Rupture of an Industrial GFRP Composite Mitered Elbow Pipe

Abstract

1. Introduction

2. Background

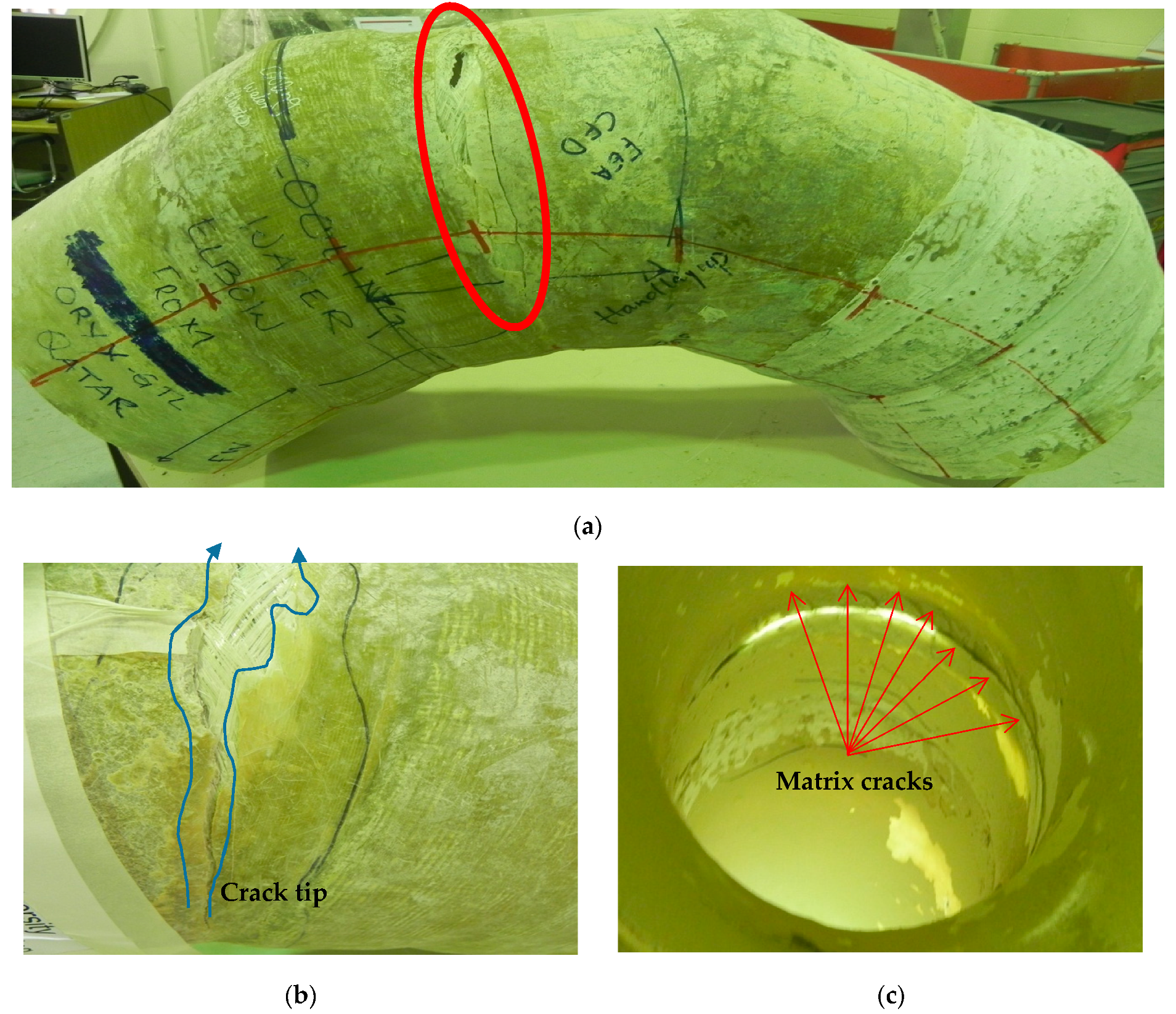

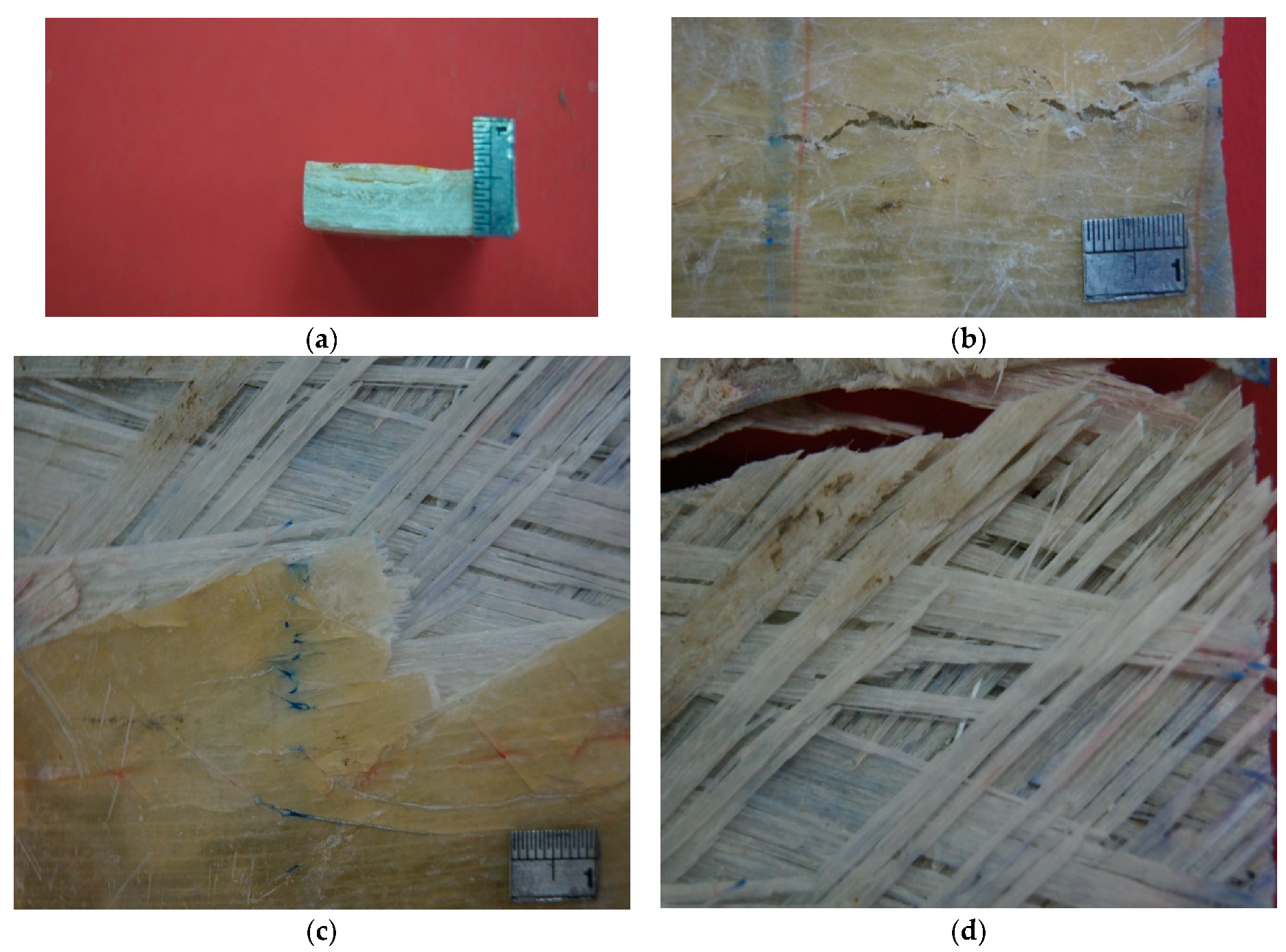

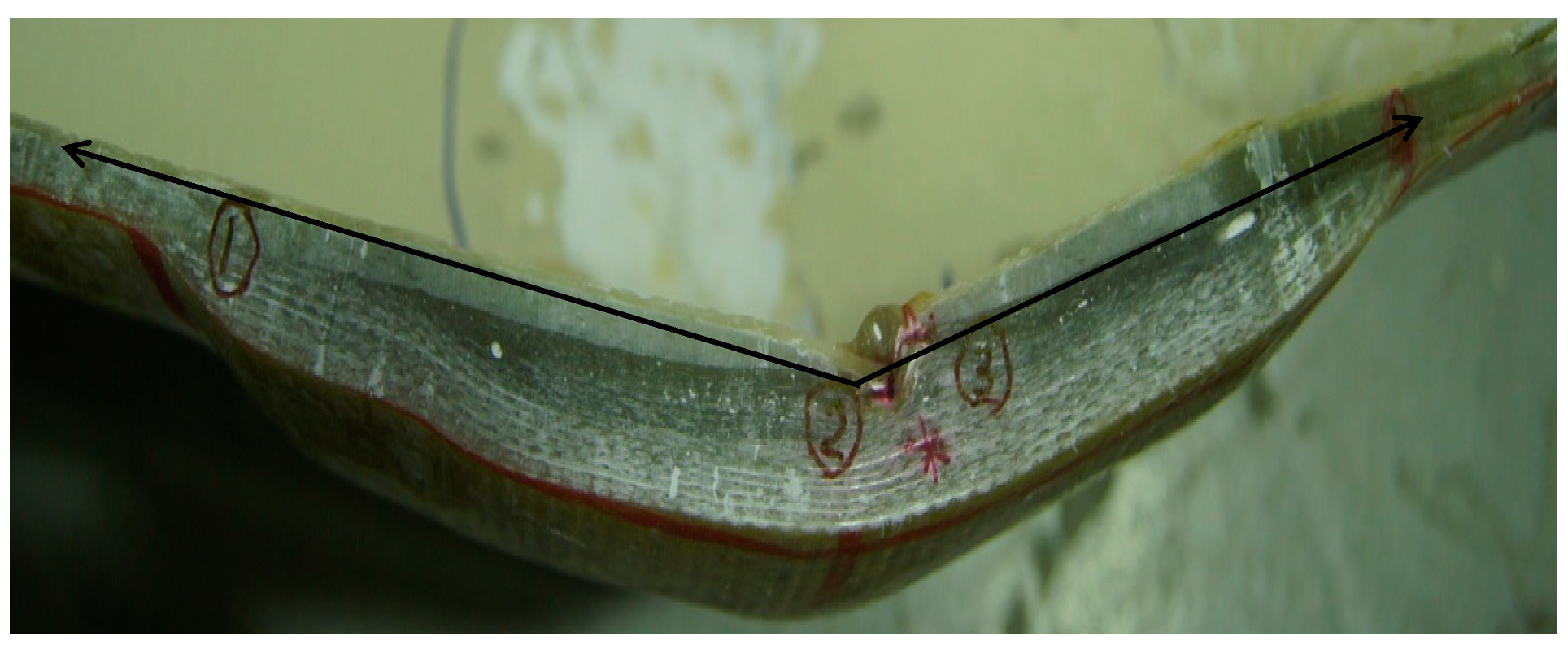

3. Initial Inspection

4. Chemical Analyses

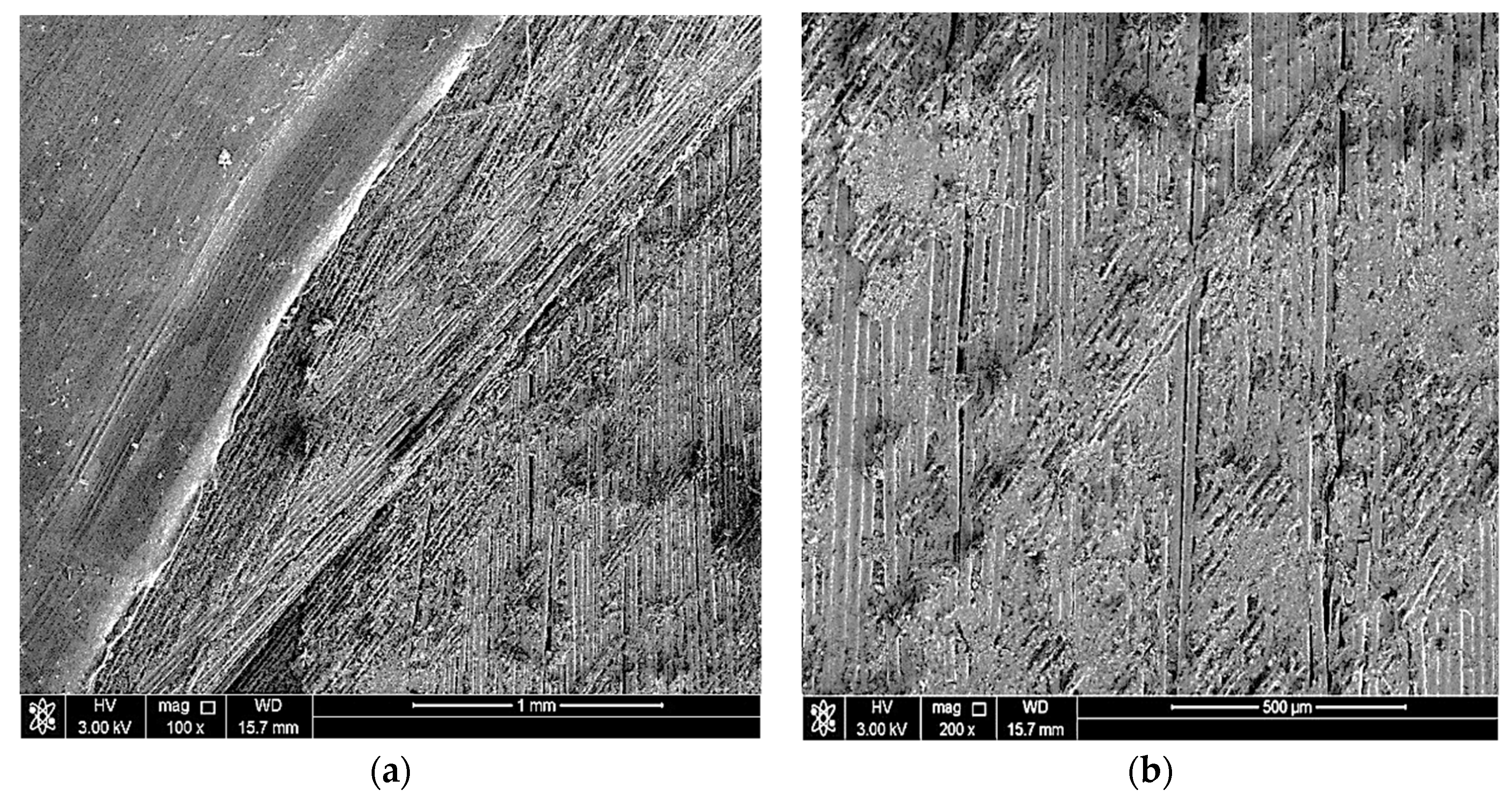

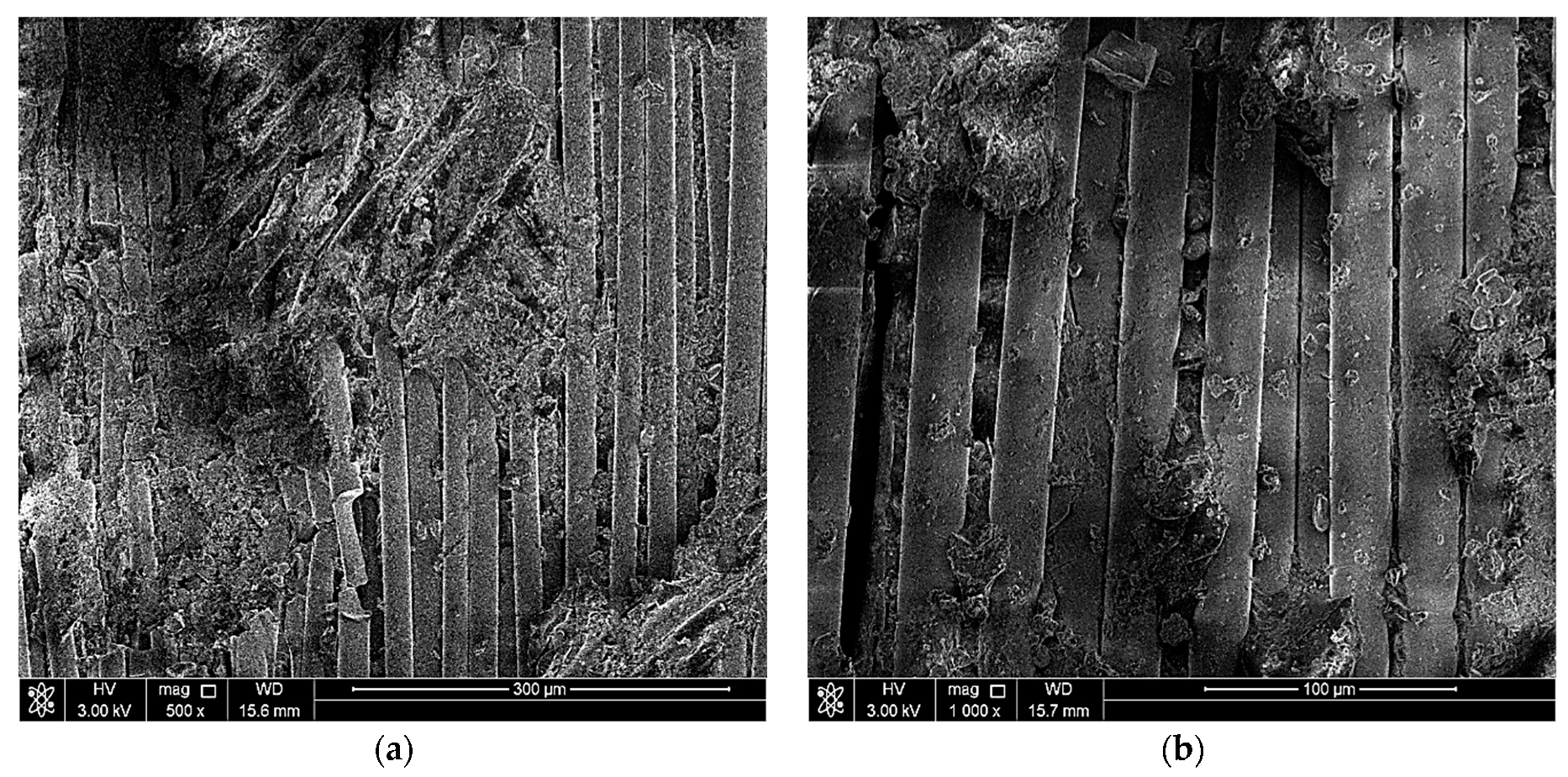

5. Sem Examination

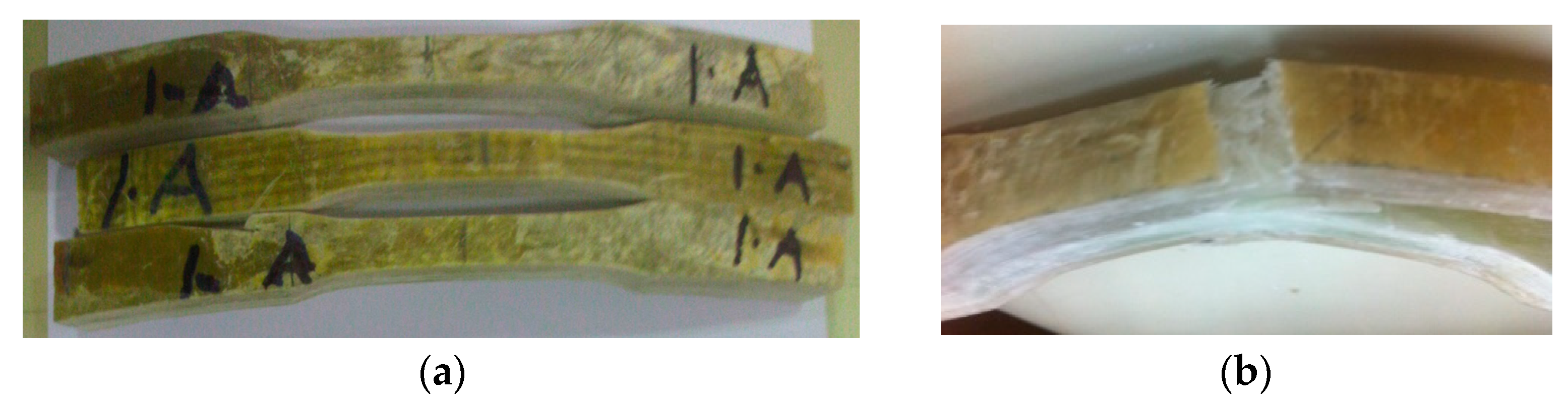

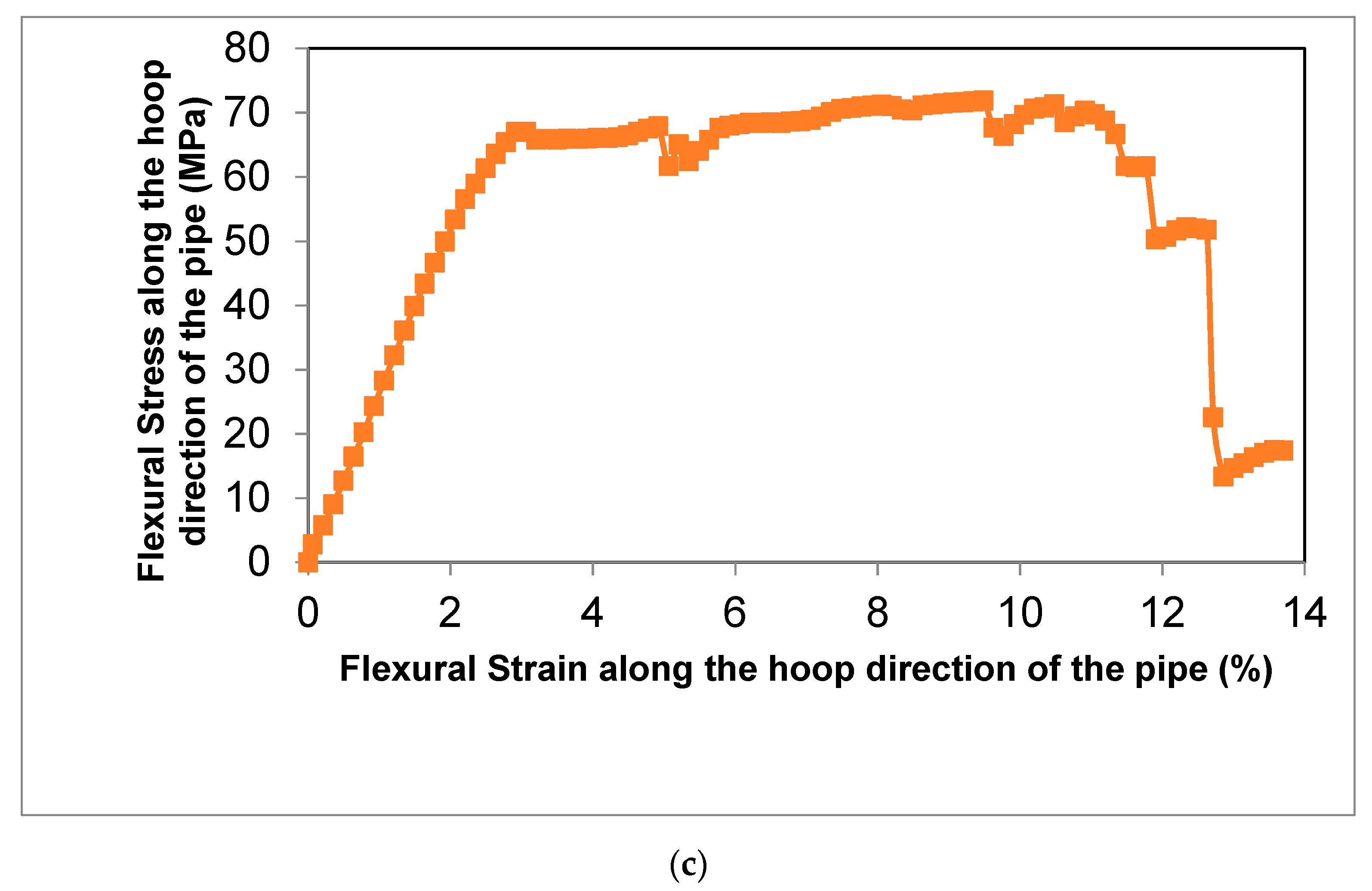

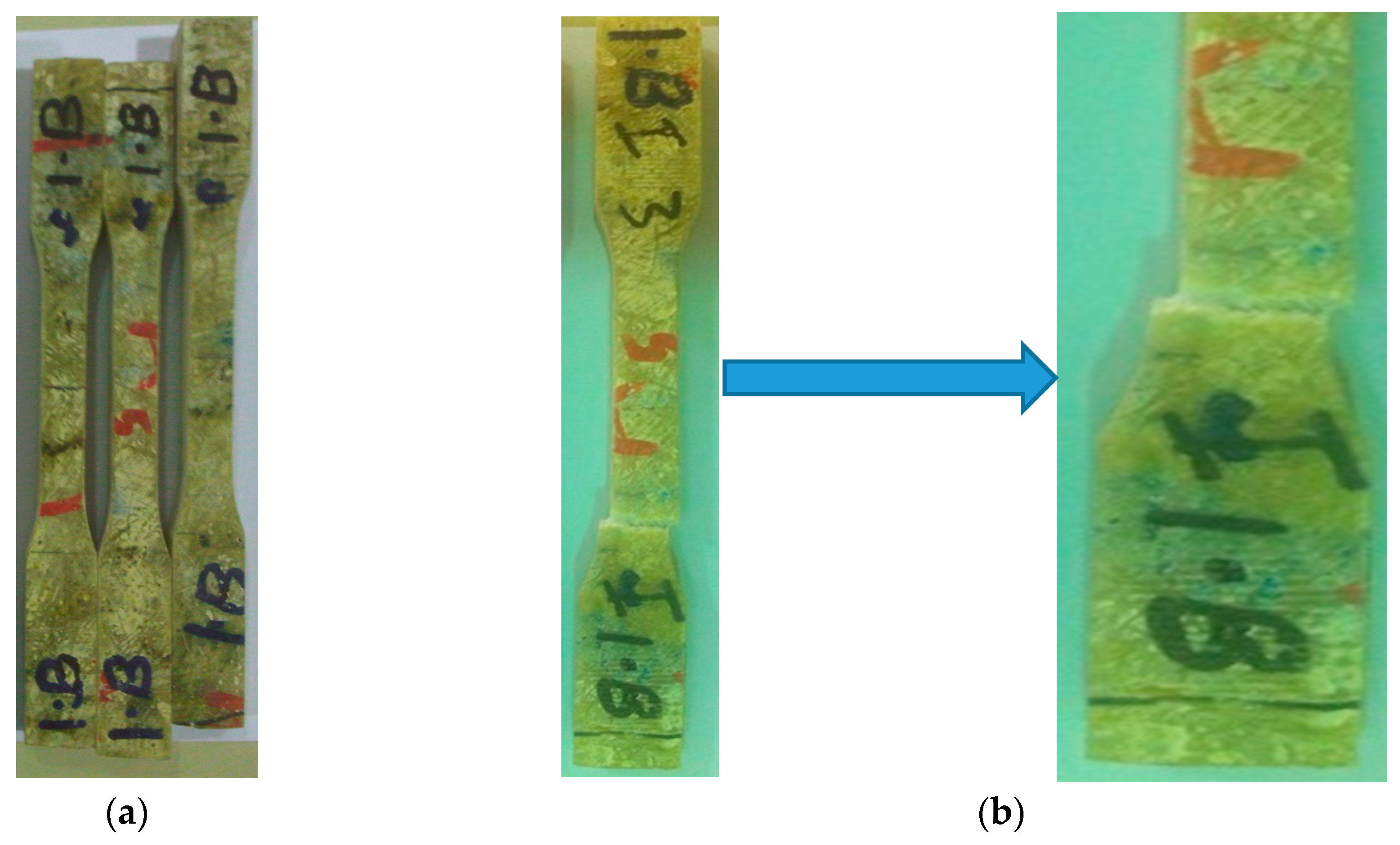

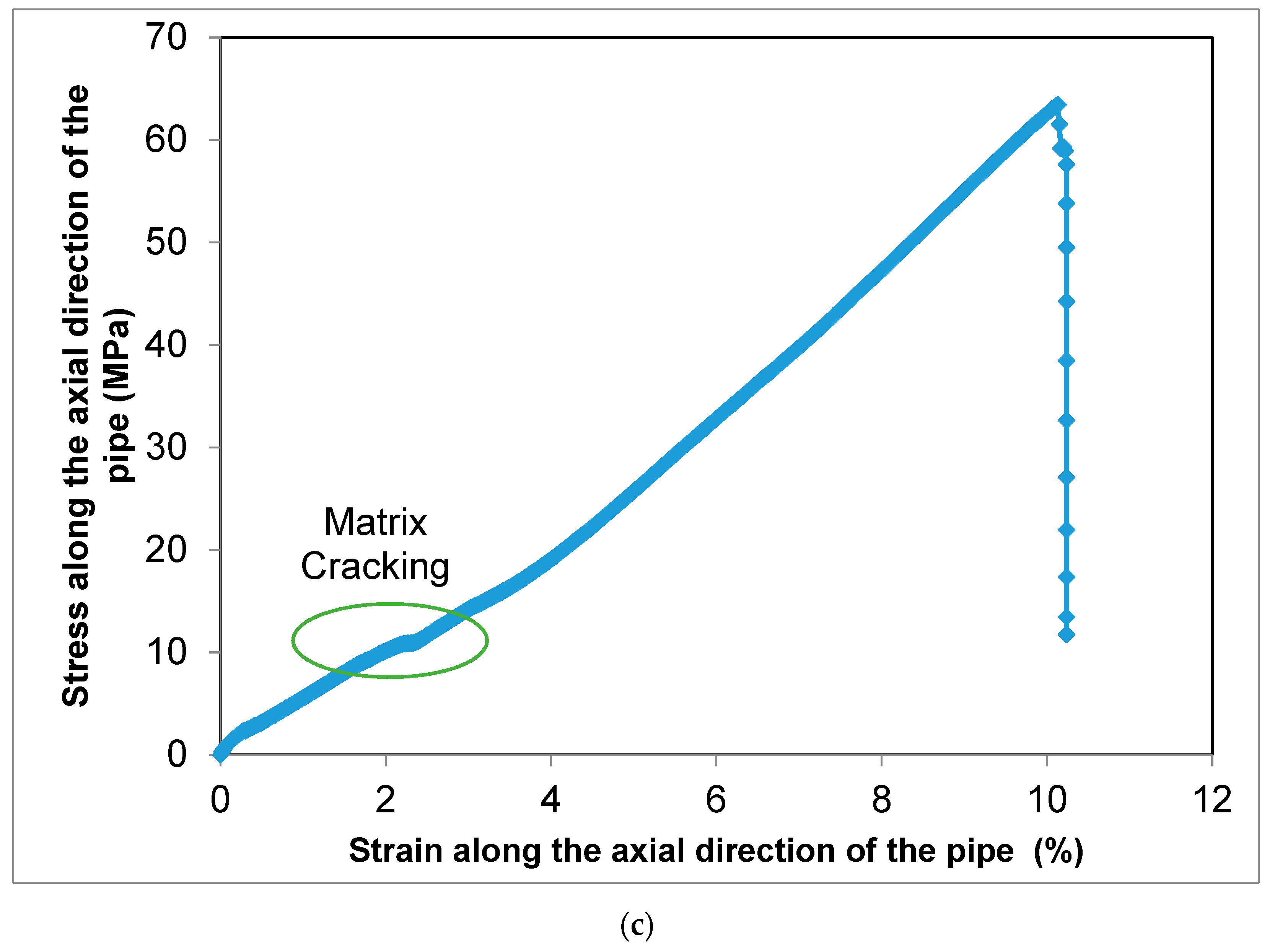

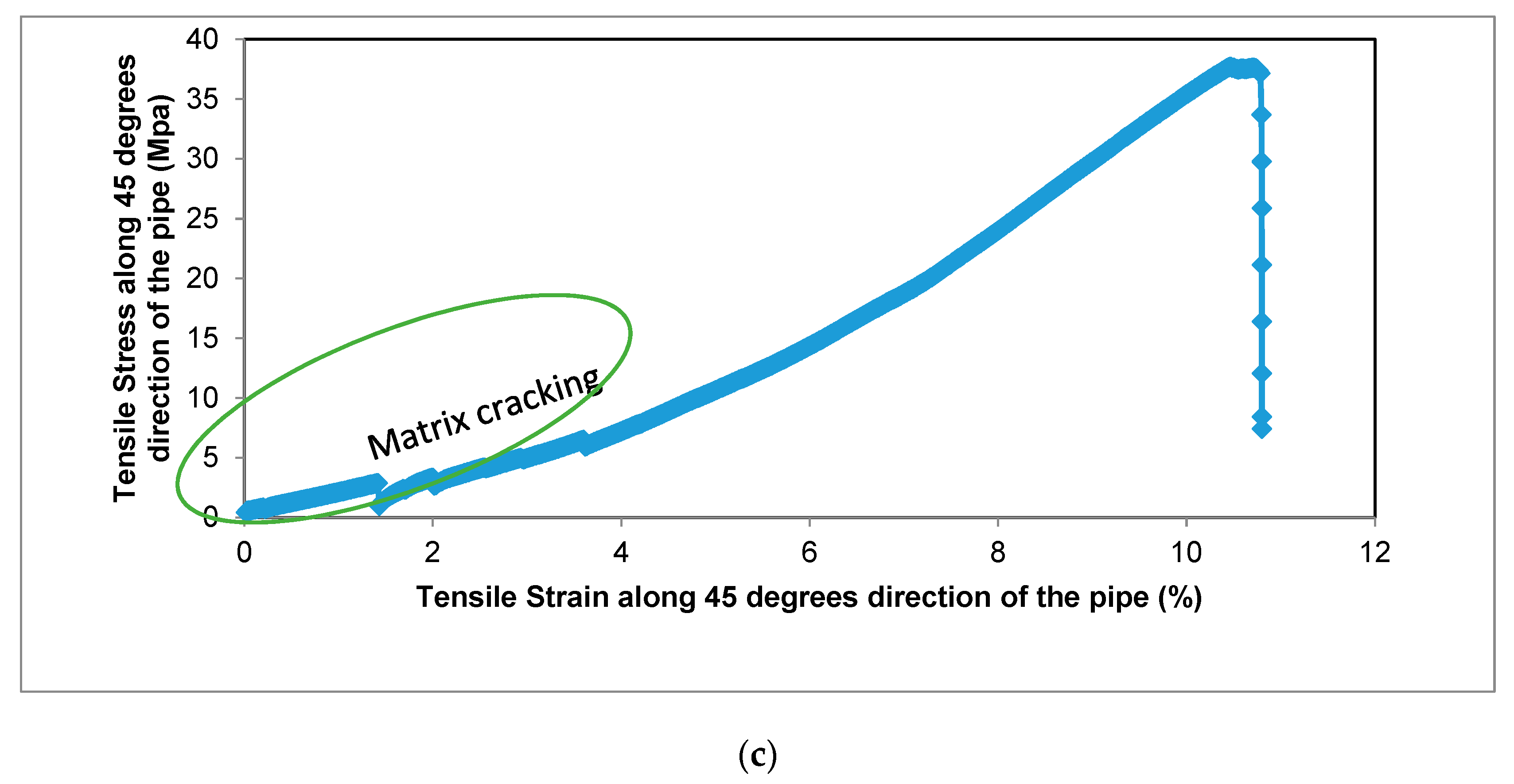

