Adjustment of Hydrophobic Properties of Cellulose Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Cellulose

2.2. Acid Hydrolysis

2.3. Chemical Modification

2.4. Films of Cellulose Esters

2.5. Coating of Paperboard

2.6. X-ray Diffraction

2.7. Wetting Enthalpy

2.8. Sorption of Water Vapor

2.9. Performance Properties of Materials

3. Results and Discussion

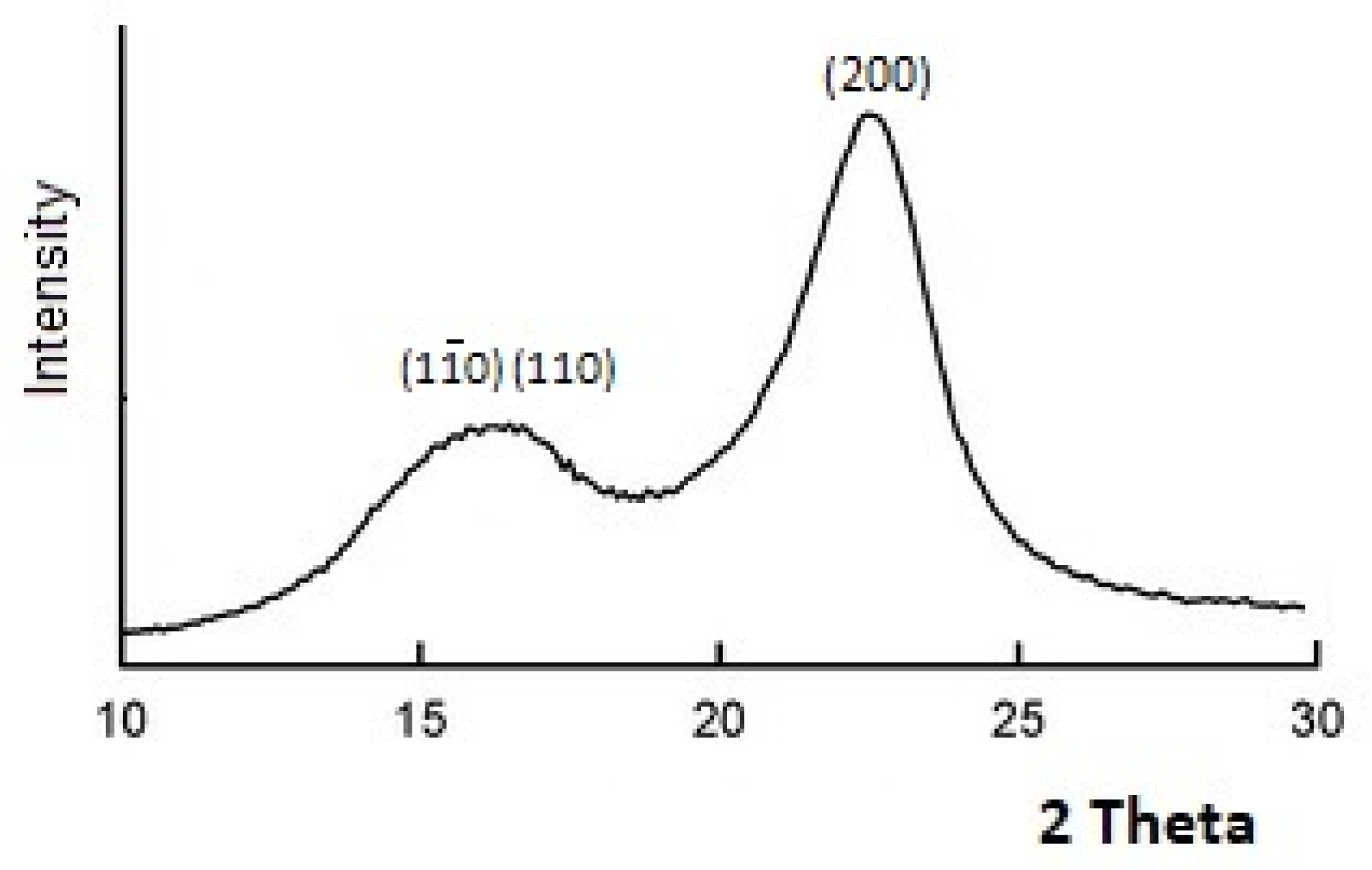

3.1. Structural Studies of Original Cellulose and Hydrolyzed Cellulose Samples

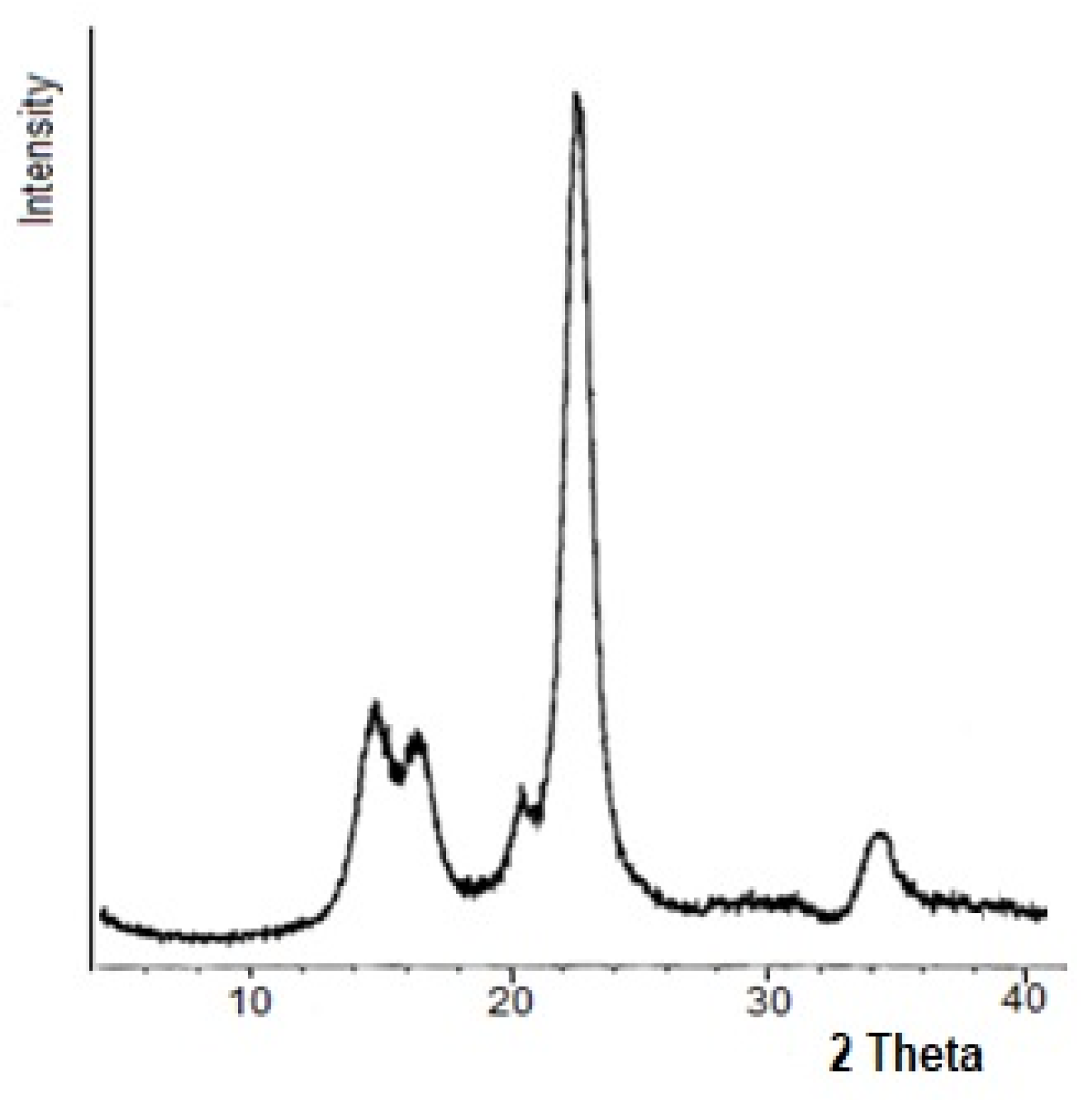

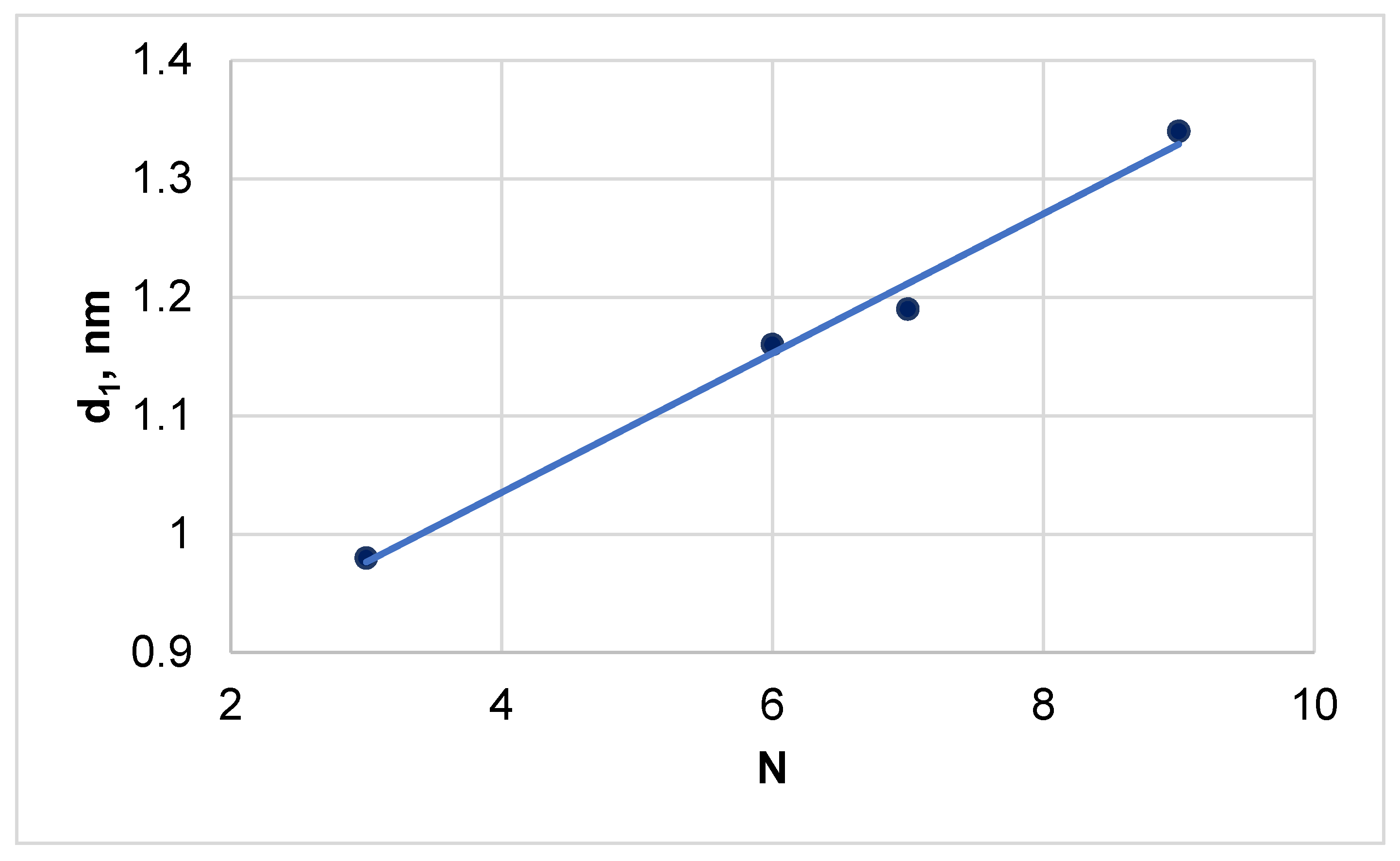

