Abstract

Carboxymethyl cellulose (CMC) is one of the most promising cellulose derivatives. Due to its characteristic surface properties, mechanical strength, tunable hydrophilicity, viscous properties, availability and abundance of raw materials, low-cost synthesis process, and likewise many contrasting aspects, it is now widely used in various advanced application fields, for example, food, paper, textile, and pharmaceutical industries, biomedical engineering, wastewater treatment, energy production, and storage energy production, and storage and so on. Many research articles have been reported on CMC, depending on their sources and application fields. Thus, a comprehensive and well-organized review is in great demand that can provide an up-to-date and in-depth review on CMC. Herein, this review aims to provide compact information of the synthesis to the advanced applications of this material in various fields. Finally, this article covers the insights of future CMC research that could guide researchers working in this prominent field.

1. Introduction

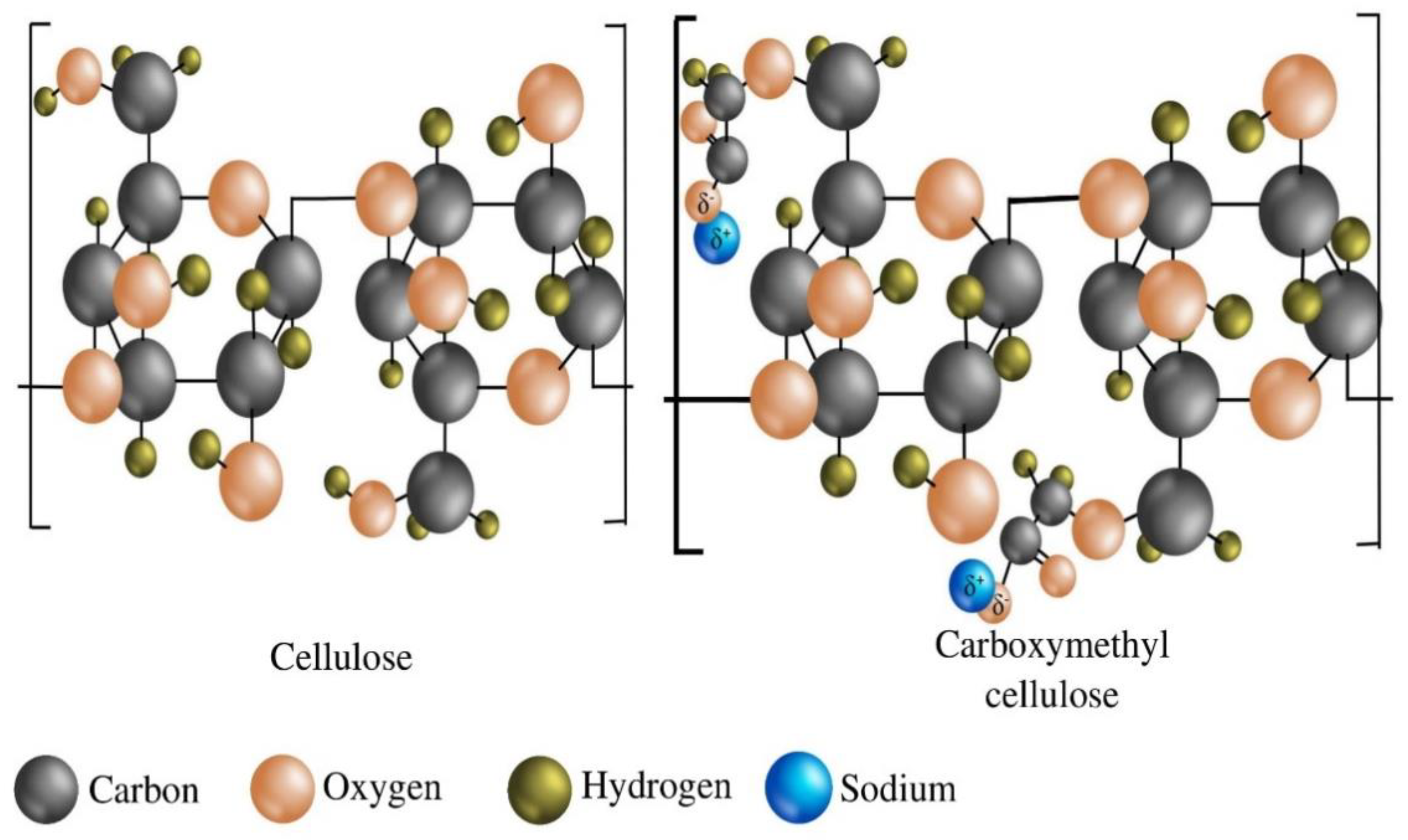

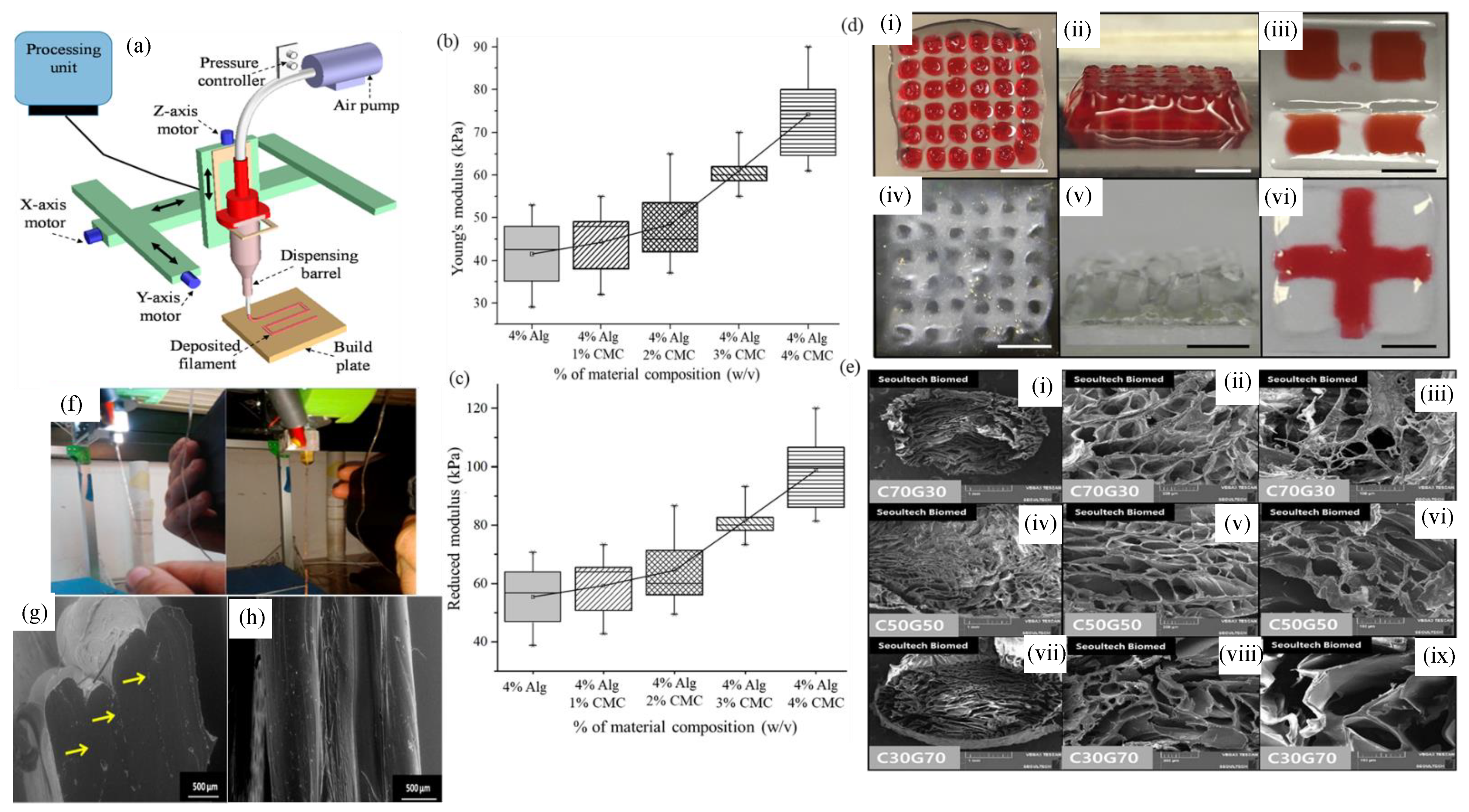

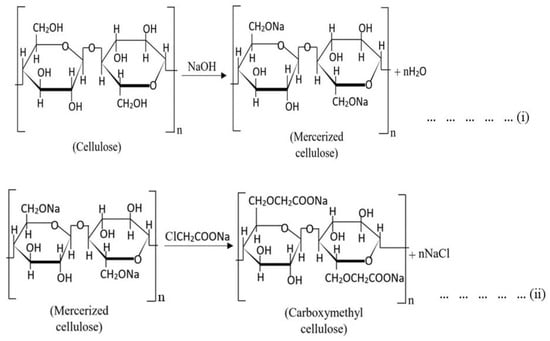

Carboxymethyl cellulose (CMC) is an anionic, water-soluble derivative of cellulose, a linear polysaccharide of anhydro-glucose. The repeating units are connected by β-1,4-glycosidic bonds. At the molecular level, the major difference between CMC and cellulose is only some anionic carboxymethyl groups (i.e., –CH2COOH) in the CMC structure that replace the hydrogen atoms from some hydroxyl groups present in the pristine cellulose infrastructure (Figure 1). CMC was first synthesized in 1918. However, the commercial production of these all-important polymeric materials was first depicted in Germany in the early 1920s [1].

Figure 1.

The fundamental structural difference between cellulose and carboxymethyl cellulose (CMC).

Initially, as the archetypal celluloses were mainly extracted from wood and other plant-based precursors that contained a high percentage of cellulose fibers naturally, the production of CMC was then ultimately dependent on such specific wood-based plants [2,3,4]. However, day-by-day cellulose-containing materials have been introduced by many researchers in the literature as effectual alternative candidates in this context. Among them, some plant-based precursors (e.g., sago palm [5], corn cobs [6], corn husk [7], corn stalks [8], durian rind [9], banana pseudo-stem [10], maize stalks [11], cacao pod husks [12], the pulp of Eucalyptus globulus [13], orange peel [14], pineapple peel [15], sugarcane bagasse [16], Asparagus officinalis stalk end [17], etc.), as well as some waste-materials (such as waste paper sludge [18], wastepaper [19], knitted rags [20], waste textiles [21], cotton gin wastes [22], and waste cotton linters from textile industries [23], etc.) have attracted the attention of researchers to be applied for the bulk or commercial production of CMC.

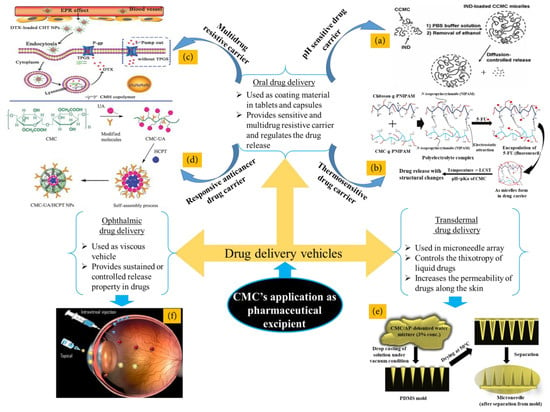

Due to the facile, low-cost synthesis process, an abundance of raw materials, characteristic surface properties [24,25], mechanical strength [26], different formability [27,28], tuneable hydrophilicity [29,30,31,32], a viscosity [33], rheological properties [34], and likewise hundreds of other contrasting aspects, CMC and CMC-based hybrid materials have found a wide range of applications in the biomedical, pharmaceutical, textile, construction, food, plastics, cosmetics, paper, and oil industries. For instance, in biomedical fields, CMC and its composites are widely used in tissue engineering [35,36,37,38], bone-tissue engineering [39,40,41], wound dressing [31,32,42,43,44], absorbent nonwovens [30], fabrication of 3D-scaffolds for biocompatible implants [45,46], artificial organs or mimics of extracellular polymeric matrix [47,48], diagnosis of various diseases [49,50], etc. for various purposes. Over the last few years, CMC-based hydrogels, films, or other hybrid materials have gained much interest in pharmaceutical applications, especially for drug delivery [51,52], drug emulsification [53,54], and stabilization purposes [55,56] due to their excellent biocompatibility, high stability, pH sensitivity, and binding capacity against pharmaceutically active compounds like drugs, enzymes. Moreover, CMC and its derivatives are used in textile digital printing due to their thickening and color sharpening feature [57,58], in textile weaving as sizing and finishing agents [59,60], and used in smart, antimicrobial, antiradical, antioxidant, or absorbent textiles because of their pH or thermosensitivity, hygienic, and hygroscopic features [30,31,32,61,62,63]. CMCs are used as various auxiliary agents like thickeners, emulsion stabilizers, adhesive stabilizers, and moisture binders in numerous food products and their packaging due to the odorless, tasteless, non-caloric, and physiologically inert properties [26,64,65,66,67,68]. Additionally, in environmentally favorable energy production, storage, and wastewater treatment, the role of CMC in various aspects has been demonstrated by many researchers thus far in the literature. As a cost-efficient binder in biomass pellets (for reduction of excessive fuel-loss) [69,70], auxiliary material for electrodes in battery cells [71,72,73], supercapacitor aerogels for efficient energy storage [74,75], CMC and its various composites have attracted huge attention during recent years. In water treatment processes, CMC-based hybrid composites, especially their hydrogels, have demonstrated some promising results over the past two decades for effective removal of dye pollutants [76,77,78], various inorganic metal ions (including heavy metals in their complex ionic states) [79,80,81], and even some radionuclides [82,83] from various contaminated waters. Moreover, applications of CMC have also been proposed in various fields such as in the paper industry to provide strengthening property, good printability or ink retention, color stability, fire retardancy features of CMC [84,85,86,87]; in paper or wood adhesives for a better adhesion property [88,89]; and in Si anodic electrodes for their potential binding capacity and cyclic performance [90]. Additionally, CMC has been used in the construction industry [91,92], cosmetics [93], dental profession [94], liquid detergent [95], fertilizer industry [96,97], oil industry [98,99], etc.