6. Mechanical Testing

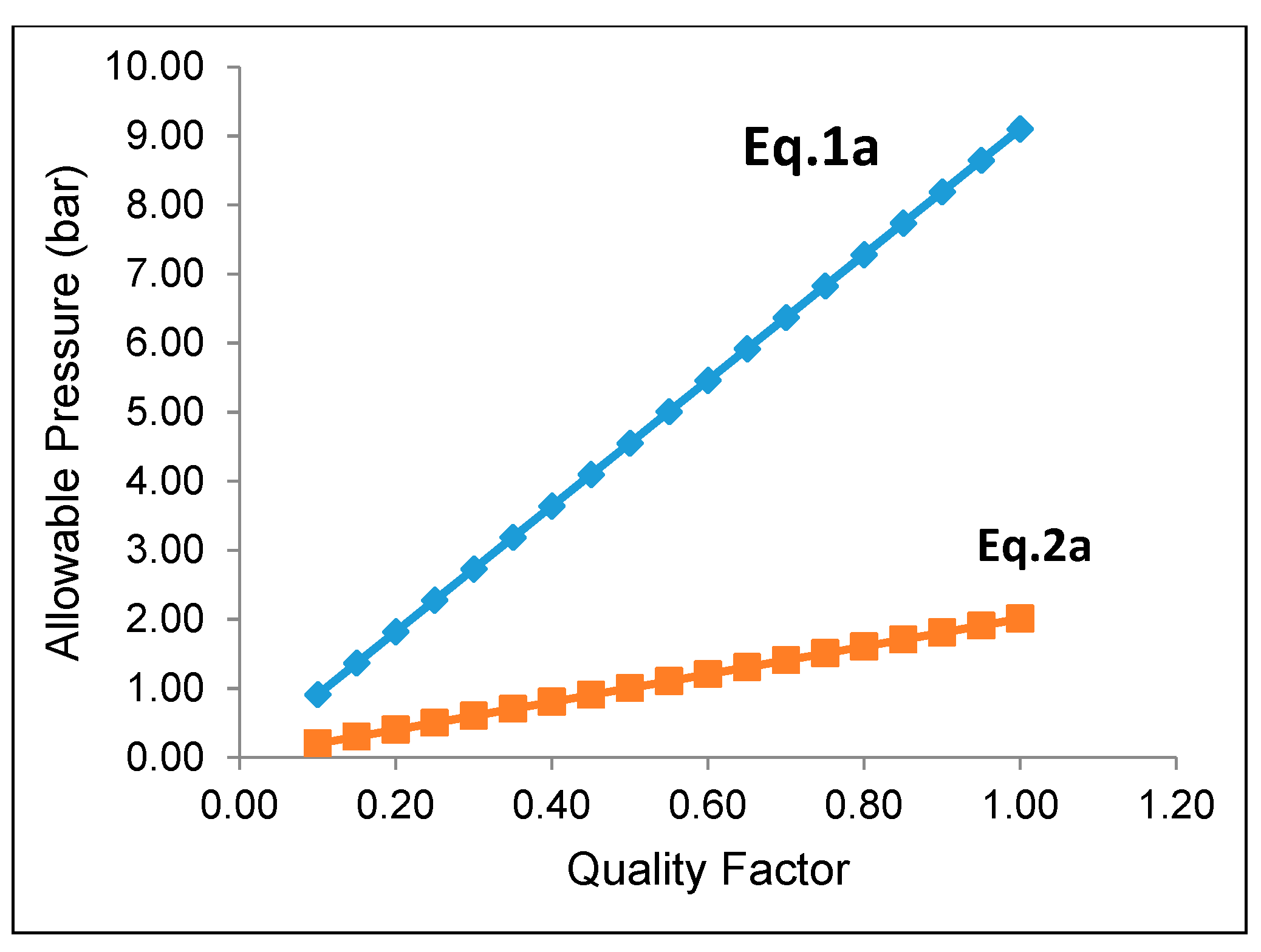

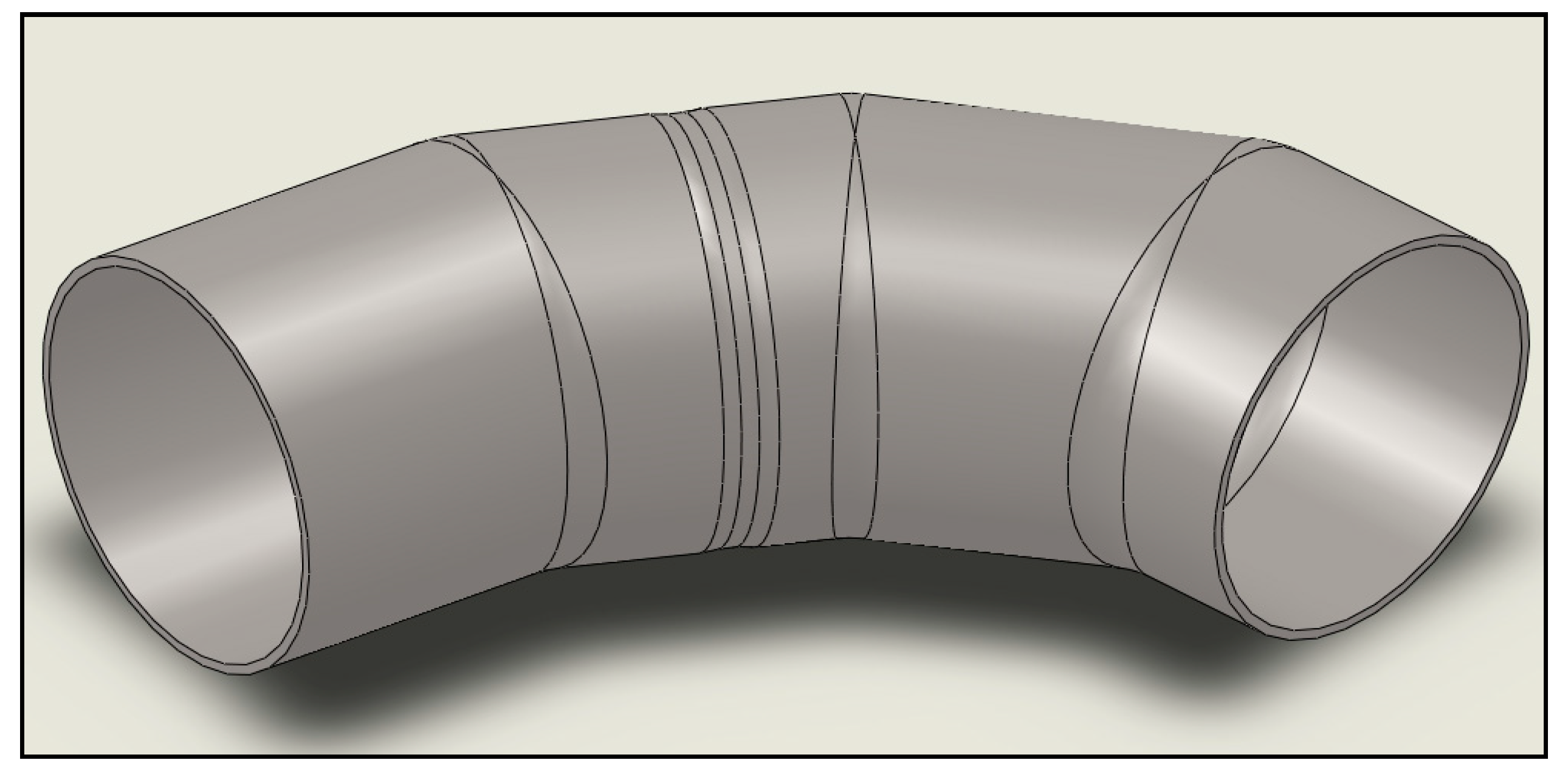

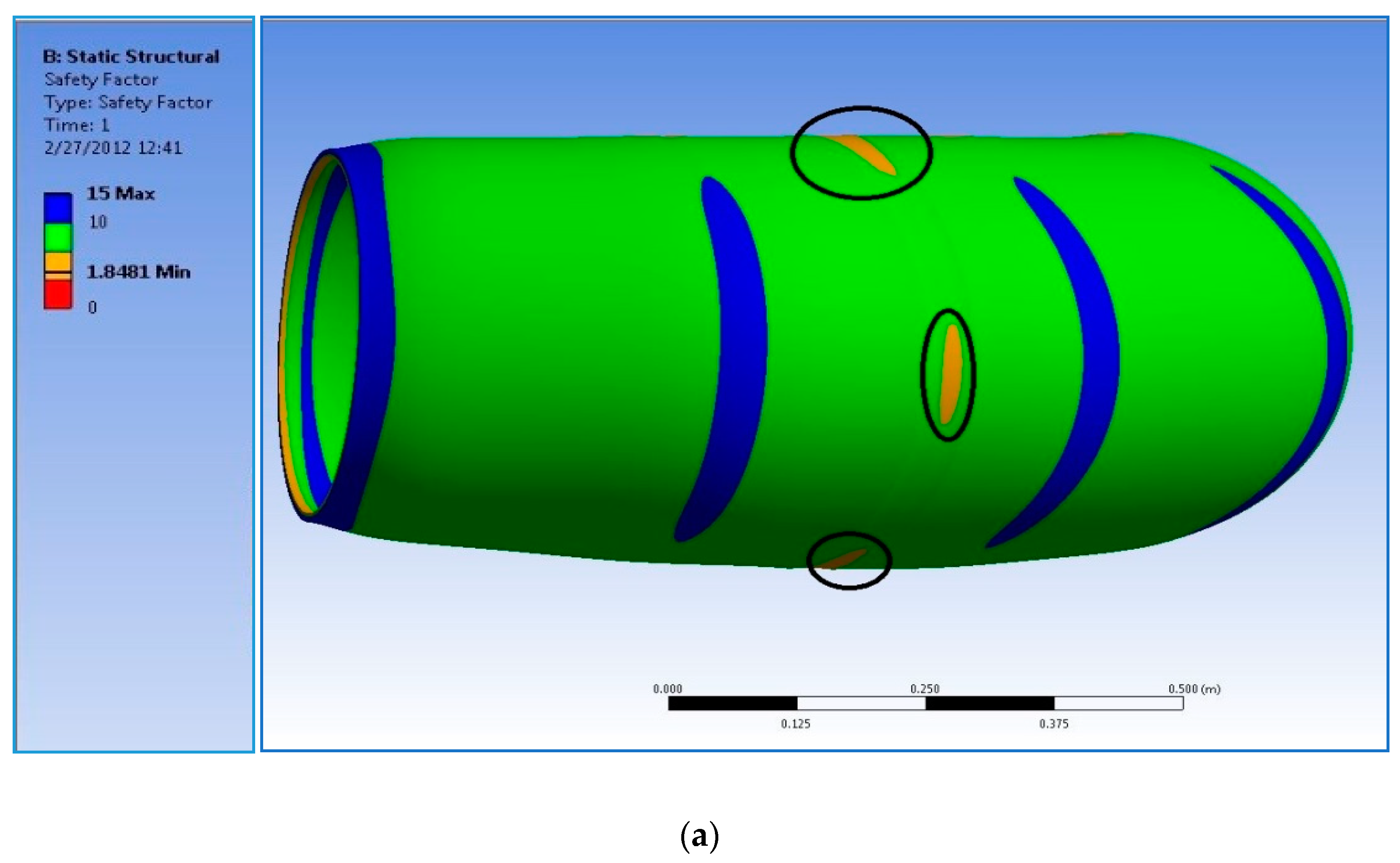

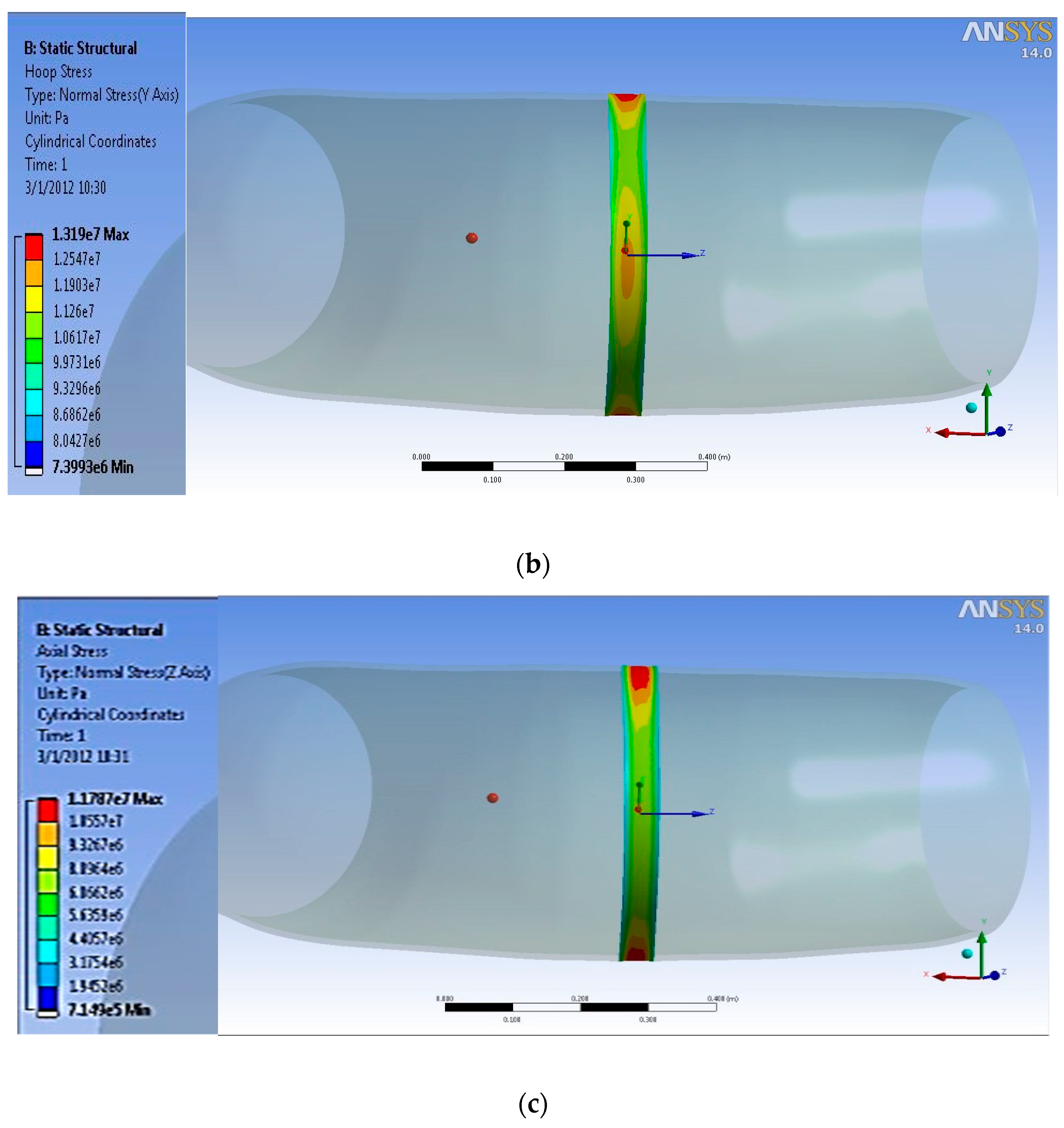

7. Analytical Analysis

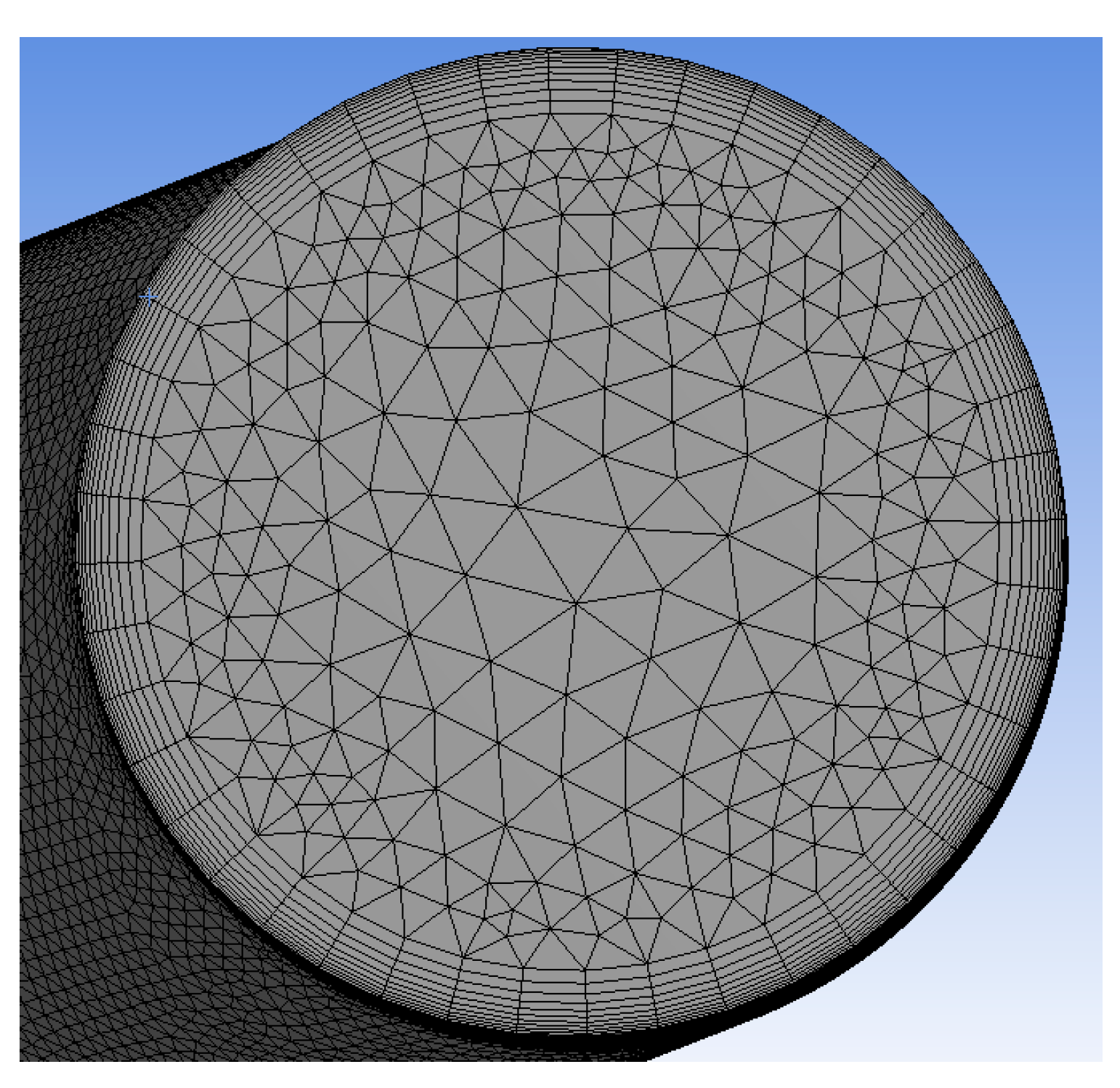

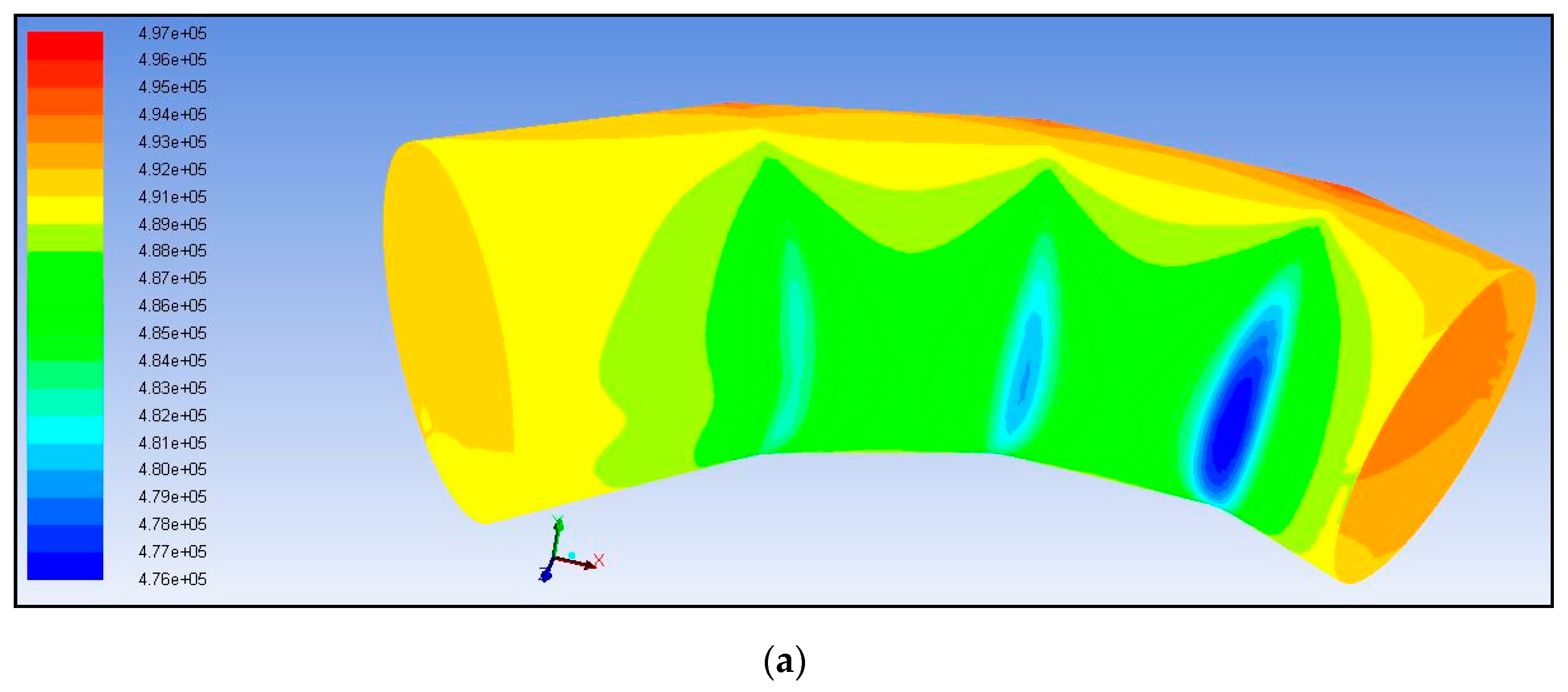

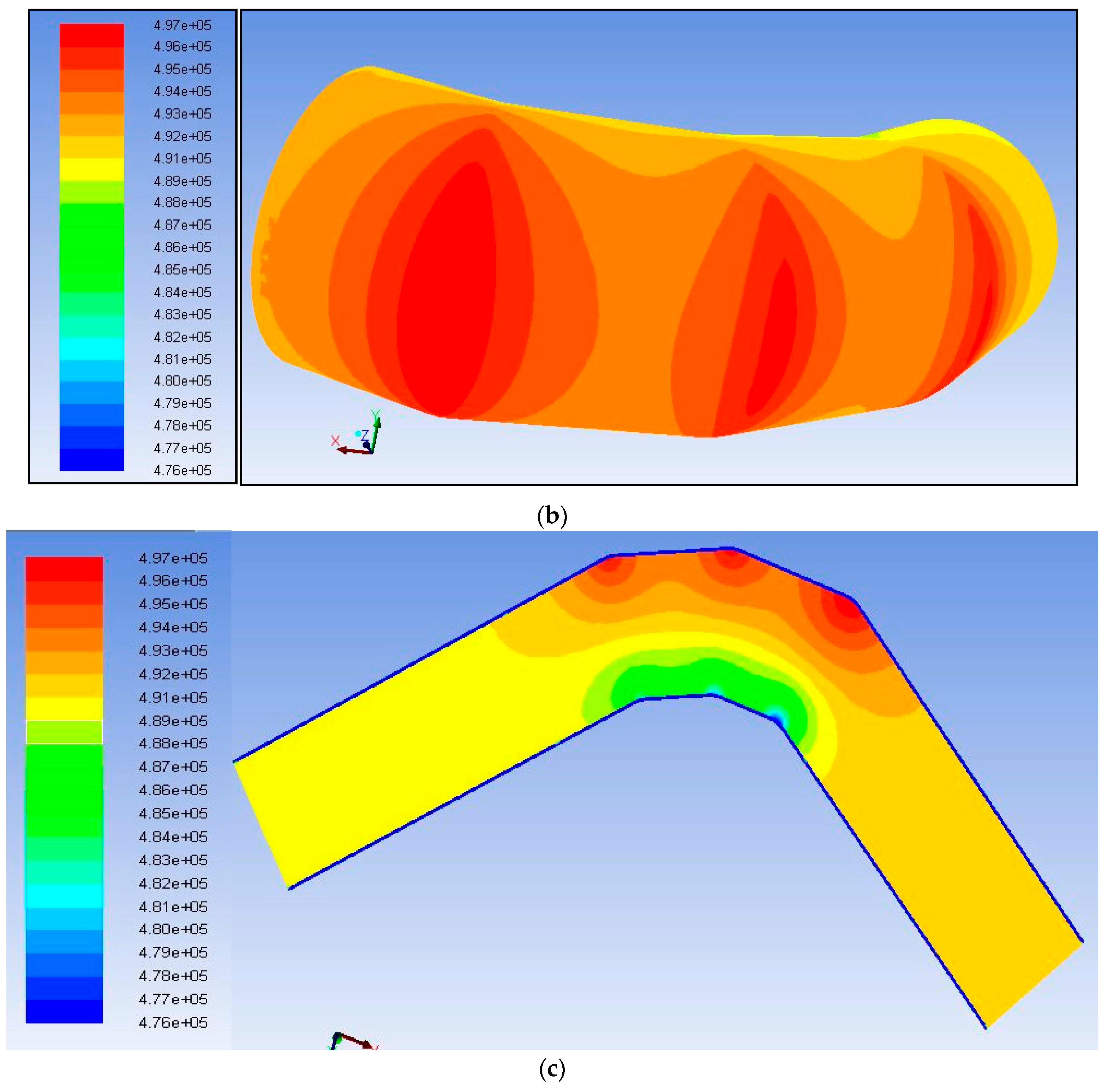

8. Numerical Analyses

- Variable-flowing water continuously eroded and debonded the matrix from the fibers at the innermost layer.

- The combined effect of fiber–matrix debonding and impact accelerated matrix removal at the innermost layer, which initiated the crack.

