Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers

Abstract

1. Introduction

2. Method for Achieving High Performances of Electroadhesion

2.1. Equations Governing Electroadhesion Forces

2.2. Electrical Breakdown

2.3. Mechanical Breakdown

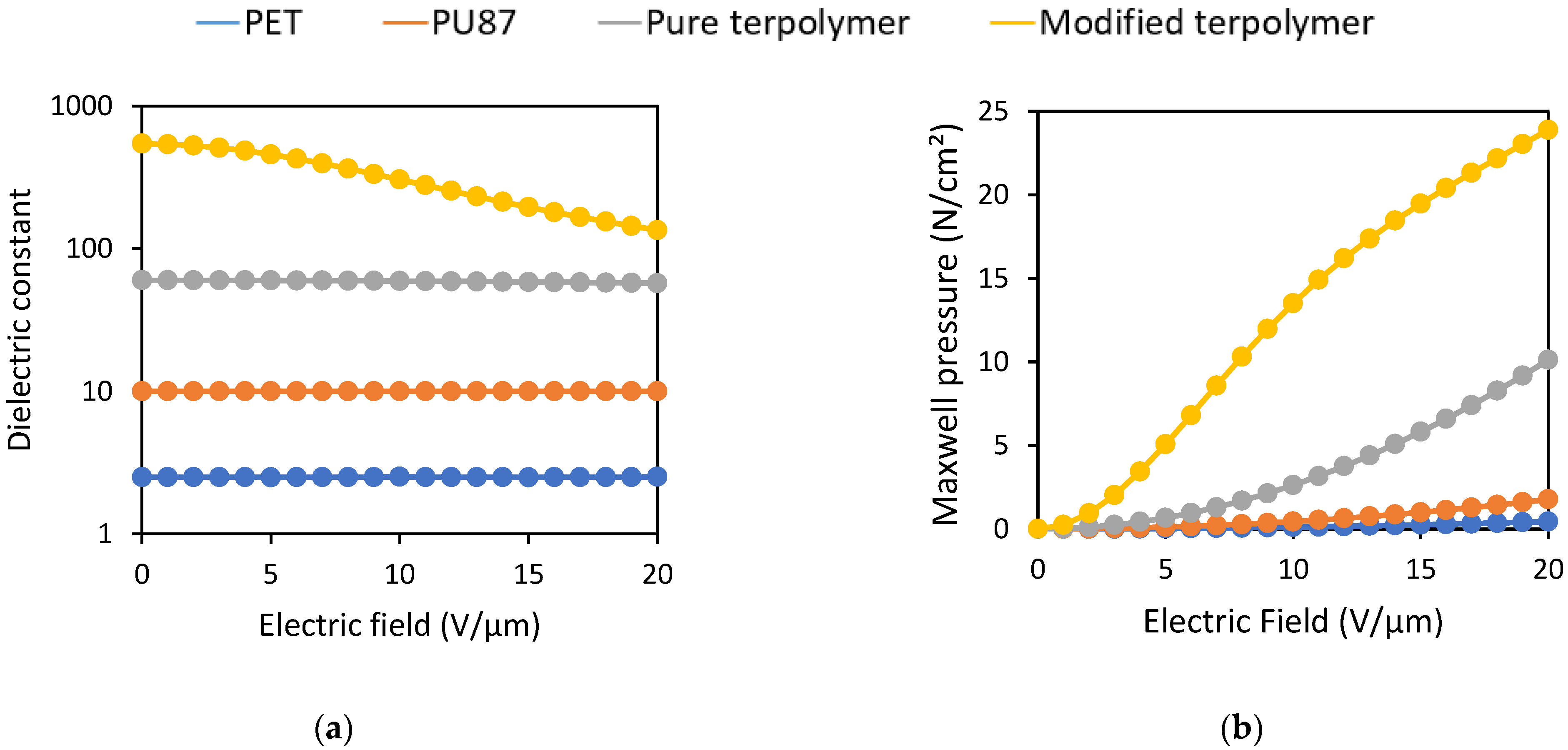

2.4. Selection of Polymer Matrix

3. Fabrication Process and Characterization Test Bench

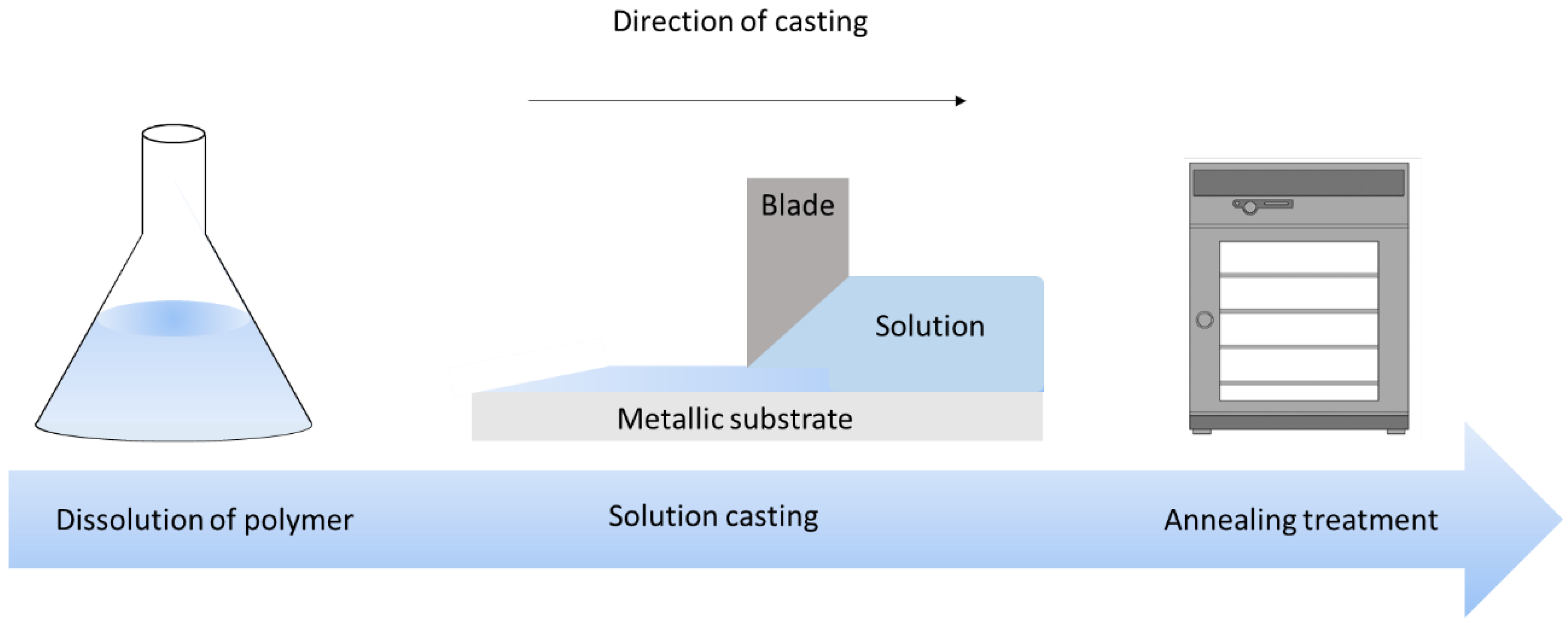

3.1. Sample Preparation

