Study of the Structural Mechanical Properties of Drainage Canals Rehabilitated by Spraying Method

Abstract

:1. Introduction

2. Materials and Test

2.1. Raw Materials

2.1.1. Compression and Flexural Tests

2.1.2. Tensile Adhesive Strength Test

2.1.3. Impermeability Test

2.2. Design of Test Model

2.2.1. Experimental Modelling

2.2.2. Test Site

2.2.3. Design of Loading Program

2.2.4. Test Content and Equipment Arrangement

- (1)

- Arrangement of displacement measuring points

- (2)

- Arrangement of strain measuring points

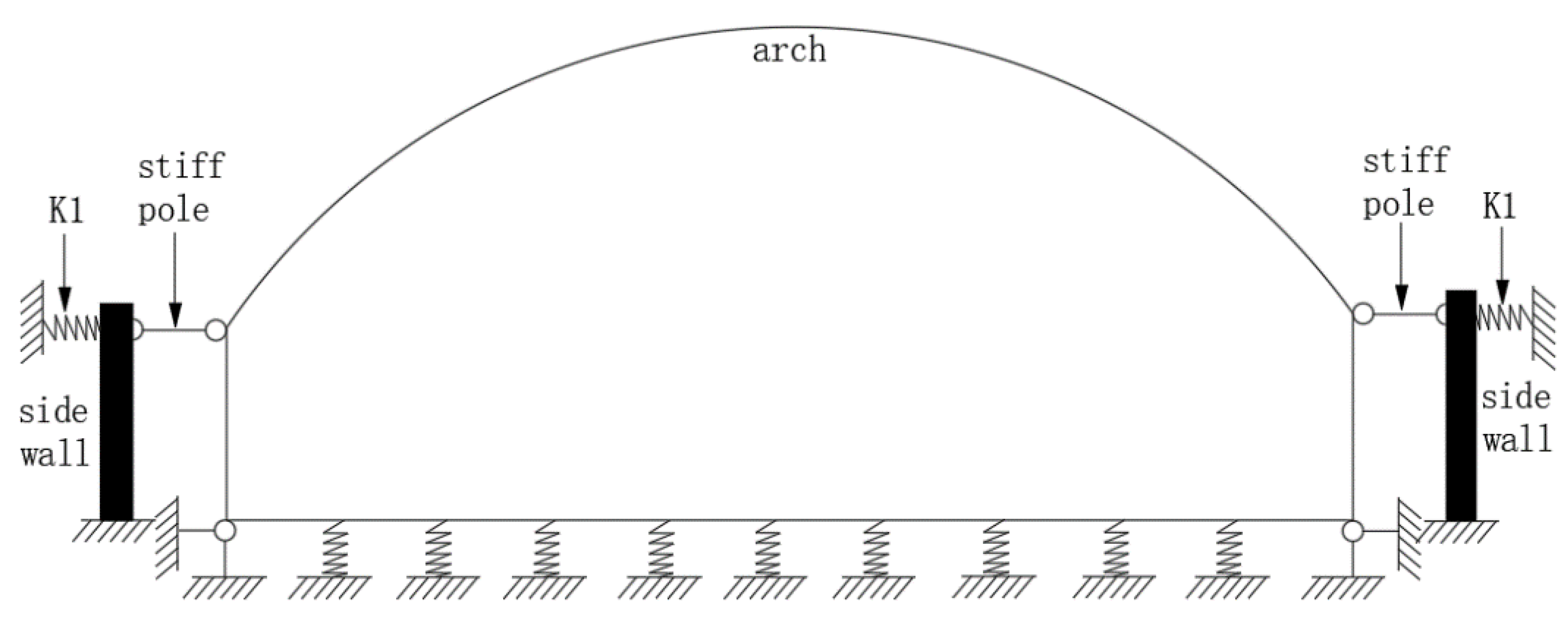

2.3. Simulation Process

2.3.1. Material Properties and Meshing

2.3.2. Model Simplification

3. Material Performance and Experimental Results

3.1. Material Performance

3.1.1. Compression and Flexural Tests

3.1.2. Tensile Adhesive Strength Test

3.1.3. Impermeability Test

3.2. Experimental Results

3.2.1. Test Process and Fracture Description

3.2.2. Displacement Monitoring Results

3.2.3. Strain Monitoring Results

3.3. Simulation Results

4. Conclusions and Future Outlook

- H-70 has high early strength, can rapidly harden on the wet pipe surface, and has an extremely dense slurry. It has excellent impermeability and durability and greatly extends the service life of the repaired drainage pipeline. The normal service ultimate bearing capacity of the arched structure repaired by H-70 reaches 150 kN.

- The first crack on the arch appeared when unilateral stress was applied during the unloading process. During the test, the crack developed slowly, with a maximum crack width of 0.27 mm. After unloading, all the cracks closed well and the maximum crack width was 0.02 mm.

- The canal structure had a lateral displacement constraint on the lining structure. According to the test results, the strain and settlement of the bottom plate are small and most of the loads are transmitted to the foundation through this combination. The lateral displacement of the vault was significantly greater than the vertical deflection and lateral wall displacement and the left displacement was greater than the right displacement. The strain of the vault and arch waist was greater than that of the arch foot.

