Effect of Sodium Carboxymethyl Cellulose on Water and Salt Transport Characteristics of Saline–Alkali Soil in Xinjiang, China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Design

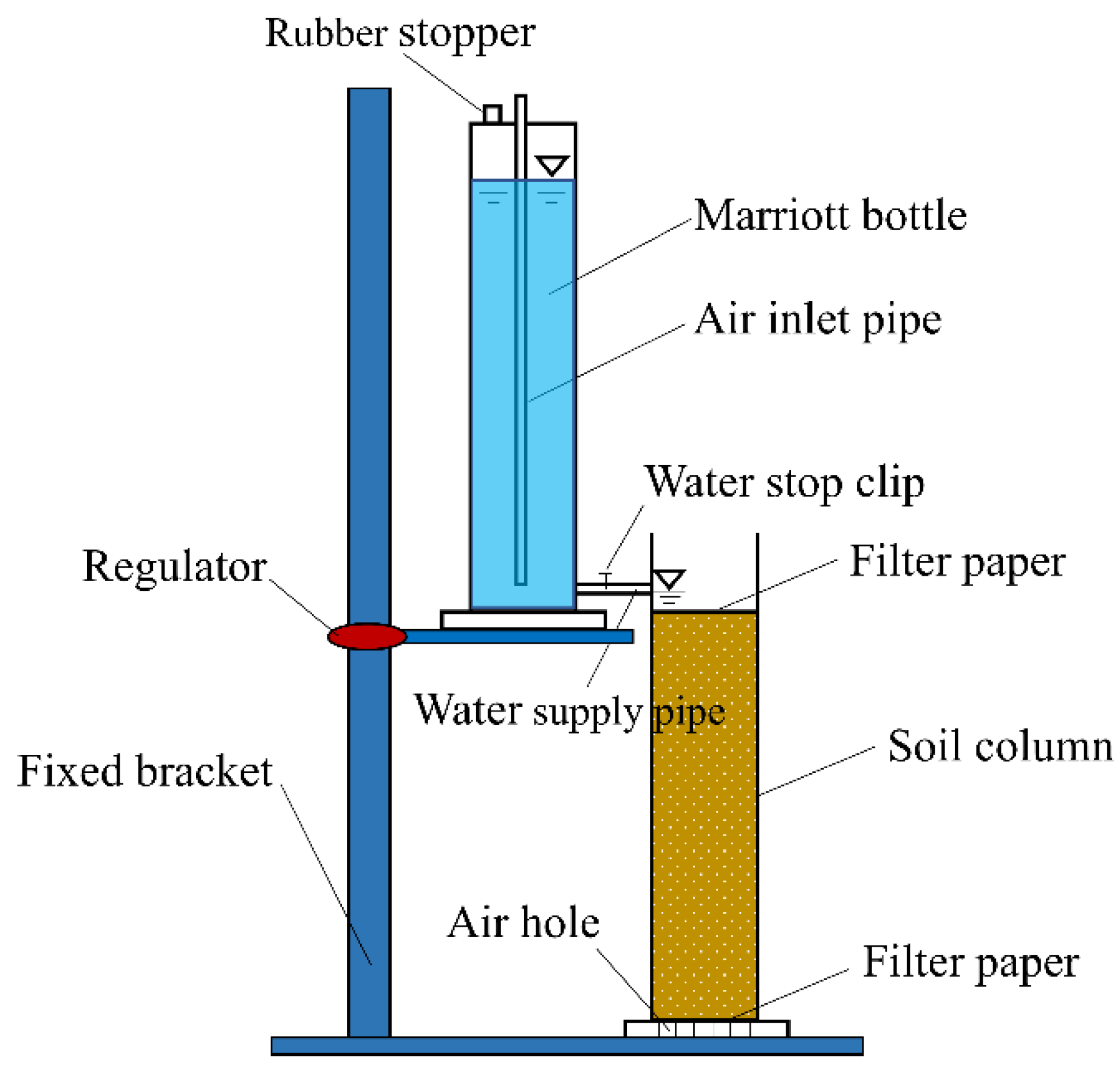

2.2.1. Experimental Process

2.2.2. Analytical Methods

2.3. Infiltration Model

2.4. Statistical Analysis

3. Results and Discussion

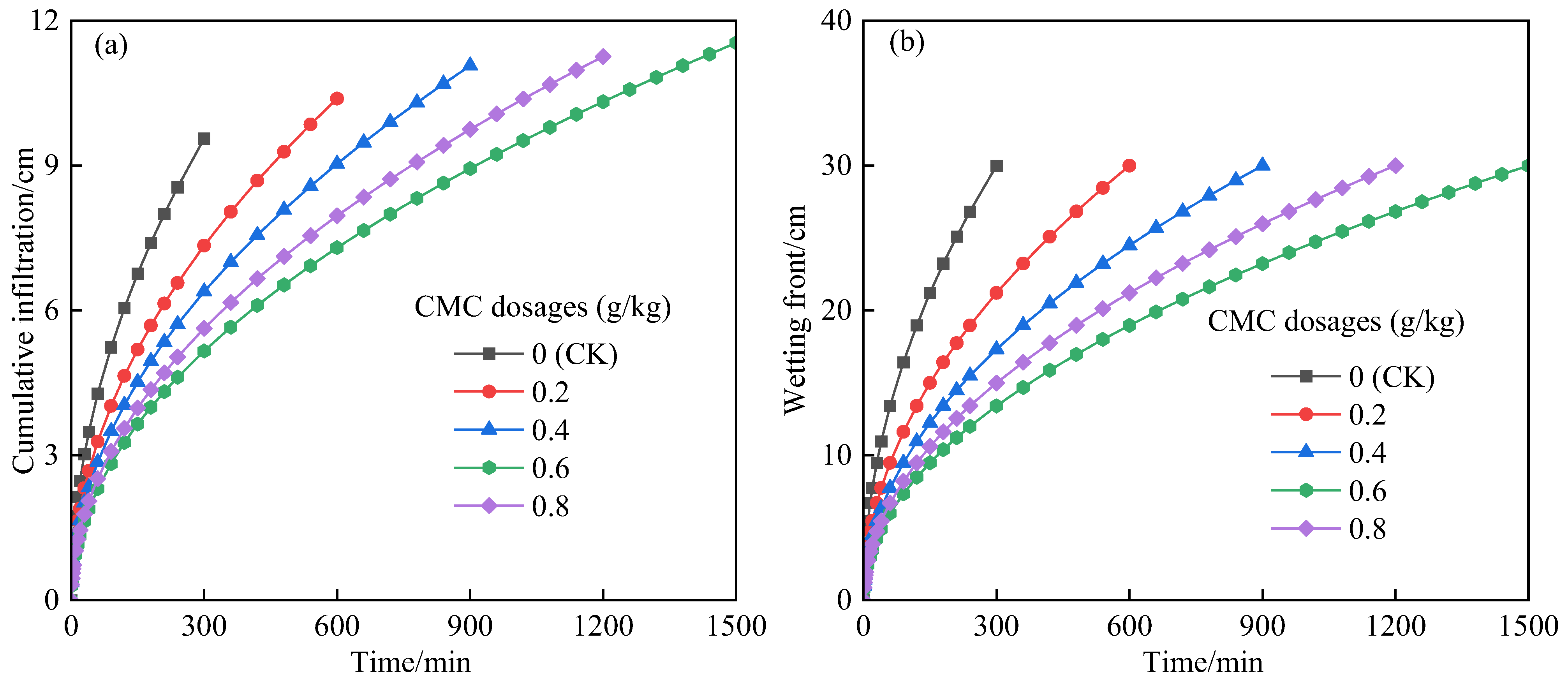

3.1. Water Infiltration: CMC Dosage Effect