However, the application of CMC in these fields highly depends upon the purity, degree of polymerization (DP), degree of substitution (DS), and uniformity, which govern the performance of the resulting products such as solubility, particle size, viscosity, rheological properties, etc. TypicallyCMC products are divided into three different grades: food-grade, pharmaceutical grade, and industrial grade CMC based on purity and DS [7,69]. The industrial-grade CMCs cannot be used for pharmaceutical or biomedical purposes such as drug delivery, tissue or organ implantation in vivo, wound dressing, etc., due to their impure chemical compositions and characteristics. In contrast, high-cost purified pharmaceutical grade CMC products are not necessary for applications in the construction, plastic, or oil industries instead of the cheaper ones (i.e., industrial-grade products). Additionally, mechanical strength, viscosity, and rheological properties also significantly restrict the application fields of synthesized CMC products. Therefore, the characterization of a CMC product is also an essential step for determining its further applications and marketization in different areas. Among the various characterization techniques, scanning electron microscopic (SEM) analysis [100], Fourier transformation infrared ray (FTIR) spectroscopy [101], and thermo-gravimetric analysis (TGA) [102] have been used. Although numerous research works have been published so far that introduce different uses and applications of CMC in various fields, all the findings are scattered throughout the literature. In 1945, Hollabaugh et al. [103] tried to summarize some of the application fields of CMC. Later on, in 2005, Heinze and his co-workers [104] exhumed an overview of carboxymethylated starch and cellulose production and their characterization techniques in their study. In 2017, Kukrety et al. [105] assembled the works of CMC synthesis from various waste biomass resources in their review. However, non-conventional waste resources of CMC, like waste paper, paper sludge, waste textiles, knitted rags, waste cotton linters from textile industries, and various conventional plant-based resources, were excluded from that study. Overall, there has been no major up-to-date review work where all the potential sources of CMC, their essential characterization techniques, and their uses and applications in numerous fields have been assembled and discussed together.

To envision this, herein, we discuss and assemble the reported works on CMC based on their sources, characterization, and applications in numerous fields like biomedical, pharmaceutical, construction, food and textile industries, energy production, water treatment processes, etc. Furthermore, synthesis roots of CMC from its various conventional (i.e., plant-based) and non-conventional (e.g., waste materials) precursors and their essential characterization techniques such as scanning electron microscopic technique, Fourier transform infrared spectroscopy, thermo-gravimetric analysis, etc. will be discussed here extensively. Furthermore, analysis of various physicochemical and mechanical properties of CMC products, like their rheological properties, viscosity, determination of the DS, DP, etc., will be elaborately discussed in separate sections. Thus, this work will provide an up-to-date and systematic overview of CMC from which researchers, scientists, or industry can quickly obtain the general up-to-date applications of this material at a glance, based on their sources as well as various critical properties, for example, viscosity, DS, and so on. Additionally, recommendations for further research works are also provided.

2. Characteristics of CMC

The answer of how CMC responds when it is used for a variety of conditions or applications is the central pivotal point to define the character of CMC. This section highlights the properties or parameters that directly impact CMC applications or behavior of the final products of CMC, such as rheology, viscosity, and DS. In contrast, rheology defines the physical properties and the flow and fracture behavior of the CMC’s final products (under different pressures). However, the rheological properties (stress-strain flow behavior, pseudoplasticity, viscoelasticity, and thixotropy) are primarily controlled by the viscosity. Likewise, viscosity is interrelated to the DS of CMC. Thus, the overall characteristics of CMC for various application purposes can be defined by the suggested three significant parameters (rheology, viscosity, and DS).

2.1. Rheological Properties

In between the discussion of the characterization of matter, rheology plays a vital role in connecting the study of the flowing behavior of matter and its deformation under the force of application. Moreover, the rheological study of materials gives an overall idea about the flow system like thixotropy, pseudoplastic, viscoelastic, and stress-strain flow behavior. After all, this behavior or properties of rheology are closely interrelated to the structure of polymer systems such as structure, particle size, concentration, shape or surface characterization, etc. According to the study of structure, CMC shows some complex and interesting flow behaviors under stress-strain action that directly impact the various application purposes of CMC such as food packaging, film fabrication, or coating of materials, etc. [106,107]. CMC’s thixotropy, pseudoplastic, or viscoelastic behavior is directly attached to suspension injection, paint, adhesive, food processing, cosmetics, etc. Here, the rheological characterization of CMC is discussed under the following subtopics.

2.1.1. Stress-Strain Flow Behavior

For the application of CMC for various purposes, how or how fast CMC-based materials deform under applied force or various conditions are general questions that must be answered. Deformation study of materials is defined as the amount of strain under applied stress. The stress-strain relationship of materials to determine its flow behavior also helps to prescribe the CMC, whether it is suitable for a specified condition or not. As a polymeric derivative, CMC often behaves like a non-Newtonian fluid. CMC sometimes follows the property of Newtonian fluid or viscous flow behavior in low concentrations. Therefore, according to the Ghannam and Esmail (1997) investigation [34], CMC covers the Newtonian character at 1% and non-Newtonian above 1% (or 2–5%). The investigation followsthe shear stress-shear rate curves, which mainly were linear for all concentrations (1–5%), as shown in the Supplementary Materials (Figure S1a). Still, the viscosity-shear rate curves were nearly horizontal type (below or at 1%) or decreasing linear type (above 1% or up to 5%), as shown in the Supplementary Materials (Figure S1b). The horizontal curve indicates the flow is viscous or has a Newtonian character. Gradually decreasing curves define the shear thinning behavior (STB) or non-Newtonian character, indicating sharp and highest flow behavior. Other CMC properties like thixotropy, pseudoplastic, and viscoelastic behavior are fully interconnected to STB. Above all, STB plays an important role during the various applications of CMC, which control the film fabrication, packaging, injection molding, or melt strength property of CMC [34,107].

In the last decade, Benchabane et al. (2008) [108] noticed a critical shear rate (CSR) curve (ᵞc1) in the viscosity-shear rate graph against all concentrations (0.2 to 7%) of the CMC polymer solution. According to the author’s discussion, the CSR limiting value helps define the change of the flow behavior of CMC. For example, below the critical concentration (<1% or 0.2 to 0.8%), CMC exhibits shear-thinning behavior; and above at 1%, CMC exhibits transition behavior (shear-thickening to shear-thinning) due to the gradually increasing shear rate. Moreover, in between ᵞc1 < ᵞ < 1000 s−1, CMC exhibits Newtonian and non-Newtonian shear thinning behavior.

CMC’s flow study behavior, shear stress-strain behavior, transient shear stress (TSS) response, rheopexy (time-dependent shear stress), and yield stress of polymer solution are other necessary tests or parameters. The TSS response means a change in shear stress over a lower shear rate. Among these parameters, above 3% (i.e., 4–5%), CMC solution and rheopexy exhibit under the low shear rate (less than 10 s−1) and not otherwise [34]. Characteristics of rheopexy discuss the complex flows related to viscoelastic (linear and non-linear) behavior [109] and the thixotropic structure of CMC liquid [34,109]. Furthermore, the yield stress test of CMC provides information about the deforming ability of a CMC solution under applied stress. For example, CMC deforms easily, starts to flow, and maintains fluid behavior when the applied stress is crossed with the yield stress [34,109].

2.1.2. Pseudoplastic and Viscoelastic Behavior

The pseudoplastic or viscoelastic properties of materials describe the flow behavior or response of the material under stress in an application purpose. Pseudoplasticity is defined as the shear-thinning behavior of fluid material. The CMC long-chain’s easy orientation under shear stress is the main reason behind the display of CMC pseudoplasticity. The viscosity gradually falls under the stress of the CMC and increases their flow behavior index. Moreover, the pseudoplastic behavior of CMC is affected by factors like DS value, molecular weight, and temperature. For example, pseudoplasticity is higher in high molecular weight and the DS value between 0.9 to 1.2 [34,109,110]. After all, CMC is widely applied in food processing (condensed milk, mayonnaise, etc.) or some cosmetics (lotion, toothpaste, etc.) for their pseudoplastic behavior.

On the other hand, the viscoelasticity of the polymer defines the possibility of exposure of both the viscous and elastic behavior of the polymer [107]. Furthermore, it is also defined as a time-dependent response (or relaxation time) under applied constant stress. The molecular structure of CMC is responsible for displaying viscoelasticity because CMC has a long chain, entanglement property, and high relaxation time. The response of viscoelasticity CMC polymers can be investigated by creep-recovery and dynamic test during application purposes. Among them, creep compliance, and elastic recovery index is calculated during the creep-recovery test to understand the response of viscoelastic behavior. Higher creep compliance, and flexible recovery index indicate the possibility of showing better viscoelasticity of CMC [34,108] because CMC is easily deformed by giving stress at higher creep compliance.

Moreover, the response of viscoelasticity depends on the concentration of the CMC solution. According to the proposal of Ghannam and Esmail (1997) [34] and Benchabane et al. (2008) [108], the viscoelasticity of CMC was above 3% and 2.5% concentration of CMC solution, respectively. Furthermore, at a low concentration of CMC (below 2.5 or 3%), CMC behaves as a viscous flow. However, above 3%, CMC acts like an elastic solid. Based on their viscoelastic behavior, CMC has been widely applied in a hydrogel form in the biomedical, drug delivery, and agriculture fields [111,112] as a stabilizer or thickener in food products [113] and so on.

2.1.3. Thixotropy

Thixotropy is the most important property of non-Newtonian fluids and follows the STB [114]. Its behavior is mostly in contrast to the rheopexy illustrated in the Supplementary Materials (Figure S2a) [115]. CMC’s long-chain polymer demonstrates thixotropy for forming three-dimensional structures by intermolecular attraction. Generally speaking, thixotropy is defined as the transformation behavior of a shear-thinning system, where a high consistency gel is transformed to a low consistency solution. After a long time of rest, the thixotropic solution is again transformed into a gel form. CMC formulates a time-dependent hysteresis loop during the thixotropy behavior by two curves, like an up- and down-curve shown in the Supplementary Materials (Figure S2b) [110]. The up-curve indicates CMC’s high consistency or viscosity or defines the increase of shear rate against stress up to the desired value. After assuming the desired shear rate, viscosity, or consistency of fluid decreased with shear rate, this indicates the hysteresis loop’s downward curve. The thixotropy of CMC sometimes depends on its DS value or concentration factor. In the twentieth century, Feddersen and Throp (1993) [110] investigated the sharp thixotropy of CMC with low DS value (0.4 to 0.7) and high concentration or viscosity. During high concentration, thixotropy is higher than a lower concentration of the fluid due to the formation of higher insoluble regions in the fluid. According to Ghannam and Esmail (1997) [34], the thixotropy of CMC is uncountable with a 1 to 3% concentration of CMC solution. Above 3% (i.e., 4% or 5%), the thixotropy of CMC accelerates with an increasing concentration of CMC, whereas at 5% CMC, the solution shows higher and sharper thixotropic behavior than the 4% concentration of CMC. After all, CMC is widely used in various industrial applications as a thixotropic fluid, such as in pharmaceuticals (liquid or disperse drug, sustained drug release, drug coating, parenteral suspension, etc.); paints; adhesives; or foods. For example, in dispersing a drug, the thixotropy of CMC enhances a drug’s stability by gel-sol-gel transforms.

Moreover, in parenteral suspension injection, thixotropic fluid (CMC) plays an essential role in making the injection feel comfortable and accessible through the skin. When applying the pressure on the syringe plunger during injection, suspending the suspension particles are easily broken down and decrease their viscosity. A low viscosity (or consistency) of the syringe solution allows suspended drug particles to pass easily inside the skin without any panic effect. After injecting the drug, suspended particles are again aggregated and enhance their consistency inside the skin. This behavior also helps with the sustained release of drugs in the human body.