3.2. Experimental Setup of the Electroadhesion Test

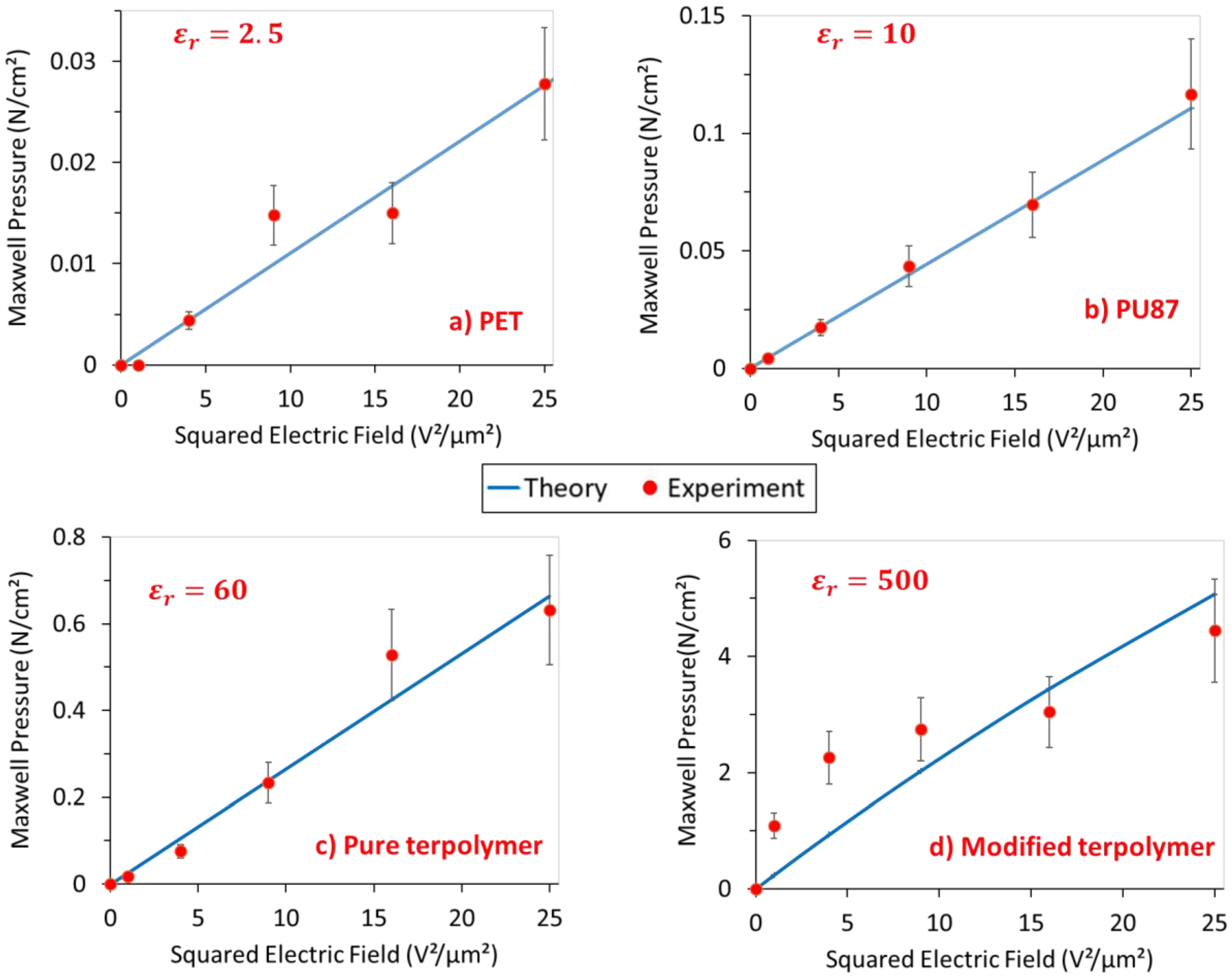

4. Results and Discussions

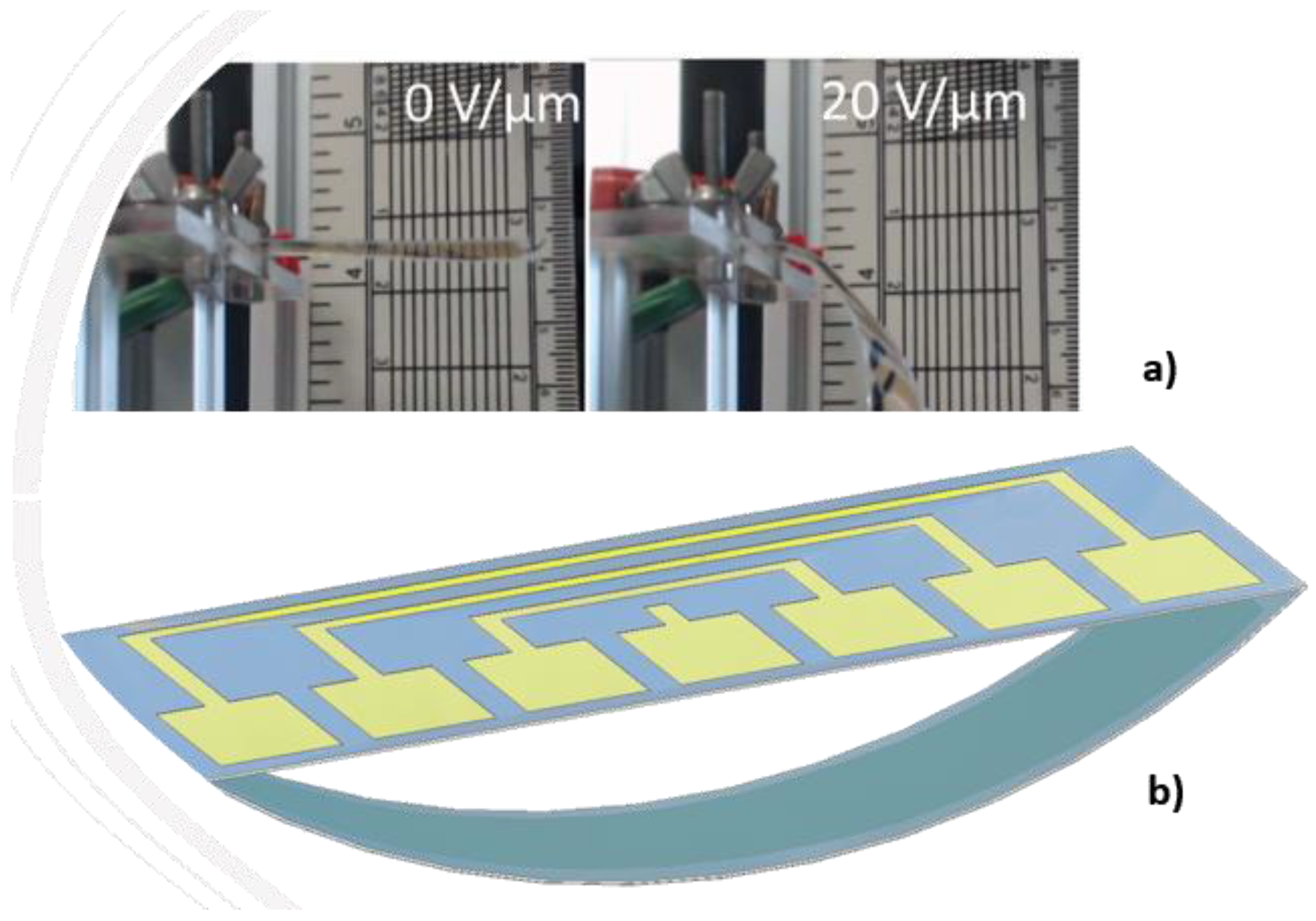

5. Applications to Active Control of Displacement and Stiffness for Electroactive Materials

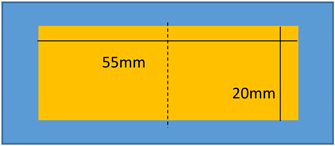

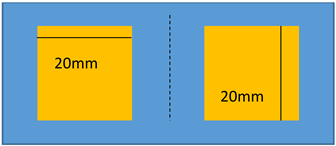

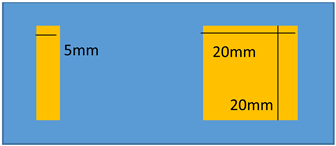

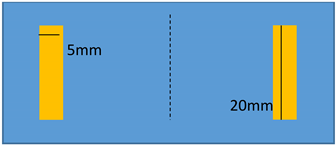

| Pattern of Bottom Electrode Sample with Dimension of (70 × 30) mm² | Picture | Tip Displacement |