- The lining structure can be simplified as a closed frame without settlement at both ends of the bottom plate. The middle area of the bottom plate and the top of the side wall were loaded with only compressive springs. The comparative test and finite element analysis showed that under the constraint of canal structure, the bending moment of vault and arch foot were greatly reduced and the effect on the arch foot was more obvious.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Statistical Yearbook of Urban Construction in 2022. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/sjfb/tjxx/index.html (accessed on 1 May 2022).

- Niu, S. Pipe Inner-repairing Technique Abroad and Development of CIPP Repairing Technology in our Country. Pipeline Tech. Equipment. 2003, 2, 22–24. [Google Scholar]

- CJJ/T 210, 2014; Technical Specification for Trenchless Rehabilitation and Renewal of Urban Sewer Pipeline. Standard Press: Beijing, China, 2014.

- Zhou, W.; Li, C.; Ma, B. Buckling Strength of a Thin-Wall Stainless Steel Liner Used to Rehabilitate Water Supply Pipelines. J. Pipeline Syst. Eng. Pract. 2015, 7, 04015017. [Google Scholar] [CrossRef]

- Dong, S.; Zhou, W.; Zhang, H. An Updated Structure for a Stainless Steel Liner and the Estimation of its Buckling Strength. Tunn. Undergr. Space Technol. 2018, 72, 9–16. [Google Scholar] [CrossRef]

- Ma, B. Trenchless Pipeline Rehabilitation and Renewal Technology; China Communications Press: Beijing, China, 2014. [Google Scholar]

- Najafi, M. Trenchless Technology; McGraw Hill: New York, NY, USA, 2004. [Google Scholar]

- Meland, I.S. Durability of Building Materials and Components 8. Institute for Research in Construction; National Research Council Canada: Ottawa, ON, Canada, 1999; pp. 170–179.

- Kong, Y. Study and Application of Cast In-Situ Method for Pipeline and Manhole Trenchless Rehabilitation; China University of Geosciences: Wuhan, China, 2017. [Google Scholar]

- Wang, T.; Zhao, Y.; Ma, B.; Zeng, C. Durability Study on High-Performance Fiber-Reinforced Mortar under Simulated Wastewater Pipeline Environment. Materials 2021, 14, 3781. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Zeng, C.; Ma, B.; Gong, C.; Liao, B.; Zhao, Y.; Ma, C.; Kong, Y. Experimental Investigations of a Tunnel Lining Segment Strengthened by In Situ Spraying Mortar. Appl. Sci. 2022, 12, 3722. [Google Scholar] [CrossRef]

- Water Research Centre. Structural Tests on a Renovated Brickwork Sewer at St. Helens, Merseyside; WRc Engineering: Swindon, UK, 1983. [Google Scholar]

