Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity

Abstract

:1. Introduction

2. Materials and Methods

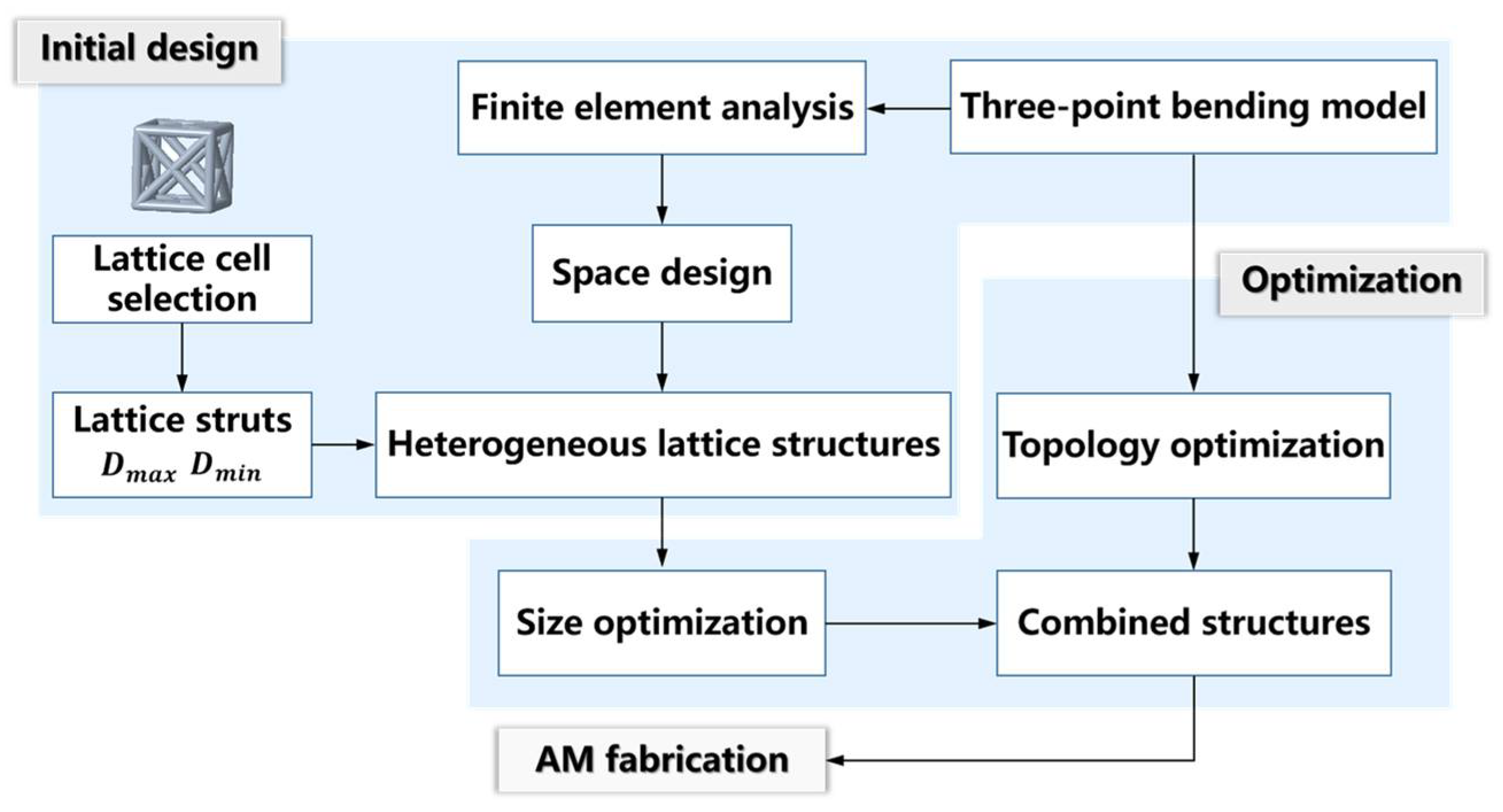

2.1. General Design Approach for Heterogeneous Lattice Structures

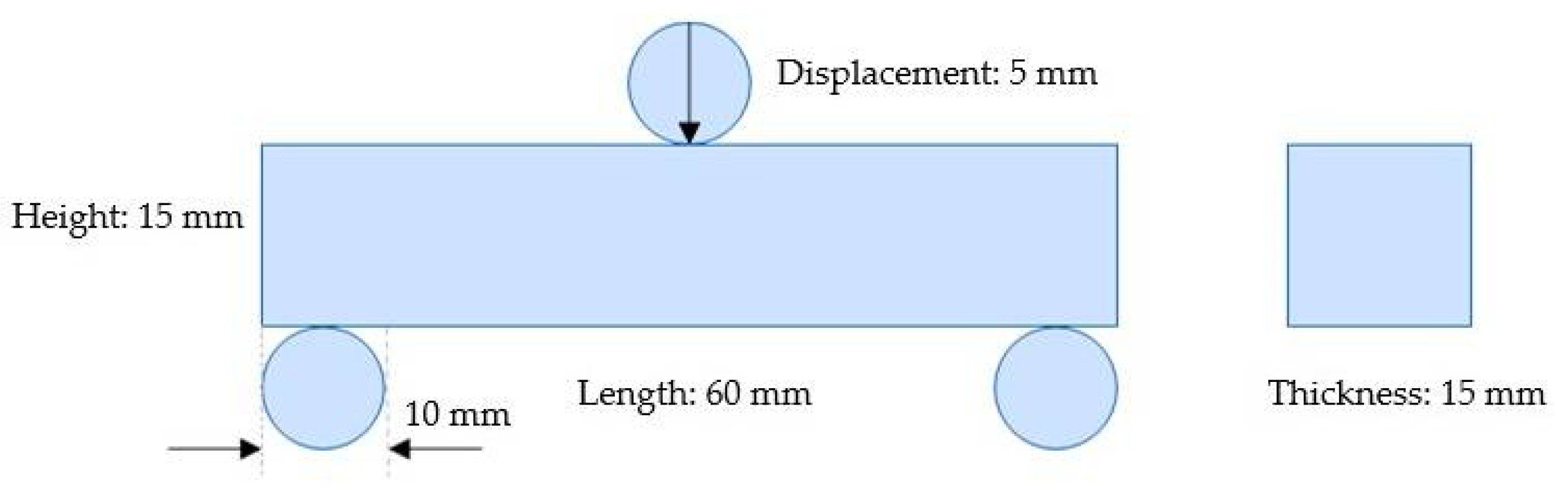

