Characterization and Performance Enhancement of Cement-Based Thermoelectric Materials

Abstract

1. Introduction

- ▪

- What is the duration of the TE phenomenon observed in enhanced cement-based TE materials?

- ▪

- Was the TE observed in dry or saturated samples?

- ▪

- Does the level of sample hydration affect the TE phenomenon?

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Curing

2.3. Characterization Techniques

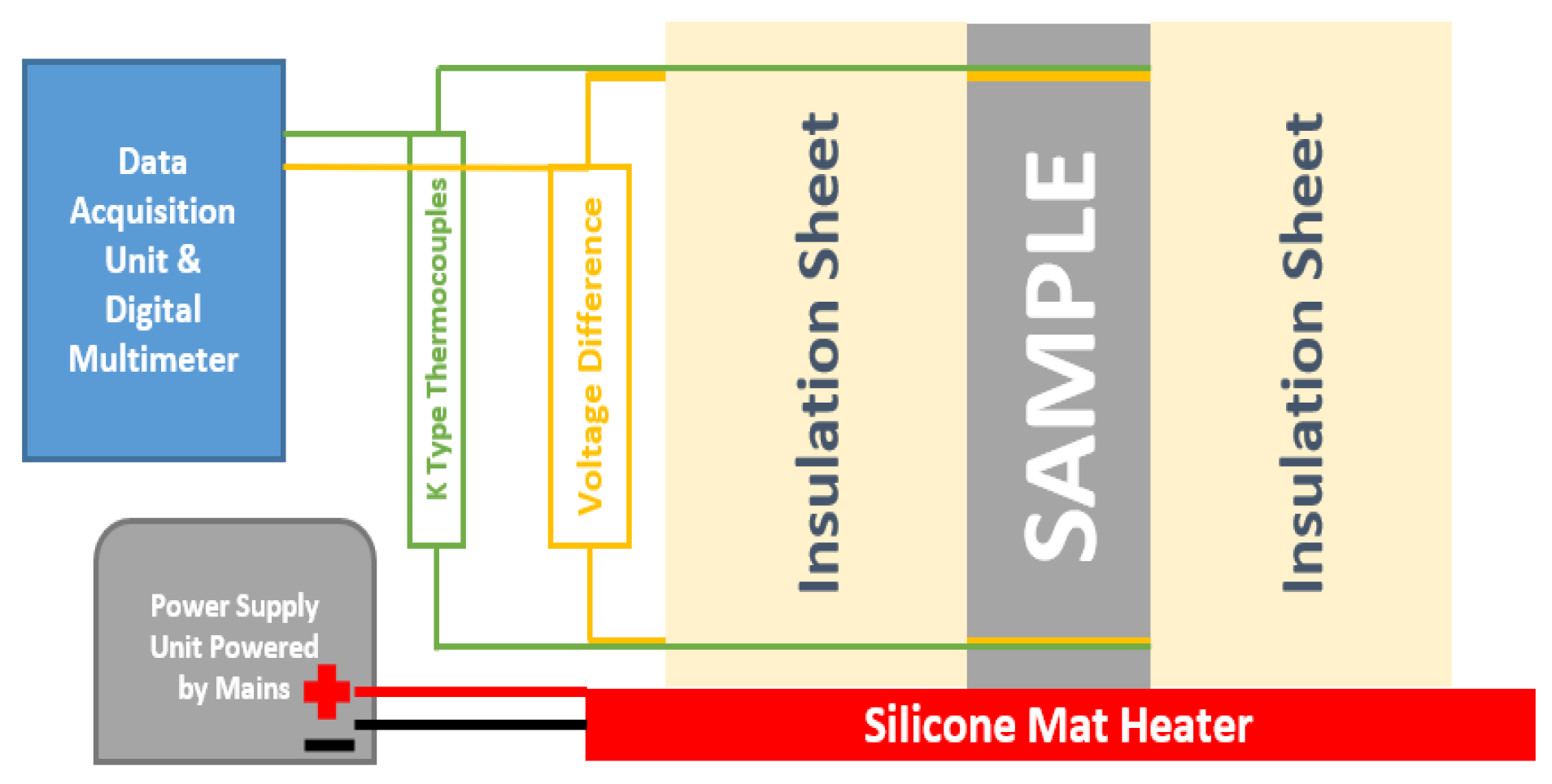