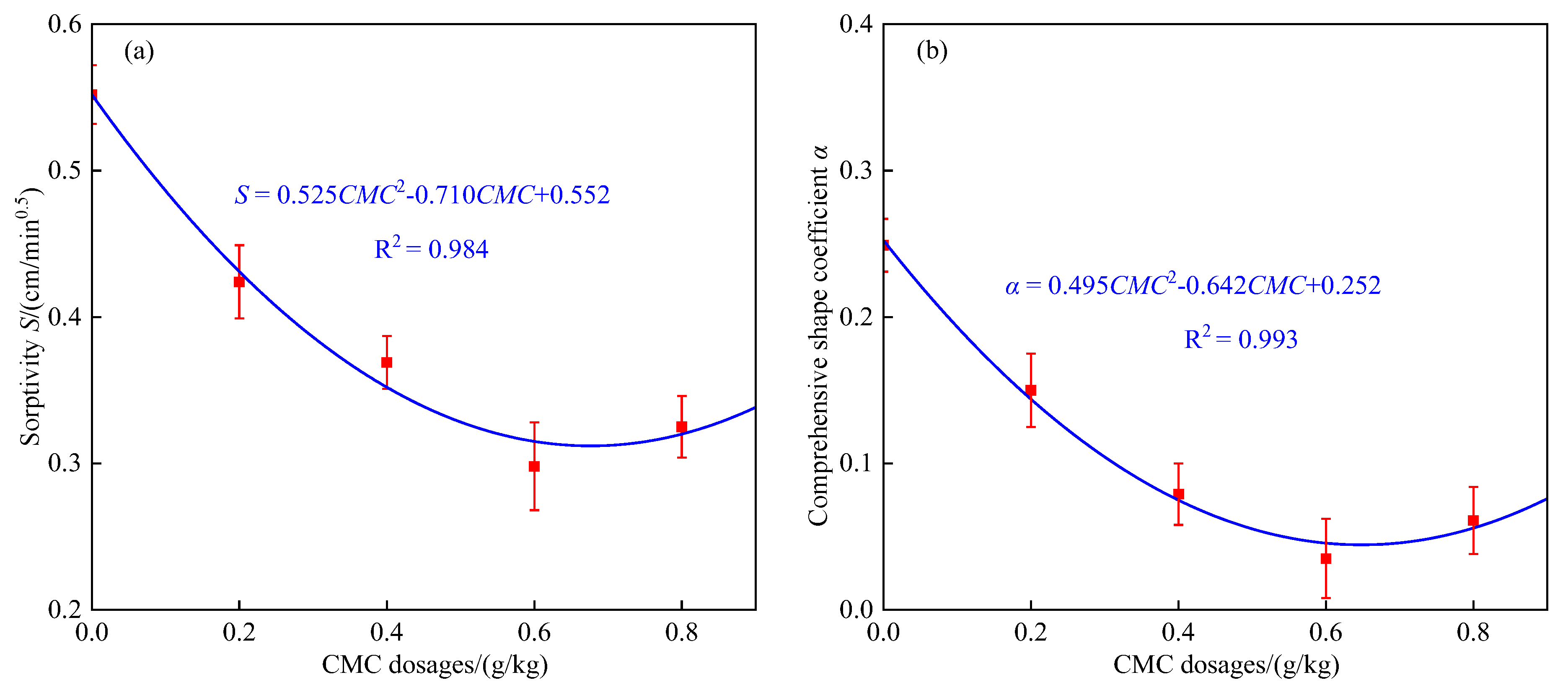

3.2. Infiltration Model Parameters: CMC Dosage Effect

3.3. Accuracy Analysis of Algebraic Model to Simulate Water Content Profile of CMC-Treated Soil

3.4. Water–Salt Distribution: CMC Dosage Effect

3.5. Salt Leaching: CMC Dosage Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Xin, L.; Tan, M.; Li, X.; Wang, J. Impact of spatiotemporal change of cultivated land on food-water relations in China during 1990–2015. Sci. Total Environ. 2020, 716, 137119. [Google Scholar] [CrossRef]

- Timsina, J. Can organic sources of nutrients increase crop yields to meet global food demand? Agronomy 2018, 8, 214. [Google Scholar] [CrossRef] [Green Version]

- Van Dijk, M.; Morley, T.; Rau, M.L.; Saghai, Y. A meta-analysis of projected global food demand and population at risk of hunger for the period 2010–2050. Nat. Food 2021, 2, 494–501. [Google Scholar] [CrossRef]

