A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials

Abstract

1. Introduction

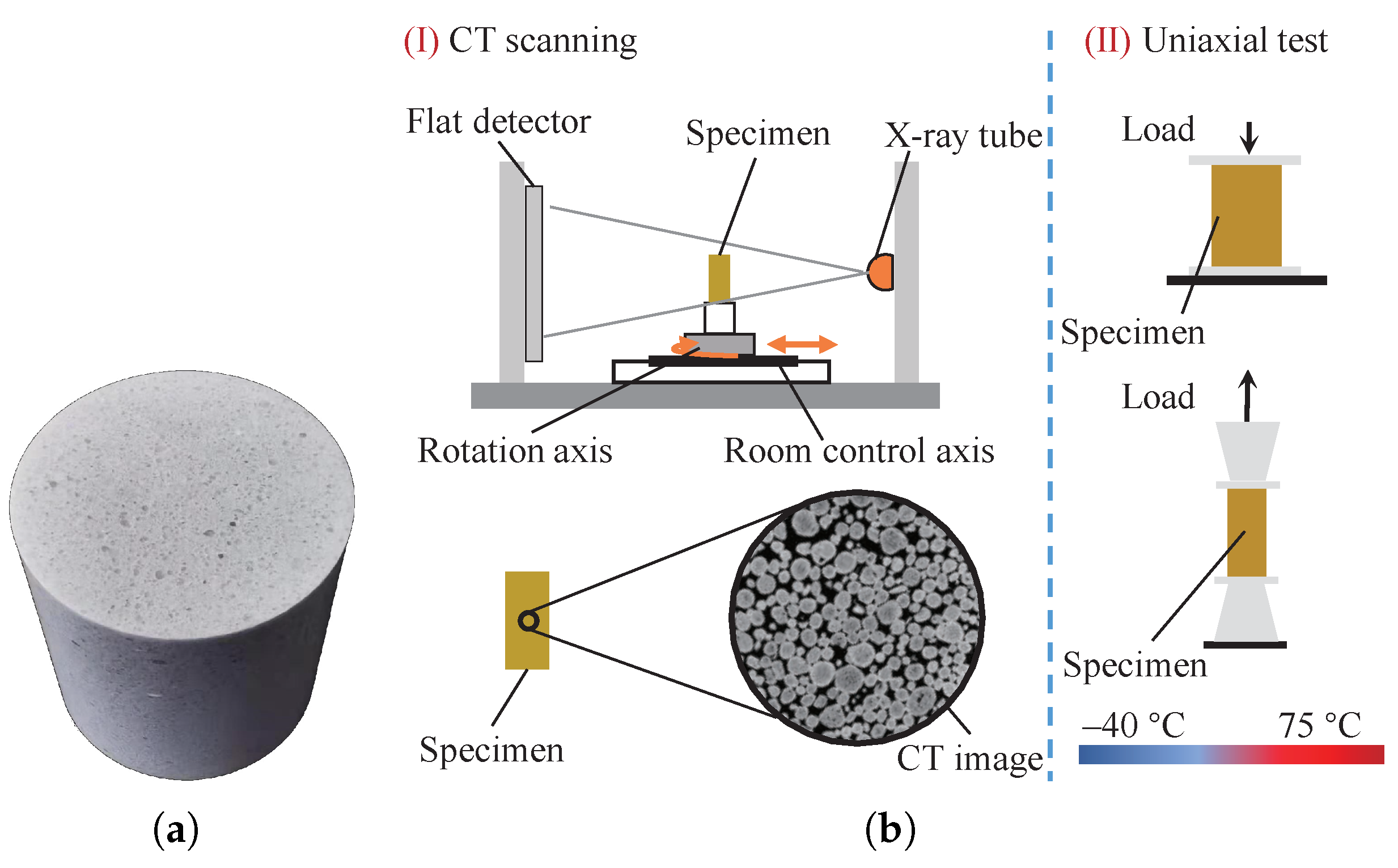

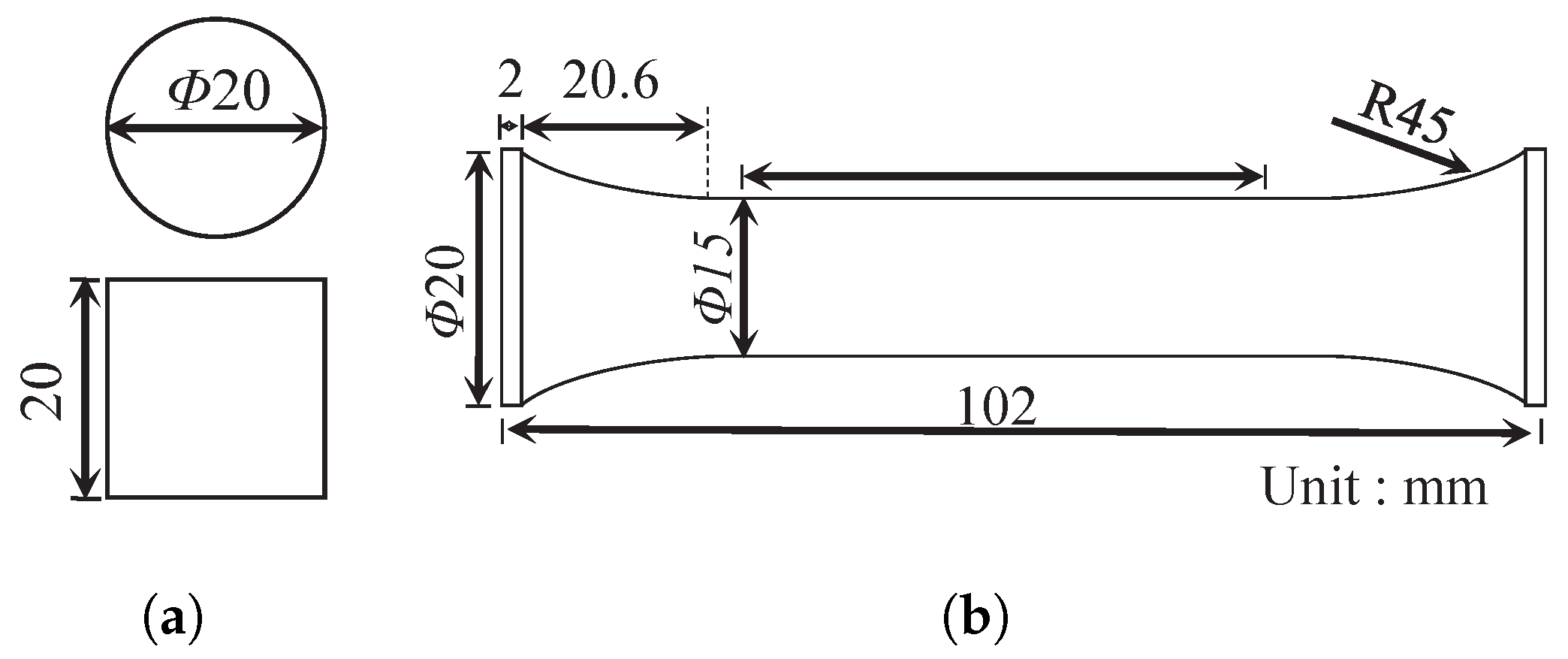

2. Experimental Testing

2.1. Specimens Preparation and Test Conditions

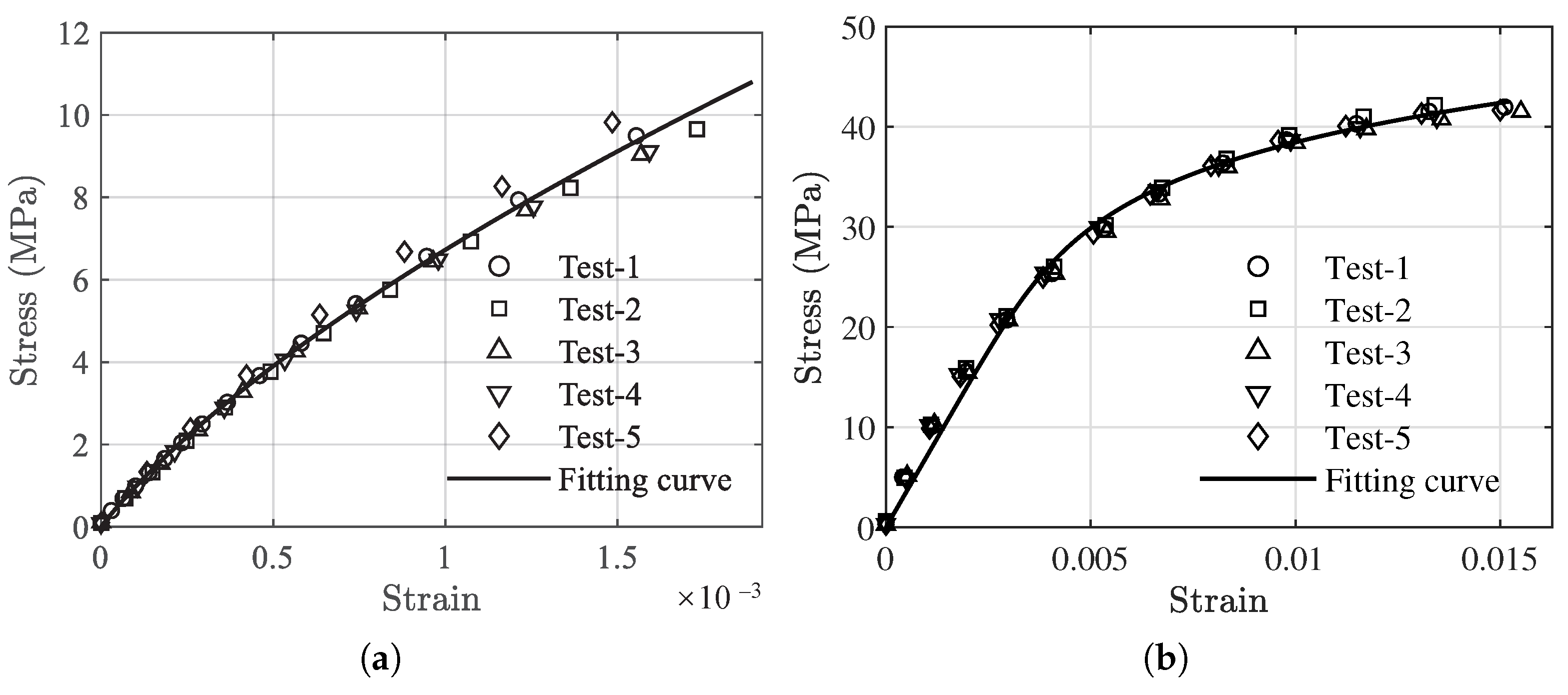

2.2. Test Results

3. Constitutive Model Development

3.1. Stress–Strain Model under Single Temperature

3.2. Tension

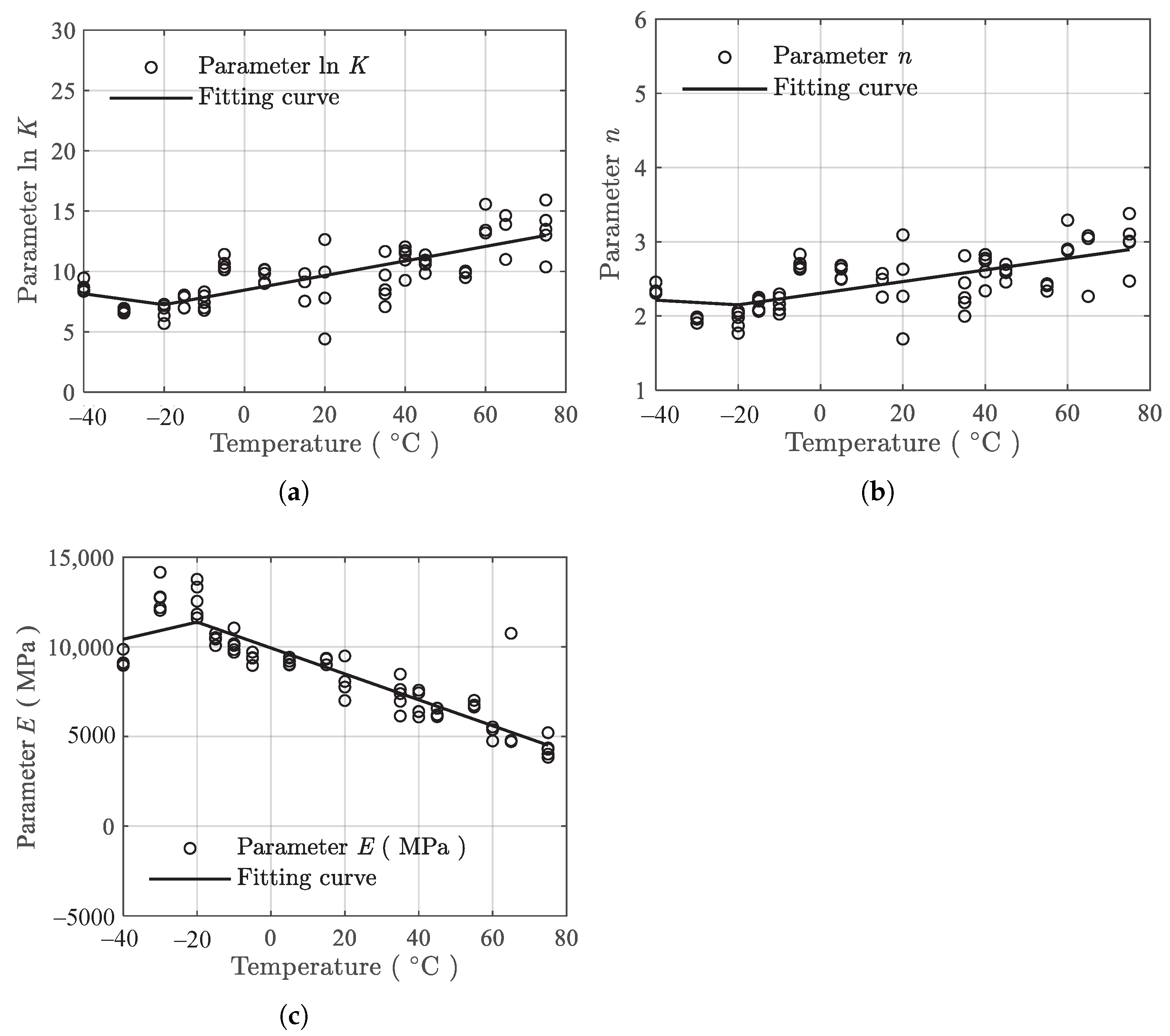

3.2.1. Model Parameters under Different Temperatures

3.2.2. Temperature Dependence Modeling

3.3. Compression

3.3.1. Model Parameters under Different Temperatures

3.3.2. Temperature Dependence Modeling

4. Model Validations and Comparisons

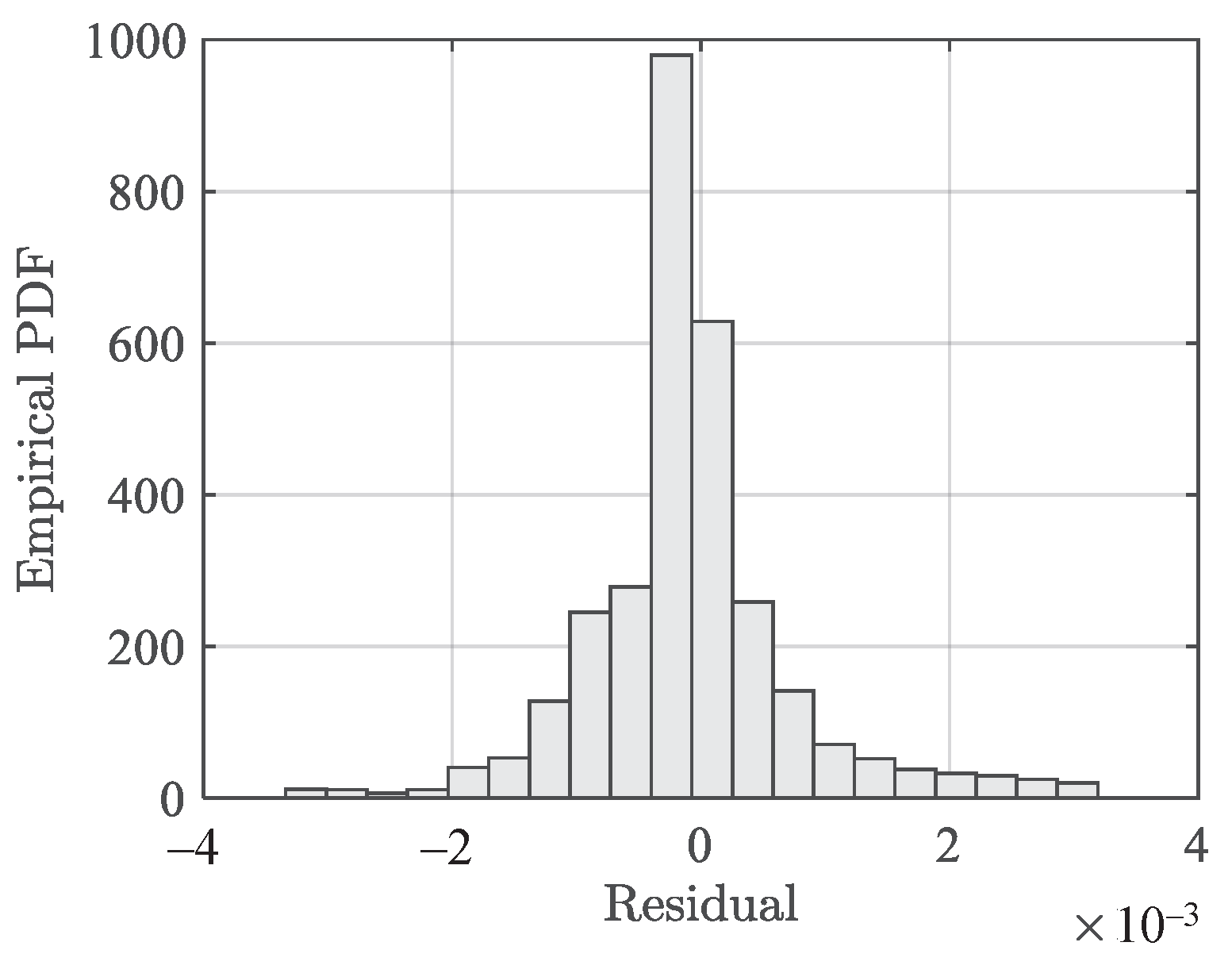

4.1. Validation Using Independent Sets of Testing Data

4.2. Validation Using Third-Party Data

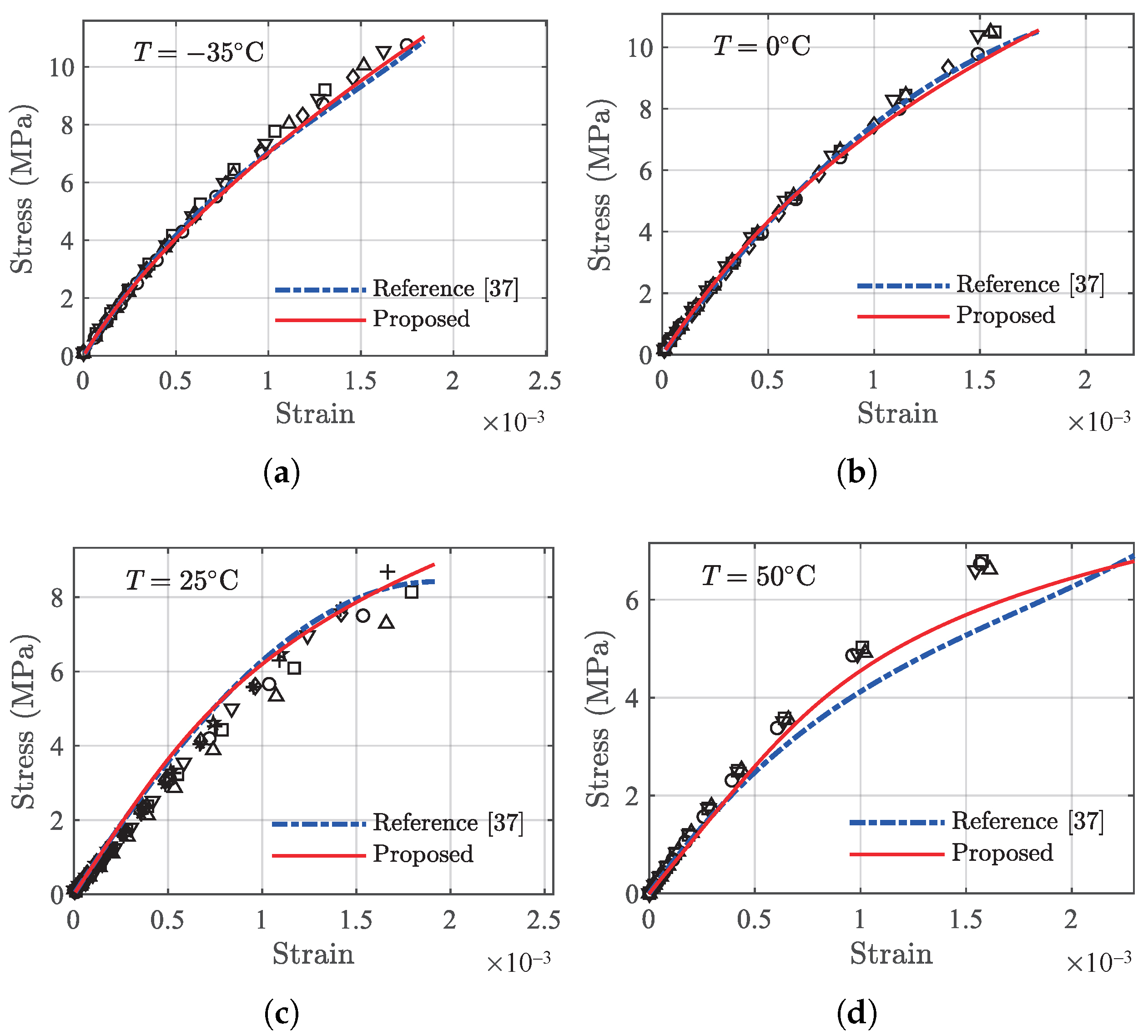

