The Effect of Salinized Nano ZrO2 Particles on the Microstructure, Hardness, and Wear Behavior of Acrylic Denture Tooth Nanocomposite

Abstract

:1. Introduction

2. Materials and Methods

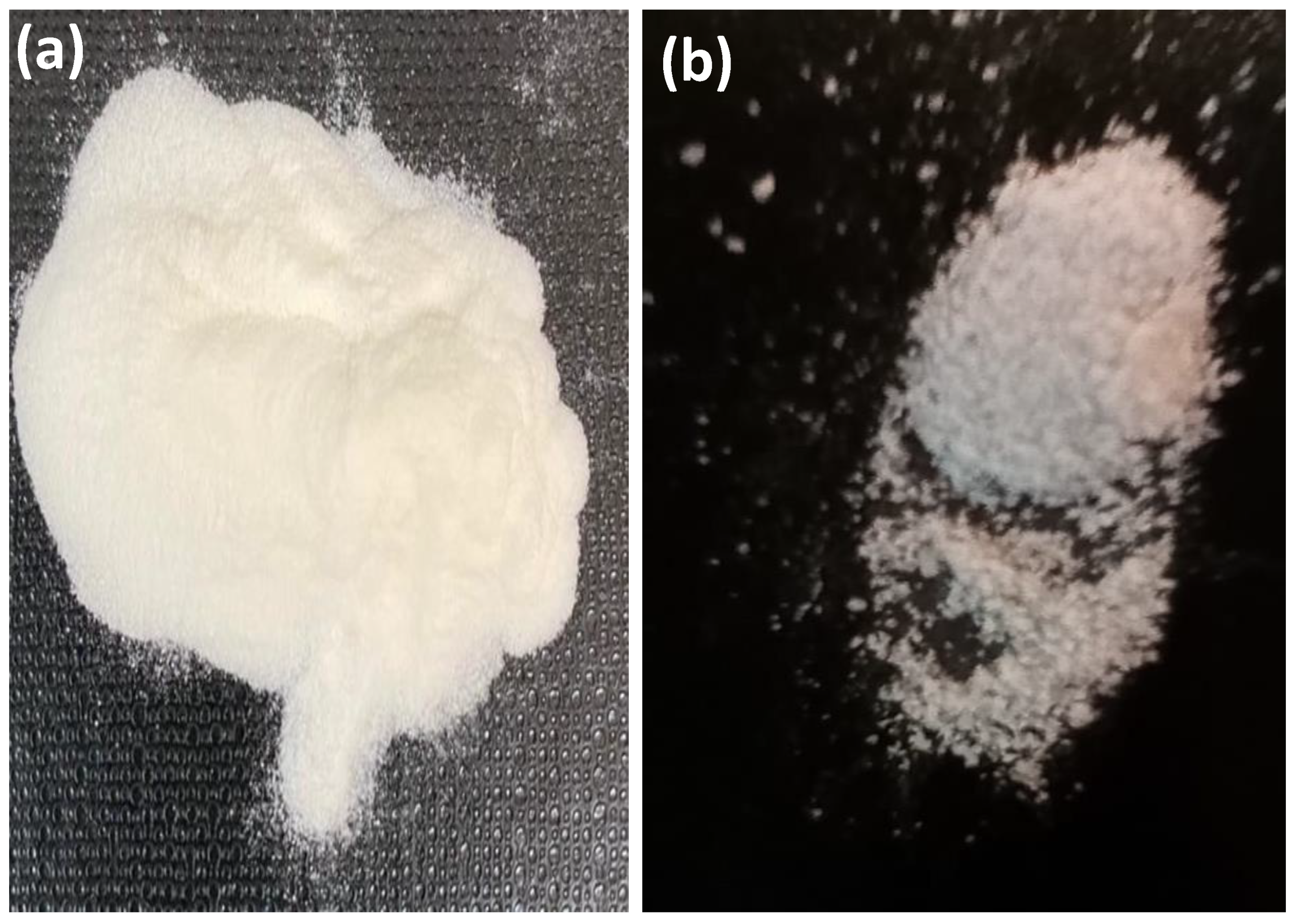

2.1. ZrO2 Nanoparticles Surface Treatment

2.2. PMMA Powder of Artificial Teeth/ZrO2 Nanocomposite Preparation

2.3. Micro-Hardness Test Procedure

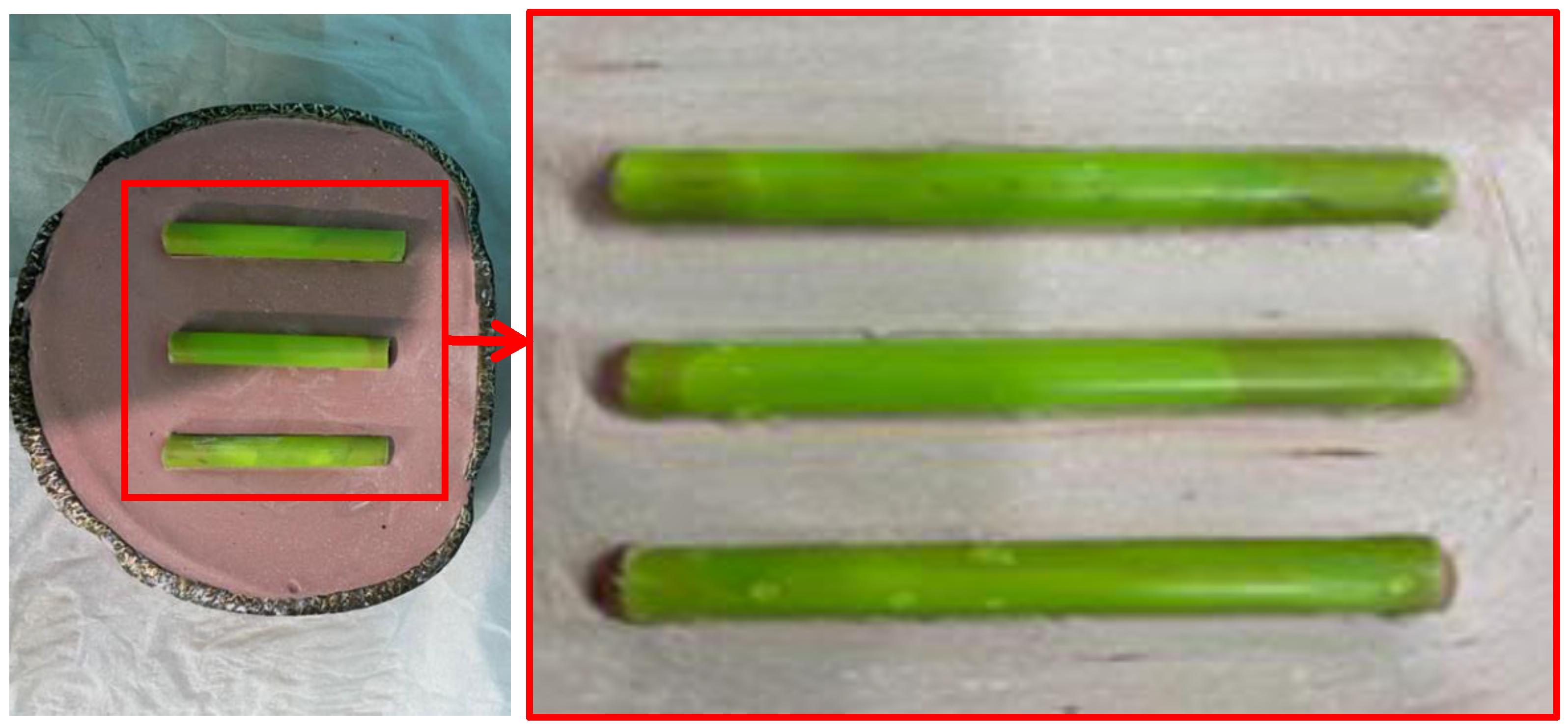

2.4. Wear Testing with Natural Teeth Surface Antagonist

- (A)

- Descriptive data: Descriptive statistics were calculated in the form of Mean ± Standard deviation (SD), median, range (Max-Min).

- (B)

- ANOVA—test: One-way ANOVA (Analysis of variance) was used to compare between the three groups under study. Tukey Post hoc test was performed for the evaluation of statistical significance among the groups. p-value ≤ 0.05 is considered to be statistically significant.