- Prăvălie, R.; Patriche, C.; Borrelli, P.; Panagos, P.; Roșca, B.; Dumitraşcu, M.; Nita, I.A.; Săvulescu, I.; Birsan, M.V.; Bandoc, G. Arable lands under the pressure of multiple land degradation processes. A global perspective. Environ. Res. 2021, 194, 110697. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.D.; Guo, J.L.; Han, M.Y.; Chen, G.Q. An overview of arable land use for the world economy: From source to sink via the global supply chain. Land Use Policy 2018, 76, 201–214. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, M.; Yang, L.; Masot, A.N.; Luis, J.; Gascón, G. Calculation of ecological compensation standards for arable land based on the value flow of support services. Land 2021, 10, 719. [Google Scholar] [CrossRef]

- Liang, J.; Li, Y.; Si, B.; Wang, Y.; Chen, X.; Wang, X.; Chen, H.; Wang, H.; Zhang, F.; Bai, Y.; et al. Optimizing biochar application to improve soil physical and hydraulic properties in saline-alkali soils. Sci. Total Environ. 2021, 771, 144802. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Tu, W.; Mu, L.; Sun, Z.; Hu, Q.; Yang, Y. Saline alkali water desalination project in southern Xinjiang of China: A review of desalination planning, desalination schemes and economic analysis. Renew. Sustain. Energy Rev. 2019, 113, 109268. [Google Scholar] [CrossRef]

- Wang, X.; Xue, Z.; Lu, X.; Liu, Y.; Liu, G.; Wu, Z. Salt leaching of heavy coastal saline silty soil by controlling the soil matric potential. Soil Water Res. 2019, 14, 132–137. [Google Scholar] [CrossRef] [Green Version]

- Tuan Mohamood, N.F.A.Z.; Abdul Halim, A.H.; Zainuddin, N. Carboxymethyl cellulose hydrogel from biomass waste of oil palm empty fruit bunch using calcium chloride as crosslinking agent. Polymers 2021, 13, 4056. [Google Scholar] [CrossRef]

- Guarnizo-Herrero, V.; Torrado-Salmerón, C.; Pabón, N.S.T.; Durán, G.T.; Morales, J.; Torrado-Santiago, S. Study of different chitosan/sodium carboxymethyl cellulose proportions in the development of polyelectrolyte complexes for the sustained release of clarithromycin from matrix tablets. Polymers 2021, 13, 2813. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jiang, Z.; Li, Y.; Kong, F.; Xi, M. Inorganic carbon sequestration and its mechanism of coastal saline-alkali wetlands in Jiaozhou Bay, China. Geoderma 2019, 351, 221–234. [Google Scholar] [CrossRef]

- Qiu, Z.; Zhang, R.; Qiu, H.; Gao, J. Effects of superabsorbents containing montmorillonite and polysaccharide on soil physical properties. Soil Fertil. Sci. China 2013, 3, 11–16. [Google Scholar]

- Xi, Q.; Zhao, Y.; Li, S. Effects of three kinds of soil amendments on shear strength of aeolian soil. Acta Pedol. Sin. 2018, 55, 1401–1410. [Google Scholar]

- Li, H.; Wang, Q.; Tao, W.; Chai, J.; Zhao, G. Effects of different amendments on the yield of surface runoff and loss of nutrients along loess slope soybean farmland. Sci. Soil Water Conserv. 2017, 15, 117–125. [Google Scholar]

- Wu, J.; Tao, W.; Wang, H.; Wang, Q. Influence of sodium carboxyl methyl cellulose on soil aggregate structure and soil water movement. Trans. Chin. Soc. Agric. Eng. 2015, 31, 117–123. [Google Scholar]

- Halidaimu, J.; Ning, S.; Wang, Q.; Zhang, J. Comparative analysis of the effects of PAM and CMC on soil infiltration and evaporation. J. Soil Water Conserv. 2020, 34, 121–127. [Google Scholar]

- Kebede, B.; Tsunekawa, A.; Haregeweyn, N.; Tsubo, M.; Mulualem, T.; Mamedov, A.I.; Meshesha, D.T.; Adgo, E.; Fenta, A.A.; Ebabu, K.; et al. Effect of polyacrylamide integrated with other soil amendments on runoff and soil loss: Case Study from Northwest Ethiopia. Int. Soil Water Conserv. Res. 2022, in press. [Google Scholar] [CrossRef]

- Liang, J.; Shi, W. Poly-γ-glutamic acid improves water-stable aggregates, nitrogen and phosphorus uptake efficiency, water-fertilizer productivity, and economic benefit in barren desertified soils of Northwest China. Agric. Water Manag. 2021, 245, 106551. [Google Scholar] [CrossRef]