|---|---|---|

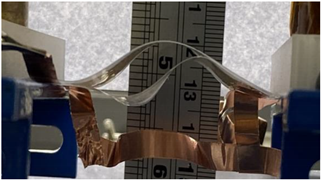

(a) Under an applied electric field, a generation of a static force on the whole active surface makes the two samples stick together. A tip displacement is recorded equal to 30 mm when the samples are subjected to an electric field of around 5 V/µm. |  | 0 mm (0 V/µm) |

| 30 mm (~5 V/µm) | |

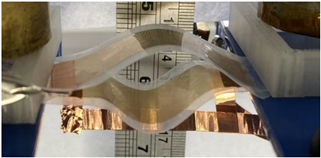

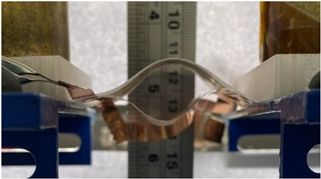

(b) Interestingly, when the input high voltage is ON, the two samples attract each other, but not on the whole surface. Obviously, the two side edges stick together, where there is a presence of the active electrodes. No actuation manifests at the center, which is logical based on the specified pattern design. A tip displacement of each side is equal to 15 mm, allowing to create a “sinus” form of the below sample. |  | 15 mm (~5 V/µm) |