4.3. Model Comparisons

4.3.1. Tension

4.3.2. Compression

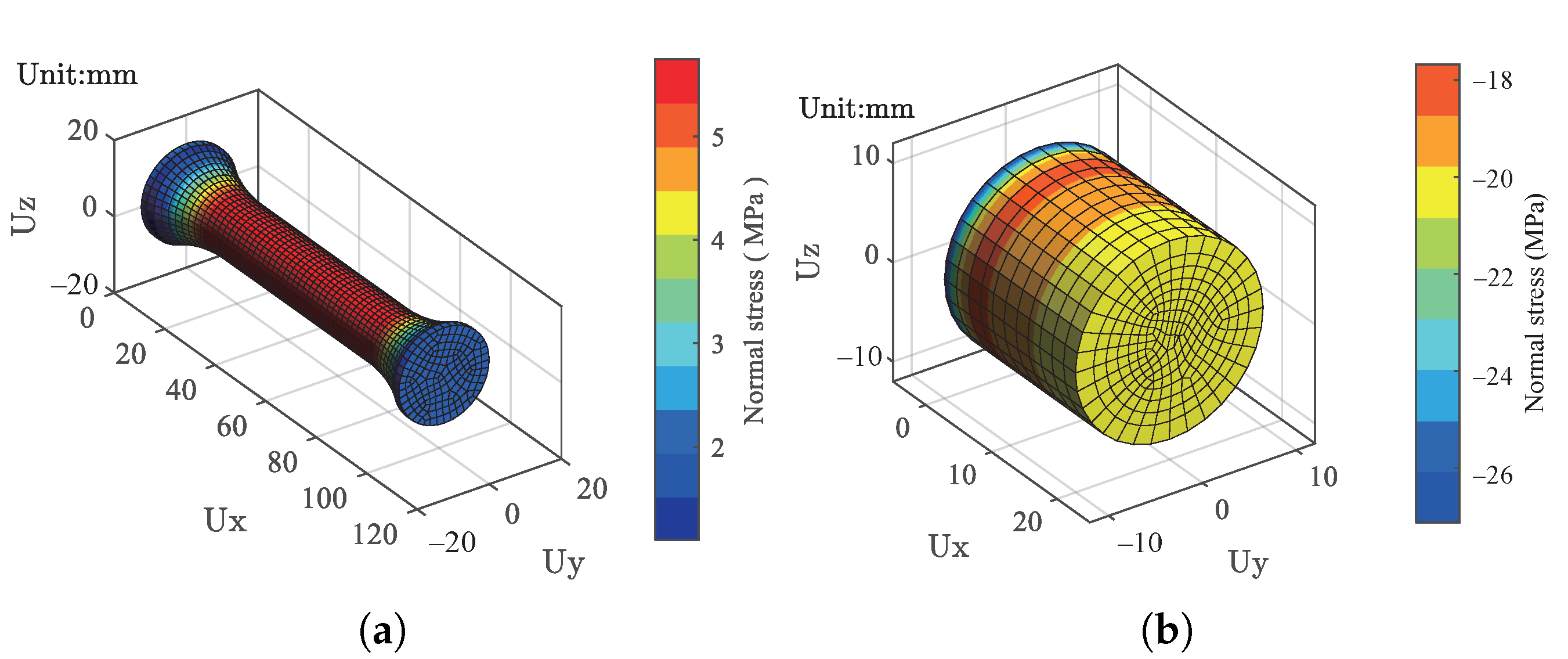

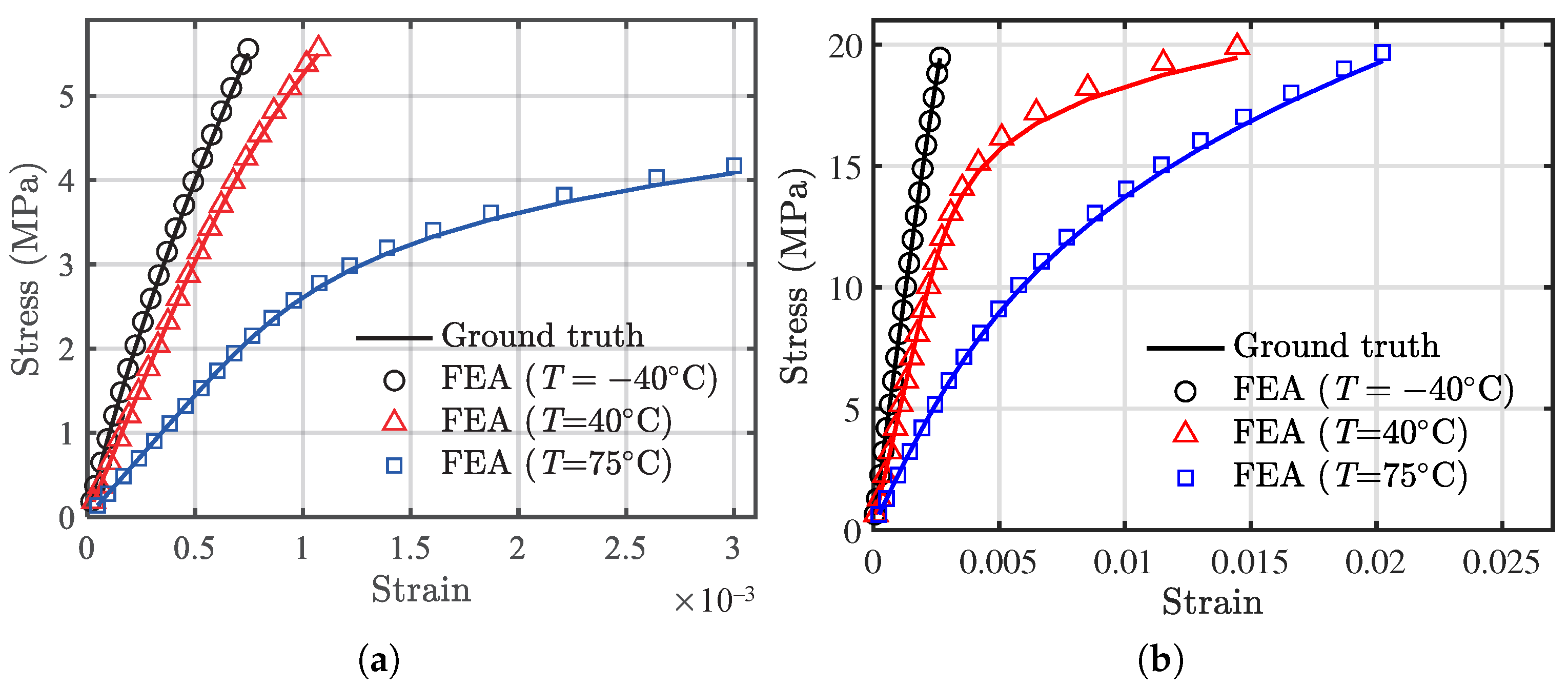

5. A User Material Implementation of the Model

6. Conclusions

- The proposed method can unify the temperature effect by modeling the temperature dependence of the constitutive model parameters, thus providing an alternative to the existing temperature correction factor-based methods. Furthermore, such a treatment allows a minimal number of fitting parameters compared to the existing models.

- The proposed method provides a general approach to model the stress–strain behaviors of PBMs. The basic assumption that the stress–strain response is an accumulation of an elastic term and a power-law plastic term is observed in many other materials such as various metals. The effectiveness and generality of the model are validated and demonstrated by two independent preponderate data sets in the temperature range −40–75 C.