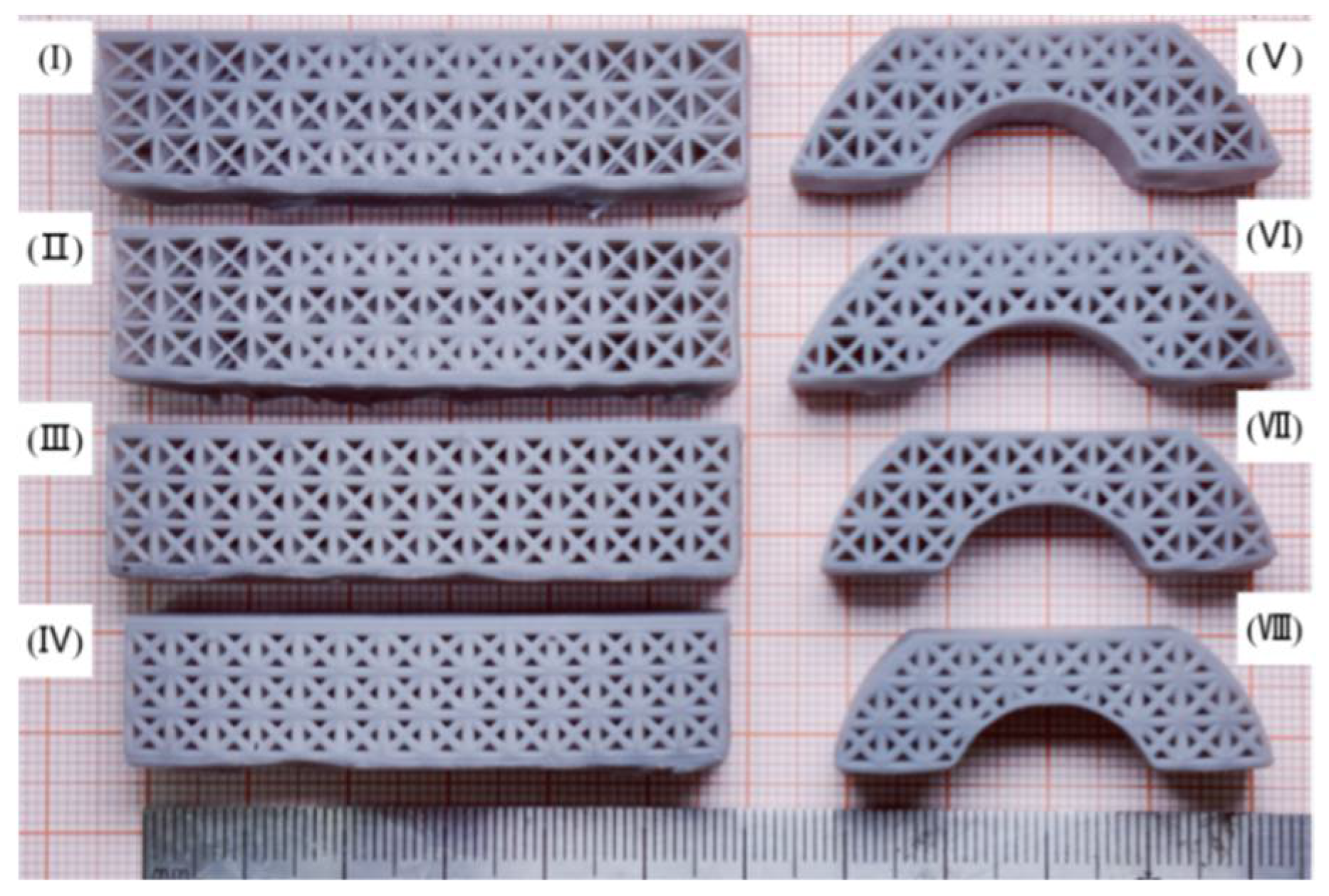

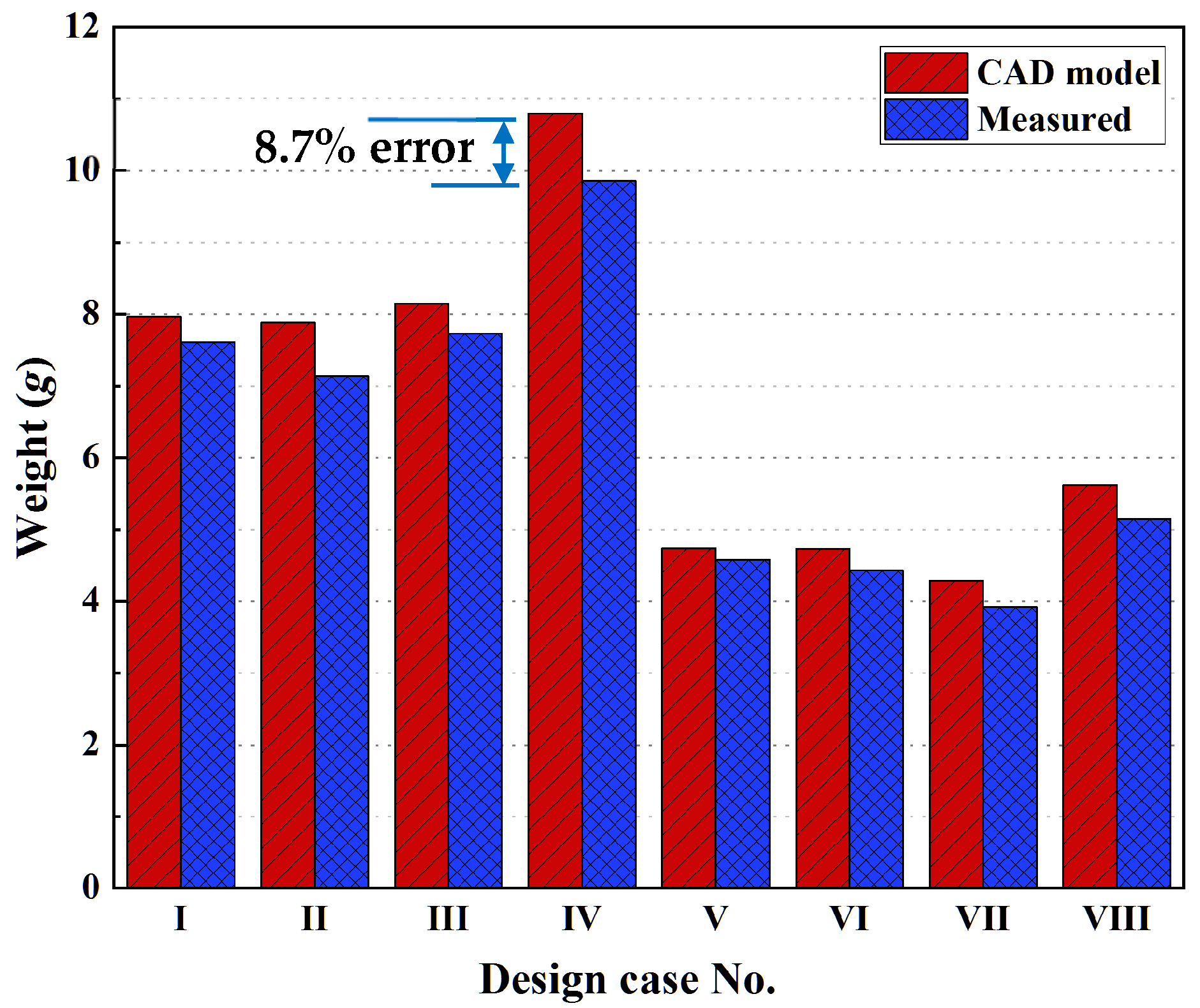

2.2. Material, Fabrication, and Three-Point Bending Testing of Lattice Structural Samples

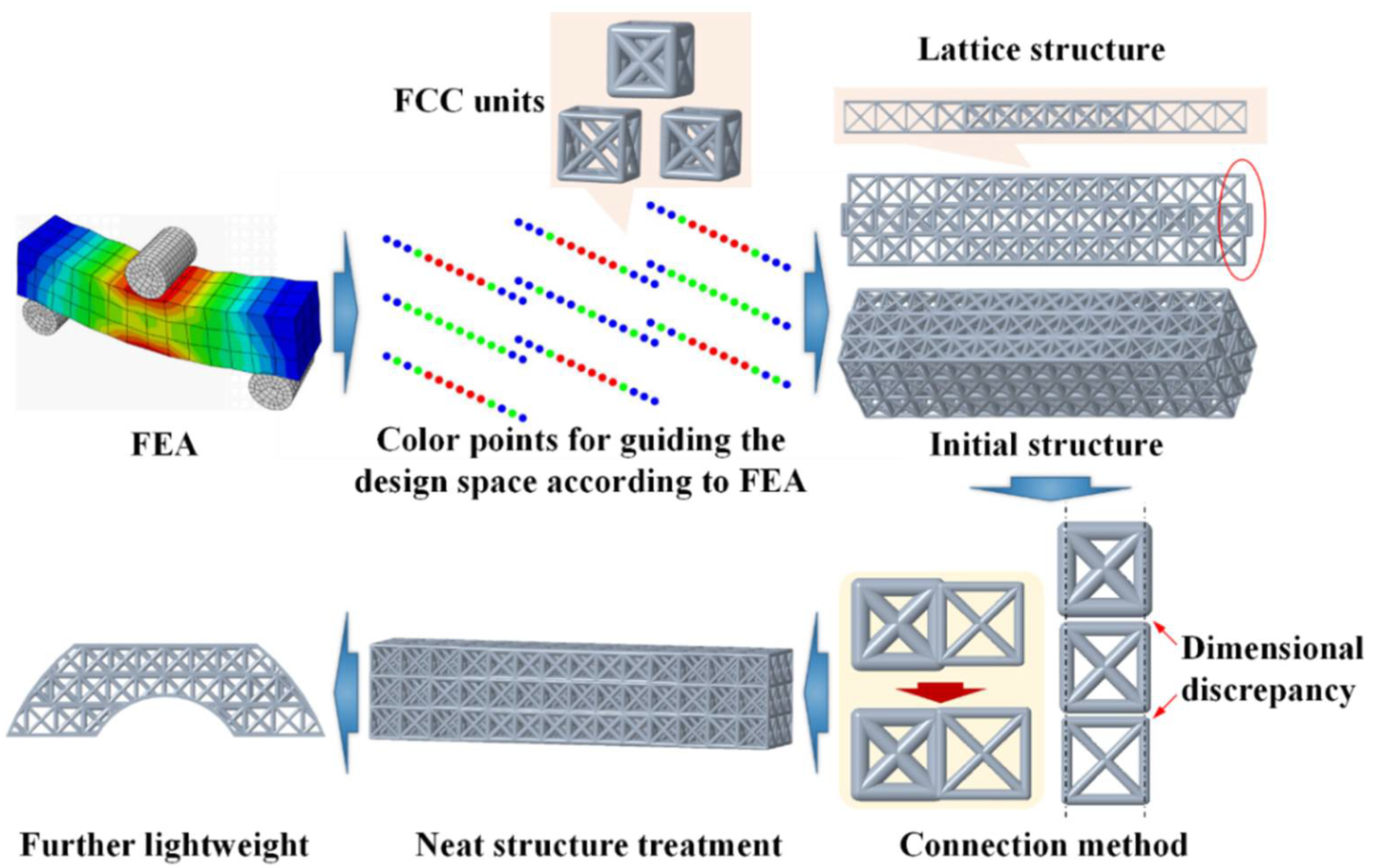

3. Initial Design of a Stress-Adapted Heterogeneous Lattice Structure