(c) When both samples are subjected to an electric field of approximately 5 V/µm, the two samples stick together only on the right-hand side, where the active surface is large enough to generate sufficient electrostatic force. The left-hand side, on the other hand, does not produce obvious electroadhesion phenomenon, especially when a part of the top electrode is removed from the above sample. Thus, the effective surface of the electrodes is too small to provoke any action. Interestingly, the resulting displacement of the below sample is assimilated to a “sinus” form, but with a period double to the one obtained from the case b. |  | 10 mm (~5 V/µm) |

(d) When both samples are subjected to an electric field of approximately 5 V/µm, no displacement is observed. The effective surface of the electrodes is too small on both sides, and thus, no action can be provoked. |  | 0 mm (~5 V/µm) |

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Johnsen, A.; Rahbek, K. A Physical Phenomenon and Its Applications to Telegraphy, Telephony, Etc. J. Inst. Elect. Eng. 1923, 61, 713–725. [Google Scholar] [CrossRef]

- Rahbek, K. Electroadhesion Apparatus. U. S. Patent 2,025,123, 24 December 1935. [Google Scholar]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Versatile Soft Grippers with Intrinsic Electroadhesion Based on Multifunctional Polymer Actuators. Adv. Mater. 2016, 28, 231–238. [Google Scholar] [CrossRef]

- Digumarti, K.M.; Cao, C.; Guo, J.; Conn, A.T.; Rossiter, J. Multi-Directional Crawling Robot with Soft Actuators and Electroadhesive Grippers. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018. [Google Scholar]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef]

- Graule, M.A.; Chirarattananon, P.; Fuller, S.B.; Jafferis, N.T.; Ma, K.Y.; Spenko, M.; Kornbluh, R.; Wood, R.J. Perching and Takeoff of a Robotic Insect on Overhangs Using Switchable Electrostatic Adhesion. Science 2016, 352, 978–982. [Google Scholar] [CrossRef]

- Guo, J.; Xiang, C.; Rossiter, J. A Soft and Shape-Adaptive Electroadhesive Composite Gripper with Proprioceptive and Exteroceptive Capabilities. Mater. Des. 2018, 156, 586–587. [Google Scholar] [CrossRef]

- Heath, C.J.C.; Bond, I.P.; Potter, K.D. Integrating Electrostatic Adhesion to Composite Structures. In Industrial and Commercial Applications of Smart Structures Technologies 2015, Proceedings of SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 1 April 2015; Farinholt, K.M., Griffin, S.F., Eds.; SPIE. Digital Library: San Diego, CA, USA, 2015; p. 94330D. [Google Scholar]

- Han, A.K.; Hajj-Ahmad, A.; Cutkosky, M.R. Hybrid Electrostatic and Gecko-Inspired Gripping Pads for Manipulating Bulky, Non-Smooth Items. Smart Mater. Struct. 2021, 30, 025010. [Google Scholar] [CrossRef]

- Le, M.Q.; Ganet, F.; Audigier, D.; Capsal, J.-F.; Cottinet, P.-J. Printing of Microstructure Strain Sensor for Structural Health Monitoring. Appl. Phys. A 2017, 123, 354. [Google Scholar] [CrossRef]

- Thetpraphi, K.; Kanlayakan, W.; Chaipo, S.; Moretto, G.; Kuhn, J.; Audigier, D.; Le, M.Q.; Cottinet, P.-J.; Petit, L.; Capsal, J.-F. 3D-Printed Electroactive Polymer Force-Actuator for Large and High Precise Optical Mirror Applications. Addit. Manuf. 2021, 47, 102199. [Google Scholar] [CrossRef]

- Bauer, S.; Bauer-Gogonea, S.; Graz, I.; Kaltenbrunner, M.; Keplinger, C.; Schwödiauer, R. 25th Anniversary Article: A Soft Future: From Robots and Sensor Skin to Energy Harvesters. Adv. Mater. 2014, 26, 149–162. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, Fabrication and Control of Soft Robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef]

