Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Dyeing Apparatus

2.3. Methods

2.3.1. Green Synthesis of Se-NPs

2.3.2. Dyeing Procedure of Wool Fabrics with Selenium NPs

2.4. Characterization

2.5. Functional Properties of Se-Dyed Wool Fabrics

2.5.1. Antimicrobial Activity

2.5.2. UV-Protection Properties

2.6. Testing

2.6.1. Color Measurements

2.6.2. Fastness Properties

2.6.3. Durability Test

2.6.4. Mechanical Properties

2.7. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Se-NPs and Dyed Wool Fabrics

3.1.1. Transmission Electron Microscopy (TEM)

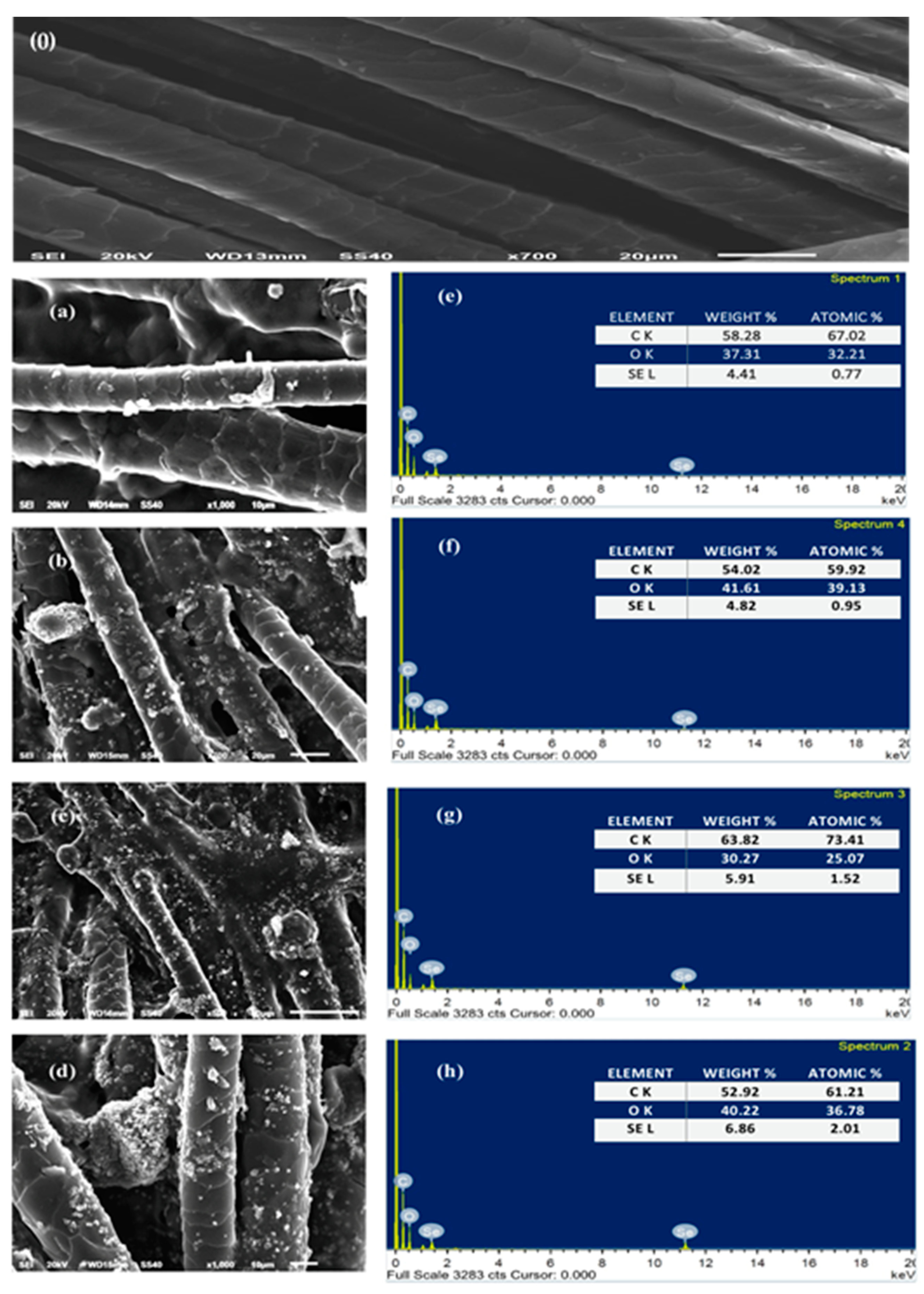

3.1.2. SEM and EDX Analysis

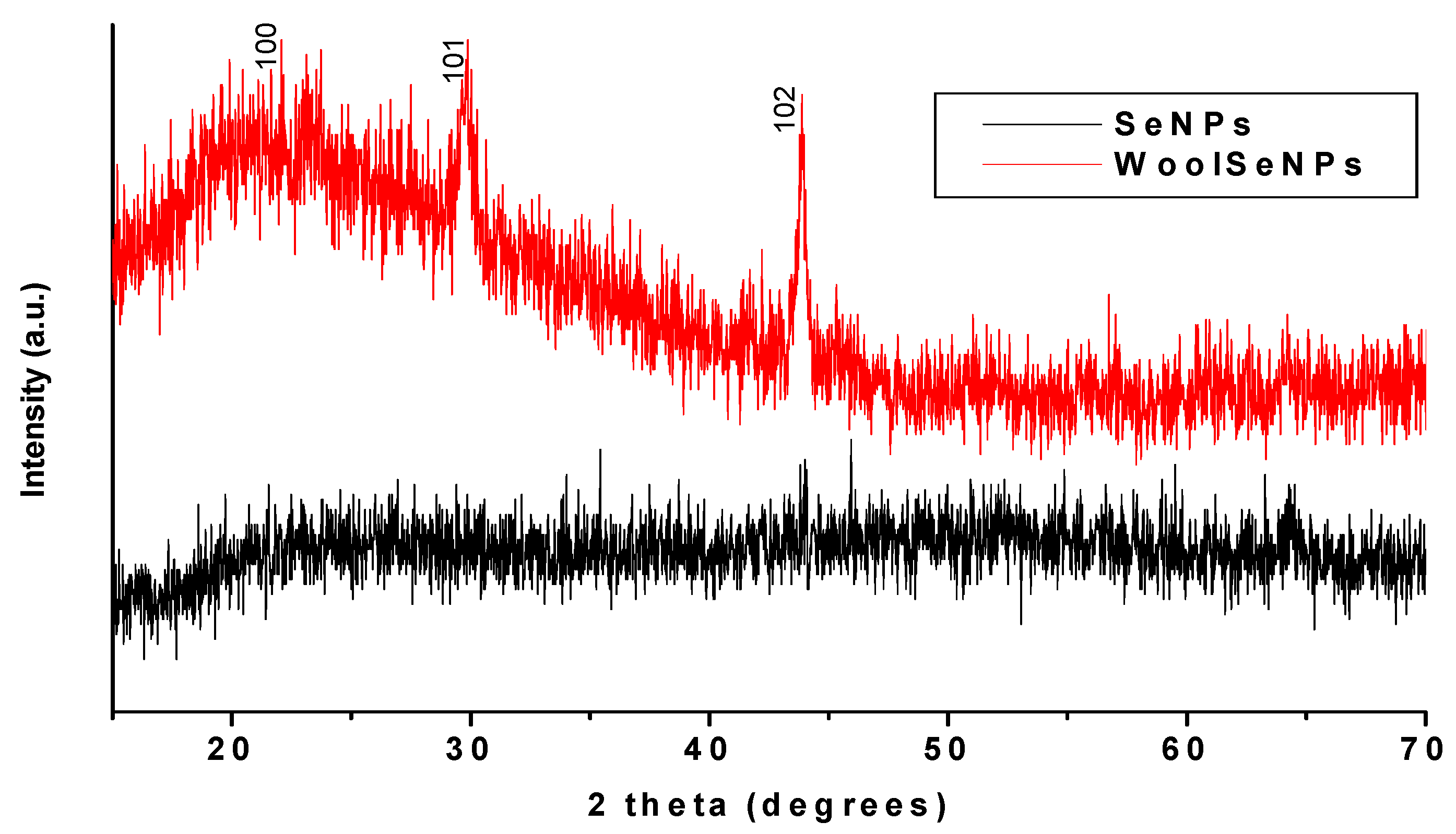

3.1.3. X-ray Diffraction (XRD)

3.2. Functional Properties of Se-NP Dyed Wool Fabrics

3.2.1. Biological Activity

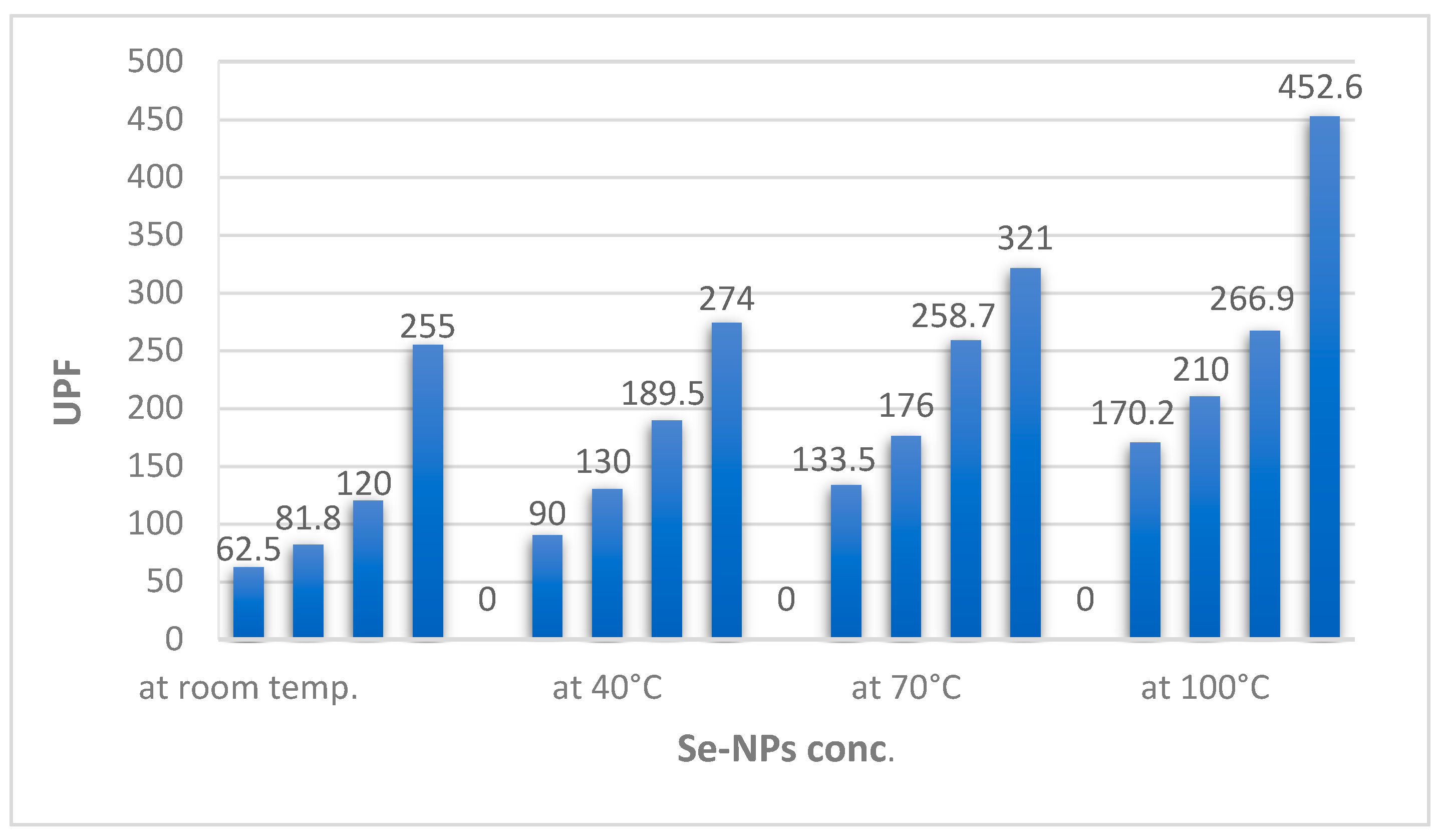

3.2.2. UV-Protection Properties

3.3. Color Characteristics and Color Fastness of Se-Dyed Wool Fabrics

3.4. Mechanical properties of Se-Dyed Wool Fabrics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yetisen, A.K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M.R.; Hinestroza, J.P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S.H. Nanotechnology in textiles. ACS Nano 2016, 10, 3042–3068. [Google Scholar] [CrossRef] [PubMed]