2.5. Microstuctur Investigation

3. Results

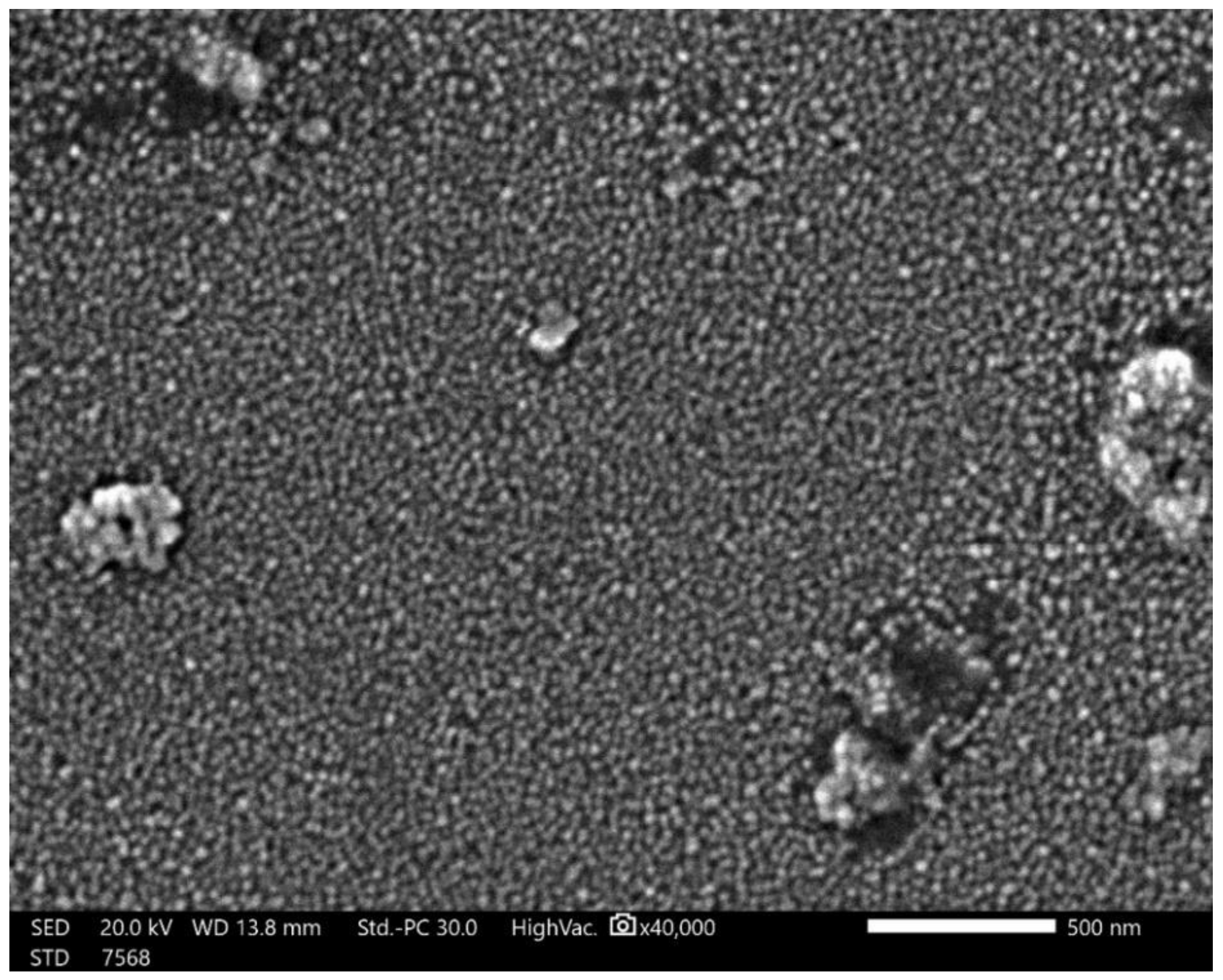

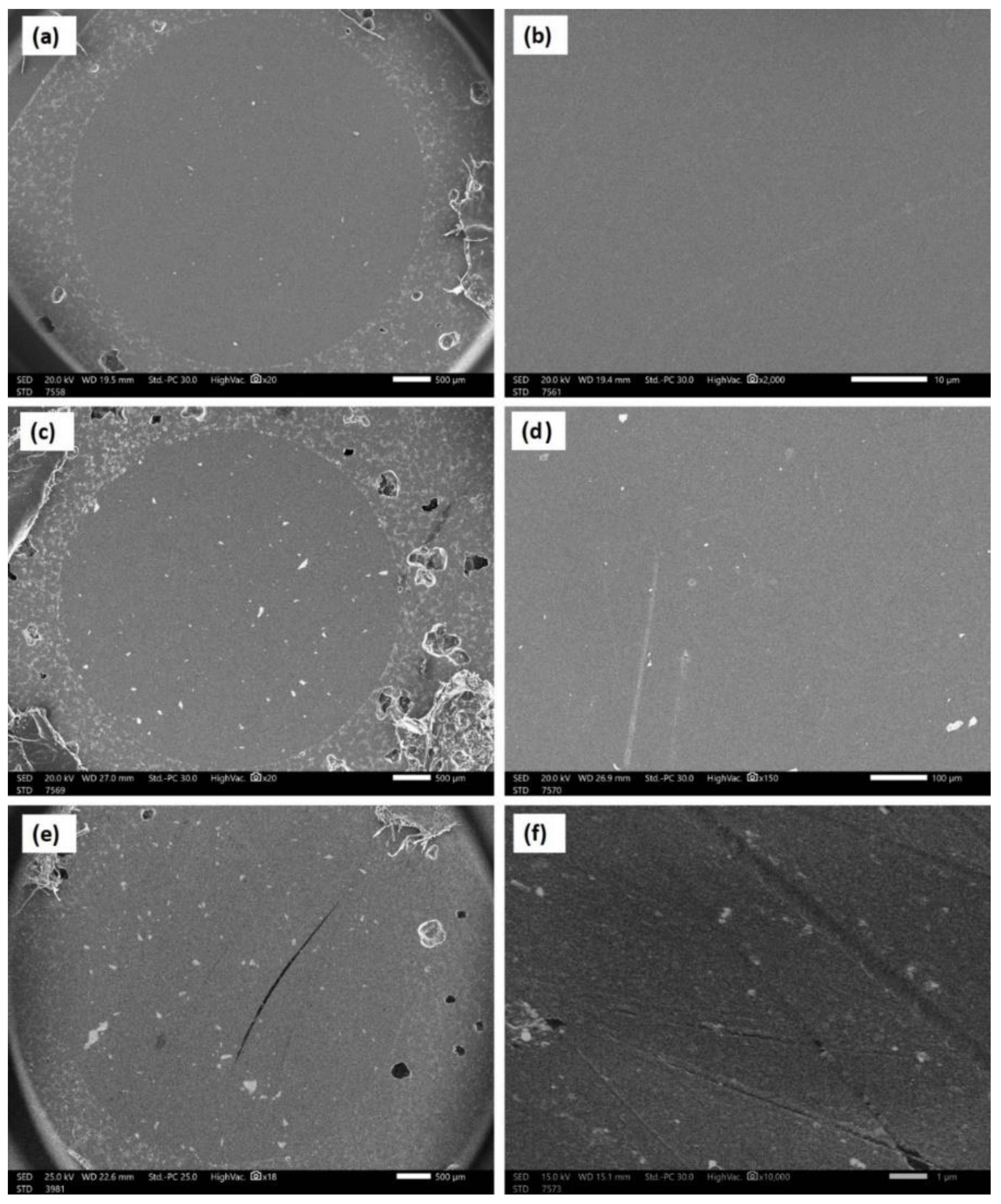

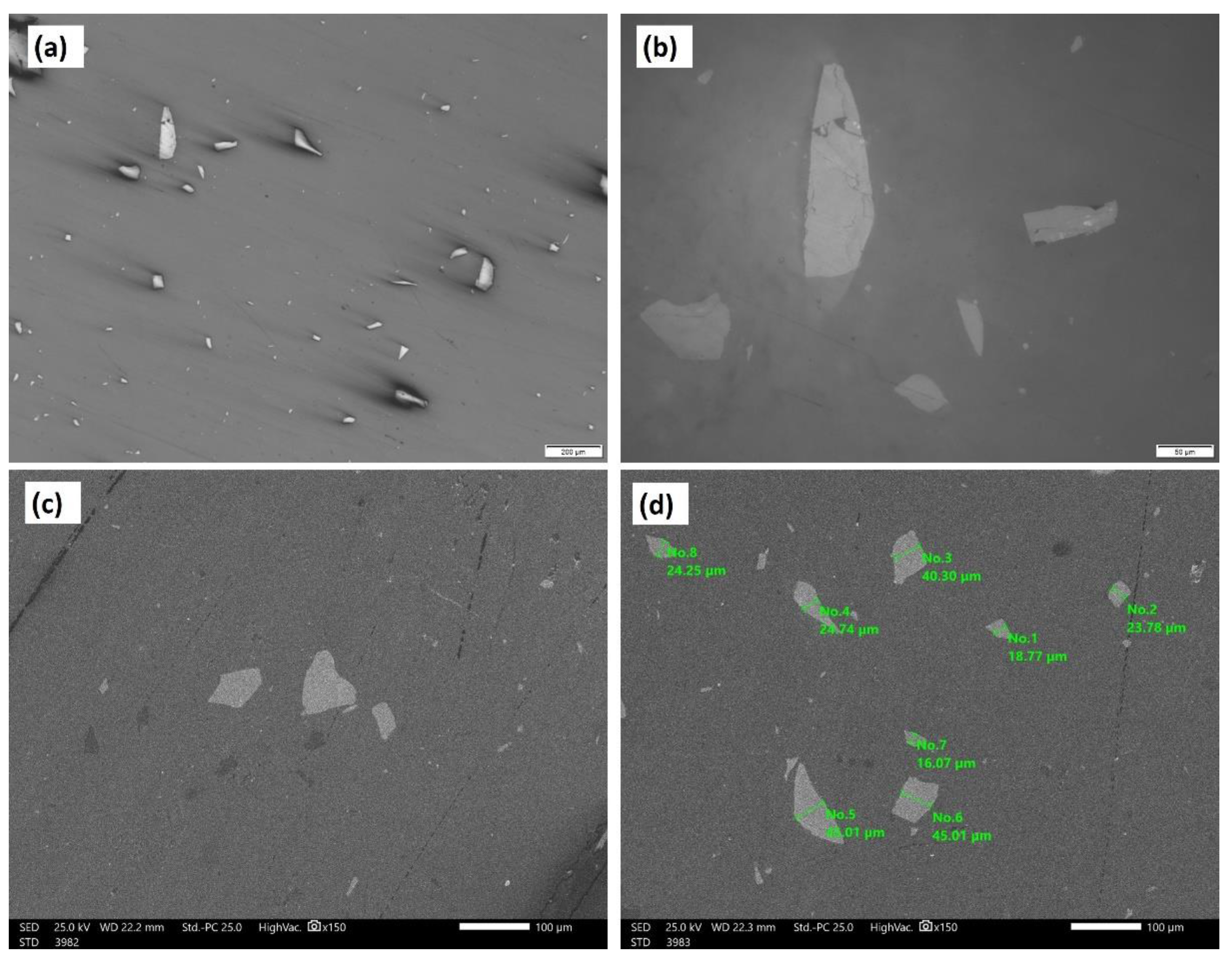

3.1. Acrylic/ZrO2 Nanocomposites Microstructure

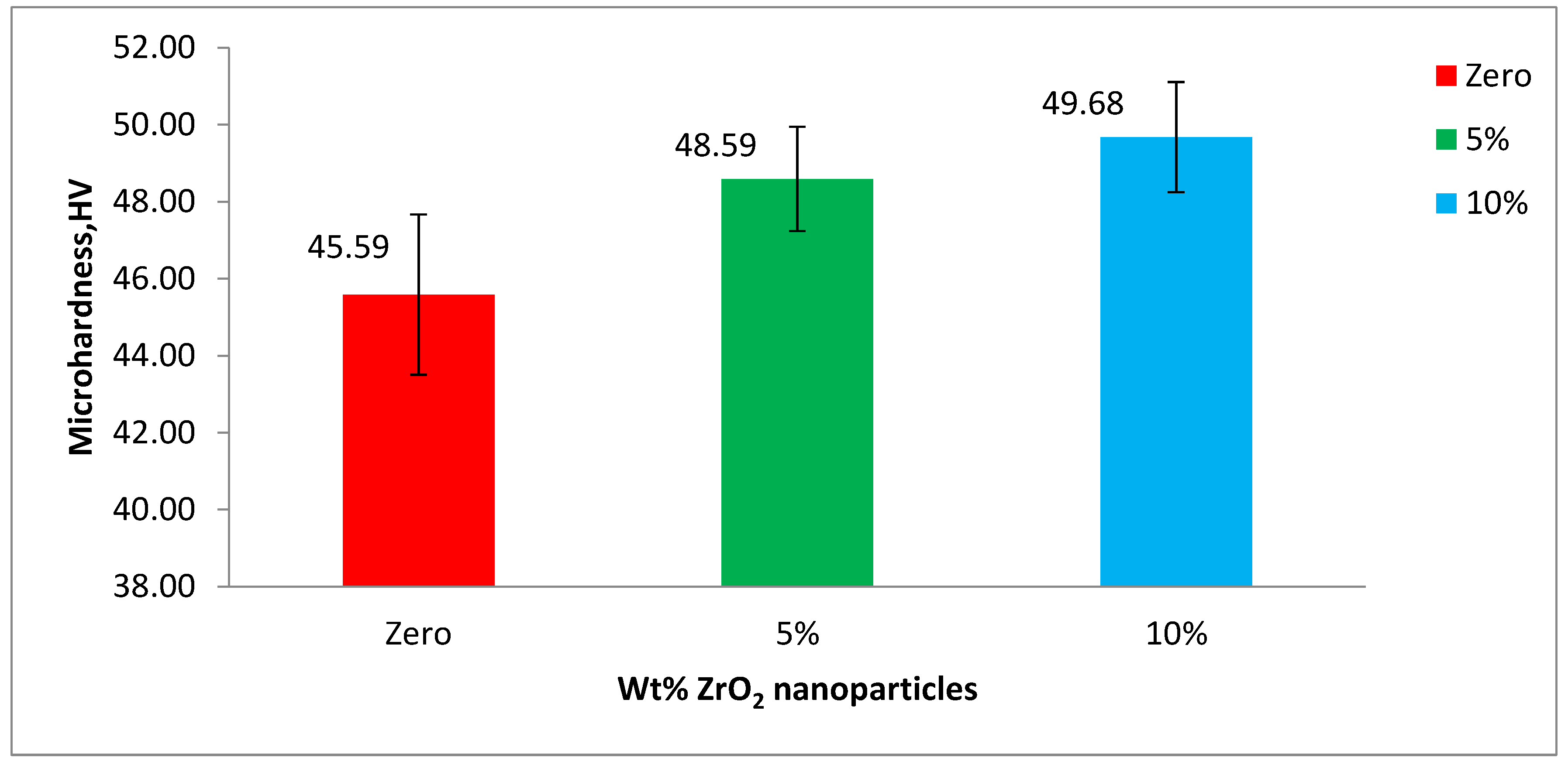

3.2. Micro-Hardness Analysis

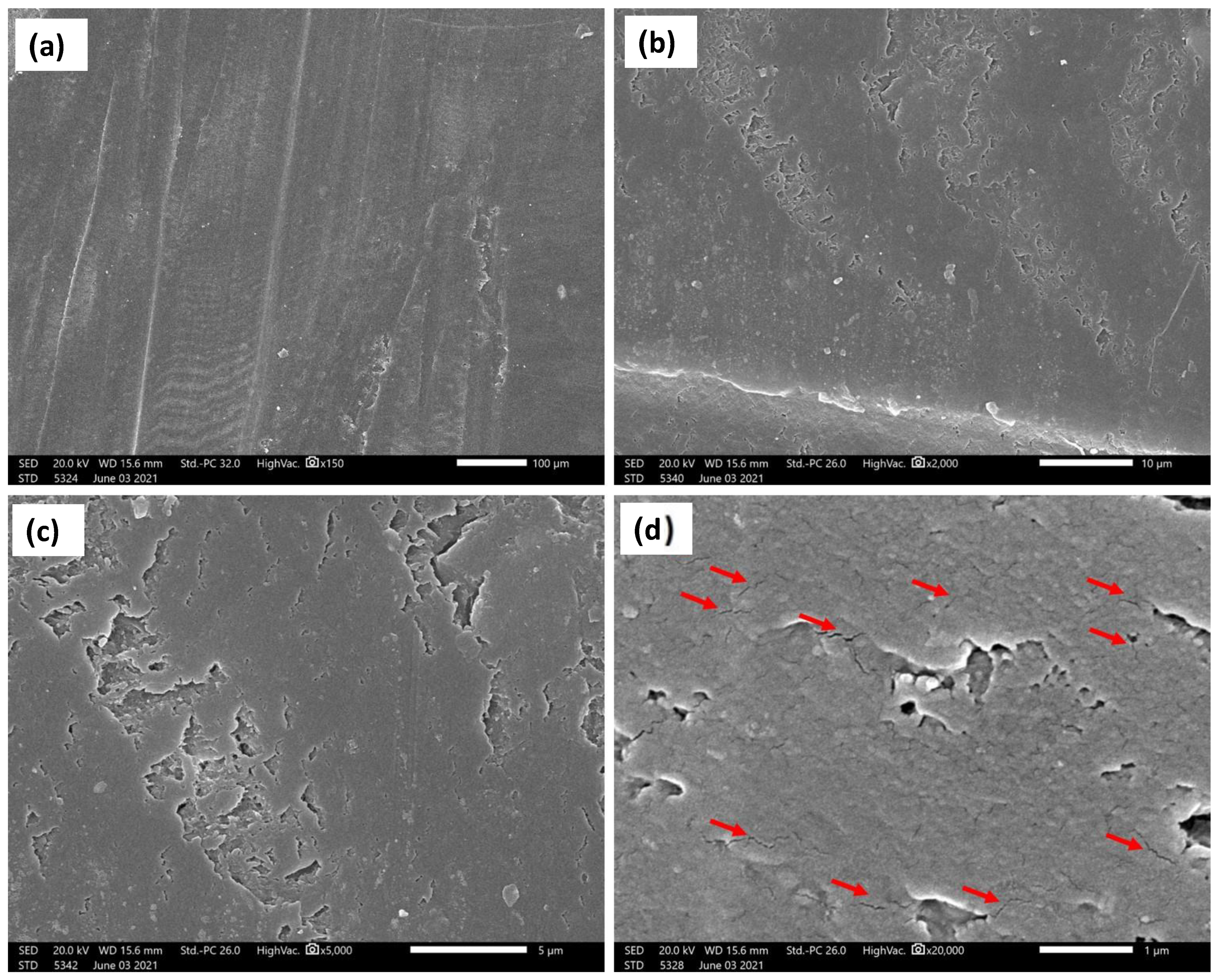

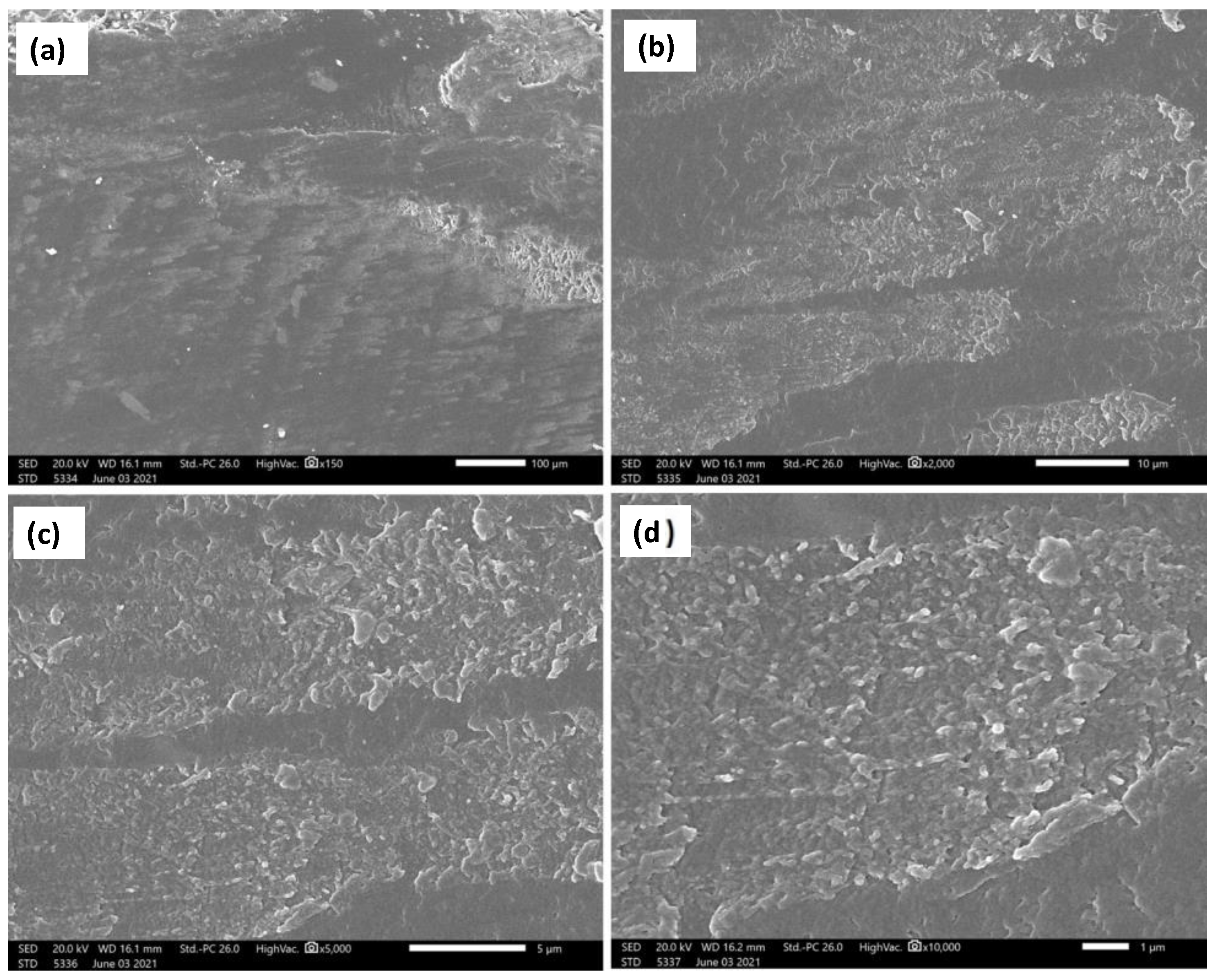

3.3. Wear Behavior

4. Discussion

5. Conclusions

- (1)

- The microstructural investigation of reinforced denture teeth indicates sound material preparation using the applied regime without porosity or macro defects. No segregation was observed for the nanoparticles; only submicron-sized ZrO2 particles were found.

- (2)

- The addition of zirconium oxide nanofillers to PMMA at both 5% and 10% increased the microhardness, with values up to 49.7 HV found after the addition of 10 wt.% ZrO2.