- Bar-Cohen, Y.; Anderson, I.A. Electroactive Polymer (EAP) Actuators—Background Review. Mech. Soft Mater. 2019, 1, 5. [Google Scholar] [CrossRef]

- Capsal, J.-F.; Galineau, J.; Lallart, M.; Cottinet, P.-J.; Guyomar, D. Plasticized Relaxor Ferroelectric Terpolymer: Toward Giant Electrostriction, High Mechanical Energy and Low Electric Field Actuators. Sens. Actuators A Phys. 2014, 207, 25–31. [Google Scholar] [CrossRef]

- Bar-cohen, Y. Electroactive Polymers as Artificial Muscles—Reality and Challenges. In Proceedings of the 19th AIAA Applied Aerodynamics Conference, Reston, VA, USA, 11 June 2001. [Google Scholar]

- Thetpraphi, K.; Le, M.Q.; Houachtia, A.; Cottinet, P.; Petit, L.; Audigier, D.; Kuhn, J.; Moretto, G.; Capsal, J. Surface Correction Control Based on Plasticized Multilayer P(VDF-TrFE-CFE) Actuator—Live Mirror. Adv. Opt. Mater. 2019, 7, 1900210. [Google Scholar] [CrossRef]

- Schiava, N.D.; Pedroli, F.; Thetpraphi, K.; Flocchini, A.; Le, M.-Q.; Lermusiaux, P.; Capsal, J.-F.; Cottinet, P.-J. Effect of Beta-Based Sterilization on P(VDF-TrFE-CFE) Terpolymer for Medical Applications. Sci. Rep. 2020, 10, 8805. [Google Scholar] [CrossRef]

- Wang, T.; Farajollahi, M.; Choi, Y.S.; Lin, I.-T.; Marshall, J.E.; Thompson, N.M.; Kar-Narayan, S.; Madden, J.D.W.; Smoukov, S.K. Electroactive Polymers for Sensing. Interface Focus 2016, 6, 26. [Google Scholar] [CrossRef] [PubMed]

- Jung, K.; Kim, K.J.; Choi, H.R. A Self-Sensing Dielectric Elastomer Actuator. Sens. Actuators A Phys. 2008, 143, 343–351. [Google Scholar] [CrossRef]

- Ganet, F.; Le, M.Q.; Capsal, J.F.; Lermusiaux, P.; Petit, L.; Millon, A.; Cottinet, P.J. Development of a Smart Guide Wire Using an Electrostrictive Polymer: Option for Steerable Orientation and Force Feedback. Sci. Rep. 2016, 5, 18593. [Google Scholar] [CrossRef]

- Liu, Q.; Le, M.Q.; Richard, C.; Liang, R.; Cottinet, P.-J.; Capsal, J.-F. Enhanced Pseudo-Piezoelectric Dynamic Force Sensors Based on Inkjet-Printed Electrostrictive Terpolymer. Org. Electron. 2019, 67, 259–271. [Google Scholar] [CrossRef]

- Cottinet, P.-J.; Le, M.-Q.; Degraff, J.; Souders, C.; Liang, Z.; Wang, B.; Zhang, C. Strain Phenomenon in Carbon Nanotube Buckpaper Actuator: Experiments and Modeling. Sens. Actuators A Phys. 2013, 194, 252–258. [Google Scholar] [CrossRef]

- Mokni, M.; Pedroli, F.; D’Ambrogio, G.; Le, M.-Q.; Cottinet, P.-J.; Capsal, J.-F. High-Capacity, Fast-Response, and Photocapacitor-Based Terpolymer Phosphor Composite. Polymers 2020, 12, 349. [Google Scholar] [CrossRef] [PubMed]

- Hinchet, R.; Shea, H. High Force Density Textile Electrostatic Clutch. Adv. Mater. Technol. 2020, 5, 1900895. [Google Scholar] [CrossRef]

- Capsal, J.-F.; Galineau, J.; Le, M.-Q.; Dos Santos, F.D.; Cottinet, P.-J. Enhanced Electrostriction Based on Plasticized Relaxor Ferroelectric P(VDF-TrFE-CFE/CTFE) Blends. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1368–1379. [Google Scholar] [CrossRef]