- Zarghamee, M.S.; Valentine, D.P. Behavior of Thermoplastic Liners within Degraded Concrete Pipe. In Proceedings of the American Society of Civil Engineers Pipeline Division Specialty Conference 2006, Chicago, IL, USA, 30 July–2 August 2006; pp. 1–7. [Google Scholar]

- Zhao, Y.; Ma, B.; Ariaratnam, S.T.; Zeng, C.; Yan, X.; Wang, F.; Wang, T.; Zhu, Z.; He, C.; Shi, G.; et al. Structural Performance of Damaged Rigid Pipe Rehabilitated by Centrifugal Spray on Mortar Liner. Tunn. Undergr. Space Technol. 2021, 116, 104117. [Google Scholar] [CrossRef]

- Wang, Y.; Qian, X.; Liew, J.R.; Zhang, M.H. Experimental Behavior of Cement Filled Pipe-in-Pipe Composite Structures under Transverse Impact. Int. J. Impact Eng. 2014, 72, 1–16. [Google Scholar] [CrossRef]

- McAlpine, G. Structural Rehabilitation of Semi Elliptical Concrete Sewers. In Proceedings of the Pipeline Division Specialty Conference 2006, Chicago, IL, USA, 30 July–2 August 2006; pp. 1–7. [Google Scholar]

- Zhao, J.Q.; Daigle, L. Structural Performance of Sliplined Watermain. Can. J. Civ. Eng. 2001, 28, 969–978. [Google Scholar] [CrossRef]

- Cao, X. Stress Analysis and Calculation of Repairing Drainage Pipeline with Cement Mortar Spraying Method. Low Temp. Archit. Technol. 2021, 43, 125–129. [Google Scholar]

- Shi, G.; Ma, B.; Yang, C.; Zeng, C. Structural Performance of Reinforced Concrete Pipe Repaired by Cement Mortar Spraying Method. China Water Wastewater 2020, 36, 32–38. [Google Scholar]

- Law, T.M.; Moore, I.D. Installed Geometry of Cast-in-Place Polymer Sewer Liners. J. Perform. Constr. Facil. 2007, 21, 172–176. [Google Scholar]

- Najafi, M.; Sever, F. Structural Capabilities of No-Dig Manhole Rehabilitation Products; WERF Report INFR1R12. 2015. Available online: https://cfpub.epa.gov/si/si_public_record_report.cfm?Lab=NRMRL&dirEntryId=332730 (accessed on 13 May 2022).

- An, G.; Liu, T.; Zhang, H. The Method and Application of the Wall Thickness Calculation of Sewers’ Liner Pipe. Spec. Struct. 2014, 31, 91–95. [Google Scholar]

- CJJ 181, 2012; Technical Specification for Inspection and Evaluation of of Urban Sewer. Standard Press: Beijing, China, 2012.

- GB/T17671, 1999; Method of Testing Cements-Determination of Strength. Standard Press: Beijing, China, 1999.

- JGJ/T 70, 2009; Standard for Test Method of Performance on Building Mortar. Standard Press: Beijing, China, 2009.

- GB/T 50152, 2012; Standard for Test Method of Concrete Structures. Standard Press: Beijing, China, 2012.