3.2. Structural Studies of Cellulose Esters

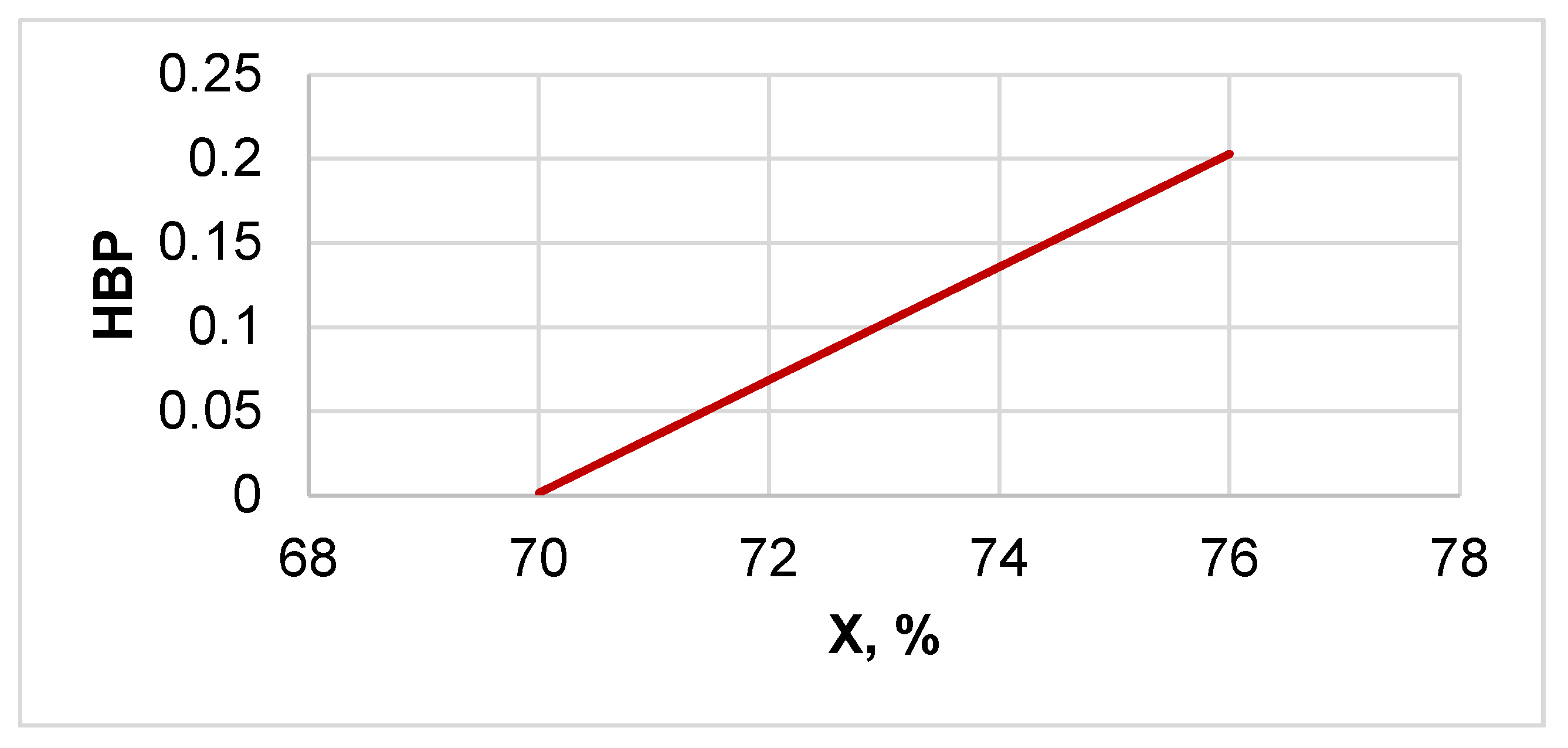

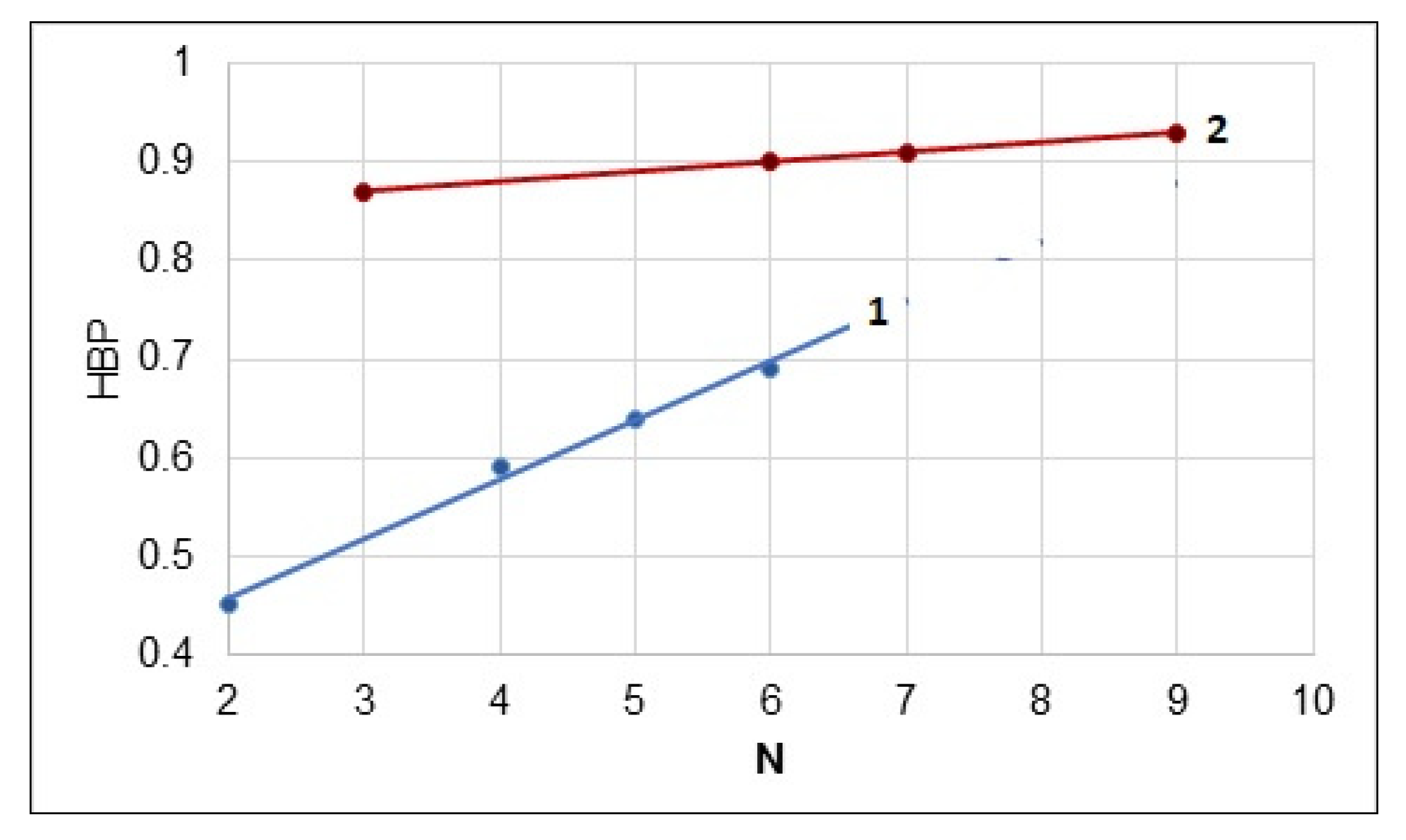

3.3. Study of Hydrophilic and Hydrophobic Properties of Cellulose and Its Esters

3.4. Performance Properties of Cellulose Esters