- Strong, R.; Troxel, D. An Electrotactile Display. IEEE Trans. Man Mach. Syst. 1970, 11, 72–79. [Google Scholar] [CrossRef]

- Ivkovic, B.; Djurdjanovic, M.; Stamenkovic, D. The Influence of the Contact Surface Roughness on the Static Friction Coefficient. Tribol. Ind. 2000, 22, 41–44. [Google Scholar]

- Lessel, M.; Loskill, P.; Hausen, F.; Gosvami, N.N.; Bennewitz, R.; Jacobs, K. Impact of van Der Waals Interactions on Single Asperity Friction. Phys. Rev. Lett. 2013, 111, 035502. [Google Scholar] [CrossRef] [PubMed]

- Rubinstein, S.M.; Cohen, G.; Fineberg, J. Contact Area Measurements Reveal Loading-History Dependence of Static Friction. Phys. Rev. Lett. 2006, 96, 256103. [Google Scholar] [CrossRef] [PubMed]

- Parker, R.C.; Hatch, D. The Static Coefficient of Friction and the Area of Contact. Proc. Phys. Soc. Sect. B 1950, 63, 185–197. [Google Scholar] [CrossRef]

- Bowden, F.P.; Tabor, D. The Friction and Lubrication of Solid; Clarendon Press: Oxford, UK, 2001; ISBN 978-0-19-850777-2. [Google Scholar]

- Hulikal, S.; Lapusta, N.; Bhattacharya, K. Static and Sliding Contact of Rough Surfaces: Effect of Asperity-Scale Properties and Long-Range Elastic Interactions. J. Mech. Phys. Solids 2018, 116, 217–238. [Google Scholar] [CrossRef]

- Pedroli, F.; Flocchini, A.; Marrani, A.; Le, M.-Q.; Sanseau, O.; Cottinet, P.-J.; Capsal, J.-F. Boosted Energy-Storage Efficiency by Controlling Conduction Loss of Multilayered Polymeric Capacitors. Mater. Des. 2020, 192, 108712. [Google Scholar] [CrossRef]

- Pedroli, F.; Marrani, A.; Le, M.-Q.; Sanseau, O.; Cottinet, P.-J.; Capsal, J.-F. Reducing Leakage Current and Dielectric Losses of Electroactive Polymers through Electro-Annealing for High-Voltage Actuation. RSC Adv. 2019, 9, 12823–12835. [Google Scholar] [CrossRef]

- Della Schiava, N.; Le, M.-Q.; Galineau, J.; Dos Santos, F.D.; Cottinet, P.-J.; Capsal, J.-F. Influence of Plasticizers on the Electromechanical Behavior of a P(VDF-TrFE-CTFE) Terpolymer: Toward a High Performance of Electrostrictive Blends. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 355–369. [Google Scholar] [CrossRef]

- Schiava, N.D.; Thetpraphi, K.; Le, M.-Q.; Lermusiaux, P.; Millon, A.; Capsal, J.-F.; Cottinet, P.-J. Enhanced Figures of Merit for a High-Performing Actuator in Electrostrictive Materials. Polymers 2018, 10, 263. [Google Scholar] [CrossRef]

- Le, M.Q.; Capsal, J.-F.; Galineau, J.; Ganet, F.; Yin, X.; Yang, M.; Chateaux, J.-F.; Renaud, L.; Malhaire, C.; Cottinet, P.-J.; et al. All-Organic Electrostrictive Polymer Composites with Low Driving Electrical Voltages for Micro-Fluidic Pump Applications. Sci. Rep. 2015, 5, 11814. [Google Scholar] [CrossRef]

- Ganet, F.; Le, M.-Q.; Capsal, J.F.; Gérard, J.F.; Pruvost, S.; Duchet, J.; Livi, S.; Lermusiaux, P.; Millon, A.; Cottinet, P.-J. Haptic Feedback Using an All-Organic Electroactive Polymer Composite. Sens. Actuators B Chem. 2015, 220, 1120–1130. [Google Scholar] [CrossRef]

- Meijer, H.E.H.; Govaert, L.E. Mechanical Performance of Polymer Systems: The Relation between Structure and Properties. Prog. Polym. Sci. 2005, 30, 915–938. [Google Scholar] [CrossRef]