2.3.1. Seebeck Coefficient Test

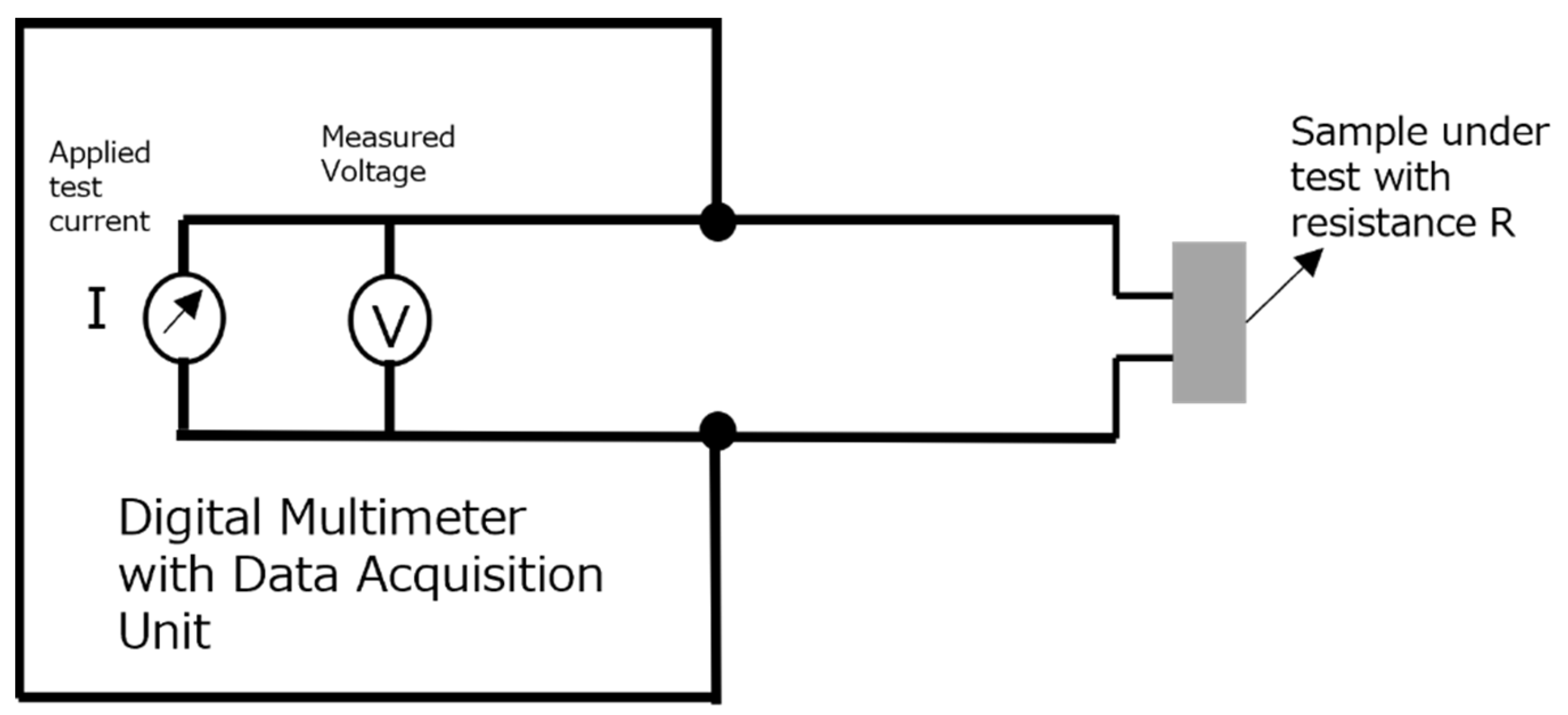

2.3.2. Electrical Conductivity Test

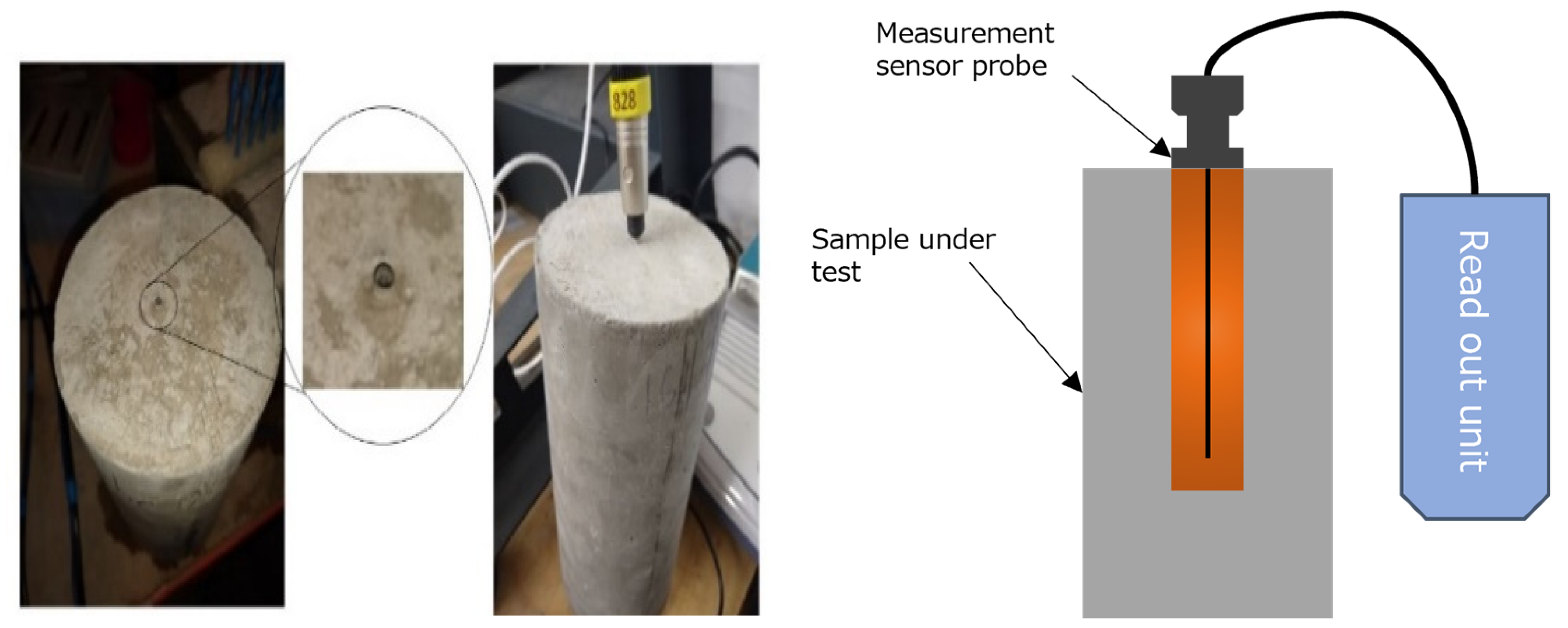

2.3.3. Thermal Conductivity Test

3. Results

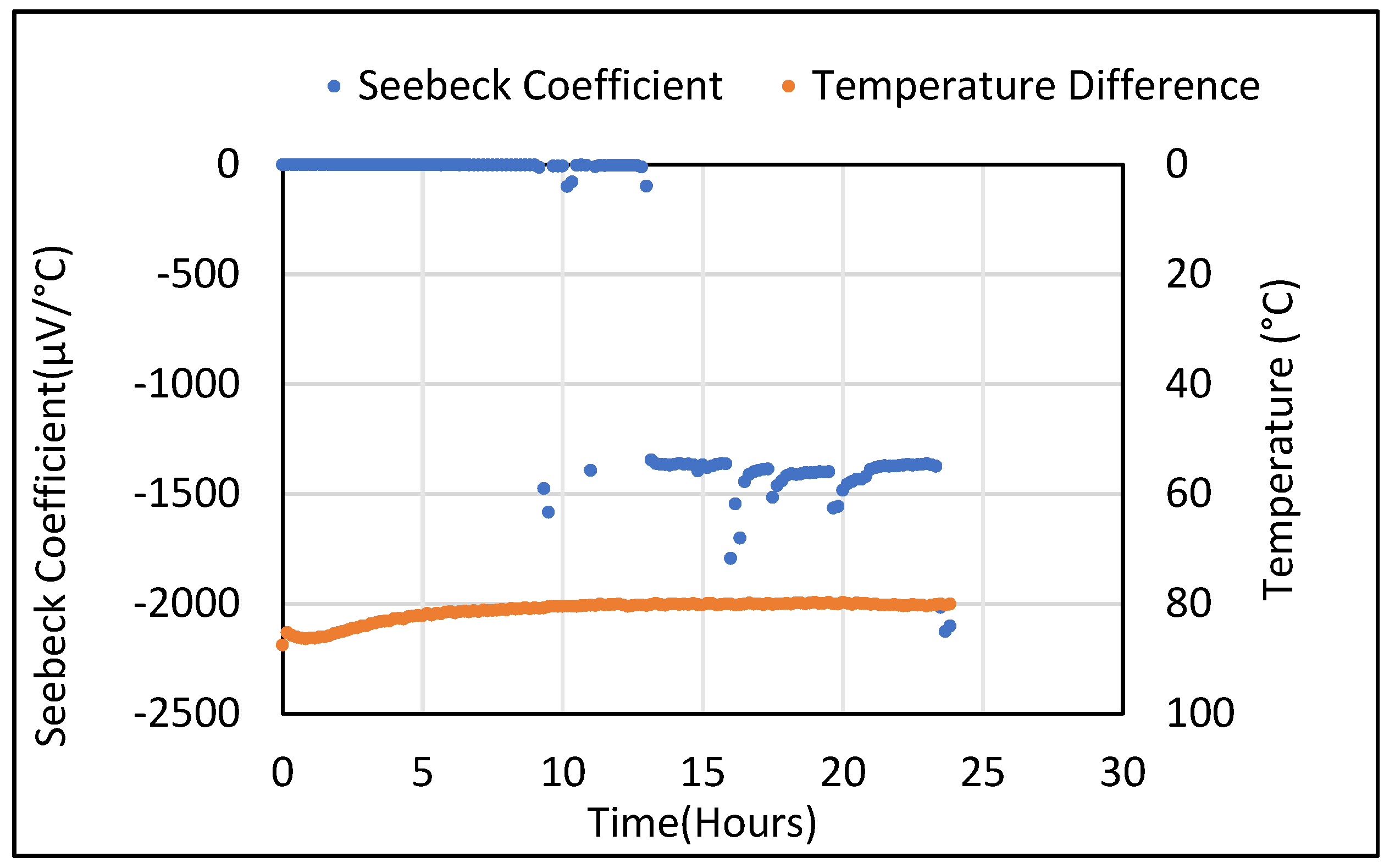

