A Review of Bioplastics and Their Adoption in the Circular Economy

Abstract

1. Introduction

1.1. Environmental Impact of Plastics

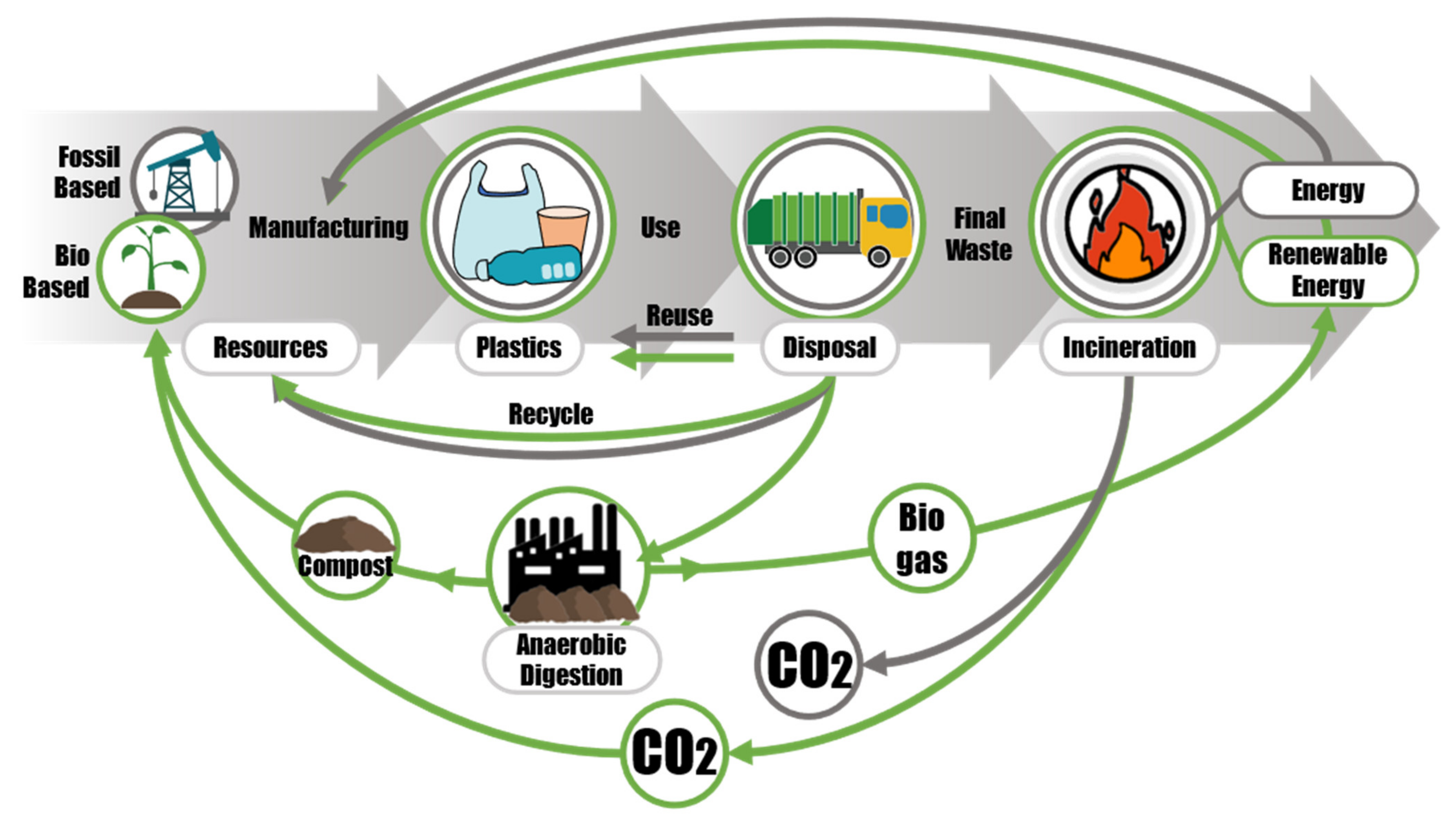

1.2. Circular Economy and Bioplastics

2. Bioplastics: Definitions and Market

2.1. Production Routes of Bio-Based Plastics and Main Examples

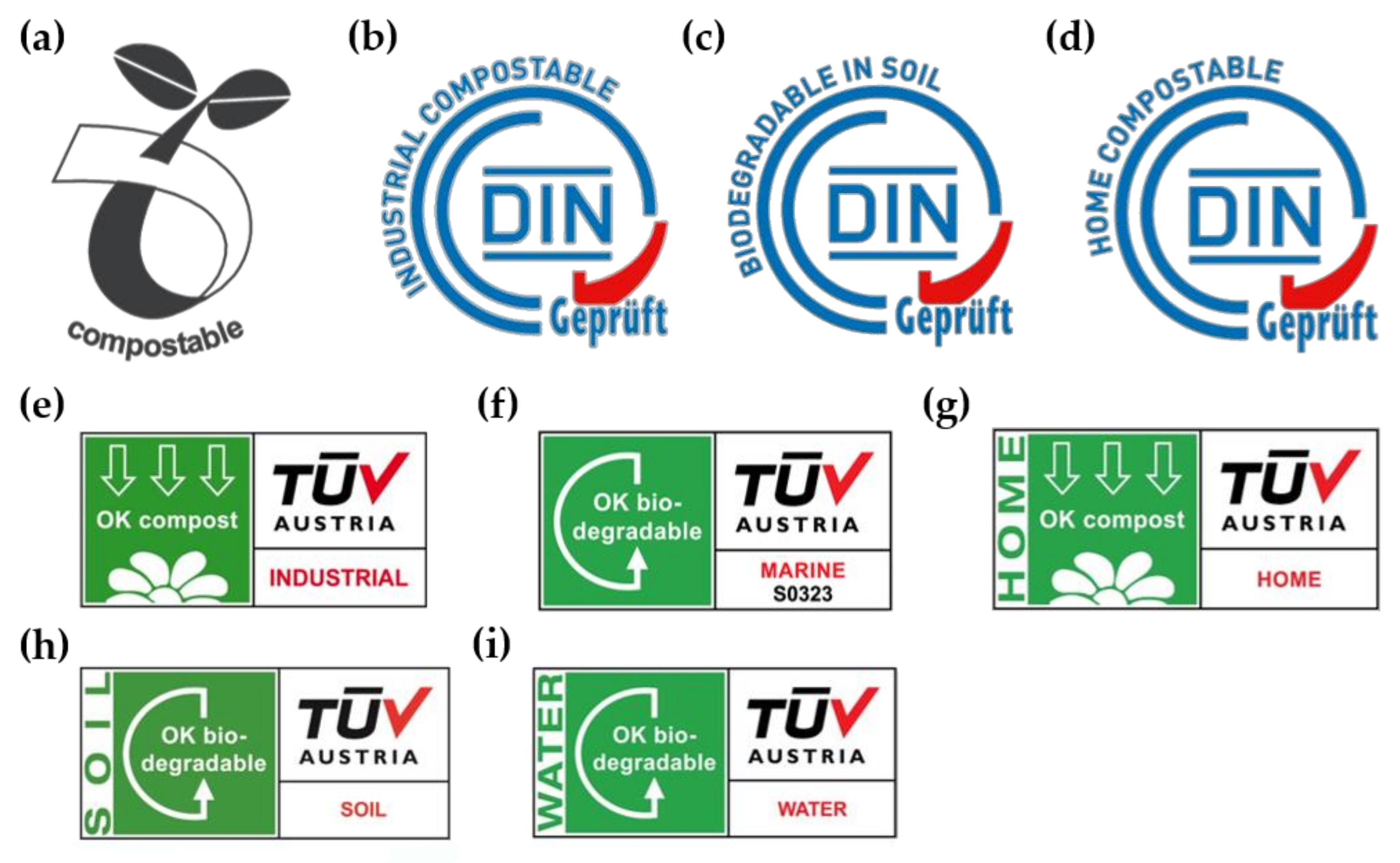

2.2. Biodegradability and Compostability Standards

2.3. Overview of Abiotic and Biotic Degradation Mechanisms

3. Life Cycle Assessment of Bioplastics

3.1. Life Cycle Assessment Research on Bioplastics

3.2. End-of-Life Options for Bioplastics

4. Bioplastics: Summary of Opportunities and Possible Challenges

4.1. Lack of Comparable LCA Studies

4.2. Issues Relating to Standards and Regulations

4.3. Land and Water Use

4.4. Issues Related to the Waste Disposal System

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Commission. The European Green Deal COM(2019) 640 Final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. A New Circular Economy Action Plan For a Cleaner and More Competitive Europe COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- United Nations Sustainable Development Knowledge Platform the 2030 Agenda for Sustainable Development. Available online: https://sdgs.un.org/2030agenda (accessed on 5 April 2021).