3.1. Mechanical Performance-Guided Lightweight Design Target

3.2. Stress-Adapted Arrangements of Different-Sized Lattice Units

4. Optimization Design of a Further-Lightened Heterogeneous Lattice Structure

4.1. Dimensional Optimization of Lattice Units

4.2. Topology Optimization for the Further Weight Reduction

4.3. Geometric Boolean Operation for the Combination of Lattices and Topology-Optimized Outer Shape

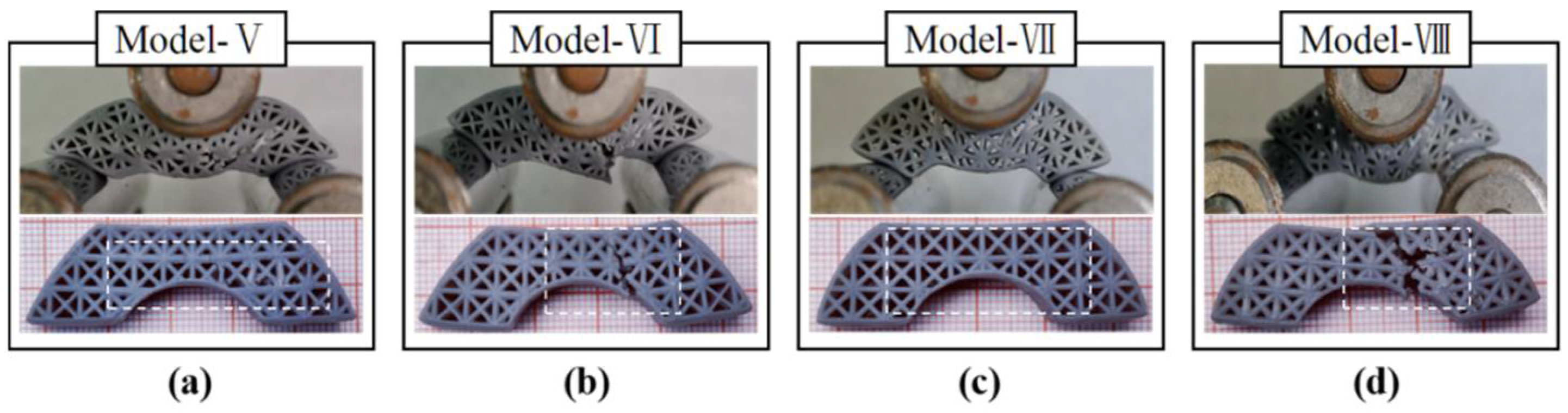

5. Experimental Results and Discussion