2.2. Viscosity

Viscosity is a measure of a fluid’s resistance to flow and defines the internal friction of a moving fluid. CMC is a polymeric material and provides a viscose solution in an aqueous medium due to its high solubility in water. Therefore, the viscosity parameter plays a vital role in describing the fluid behaviors, properties (thickening, emulsifying, etc.), and property-based applications of aqueous Na–CMC (or H–CMC). Because the high or low viscosity of the applied medium is maintained with increasing or decreasing CMC concentration, respectively; on the other hand, the viscosity property of CMC also depends on or is influenced by the source parameters (like cellulose particle size, molecular weight, and DS) and synthesis conditions (concentration of NaOH, reaction temperature, and pH of solution) of CMC from cellulose, as depicted in the Supplementary Materials (Figure S3) [10,116,117,118,119].

However, viscosity is considered the most critical parameter in various application purposes. For example, CMC is used in the food industry while the low viscosity type CMC acts as a moisture binder, and high viscosity type CMC acts as a gelation agent [120]. The lower viscosity-based CMC is used with sodium bentonite as a viscosity modifier or dispersion media in a drilling mud system. CMC increases the dispersion viscosity of bentonite and reduces the fluid losses in a drilling system [121]. Therefore in biomedical, tissue engineering, pharmaceutical, textile dye processing, foods, and cosmetic applications, the viscosity of CMC provides the recommended rheological properties. In soft tissue filler engineering, the lower-viscosity CMC hydrogels offer a softer feel via high spreading accessibility. Higher-viscosity CMC hydrogels give a firmer feel via less spreading accessibility [122]. For drug delivery purposes, CMC/MCC (microcrystalline cellulose) is used as biocomposite film-forming materials for drug delivery vehicles (such as hard capsules). CMC acts as a filler and improves the film’s strength by providing high viscosity [123].

Similarly, CMC has also been used recently to maintain the role of intrinsic viscosity of CMC/rosin/PEG (polyethylene glycol) drug nano-carriers [124]. CMCs are widely used in foods based on their viscosity characteristics and provide the recommended rheological properties, good texture, and mouth feel profiles. CMC is used as highly viscous materials in emulsified food or thickening juice [125,126]. Moreover, it is used in semisolid dairy products depending on their viscosity (low or high) to control the viscoelastic properties [66]. Due to control of the thixotropy and pseudoplastic behavior of cosmetics, CMC has been used with hyaluronic acid to develop a gel for application in cosmetics as CMC creates a better viscosity and texture profile in the gel [127].

2.3. Degree of Substitution

In cellulose chemistry, the reactive groups of cellulose are the most critical parameters in identifying their chemical activity. Three hydroxyls (–OH) reactive groups in anhydroglucose units of cellulose were introduced with the DS. The DS range is generally expressed for each unit zero to three. The DS value is technically defined as the average number of substitutes of the reactive group by other active molecules in the polymer chain. During the synthesis of CMC from cellulose, the value of DS is determined by the number of substituent groups (carboxymethyl) attached to each anhydroglucose unit.

The DS plays a vital role in the case of CMC properties as the solubility, emulsibility, thickening property, acid resistance, viscosity, stability, and salt tolerance properties of CMC depend significantly on the DS value [128]. For example, the CMC polymer is entirely insoluble but is swellable under the 0.4 DS value. In contrast, CMC is fully soluble beyond 0.4 (DS) [11,119]. The increasing solubility with DS has increased carboxymethyl substitution and substitution uniformity along the macromolecular chain [129,130]. In another article, D.N. S. Hon (2001) [131] proposed that CMC with DS values from 0.1 to 0.4 and 0.5 is soluble in cold and normal alkali (4–8% NaOH) solution, respectively. Over and above, the decreasing particle size and increasing DS value of CMC affects the viscosity-increase [119], salt or alcohol tolerance, and enhancing hygroscopicity [132]. Therefore, CMC’s crystallinity is also related to DS, while the crystallinity was demonstrated under the DS of 0.82 and disappeared beyond 1.0 [129]. The degree of CMC substitution also directs the properties of cellulose substrates. Controlling DS allows the balance of properties between CMC and cellulose substrates [30,31,32].

However, many researchers have reported on the synthesis of CMC in the last decade. It is noteworthy that depending on the source of CMC’s cellulose and synthesis procedure, the DS value of CMC varies from one to another. For example, based on different sources, the recommended DS values at optimum condition are 0.17 (Musa paradisiacal fruit) [133]; 0.28 (Musa parasidiaca stem) [133]; 0.29 (oil palm fiber) [134]; 0.31 (palm kernel cake) [134]; 0.33 (Tithonia diversifolia stalk) [133]; 0.35 (M. sinensis) [135]; 0.3–0.4 (cotton fiber) [30,31,32]; 0.51 (seaweed) [136]; 0.67 (sugar beet pulp) [137]; 0.76 (C. papyrus) [135]; 0.80 (E. crassipes) [135]; 0.82 (sago waste) [5]; 0.87 (durian rind) [9]; 1.07 (office waste paper) [19]; 2.39 (corn leaves) [138]; 1.21 (waste disposable paper cups) [139]; 1.76 (water hyacinth) [140]; 2.41 (corn husk) [119], etc. On the other hand, synthesis techniques including the range of concentration of reagents (NaOH, MCA) or reaction temperature and time, significantly impact the DS values. In particular, the value of DS can be fine-tuned by the concentration of reagents like isobutanol, ethanol, NaOH, and etherification agent (MCA). For example, depending on the varying concentration of NaOH, V. Pushpamalar (2006) [5]; P. Rachtanapun et al. (2012) [9]; A. H. Saputra et al. (2014) [140]; M. S. Yeasmin et al. (2015) [119]; and Ibikunle et al. (2020) [141] reported a range of DS of 0.51–0.82 (for sago waste) [5]; 0.56–0.87 (for durian rind) [9]; 0.14–1.76 (for water hyacinth) [140]; 0.1–2.41 (for corn husk) [119]; and 0.15–0.93 (for African star apple seed shell) [141], respectively. A higher DS value was determined mostly against 30% NaOH [116,119,141] and negligible at 25% and 10% NaOH [5,140].

Interestingly, under or above the 30% NaOH, the DS value often declines due to low reaction rate and polymer degradation [116]. Thus, 30% NaOH has been considered to be optimum for CMC synthesis from various sources with good DS values. Similarly, several research articles have demonstrated that during the etherification of cellulose, changing the concentration of MCA and various solvents (isobutanol, ethanol, etc.) has impacts on DS values [5,19,119,138,140]. For the carboxymethylation of cotton cellulose, the increase in the concentration of monochloroacetic acid-enhanced DS [30]. The effect of reaction time and temperature on DS has been reported by G. Joshi et al. (2014) [19], while DS increased up to 50 °C (optimum temperature) and 3 h (optimum time) reaction time. The DS decreased beyond the optimum temperature and time due to improving oxidant atmosphere and oxidative degradation of CMC. This similar reaction time (3 h) has been validated by V. Pushpamalar (2006) [5] for an optimum DS value against 45 °C. However, in 2015, M. S. Yeasmin et al. [119] used a prolonged reaction time (3.5 h) and a slightly higher temperature (55 °C) in comparison with other researchers and optimized their process to achieve a higher DS value from corn husk cellulose.

Furthermore, the effect of starting material (cellulose) particle size on DS has been reported by MS Yasmin et al. (2015) [119] and MS Rahman et al. (2020) [142]. According to their investigations, the highest DS was found with the smallest particles of cellulose; for example, a DS of 2.41 was found with 74 µm while the decreased DS of 1.83 was observed with an increasing particle size cellulose of 100 µm. As reported by the authors, a smaller particle size of cellulose imparts a higher surface area than larger particle size, which facilitates the high degree of collision between the reactant and cellulose particles; thus, the more hydroxyl groups are easily substituted by the carboxyl group. According to the author’s claim, they obtained the highest DS value in a single step instead of many actions, making the low process cost, less time-consuming, and more eco-friendly than those reported in other papers [119,142].

CMC has wide applications in different fields depending on their DS values. For example, C. Arthur (1989) [143] synthesized CMC with a DS value of 0.5–1.2. Between this range, CMC is widely used in food additives, paper size, paints, coatings, detergents, and oil-well drilling muds. In contrast, Coffey et al. (2006) [144] and Baiqiao et al. (2009) [145] published an article on the synthesis of CMC with a DS value of 0.6–0.95, which has the greatest use in the food industry. However, in 2011, based on the “Joint FAO/WHO Expert Committee on Food Additives, 2011” principle, Casaburi et al. (2018) [128] also proposed CMCs with a DS interval of 0.2–1.5 for food applications. Among the various uses of CMC in food applications, CMC is widely used to increase the durability of acidic milk drinks. CMC has been used as a stabilizer and improves the stability of milk; this property is ameliorated with increasing DS [145] because increasing DS values improve the electrostatic repulsion in casein particles, reducing the milk sedimentation or phase splitting [68]. Moreover, Parikh et al. [31,32] developed cotton burn dressings by partially exchanging sodium cations with silver cations from sodium carboxymethyl cotton for wound dressing or drug delivery purposes. The resulting carboxymethyl gauze/nonwovens with DS of 0.3–0.4 retained a greater amount of silver nitrate solution for better antimicrobial treatment. CMC is used as a hydrogel form with a proper DS value. For example, P. Komorowska et al. (2017) [146] synthesized CMCs with DS values of 0.62–0.79 to make a strong synergism-based Na-CMC/propylene glycol/H2O hydrogel.

Furthermore, in developing the protein–CMC complex, the DS of CMC is an essential factor. During complexation, on the one hand, higher DS inhibits the complex formation. On the other hand, a lower DS provides a better complexation environment between protein and CMC. Y. Wang et al. (2019) [147] reported the highest optical density (higher LPI-CMC complex form) with low DS (0.7) during the interaction between lentil protein isolate (LPI) and CMC.

On the other hand, depending on the suitable DS value, CMC is used in lithium-ion batteries as a suitable binder in the anode. BR Lee and ES Oh (2013) [148] demonstrated CMC as a binder for a Li4Ti5O12 (LTO) anode with an optimum DS vale (1.2). High DS (1.2) improves the strong binding capacity between LTOs, has high ion conductivity, good lithium-ion mobility in the cell, and provides the best cell performance. After all, the DS value of CMC provides an overall performance of the property of CMC. This section has critically reviewed the importance of DS and how the values of DS vary depending on the starting material, reaction conditions, physical factors, for example, particle size, etc.

3. Synthesis of CMC from Its Various Sources

3.1. CMCs from Various Plant-Based Precursor Materials

From the earliest production of CMC, the terrestrial precursors of cellulose have been used most of the time. However, the concomitance of other compositional essences such as lignin, pectin, hemicellulose, and minerals without the expected cellulose extent demands excess energy input and costs for their removal with some excessive pre-treatment steps. Consequently, the use of conventional terrestrial cellulosic precursors is losing interest day by day in CMC production due to their limited availability and expensive cost-expanding pre-treatment steps. Many researchers have reported a moderate amount of cellulose percentage (i.e., 31~60%) in numerous agricultural by-products and wastes such as fruit peels, straws, corn cobs, leaves, etc. [149]. Therefore, an emerging interest has grown in recent years to utilize these materials in commercial CMC production for various applications, according to the properties of the obtained CMC. It is worth mentioning that the synthesized CMCs from different plant-based or agricultural precursors may not show similar physiochemical or morphological characteristics (e.g., DS, rheological properties, viscosity, water, and oil retaining capacity, etc.). Therefore, their targeted fields of application may vary from each other. To improve their existing properties or add new properties, the production of CMC from cotton fibers, which consist of about 95% cellulose, has been carried out [30,31,32].

A significant advantage of plant-based precursors is their high availability in different regions around the world. Compared to the commercial precursors of CMC (such as wood), they are more highly available in other areas of the world at a negligible cost, or sometimes even free of charge. For instance, Meenakshi et al. (2002) [150] reported banana pseudo-stem (i.e., an agricultural waste) as a potential source of cellulose. A few years later, Adinugraha et al. (2005) [10] synthesized a technical grade CMC (of 98.23% purity) from this agricultural waste. The following year, Pushpamalar et al. [5] demonstrated a facile synthesis of commercial-grade CMC products from sago thwacks, which are the waste by-products of various food industries. Bamboo shavings are waste by-products of bamboo industries that contain a considerable amount of cellulose (i.e., 33–45%), along with lignin, protein, hemicellulose, and pectin, as well as some other minor extracts [151,152,153].

Nevertheless, many of these materials are often incinerated or discarded from the industries every year. A few years back, Chen et al. (2014) [117] synthesized technical grade CMCs from abundant waste materials that possessed diversified viscous properties as well as DS values. Flexibility in such properties made it a highly promising precursor for the industrial production of CMC for application purposes. Corncob is considered a waste material after removing the seeds of maize (Zea mays), which is abundantly grown in different regions worldwide. According to Sing et al. (2012) [6], around 16,780,000 tons of maize cereals were produced annually only in India during 2011. Therefore, the authors paid attention to this plentiful waste for synthesizing CMC and obtained a high-quality product with a moderate DS value (i.e., 1.18). A fibrous, low-protein by-product of palm oil cultivation industries (i.e., oil palm fronds) has been proposed as another low-cost precursor of CMC. In 2015, a rough annual production of about 164 million tons of oil palm fronds was reported in [154]. In that study, the author synthesized a high purity CMC product with a high production yield (i.e., 170.1%) and a moderate DS value (i.e., 1.1) from this low-cost precursor through the conventional alkylation-etherification process. Water hyacinth, a free-floating abundant invasive plant of aquatic environments, can be utilized as an effectual precursor of CMCs [140]. A noxious weed (i.e., Lantana camara L.) that can impart various negative impacts on land productivity and consequently, even on the biodiversity of the total ecosystem, was also reported as an influential precursor for the synthesis of a non-Newtonian pseudoplastic CMC product with high viscosity and moderate DS value (i.e., 1.22) by a research team [11]. Similarly, the feasibility of CMC synthesis from numerous plant-based precursors has been demonstrated in dozens of studies by multiple researchers. A list of such adequate studies has been summarized in the Supplementary Materials (Table S1).