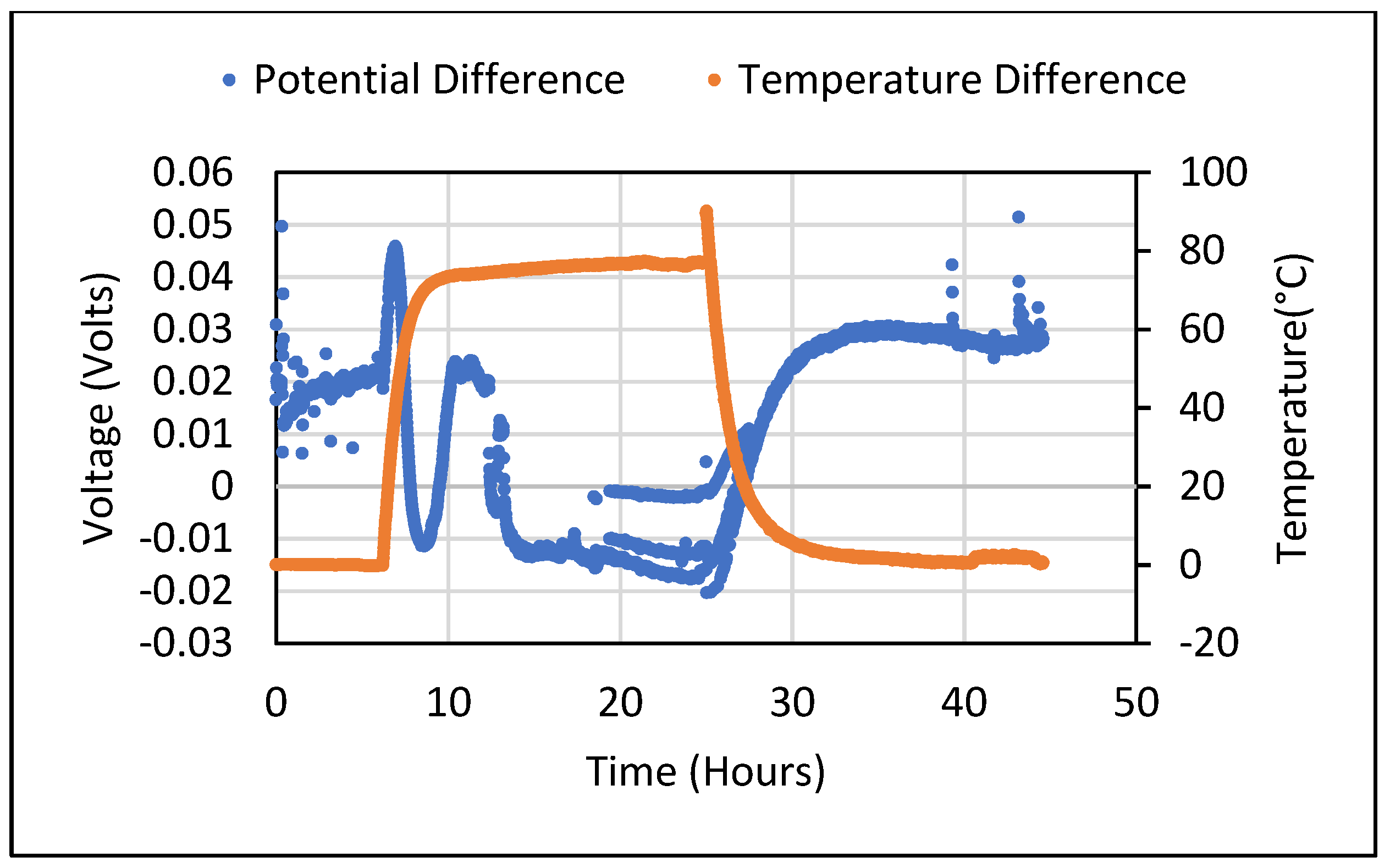

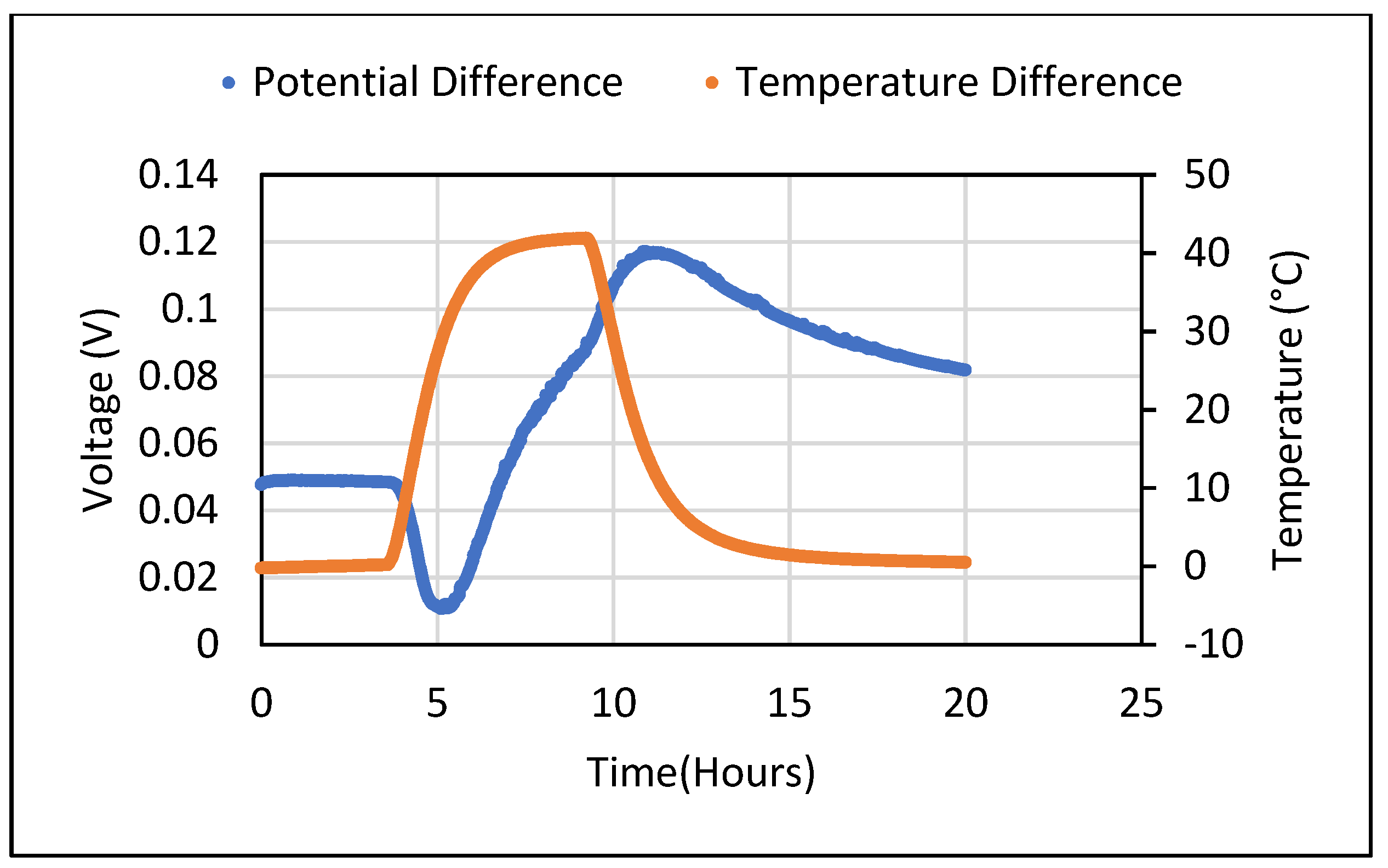

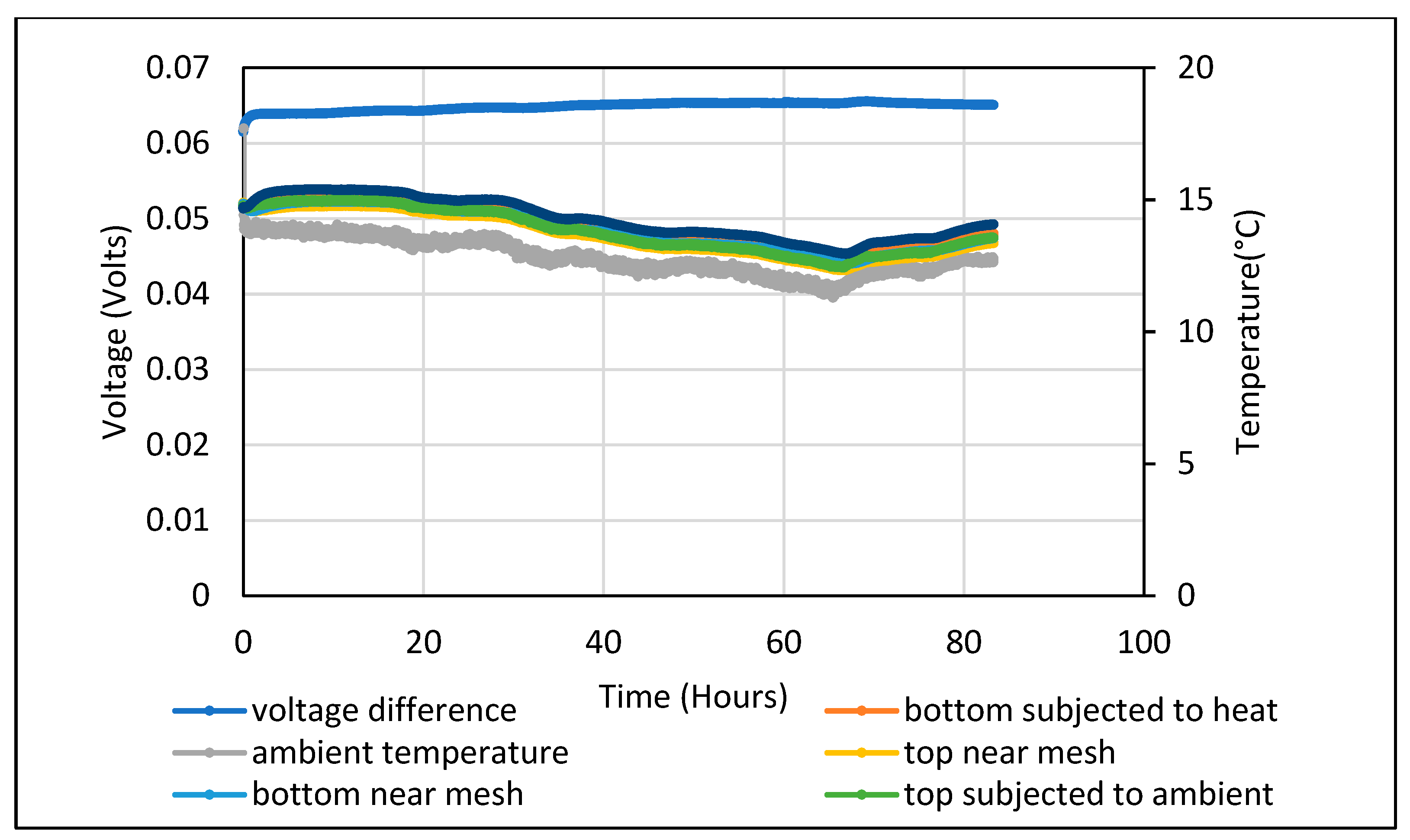

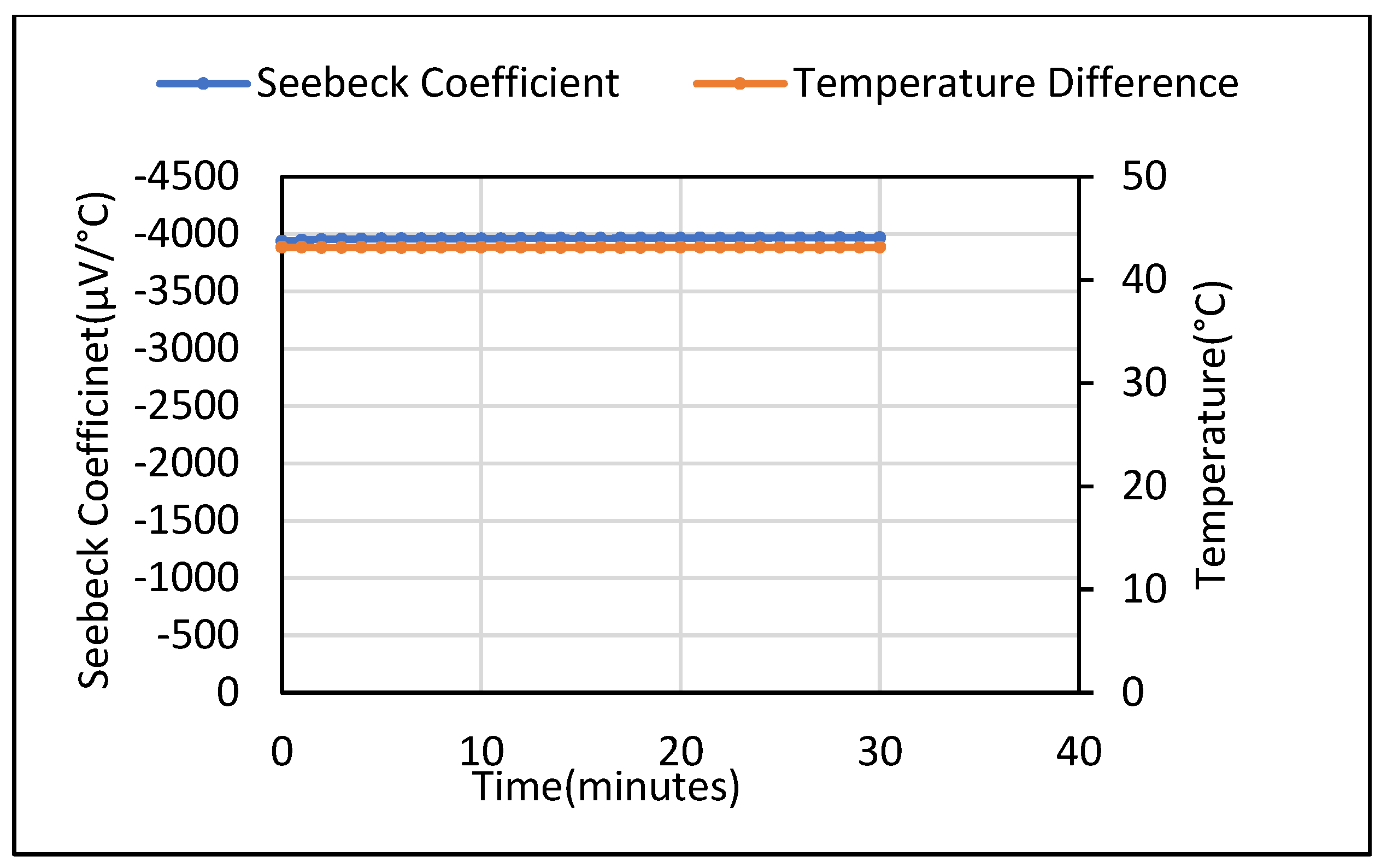

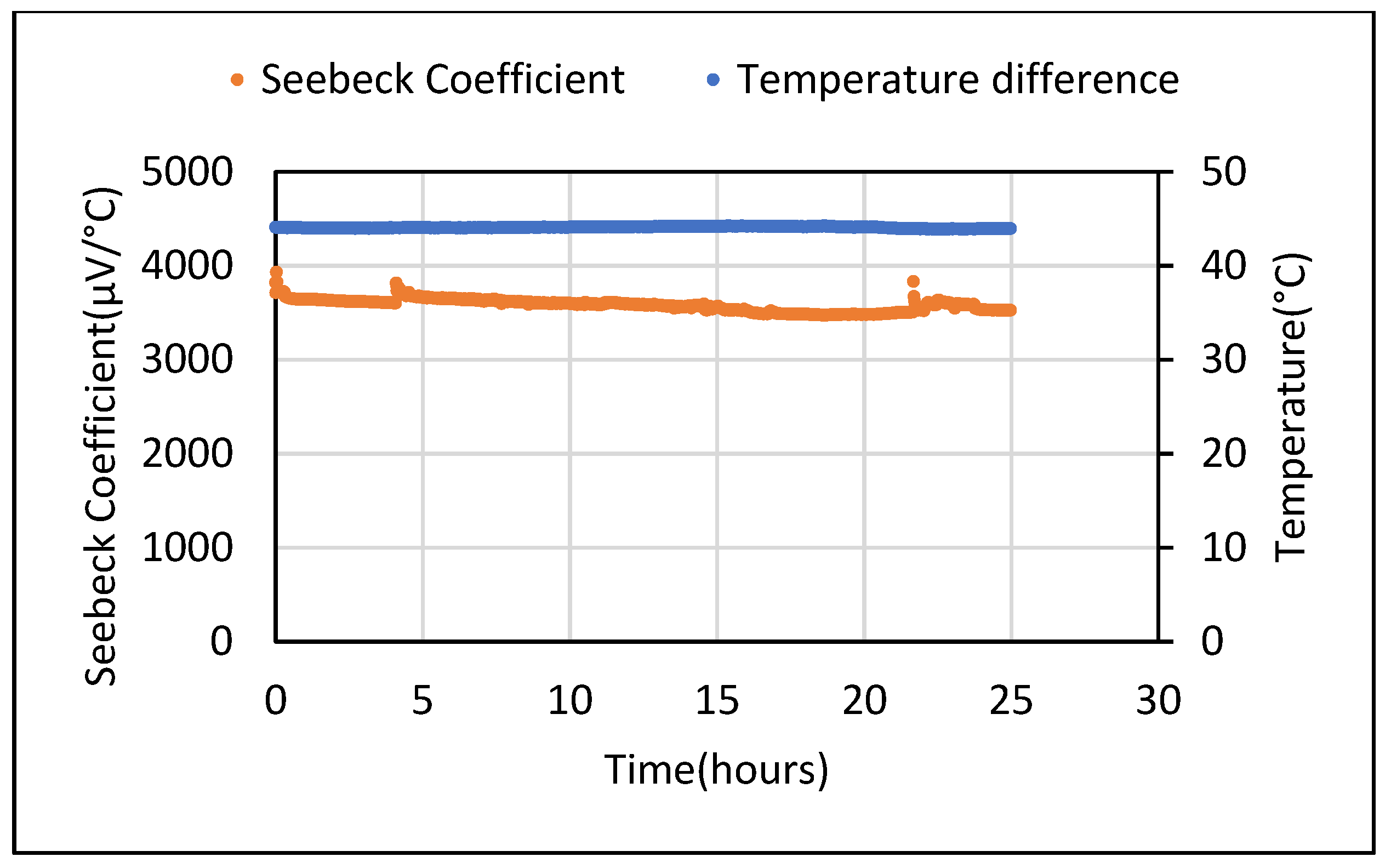