- Abou Elmaaty, T.; Elsisi, H.G.; Elsayad, G.M.; Elhadad, H.H.; Sayed-Ahmed, K.; Plutino, M.R. Fabrication of New Multifunctional Cotton/Lycra Composites Protective Textiles through Deposition of Nano Silica Coating. Polymers 2021, 13, 2888. [Google Scholar] [CrossRef]

- Castellano, A.; Colleoni, C.; Iacono, G.; Mezzi, A.; Plutino, M.R.; Malucelli, G.; Rosace, G. Synthesis and characterization of a phosphorous/nitrogen based sol-gel coating as a novel halogen- and formaldehyde-free flame retardant finishing for cotton fabric. Polym. Degrad. Stab. 2019, 162, 148–159. [Google Scholar] [CrossRef]

- Plutino, M.R.; Colleoni, C.; Donelli, I.; Freddi, G.; Guido, E.; Maschi, O.; Mezzi, A.; Rosace, G. Sol-gel 3-glycidoxypropyltriethoxysilane finishing on different fabrics: The role of precursor concentration and catalyst on the textile performances and cytotoxic activity. J. Colloid Interface Sci. 2017, 506, 504–517. [Google Scholar] [CrossRef] [PubMed]

- Rosace, G.; Guido, E.; Colleoni, C.; Brucale, M.; Piperopoulos, E.; Milone, C.; Plutino, M.R. Halochromic resorufin-GPTMS hybrid sol-gel: Chemical-physical properties and use as pH sensor fabric coating. Sens. Actuators B Chem. 2017, 241, 85–95. [Google Scholar] [CrossRef]