- Teo, B.; Chakraborty, A.; Palash, M.L.; Lew, J.H.; Matar, O.K.; Müller, E.A.; Thant, M.; Maung, M.; Luckham, P.F. Adsorption of hydrolysed polyacrylamide onto calcium carbonate. Polymers 2022, 14, 405. [Google Scholar] [CrossRef]

- Albalasmeh, A.A.; Hamdan, E.H.; Gharaibeh, M.A.; Hanandeh, A. El improving aggregate stability and hydraulic properties of sandy loam soil by applying polyacrylamide polymer. Soil Tillage Res. 2021, 206, 104821. [Google Scholar] [CrossRef]

- Cao, Y.; She, D. Effects of biochar and PAM application on saline soil hydraulic properties of coastal reclamation region. Chinese J. Appl. Ecol. 2017, 28, 3684–3690. [Google Scholar]

- Alimu, A.; Yao, H.; Song, Y.; Fei, Y.; She, D. Effects of soil structure improvement on chlorophyll fluorescence parameters and yield of rice in a coastal reclamation region. Chin. J. Appl. Ecol. 2019, 30, 3435–3442. [Google Scholar]

- Ni, H.; Zhu, Y.; Liu, S.; Li, K.; Lu, Z.; Zhao, L. Effects of water retention agent and organic acid soil conditioner on saline-alkali soil improvement and wheat yield. Shandong Agric. Sci. 2020, 52, 121–125. [Google Scholar]

- Tan, S.; Wang, Q.; Xu, D.; Zhang, J.; Shan, Y. Evaluating effects of four controlling methods in bare strips on soil temperature, water, and salt accumulation under film-mulched drip irrigation. Field Crop. Res. 2017, 214, 350–358. [Google Scholar] [CrossRef]

- Fu, Q.; Hou, R.; Li, T.; Li, Y.; Liu, D.; Li, M. A new infiltration model for simulating soil water movement in canal irrigation under laboratory conditions. Agric. Water Manag. 2019, 213, 433–444. [Google Scholar] [CrossRef]

- Xu, X. Determination of eight major ions of soil soluble salts. Nonferrous Met. Xinjiang 2022, 45, 93–94. [Google Scholar]

- Wei, K.; Zhang, J.; Wang, Q.; Guo, Y.; Mu, W. Irrigation with ionized brackish water affects cotton yield and water use efficiency. Ind. Crops Prod. 2022, 175, 114244. [Google Scholar] [CrossRef]

- Tan, S.; Wang, Q.; Xu, D.; Zhang, J.; Shan, Y. Performance of AquaCrop model for cotton growth simulation under film-mulched drip irrigation in southern Xinjiang, China. Agric. Water Manag. 2018, 196, 99–113. [Google Scholar] [CrossRef]

- Philip, J.R. Theory of Infiltration; Academic Press, Inc.: Cambridge, MA, USA, 1969; Volume 5. [Google Scholar]

- Wang, Q.; Horton, R.; Shao, M. Algebraic model for one-dimensional infiltration and soil water distribution. Soil Sci. 2003, 168, 671–676. [Google Scholar] [CrossRef]

- Su, L.; Li, M.; Wang, Q.; Zhou, B.; Shan, Y.; Duan, M.; Ning, S. Algebraic model for one-dimensional horizontal water flow with arbitrary initial soil water content. Soil Res. 2021, 59, 511–524. [Google Scholar] [CrossRef]

- Qiao, Y.; Wu, J.; Xu, Y.; Fang, Z.; Zheng, L. Remediation of cadmium in soil by biochar-supported iron phosphate nanoparticles. Ecol. Eng. 2017, 106, 515–522. [Google Scholar] [CrossRef]

- Ning, S.; Jumai, H.; Wang, Q.; Zhou, B.; Su, L.; Shan, Y.; Zhang, J. Comparison of the effects of polyacrylamide and sodium carboxymethylcellulose application on soil water infiltration in sandy loam soils. Adv. Polym. Technol. 2019, 2019, 6869454. [Google Scholar] [CrossRef]