3.2. Production of CMCs from Non-Conventional Precursor Materials

Aside from conventional plant-based cellulosic precursors, some waste materials of the textiles industries (e.g., knitted rag, cotton linters) as well as regularly used household and office products (e.g., office waste papers, paper sludge, waste textiles, etc. are available almost free of charge, which can be utilized for the synthesis of CMCs. Production of CMC and its various composites for numerous applications from these waste materials reduces the production cost and plays a vital role in preventing environmental pollution. For instance, cotton linters are a waste product of cotton cleaning factories. In 1954, Ott et al. [155] found that almost 3–5% of cotton fibers are wasted as cotton linters, which contain a high percentage of cellulose (i.e., about 90%) in their raw states. Hence, they can synthesize different grades of CMC products for numerous applications. A few years back, Jahan et al. (2007) [23] reported a facile synthesis of water-soluble CMC from cotton linters that demonstrated an appreciable DS value with high viscosity. In another study, Hivechi et al. (2015) [156] reported a cost-effective, environmentally friendly process for the synthesis of CMC from cotton linters using ultrasonic and microwave radiation that facilitated the conventional approach (i.e., alkylation-etherification) of CMC production. Fakrul Alam and Mondal (2012) [20] synthesized carboxymethylated cellulose from the knitted rag, which is a common waste material of almost all textile industries and contains a high percentage of ɑ-cellulose (e.g., 95–98%). To investigate the effect of multiple carboxymethylation steps on the CMC quality and grade, the authors conducted consecutive seven-step carboxymethylation using the same experimental conditions and chemicals listed in the Supplementary Materials (Table S2). Multiple carboxymethylation steps of the crude cellulose demonstrated high yield (%) of CMC, DS, molecular weight, and water solubility. More specifically, in the first carboxymethylation, the DS value and yield of CMC obtained were only 0.91 and 360%, respectively. In contrast, after repeating the process seven times, these values reached up to 2.84 and 1494%, respectively.

Recently, Li et al. (2020) [157] synthesized CMC from office waste papers to fabricate an environmentally friendly, low-cost, crust-dust suppressant. However, a few years earlier, Joshi and his co-workers (2015) [19] demonstrated the feasibility of CMC synthesis from mixed office waste papers after deinking and pulping them. It is worth mentioning that deinking is an ancient process for reusing waste papers. The ink particles are removed from fiber surfaces either by chemical treatment methods such as alkali boiling [157]. The dispersed ink particles are removed from the fiber suspensions by the floatation method [158]. Therefore, a thousand tons of waste paper daily obtained from various offices and industries can be utilized as a plentiful precursor of CMC. Table S2 in the Supplementary Materials assembles some of the most promising research works based on the synthesis of CMCs from such waste cellulosic materials. We have summarized their grave essences in brief.

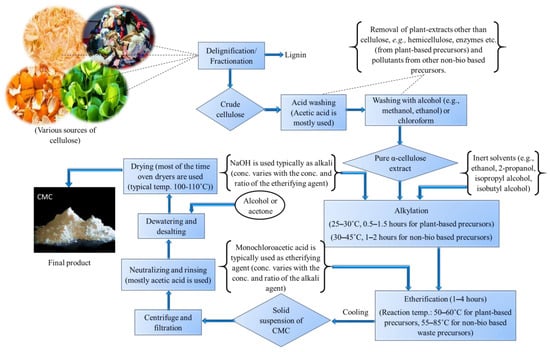

3.3. Synthesis Route of CMC

The conventional method for CMC synthesis is the alkylation-etherification process. In every research work related to the synthesis of CMC, this idiosyncratic process has long been used from the very beginning of CMC synthesis from various cellulosic precursors. The only difference between these works is in the applied ratios of the affined chemicals to the cellulosic extents of the precursors and variation in the reaction parameters such as temperature, reaction time, pH, etc. It is noteworthy that all of the natural and industrial cellulosic precursors (e.g., leaves, stems, pulps, paper wastes, microbial as well as various textile-based precursors such as cotton linters, knitted rags, etc.) may not possess similar compositional characteristics that can provide a fixed amount of cellulose extract every time. Most precursors contain a considerable amount of lignin, pectin, ash, and other minerals (e.g., phosphorous, potassium, calcium, etc.) besides the cellulosic percentiles. Therefore, on occasion, some pre-carboxymethylation steps such as proteolysis (treatment with protease enzyme), inactivation of various enzymes of the plant-based precursors (e.g., deactivation of pectic enzymes present in orange peels) [14], delignification, dewaxing [140], bleaching, defatting [14], and acid washing, as well as treatment with some essential chemical compounds (e.g., methanol, ethanol, chloroform, etc.) [11,13,159] and removal of hemicellulose [140] are carried out for the extraction of pure ɑ-cellulose from natural sources.

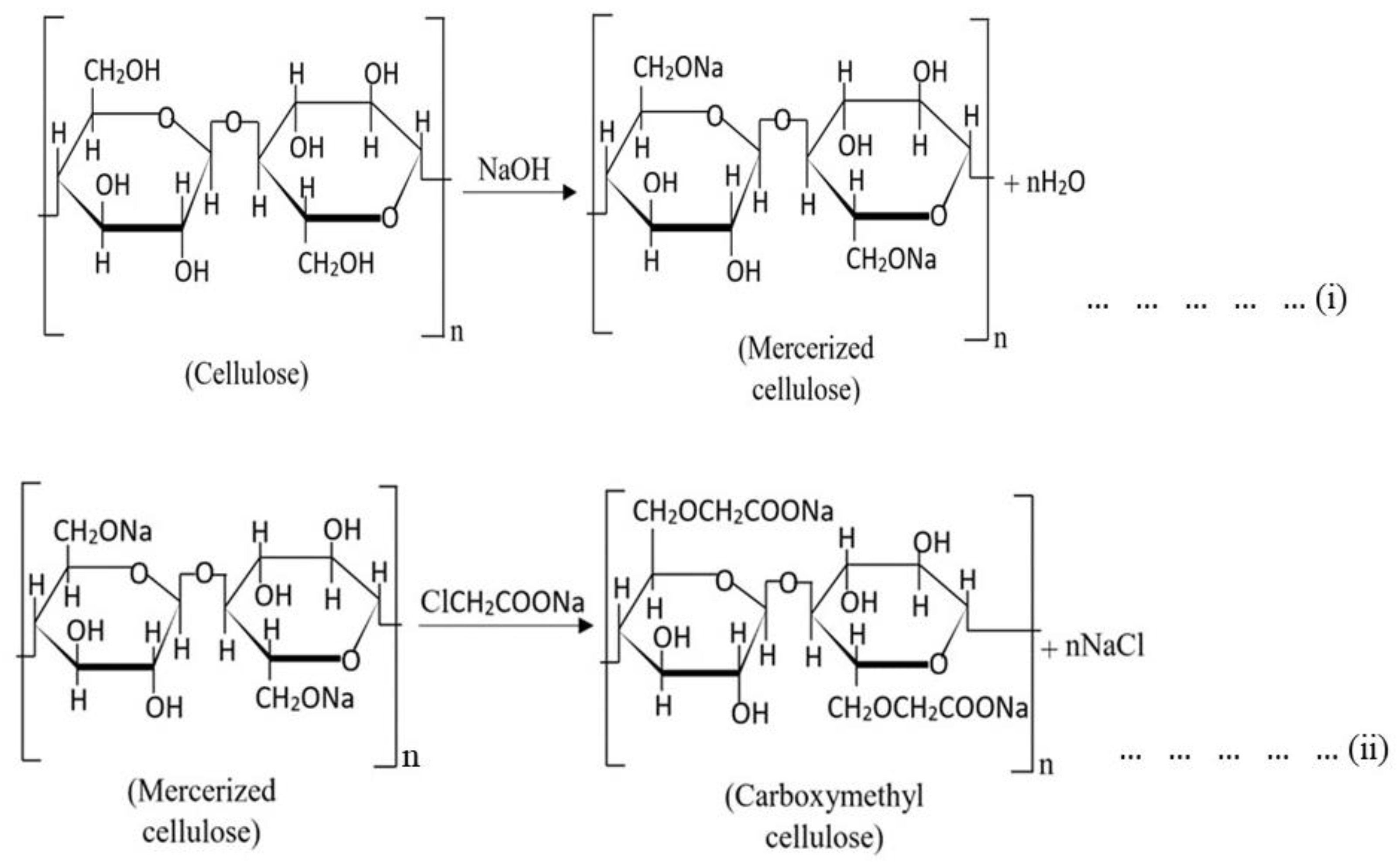

Carboxymethylation of the pure ɑ-cellulose is performed basically in two significant steps. In the first step, the pre-purified cellulose extracts are mixed with alkali reagents (e.g., NaOH) in a reaction vessel for a specific time. During this time, the pure cellulose contents are mercerized. Subsequently, –OH functional groups from each AGU unit are substituted by –ONa groups targeted for the posterior substitution by carboxymethyl groups in the etherification step (Scheme 1, reaction (i)). Concentrations of the alkali, ratios between the alkali and cellulose, and reaction temperature should be maintained very carefully. A slight change in these parameters can significantly change the final product’s DS value and other physicochemical properties. An inert solvent (such as ethanol [31,32,160], 2-propanol [161], isopropyl alcohol [6,22,162], or isobutyl alcohol [137], etc.) is added in this step as a diluent as well as a swelling agent that facilitates the penetration of the affined reagents into the cellulose structure.

Scheme 1.

Chemical reactions of CMC synthesis from cellulose [6,7,19,31,32,157].

(i) An etherifying agent is added into the reaction vessel in the next step (i.e., etherification). NaMCA is often used as an etherifying agent [7,10,19,157,163]. However, some researchers have modified their process using other reagents, such as diazomethane [15], instead of the conventional etherifying agent. The mercerized cellulose is stirred continuously with the reagent for a certain time. An optimized temperature is required to obtain the best result, and therefore, the reaction temperature should be maintained carefully. During this step, the reactions can be represented as reaction (ii) (Scheme 1).

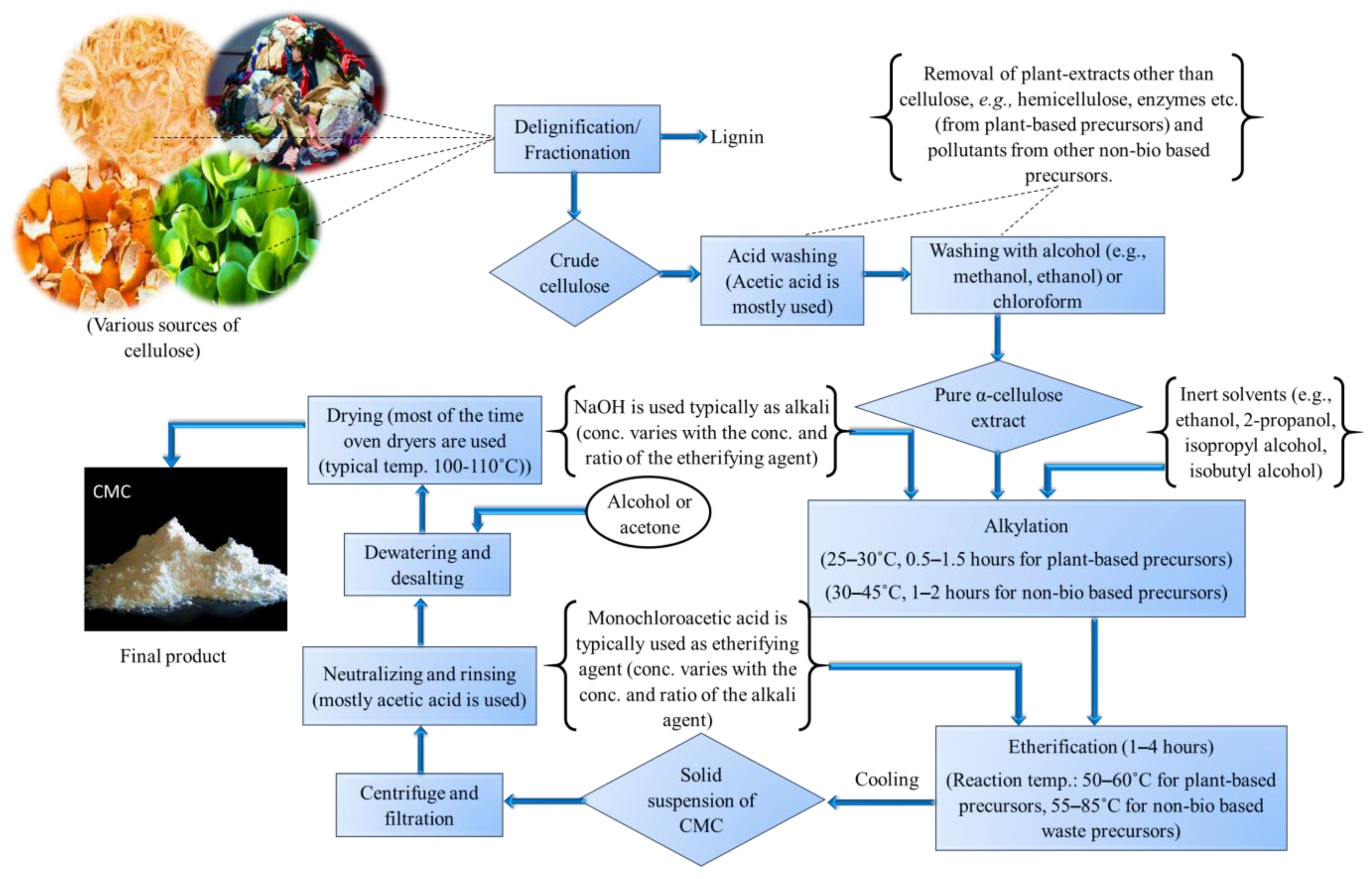

After mercerization and etherification, a solid suspension of CMC is obtained. Then, after ensuring that the pure product is free from other impurities, the suspension is then centrifuged and filtered with a congruous filtration medium [5,8,14,15,18,19,163]. The product is then polished and finalized by performing some post-treatment procedures such as neutralizing with weak acids (e.g., primarily acetic acid is used [9,14,157,160]), washing with alcohol for dewatering and desalting [7,10,16,20,139] and/or acetone [6,163], and finally drying the obtained solid product at a specific temperature (mostly, oven drying is carried out rather than sun drying to maintain the temperature correctly. A flow diagram depicting the entire process of CMC production from its various precursor materials is shown in Figure 2.