5.1. Mechanical Performance Indices for Comparisons

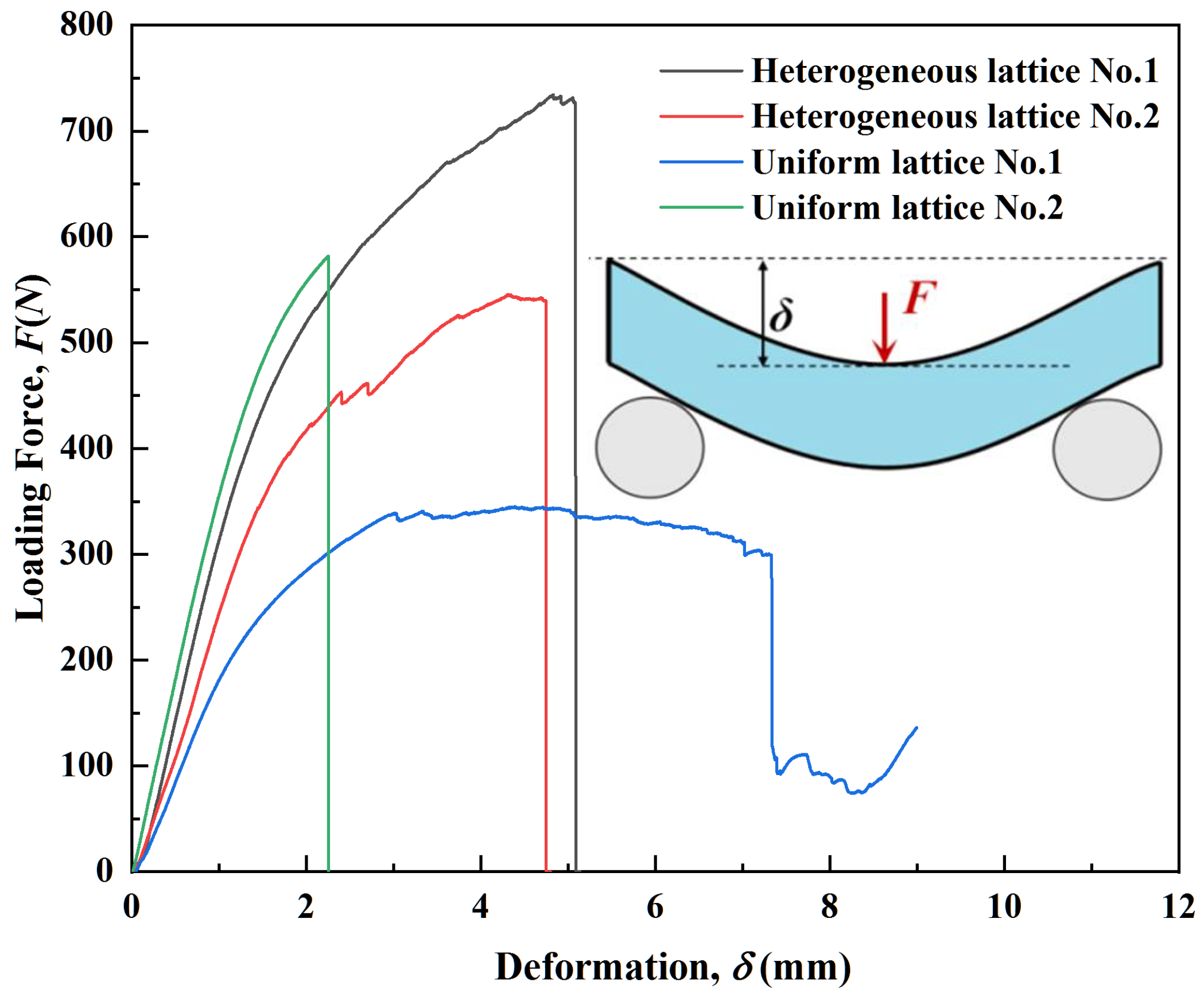

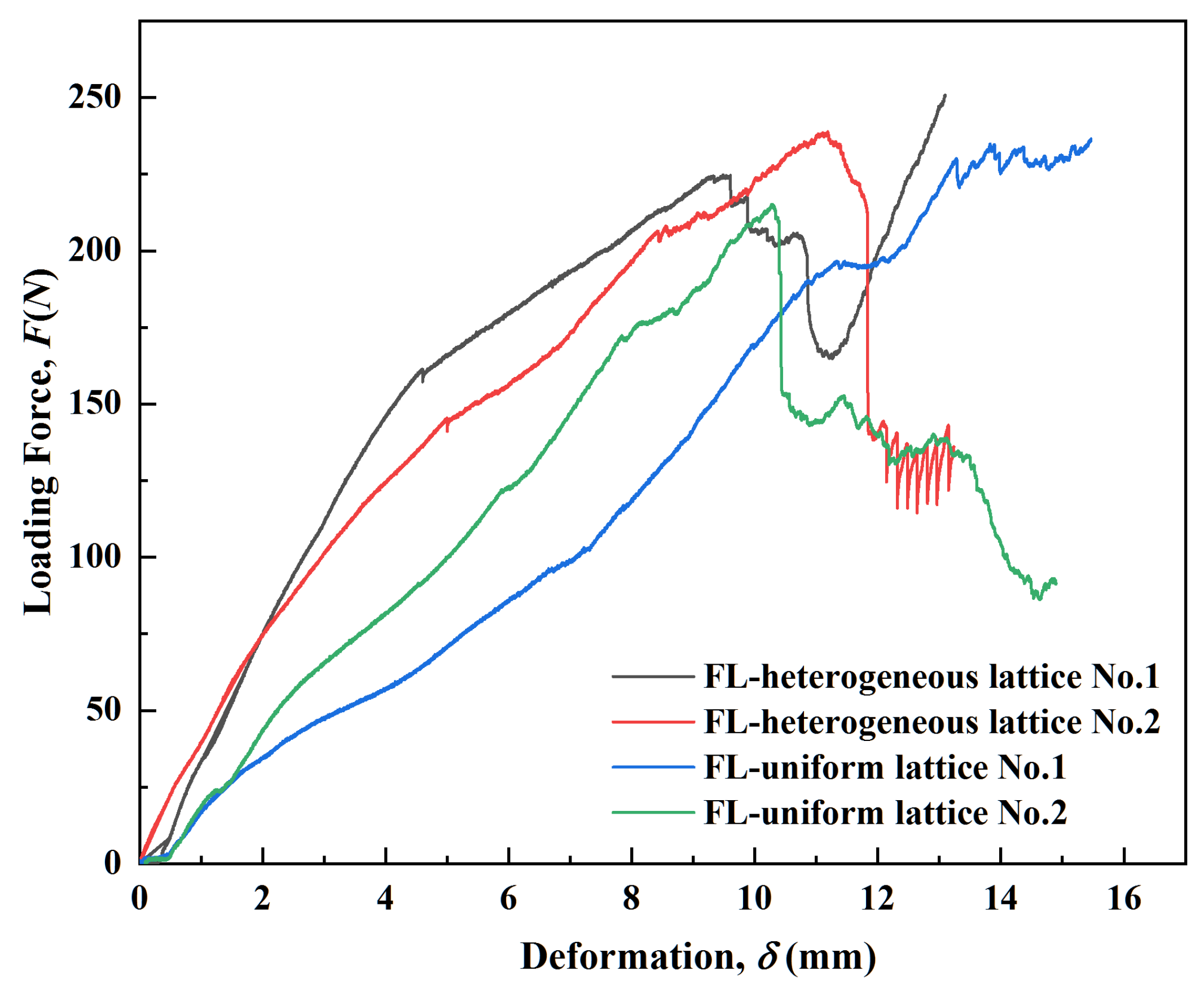

5.2. Experimental Results

5.3. Mechanical Performance of Heterogeneous Lattices Compared to the Uniform Ones