- As pressure fluctuated inside the elbow pipe, the initial cracks in the weakest location started to grow until they reached the outer surface, which resulted in the rupture of the pipeline at the elbow pipe location.

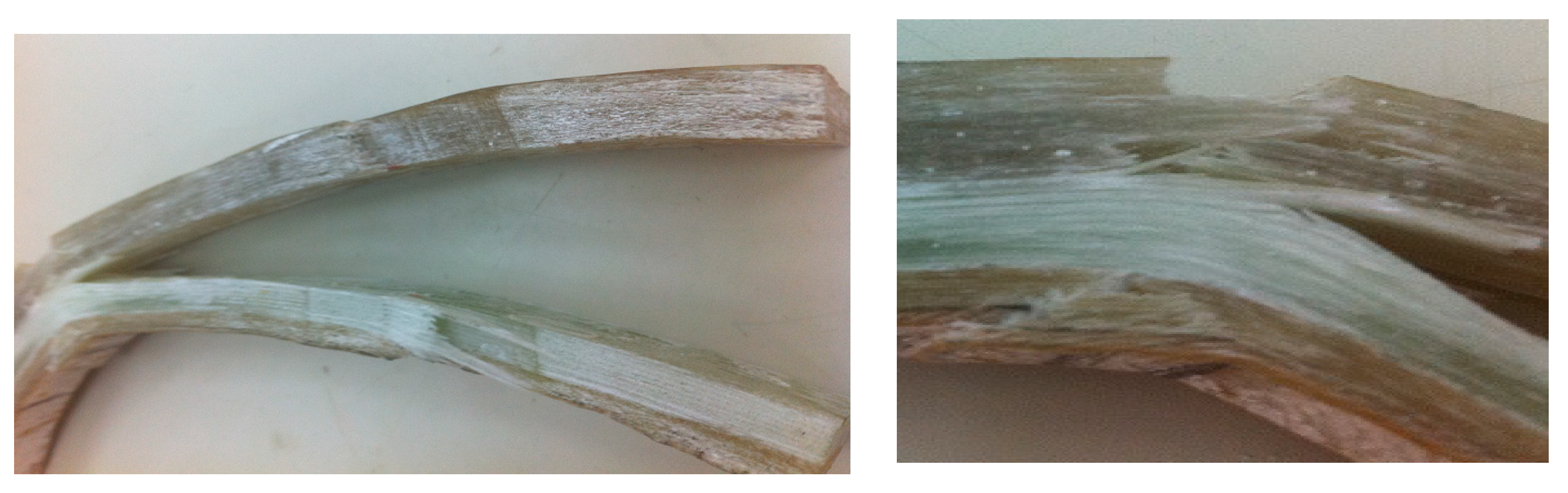

9. Discussion

10. Conclusions

- The elbow-joint was not correctly designed and was carelessly and poorly manufactured.

- The fiber reinforcement was E-glass and S-glass, provided by the material datasheet.

- The fiber–matrix interface was poor.