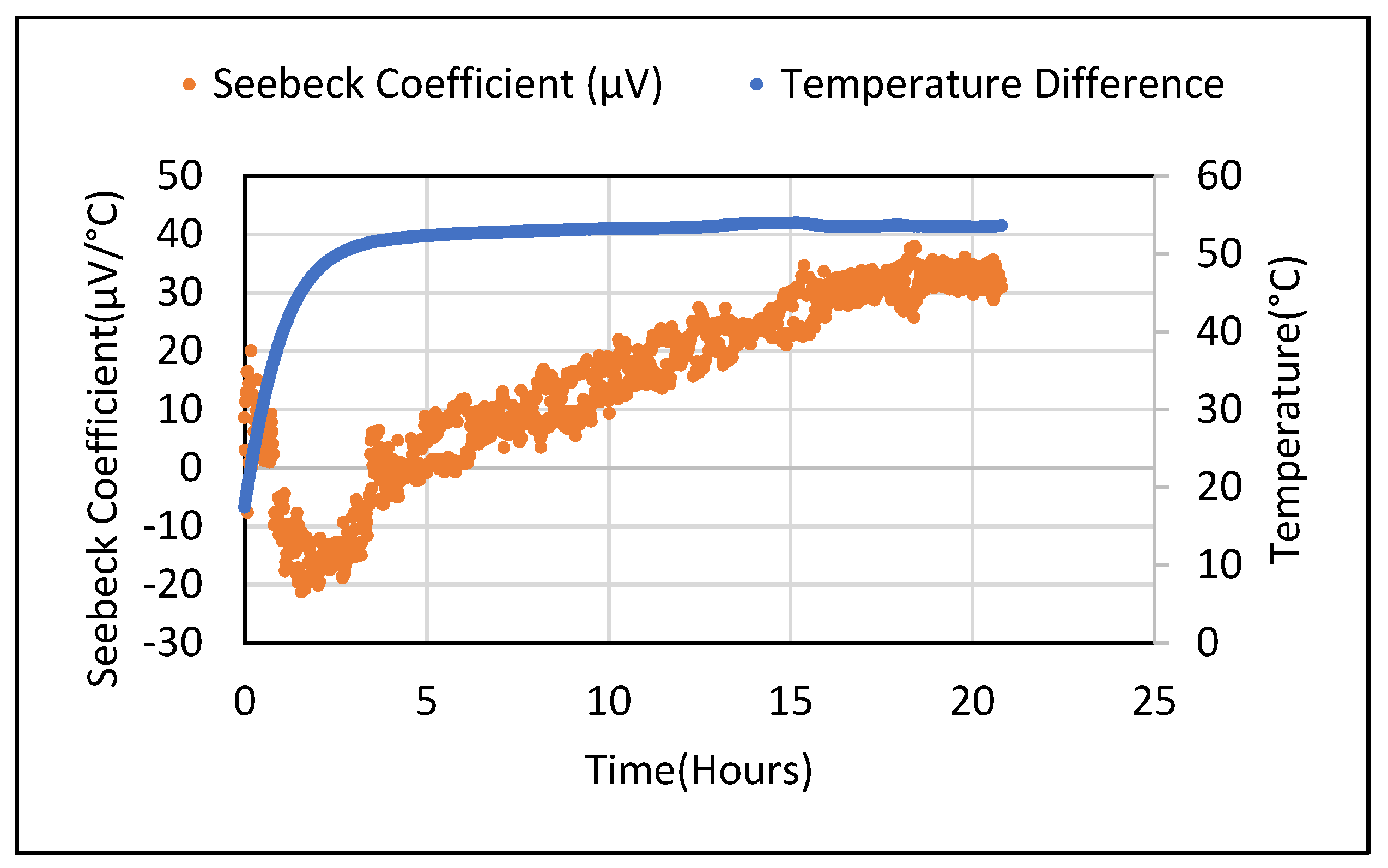

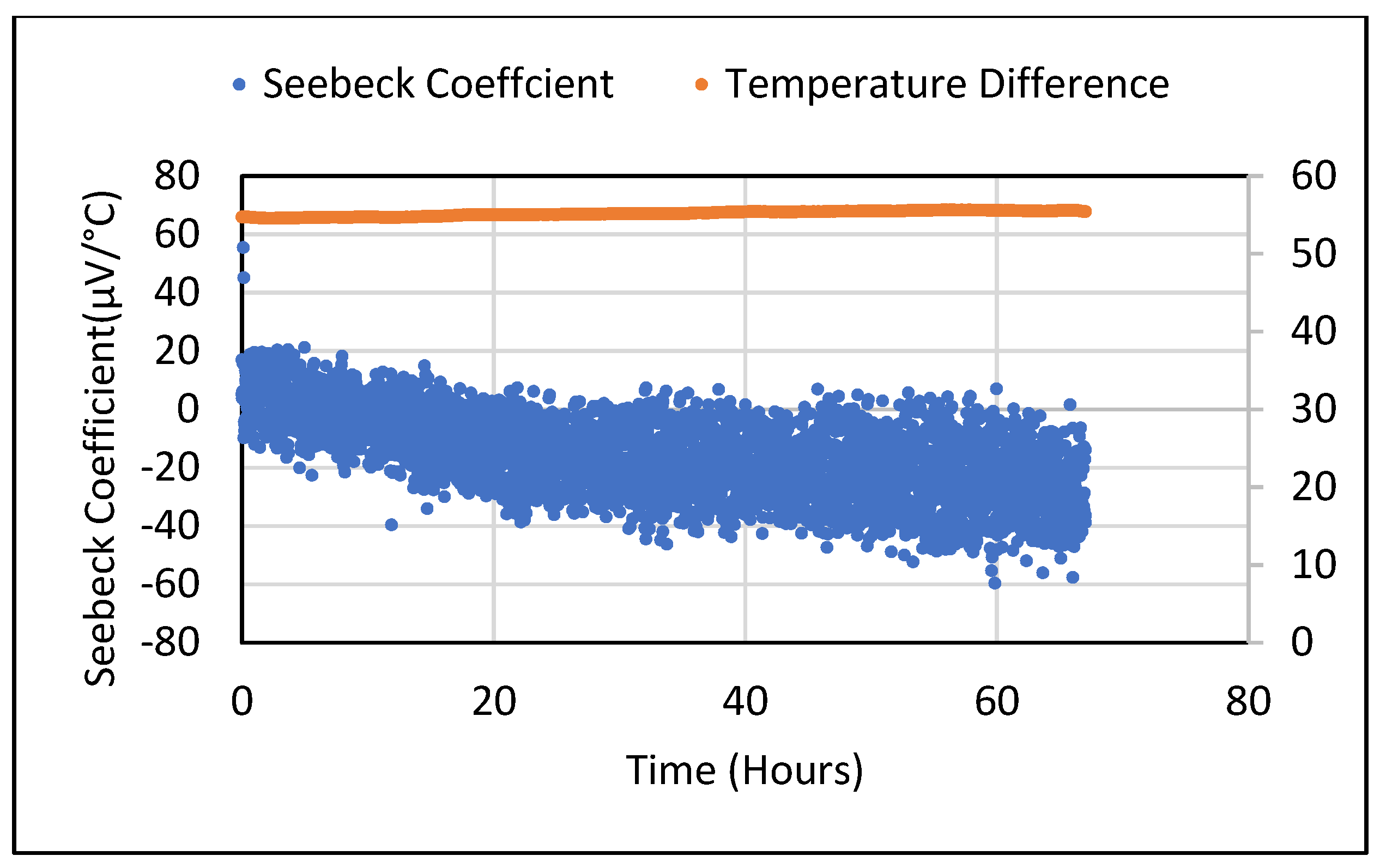

3.1. Seebeck Coefficient Test

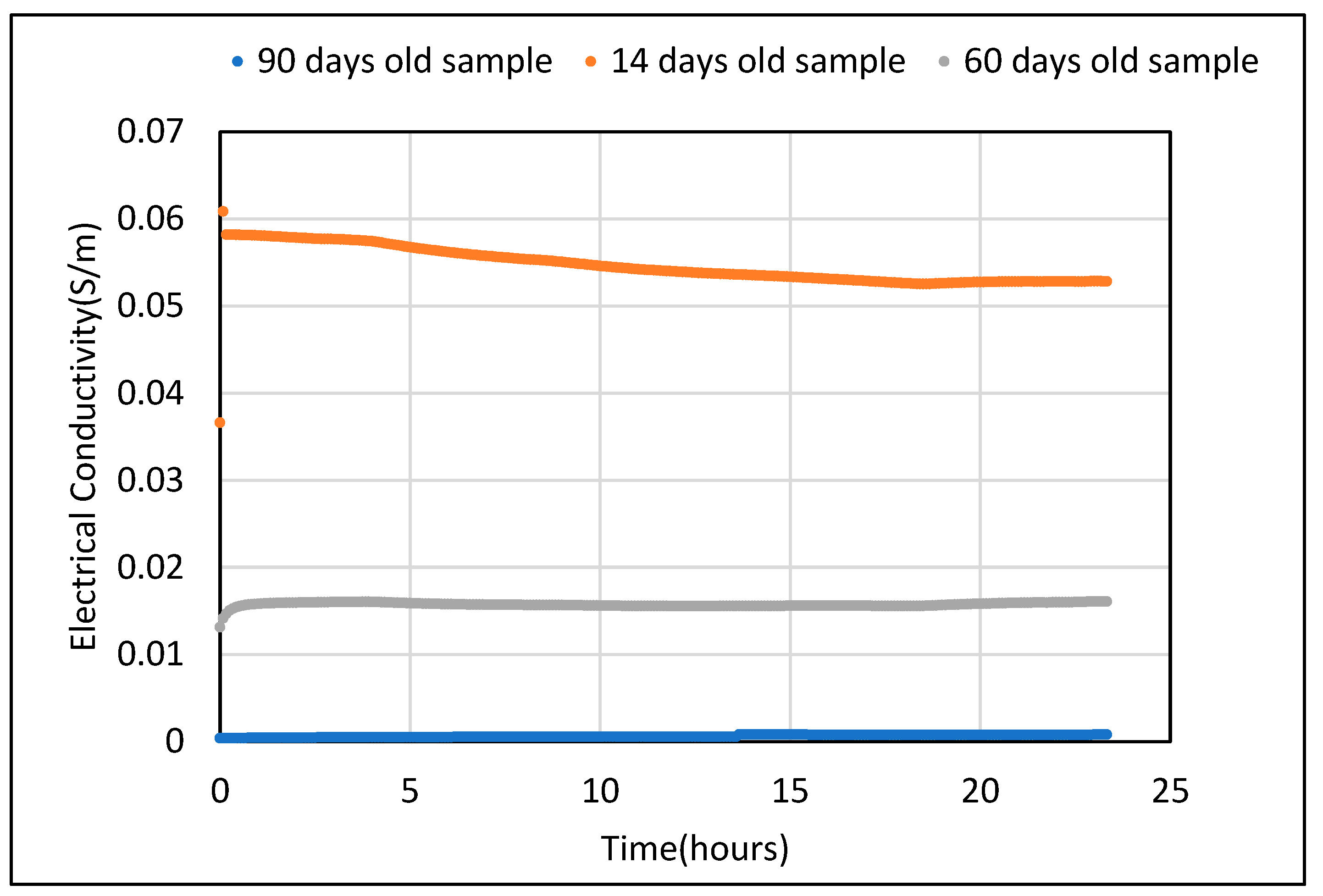

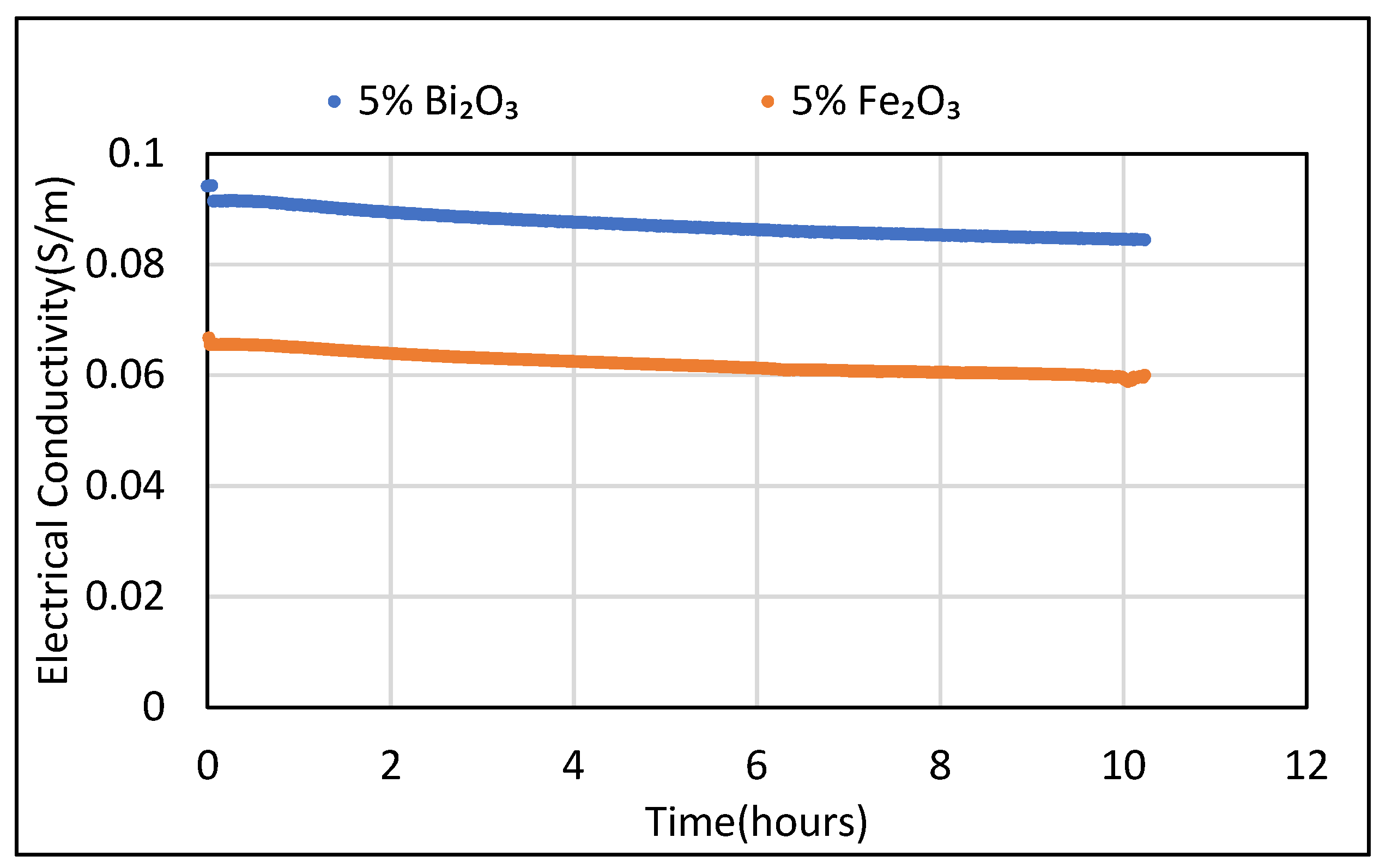

3.2. Electrical Conductivity Test