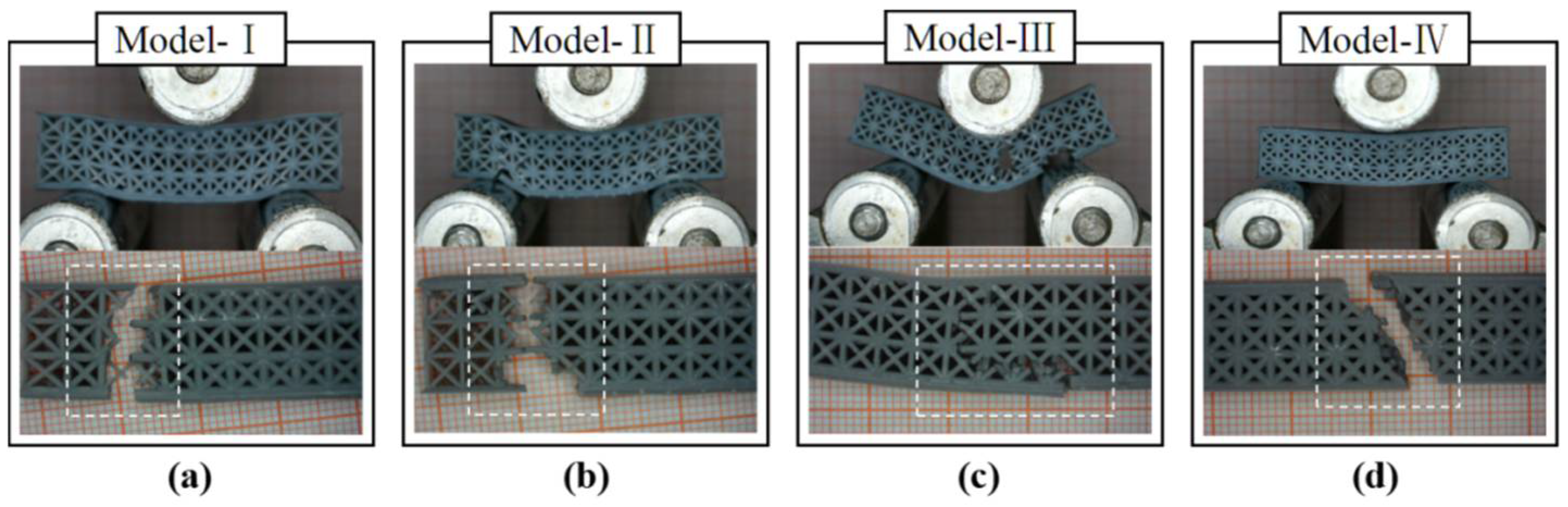

5.4. Macroscale Perspective of Failure Behavior

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar] [CrossRef]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1–4, 64–76. [Google Scholar] [CrossRef]