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef]

- Pilla, S. (Ed.) Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 9781118203699. [Google Scholar]

- George, A.; Sanjay, M.R.; Srisuk, R.; Parameswaranpillai, J.; Siengchin, S. A comprehensive review on chemical properties and applications of biopolymers and their composites. Int. J. Biol. Macromol. 2020, 154, 329–338. [Google Scholar] [CrossRef]

- European Environment Agency. The Circular Economy and the Bioeconomy—Partners in Sustainability; European Environment Agency: Copenhagen, Denmark, 2018; ISBN 9789292139742. [Google Scholar]

- Razza, F.; Briani, C.; Breton, T.; Marazza, D. Metrics for quantifying the circularity of bioplastics: The case of bio-based and biodegradable mulch films. Resour. Conserv. Recycl. 2020, 159. [Google Scholar] [CrossRef]

- Barillari, F.; Chini, F. Biopolymers—Sustainability for the Automotive Value-added Chain. ATZ Worldw. 2020, 122, 36–39. [Google Scholar] [CrossRef]

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent advances in bioplastics: Application and biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef]

- Kaplan, D.L. Introduction to Biopolymers from Renewable Resources. In Biopolymers from Renewable Resources; Springer: Berlin/Heidelberg, Germany, 1998; pp. 1–29. [Google Scholar]

- European Bioplastics. Bioplastics Market. Available online: https://www.european-bioplastics.org/market/ (accessed on 1 November 2020).

- European Commission. A European Strategy for Plastics in a Circular Economy COM(2018) 28 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable Plastic Blends Create New Possibilities for End-of-Life Management of Plastics but They Are Not a Panacea for Plastic Pollution. Environ. Sci. Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Worrell, E.; Patel, M.K. Open-loop recycling: A LCA case study of PET bottle-to-fibre recycling. Resour. Conserv. Recycl. 2010, 55, 34–52. [Google Scholar] [CrossRef]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef]

- Kawasaki, J.; Silalertruksa, T.; Scheyvens, H.; Yamanoshita, M. Environmental sustainability and climate benefits of green technology for bioethanol production in Thailand. J. Int. Soc. Southeast Asian Agric. Sci. 2015, 21, 78–95. [Google Scholar]

- Brizga, J.; Hubacek, K.; Feng, K. The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints. One Earth 2020, 3, 45–53. [Google Scholar] [CrossRef]

- Yates, M.R.; Barlow, C.Y. Life cycle assessments of biodegradable, commercial biopolymers—A critical review. Resour. Conserv. Recycl. 2013, 78, 54–66. [Google Scholar] [CrossRef]

- Spierling, S.; Knüpffer, E.; Behnsen, H.; Mudersbach, M.; Krieg, H.; Springer, S.; Albrecht, S.; Herrmann, C.; Endres, H.J. Bio-based plastics—A review of environmental, social and economic impact assessments. J. Clean. Prod. 2018, 185, 476–491. [Google Scholar] [CrossRef]

- Matsuura, E.; Ye, Y.; He, X. Sustainability opportunities and challenges of bioplastics. Master Thesis, School of Engineering, Blekinge Institute of Technology, Karlskrona, Sweden, 2008. [Google Scholar]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Sustainability assessments of bio-based polymers. Polym. Degrad. Stab. 2013, 98, 1898–1907. [Google Scholar] [CrossRef]

- Álvarez-Chávez, C.R.; Edwards, S.; Moure-Eraso, R.; Geiser, K. Sustainability of bio-based plastics: General comparative analysis and recommendations for improvement. J. Clean. Prod. 2012, 23, 47–56. [Google Scholar] [CrossRef]

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserv. Recycl. 2017, 122, 295–306. [Google Scholar] [CrossRef]

- Bisinella, V.; Albizzati, P.F.; Astrup, T.F.; Damgaard, A. Life Cycle Assessment of Grocery Carrier Bags; Danish Environmental Protection Agency: Copenhagen, Denmark, 2018; pp. 1–144. [Google Scholar]

- Rutkowska, M.; Krasowska, K.; Heimowska, A.; Steinka, I.; Janik, H. Degradation of polyurethanes in sea water. Polym. Degrad. Stab. 2002, 76, 233–239. [Google Scholar] [CrossRef]

- Saygin, H.; Baysal, A. Degradation of subµ-sized bioplastics by clinically important bacteria under sediment and seawater conditions: Impact on the bacteria responses. J. Environ. Sci. Health Part A 2020, 56, 1–12. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef]

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of polylactide bottles in real and simulated composting conditions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

- Accinelli, C.; Saccà, M.L.; Mencarelli, M.; Vicari, A. Deterioration of bioplastic carrier bags in the environment and assessment of a new recycling alternative. Chemosphere 2012, 89, 136–143. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef]

- Nakajima, H.; Dijkstra, P.; Loos, K. The Recent Developments in Biobased Polymers toward General and Engineering Applications: Polymers that are Upgraded from Biodegradable Polymers, Analogous to Petroleum-Derived Polymers, and Newly Developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- Bishop, G.; Styles, D.; Lens, P.N.L. Environmental performance comparison of bioplastics and petrochemical plastics: A review of life cycle assessment (LCA) methodological decisions. Resour. Conserv. Recycl. 2021, 168, 105451. [Google Scholar] [CrossRef]