Figure 2.

Schematic representation of CMC production from its various precursors.

3.3.1. Factors Affecting the Characteristics of CMC

The Temperature of the Etherification Process

The temperature of the etherification process plays an important role in the DS, degree of polymerization (DP), and other physicochemical properties such as viscosity, swelling behavior, thixotropy, etc., of the final product. The product’s best DS value is obtained only at a specific temperature. For instance, Pushpamalakar et al. (2006) [5] obtained the highest DS of their products (0.821) at 45 °C reaction temperature. Above and below this temperature, the DS value decreased significantly. Golbaghi et al. (2017) [16] obtained the best DS value of their sugarcane bagasse-derived CMC product at 57.85 °C after conducting dozens of reactions at different temperatures from 30 °C to 70 °C.

Similarly, Singh et al. (2012) [6] reported the highest DS value of their corn cob-derived CMC products only at 60 °C temperature. Silva et al. (2004) [164] investigated the effect of reaction temperature on the carboxymethylation of cashew tree gum-derived cellulose. DS value of their carboxymethylated product diminished considerably (i.e., from 0.75 to 0.16) as the reaction temperature was enhanced up to 70 °C from 30 °C. However, the reaction yield was increased (i.e., from 32% to 57%) at the same environmental conditions. Hence, the optimum temperature is not the same for every terrestrial or other cellulosic precursors. However, they introduced their reaction optimizing tendency within a specific range of temperatures. Outcomes of various studies revealed that most carboxymethylation reaction temperatures were optimized at 50 °C–60 °C for terrestrial precursors of cellulose [6,7,9,10,11,13,16,161]. However, some exceptions have also been reported in other studies [5,14].

On the other hand, the optimum temperature crossed over 70 °C for the carboxymethylation while using various non-biological waste materials as a precursor of CMC [19,20,139,157]. This phenomenon can be explained by facilitating the forward reaction kinetics of carboxymethylation as the temperature was raised to the optimizing point. Once the temperature is presented to an end, the posterior aggrandizement of the weather increases the reaction kinetics. Still, it induces the degradation of the cellulose structure in the presence of atmospheric oxygen, which diminishes the CMC production automatically [5,6,19]. Therefore, the optimum temperature for carboxymethylation largely depends upon the precursor of cellulose to obtain the best production yield, and it is crucial to maintain the reaction temperature properly.

Dosage of the Etherifying Agent

The dosage of the etherifying agent has a significant impact on the final product’s physicochemical properties and DS values. Casaburi et al. (2017) [128] synthesized a highly purified CMC from bacterial cellulose where the Gluconacetobacter xylinus strain was used as the precursor. The authors demonstrated a significant enhancement in the DS value while gradually increasing the dosage of an etherifying agent (NaMCA) per mole of AGU. However, after a certain point (i.e., NaMCA: AGU = 2:1), the DS value started to decline. Similar results have also been found by some other researchers. A few years ago, Joshi et al. (2015) [19] received the highest DS value of their product (1.07) by using 0.11 M NaMCA as an etherifying agent. Afterward, using both the higher or lower concentrations of the reagent around this value significantly reduced the DS of the CMC. Almost similar results were reported by Pushpamalakar et al. (2006) [5] while synthesizing CMC from sago wastes (i.e., a by-product of the sago starch production industries). They obtained the maximum DS value (0.77) of the synthesized CMC using 6 g of NaMCA per gram of the precursor as an etherifying agent. Upgrading or reducing the dosage of NaMCA from this point diminished the DS value. Such a phenomenon can be attributed to the fact that enhancing the dosage of the etherifying agent up to the optimum point enhances the availability of the acid molecules in the proximity of the cellulose hydroxyls, thereby facilitating the carboxymethylation [165]. Later, the addition of an excess amount of NaMCA over this optimum value brings no payments at all due to the exiguity of the mercerized cellulose alkoxides that can react with this etherifying agent [11]. However, the redundant chemicals then react with the available mercerizing agent (i.e., NaOH) in the reaction vessel, form a by-product (sodium glycolate) presented in reaction (iii), and consequently reduce the rate of the significant carboxymethylation reactions [11]:

| NaOH + Cl-CH2COONa → OH-CH2COONa + NaCl … … … … … | (iii) |

The Concentration of the Alkali

The concentration of the alkali used for the mercerization of the cellulose (i.e., NaOH) also plays a vital role in ascertaining the DS of the final product. A few years back, Mastrantonio et al. (2014) [163] synthesized a technical grade CMC using short cellulose fibers from paper industry effluents. They experienced a considerable reduction in both the DS value and yield of the final product when the concentration of NaOH was enhanced from 7.0 g/mL to 10.5 g/mL. Similar outcomes have also been demonstrated by some other researchers. For instance, Bhandari et al. (2012) [166] reported that the DS value of their carboxymethylated product decreased from 0.56 to 0.46 when the alkali dosages were increased by 20 g.

Furthermore, a noticeable reduction in reaction efficiency was also experienced. More specifically, the reaction efficiency decreased from 20.12% to 16.39% as the dosage of NaOH was increased from 30 g to 50 g, respectively. Pushpamalakar et al. (2006) [5] reported that increasing the concentration of NaOH up to a certain amount (i.e., 25%) enhanced the DS value of their sago waste-derived CMC. However, the posterior enhancements in this concentration caused a considerable reduction in the DS. Casaburi et al. (2017) [128] obtained an increasing DS of their bacterial (Gluconacetobacter xylinus) cellulose-derived CMC while it enhanced the alkali concentration up to an optimizing point at the mercerization step. Similar results were also reported by Rachtanapun et al. (2011) [159] for their Mimosa pigra derived CMC films and powders. Although their product’s DS value was enhanced considerably up to a 50% NaOH concentration, it suddenly started to drop from higher concentrations of alkali.

However, the key factor behind these phenomena is the alkali:etherifying agent ratio applied in the reaction procedure. It is only at a certain ratio between the alkali (NaOH) and the etherifying agent that the highest DS value and the best physicochemical and mechanical properties (e.g., tensile strength, water retention capacity, viscosity, elongation, etc.) are obtained. This is said to be the optimized ratio of a certain cellulosic precursor. Whenever the respective dosage of mercerizing or etherifying agents increases or decreases, a competitive side reaction (reaction (iii)) between these two reagents predominates the major alkylation and etherification reactions. Consequently, an unwanted by-product (i.e., sodium glycolate) is formed that leads to less polymer degradation as well as substitution of the new functional groups into cellulose structures (i.e., reduces the DS value) [22,151,164].

Moreover, the concentration of NaOH and the etherifying agents also affects the other physicochemical properties of the carboxymethylated product, such as viscosity, water retention capacity, etc. Rachtanapun et al. (2011) [159] synthesized CMC films from an invasive weed (i.e., Mimosa pigra). Each of the films synthesized using different concentrations of NaOH in their mercerization step exhibited significant differences in water vapor transmission rate and water vapor permeability in experimental conditions (e.g., 25 °C, two days, fabricated film area 28.27 cm2). Both properties increased with the increase in NaOH concentration. Varshney et al. (2006) [11] showed that the viscosity of their carboxymethylated product derived from Lantana camara (a noxious weed) was increased, as apparently, the concentrations of the mercerizing agent (i.e., NaOH) increased up to a certain point. However, the posterior enhancement dropped off with the alkali concentrations. Similar results were also reported by Rachtanapun et al. (2012) [9] and Adinugraha et al. (2005) [10].

This phenomenon can be explained as the introduction of carboxymethyl functional groups into the cellulose structure increases the hydrodynamic volume of the product, which results in a gradual enhancement of its viscosity. The DS (i.e., the introduction of carboxymethyl groups into cellulose) is highly dependent on NaOH concentration [5,128,159,166]. Thereby increasing the concentration of NaOH ultimately increases the viscosity of the product. However, after a certain point, when the hydrodynamic volume of CMC surpasses its maximum limit, applying more dosage of NaOH or increasing its concentration results in the degradation of the cellulose structure [11]. Therefore, optimizing the alkali and the etherifying agent’s concentrations and ratio should be the priority in obtaining the best outcomes from the conventional alkylation-etherification process.

4. Application of CMC

4.1. Application in Textile Industries

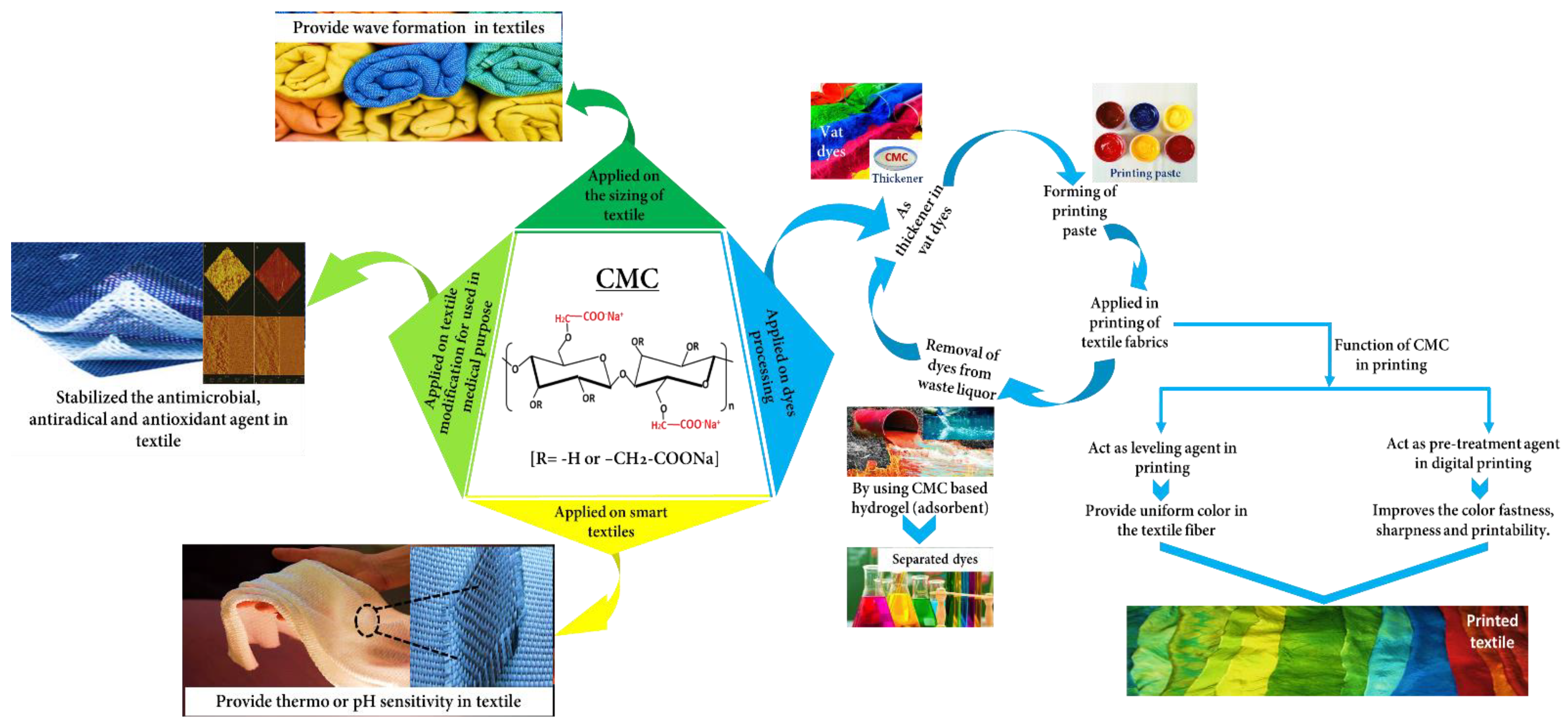

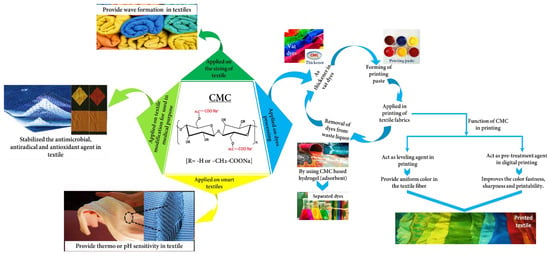

Over the years, various polysaccharide-based thickeners have been widely used in textile printing with several types of dyes and fabrics such as guar gum, tamarind, corn starch, tapioca starch, etc. CMC has recently been developed as a very effective thickening agent in paints and textile varnishes for its better water-absorbing property. For example, the synthesized CMC from lignocellulosic waste was used as a thickener in vat dyes for textile printing [57]. Modulating the thickening property of vat dyes controls the proper viscosity for yielding a good quality paint. It can also hold the dye particles in the printing area with other chemicals or printing assistants. Furthermore, it acts as a good vehicle for dye materials and promotes better binding into the textile specimens. Last year, Fangfang An et al. (2020) [167] reported the rheological properties and performance of CMC or CMHPC (carboxymethyl hydroxypropyl cellulose-CMC derivative) as a thickener more densely in the case of the printing of high-quality reactive dyes.

