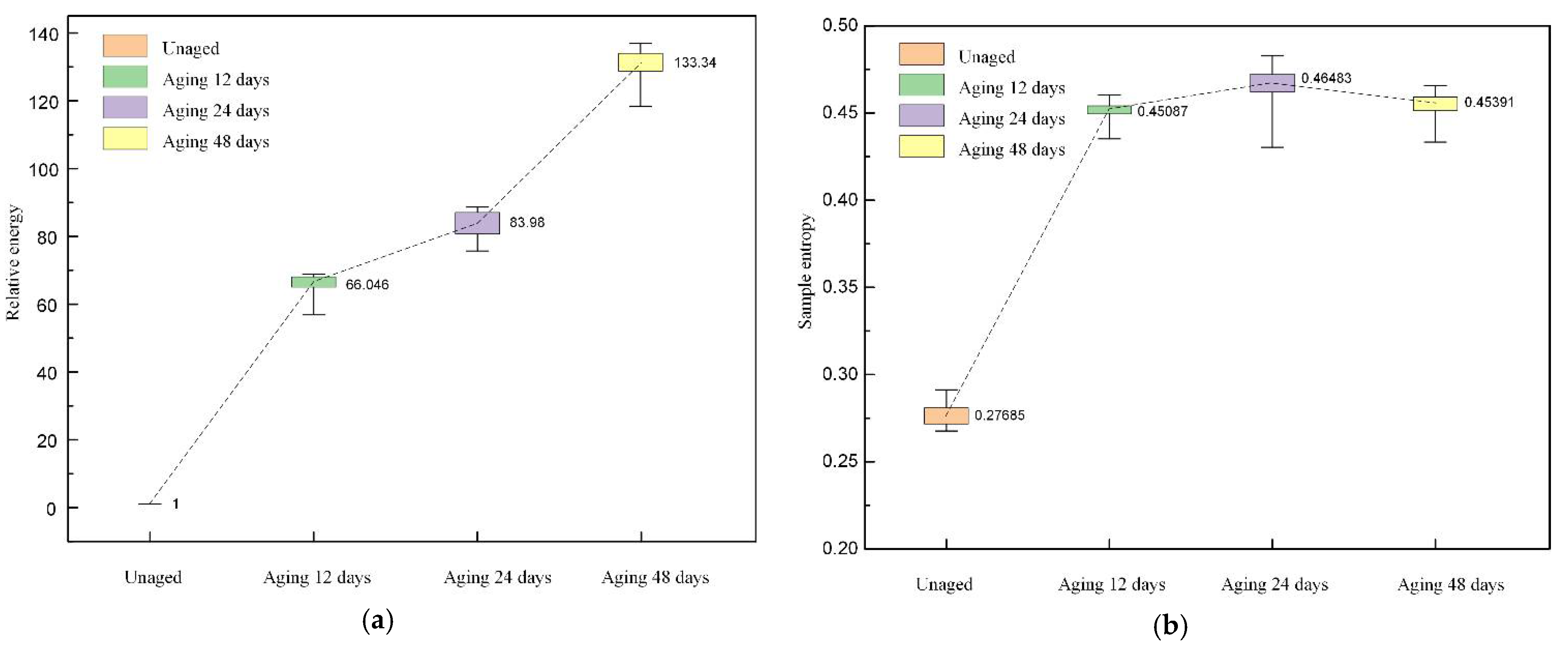

- Relative energy and sample entropy

4. Conclusions

- (1)

- The capacitance of the cable sample, the dielectric loss factor, and the amplitude of the leakage current of the cable sample gradually increased with the extension of the aging time. This indicated that the thermal aging made the dielectric properties of XLPE insulation deteriorate and the losses increase.

- (2)

- Thermal aging drove the generation of odd harmonic components in the cable leakage current and the amplitude of these harmonic components correlated with the degree of thermal aging. Among the odd harmonic components, the harmonics at 150 Hz, 450 Hz, and 650 Hz were more sensitive to the changes in the degree of thermal aging.