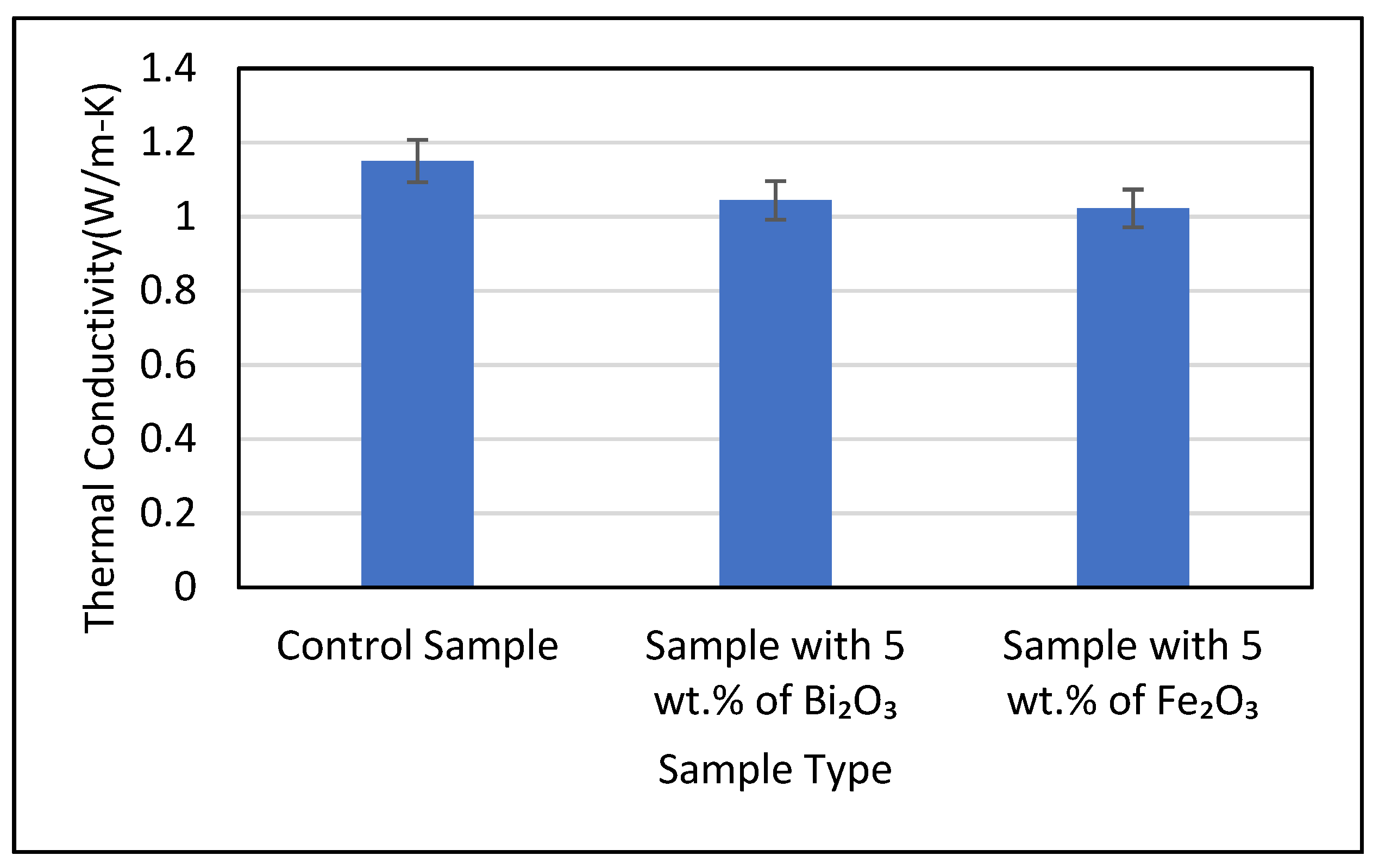

3.3. Thermal Conductivity Test

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Urbanization—Our World in Data. Available online: https://ourworldindata.org/urbanization (accessed on 11 May 2022).