- (3)

- The wear mechanism in the acrylic base material without nanoparticle addition was found to be fatigue wear; a high density of microcracks was found.

- (4)

- The addition of 5 wt.% ZrO2 significantly reduced weight loss and height loss relative to the base material, which indicates improved wear resistance.

- (5)

- Increasing the nanoparticles to 10 wt.% ZrO2 further improved the wear resistance, with no microcracks found.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stober, T.; Lutz, T.; Gilde, H.; Rammelsberg, P. Wear of resin denture teeth by two-body contact. Dent. Mater. 2006, 22, 243–249. [Google Scholar] [CrossRef]

- Kawano, F.; Ohguri, T.; Ichikawa, T.; Mizuno, I.; Hasegawa, A. Shock absorbability and hardness of commercially available denture teeth. Int. J. Prosthodont. 2002, 15, 243–247. [Google Scholar] [PubMed]

- Beall, J.R. Wear of acrylic resin teeth (progress report). J. Am. Dent. Assoc. 1943, 30, 252–256. [Google Scholar] [CrossRef]

- Adams, L.P.; Jooste, C.H.; Thomas, C.J.; Harris, A.M.P. Biostereometric quantification of clinical denture tooth wear. J. Oral Rehabil. 1996, 23, 667–674. [Google Scholar] [CrossRef]

- Satoh, Y.; Nagai, E.; Maejima, K.; Azaki, M. Wear of denture teeth by use of metal plates part 2: Abrasive wear of posterior teeth. J. Nihon Univ. 1992, 34, 16–27. [Google Scholar] [CrossRef]

- Akin, H.; Tugut, F.; Guney, U.; Akar, T. Shear bond strength of denture teeth to two chemically different denture base resins after various surface treatments. J. Prosthodont. 2014, 23, 152–156. [Google Scholar] [CrossRef]