- Dong, J.; Luo, S.; Ning, S.; Yang, G.; Pan, D.; Ji, Y.; Liu, C. MXene-Coated Wrinkled Fabrics for Stretchable and Multifunctional Electromagnetic Interference Shielding and Electro/Photo-Thermal Conversion Applications. ACS Appl. Mater. Interf. 2021, 13, 60478–60488. [Google Scholar] [CrossRef] [PubMed]

- Plutino, M.R.; Guido, E.; Colleoni, C.; Rosace, G. Effect of GPTMS functionalization on the improvement of the pH-sensitive methyl red photostability. Sens. Actuators B 2017, 238, 281–291. [Google Scholar] [CrossRef]

- Trovato, V.; Rosace, G.; Colleoni, C.; Sfameni, S.; Migani, V.; Plutino, M.R. Sol-gel based coatings for the protection of cultural heritage textiles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 777, 012007. [Google Scholar] [CrossRef]

- Ielo, I.; Galletta, M.; Rando, G.; Sfameni, S.; Cardiano, P.; Sabatino, G.; Drommi, D.; Rosace, G.; Plutino, M.R. Design, synthesis, and characterization of hybrid coatings suitable for geopolymeric-based supports for the restoration of cultural heritage. IOP Conf. Ser. Mater. Sci. Eng. 2020, 777, 012003. [Google Scholar] [CrossRef]