- (3)

- Thermal aging increased the relative energy and power spectrum energy of the sensitive harmonics and increased the disorder of the sensitive harmonic sequence.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Zhao, X.; Yin, G.; Li, S.; Zhao, J.; Ouyang, B.H. The effect of accelerated water tree ageing on the properties of XLPE cable insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1562–1569. [Google Scholar] [CrossRef]

- Al-Arainy, A.A.; Ahaideb, A.A.; Qureshi, M.I.; Malik, N.H. Statistical evaluation of water tree lengths in XLPE cables at different temperatures. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 995–1006. [Google Scholar] [CrossRef]

- Nedjar, M. Effect of thermal aging on the electrical properties of cross-linked polyethylene. J. Appl. Polym. Sci. 2009, 111, 1985–1990. [Google Scholar] [CrossRef]

- Kim, C.; Jiang, P.K.; Liu, F.; Hyon, S.; Ri, M.; Yu, Y.; Ho, M. Investigation on dielectric breakdown behavior of thermally aged cross-linked polyethylene cable insulation. Polym. Test. 2019, 80, 106045. [Google Scholar] [CrossRef]

- Kemari, Y.; Mekhaldi, A.; Teyssèdre, Y.; Teguar, Y. Correlations between structural changes and dielectric behavior of thermally aged XLPE. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1859–1866. [Google Scholar] [CrossRef]

- Suo, C.; Qin, Y.; Li, Z. Effect of thermal aging on dc conductivity of nano-CB/XLPE insulating composites. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application, Athens, Greece, 10–13 September 2018. [Google Scholar]

- Andjelkovic, D.; Rajakovic, N. Influence of accelerated aging on mechanical and structural properties of cross-linked polyethylene (XLPE) insulation. Electr. Eng. 2001, 83, 83–87. [Google Scholar] [CrossRef]

- Boukezzi, L.; Boubakeur, A.; Lallouani, M. Effect of artificial thermal aging on the crystallinity of XLPE insulation cables: X-ray study. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Vancouver, BC, Canada, 14–17 October 2007. [Google Scholar]

- Mecheri, Y.; Boukezzi, L.; Boubakeur, A.; Lallouani, M. Dielectric and mechanical behavior of cross-linked polyethylene under thermal aging. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena, Victoria, BC, Canada, 15–18 October 2000. [Google Scholar]

- Li, L.; Yong, J. A new method for on-line cable tanδ monitoring. In Proceedings of the International Conference on Harmonics and Quality of Power, Ljubljana, Slovenia, 13–16 May 2018. [Google Scholar]

- Densley, J. Review of international standards and practices for medium voltage power cable diagnostics. In Proceedings of the International Conference on Solid Dielectrics, Winchester, UK, 8–13 July 2007. [Google Scholar]

- Haikali, E.N.N.; Nyamupangedengu, C. Measured and simulated time-evolution PD characteristics of typical installation defects in MV XLPE cable terminations. SAIEE Afr. Res. J. 2019, 110, 136–144. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.K.; Lai, C.S.; Wu, R.N. Decision tree rules for insulation condition assessment of pre-molded power cable joints with artificial defects. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1636–1644. [Google Scholar] [CrossRef]

- He, B.; Zhou, Y.; Li, H.; Ye, T.; Fan, S.; Wang, X. Fault Identification of High-voltage Cable Sheath Grounding System Based on Ground Current Analysis. In Proceedings of the IEEE 4th Conference on Energy Internet and Energy System Integration, Wuhan, China, 30 October–1 November 2020. [Google Scholar]

- Marzinotto, M.; Mazzanti, G. The feasibility of cable sheath fault detection by monitoring sheath-to-ground currents at the ends of cross-bonding sections. IEEE Trans. Ind. Appl. 2015, 51, 5376–5384. [Google Scholar] [CrossRef]

- Li, Y.; Peng, F.D.; Chen, X.L.; Cheng, Y.H.; Li, X. Study on sheath circulating current of cross-linked power cables. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application, Chongqing, China, 9–12 November 2008. [Google Scholar]

- Iga, A.; Okamoto, T.; Hozumi, N.; Sasaki, S. The Application of On-Line Diagnoses for XLPE Cables by DC Component Method to On-Site Installed Cables. IEEE Trans. Power Syst. 1991, 111, 1243–1249. [Google Scholar]

- Zhu, G.; Zhou, K.; Lu, L.; Li, Y.; Xi, H.; Zeng, Q. Online Monitoring of Power Cables Tangent Delta Based on Low-Frequency Signal Injection Method. IEEE Trans. Instrum. Meas. 2021, 70, 1–8. [Google Scholar] [CrossRef]

- Rizzi, A.; Mascioli, F.M.F.; Baldini, F.; Mazzetti, C.; Bartnikas, R. Genetic optimization of a PD diagnostic system for cable accessories. IEEE Trans. Power Deliv. 2009, 24, 1728–1739. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Processing 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Xiangke, Z.; Zhenming, L.; Yajing, W. Residual Current Detection Method Based on Variational Modal Decomposition and Dynamic Fuzzy Neural Network. IEEE Access 2021, 9, 142925–142937. [Google Scholar]