- Harrison, J.P.; Boardman, C.; O’Callaghan, K.; Delort, A.-M.; Song, J. Biodegradability standards for carrier bags and plastic films in aquatic environments: A critical review. R. Soc. Open Sci. 2018, 5, 171792. [Google Scholar] [CrossRef]

- PlasticsEurope Plastics—The Facts. 2020. pp. 1–64. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 1 November 2020).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, 25–29. [Google Scholar] [CrossRef] [PubMed]

- UNEP Web Page—Beat Plastic Pollution. Available online: https://www.unep.org/interactive/beat-plastic-pollution/ (accessed on 1 November 2020).

- European Commission. Proposal for a Directive of the European Parliament and of the Council: On the Reduction of the Impact of Certain Plastic Products on the Environment COM(2018) 340 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Lebreton, L.; Slat, B.; Ferrari, F.; Sainte-Rose, B.; Aitken, J.; Marthouse, R.; Hajbane, S.; Cunsolo, S.; Schwarz, A.; Levivier, A.; et al. Evidence that the Great Pacific Garbage Patch is rapidly accumulating plastic. Sci. Rep. 2018, 8, 4666. [Google Scholar] [CrossRef] [PubMed]

- European Commission. A Circular Economy for Plastics—Insights from Research and Innovation to Inform Policy and Funding Decisions; European Commission: Brussels, Belgium, 2019; ISBN 9789279984297. [Google Scholar]

- Gallo, F.; Fossi, C.; Weber, R.; Santillo, D.; Sousa, J.; Ingram, I.; Nadal, A.; Romano, D. Marine litter plastics and microplastics and their toxic chemicals components: The need for urgent preventive measures. Environ. Sci. Eur. 2018, 30, 13. [Google Scholar] [CrossRef] [PubMed]

- UNEP. Marine Litter Vital Graphics; UNEP: Nairobi, Kenya, 2016; ISBN 9788277011530. [Google Scholar]

- Gregory, M.R. Environmental implications of plastic debris in marine settings—Entanglement, ingestion, smothering, hangers-on, hitch-hiking and alien invasions. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2013–2025. [Google Scholar] [CrossRef] [PubMed]

- Zettler, E.R.; Mincer, T.J.; Amaral-Zettler, L.A. Life in the “plastisphere”: Microbial communities on plastic marine debris. Environ. Sci. Technol. 2013, 47, 7137–7146. [Google Scholar] [CrossRef]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Rochman, C.M.; Tahir, A.; Williams, S.L.; Baxa, D.V.; Lam, R.; Miller, J.T.; Teh, F.-C.; Werorilangi, S.; Teh, S.J. Anthropogenic debris in seafood: Plastic debris and fibers from textiles in fish and bivalves sold for human consumption. Sci. Rep. 2015, 5, 14340. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.; Love, D.C.; Rochman, C.M.; Neff, R.A. Microplastics in Seafood and the Implications for Human Health. Curr. Environ. Health Rep. 2018, 5, 375–386. [Google Scholar] [CrossRef]

- Dehaut, A.; Cassone, A.-L.; Frère, L.; Hermabessiere, L.; Himber, C.; Rinnert, E.; Rivière, G.; Lambert, C.; Soudant, P.; Huvet, A.; et al. Microplastics in seafood: Benchmark protocol for their extraction and characterization. Environ. Pollut. 2016, 215, 223–233. [Google Scholar] [CrossRef] [PubMed]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics; Ellen MacArthur Found: Cowes, UK, 2016; p. 120. [Google Scholar]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; European Commission: Brussels, Belgium, 2018; ISBN 9789279941450. [Google Scholar]

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Sander, M.; Filatova, T.; Weber, M. Biodegradability of Plastics in the Open Environment; ETH Zurich: Zürich, Switzerland, 2020; ISBN 9783982030180. [Google Scholar]

- European Commission Directorate-General for Environment. Plastic Waste in the Environment—Final Report; European Commission: Brussels, Belgium, 2011; p. 171. [Google Scholar]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Madhavan Nampoothiri, K.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Chanprateep, S. Current trends in biodegradable polyhydroxyalkanoates. J. Biosci. Bioeng. 2010, 110, 621–632. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Guo, B.H. Poly(butylene succinate) and its copolymers: Research, development and industrialization. Biotechnol. J. 2010, 5, 1149–1163. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent Developments in Bio-Based Polymers Analogous to Petroleum-Derived Ones for Packaging and Engineering Applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef] [PubMed]