| Serial Number | Physical Parameter | Prototype | Test Model | |

|---|---|---|---|---|

| 1 | Geometric parameter | Arch span/mm | 5000 | 2500 |

| 2 | Arch height/mm | 1600 | 800 | |

| 3 | Arch thickness/mm | 150 | 75 | |

| 4 | Side wall height/mm | 1400 | 700 | |

| 5 | Side wall thickness/mm | 150 | 75 | |

| 6 | Floor thickness/mm | 150 | 50 | |

| 7 | Length of member/mm | 1000 | 500 | |

| 8 | Protective layer thickness | Arch/mm | 20 | 10 |

| 9 | Side wall/mm | 20 | 10 | |

| 10 | Floor/mm | 30 | 15 | |

| Specimen | 28 Days Tensile Adhesive Strength /MPa | Failure Interface |

|---|---|---|

| Ordinary mortar | 0.42 | Bond surface |

| H-70 | 3.24 | Cement test block |

| Serial Number | Water/Material Ratio | Permeable Pressure/MPa |

|---|---|---|

| 1 | 0.13 | 2.4 |

| 2 | 0.15 | 2.2 |

| 3 | 0.17 | 2.0 |

| 4 | 0.20 | 1.6 |

| Load Series | Displacement /mm | Remark | ||||||

|---|---|---|---|---|---|---|---|---|

| VD1 | VD2 | VD3 | VD4 | VD5 | HD1 | HD2 | ||

| A1 | −0.01 | 0.00 | 0.00 | 0.00 | −0.07 | −0.03 | 0.01 | Synchronous loading |

| A2 | −0.01 | 0.00 | 0.00 | −0.01 | 0.08 | −0.10 | 0.01 | |

| A3 | −0.01 | 0.00 | 0.00 | −0.01 | 0.13 | −0.11 | 0.02 | |

| A4 | −0.01 | 0.00 | 0.00 | −0.01 | 0.02 | −0.04 | 0.01 | All unloading |

| B1 | −0.02 | 0.00 | 0.00 | −0.01 | −0.01 | −0.05 | 0.04 | F1/F2 Synchronous Loading |

| B2 | −0.02 | 0.00 | 0.00 | 0.00 | 0.00 | −0.05 | 0.05 | |

| B3 | −0.02 | 0.00 | −0.01 | −0.01 | 0.00 | −0.06 | 0.04 | F2/F3 Synchronous Loading |

| B4 | −0.01 | 0.00 | −0.01 | −0.01 | 0.07 | −0.12 | 0.04 | |

| B5 | 0.00 | 0.01 | −0.01 | −0.02 | 0.08 | −0.15 | 0.01 | Synchronous loading |

| B6 | −0.01 | 0.01 | −0.01 | −0.02 | −0.04 | −0.15 | 0.01 | F2 Unloading |

| B7 | −0.01 | 0.00 | −0.01 | −0.02 | −0.04 | −0.08 | 0.02 | F1/F3 Unloading |

| C1 | 0.00 | 0.00 | −0.01 | −0.03 | −0.07 | −0.12 | 0.02 | F2/F3 loading |

| C2 | 0.00 | 0.00 | −0.01 | −0.03 | −0.10 | −0.17 | 0.03 | |

| C3 | −0.01 | 0.01 | 0.00 | −0.03 | −0.18 | −0.19 | 0.02 | F1/F2 loading |

| C4 | −0.01 | 0.01 | 0.00 | −0.03 | −0.25 | −0.18 | 0.04 | |

| C5 | −0.01 | 0.00 | 0.01 | −0.03 | −0.32 | −0.19 | 0.07 | Synchronous loading |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, C.; Gong, C.; Wang, F.; Zhu, Z.; Zhao, Y.; Ariaratnam, S.T. Study of the Structural Mechanical Properties of Drainage Canals Rehabilitated by Spraying Method. Polymers 2022, 14, 2781. https://doi.org/10.3390/polym14142781

Zeng C, Gong C, Wang F, Zhu Z, Zhao Y, Ariaratnam ST. Study of the Structural Mechanical Properties of Drainage Canals Rehabilitated by Spraying Method. Polymers. 2022; 14(14):2781. https://doi.org/10.3390/polym14142781

Chicago/Turabian StyleZeng, Cong, Chenkun Gong, Fuzhi Wang, Zihao Zhu, Yahong Zhao, and Samuel T. Ariaratnam. 2022. "Study of the Structural Mechanical Properties of Drainage Canals Rehabilitated by Spraying Method" Polymers 14, no. 14: 2781. https://doi.org/10.3390/polym14142781

APA StyleZeng, C., Gong, C., Wang, F., Zhu, Z., Zhao, Y., & Ariaratnam, S. T. (2022). Study of the Structural Mechanical Properties of Drainage Canals Rehabilitated by Spraying Method. Polymers, 14(14), 2781. https://doi.org/10.3390/polym14142781