Based on the high-viscosity and film-forming properties, CMC has been proposed to harness many purposes in the textile industry. Due to having a water solubility property, it has been highly suggested for use in printing pastes, sizes, finishes, and lubricants. Furthermore, in textile fabrics, crude CMC occupies a vast position and acts as a sizing agent, including the sizing of filament threads, yarns, and other textile materials. The low toxicity, biocompatibility, water solubility, and ease of removal by the washing property enhance its priority in textile sizing applications. For example, CMC and starch-based hybrids act as sizing agents in cotton fabrics or yarns [59]. CMC acts as an additive, increasing the adhesion of starch sizes to cotton and cotton blends. Moreover, CMC often applies to textiles as a sizing agent in the form of CMC-g-polyvinyl alcohol, CMC-g-polymethyl methacrylate, etc. [20,60].

Moreover, in silk fabrics, CMC is applied as a pre-treatment and leveling agent to improve the color fastness and adjust the color difference in digital printing. During textile printing, CMC controls the viscosity of color with a mixture of other agents and enhances the dye’s hydrophilicity and penetration [88], which provide better sharpness and printability of color. For example, the CMC/sodium alginate/dextrin mixture proposed by Dong-Seok et al. (2013) [58] was used for the digital printing of textiles. On the other hand, Kolmana et al. (2017) [168] developed CMC-based silica/polyelectrolyte complexes for painting applications. During canvas painting on textiles, CMC enhances adhesion between the complex and cotton fiber, which improves the strength of the materials. In cotton fabrics, the introduction of CMC increased water (or antimicrobial liquid) retention for absorbent and wound dressings [30,31,32]. Such newly added properties can be achieved without losing fiber integrity and carding ability using an appropriate CMC substitution. As a result, carboxymethylated cotton fibers are applicable in the fabrication of various personal hygiene and wound care nonwoven products.

Furthermore, CMC hydrogels have taken a broad position in textile waste management, where CMC hydrogels are used as an environmentally friendly adsorbent for removing dyes from wastewater or solution. Various researchers have proposed different CMC-based hydrogels due to the variation in pigments (likes organic or azo dyes, anionic or cationic dyes, etc.). This is broadly discussed in the wastewater treatment part of this review article. Here, one example is disclosed for demonstration as part of the textile application. Like, recently, Kokkarachedu and his fellows (2017) [169] formulated a CMC/acrylamide/graphene oxide hydrogel, which is used for the removal of organic-based dye (Acid Blue-133) from waste liquor via the adsorption method.

A few CMC composites have been examined as bioresorbable textile materials for rapid and efficient hemostasis purposes in modern medical textiles. Recently, Suchý et al. [170] proposed a CMC/hyaluronic acid (HA) or CMC/HA/etamsylate composite-based (with or without active ingredient) hemostatic nonwoven textile for faster blood clotting and wound healing. To provide proper therapeutic care in the human body, the release of active ingredients from medical textiles was also controlled using CMC as the coating material. This information was applied by Roy et al. (2017) [171], and they developed a chitosan/CMC/glutaraldehyde-based microcapsule for application on cosmetic textiles. Furthermore, during wet wound care, the CMC (as an acid form) is used in combination with collagen (collagen/CMC) to form nonwoven textiles [172]. CMC provides excellent mechanical properties during application and ensures safer wound care in wet conditions. Moreover, to monitor health and biomedicine activity, CMC is used as carbonized CMC (smart fabrics) on flexible electronics [173].

However, CMC derivatives are also being introduced in textile products due to their antimicrobial activity. Likewise, Ebru Bozaci and his co-workers (2015) [61] fabricated cotton fabrics by a fumaric acid/CMC-based silver nanocomposite, a safe, hygienic, comfortable, biodegradable composite, and has excellent antimicrobial activity. In the fabrication of nanoparticles, CMC acts as a stabilizing and reducing agent and reduces the silver nanoparticles by hydrolyzing CMC. In the current year, CMC was used as a coating material on nonwoven fabrics and developed a better or favorable antimicrobial textile with the presence of AgNPs (silver nanoparticles). This type of antimicrobial-based nonwoven textile was tested on rat skin (for wound healing) by Montaser et al. (2021) [174].

Additionally, some CMC derivatives have been formulated by introducing different antioxidant or antiradical materials. Thus, they are widely used in wound healing application-based textile materials. Krizova and Wiener (2013) [62] formulated polyphenols (antioxidant or antiradical material) and CMC-based fresh gel for textile materials. Generally, this gel is applied to wound healing textile cotton for the protection of healing cells from oxidative damage, where CMC acts as a controlled release carrier of polyphenols and stabilizers in textiles.

In modern times, smart or intelligent textiles increased as priorities in the textile industry’s revolution. Innovative materials are defined as environmentally responsive textiles like thermosensitive, pH-sensitive textiles, etc. Additionally, CMC or its derivatives are used as part of the component in the production of innovative materials. According to the research by the Chinese and Japanese, CMC can be used in thermosensitive textiles in a hydrogel form like the photographed CMC/acrylic acid/poly-N-isopropyl acrylamide (PNIPAM) hydrogel [175], which is used in innovative fabrics for formulating thermosensitive water-absorbing features of materials. The presence of toxic PNIPAM has a poisonous effect in this thermosensitive hydrogel, which is very problematic. Due to the poisonous effect of PNIPAM, Selestina and Vanja (2011) [63] proposed a new non-toxic, biodegradable and, pH and thermosensitive CMC-based hydrogel to fabricate knitted cotton fabric. During fabrication, this hydrogel formed a thin layer on the textile fabric surface, which showed better absorbance sensitivity in the different pH solutions and changing temperature when the fabricated textile was drowned in solution, where the concentration of CMC controls the pH or thermosensitive property of the hydrogel. Recently, a three-layer-based (chitosan/CMC/indicator dye) non-invasive, biocompatible, comfortable, and sweat pH-lactate sensitive textile was examined by Promphet et al. (2019) [176].

Various textile-based CMC applications have been shown by many researchers focusing on thickeners in dyes, pre-treatment or film-forming or sizing agents in fabrics, adsorbents for dye removal, its derivatives or composite form in antimicrobial or antioxidant purposes, and intelligent textiles. However, these properties were hardly combined in a single review paper showed in the Supplementary Materials (Table S3). Therefore, herein, we gathered up-to-date reported CMC data for textile applications and critically reviewed and summarized it, especially emphasizing four parts such as dye processing, sizing of the textile, modification of medical-based materials, and bright fabric (Figure 3). Additionally, we unveiled the specific function of CMC for use in textile applications that would be worthy for people interested in this field.

Figure 3.

Schematic representation of the textile-based CMC application.

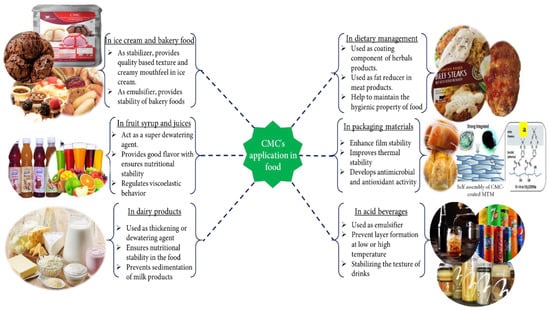

4.2. Application in Food Industries

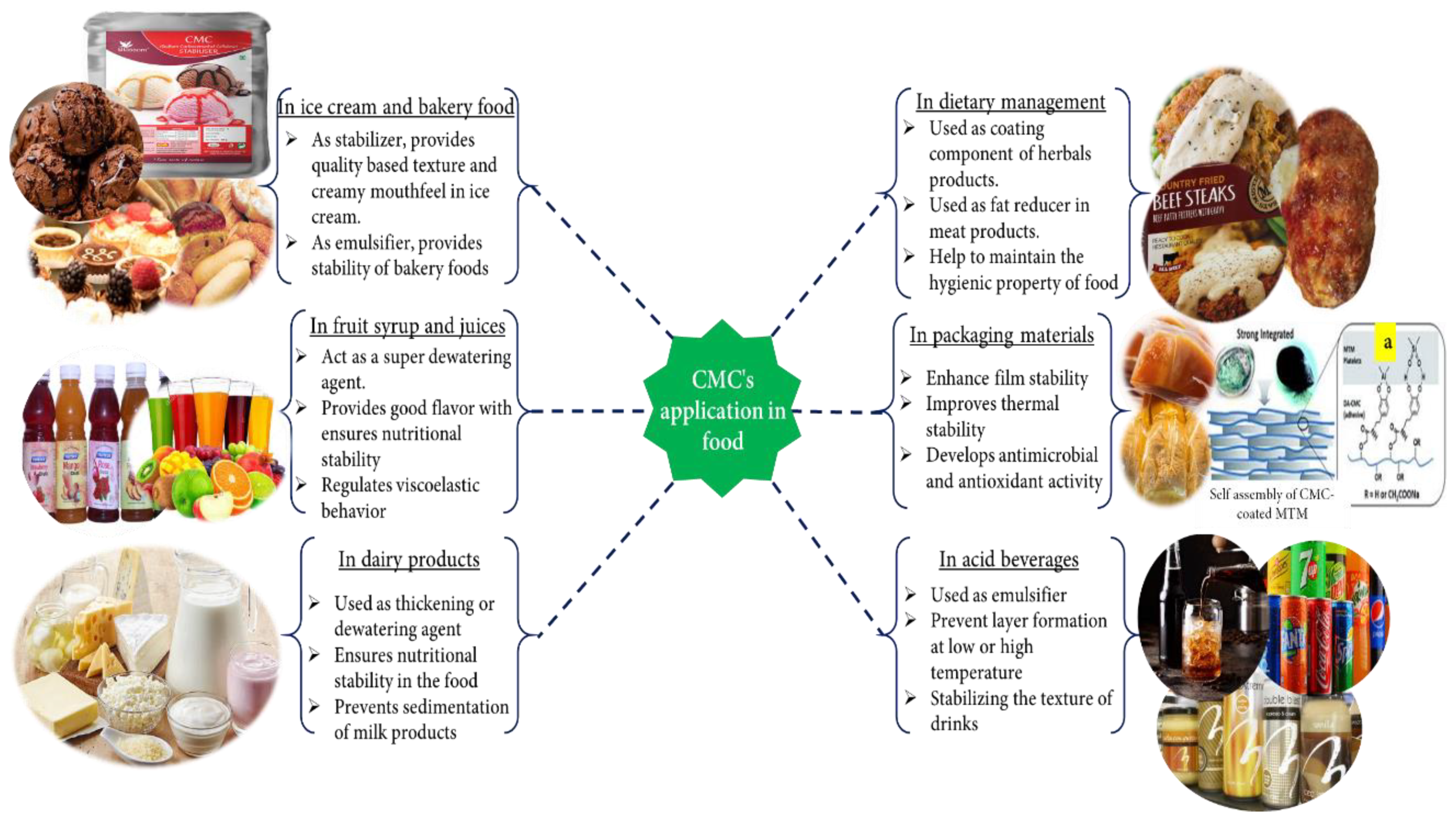

The food industry plays an essential role in providing food to human society. There are many auxiliary agents, for example, various polysaccharide (alginates, gums, agar, some pectin and galactomannans, modified starches, modified cellulose, CMC, etc.) [177,178], hydrocolloids like soluble soybean polysaccharide (SSPS), sugar beet pectin (SBP), and xanthan gum powder [177,179] that are used in the food industry as a binder, thickener, fixing agent, and emulsifier to make quality foods. CMC is frequently used in the food industry (Figure 4) as an auxiliary agent due to some of its excellent properties, such as being odorless, tasteless, noncaloric, physiologically inert, forms a clear solution without opacity, preventing the capacity of gravitational separation of suspended particles, etc. [180,181].