- Veiga, F.; Bhujangrao, T.; Suárez, A.; Aldalur, E.; Goenaga, I.; Gil-Hernandez, D. Validation of the Mechanical Behavior of an Aeronautical Fixing Turret Produced by a Design for Additive Manufacturing (DfAM). Polymers 2022, 14, 2177. [Google Scholar] [CrossRef] [PubMed]

- Niutta, C.B.; Ciardiello, R.; Tridello, A. Experimental and Numerical Investigation of a Lattice Structure for Energy Absorption: Application to the Design of an Automotive Crash Absorber. Polymers 2022, 14, 1116. [Google Scholar] [CrossRef] [PubMed]

- De la Rosa, S.; Mayuet, P.F.; Salgueiro, J.R.M.; Rodríguez-Parada, L. Design of Customized TPU Lattice Structures for Additive Manufacturing: Influence on the Functional Properties in Elastic Products. Polymers 2021, 13, 4341. [Google Scholar] [CrossRef]

- Sohrabian, M.; Vaseghi, M.; Khaleghi, H.; Dehrooyeh, S.; Kohan, M.S.A. Structural Investigation of Delicate-Geometry Fused Deposition Modeling Additive Manufacturing Scaffolds: Experiment and Analytics. J. Mater. Eng. Perform. 2021, 30, 6529–6541. [Google Scholar] [CrossRef]

- Al Hassanieh, S.; Alhantoobi, A.; Khan, K.A.; Khan, M.A. Mechanical Properties and Energy Absorption Characteristics of Additively Manufactured Lightweight Novel Re-Entrant Plate-Based Lattice Structures. Polymers 2021, 13, 3882. [Google Scholar] [CrossRef]

- Aziz, A.R.; Zhou, J.; Thorne, D.; Cantwell, W.J. Geometrical Scaling Effects in the Mechanical Properties of 3D-Printed Body-Centered Cubic (BCC) Lattice Structures. Polymers 2021, 13, 3967. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Zhao, Y.F. A Survey of Modeling of Lattice Structures Fabricated by Additive Manufacturing. J. Mech. Des. 2017, 139, 100906. [Google Scholar] [CrossRef]

- Ranganathan, S. On the geometry of coincidence-site lattices. Acta Crystallogr. 1966, 21, 197–199. [Google Scholar] [CrossRef]

- Aremu, A.; Brennan-Craddock, J.; Panesar, A.S.; Ashcroft, I.; Hague, R.; Wildman, R.; Tuck, C. A voxel-based method of constructing and skinning conformal and functionally graded lattice structures suitable for additive manufacturing. Addit. Manuf. 2017, 13, 1–13. [Google Scholar] [CrossRef]

- Jin, Q.-Y.; Yu, J.-H.; Ha, K.-S.; Lee, W.-J.; Park, S.-H. Multi-dimensional lattices design for ultrahigh specific strength metallic structure in additive manufacturing. Mater. Des. 2021, 201, 109479. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, F.; Wang, M.Y. Concurrent design with connectable graded microstructures. Comput. Methods Appl. Mech. Eng. 2017, 317, 84–101. [Google Scholar] [CrossRef]

- Chang, P.S.; Rosen, D.W. The size matching and scaling method: A synthesis method for the design of mesoscale cellular structures. Int. J. Comput. Integr. Manuf. 2013, 26, 907–927. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.-J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Daynes, S.; Feih, S.; Lu, W.F.; Wei, J. Optimisation of functionally graded lattice structures using isostatic lines. Mater. Des. 2017, 127, 215–223. [Google Scholar] [CrossRef]

- Teufelhart, S. Investigation of the Capability of Flux of Force Oriented Lattice Structures for Lightweight Design. Adv. Mater. Res. 2014, 907, 75–87. [Google Scholar] [CrossRef]

- Kang, D.-S.; Park, S.-H.; Son, Y.; Yeon, S.-M.; Kim, S.H.; Kim, I.-Y. Multi-lattice inner structures for high-strength and light-weight in metal selective laser melting process. Mater. Des. 2019, 175, 107786. [Google Scholar] [CrossRef]

- Pham, M.-S.; Liu, C.; Todd, I.; Lertthanasarn, J. Damage-tolerant architected materials inspired by crystal microstructure. Nature 2019, 565, 305–311. [Google Scholar] [CrossRef]

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, P.; Biyikli, E.; Bai, J.; Robbins, J.; To, A. Efficient design optimization of variable-density cellular structures for additive manufacturing: Theory and experimental validation. Rapid Prototyp. J. 2017, 23, 660–677. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, X.; Liu, S. Finite-Element-Mesh Based Method for Modeling and Optimization of Lattice Structures for Additive Manufacturing. Materials 2018, 11, 2073. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufac-turing. Addit. Manuf. 2020, 33, 101116. [Google Scholar]