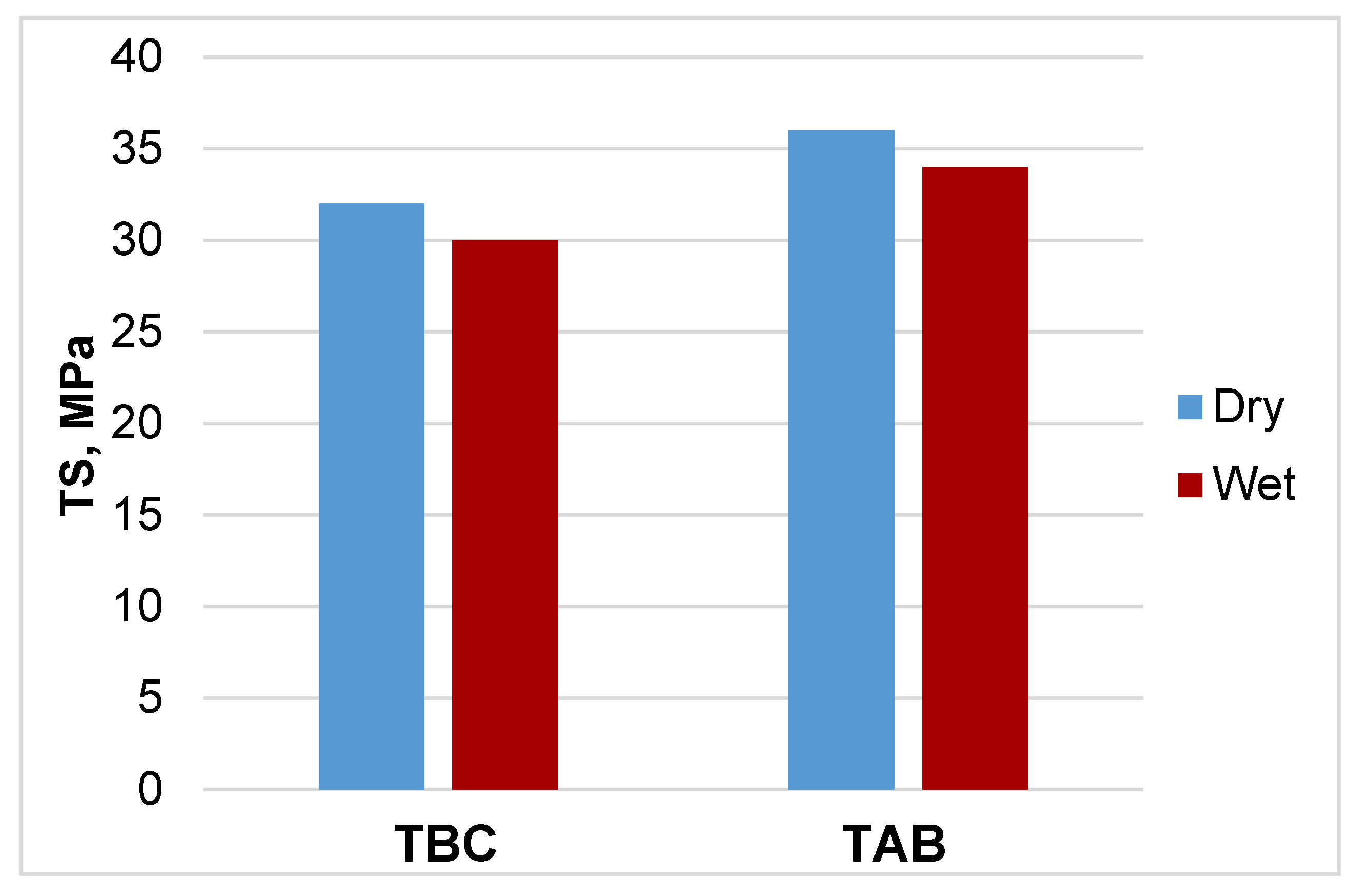

3.4.1. Mechanical Properties of Hydrophobic Cellulose Esters

3.4.2. Performance Properties of Coating Layers

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Payen, A. Mémoire sur la composition du tissu propre des plantes et du ligneux. Comptes Rendus 1838, 7, 1052–1056. [Google Scholar]

- Klemm, D.; Heublein, B.; Fink, H.-P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. 2005, 44, 2–37. [Google Scholar] [CrossRef] [PubMed]

- Gross, R.A.; Scholz, C. Biopolymers from Polysaccharides and Agro Proteins; ACS: Washington, DC, USA, 2000. [Google Scholar]

- Zhao, Y.; Li, J. Excellent chemical and material cellulose from tunicates: Diversity in cellulose production yield and chemical and morphological structures from different tunicate species. Cellulose 2014, 21, 3427–3441. [Google Scholar] [CrossRef]