These CMC features help improve food quality and the desired good mouthfeel to ensure food safety. Usually, CMC is used as various auxiliary agents in the food industry, such as thickeners, emulsion stabilizers, additive stabilizers, moisture binders, suspending and improving texture, water retaining (or dewatering), etc. Additionally, CMC is used to fine-tune the rheological property, structure, flavor, and appearance of products and their pseudoplastic properties. In addition, it is used as a coating or packaging material to ensure the long time safety of food products [182]. Many studies have appeared on the use of CMC in food products in the literature. For example, CMC is used as a thickener in nano-emulsions based on olive oil to improve the physical property and stability via controlling particle size, concentration, and texture [125]. Depending on the viscosity, CMC is used in the food industry. Namely, low viscosity type CMC acts as a moisture binder, and high viscosity type CMC acts as a gelation agent [120].

Furthermore, it is used in semisolid dairy products, salad dressing, and fruit syrup as a thickener [183,184,185]. Nowadays, in fruit syrup or juice, CMC is used as a hydrogel (dewatering agent) to ensure food safety. In the conventional thickening process, heat is essential, where the super absorbing or dewatering process in the presence of heat is not essential [126]. CMC is utilized in milk and cream products, condiments and bakery food, acidic dairy products, and ice cream, acid beverages, spreads, and wine as an emulsifier [186,187]. In ice cream, 0.5% CMC is used as a stabilizer to produce the best quality ice cream. CMC with medium viscosity enhances the texture quality and provides creamy mouthfeel via eliminating the over-crystal growth of lactose in cream [120,185]. In cocoa and acid milk drinks, CMC is often used for stabilizing the texture of drinks, preventing sedimentation and layer forming in drinks at low and high temperatures [130]. Due to stabilized dietary fiber or nutrients in fruit-based beverages, CMC has recently been used as a stabilizer in a drink as a blended form of CMC and gum tragacanth [188].

In the last couple of years, the use of CMCs in food has moved from a normal to advanced level in food as they are hygienic, biocompatible, and human disease prevention or dietary management. For example, due to the prevention of gastrointestinal infection, Dafe et al. (2017) [189] developed CMC/k-carrageenan mixed food vehicle to supply probiotic-based food in the colon. While suggested, food controlled the gastrointestinal tract or mucosa’s health and improved the immune system. Similarly, in 2019, Ngamekaue et al. [190] proposed another coating material for delivering a herbal oil-loaded microcapsule (a blend of holy basil oil and gelatin) the intestine. Simultaneously, a CMC/beeswax coating composite protects the microcapsule from acid, moisture, or oxidative elements and helps control the herbal product after reaching the intestine. Suggested herbal products act as good antioxidants, anticancer agents, etc., in the human body and help protect non-communicable diseases. Therefore, due to extending the shelf life, essential oil and grape seed extract bio-based CMC coatings have also been applied on seafood [191].

High fats in the food (meat) are a significant barrier to making healthy food products. To solve this problem, CMC derivatives are used as fat replacers or reducers. As fat replacers, Gibis and colleagues (2015) [192] used CMC and MCC (microcrystalline cellulose) when making fried beef patties where 0.5% CMC concentration was chosen as a good fat replacer and excellent flavor, texture, and juiciness supplier. On the other hand, Han et al. (2017) [193] designed high nutrition and lowest fat-based healthier meat products. During meat processing, CMC and other dietary fibers (such as cellulose, chitosan, inulin, pectin, etc.) are used as fat reducers, nutrition enhancers, and texture modifiers that help to reduce the chances of colon cancer, cardiovascular disease, etc.

In the last decade, some researchers have disclosed the use of CMC as food packaging material. Khezrian et al. (2017) [194] developed an essential oil doped montmorillonite/chitosan/CMC nanocomposite-based active packaging material to extend the shelf life of camel meat. Moreover, as a primary packaging material, biodegradable and ecofriendly PVP–CMC hydrogel film is also widely used for food goods [195]. CMC/PVA/zeolite doped with a metal cation-based film has been reported as a biodegradable and antimicrobial packaging material. This antimicrobial property prevents food from spoiling and increases the shelf life of goods [196]. CMC-CHPS (chickpea hull polysaccharides) films produce antioxidant and antimicrobial activities in the packaging materials [197]. Recently, high thermal stability and high stiffness-based packaging materials have also been developed by conjugation of CMC, dopamine, and montmorillonite [198].

Figure 4.

Various applications of CMC in food. (a) Assembly of CMC in coating composition [198]. Reproduced with permission from [198]. Copyright 2021, Royal Society of Chemistry.

Figure 4.

Various applications of CMC in food. (a) Assembly of CMC in coating composition [198]. Reproduced with permission from [198]. Copyright 2021, Royal Society of Chemistry.

4.3. Application in the Water Treatment Process

In the present day, water pollution has become one of the most crucial issues worldwide. An immense number of pollutants come from various industries and household deeds every day and enter into aquatic environments, which further causes several types of disorders in different living organisms and human beings. There is no absolute limit on how many types of pollutants can be present in wastewater that has come from multiple industries or other household activities. However, to the best of the author’s knowledge, CMC-based materials have been mainly used thus far for the removal of various organic-inorganic dyes [74,199,200,201], inorganic ionic pollutants (both anions and cations) [202,203,204,205], as well as various radioactive species [83,206,207,208] from polluted waters in different experimental conditions.

Dyes are considered the most hazardous compounds in aquatic environments [209,210,211,212]. A wide spectrum of their applications in various industries such as food, paint, textiles, pulp, paper, rubber, plastics, tannery, cosmetics, and dozens of structural and manufacturing industries have turned the waste dye effluents into a crucial factor in wastewater treatment works [213,214,215] Moreover, their long-term durability against light, heat, and other oxidizing agents, slow rate of biodegradation, and variety of chemical compositions have made them a more intricate issue in environmental pollutions [216]. Furthermore, inorganic ionic pollutants, especially heavy metal ions, and some reactive anions have been marked as highly harmful to the health of various living beings [217,218,219,220].

CMC has been demonstrated as active material in various water treatment works during the past few years by many researchers. However, some researchers have elicited some excellent innovative hybrid materials with CMC to remove various pollutants from wastewater in recent years, as presented in the Supplementary Materials (Table S4). For example, Salama et al. (2018) [201] synthesized a nano-adsorbent material (i.e., CMC/Fe3O4) by the co-precipitation method for the adsorption of methylene blue dye from the experimental polluted aqueous solution, where about 48 mg of methylene blue hues were adsorbed per gram of the adsorbent at pH 3, and maximum adsorption efficiency was obtained at pH 7 (i.e., 64 mg/g). In the same year, Hong and his co-workers (2018) [70] investigated the scavenging performance of another CMC embedded polyurethane composite against various metal pollutants from industrial waters. The composite material demonstrated some excellent adsorption efficiencies against various ionic contaminants. Up to 216.1 mg of Pb2+, 78.7 mg of Cu2+, and 98 mg of Cd2+ ions were removed by each gram of the adsorbent. Most recently, Manzoor and his co-workers (2019) [221] synthesized a chitosan/CMC hybrid adsorbents using arginine cross-linkers that showed a better adsorption capacity against Cd2+ and Pb2+ ions (up to 168.5 mg/g and 182.5 mg/g, respectively) in experimental conditions. Gasemloo et al. (2019) [222] demonstrated a sulfated-CMC-based nano-filter membrane technology (cross-linked with glutaraldehyde) that showed a high removal efficiency against Cr(VI) at optimum conditions (i.e., maximum pollutant removal 79.85% at 3 bar pressure and pH 4). Additionally, Wei et al. (2015) [223] demonstrated an ultrathin fibrous CMC-based cross-linked nanocomposite material (cross-linked with epichlorohydrin) that showed a super-dynamic removal of Cd2+ ions from experimental wastewater. Moreover, up to 150.60 ± 10.47 mg of the pollutants were removed per gram of the adsorbent at optimum conditions. Likewise, other researchers have also reported dozens of such effective outcomes that reveal the potentialities of CMC-based composite materials for efficient removal of various organic-inorganic pollutants in wastewater treatments.

Moreover, some researchers have reported some excellent adsorption capacity of CMC-based composite materials against radioactive pollutants from wastewaters. For instance, 137Cs (half-life 30.1 years) is a randomly found radioactive element in nuclear wastewaters, which is considered as causing many diseases such as genetic disordering, cancer, etc. [224,225]. In 2018, Rethinasabapathy et al. [207] synthesized a layered structured multifunctional polyhedral oligomeric silsesquioxane (POSS) modified Fe-aminoclay/CMC composite that exhibited adsorption capacity against radioactive Cs ions as well as methylene blue and chrysoidine dyes (152 mg/g, 438 mg/g, and 791 mg/g, respectively). In the following year, Zhang and his co-workers (2020) [226] fabricated a CMC-based hybrid adsorbent (cross-linked with ammonium phosphomolybdate). They demonstrated its excellent adsorption capacity against radioactive 137Cs (64.20 mg/g) from nuclear wastewater. Furthermore, Eun et al. (2020) [179] demonstrated a Prussian-blue embedded CMC nanofibrous membrane technology that showed a competitive adsorption capacity against radioactive 137Cs (maximum 130 mg/g) from laboratory-based experimental aqueous environments. A few years ago, Shao et al. (2008) [206] synthesized a CMC grafted multi-walled carbon nanotube (CMC-g-MCNT) adsorbent for radioactive uranium sorption from nuclear wastewater. Uranium is an essential element of nuclear power plants, and atomic energy programs have found UO22+ soluble cationic forms in wastewater around the plants [206]. The authors demonstrated an extreme adsorption capacity of their synthesized CMC-g-MCNT sorbent against UO22+ nuclides (i.e., up to 98% of pollutants were removed using only 1g/L adsorbent). Furthermore, Cai, along with his research team (2017) [83], fabricated a core-shell structured Fe3O4-modified CMC composite material that exhibited a moderate extraction capacity against the radioactive 152+154Eu nuclide (i.e., maximum removal 2.78 × 10−4 mol/g at 293 k) from wastewater.

The above-mentioned discussion was just a glimpse of the potentialities of various CMC-based composite materials for wastewater treatment purposes. More effective research outcomes with a brief detail have been summarized in the Supplementary Materials (Table S4). Here, it is worth mentioning that the CMC-based composites will naturally exhibit a better adsorption tendency toward the metal ions and other cationic pollutants than anionic contaminants due to the presence of electronegative carboxymethyl groups (-COOH) on their surface. Electrostatic repulsion between the anionic pollutants and the opposing surface charges makes it harder for the adsorbents to bind the negatively charged impurities efficiently for a long time. Perhaps this is the only reason behind the frugality of research attempts in the literature about anionic pollutant removal by CMC-based composite materials in wastewater treatment compared to cationic pollutants.

Therefore, we suggest focusing on the fabrication of CMC-based, more effective, and low-cost hybrid materials, especially nano-hybrid super-absorbent materials. Future research works to remove various cationic pollutants such as metal ions, cationic dyes, and different cationic radioactive materials in wastewater treatment are needed. Additionally, surface modification of the CMC-based adsorbents by hybridization with varying types of organic-inorganic positively charged species may make them more promising in the future for the treatment of both cationic and anionic pollutants contemporaneously.