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PBMs | Polymer-bonded composites materials |

| RO | Ramberg–Osgood |

| CT | Computed tomography |

| SSE | Sum of squared errors |

| MAE | Mean absolute error |

| RMSE | Root mean square error |

| FEA | Finite element analysis |

References

- Vavlekas, D.; Ansari, M.; Hao, H.; Fremy, F.; McCoy, J.L.; Hatzikiriakos, S.G. Zero Poisson’s ratio PTFE in uniaxial extension. Polym. Test. 2016, 55, 143–151. [Google Scholar] [CrossRef]

- Dutoit, B.; Besse, P.A.; Blanchard, H.; Guérin, L.; Popovic, R. High performance micromachined Sm2Co17 polymer bonded magnets. Sens. Actuators A Phys. 1999, 77, 178–182. [Google Scholar] [CrossRef]

- Wang, B.; Kari, L. Constitutive model of isotropic magneto-sensitive rubber with amplitude, frequency, magnetic and temperature dependence under a continuum mechanics basis. Polymers 2021, 13, 472. [Google Scholar] [CrossRef]

- Palmer, S.; Field, J.E.; Huntley, J. Deformation, strengths and strains to failure of polymer bonded explosives. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1993, 440, 399–419. [Google Scholar]

- Siviour, C.; Gifford, M.; Walley, S.; Proud, W.; Field, J. Particle size effects on the mechanical properties of a polymer bonded explosive. J. Mater. Sci. 2004, 39, 1255–1258. [Google Scholar] [CrossRef]

- Sang, J.; Hirahara, H.; Aisawa, S.; Kang, Z.; Mori, K. Direct Bonding of Polypropylene to Aluminum Using Molecular Connection and the Interface Nanoscale Properties. ACS Appl. Polym. Mater. 2019, 1, 2450–2459. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Wang, B.; Zhang, X. Interfacial enhancement for carbon fibre reinforced electron beam cured polymer composite by microwave irradiation. Polymer 2020, 192, 122327. [Google Scholar] [CrossRef]