- Taha, H.; Sailor, D.; Akbari, H. High-Albedo Materials for Reducing Building Cooling Energy Use; California Institute for Energy Efficiency: Berkeley, CA, USA, 1992. [Google Scholar] [CrossRef][Green Version]

- Phelan, P.E.; Kaloush, K.; Miner, M.; Golden, J.; Phelan, B.; Silva, H., III; Taylor, R.A. Urban Heat Island: Mechanisms, Implications, and Possible Remedies. Annu. Rev. Environ. Resour. 2015, 40, 285–307. [Google Scholar] [CrossRef]

- Palme, M.; Inostroza, L.; Villacreses, G.; Lobato-Cordero, A.; Carrasco, C. From urban climate to energy consumption. Enhancing building performance simulation by including the urban heat island effect. Energy Build 2017, 145, 107–120. [Google Scholar] [CrossRef]

- Ang, B.W.; Wang, H.; Ma, X. Climatic influence on electricity consumption: The case of Singapore and Hong Kong. Energy 2017, 127, 534–543. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Berdahl, P.; Wood, K.; Skilton, W.; Petersheim, J. A novel technique for the production of cool colored concrete tile and asphalt shingle roofing products. Sol. Energy Mater. Sol. Cells 2010, 94, 946–954. [Google Scholar] [CrossRef]

- Akbari, H.; Rose, L.S. Characterizing the Fabric of the Urban Environment: A Case Study of Salt Lake City, Utah. February 2001. Available online: https://digital.library.unt.edu/ark:/67531/metadc736137/ (accessed on 11 May 2022).

- Santamouris, M. On the energy impact of urban heat island and global warming on buildings. Energy Build. 2014, 82, 100–113. [Google Scholar] [CrossRef]

- Yildiz, F. Potential Ambient Energy-Harvesting Sources and Techniques. J. Technol. Stud. 2009, 35, 40–48. [Google Scholar] [CrossRef]

- Matiko, J.W.; Grabham, N.J.; Beeby, S.P.; Tudor, M.J. Review of the application of energy harvesting in buildings. Meas. Sci. Technol. 2014, 25, 012002. [Google Scholar] [CrossRef]

- Ahmad, S.; Abdul Mujeebu, M.; Farooqi, M.A. Energy harvesting from pavements and roadways: A comprehensive review of technologies, materials, and challenges. Int. J. Energy Res. 2019, 43, 1974–2015. [Google Scholar] [CrossRef]

- Ouldboukhitine, S.-E.; Belarbi, R.; Jaffal, I.; Trabelsi, A. Assessment of green roof thermal behavior: A coupled heat and mass transfer model. Build. Environ. 2011, 46, 2624–2631. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, Q.; Zhao, L.; Hao, L.; Yang, C. Enhanced thermoelectric properties of carbon fiber reinforced cement composites. Ceram. Int. 2016, 42, 11568–11573. [Google Scholar] [CrossRef]

- Tritt, T.M. Thermoelectric Materials: Principles, Structure, Properties, and Applications. Encycl. Mater. Sci. Technol. 2002, 1–11. [Google Scholar] [CrossRef]

- Matsumoto, R.; Hoshina, Y.; Akuzawa, N. Thermoelectric Properties and Electrical Transport of Graphite Intercalation Compounds n.d. Mater. Trans. 2009, 50, 1607–1611. [Google Scholar] [CrossRef]

- Sun, M.; Li, Z.; Mao, Q.; Shen, D. Study on the Hole Conduction Phenomenon in Carbon Fiber-Reinforced Concrete. Cem. Concr. Res. 1998, 28, 549–554. [Google Scholar] [CrossRef]

- Sun, M.; Li, Z.; Mao, Q.; Shen, D. Thermoelectric percolation phenomenon in carbon fiber reinforced concrete. Cem. Concr. Res. 1998, 28, 1707–1712. [Google Scholar] [CrossRef]

- Yao, W.; Xia, Q. Preparation and thermoelectric properties of bismuth telluride-carbon fiber reinforced cement composites. Gongneng Cailiao/J. Funct Mater. 2014, 45, 15134–15137. [Google Scholar] [CrossRef]

- Wei, J.; Hao, L.; He, G.; Yang, C. Enhanced thermoelectric effect of carbon fiber reinforced cement composites by metallic oxide/cement interface. Ceram. Int. 2014, 40, 8261–8263. [Google Scholar] [CrossRef]

- Ji, T.; Zhang, X.; Li, W. Enhanced thermoelectric effect of cement composite by addition of metallic oxide nanopowders for energy harvesting in buildings. Constr. Build. Mater. 2016, 115, 576–581. [Google Scholar] [CrossRef]

- Wei, J.; Hao, L.; He, G.P.; Yang, C.L. Thermoelectric power of carbon fiber reinforced cement composites enhanced by Ca3Co4O9. Appl. Mech. Mater. 2013, 320, 354–357. [Google Scholar] [CrossRef]

- Ji, T.; Zhang, X.; Zhang, X.; Zhang, Y.; Li, W. Effect of Manganese Dioxide Nanorods on the Thermoelectric Properties of Cement Composites. J. Mater. Civ. Eng. 2018, 30, 04018224. [Google Scholar] [CrossRef]

- Ghahari, S.A.; Ghafari, E.; Lu, N. Effect of ZnO nanoparticles on thermoelectric properties of cement composite for waste heat harvesting. Constr. Build. Mater. 2017, 146, 755–763. [Google Scholar] [CrossRef]

- Wei, J.; Zhao, L.; Zhang, Q.; Nie, Z.; Hao, L. Enhanced thermoelectric properties of cement-based composites with expanded graphite for climate adaptation and large-scale energy harvesting. Energy Build. 2018, 159, 66–74. [Google Scholar] [CrossRef]

- Chen, N.; Gascoin, F.; Snyder, G.J.; Müller, E.; Karpinski, G.; Stiewe, C. Macroscopic thermoelectric inhomogeneities in (AgSbTe2)x(PbTe)1−x. Appl. Phys. Lett. 2005, 87, 171903. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Dale, C. Troubleshooting Low Voltage Measurement Problems; Keithley Instruments: Cleveland, OH, USA, August 2010; Available online: https://download.tek.com/document/Article_TrblshLowVolt.pdf (accessed on 11 May 2022).

- Layssi, H.; Ghods, P.; Alizadeh, A.R.; Salehi, M. Electrical resistivity of comcrete—Concepts, applications and measurement techniques. Concr. Int. 2015, 37, 41–46. [Google Scholar]

- Hansson, I.L.H.; Hansson, C.M. Elecrtical resistivity measurements of Portland cement based materials. Cem. Conc. Res. 1983, 13, 675–683. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Seebeck effect in carbon fiber-reinforced cement. Cem. Concr. Res. 1999, 29, 1989–1993. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D. Seebeck effect in steel fiber reinforced cement. Cem. Concr. Res. 2000, 30, 661–664. [Google Scholar] [CrossRef]

- Demirel, B.; Yazicioglu, S. Thermoelectric behavior of carbon fiber reinforced lightweight concrete with mineral admixtures. New Carbon Mater. 2008, 23, 21–24. [Google Scholar] [CrossRef]

- Wei, J.; Nie, Z.; He, G.; Hao, L.; Zhao, L.; Zhang, Q. Energy harvesting from solar irradiation in cities using the thermoelectric behavior of carbon fiber reinforced cement composites. RSC Adv. 2014, 4, 48128–48134. [Google Scholar] [CrossRef]

- Wei, J.; Fan, Y.; Zhao, L.; Xue, F.; Hao, L.; Zhang, Q. Thermoelectric properties of carbon nanotube reinforced cement-based composites fabricated by compression shear. Ceram. Int. 2018, 44, 5829–5833. [Google Scholar] [CrossRef]

- Tzounis, L.; Liebscher, M.; Fuge, R.; Leonhardt, A.; Mechtcherine, V. P- and n-type thermoelectric cement composites with CVD grown p- and n-doped carbon nanotubes: Demonstration of a structural thermoelectric generator. Energy Build. 2019, 191, 151–163. [Google Scholar] [CrossRef]

- Wei, J.; Zhang, Q.; Zhao, L.; Hao, L.; Nie, Z. Effect of moisture on the thermoelectric properties in expanded graphite/carbon fiber cement composites. Ceram. Int. 2017, 43, 10763–10769. [Google Scholar] [CrossRef]

- Ghosh, S.; Harish, S.; Rocky, K.A.; Ohtaki, M.; Saha, B.B. Graphene enhanced thermoelectric properties of cement based composites for building energy harvesting. Energy Build. 2019, 202, 109419. [Google Scholar] [CrossRef]

- Ghosh, S.; Harish, S.; Ohtaki, M.; Saha, B.B. Enhanced figure of merit of cement composites with graphene and ZnO nanoinclusions for efficient energy harvesting in buildings. Energy 2020, 198, 117396. [Google Scholar] [CrossRef]

- Singh, A.P.; Mishra, M.; Chandra, A.; Dhawan, S.K. Graphene oxide/ferrofluid/cement composites for electromagnetic interference shielding application. Nanotechnology 2011, 22, 465701. [Google Scholar] [CrossRef]

- Xie, P.; Gu, P.; Beaudoin, J.J. Electrical percolation phenomena in cement composites containing conductive fibres. J. Mater. Sci. 1996, 31, 4093–4097. [Google Scholar] [CrossRef]

- Su, J.K.; Yang, C.C.; Wu, W.B.; Huang, R. Effect of moisture content on concrete resistivity measurement. J. Chin. Inst. Eng. Trans. Chin. Inst. Eng. A/Chung-Kuo K Ch’eng Hsuch K’an 2002, 25, 117–122. [Google Scholar] [CrossRef]