- Labet, M.; Thielemans, W. Synthesis of polycaprolactone: A review. Chem. Soc. Rev. 2009, 38, 3484. [Google Scholar] [CrossRef]

- Aslam, M.; Kalyar, M.A.; Raza, Z.A. Polyvinyl alcohol: A review of research status and use of polyvinyl alcohol based nanocomposites. Polym. Eng. Sci. 2018, 58, 2119–2132. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly(butylene adipate- co -terephthalate)-PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15. [Google Scholar] [CrossRef]

- Auras, R.; Lim, L.-T.; Selke, S.E.M.; Tsuji, H. (Eds.) Poly(Lactic Acid); John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; Volume 53, ISBN 9780470649848. [Google Scholar]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic Acid Technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Mehta, R.; Kumar, V.; Bhunia, H.; Upadhyay, S.N. Synthesis of poly(lactic acid): A review. J. Macromol. Sci. Polym. Rev. 2005, 45, 325–349. [Google Scholar] [CrossRef]

- Pantani, R.; Sorrentino, A. Influence of crystallinity on the biodegradation rate of injection-moulded poly(lactic acid) samples in controlled composting conditions. Polym. Degrad. Stab. 2013, 98, 1089–1096. [Google Scholar] [CrossRef]

- Perego, G.; Cella, G.D.; Bastioli, C. Effect of molecular weight and crystallinity on poly(lactic acid) mechanical properties. J. Appl. Polym. Sci. 1996, 59, 37–43. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef] [PubMed]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)—Mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef] [PubMed]

- Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality. Materials 2018, 11, 1191. [Google Scholar] [CrossRef] [PubMed]

- Meraldo, A. Introduction to Bio-Based Polymers; Elsevier Inc.: Amsterdam, The Netherlands, 2016; ISBN 9780323371001. [Google Scholar]

- Bechthold, I.; Bretz, K.; Kabasci, S.; Kopitzky, R.; Springer, A. Succinic acid: A new platform chemical for biobased polymers from renewable resources. Chem. Eng. Technol. 2008, 31, 647–654. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Aditiya, H.B.; Mahlia, T.M.I.; Chong, W.T.; Nur, H.; Sebayang, A.H. Second generation bioethanol production: A critical review. Renew. Sustain. Energy Rev. 2016, 66, 631–653. [Google Scholar] [CrossRef]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Law, R.C. 5. Applications of cellulose acetate 5.1 Cellulose acetate in textile application. Macromol. Symp. 2004, 208, 255–266. [Google Scholar] [CrossRef]

- Rustemeyer, P. 5.2 CA filter tow for cigarette filters. Macromol. Symp. 2004, 208, 267–292. [Google Scholar] [CrossRef]

- Shibata, T. 5.6 Cellulose acetate in separation technology. Macromol. Symp. 2004, 208, 353–370. [Google Scholar] [CrossRef]

- Fischer, S.; Thümmler, K.; Volkert, B.; Hettrich, K.; Schmidt, I.; Fischer, K. Properties and applications of cellulose acetate. Macromol. Symp. 2008, 262, 89–96. [Google Scholar] [CrossRef]

- Puls, J.; Wilson, S.A.; Hölter, D. Degradation of Cellulose Acetate-Based Materials: A Review. J. Polym. Environ. 2011, 19, 152–165. [Google Scholar] [CrossRef]

- Rose, M.; Palkovits, R. Cellulose-Based Sustainable Polymers: State of the Art and Future Trends. Macromol. Rapid Commun. 2011, 32, 1299–1311. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Chen, J. Synthetic Textile Fibers. In Textiles and Fashion; Elsevier: Amsterdam, The Netherlands, 2015; pp. 79–95. [Google Scholar]

- Liu, H.; Xie, F.; Yu, L.; Chen, L.; Li, L. Thermal processing of starch-based polymers. Prog. Polym. Sci. 2009, 34, 1348–1368. [Google Scholar] [CrossRef]

- Zhang, Y.; Rempel, C.; Liu, Q. Thermoplastic Starch Processing and Characteristics—A Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 1353–1370. [Google Scholar] [CrossRef] [PubMed]

- Da Róz, A.L.; Carvalho, A.J.F.; Gandini, A.; Curvelo, A.A.S. The effect of plasticizers on thermoplastic starch compositions obtained by melt processing. Carbohydr. Polym. 2006, 63, 417–424. [Google Scholar] [CrossRef]

- Lörcks, J. Properties and applications of compostable starch-based plastic material. Polym. Degrad. Stab. 1998, 59, 245–249. [Google Scholar] [CrossRef]

- Santana, Á.L.; Angela, A.; Meireles, M. New Starches are the Trend for Industry Applications: A Review. Food Public Health 2014, 4, 229–241. [Google Scholar] [CrossRef]