- Keshk, S. Bacterial cellulose production and its industrial applications. J. Bioproces. Biotechniq. 2015, 4, 1–10. [Google Scholar] [CrossRef]

- Sjöström, E. Wood Chemistry, Fundamentals and Applications; Academic Press: London, UK, 1993. [Google Scholar]

- Małachowska, E.; Dubowik, M.; Lipkiewicz, A.; Przybysz, K.; Przybysz, P. Analysis of cellulose pulp characteristics and processing parameters for efficient paper production. Sustainability 2020, 12, 7219. [Google Scholar] [CrossRef]

- Krässig, H.A. Cellulose, Structure, Accessibility and Reactivity; Gordon and Breach Publishers: Philadelphia, PA, USA, 1993. [Google Scholar]

- Eliza, M.Y.; Shahruddin, M.; Noormaziah, J.; Wan Rosli, W.D. Carboxymethyl cellulose (CMC) from oil palm empty fruit bunch (OPEFB) in the new solvent dimethyl sulfoxide (DMSO)/tetrabutylammonium fluoride (TBAF). J. Phys. Conf. Ser. 2015, 622, 1–10. [Google Scholar] [CrossRef]

- Ioelovich, M. Models of supramolecular structure and properties of cellulose. J. Polym. Sci. Ser. A. 2016, 58, 925–943. [Google Scholar] [CrossRef]

- Ioelovich, M.; Leykin, A. Study of sorption properties of cellulose and its derivatives. Bioresources 2011, 6, 178–195. [Google Scholar]

- Ioelovich, M. Cellulose: Nanostructured Natural Polymer; LAP: Saarbrücken, Germany, 2015. [Google Scholar]

- Wei, D.W.; Wei, H.; Gauthier, A.C.; Song, J.; Jin, Y.; Xiao, H. Superhydrophobic modification of cellulose and cotton textiles: Methodologies and applications. J. Biores. Bioprod. 2020, 5, 1–15. [Google Scholar] [CrossRef]

- Xia, Z.; Li, J.; Zhang, J.; Zhang, X.; Zheng, X.; Zhang, J. Processing and valorization of cellulose, lignin and lignocellulose using ionic liquids. J. Bioresour. Bioprod. 2020, 5, 79–95. [Google Scholar] [CrossRef]

- Freire, C.S.R.; Silvestre, A.J.D.; Neto, C.P.; Rocha, R.M.A. An efficient method for determination of the degree of substitution of cellulose esters of long chain aliphatic acids. Cellulose 2005, 12, 449–458. [Google Scholar] [CrossRef]

- Ahvenainen, P.; Kontro, I.; Svedström, K. Comparison of sample crystallinity determination methods by X-ray diffraction for challenging cellulose I materials. Cellulose 2016, 23, 1073–1086. [Google Scholar] [CrossRef]

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and opportunities in the characterization of cellulose. Front. Plant Sci. 2019, 9, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Aripov, K.H.; Ioelovich, M. Comparative study of supramolecular structure of cellulose in cotton fibers of Gossypium hirsutum and Gossypium barbadense. Cellul. Chem. Technol. 2020, 54, 635–641. [Google Scholar] [CrossRef]

- Wadső, I.; Goldberg, R. Standards in isothermal microcalorimetry. Pure Appl. Chem. 2001, 73, 1625–1639. [Google Scholar] [CrossRef]

- Lipatov, Y.S.; Shilov, V.V.; Gomza, Y.P.; Kruglak, N.E. X-ray Methods for Studying of Polymer Systems; Science: Kiev, Ukraine, 1982. [Google Scholar]

- Kuzmina, L.G.; Konstantinov, I.I.; Churakov, A.V.; Lermontova, E.K. X-ray structure and DSC of mesomorphous 4-n-butyloxyphenyl-4’-methacryloyloxybenzoate. Mol. Cryst. Liquid Cryst. 2020, 708, 92–97. [Google Scholar] [CrossRef]

- Chemeris, M.M.; Salin, B.N.; Veveris, G.P.; Ioelovich, M. Study of supramolecular structure of triesters of cellulose. Wood Chem. 1991, 1, 51–54. [Google Scholar]