- Chen, W.; Wang, Z.Z.; Xie, H.B.; Yu, W.X. Characterization of surface EMG signal based on fuzzy entropy. IEEE Trans. Neural Syst. Rehabil. Eng. 2007, 15, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Chaudhury, K.N.; Unser, M. Construction of Hilbert Transform Pairs of Wavelet Bases and Gabor-like Transforms. IEEE Trans. Signal Processing 2009, 57, 3411–3425. [Google Scholar] [CrossRef]

- Teng, W. Application of kernel principal component and Pearson correlation coefficient in prediction of mine pressure failure. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017. [Google Scholar]

- Wu, F.; Jiang, X.; Ma, W. A Feature Extraction Method of Network Traffic for Time-Frequency Synchronization Applications. In Proceedings of the 2017 International Conference on Computer Systems, Electronics and Control (ICCSEC), Dalian, China, 25–27 December 2017. [Google Scholar]

- Qi, Y.; Xu, Z.; Zhou, C. The Research of Time-Frequency Feature Extraction of Loudspeaker Acoustic Signal by Pre Emphasis in Time Domain. In Proceedings of the 2008 Second International Symposium on Intelligent Information Technology Application, Shanghai, China, 20–22 December 2008. [Google Scholar]

- Alcaraz, R.; Rieta, J.J. A review on sample entropy applications for the non-invasive analysis of atrial fibrillation electrocardiograms. Biomed Signal Processing 2010, 5, 1–14. [Google Scholar] [CrossRef]

- Pincus, S.M. Assessing serial irregularity and its implications for health. Ann. N. Y. Acad. Sci. 2001, 954, 245–267. [Google Scholar] [CrossRef] [PubMed]

| Harmonic Frequency (Hz) | Unaged | Aging 12 Days | Aging 24 Days | Aging 48 Days | ||||

|---|---|---|---|---|---|---|---|---|

| ρ | HRI (%) | ρ | HRI (%) | ρ | HRI (%) | ρ | HRI (%) | |

| 150 | 0.0273 | 2.0761 | 0.1348 | 13.2395 | 0.1445 | 14.4843 | 0.1478 | 14.7071 |

| 250 | 0.0127 | 0.8584 | 0.0363 | 2.6265 | 0.0586 | 5.8067 | 0.0379 | 3.0394 |

| 350 | 0.0081 | 0.4936 | 0.0705 | 7.5498 | 0.0469 | 4.6530 | 0.0496 | 4.6078 |

| 450 | 0.0064 | 0.4367 | 0.1363 | 14.8848 | 0.0984 | 10.7732 | 0.1334 | 14.4038 |

| 550 | 0.0069 | 0.4311 | 0.0621 | 6.6498 | 0.0540 | 5.7957 | 0.0513 | 5.3084 |

| 650 | 0.0051 | 0.4188 | 0.0770 | 8.4036 | 0.1424 | 15.8693 | 0.0852 | 9.0979 |

| 750 | 0.0049 | 0.4198 | 0.0648 | 7.0084 | 0.0784 | 8.5950 | 0.0600 | 6.4019 |

| 850 | 0.0057 | 0.4246 | 0.0686 | 7.4309 | 0.04132 | 4.4566 | 0.0260 | 2.5617 |

| 950 | - | - | 0.0508 | 5.5170 | 0.0329 | 3.5663 | 0.0497 | 5.2813 |

| Characteristic Parameter | Expression | Characteristic Parameter | Expression |

|---|---|---|---|

| Mean value | Root-mean-square value | ||

| Variance | Square root amplitude | ||

| Absolute mean value | Crest factor | ||

| Maximum value | Waveform factor | ||

| Minimum value | Pulse factor | ||

| Peak-to-peak value | Margin factor |

| Characteristic Parameter | Expression |

|---|---|

| Mean frequency | |

| Standard deviation frequency | |

| Center of gravity frequency | |

| Root-mean-square frequency |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, H.; Zhang, H.; Du, B. Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current. Polymers 2022, 14, 3147. https://doi.org/10.3390/polym14153147

Liu Y, Wang H, Zhang H, Du B. Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current. Polymers. 2022; 14(15):3147. https://doi.org/10.3390/polym14153147

Chicago/Turabian StyleLiu, Yong, Hao Wang, Han Zhang, and Boxue Du. 2022. "Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current" Polymers 14, no. 15: 3147. https://doi.org/10.3390/polym14153147

APA StyleLiu, Y., Wang, H., Zhang, H., & Du, B. (2022). Thermal Aging Evaluation of XLPE Power Cable by Using Multidimensional Characteristic Analysis of Leakage Current. Polymers, 14(15), 3147. https://doi.org/10.3390/polym14153147