- Mohamad Yazid, N.S.; Abdullah, N.; Muhammad, N.; Matias-Peralta, H.M. Application of Starch and Starch-Based Products in Food Industry. J. Sci. Technol. 2018, 10. [Google Scholar] [CrossRef]

- Samsudin, H.; Hani, N.M. Use of Starch in Food Packaging. In Starch-Based Materials in Food Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 229–256. [Google Scholar]

- Rehm, B.H.A. Bacterial polymers: Biosynthesis, modifications and applications. Nat. Rev. Microbiol. 2010, 8, 578–592. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yin, J.; Chen, G.-Q. Polyhydroxyalkanoates, challenges and opportunities. Curr. Opin. Biotechnol. 2014, 30, 59–65. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y. Bacterial polyhydroxyalkanoates. Biotechnol. Bioeng. 2000, 49, 1–14. [Google Scholar] [CrossRef]

- Reddy, C.S.K.; Ghai, R.; Kalia, V. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef]

- Kathiraser, Y.; Aroua, M.K.; Ramachandran, K.B.; Tan, I.K.P. Chemical characterization of medium-chain-length polyhydroxyalkanoates (PHAs) recovered by enzymatic treatment and ultrafiltration. J. Chem. Technol. Biotechnol. 2007, 82, 847–855. [Google Scholar] [CrossRef]

- Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Bioplastics with a green agenda. Curr. Opin. Microbiol. 2010, 13, 321–326. [Google Scholar] [CrossRef]

- Hazer, B.; Steinbüchel, A. Increased diversification of polyhydroxyalkanoates by modification reactions for industrial and medical applications. Appl. Microbiol. Biotechnol. 2007, 74, 1–12. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y. Medical applications of biopolyesters polyhydroxyalkanoates. Chin. J. Polym. Sci. 2013, 31, 719–736. [Google Scholar] [CrossRef]

- ISO Online Browsing Platform. Available online: https://www.iso.org/obp/ui#home (accessed on 1 November 2020).

- CEN Online Standards Search. Available online: https://standards.cen.eu/dyn/www/f?p=CENWEB:105::RESET:::: (accessed on 1 November 2020).

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Briassoulis, D.; Degli Innocenti, F. Standards for Soil Biodegradable Plastics. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Springer: Berlin/Heidelberg, Germany, 2017; pp. 139–168. [Google Scholar]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Ahn, H.K.; Huda, M.S.; Smith, M.C.; Mulbry, W.; Schmidt, W.F.; Reeves, J.B. Biodegradability of injection molded bioplastic pots containing polylactic acid and poultry feather fiber. Bioresour. Technol. 2011, 102, 4930–4933. [Google Scholar] [CrossRef] [PubMed]

- Tabasi, R.Y.; Ajji, A. Selective degradation of biodegradable blends in simulated laboratory composting. Polym. Degrad. Stab. 2015, 120, 435–442. [Google Scholar] [CrossRef]

- Lucas, N.; Bienaime, C.; Belloy, C.; Queneudec, M.; Silvestre, F.; Nava-Saucedo, J.E. Polymer biodegradation: Mechanisms and estimation techniques—A review. Chemosphere 2008, 73, 429–442. [Google Scholar] [CrossRef] [PubMed]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the Future? The Impact of Biodegradable Polymers on the Environment and on Society. Angew. Chem. Int. Ed. 2019, 58, 50–62. [Google Scholar] [CrossRef]

- Fojt, J.; David, J.; Přikryl, R.; Řezáčová, V.; Kučerík, J. A critical review of the overlooked challenge of determining micro-bioplastics in soil. Sci. Total Environ. 2020, 745, 140975. [Google Scholar] [CrossRef] [PubMed]

- Flemming, H.C. Relevance of biofilms for the biodeterioration of surfaces of polymeric materials. Polym. Degrad. Stab. 1998, 59, 309–315. [Google Scholar] [CrossRef]

- Gu, J.D. Microbiological deterioration and degradation of synthetic polymeric materials: Recent research advances. Int. Biodeterior. Biodegrad. 2003, 52, 69–91. [Google Scholar] [CrossRef]

- Pauli, N.-C.; Petermann, J.S.; Lott, C.; Weber, M. Macrofouling communities and the degradation of plastic bags in the sea: An in situ experiment. R. Soc. Open Sci. 2017, 4, 170549. [Google Scholar] [CrossRef] [PubMed]

- European Commission Joint Research Centre. EC-JRC Product Environmental Footprint (PEF) Guide; European Commission Joint Research Centre: Brussels, Belgium, 2012; p. 154. [Google Scholar]