- Li, Y.F.; Sio, W.K.; Yang, T.H.; Tsai, Y.K. A Constitutive Model of High-Early-Strength Cement with Perlite Powder as a Thermal-Insulating Material Confined by Caron Fiber Reinforced Plastics at Elevated Temperatures. Polymers 2020, 12, 2369. [Google Scholar] [CrossRef]

- Skokov, K.; Karpenkov, D.Y.; Kuz’Min, M.; Radulov, I.; Gottschall, T.; Kaeswurm, B.; Fries, M.; Gutfleisch, O. Heat exchangers made of polymer-bonded La (Fe, Si) 13. J. Appl. Phys. 2014, 115, 17A941. [Google Scholar] [CrossRef]

- Berezvai, S.; Kossa, A. Performance of a parallel viscoelastic-viscoplastic model for a microcellular thermoplastic foam on wide temperature range. Polym. Test. 2020, 84, 106395. [Google Scholar] [CrossRef]

- Yang, T.C. Effect of extrusion temperature on the physico-mechanical properties of unidirectional wood fiber-reinforced polylactic acid composite (WFRPC) components using fused deposition modeling. Polymers 2018, 10, 976. [Google Scholar] [CrossRef]

- Guo, H.; Guo, W.; Amirkhizi, A.V.; Zou, R.; Yuan, K. Experimental investigation and modeling of mechanical behaviors of polyurea over wide ranges of strain rates and temperatures. Polym. Test. 2016, 53, 234–244. [Google Scholar] [CrossRef]

- Abdel-Wahab, A.A.; Ataya, S.; Silberschmidt, V.V. Temperature-dependent mechanical behaviour of PMMA: Experimental analysis and modelling. Polym. Test. 2017, 58, 86–95. [Google Scholar] [CrossRef]

- Senden, D.J.; Krop, S.; van Dommelen, J.; Govaert, L. Rate-and temperature-dependent strain hardening of polycarbonate. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 1680–1693. [Google Scholar] [CrossRef]