- Bao, C. Cellulose Acetate/Plasticizer Systems: Structure, Morphology and Dynamics; University Claude Bernard: Lyon, France, 2015. [Google Scholar]

- Cellulose Esters Market. Available online: https://www.marketsandmarkets.com/Market-Reports/cellulose-esters-market-173641209.html?gclid=CjwKCAjwvMqDBhB8EiwA2iSmPFkUNrnEjJQa9_mCyMiPTzXDpemnnI4ZbLVbTzBOMPZqF6QeXEJaxoCtgUQAvD_BwE (accessed on 1 July 2018).

- Cellulose and its Derivatives (Cellulose Esters and Ethers); Polymer Properties. Database, 2015–2021. Available online: http://polymerdatabase.com/polymer%20classes/Cellulose%20type.html (accessed on 8 January 2015).

- Eastman Cellulose Esters for Formulated Products; Eastman Brochure: Kingsport, TN, USA; Available online: https://www.eastman.com/Literature_Center/E/E325.pdf (accessed on 5 February 2020).

| Sample | * Yield, % | X % | L, nm | d, nm |

|---|---|---|---|---|

| OCM | 0 | 70 | 6.2 | 0.393 |

| HC-1 | 96 | 72 | 7.0 | 0.391 |

| HC-2 | 94 | 74 | 8.5 | 0.390 |

| HC-3 | 90 | 77 | 8.7 | 0.389 |

| Sample | N | d1, nm | d2, nm |

|---|---|---|---|

| TAC | 3 | 0.98 | 0.45 |

| TPC | 6 | 1.16 | 0.46 |

| TAB | 7 | 1.19 | 0.45 |

| TBC | 9 | 1.34 | 0.45 |

| Sample | X, % | S, % | Q, J/g | HIP | HBP |

|---|---|---|---|---|---|

| OCM | 70 | 8.6 | 50 | 1 | 0 |

| HC-1 | 72 | 8.0 | 47 | 0.93 | 0.07 |

| HC-2 | 74 | 7.4 | 43 | 0.86 | 0.14 |

| HC-3 | 77 | 6.8 | 40 | 0.80 | 0.20 |

| Sample | N | S, % | Q, J/g | HIP | HBP |

|---|---|---|---|---|---|

| DAC | 2 | 4.8 | 27 | 0.55 | 0.45 |

| DPC | 4 | 3.5 | 21 | 0.41 | 0.59 |

| DAB | 5 | 3.1 | 18 | 0.36 | 0.64 |

| DBC | 6 | 2.8 | 15 | 0.31 | 0.69 |

| TAC | 3 | 1.2 | 6 | 0.13 | 0.87 |

| TPC | 6 | 0.9 | 5 | 0.10 | 0.90 |

| TAB | 7 | 0.8 | 4 | 0.09 | 0.91 |

| TBC | 9 | 0.5 | 4 | 0.07 | 0.93 |

| Coating Layer | * Coating, % | Water Absorption, Cobb Test, g/m2 | Grease (Oil) Resistance, Kit Test No. (%) |

|---|---|---|---|

| No | 0 | 98 | 1 (0%) |

| TBC | 5 | 0.4 | 11 (95%) |

| 10 | 0.1 | 12 (100%) | |

| TAB | 5 | 0.6 | 11 (95%) |

| 10 | 0.2 | 12 (100%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ioelovich, M. Adjustment of Hydrophobic Properties of Cellulose Materials. Polymers 2021, 13, 1241. https://doi.org/10.3390/polym13081241

Ioelovich M. Adjustment of Hydrophobic Properties of Cellulose Materials. Polymers. 2021; 13(8):1241. https://doi.org/10.3390/polym13081241

Chicago/Turabian StyleIoelovich, Michael. 2021. "Adjustment of Hydrophobic Properties of Cellulose Materials" Polymers 13, no. 8: 1241. https://doi.org/10.3390/polym13081241

APA StyleIoelovich, M. (2021). Adjustment of Hydrophobic Properties of Cellulose Materials. Polymers, 13(8), 1241. https://doi.org/10.3390/polym13081241