- Rosace, G.; Cardiano, P.; Urzì, C.; De Leo, F.; Galletta, M.; Ielo, I.; Plutino, M.R. Potential roles of fluorine-containing sol-gel coatings against adhesion to control microbial biofilm. IOP Conf. Ser. Mater. Sci. Eng. 2018, 459, 012021. [Google Scholar] [CrossRef]

- Grancarić, A.M.; Tarbuk, A.; Sutlović, A.; Castellano, A.; Colleoni, C.; Rosace, G.; Plutino, M.R. Enhancement of acid dyestuff salt-free fixation by a cationizing sol-gel based coating for cotton fabric. Colloids Surf. A Physicochem. Eng. Asp. 2021, 612, 125984. [Google Scholar] [CrossRef]

- Puoci, F.; Saturnino, C.; Trovato, V.; Iacopetta, D.; Piperopoulos, E.; Triolo, C.; Bonomo, M.G.; Drommi, D.; Parisi, O.I.; Milone, C.; et al. Sol–Gel Treatment of Textiles for the Entrapping of an Antioxidant/Anti-Inflammatory Molecule: Functional Coating Morphological Characterization and Drug Release Evaluation. Appl. Sci. 2020, 10, 2287. [Google Scholar] [CrossRef] [Green Version]

- Ielo, I.; Giacobello, F.; Sfameni, S.; Rando, G.; Galletta, M.; Trovato, V.; Rosace, G.; Plutino, M.R. Nanostructured Surface Finishing and Coatings: Functional Properties and Applications. Materials 2021, 14, 2733. [Google Scholar] [CrossRef] [PubMed]

- AbouElmaaty, T.; Abdeldayem, S.A.; Ramadan, S.M.; Sayed-Ahmed, K.; Plutino, M.R. Coloration and Multi-Functionalization of Polypropylene Fabrics with Selenium Nanoparticles. Polymers 2021, 13, 2483. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Eid, B.M.; El-Aziz, E.A.; Elmaaty, T.M.A.; Ramadan, S.M. Loading of chitosan–Nano metal oxide hybrids onto cotton/polyester fabrics to impart permanent and effective multifunctions. Int. J. Biol. Macromol. 2017, 105, 769–776. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Eid, B.M.; El-Aziz, E.A.; Elmaaty, T.M.A.; Ramadan, S.M. Multifunctional cellulose-containing fabrics using modified finishing formulations. RSC Adv. 2017, 7, 33219–33230. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, N.A.; Eid, B.M.; El-Aziz, E.A.; Elmaaty, T.M.A. Functionalization of linen/cotton pigment prints using inorganic nano structure materials. Carbohydr. Polym. 2013, 97, 537–545. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, N.A.; Eid, B.M.; Elmaaty, T.M.A.; El-Aziz, E.A. A smart approach to add antibacterial functionality to cellulosic pigment prints. Carbohydr. Polym. 2013, 94, 612–618. [Google Scholar] [CrossRef] [PubMed]

- El-bisi, M.; Othman, R.; Yassin, F.A. Improving antibacterial and ultraviolet properties of cotton fabrics via dual effect of nano-metal oxide and Moringa oleifera extract. Egypt. J. Chem. 2020, 63, 3441–3451. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; El-Aziz, E.A.; Eid, B.M.; Elmaaty, T.M.A. Single-stage process for bifunctionalization and eco-friendly pigment coloration of cellulosic fabrics. J. Text. Inst. 2016, 107, 1022–1029. [Google Scholar]

- Ibrahim, N.A.; Eid, B.M.; Abdel-Aziz, M.S. Effect of plasma superficial treatments on antibacterial functionalization and coloration of cellulosic fabrics. Appl. Surf. Sci. 2017, 392, 1126–1133. [Google Scholar] [CrossRef]

- Ibrahim, N.A.; Nada, A.A.; Eid, B.M.; Al-Moghazy, M.; Hassabo, A.G.; Abou-Zeid, N.Y. Nano-structured metal oxides: Synthesis, characterization and application for multifunctional cotton fabric. Adv. Nat. Sci. Nanosci. Nanotechnol. 2018, 9, 35014. [Google Scholar] [CrossRef]

- Eid, B.M.; Ibrahim, N.A. Recent developments in sustainable finishing of cellulosic textiles employing biotechnology. J. Clean. Prod. 2021, 284, 124701–124722. [Google Scholar] [CrossRef]

- Barattucci, A.; Plutino, M.R.; Faggi, C.; Bonaccorsi, P.; Monsù Scolaro, L.; Aversa, M.C. Mono- and trinuclear tripodal platinum(II) chelated complexes containing a pyridine/sulfoxide based anchoring framework. Eur. J. Inorg. Chem. 2013, 19, 3412–3420. [Google Scholar] [CrossRef]

- Ibrahim, H.M.; Zaghloul, S.; Hashem, M.; El-Shafei, A. A green approach to improve the antibacterial properties of cellulose based fabrics using Moringa oleifera extract in presence of silver nanoparticles. Cellulose 2021, 28, 549–564. [Google Scholar] [CrossRef]