- Sakai, T.; Kurakazu, M.; Akagi, Y.; Shibayama, M.; Chung, U.I. Effect of swelling and deswelling on the elasticity of polymer networks in the dilute to semi-dilute region. Soft Matter 2012, 8, 2730–2736. [Google Scholar] [CrossRef]

- Van Loock, F.; Fleck, N.A. Deformation and failure maps for PMMA in uniaxial tension. Polymer 2018, 148, 259–268. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Z. A novel constitutive model of shape memory polymers combining phase transition and viscoelasticity. Polymer 2018, 143, 298–308. [Google Scholar] [CrossRef]

- Johnsen, J.; Clausen, A.H.; Grytten, F.; Benallal, A.; Hopperstad, O.S. A thermo-elasto-viscoplastic constitutive model for polymers. J. Mech. Phys. Solids 2019, 124, 681–701. [Google Scholar] [CrossRef]

- Somarathna, H.; Raman, S.N.; Mohotti, D.; Mutalib, A.A.; Badri, K.H. Hyper-viscoelastic constitutive models for predicting the material behavior of polyurethane under varying strain rates and uniaxial tensile loading. Constr. Build. Mater. 2020, 236, 117417. [Google Scholar] [CrossRef]

- Williamson, D.; Siviour, C.; Proud, W.; Palmer, S.; Govier, R.; Ellis, K.; Blackwell, P.; Leppard, C. Temperature–time response of a polymer bonded explosive in compression (EDC37). J. Phys. D Appl. Phys. 2008, 41, 085404. [Google Scholar] [CrossRef]

- Walley, S.; Taylor, N.; Williamson, D. Temperature and strain rate effects on the mechanical properties of a polymer-bonded explosive. Eur. Phys. J. Spec. Top. 2018, 227, 127–141. [Google Scholar] [CrossRef]

- Chen, X.D.; Chang, X.L.; Zhang, Y.H.; Wang, B.; Zhang, Q.; Zhang, X. Tensile Mechanical Properties of HTPB Propellant at Low Temperature. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2018; Volume 765, pp. 54–59. [Google Scholar]

- Zheng, B.; Deng, T.; Li, M.; Huang, Z.; Zhou, H.; Li, D. Flexural behavior and fracture mechanisms of short carbon fiber reinforced polyether-ether-ketone composites at various ambient temperatures. Polymers 2019, 11, 18. [Google Scholar] [CrossRef]

- Vipulanandan, C.; Mebarkia, S. Effect of strain rate and temperature on the performance of epoxy mortar. Polym. Eng. Sci. 1990, 30, 734–740. [Google Scholar] [CrossRef]

- Unger, R.; Arash, B.; Exner, W.; Rolfes, R. Effect of temperature on the viscoelastic damage behaviour of nanoparticle/epoxy nanocomposites: Constitutive modelling and experimental validation. Polymer 2020, 191, 122265. [Google Scholar] [CrossRef]

- Wang, P.; Yu, H.; Ma, R.; Wang, Y.; Liu, C.; Shen, C. Temperature-dependent orientation of poly (ether ether ketone) under uniaxial tensile and its correlation with mechanical properties. J. Therm. Anal. Calorim. 2020, 141, 1361–1369. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, Z. A novel fractional viscoelastic constitutive model for shape memory polymers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1125–1134. [Google Scholar] [CrossRef]

- Zubelewicz, A.; Thompson, D.G.; Ostoja-Starzewski, M.; Ionita, A.; Shunk, D.; Lewis, M.W.; Lawson, J.C.; Kale, S.; Koric, S. Fracture model for cemented aggregates. AIP Adv. 2013, 3, 012119. [Google Scholar] [CrossRef]

- Ge, S.; Zhang, W.; Sang, J.; Yuan, S.; Lo, G.V.; Dou, Y. Mesoscale Simulation to Study Constitutive Properties of TATB/F2314 PBX. Materials 2019, 12, 3767. [Google Scholar] [CrossRef] [PubMed]

- Li-Mayer, J.; Williamson, D.; Lewis, D.; Connors, S.; Iqbal, M.; Charalambides, M. Characterization and Micromechanical Modelling of a Temperature Dependent Hyper-Viscoelastic Polymer Bonded Explosive. Cranfield Online Res. Data (CORD) 2017. [Google Scholar] [CrossRef]

- Pulla, S.; Karaca, H.; Lu, Y. Numerical design of shape memory polymer composites with temperature-responsive SMA fillers. Compos. Part B Eng. 2016, 96, 287–294. [Google Scholar] [CrossRef]

- Tschoegl, N.W.; Knauss, W.G.; Emri, I. The effect of temperature and pressure on the mechanical properties of thermo-and/or piezorheologically simple polymeric materials in thermodynamic equilibrium—A critical review. Mech. Time-Depend. Mater. 2002, 6, 53–99. [Google Scholar] [CrossRef]

- GJB 772A-1997. Explosive Test Method; China Ordnance Industrial Standardization Research Institute: Beijing, China, 1997. [Google Scholar]

- ISO 527-1. Plastics-Determination of Tensile Properties. Part 1: General Principles; International Organization for Standardization: Geneva, Switzerland, 1993. [Google Scholar]

- Khanna, Y.P.; Kumar, R. The glass transition and molecular motions of poly (chlorotrifluoroethylene). Polymer 1991, 32, 2010–2013. [Google Scholar] [CrossRef]

- Ramberg, W.; Osgood, W.R. Description of Stress-Strain Curves by Three Parameters; NASA Technical Note NO.902; NASA: Washington, DC, USA, 1943. [Google Scholar]

- Chang, B.; Wang, X.; Long, Z.; Li, Z.; Gu, J.; Ruan, S.; Shen, C. Constitutive modeling for the accurate characterization of the tension behavior of PEEK under small strain. Polym. Test. 2018, 69, 514–521. [Google Scholar] [CrossRef]