- Nessi, S.; Bulgheroni, C.; Konti, A.; Sinkko, T.; Tonini, D.; Pant, R. Comparative Life-Cycle Assessment of Alternative Feedstock for Plastics Production; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Technical Committee ISO/TC 207. ISO Environmental Management—Life Cycle Assessment—Principles and Framework (ISO 14040:2006). Environ. Manag. Syst. Requir. 2004, 44, 32. [Google Scholar]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; European Commission: Brussels, Belgium, 2010; ISBN 9789279190926. [Google Scholar]

- Finkbeiner, M. Product environmental footprint—Breakthrough or breakdown for policy implementation of life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 266–271. [Google Scholar] [CrossRef]

- PlasticsEurope PlasticsEurope Website—Eco-profiles. Available online: https://www.plasticseurope.org/en/resources/eco-profiles (accessed on 1 November 2020).

- Hauschild, M.; Huijibregts, M.A.J. Life Cycle Impact Assessment; LCA Compendium—The Complete World of Life Cycle Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; Springer: Dordrecht, The Netherlands, 2015; ISBN 978-94-017-9743-6. [Google Scholar]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. Characterisation Factors of the ILCD Recommended Life Cycle Impact Assessment Methods; European Commission: Brussels, Belgium, 2012; ISBN 9789279227271. [Google Scholar]

- Dintcheva, N.T.; La Mantia, F.P. Durability of a starch-based biodegradable polymer. Polym. Degrad. Stab. 2007, 92, 630–634. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Infurna, G.; Baiamonte, M.; D’Anna, F. Natural compounds as sustainable additives for biopolymers. Polymers 2020, 12, 732. [Google Scholar] [CrossRef] [PubMed]

- Dintcheva, N.; La Mantia, F.P.; Arrigo, R. Natural compounds as light stabilizer for a starch-based biodegradable polymer. J. Polym. Eng. 2014, 34, 441–449. [Google Scholar] [CrossRef]

- Arrigo, R.; Morici, E.; Dintcheva, N.T. Biopolyester-based systems containing naturally occurring compounds with enhanced thermooxidative stability. J. Appl. Biomater. Funct. Mater. 2016, 14, e455–e462. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Arrigo, R.; Baiamonte, M.; Rizzarelli, P.; Curcuruto, G. Concentration-dependent anti-/pro-oxidant activity of natural phenolic compounds in bio-polyesters. Polym. Degrad. Stab. 2017, 142, 21–28. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Baiamonte, M.; Spera, M. Assessment of pro-oxidant activity of natural phenolic compounds in bio-polyesters. Polym. Degrad. Stab. 2018, 152, 280–288. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; D’anna, F. Anti-/pro-oxidant behavior of naturally occurring molecules in polymers and biopolymers: A brief review. ACS Sustain. Chem. Eng. 2019, 7, 12656–12670. [Google Scholar] [CrossRef]

- Soroudi, A.; Jakubowicz, I. Recycling of bioplastics, their blends and biocomposites: A review. Eur. Polym. J. 2013, 49, 2839–2858. [Google Scholar] [CrossRef]

- De Andrade, M.F.C.; Souza, P.M.S.; Cavalett, O.; Morales, A.R. Life Cycle Assessment of Poly(Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Recycling of Bioplastics: Routes and Benefits. J. Polym. Environ. 2020, 28, 2551–2571. [Google Scholar] [CrossRef]

- Bátori, V.; Åkesson, D.; Zamani, A.; Taherzadeh, M.J.; Sárvári Horváth, I. Anaerobic degradation of bioplastics: A review. Waste Manag. 2018, 80, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Heaven, S.; Banks, C.J. Degradation of some EN13432 compliant plastics in simulated mesophilic anaerobic digestion of food waste. Polym. Degrad. Stab. 2018, 147, 76–88. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Botta, L.; Morreale, M.; Scaffaro, R. Effect of small amounts of poly(lactic acid) on the recycling of poly(ethylene terephthalate) bottles. Polym. Degrad. Stab. 2012, 97, 21–24. [Google Scholar] [CrossRef]

- Alaerts, L.; Augustinus, M.; Van Acker, K. Impact of bio-based plastics on current recycling of plastics. Sustainability 2018, 10, 1487. [Google Scholar] [CrossRef]

- Gere, D.; Czigany, T. Future trends of plastic bottle recycling: Compatibilization of PET and PLA. Polym. Test. 2020, 81, 106160. [Google Scholar] [CrossRef]

- Samper, M.D.; Bertomeu, D.; Arrieta, M.P.; Ferri, J.M.; López-Martínez, J. Interference of biodegradable plastics in the polypropylene recycling process. Materials 2018, 11, 1886. [Google Scholar] [CrossRef] [PubMed]