- De Luca, G.; Bonaccorsi, P.; Trovato, V.; Mancuso, A.; Papalia, T.; Pistone, A.; Casaletto, M.P.; Mezzi, A.; Brunetti, B.; Minuti, l.; et al. Tripodal tris-disulfides as capping agents for a controlled mixed functionalization of gold nanoparticles. New J. Chem. 2018, 42, 16436–16440. [Google Scholar] [CrossRef]

- Mehravani, B.; Ribeiro, A.I.; Zille, A. Gold Nanoparticles Synthesis and Antimicrobial Effect on Fibrous Materials. Nanomaterials 2021, 11, 1067. [Google Scholar] [CrossRef]

- Ielo, I.; Iacopetta, D.; Saturnino, C.; Longo, P.; Galletta, M.; Drommi, D.; Rosace, G.; Sinicropi, M.S.; Plutino, M.R. Gold Derivatives Development as Prospective Anticancer Drugs for Breast Cancer Treatment. Appl. Sci. 2021, 11, 2089. [Google Scholar] [CrossRef]

- Ielo, I.; Rando, G.; Giacobello, F.; Sfameni, S.; Castellano, A.; Galletta, M.; Drommi, D.; Rosace, G.; Plutino, M.R. Synthesis, Chemical–Physical Characterization, and Biomedical Applications of Functional Gold Nanoparticles: A Review. Molecules 2021, 26, 5823. [Google Scholar] [CrossRef]

- Riaz, S.; Ashraf, M.; Hussain, T.; Hussain, M.T.; Rehman, A.; Javid, A.; Iqbal, K.; Basit, A.; Aziz, H. Functional finishing, and coloration of textiles with nanomaterials. Color. Technol. 2018, 134, 327–346. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Localized Surface Plasmon Resonance for Optical Fiber-Sensing Applications. In Nanoplasmonics—Fundamentals and Applications; Intech Open: London, UK, 2017; Chapter 17. [Google Scholar]

- Wang, X.; Xu, D.; Jaquet, B.; Yang, Y.; Wang, J.; Huang, H.; Chen, Y.; Gerhard, C.; Zhang, K. Structural Colors by Synergistic Birefringence and Surface Plasmon Resonance. ACS Nano 2020, 14, 16832–16839. [Google Scholar] [CrossRef] [PubMed]

- Tan, K.B.; Vakili, M.; Horri, B.A.; Poh, P.E.; Abdullah, A.Z.; Salamatinia, B. Adsorption of dyes by nanomaterials: Recent developments and adsorption mechanisms. Sep. Purif. Technol. 2015, 150, 229–242. [Google Scholar] [CrossRef]

- Kafafy, H.; Helmy, H.; Zaher, A. Treatment of cotton and wool fabrics with different nanoparticles for multifunctional properties. Egyptian J. Chem. 2021, 64, 5255–5267. [Google Scholar] [CrossRef]

- Wu, M.; Ma, B.; Pan, T.; Chen, S.; Sun, J. Silver-nanoparticle-colored cotton fabrics with tunable colors and durable antibacterial and self-healing superhydrophobic properties. Adv. Funct. Mater. 2016, 26, 569–576. [Google Scholar] [CrossRef]

- Razmkhah, M.; Montazer, M.; Rezaie, A.B.; Rad, M.M. Facile technique for wool coloration via locally forming of nano selenium photocatalyst imparting antibacterial and UV protection properties. J. Ind. Eng. Chem. 2021, 101, 153–164. [Google Scholar] [CrossRef]

- Abdelrahman, M.S.; Nassar, S.H.; Mashaly, H.; Mahmoud, S.; Maamoun, D.; El-Sakhawy, M.; Khattab, T.; Kamel, S. Studies of polylactic acid and metal oxide nanoparticles-based composites for multifunctional textile prints. Coatings 2020, 10, 58. [Google Scholar] [CrossRef] [Green Version]

- Johnston, J.H.; Lucas, K.A. Nanogold synthesis in wool fibres: Novel colourants. Gold Bull. 2011, 44, 85–89. [Google Scholar] [CrossRef]

- Rehan, M.; Elshemy, N.S.; Haggag, K.; Montaser, A.S.; Ibrahim, G.E. Phytochemicals and volatile compounds of peanut red skin extract: Simultaneous coloration and in situ synthesis of silver nanoparticles for multifunctional viscose fibers. Cellulose 2020, 27, 9893–9912. [Google Scholar] [CrossRef]

- Tang, B.; Yao, Y.; Chen, W.; Chen, X.; Zou, F.; Wang, X. Kinetics of dyeing natural protein fibers with silver nanoparticles. Dye. Pigment. 2018, 148, 224–235. [Google Scholar] [CrossRef]

- Jafari-Kiyan, A.; Karimi, L.; Davodiroknabadi, A. Producing colored cotton fabrics with functional properties by combining silver nanoparticles with nano titanium dioxide. Cellulose 2017, 24, 3083–3094. [Google Scholar] [CrossRef]

- Tang, B.; Li, J.; Hou, X.; Afrin, T.; Sun, L.; Wang, X. Colorful and antibacterial silk fiber from anisotropic silver nanoparticles. Ind. Eng. Chem. Res 2013, 52, 4556–4563. [Google Scholar] [CrossRef]