- Tectronix. Low Level Measurements Handbook, 7th ed.; Precision DC Current, Voltage, and Resistance Measurements; Keithlet: Cleveland, OH, USA, 1972; Available online: https://download.tek.com/document/LowLevelHandbook_7Ed.pdf (accessed on 11 May 2022).

| Sr No. | Sample Details | Electrical Conductivity | Seebeck Coefficient | Thermal Conductivity | Reference |

|---|---|---|---|---|---|

| 1 | Carbon fiber-reinforced cement 40 × 40 × 40 mm | Two-wire DC method using multimeter | Potentiometer measured voltage and thermostats achieved and measured ∆T | Not measured | [17] |

| 2 | 1. Carbon fiber-reinforced cement 75 × 15 × 15 mm 2. Bromine intercalated CFRC 75 × 15 × 15 mm | Not measured | Hot side: Resistance plate heater (up to 65 °C) Cold side: Close to room temperature Contacts: Silver paste, copper foil and copper wire Instrument: Keithley Multimeter | Not measured | [30,31] |

| 3 | Carbon fiber -reinforced cement along with silica fume and fly ash 100 × 100 × 100 mm | Not measured | Thermocouples measured temperature gradient Multimeter measured Seebeck voltage | Not measured | [32] |

| 4 | Carbon fiber-reinforced cement | Four-wire DC using multimeter Sample: 160 × 40 × 40 mm | Hot side: Ceramic resistance heater (up to 90 °C) Cold side: At room temperature (maintained at 25 °C) Contacts: Copper plate and copper wire Instrument: Fluke B15 multimeter Sample: 160 × 40 × 40 mm | Steady state method in thermal Conductometer sample: 180 mm diameter and 20 mm height | [33] |

| 5 | Carbon Nanotube-reinforced cement composite | Four-wire DC using multimeter Sample: 10 × 10 × 40 mm | Hot side: Resistance plate heater (up to 100 °C) Cold side: 5 °C higher than hot side temperature (starting at 30 °C) Contacts: Silver paste and copper wire Instrument: T type thermocouple and multimeter Sample: 10 × 10 × 40 mm | Laser flash diffusion analysis sample: 12.7 mm diameter and 1.0–3.0 mm height Measured for 3 samples and averaged values considered | [34] |

| 6 | P- and N-doped carbon nanotube-enhanced cement composite 60 × 10 × 10 mm | Two-wire DC using multimeter | Hot side: Resistance heater (40–50 °C) Cold side: At ambient temperature (25 °C) Contacts: Silver paste and copper wire Instrument: IR thermometer and multimeter | Not measured | [35] |

| 7 | Cement composite enhanced with expanded graphite and carbon fiber 40 × 10 × 10 mm | Four-probe DC method using silver paste and conductive wires as contact | Hot side: Resistance heater (33–80 °C) Cold side: Ambient side also heated Contacts: Silver paste and type T thermocouples for temperature Instrument: DMM and data Acquisition unit | Not measured | [36] |

| 8 | Cement composite enhanced with expanded graphite and carbon fiber 40 × 10 × 10 mm | Four-probe DC method using silver paste and conductive wires as contact using a DMM | Hot side: Ceramic resistance heater (30–100 °C) Cold side: Ambient side also heated (5 °C above hot side end) Contacts: Silver paste and type T thermocouples for temperature Instrument: DMM and data acquisition unit | Laser flash diffusivity analysis sample: 12.7 mm diameter and 1.0 mm–3.0 mm height Measurements carried out at room Temperature | [24] |

| 9 | Graphene-enhanced cement composite 10 × 4 × 4 mm | Four-probe DC using RZ2001i Ozawa Science thermoelectric characterizing device | Steady DC method used for Seebeck coefficient measurement Range: Room temperature to 75 °C | DSC and LFA method used for thermal conductivity tests in inert environment (nitrogen gas was supplied) Range: 25–75 °C | [37] |

| 10 | Cement composite enhanced with stainless steel fibers 75 × 15 × 15 mm | Four-probe DC using multimeter Contacts: Copper foil, silver paint and copper wires | Hot side: Resistance plate heater (up to 85 °C) Contacts: Silver paste and copper wire Type T thermocouples for temperature Instrument: Keithley multimeter | Not measured | [38] |

| 11 | CFRC cement composite enhanced with Ca3Co4O9 160 × 40 × 40 mm | Not measured | Hot side: Resistance plate heater Cold side: Maintained at room temperature Contacts: Copper plates and copper wires Instrument: Fluke B15 multimeter with a voltage amplifier | Not measured | [21] |

| 12 | CFRC cement composite enhanced with metal oxides Bi2O3 and Fe2O3 160 × 40 × 40 mm | Not measured | Hot side: Resistance plate heater (up to 90 °C) Cold side: Maintained at room temperature Contacts: Not mentioned Instrument: Fluke B15 multimeter with a voltage amplifier | Not measured | [19] |

| 13 | Cement composites enhanced with pyrolytic carbon fiber and Fe2O3 10 × 10 × 40 mm | Four-probe DC method using silver paste and conductive wires as contacts | Hot side: Resistance heater (35–80 °C), gradient of 5 °C was maintained Cold side: Maintained at room temperature Contacts: Silver paste Instrument: Thermocouple and multimeter | Determined theoretically using assumed values | [13] |

| 14 | Cement composites enhanced with ZnO and α-Fe2O3 nanopowders 40 × 40 × 160 mm | Four-probe DC using copper wires and silver paste as contacts Instrument: Fluke B15 multimeter | Hot side: Resistance plate heater (up to 70 °C) Cold side: At room temperature by contact with flowing water Contacts: Copper plate Instrument: K type thermocouple and Fluke B15 multimeter | Steady state method used for measurement where cold side was kept at 20 °C and hot side at 70 °C Sample size 300 × 300 × 20 mm | [20] |

| 15 | MgO2-enhanced cement composites 40 × 40 × 160 mm | Four-probe DC embedded copper meshes and silver adhesives used for contact | Hot side: Resistance heater up to 60 °C (temperature gradients of up to 50 °C) Cold side: At room temperature Contacts: Copper plate, conductive wires and silver paper Instrument: K type thermocouple and Fluke 289C multimeter | Steady state thermal conductivity tester used for a sample of 130 mm diameter and 40 mm height | [22] |

| 16 | Cement composites enhanced with ZnO and Al-doped ZnO powders | Two-probe AC impedance measurement for cylindrical samples of 70 mm height and 35 mm diameter | Hot side: Resistance heater up to 85 °C Cold side: At room temperature (23 ± 2 °C) Contacts: Copper plates and copper wires Instrument: Omega CN616 temperature controller and Keithley multimeter 40 × 40 mm of surface area | Longitudinal guarded comparative calorimeter used for cylindrical samples of 25.4 mm diameter and 50.8 mm height | [23] |

| 17 | Graphene- and nano-ZnO-enhanced cement composites | Four-probe DC using RZ20001i Ozawa Science thermoelectric characterizing device 4 × 4 × 10 mm | Steady state DC method used for Seebeck coefficient measurement Range: Room temperature to 75 °C 4 × 4 × 10 mm | Laser flash diffusivity analysis and differential scanning calorimeter used for sample having 17 mm diameter and 2 mm height | [32] |

| Contents | Percentage (%) |

|---|---|

| SiO2 | 18.29% |

| Al2O3 | 5.08% |

| Fe2O3 | 2.78% |

| CaO | 63.89% |

| SO3 | 2.64% |

| F. Cao | 1.57% |

| Loss on Ignition (LOI) | 2.79% |

| Na2O Eq. (Alkali Equivalent) | 0.59% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jani, R.; Holmes, N.; West, R.; Gaughan, K.; Liu, X.; Qu, M.; Orisakwe, E.; Stella, L.; Kohanoff, J.; Yin, H.; et al. Characterization and Performance Enhancement of Cement-Based Thermoelectric Materials. Polymers 2022, 14, 2311. https://doi.org/10.3390/polym14122311

Jani R, Holmes N, West R, Gaughan K, Liu X, Qu M, Orisakwe E, Stella L, Kohanoff J, Yin H, et al. Characterization and Performance Enhancement of Cement-Based Thermoelectric Materials. Polymers. 2022; 14(12):2311. https://doi.org/10.3390/polym14122311

Chicago/Turabian StyleJani, Ruchita, Niall Holmes, Roger West, Kevin Gaughan, Xiaoli Liu, Ming Qu, Esther Orisakwe, Lorenzo Stella, Jorge Kohanoff, Hongxi Yin, and et al. 2022. "Characterization and Performance Enhancement of Cement-Based Thermoelectric Materials" Polymers 14, no. 12: 2311. https://doi.org/10.3390/polym14122311

APA StyleJani, R., Holmes, N., West, R., Gaughan, K., Liu, X., Qu, M., Orisakwe, E., Stella, L., Kohanoff, J., Yin, H., & Wojciechowski, B. (2022). Characterization and Performance Enhancement of Cement-Based Thermoelectric Materials. Polymers, 14(12), 2311. https://doi.org/10.3390/polym14122311