- Mello, P.C.; Coppedê, A.R.; Macedo, A.P.; Da, M.; De Mattos, G.C.; Cristina, R.; Rodrigues, S.; Ribeiro, R.F. Abrasion wear resistance of different artificial teeth opposed to metal and composite antagonists. J. Appl. Oral Sci. 2009, 17, 451–457. [Google Scholar] [CrossRef]

- Kamonwanon, P.; Yodmongkol, S.; Chantarachindawong, R.; Thaweeboon, S.; Thaweeboon, B.; Srikhirin, T. Wear resistance of a modified polymethyl methacrylate artificial tooth compared to five commercially available artificial tooth materials. J. Prosthet. Dent. 2015, 114, 286–292. [Google Scholar] [CrossRef] [PubMed]

- Stober, T.; Henninger, M.; Schmitter, M.; Pritsch, M.; Rammelsberg, P. Three-body wear of resin denture teeth with and without nanofillers. J. Prosthet. Dent. 2010, 103, 108–117. [Google Scholar] [CrossRef]

- Suwannaroop, P.; Chaijareenont, P.; Koottathape, N.; Takahashi, H.; Arksornnukit, M. In vitro wear resistance, hardness and elastic modulus of artificial denture teeth. Dent. Mater. J. 2011, 30, 461–468. [Google Scholar] [CrossRef] [Green Version]

- Gürbüz, Ö.A.; Ünalan, F.; Kursoglu, P. In vitro wear of denture teeth acrylic resin milled glass fiber composite. Oral Health Dent. Manag. Black Sea Ctries. 2005, 4, 46–51. [Google Scholar]

- Gad, M.M.; Rahoma, A.; Al-Thobity, A.M.; ArRejaie, A.S. Influence of incorporation of ZrO2 nanoparticles on the repair strength of polymethyl methacrylate denture bases. Int. J. Nanomed. 2016, 11, 5633–5643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghaffari, T.; Barzegar, A.; Rad, F.H.; Moslehifard, E.; Author, C. Effect of nanoclay on thermal conductivity and flexural strength of polymethyl methacrylate acrylic resin. J. Dent. Shiraz. Univ. Med. Sci. 2016, 17, 121–127. [Google Scholar]