- Tang, B.; Sun, L.; Kaur, J.; Yu, Y.; Wang, X. In-situ synthesis of gold nanoparticles for multifunctionalization of silk fabrics. Dye. Pigment. 2014, 103, 183–190. [Google Scholar] [CrossRef]

- Yao, Y.; Tang, B.; Chen, W.; Sun, L.; Wang, X. Sunlight-induced coloration of silk. Nanoscale Res. Lett. 2016, 11, 293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Emam, H.E.; Rehan, M.; Mashaly, H.M.; Ahmed, H.B. Large scaled strategy for natural/synthetic fabrics functionalization via immediate assembly of AgNPs. Dye. Pigment. 2016, 133, 173–183. [Google Scholar] [CrossRef]

- Tang, B.; Sun, L.; Li, J.; Kaur, J.; Zhu, H.; Qin, S.; Yao, Y.; Chen, W.; Wang, X. Functionalization of bamboo pulp fabrics with noble metal nanoparticles. Dye. Pigment. 2015, 113, 289–298. [Google Scholar] [CrossRef]

- Tang, B.; Yao, Y.; Li, J.; Qin, S.; Zhu, H.; Kaur, J.; Chen, W.; Sun, L.; Wang, X. Functional application of noble metal nanoparticles in situ synthesized on ramie fibers. Nanoscale Res. Lett. 2015, 10, 366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mowafi, S.; Rehan, M.; Mashaly, H.M.; Abou El-Kheir, A.; Emam, H.E. Influence of silver nanoparticles on the fabrics functions prepared by in-situ technique. J. Text. Inst. 2017, 108, 1828–1839. [Google Scholar] [CrossRef]

- Hong, Z. Preparation and antioxidant properties of selenium nanoparticles-loaded chitosan microspheres. Int. J. Nanomed. 2017, 12, 4527–4539. [Google Scholar]

- Zhai, X.; Zhang, C.; Zhao, G.; Stoll, S.; Ren, F.; Leng, X. Antioxidant capacities of the selenium nanoparticles stabilized by chitosan. J. Nanobiotechnology 2017, 15, 4. [Google Scholar] [CrossRef] [Green Version]

- Nastulyavichus, A.; Kudryashov, S.; Smirnov, N.; Saraeva, I.; Rudenko, A.; Tolordava, E.; Ionin, A.; Romanova, Y.; Zayarny, D. Antibacterial coatings of Se and Si nanoparticles. Appl. Surf. Sci 2019, 469, 220–225. [Google Scholar] [CrossRef]

- Huang, X.; Chen, X.; Chen, Q.; Yu, Q.; Sun, D.; Liu, J. Investigation of functional selenium nanoparticles as potent antimicrobial agents against superbugs. Acta Biomater. 2016, 30, 397–407. [Google Scholar] [CrossRef] [PubMed]

- Yip, J.; Liu, L.; Wong, K.H.; Leung, P.H.M.; Yuen, C.W.M.; Cheung, M.C. Investigation of antifungal and antibacterial effects of fabric padded with highly stable selenium nanoparticles. J. Appl. Polym. Sci. 2014, 131, 8886–8893. [Google Scholar] [CrossRef]

- Elmaaty, T.A.; El-Nagare, K.; Raouf, S.; Abdelfattah, K.; El-Kadi, S.; Abdelaziz, E. One-step green approach for functional printing and finishing of textiles using silver and gold NPs. RSC Adv. 2018, 8, 25546–25557. [Google Scholar] [CrossRef] [Green Version]

- Elmaaty, T.A.; Raouf, S.; Sayed-Ahmed, K. Novel one step printing and functional finishing of wool fabric using selenium nanoparticles. Fiber Polym. 2019, 21, 1983–1991. [Google Scholar] [CrossRef]

- Vieira, A.P.; Stein, E.M.; Andreguetti, D.X.; Cebrián-Torrejón, G.; Doménech-Carbó, A.; Colepicolo, P.; Ferreira, A.M.D.C. “Sweet Chemistry”: A Green Way for Obtaining Selenium Nanoparticles Active against Cancer Cells. J. Braz. Chem. Soc. 2017, 28, 2021–2027. [Google Scholar] [CrossRef]

- Slavin, Y.N.; Asnis, J.; Häfeli, U.O.; Bach, H. Metal nanoparticles: Understanding the mechanisms behind antibacterial activity. J. Nanobiotechnology 2017, 15, 65. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Taylor, E.W.; Wan, X.; Peng, D. Impact of heat treatment on size, structure, and bioactivity of elemental selenium nanoparticles. Int. J. Nanomed. 2012, 7, 815. [Google Scholar] [CrossRef] [Green Version]

- Adomaviciute, E.; Stanys, S.; Žilius, M.; Juškaite, V.; Pavilonis, A.; Briedis, V. Formation and biopharmaceutical characterization of electrospun PVP mats with propolis and silver nanoparticles for fast releasing wound dressing. Biomed. Res. Int. 2016, 2016, 4648287. [Google Scholar] [CrossRef]