- Irregular thickness: the joints between the straight pipe sections received a more significant amount of reinforcement. This increase in thickness caused the areas of lesser thickness to become inherent weak spots.

- Although the investigated GFRP elbow is not proper, the manufacturer’s specification indicates a minimum allowable thickness of 5.3 mm on the straight pipe. While this may be adequate for straight pipe sections, it is not enough to resist the elbow’s stress intensification.

- It is recommended that sections with a thickness of less than 15 mm be reinforced using overwrapped composites. During the remedy process, enough tension must be applied to the overwrapped composites to achieve a better wetting of fibers by the resin. It is well-known that high fiber tension levels in the fiber-reinforced pipes increase the load-carrying capacity and the stiffness of composite pipes.

- For future installations, it is recommended that the fabrication process is controlled to ensure adherence to standards relating to the glass/resin ratio and proper layup process. The use of ±45° fiber orientation does not provide adequate axial reinforcement.

- The use of multiple layers of chopped strand mat glass fiber would result in a component more suitable to withstand the applied loads for the elbow’s design life.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Abtah, F.; Mahdi, E.; Gowid, S. The use of composite to eliminate the effect of welding on the bending behavior of metallic pipes. Compos. Struct. 2020, 235, 111793. [Google Scholar] [CrossRef]

- Gowid, S.; Mahdi, E.; Al-Abtah, F. Modeling and optimization of the crushing behavior and energy absorption of plain weave composite hexagonal quadruple ring systems using artificial neural network. Compos. Struct. 2019, 229, 1114793. [Google Scholar] [CrossRef]

- Gowid, S.; Mahdi, E.; Renno, J.; Sassi, S.; Kharmanda, G.; Shokry, A. Experimental investigation of the crashworthiness performance of fiber and fiber steel-reinforced composites tubes. Compos. Struct. 2020, 251, 112655. [Google Scholar] [CrossRef]

- Swihart, J.J. Fiberglass Pipe Literature Review; Department of the Interior, Bureau of Reclamation, PO Box 25007, Denver CO 80225-0007: Research and Development Office: Denver, CO, USA, 2016.