- Su, L.; Wang, J.; Qin, X.; Wang, Q. Approximate solution of a one-dimensional soil water infiltration equation based on the brooks-corey model. Geoderma 2017, 297, 28–37. [Google Scholar] [CrossRef]

- Santhi, C.; Arnold, J.G.; Williams, J.R.; Dugas, W.A.; Srinivasan, R.; Hauck, L.M. Validation of the SWAT model on a large river basin with point and nonpoint sources. J. Am. Water Resour. Assoc. 2001, 37, 1169–1188. [Google Scholar] [CrossRef]

- Olad, A.; Zebhi, H.; Salari, D.; Mirmohseni, A.; Reyhani, A. Slow-Release NPK fertilizer encapsulated by carboxymethyl cellulose-based nanocomposite with the function of water retention in soil. Mater. Sci. Eng. C 2018, 90, 333–340. [Google Scholar] [CrossRef]

- Van Koetsem, F.; Van Havere, L.; Du Laing, G. Impact of carboxymethyl cellulose coating on iron sulphide nanoparticles stability, transport, and mobilization potential of trace metals present in soils and sediment. J. Environ. Manage. 2016, 168, 210–218. [Google Scholar] [CrossRef]

| Soil Particle Composition (%) | Soil Texture | BD (g/cm3) | θi (cm3/cm3) | θs (cm3/cm3) | SCi (g/kg) | pH | ||

|---|---|---|---|---|---|---|---|---|

| Sand | Silt | Clay | ||||||

| 83.61 | 15.1 | 1.29 | Loamy sand soil | 1.57 | 0.033 | 0.431 | 4.40 | 7.86 |

| CMC Dosages (g/kg) | Philip Model | Algebraic Model | ||

|---|---|---|---|---|

| Sorptivity S (cm/min0.5) | Determination Coefficient (R2) | Comprehensive Shape Coefficient (α) | Determination Coefficient (R2) | |

| 0 (CK) | 0.552 | 0.994 | 0.249 | 0.989 |

| 0.1 | 0.424 | 0.987 | 0.150 | 0.964 |

| 0.2 | 0.369 | 0.985 | 0.079 | 0.987 |

| 0.4 | 0.298 | 0.988 | 0.035 | 0.976 |

| 0.6 | 0.325 | 0.986 | 0.061 | 0.983 |

| CMC Dosages (g/kg) | Desalination Rate (%) | Desalination Intensity (%) | Leaching Efficiency (g/L) |

|---|---|---|---|

| 0 (CK) | 40.07 e | 5.27 e | |

| 0.1 | 48.59 d | 21.27 d | 5.89 d |

| 0.2 | 53.84 c | 34.37 c | 6.12 c |

| 0.4 | 62.97 a | 57.15 a | 6.87 a |

| 0.6 | 56.98 b | 42.20 b | 6.37 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, Q.; Shan, Y.; Guo, Y.; Mu, W.; Wei, K.; Sun, Y. Effect of Sodium Carboxymethyl Cellulose on Water and Salt Transport Characteristics of Saline–Alkali Soil in Xinjiang, China. Polymers 2022, 14, 2884. https://doi.org/10.3390/polym14142884

Zhang J, Wang Q, Shan Y, Guo Y, Mu W, Wei K, Sun Y. Effect of Sodium Carboxymethyl Cellulose on Water and Salt Transport Characteristics of Saline–Alkali Soil in Xinjiang, China. Polymers. 2022; 14(14):2884. https://doi.org/10.3390/polym14142884

Chicago/Turabian StyleZhang, Jihong, Quanjiu Wang, Yuyang Shan, Yi Guo, Weiyi Mu, Kai Wei, and Yan Sun. 2022. "Effect of Sodium Carboxymethyl Cellulose on Water and Salt Transport Characteristics of Saline–Alkali Soil in Xinjiang, China" Polymers 14, no. 14: 2884. https://doi.org/10.3390/polym14142884

APA StyleZhang, J., Wang, Q., Shan, Y., Guo, Y., Mu, W., Wei, K., & Sun, Y. (2022). Effect of Sodium Carboxymethyl Cellulose on Water and Salt Transport Characteristics of Saline–Alkali Soil in Xinjiang, China. Polymers, 14(14), 2884. https://doi.org/10.3390/polym14142884