- Lu, Z.; Mao, C.; Meng, M.; Liu, S.; Tian, Y.; Yu, L.; Sun, B.; Li, C.M. Fabrication of CeO2 nanoparticle-modified silk for UV protection and antibacterial applications. J. Colloid Interface Sci. 2014, 435, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.Z.; Baheti, V.; Ashraf, M.; Hussain, T.; Ali, A.; Javid, A.; Rehman, A. Development of UV protective, superhydrophobic and antibacterial textiles using ZnO and TiO2 nanoparticles. Fibers Polym. 2018, 19, 1647–1654. [Google Scholar] [CrossRef]

- Chitichotpanya, P.; Pisitsak, P.; Chitichotpanya, C. Sericin—Copper-functionalized silk fabrics for enhanced ultraviolet protection and antibacterial properties using response surface methodology. Text. Res. J. 2019, 89, 1166–1179. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R.; Monaco, M.M.; Iervolino, G.; Vaiano, V. Photocatalytic Degradation of Azo Dye Reactive Violet 5 on Fe-Doped Titania Catalysts under Visible Light Irradiation. Catalysts 2019, 9, 645. [Google Scholar] [CrossRef] [Green Version]

- Zuorro, A.; Maffei, G.; Lavecchia, R. Kinetic modeling of azo dye adsorption on non-living cells of Nannochloropsis oceanica. J. Environ. Chem. Eng. 2017, 5, 4121–4127. [Google Scholar] [CrossRef]

- Panusa, A.; Zuorro, A.; Lavecchia, R.; Marrosu, G.; Petrucci, R. Recovery of Natural Antioxidants from Spent Coffee Grounds. J. Agric. Food Chem. 2013, 61, 4162–4168. [Google Scholar] [CrossRef]