- Guan, X.; Jha, R.; Liu, Y. Model selection, updating, and averaging for probabilistic fatigue damage prognosis. Struct. Saf. 2011, 33, 242–249. [Google Scholar] [CrossRef]

- Huo, H.; He, J.; Guan, X. A Bayesian fusion method for composite damage identification using Lamb wave. Struct. Health Monit. 2020. [Google Scholar] [CrossRef]

- He, J.; Chen, J.; Guan, X. Lifetime distribution selection for complete and censored multi-level testing data and its influence on probability of failure estimates. Struct. Multidiscip. Optim. 2020, 62, 1–17. [Google Scholar] [CrossRef]

- Okereke, M.I.; Akpoyomare, A.I. Two-process constitutive model for semicrystalline polymers across a wide range of strain rates. Polymer 2019, 183, 121818. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, D.; Zhang, H.; Huang, L.; Yao, Y.; Li, G.; Mobasher, B. Mechanical characterization of the tensile properties of glass fiber and its reinforced polymer (GFRP) composite under varying strain rates and temperatures. Polymers 2016, 8, 196. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Liu, Y.; Ran, Z. Microscopic failure mechanisms of fiber-reinforced polymer composites under transverse tension and compression. Compos. Sci. Technol. 2012, 72, 1818–1825. [Google Scholar] [CrossRef]

- Su, C.; Wei, Y.; Anand, L. An elastic–plastic interface constitutive model: Application to adhesive joints. Int. J. Plast. 2004, 20, 2063–2081. [Google Scholar] [CrossRef]

- Koloor, S.S.R.; Rahimian-Koloor, S.; Karimzadeh, A.; Hamdi, M.; Petr, M.; Tamin, M. Nano-level damage characterization of graphene/polymer cohesive interface under tensile separation. Polymers 2019, 11, 1435. [Google Scholar] [CrossRef]

- He, J.; Huo, H.; Guan, X.; Yang, J. A Lamb wave quantification model for inclined cracks with experimental validation. Chin. J. Aeronaut. 2021, 34, 601–611. [Google Scholar] [CrossRef]

- Du, Y.M.; Ma, Y.H.; Wei, Y.F.; Guan, X.; Sun, C. Maximum entropy approach to reliability. Phys. Rev. E 2020, 101, 012106. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.M.; Chen, J.F.; Guan, X.; Sun, C. Maximum Entropy Approach to Reliability of Multi-Component Systems with Non-Repairable or Repairable Components. Entropy 2021, 23, 348. [Google Scholar] [CrossRef] [PubMed]

| Tension | Compression | |||

|---|---|---|---|---|

| T (C) | Num. | Usage | Num. | Usage |

| −40 | 5 | M | 5 | M |

| −35 | 5 | V | ||

| −30 | 6 | M | 6 | M |

| −25 | 5 | M | ||

| −20 | 5 | M | 5 | V |

| −15 | 5 | M | 5 | M |

| −10 | 5 | M | ||

| −5 | 5 | M | 5 | M |

| 0 | 5 | V | ||

| 5 | 5 | M | 5 | M |

| 10 | 5 | V | ||

| 15 | 3 | M | 5 | M |

| 20 | 4 | M | 4 | M |

| 25 | 8 | V | 6 | M |

| 30 | 5 | V | ||

| 35 | 5 | M | 5 | M |

| 40 | 5 | M | 5 | M |

| 45 | 5 | M | 6 | M |

| 50 | 4 | V | 6 | V |

| 55 | 3 | M | 6 | M |

| 60 | 3 | M | 1 | M |

| 65 | 3 | M | 2 | M |

| 75 | 5 | M | 5 | M |

| Parameters | Tension | Compression |

|---|---|---|

| E (MPa) | 7103 | |

| K | 214.5 | |

| n | 1.779 | 6.955 |

| Mode | Usage | Temperature (C) | MAE | RMSE |

|---|---|---|---|---|

| Tension | M | −30 | ||

| M | −20 | |||

| V | −35 | |||

| V | 0 | |||

| V | 25 | |||

| V | 50 | |||

| Compression | M | −25 | ||

| M | −15 | |||

| V | −20 | |||

| V | 10 | 0.001741 | 0.002460 | |

| V | 30 | 0.001100 | 0.001778 | |

| V | 50 | 0.001195 | 0.001688 |

| Model | Temperature (C) | MAE | RMSE |

|---|---|---|---|

| Proposed Model | −35 | ||

| 0 | |||

| 25 | |||

| 50 | |||

| Reference Model [37] | −35 | ||

| 0 | |||

| 25 | |||

| 50 |

| Model | Temperature (C) | MAE | RMSE |

|---|---|---|---|

| Proposed Model | −20 | ||

| 10 | 0.001741 | 0.002460 | |

| 30 | 0.001100 | 0.001778 | |

| 50 | 0.001195 | 0.001688 | |

| Reference Model [37] | −20 | ||

| 10 | |||

| 30 | 0.001262 | 0.002824 | |

| 50 | 0.002111 | 0.003094 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, X.; Yuan, H.; Tang, W.; He, J.; Guan, X. A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials. Polymers 2021, 13, 1393. https://doi.org/10.3390/polym13091393

Duan X, Yuan H, Tang W, He J, Guan X. A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials. Polymers. 2021; 13(9):1393. https://doi.org/10.3390/polym13091393

Chicago/Turabian StyleDuan, Xiaochang, Hongwei Yuan, Wei Tang, Jingjing He, and Xuefei Guan. 2021. "A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials" Polymers 13, no. 9: 1393. https://doi.org/10.3390/polym13091393

APA StyleDuan, X., Yuan, H., Tang, W., He, J., & Guan, X. (2021). A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials. Polymers, 13(9), 1393. https://doi.org/10.3390/polym13091393