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, Y.; Wang, Y.; Jiang, G.; Liang, M.; Chen, X.; Long, G. A fractal model for kozeny–Carman constant and dimensionless permeability of fibrous porous media with roughened surfaces. Fractals 2019, 27, 1950116. [Google Scholar] [CrossRef]

- Mahdi, E.; Farag, M.H. New approach of pipelines joining using fiber reinforced plastics composites. Compos. Struct. 2019, 228, 111341. [Google Scholar]

- Qiao, T.; Zhang, G.; Xu, Y.; Zhang, B. Fabrication and finite element analysis of composite elbows. Materials 2019, 12, 3778. [Google Scholar] [CrossRef]

- Woldemariam, M.H.; Belingardi, G.; Koricho, E.G.; Reda, D.T. Effects of nanomaterials and particles on mechanical properties and fracture toughness of composite materials: A short review. AIMS Mater. Sci. 2019, 6, 1191–1212. [Google Scholar] [CrossRef]

- Vlaskina, S.I.; Kruchinin, S.P.; Kuznetsova, E.Y.; Rodionov, V.E.; Mishinova, G.N.; Svechnikov, G.S. Nanostructures in silicon carbide crystals and films. Int. J. Mod. Phys. B 2016, 30, 1642019. [Google Scholar] [CrossRef]

- Laban, O.; Gowid, S.; Mahdi, E.; Musharavati, F. Experimental investigation and artificial intelligence-based modeling of the residual impact damage effect on the crashworthiness of braided carbon/kevlar tubes. Compos. Struct. 2020, 243, 112247. [Google Scholar] [CrossRef]

- Reid, S.R.; Zhou, G. Impact Behavior of Fibre-Reinforced Composite Materials and Structures; Woodhead Publishing Ltd. and CRC Press LLC: Cambridge, UK, 2000. [Google Scholar]

- Taktak, R.; Guermazi, N.; Kallel, T.K. Effect of E-Glass fiber and ply orientation on the mechanical behavior of FRP composites used for pressure pipe. Int. J. Adv. Manuf. Technol. 2017, 92, 1741–1749. [Google Scholar] [CrossRef]

- Toh, W.; Tan, L.B.; Tse, K.M.; Giam, A.; Raju, K.; Lee, H.P.; Tan VB, C. Material characterization of filament-wound composite pipe. Compos. Struct. 2018, 206, 474–483. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; Rohem NR, F.; Sampaio, E.M.; de Barros, S. Failure pressure analysis of composite repair system for wall loss defect of metallic pipelines. Compos. Struct. 2017, 176, 1013–1019. [Google Scholar] [CrossRef]

- Altenbach, H.; Sadowski, T. Failure and Damage Analysis of Advanced Materials; Springer-Verlag Wien: New York, NY, USA, 2015; ISBN 978-3-7091-1835-1. [Google Scholar]

- Kar, R.J. Composite Failure Analysis Handbook; Department of Transportation: Hawthorne, CA, USA, 1977.

- Das, R.; Baishya, N. Failure analysis of bonded composite pipe joints subjected to internal pressure and axial loadin. Procedia Eng. 2016, 144, 1047–1054. [Google Scholar] [CrossRef]

- Chakraverty, A.P.; Dash, S.; Maharana, H.S.; Beura, S.; Mohanty, U.K. A novel investigation on durability of GRE composite pipe for prolonged sea water transportation. Compos. Commun. 2020, 17, 42–50. [Google Scholar] [CrossRef]

- Silva, N.S.; Netto, T.A.; Bastian, F.L.; Silva RA, F. On the effect of the ply stacking sequence on the failure of composite pipes under external pressure. Mar. Struct. 2020, 70, 102658. [Google Scholar] [CrossRef]

- Affolter, C.; Barbezat, M.; Piskoty, G.; Neuner, O.; Terrasi, G. Failure of a sag water pipe triggered by aging of the GFRP composite relining. Eng. Fail. Anal. 2018, 84, 358–370. [Google Scholar] [CrossRef]

- Rafiee, R.; Sharifi, P. Stochastic failure analysis of composite pipes subjected to random excitation. Constr. Build. Mater. 2019, 224, 950–961. [Google Scholar] [CrossRef]

- Chang, F.K.; Springer, G.S. The strengths of fiber-reinforced composite bends. J. Compos. Mater. 1986, 20, 30–45. [Google Scholar] [CrossRef]

- Abdelouahed, E.; Mokhtari, M.; Benzaama, H. Finite element analysis of the thermo-mechanical behavior of composite pipe elbows under bending and pressure loading. Frat. Integrità Strutt. 2019, 13, 698–713. [Google Scholar] [CrossRef]

- Sebaey, T.; Mahdi, E. Using thin-plies to improve the damage resistance and tolerance of aeronautical CFRP composites. Compos. Part A Appl. Sci. Manuf. 2016, 86, 31–38. [Google Scholar] [CrossRef]

- Ebrahimi, H.; Mahdi, E.; Hashemi, H.; Vaziri, A. Honeycomb sandwich panels subjected to combined shock and projectile impact. Int. J. Impact Eng. 2016, 95, 1–11. [Google Scholar] [CrossRef]

- Mahdi, E.; Sebaey, T. Crushing behavior of hybrid hexagonal/octagonal cellular composite system: Aramid/carbon hybrid composite. Mater. Des. 2014, 63, 6–13. [Google Scholar] [CrossRef]

- Risby, M.S.; Wong, S.V.; Hamouda AM, S.; Khairul, A.R.; Elsadig, M. Ballistic performance of coconut shell powder/twaron fabricagainst non-armour piercing projectiles. Def. Sci. J. 2008, 58, 248–255. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, H.; Zu, L. Design of filament-wound composite elbows based on non-geodesic trajectories. Compos. Struct. 2018, 189, 635–640. [Google Scholar] [CrossRef]

- Mahdi, E.; Ochoa DR, H.; Vaziri, A.; Dean, A.; Kucukvar, M. Khalasa date palm leaf fiber as a potential reinforcement for polymeric composite materials. Compos. Struct. 2021, 256, 11350. [Google Scholar]

- Miller, P.H. Effects of Moisture Absorption and Test Method on the Properties of E-glass/Polyester Hull Laminates. J. Compos. Mater. 2002, 36, 1065. [Google Scholar] [CrossRef]

- Mahdi, E.; Hernández, D.R.; Eltai, E.O. Effect of water absorption on the mechanical properties of long date palm leaf fiber reinforced epoxy composites. J. Biobased Mater. Bioenergy 2015, 9, 173–181. [Google Scholar] [CrossRef]

- Chung, D.D.L. Composite Materials, Science and Applications; British Library: London, UK, 2010. [Google Scholar]

- Rafiee, R.; Torabi, M.; Maleki, S. Investigating structural failure of a filament-wound composite tube subjected to internal pressure: Experimental and theoretical evaluation. Polym. Test. 2018, 67, 322–330. [Google Scholar] [CrossRef]

| General Information | ||

|---|---|---|

| Component Type | S Glass reinforced polyester resin matrix | |

| Process Type | Cooling water | |

| Location | 2.5 m underground | |

| Fabrication Process | Hand layup | |

| Service Condition | ||

| Operating condition | Design | Actual |

| Operating Temperature (°C) | 5–60 | 15–36 |

| Operating Pressure (Bar) | 0.5–7 | Up to 5 |

| Service Life (years) | 20 | 6 |

| Mechanical Properties of Polyester resin | ||

| Young modulus (GPa) | 3.45 | |

| Shear modulus (GPa) | 1.30 | |

| Poisson’s ratio | 0.33 | |

| Tensile strength (MPa) | 76.0 | |

| Compressive strength (MPa) | 129.0 | |

| Density (g/cm3) | 2.46 | |

| Element | Actual % (by Weight) | Composition of Glass Fiber Used for Water Transportation | |||

|---|---|---|---|---|---|

| Composite Overwrapped | Straight Pipe | E-Glass | C-Glass | S-Glass | |

| SiO2 | 42.2323 | 22.4456 | 52.4 | 64.4 | 64.4 |

| P2O5 | 3.1143 | NA | NS | NS | NS |

| SO3 | 1.5653 | 5.49190 | NS | NS | NS |

| K2O | 0.9113 | 2.63000 | 0.8 | 9.6 | 0.3 |

| CaO | 48.4849 | 62.2219 | 17.2 | 13.4 | NS |

| TiO2 | 1.4292 | 1.04300 | NS | NS | NS |

| Fe2O3 | 1.0174 | 3.1318 | 14.4 | 4.1 | 25.0 |

| BaO | 0.2268 | NA | NS | 0.9 | NS |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahdi Saad, E.; Gowid, S.; Cabibihan, J.J. Rupture of an Industrial GFRP Composite Mitered Elbow Pipe. Polymers 2021, 13, 1478. https://doi.org/10.3390/polym13091478

Mahdi Saad E, Gowid S, Cabibihan JJ. Rupture of an Industrial GFRP Composite Mitered Elbow Pipe. Polymers. 2021; 13(9):1478. https://doi.org/10.3390/polym13091478

Chicago/Turabian StyleMahdi Saad, Elsadig, Samer Gowid, and John John Cabibihan. 2021. "Rupture of an Industrial GFRP Composite Mitered Elbow Pipe" Polymers 13, no. 9: 1478. https://doi.org/10.3390/polym13091478

APA StyleMahdi Saad, E., Gowid, S., & Cabibihan, J. J. (2021). Rupture of an Industrial GFRP Composite Mitered Elbow Pipe. Polymers, 13(9), 1478. https://doi.org/10.3390/polym13091478