- Teimouri, M.; Mahbod, M.; Asgari, M. Topology-optimized hybrid solid-lattice structures for efficient mechanical performance. Structures 2021, 29, 549–560. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Baumgart, F. Stiffness-an unknown world of mechanical science? Injury 2000, 31, 14–23. [Google Scholar]

- Xia, J.-W.; Wu, X.-S. Evaluating the stiffness of cable-bar tensile structures based on subspaces of zero elastic stiffness and demand stiffness. Eng. Struct. 2020, 206, 110167. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Zolfagharian, A.; Jennings, M.; Reinicke, T. Structural performance of 3D-printed composites under various loads and environmental conditions. Polym. Test. 2020, 91, 106770. [Google Scholar] [CrossRef]

- Ghannadpour, S.; Mahmoudi, M.; Nedjad, K.H. Structural behavior of 3D-printed sandwich beams with strut-based lattice core: Experimental and numerical study. Compos. Struct. 2022, 281, 115113. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W.; Wadley, N.G. Metal Foams: A Design Guide; Butterworth-Heinemann: Woburn, MA, USA, 2000. [Google Scholar]

- Yin, H.; Guo, D.; Wen, G.; Wu, Z. On bending crashworthiness of smooth-shell lattice-filled structures. Thin-Walled Struct. 2022, 171, 108800. [Google Scholar] [CrossRef]

- Cristescu, N.; Craciun, E.-M.; Gaunaurd, G. Mechanics of Elastic Composites; Chapman and Hall/CRC: Boca Raton, FL, USA, 2003. [Google Scholar]

- Alabiso, W.; Schlögl, S. The Impact of Vitrimers on the Industry of the Future: Chemistry, Properties and Sustainable Forward-Looking Applications. Polymers 2020, 12, 1660. [Google Scholar] [CrossRef]

| Designed Structure Case | Design Model | Relative Density, ρ |

|---|---|---|

| (I) Heterogeneous lattice No. 1 |  | 0.429 |

| (II) Heterogeneous lattice No. 2 |  | 0.424 |

| (III) Uniform lattice No. 1 (Strut diameter of 0.8 mm) |  | 0.439 |

| (IV) Uniform lattice No. 2 (Strut diameter of 1.0 mm) |  | 0.582 |

| (V) FL–heterogeneous lattice No. 1 |  | 0.255 |

| (VI) FL–heterogeneous lattice No. 2 |  | 0.254 |

| (VII) FL–uniform lattice No. 1 (Strut diameter of 0.8 mm) |  | 0.231 |

| (VIII) FL–uniform lattice No. 2 (Strut diameter of 1.0 mm) |  | 0.303 |

| Designed Structure | Max. Loading, P [N] | Deflection, δ [mm] | Relative Flexural Rigidity | δ* | α | β | γ |

|---|---|---|---|---|---|---|---|

| (I) Heterogeneous lattice No. 1 | 727.29 | 5.08 | 0.146 | 1.116 | 0.341 | 2.601 | 0.886 |

| (II) Heterogeneous lattice No. 2 | 539.65 | 4.74 | 0.103 | 1.02 | 0.243 | 2.456 | 0.598 |

| (III) Uniform lattice No. 1 (Strut diameter of 0.8 mm) | 338.71 | 3.03 | 0.103 | 0.666 | 0.234 | 1.518 | 0.355 |

| (IV) Uniform lattice No. 2 (Strut diameter of 1.0 mm) | 581.65 | 2.25 | 0.202 | 0.495 | 0.347 | 0.850 | 0.295 |

| (V) FL–heterogeneous lattice No. 1 | 224.07 | 9.61 | 0.009 | 2.112 | 0.037 | 8.275 | 0.306 |

| (VI) FL–heterogeneous lattice No. 2 | 231.3 | 11.43 | 0.007 | 2.512 | 0.028 | 9.845 | 0.279 |

| (VII) FL–uniform lattice No. 1 (Strut diameter of 0.8 mm) | 196.22 | 11.35 | 0.005 | 2.495 | 0.020 | 10.794 | 0.219 |

| (VIII) FL–uniform lattice No. 2 (Strut diameter of 1.0 mm) | 215.07 | 10.29 | 0.005 | 2.262 | 0.016 | 7.467 | 0.117 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Shen, C. Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity. Polymers 2022, 14, 2807. https://doi.org/10.3390/polym14142807

Li B, Shen C. Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity. Polymers. 2022; 14(14):2807. https://doi.org/10.3390/polym14142807

Chicago/Turabian StyleLi, Bo, and Ciming Shen. 2022. "Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity" Polymers 14, no. 14: 2807. https://doi.org/10.3390/polym14142807

APA StyleLi, B., & Shen, C. (2022). Solid Stress-Distribution-Oriented Design and Topology Optimization of 3D-Printed Heterogeneous Lattice Structures with Light Weight and High Specific Rigidity. Polymers, 14(14), 2807. https://doi.org/10.3390/polym14142807