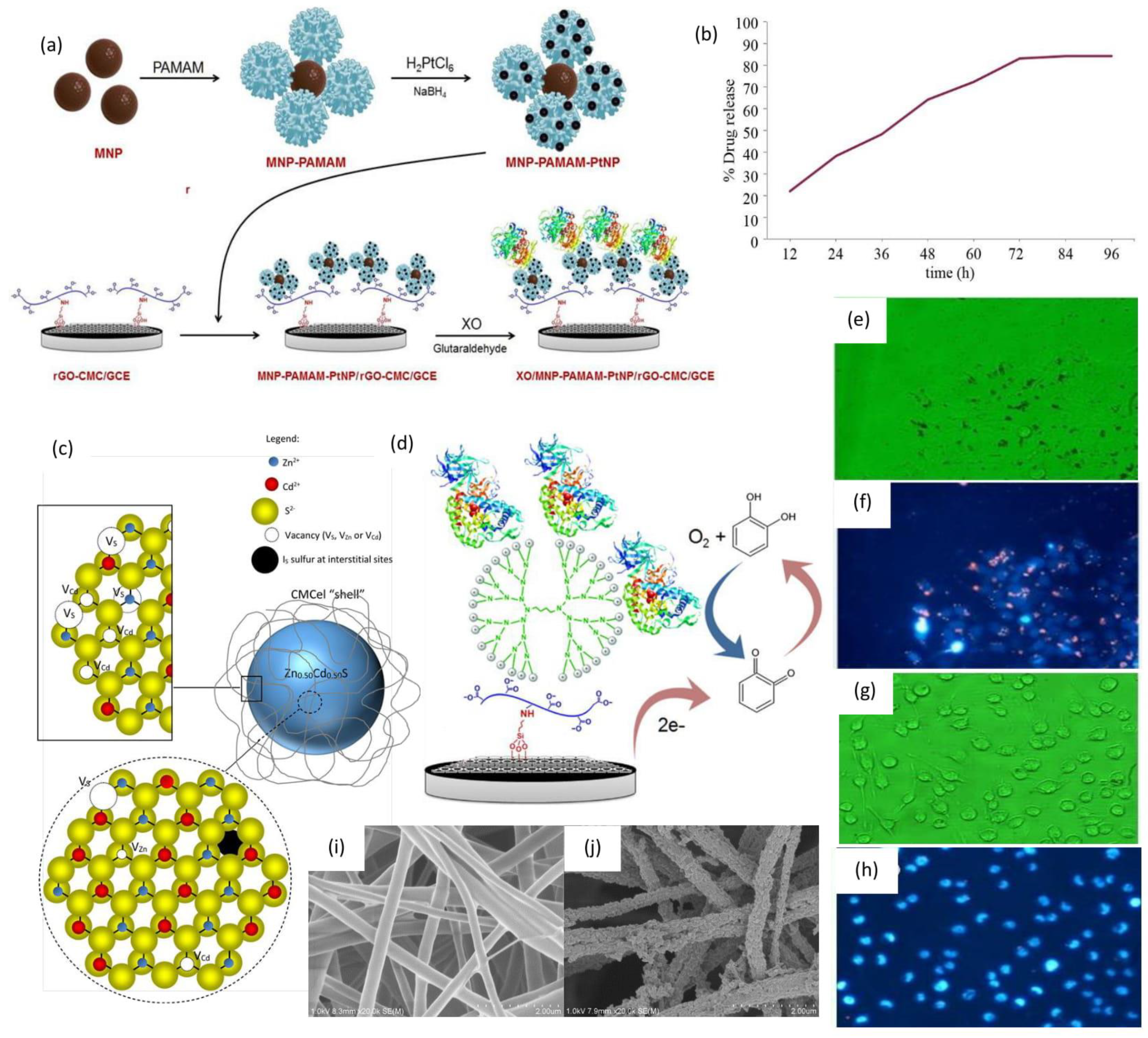

4.4. Biomedical Application

Due to the characteristic surface properties for facile cell adhesion, low cytotoxicity, excellent biocompatibility, biodegradability, and cell viability, CMC and CMC-based hybrid materials have found a wide range of applications in biomedical fields during the past few decades. In the literature, a series of research evidence on CMC-based biomaterials have been reported so far in tissue engineering, wound dressing, bio-sensing, bio-imaging, bone regeneration, drug delivery, and likewise dozens of working fields in biomedical technology. However, all of these fields are interrelated with each other. For convenience, the application fields are separately discussed below.

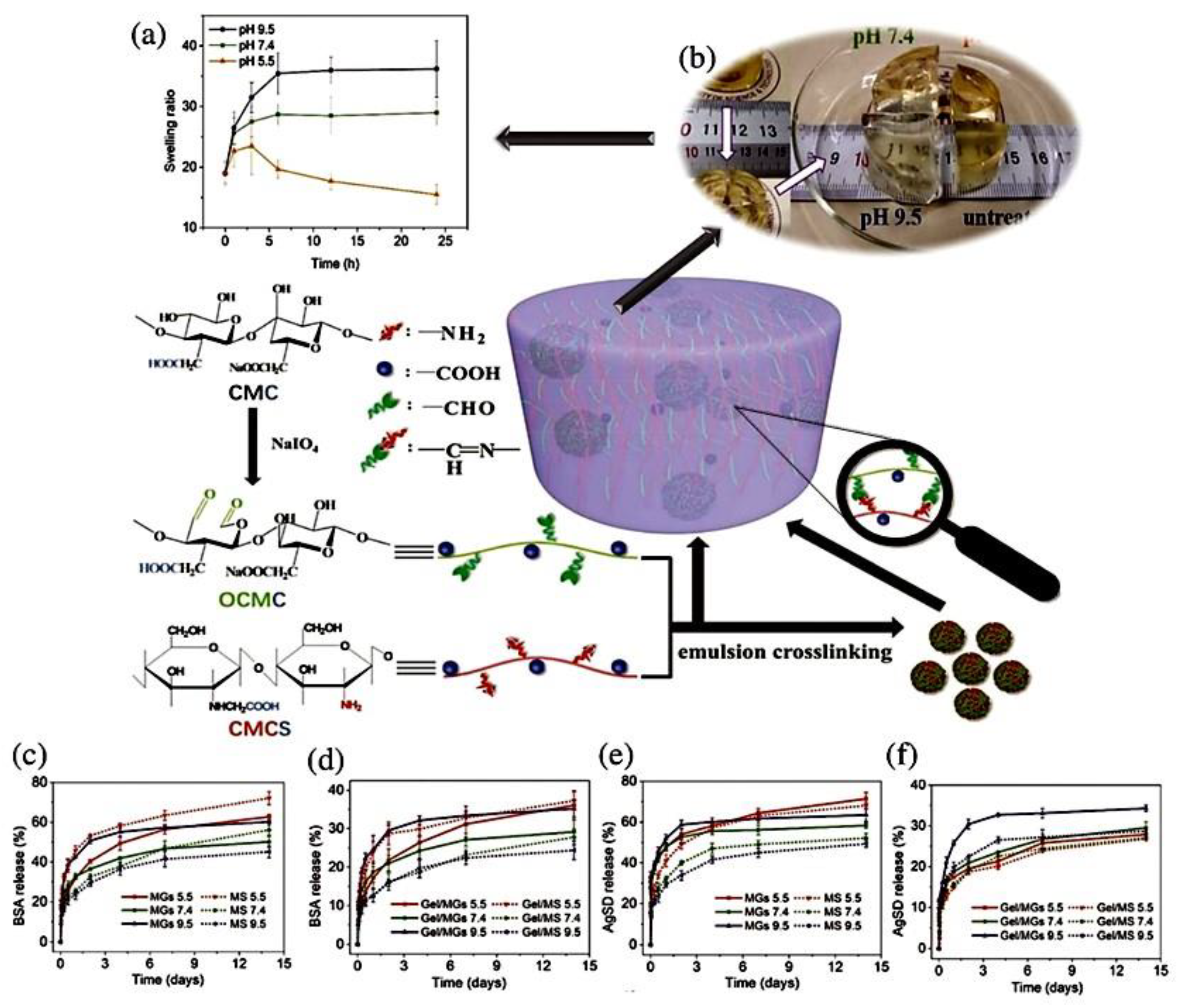

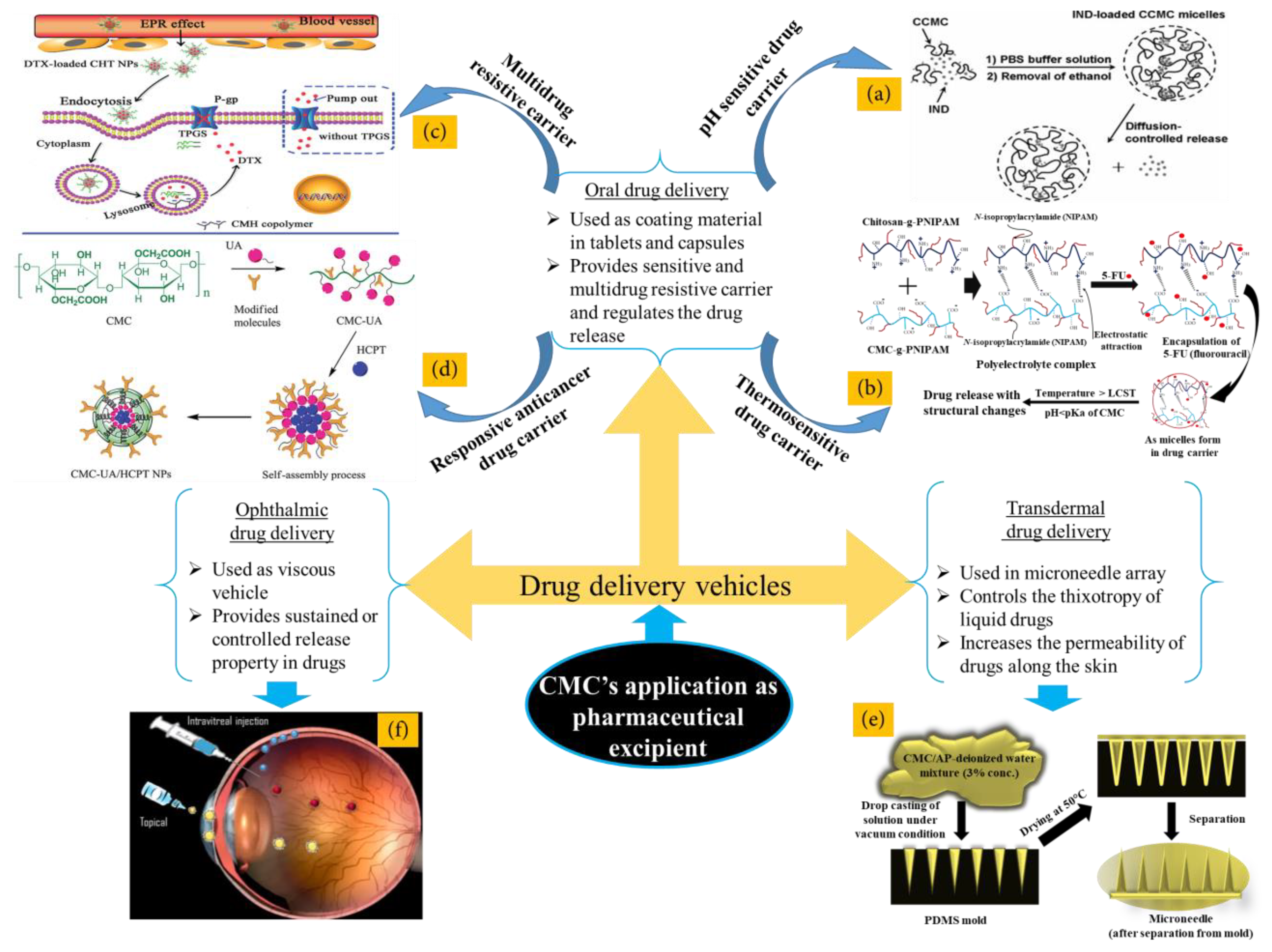

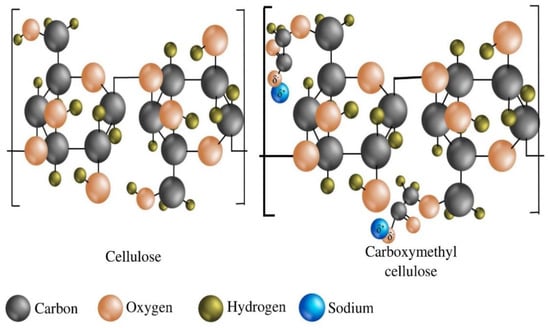

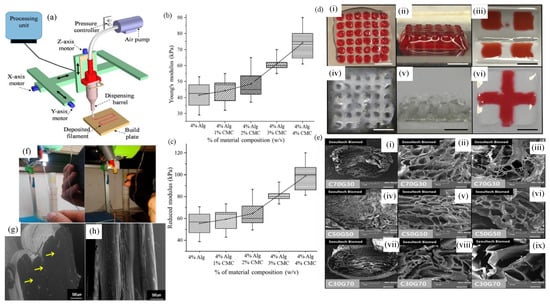

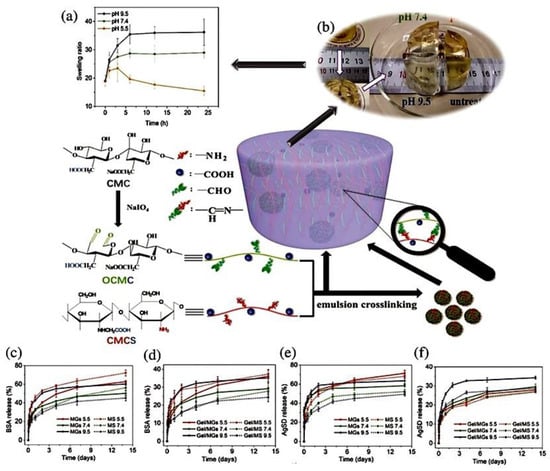

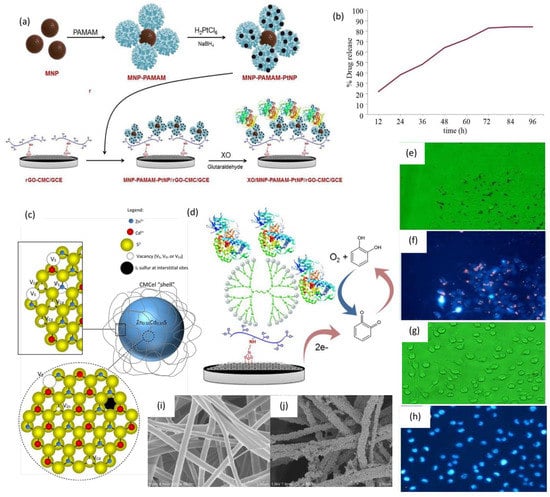

4.4.1. 3D Bioprinting Process