- Labella, R.; Braden, M.; Deb, S. Novel hydroxyapatite-based dental composites. Biomaterials 1994, 15, 1197–1200. [Google Scholar] [CrossRef]

- Ghahremani, L.; Shirkavand, S.; Akbari, F.; Sabzikari, N. Tensile strength and impact strength of color modified acrylic resin reinforced with titanium dioxide nanoparticles. J. Clin. Exp. Dent. 2017, 9, e661–e665. [Google Scholar] [CrossRef] [Green Version]

- Mc Nally, L.; O’Sullivan, D.J.; Jagger, D.C. An in vitro investigation of the effect of the addition of untreated and surface treated silica on the transverse and impact strength of poly(methyl methacrylate) acrylic resin. Biomed. Mater. Eng. 2006, 16, 93–100. [Google Scholar]

- Gad, M.M.; Al-Thobity, A.M.; Rahoma, A.; Abualsaud, R.; Al-Harbi, F.A.; Akhtar, S. Reinforcement of PMMA denture base material with a mixture of ZrO2 nanoparticles and glass fibers. Int. J. Dent. 2019, 2019, 2489393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayad, N.M.; Dawi, M.F.; Fatah, A.A. Effect of reinforcement of high-impact acrylic resin with micro-Zirconia on some physical and mechanical properties. Rev. Clínica Pesqui. Odontológica 2008, 4, 145–151. [Google Scholar]

- Gad, M.; Arrejaie, A.S.; Abdel-Halim, M.S.; Rahoma, A. The reinforcement effect of nano-zirconia on the transverse strength of repaired acrylic denture base. Int. J. Dent. 2016, 2016, 7094056. [Google Scholar] [CrossRef] [Green Version]

- Gad, M.M.; Abualsaud, R.; Rahoma, A.; Al-Thobity, A.M.; Al-Abidi, K.S.; Akhtar, S. Effect of zirconium oxide nanoparticles addition on the optical and tensile properties of polymethyl methacrylate denture base material. Int. J. Nanomed. 2018, 13, 283–292. [Google Scholar] [CrossRef] [Green Version]

- Tang, E.; Cheng, G.; Pang, X.; Ma, X.; Xing, F. Synthesis of nano-ZnO/poly(methyl methacrylate) composite microsphere through emulsion polymerization and its UV-shielding property. Colloid Polym. Sci. 2006, 284, 422–428. [Google Scholar] [CrossRef]

- Asopa, V.; Suresh, S.; Khandelwal, M.; Sharma, V.; Asopa, S.S.; Kaira, L.S. A comparative evaluation of properties of zirconia reinforced high impact acrylic resin with that of high impact acrylic resin. Saudi J. Dent. Res. 2015, 6, 146–151. [Google Scholar] [CrossRef] [Green Version]

- Safi, I.N.; Hassanen, K.A.; Ali, N.A. Assessment of zirconium oxide nano-fillers incorporation and silanation on impact, tensile strength and color alteration of heat polymerized acrylic resin. J. Baghdad Coll. Dent. 2012, 24, 36–42. [Google Scholar]

- Ergun, G.; Sahin, Z.; Ataol, A. The effects of adding various ratios of zirconium oxide nanoparticles to poly (methyl methacrylate) on physical and mechanical properties. J. Oral Sci. 2018, 60, 304–315. [Google Scholar] [CrossRef] [Green Version]

- Ali Sabri, B.; Satgunam, M.; Abreeza, N.M.; Abed, A.N. A review on enhancements of PMMA denture base material with different nano-fillers. Cogent Eng. 2021, 8, 1875968. [Google Scholar] [CrossRef]

- Mohammed, D.; Mudhaffar, M. Effect of modified zirconium oxide nano-fillers addition on some properties of heat cure acrylic denture base material. J. Baghdad Coll. Dent. 2012, 24, 1–7. [Google Scholar]

- Zidan, S.; Silikas, N.; Alhotan, A.; Haider, J.; Yates, J. Investigating the mechanical properties of ZrO2-impregnated PMMA nanocomposite for denture-based applications. Materials 2019, 12, 1344. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eltamimi, K.M.; Bayoumi, D. Microtesile bond strength of zirconia Nano-fillers reinforced acrylic resin to denture teeth after thermocylcling. Egypt. Dent. J. 2021, 67, 767–774. [Google Scholar] [CrossRef]

- Gad, M.M.; Fouda, S.M.; ArRejaie, A.S.; Al-Thobity, A.M. Comparative effect of different polymerization techniques on the flexural and surface properties of acrylic denture bases. J. Prosthodont. 2019, 28, 458–465. [Google Scholar] [CrossRef]

- Yuzugullu, B.; Acar, O.; Cetinsahin, C.; Celik, C. Effect of different denture cleansers on surface roughness and microhardness of artificial denture teeth. J. Adv. Prosthodont. 2016, 8, 333–338. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.Y.; Zhang, X.J.; Huang, Z.L.; Zhu, B.S.; Rong-Rong, R.R.C. Hybrid effects of zirconia nanoparticles with aluminum borate whiskers on mechanical properties of denture base resin PMMA. Dent. Mater. J. 2014, 33, 141–146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pero, A.C.; Scavassin, P.M.; Leite, A.R.; Marin, D.O.; Paleari, A.G.; Compagnoni, M.A. Effect of immersion cleansers on the bond strength between a denture base resin and acrylic resin teeth. Int. J. Adhes. Adhes. 2013, 44, 180–183. [Google Scholar] [CrossRef]

- Fisher, R.M.; Moore, B.K.; Swartz, M.L.; Dykema, R.W. The effects of enamel wear on the metal-porcelain interface. J. Prosthet. Dent. 1983, 50, 627–631. [Google Scholar] [CrossRef]