| Se-NPs Conc. | Temp. °C | Antimicrobial Activity ZI 1 (mm.) | |||

|---|---|---|---|---|---|

| Blank wool | G+ve | G−ve | Yeast | ||

| S. aureus | Bacillus cereus | E. coli | Candida utilis | ||

| 0 | 0 | 0 | 0 | ||

| 12.5 mM | At room temp. | 13.4 (13) 2 | 10.6 (9) | 10 (10) | 14 (13.5) |

| 25 mM | 15.9 (15) | 12.6 (12) | 13.5 (12.4) | 17.5 (16) | |

| 37.5 mM | 17.7 (17) | 14 (13.2) | 14.3 (14) | 19 (18) | |

| 50 mM | 19 (18) | 15.4 (14.8) | 18.2 (18) | 23 (22.3) | |

| 12.5 mM | At 40 °C | 13 (13) | 10.2 (10) | 9.3 (9) | 14 (12) |

| 25 mM | 14.7 (13.8) | 12 (11) | 12.5 (11) | 16.6 (15) | |

| 37.5 mM | 17 (15) | 13.8 (13) | 14 (12.3) | 18.5 (15.3) | |

| 50 mM | 18.2 (17.4) | 15 (14.3) | 17.4 (15.6) | 20.8 (20) | |

| 12.5 mM | At 70 °C | 10 (8) | 8 (8) | 8.6 (7.2) | 12 (10) |

| 25 mM | 11.5 (11) | 10 (8.5) | 9.7 (9) | 12.8 (11.2) | |

| 37.5 mM | 13 (10.3) | 10.5 (10) | 10.5 (9.2) | 14 (12.6) | |

| 50 mM | 14.8 (14) | 12 (10) | 11.5 (11) | 17.2 (15.4) | |

| 12.5 mM | At 100 °C | 8 (7) | 7.6 (6.3) | 7 (6) | 10.6 (10) |

| 25 mM | 9 (8.4) | 8.2 (7) | 8.5 (7) | 11 (9.3) | |

| 37.5 mM | 11 (10.5) | 8.8 (8) | 9 (8.2) | 11.8 (11) | |

| 50 mM | 11.8 (10) | 10 (8.8) | 10 (9) | 13.5 (12.6) | |

| Se-NPs conc. | Temp. °C | UV Protection Properties | ||

|---|---|---|---|---|

| Blank wool | UV-A Transmittance | UV-B Transmittance | UPF | |

| 10.43 | 1.72 | 33.46 | ||

| 12.5 mM | At room temp. | 2.33 | 1.58 | 62.5 (60.2) 1 |

| 25 mM | 1.51 | 1.37 | 81.8 (80) | |

| 37.5 mM | 1.46 | 0.83 | 120 (117) | |

| 50 mM | 1.21 | 0.36 | 255 (250) | |

| 12.5 mM | At 40 °C | 1.44 | 1.23 | 90 (87) |

| 25 mM | 1.32 | 0.96 | 130 (125.6) | |

| 37.5 mM | 1.04 | 0.54 | 189.5 (180.7) | |

| 50 mM | 0.76 | 0.21 | 274 (270) | |

| 12.5 mM | At 70 °C | 0.71 | 0.88 | 133.5 (130.2) |

| 25 mM | 0.52 | 0.73 | 176 (170.5) | |

| 37.5 mM | 0.35 | 0.61 | 258.7 (255) | |

| 50 mM | 0.27 | 0.42 | 321 (320) | |

| 12.5 mM | At 100 °C | 0.59 | 0.77 | 170.2 (166) |

| 25 mM | 0.5 | 0.65 | 210 (204.8) | |

| 37.5 mM | 0.41 | 0.32 | 266.9 (260) | |

| 50 mM | 0.08 | 0.06 | 452.6 (447.5) | |

| Se-NPs Conc. | Temp. °C | L * | a * | b * | c * | H * | K/S |

|---|---|---|---|---|---|---|---|

| Blank wool | Room temp. | 86.87 | 0.96 | 12.33 | 12.37 | 85.56 | 1.1 |

| 12.5 mM | 79.77 | 7.83 | 20.2 | 21.67 | 68.81 | 2.21 (2)1 | |

| 25 mM | 67.81 | 18.84 | 26.05 | 32.15 | 60.12 | 3.71 (3.5) | |

| 37.5 mM | 68.77 | 17.97 | 28.98 | 34.1 | 58.19 | 4.68 (4.3) | |

| 50 mM | 59.14 | 24.52 | 29.26 | 37.41 | 49.05 | 6.63 (6.4) | |

| 12.5 mM | 40 °C | 75.56 | 11.47 | 21.36 | 24.24 | 61.77 | 2.53 (2.5) |

| 25 mM | 64.14 | 22.06 | 27.21 | 32.75 | 57.66 | 3.34 (3.2) | |

| 37.5 mM | 66.9 | 23.85 | 29.28 | 32.15 | 51.86 | 4.23 (4) | |

| 50 mM | 42.32 | 27.34 | 30.12 | 39.77 | 44.24 | 6.31 (6) | |

| 12.5 mM | 70 °C | 42.16 | 12.82 | 15.1 | 19.81 | 49.67 | 9.8 (9.5) |

| 25 mM | 42.76 | 18.03 | 21.51 | 28.07 | 50.02 | 12.7 (12.3) | |

| 37.5 mM | 42.26 | 24.63 | 28.37 | 37.57 | 49.04 | 15.3 (15) | |

| 50 mM | 36.03 | 34.3 | 27.04 | 42.25 | 49.99 | 16.3 (16) | |

| 12.5 mM | 100 °C | 33.21 | 5.76 | 9.09 | 10.76 | 57.63 | 13.8 (13.3) |

| 25 mM | 29.27 | 13.56 | 13.56 | 18.44 | 42.63 | 18.2 (18) | |

| 37.5 mM | 28.42 | 16.96 | 16.96 | 23.01 | 42.53 | 21.7 (21.4) | |

| 50 mM | 28.43 | 17.06 | 17.06 | 23.15 | 42.53 | 22.1 (22) |

| Se-NPs Conc. | Temp. °C | WF 1 | RF 2 | LF 3 | ||

|---|---|---|---|---|---|---|

| Alt. | St. | Wet | Dry | |||

| 12.5 mM | Room temp. | 5 (5) 4 | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) |

| 25 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 37.5 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 50 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 12.5 mM | 40 °C | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) |

| 25 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 37.5 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 50 mM | 5 (5) | 5 (5) | 5 (5) | 5 (5) | 4/5 (4/5) | |

| 12.5 mM | 70 °C | 4/5 (4/5) | 4/5 (4/5) | 4/5 (4) | 4/5 (4/5) | 4 (4) |

| 25 mM | 4/5 (4/5) | 4/5 (4/5) | 4 (4) | 4/5 (4/5) | 4 (4) | |

| 37.5 mM | 4/5 (4/5) | 4/5 (4/5) | 4 (4) | 4/5 (4/5) | 4 (4) | |

| 50 mM | 4/5 (4/5) | 4/5 (4/5) | 4 (4) | 4/5 (4/5) | 4 (4) | |

| 12.5 mM | 100 °C | 4/5 (4) | 4/5 (4) | 3/4 (3) | 4 (4) | 4 (4) |

| 25 mM | 4/5 (4) | 4/5 (4) | 3/4 (3) | 4 (4) | 4 (4) | |

| 37.5 mM | 4/5 (4) | 4/5 (4) | 3/4 (3) | 4 (4) | 4 (4) | |

| 50 mM | 4/5 (4) | 4/5 (4) | 3/4 (3) | 4 (4) | 4 (4) | |

| Samples | Mechanical Properties | |

|---|---|---|

| Tensile Strength (N/cm2) | Elongation (%) | |

| Blank wool | 356.8 | 26.95 |

| Se-dyed wool at RT. | 330.8 | 25.54 |

| 40 °C | 314.5 | 23.22 |

| 70 °C | 284.4 | 20.22 |

| 100 °C | 276 | 19.94 |

| 120 °C | 176.6 | 13.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmaaty, T.A.; Raouf, S.; Sayed-Ahmed, K.; Plutino, M.R. Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles. Polymers 2022, 14, 191. https://doi.org/10.3390/polym14010191

Elmaaty TA, Raouf S, Sayed-Ahmed K, Plutino MR. Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles. Polymers. 2022; 14(1):191. https://doi.org/10.3390/polym14010191

Chicago/Turabian StyleElmaaty, Tarek Abou, Sally Raouf, Khaled Sayed-Ahmed, and Maria Rosaria Plutino. 2022. "Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles" Polymers 14, no. 1: 191. https://doi.org/10.3390/polym14010191

APA StyleElmaaty, T. A., Raouf, S., Sayed-Ahmed, K., & Plutino, M. R. (2022). Multifunctional Dyeing of Wool Fabrics Using Selenium Nanoparticles. Polymers, 14(1), 191. https://doi.org/10.3390/polym14010191