- Grzybowski, S.; Feilat, E.A.; Knight, P.; Doriott, L. Breakdown Voltage Behavior of PET Thermoplastics at DC and AC Voltages. In Proceedings of the Proceedings IEEE Southeastcon’99. Technology on the Brink of 2000 (Cat. No.99CH36300), Lexington, KY, USA, 25–28 March 1999. [Google Scholar]

- Karlsson, M. Investigation of the Dielectric Breakdown Strength of Polymer Nanocomposites. Master’s Thesis, Uppsala University, Uppsala, Sweden, June 2014. [Google Scholar]

- Capsal, J.-F.; Lallart, M.; Galineau, J.; Cottinet, P.-J.; Sebald, G.; Guyomar, D. Evaluation of Macroscopic Polarization and Actuation Abilities of Electrostrictive Dipolar Polymers Using the Microscopic Debye/Langevin Formalism. J. Phys. D Appl. Phys. 2012, 45, 205401. [Google Scholar] [CrossRef]

- Furukawa, T.; Nakajima, K.; Koizumi, T.; Date, M. Measurements of Nonlinear Dielectricity in Ferroelectric Polymers. Jpn. J. Appl. Phys. 1987, 26, 1039–1045. [Google Scholar] [CrossRef]

- Koh, K.; Sreekumar, M.; Ponnambalam, S. Experimental Investigation of the Effect of the Driving Voltage of an Electroadhesion Actuator. Materials 2014, 7, 4963–4981. [Google Scholar] [CrossRef] [PubMed]

- Ciavarella, M.; Papangelo, A. A Simplified Theory of Electroadhesion for Rough Interfaces. Front. Mech. Eng. 2020, 6, 27. [Google Scholar] [CrossRef]

- Persson, B.N.J. The Dependency of Adhesion and Friction on Electrostatic Attraction. J. Chem. Phys. 2018, 148, 144701. [Google Scholar] [CrossRef]

- GRANTA Edupack. Available online: https://grantadesign.com/education/ces-edupack/ (accessed on 1 May 2021).

- Lau, G.-K.; Heng, K.-R.; Ahmed, A.S.; Shrestha, M. Dielectric Elastomer Fingers for Versatile Grasping and Nimble Pinching. Appl. Phys. Lett. 2017, 110, 182906. [Google Scholar] [CrossRef]

- Lim, H.; Hwang, G.; Kyung, K.-U.; Kim, B.-J. Improved Electroadhesive Force by Using Fumed Alumina/PDMS Composites. Smart Mater. Struct. 2021, 30, 035007. [Google Scholar] [CrossRef]

- Heath, C.J.C.; Bond, I.P.; Potter, K.D. Electrostatic Adhesion for Added Functionality of Composite Structures. Smart Mater. Struct. 2016, 25, 025016. [Google Scholar] [CrossRef][Green Version]

- Maffli, L.; Rosset, S.; Shea, H.R. Zipping Dielectric Elastomer Actuators: Characterization, Design and Modeling. Smart Mater. Struct. 2013, 22, 104013. [Google Scholar] [CrossRef]

- Taghavi, M.; Helps, T.; Rossiter, J. Electro-Ribbon Actuators and Electro-Origami Robots. Sci. Robot. 2018, 3, 9795. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fimbel, A.; Abensur, T.; Le, M.-Q.; Capsal, J.-F.; Cottinet, P.-J. Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers. Polymers 2022, 14, 24. https://doi.org/10.3390/polym14010024

Fimbel A, Abensur T, Le M-Q, Capsal J-F, Cottinet P-J. Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers. Polymers. 2022; 14(1):24. https://doi.org/10.3390/polym14010024

Chicago/Turabian StyleFimbel, Amaury, Thierry Abensur, Minh-Quyen Le, Jean-Fabien Capsal, and Pierre-Jean Cottinet. 2022. "Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers" Polymers 14, no. 1: 24. https://doi.org/10.3390/polym14010024

APA StyleFimbel, A., Abensur, T., Le, M.-Q., Capsal, J.-F., & Cottinet, P.-J. (2022). Accurate Electroadhesion Force Measurements of Electrostrictive Polymers: The Case of High Performance Plasticized Terpolymers. Polymers, 14(1), 24. https://doi.org/10.3390/polym14010024