- Ghazal, M.; Yang, B.; Ludwig, K.; Kern, M. Two-body wear of resin and ceramic denture teeth in comparison to human enamel. Dent. Mater. 2008, 24, 502–507. [Google Scholar] [CrossRef] [PubMed]

- Ghazal, M.; Hedderich, J.; Kern, M. Wear of feldspathic ceramic, nano-filled composite resin and acrylic resinartificial teeth when opposed todifferent antagonists. Eur. J. Oral Sci. 2008, 116, 585–592. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Elnaml, A.; Shazly, M.; El-Sayed Seleman, M.M. The effect of top surface lubrication on the friction stir welding of polycarbonate sheets. Int. Polym. Process. 2021, 36, 94–102. [Google Scholar] [CrossRef]

- Shazly, M.; Ahmed, M.M.Z.; El-Raey, M. Friction stir welding of polycarbonate sheets. In Characterization of Minerals, Metals, and Materials; TMS Annual Meeting; Carpenter, J.S., Bai, C., Hwan, -Y.J., Ikhmayies, S., Li, B., Monteiro, S.N., Peng, Z., Zhang, M., Eds.; Wiley: Hoboken, NJ, USA, 2014; ISBN 9781118887868. [Google Scholar]

- Wang, S.; Gao, H.; Li, J.; Wang, Y.; Chen, C.; Yu, X.; Tang, S.; Zhao, X.; Sun, G.; Li, D. Comparative study of the photoluminescence performance and photocatalytic activity of CeO2/MgAl2O4 composite materials with an n-n heterojunction prepared by one-step synthesis and two-step synthesis methods. J. Phys. Chem. Solids 2021, 150, 109891. [Google Scholar] [CrossRef]

- Parish, C.M.; Brewer, L.N. Multivariate statistics applications in phase analysis of STEM-EDS spectrum images. Ultramicroscopy 2010, 110, 134–143. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.A.; Ebrahim, M.I. Effect of zirconium oxide nano-fillers addition on the flexural strength, fracture toughness, and hardness of heat-polymerized acrylic resin. World J. Nano Sci. Eng. 2014, 4, 50–57. [Google Scholar] [CrossRef] [Green Version]

- Chaijareenont, P.; Takahashi, H.; Nishiyama, N.; Arksornnukit, M. Effect of different amounts of 3-methacryloxypropyltrimethoxysilane on the flexural properties and wear resistance of alumina reinforced PMMA. Dent. Mater. J. 2012, 31, 623–628. [Google Scholar] [CrossRef] [Green Version]

- Esquivel, J.; Lawson, N.C.; Kee, E.; Bruggers, K.; Blatz, M.B. Wear of resin teeth opposing zirconia. J. Prosthet. Dent. 2020, 124, 488–493. [Google Scholar] [CrossRef]

- Chladek, G.; Pakieła, K.; Pakieła, W.; Zmudzki, J.; Adamiak, M.; Krawczyk, C. Effect of antibacterial silver-releasing filler on the physicochemical properties of poly(methyl methacrylate) denture base material. Materials 2019, 12, 4146. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benli, M.; Eker, B.; Yusuf, G.; Bilge, K.; Rohlig, G.; Evlioğlu, G.; Huck, O. Surface roughness and wear behavior of occlusal splint materials made of contemporary and high-performance polymers. Odontology 2020, 108, 240–250. [Google Scholar] [CrossRef]

- Nayyer, M.; Zahid, S.; Hassan, S.H.; Mian, S.A.; Mehmood, S.; Khan, H.A.; Kaleem, M.; Zafar, M.S.; Khan, A.S. Comparative abrasive wear resistance and surface analysis of dental resin-based materials. Eur. J. Dent. 2018, 12, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Matzinger, M.; Hahnel, S.; Preis, V.; Rosentritt, M. Polishing effects and wear performance of chairside CAD/CAM materials. Clin. Oral Investig. 2019, 23, 725–727. [Google Scholar] [CrossRef]

- Preis, V.; Behr, M.; Handel, G.; Schneider-Feyrer, S.; Hahnel, S.; Martin, R. Wear performance of dental ceramics after grind- ing and polishing treatments. J. Mech. Behav. Biomed. Mater. 2012, 10, 13–22. [Google Scholar] [CrossRef]

- Heintze, S.; Zellweger, G.; Cavalleri, A.; Ferracane, J. Influence of the antagonist material on the wear of different composites using two different wear simulation methods. Dent. Mater. 2006, 22, 166–175. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Tamimi, K.M.; Bayoumi, D.A.; Ahmed, M.M.Z.; Albaijan, I.; El-Sayed, M.E. The Effect of Salinized Nano ZrO2 Particles on the Microstructure, Hardness, and Wear Behavior of Acrylic Denture Tooth Nanocomposite. Polymers 2022, 14, 302. https://doi.org/10.3390/polym14020302

El-Tamimi KM, Bayoumi DA, Ahmed MMZ, Albaijan I, El-Sayed ME. The Effect of Salinized Nano ZrO2 Particles on the Microstructure, Hardness, and Wear Behavior of Acrylic Denture Tooth Nanocomposite. Polymers. 2022; 14(2):302. https://doi.org/10.3390/polym14020302

Chicago/Turabian StyleEl-Tamimi, Kawkb M., Dalia A. Bayoumi, Mohamed M. Z. Ahmed, Ibrahim Albaijan, and Mohammed E. El-Sayed. 2022. "The Effect of Salinized Nano ZrO2 Particles on the Microstructure, Hardness, and Wear Behavior of Acrylic Denture Tooth Nanocomposite" Polymers 14, no. 2: 302. https://doi.org/10.3390/polym14020302

APA StyleEl-Tamimi, K. M., Bayoumi, D. A., Ahmed, M. M. Z., Albaijan, I., & El-Sayed, M. E. (2022). The Effect of Salinized Nano ZrO2 Particles on the Microstructure, Hardness, and Wear Behavior of Acrylic Denture Tooth Nanocomposite. Polymers, 14(2), 302. https://doi.org/10.3390/polym14020302