- Cornell, D.D. Biopolymers in the existing postconsumer plastics recycling stream. J. Polym. Environ. 2007, 15, 295–299. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Infurna, G.; D’Anna, F. End-of-life and waste management of disposable beverage cups. Sci. Total Environ. 2020, 143044. [Google Scholar] [CrossRef] [PubMed]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable polymers and plastics: Performance beyond the green. N. Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef]

- IChemE. The Institution of Chemical Engineers Standards for Bio-Based, Biodegradable, and Compostable Plastic: Call for Evidence—Consultation Response from the Institution of Chemical Engineers (IChemE); IChemE: London, UK, 2019; pp. 1–25. [Google Scholar]

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Greenhouse gas emissions from home composting of organic household waste. Waste Manag. 2010, 30, 2475–2482. [Google Scholar] [CrossRef]

- Lim, S.L.; Lee, L.H.; Wu, T.Y. Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: Recent overview, greenhouse gases emissions and economic analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Baker, M.; Penny, D. Is there a reproducibility crisis? Nature 2016, 533, 452–454. [Google Scholar] [CrossRef]

- Jia, Z. Biodegradable Plastics: Breaking Down the Facts—Production, Composition and Environmental Impact; Green Peace East Asia: Hong Kong, China, 2020. [Google Scholar]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Chmielnicki, B.; Wypiór, K. Water footprint assessment of selected polymers, polymer blends, composites, and biocomposites for industrial application. Polymers 2019, 11, 1791. [Google Scholar] [CrossRef]

- CIC Raccolta dei Rifiuti Organici: In Italia Raggiunte le 6 Milioni di Tonnellate, ma Servono più Impianti. Available online: https://www.compost.it/wp-content/uploads/2019/04/CS-1-2019-CIC.pdf (accessed on 1 December 2020).

| Polymer | Bio-Based | Biodegradable |

|---|---|---|

| Polylactic acid (PLA) | y | y |

| Starch blends, thermoplastic starch (TS) | y | y |

| Polyhydroxyalkanoates (PHAs) | y | y |

| Polybutylene succinate (PBS) | y/n | y |

| Polyurethanes (PURs) | y/n | y/n |

| Polycaprolactone (PCL) | n | y |

| Polyvinyl alcohol (PVA) | n | y |

| Polybutylene adipate terephthalate (PBAT) | n | y |

| Polyethylene Furanoate (PEF) | y | n |

| Bio-polypropylene (bio-PP) | y | n |

| Polytrimethylene terephthalate (PTT) | y | n |

| Bio-polyethylene terephthalate (bio-PET) | y | n |

| Bio-polyethylene (bio-PE) | y | n |

| Bio-polyamides (bio-PAs) | y | n |

| Polymer | Technology Overview | Route |

|---|---|---|

| Polylactic acid | Fermentation of carbohydrates (e.g., starch) yields lactic acid which polymerizes to low Mn PLA. This depolymerizes to lactide, which polymerizes to high Mn PLA. | 1 |

| Polybutylene succinate | Bacterial fermentation of carbohydrates yields succinic acid, which is esterified to also obtain 1,4-butanediol. The two chemicals polymerize to PBS. | |

| Polyurethanes | Polyols obtained from plant oils are reacted with isocyanates or bio-isocyanates to yield PURs. | |

| Polyamides | Diacids derived from castor oil are reacted with a diamine to yield PAs. A typical pair is sebacic acid and decamethylenediamine (obtained from the acid). | |

| Polyethylene | Fermentation of saccharides yields bioethanol, then dehydrated to ethylene. Polymerization yields bio-PE. | |

| Thermoplastic starch | Typically obtained by gelatinization of starch (from corn, cassava, etc.) followed by casting or by extrusion of starch pellets and plasticizers. | 2 |

| Cellulose acetate | Cellulose from wood pulp is converted to a triacetate form which is then hydrolyzed to cellulose acetate. | |

| Regenerated cellulose | Cellulose is converted to a soluble form, then regenerated to obtain a film (cellophane) or a fiber (rayon). | |

| Polyhydroxyalkanoates | Intracellularly accumulated by different bacteria. Polyhydroxybutyrate was the first to be discovered. | 3 |

| Standard | Title |

|---|---|

| EN ISO 10210:2017 | Plastics—Methods for the preparation of samples for biodegradation testing of plastic materials (ISO 10210:2012) |

| EN 14995:2006 | Plastics—Evaluation of compostability—Test scheme and specifications |

| EN 13432:2000 | Packaging—Requirements for packaging recoverable through composting and biodegradation—Test scheme and evaluation criteria for the final acceptance of packaging |

| EN 14046:2003 | Packaging—Evaluation of the ultimate aerobic biodegradability of packaging materials under controlled composting conditions—Method by analysis of released carbon dioxide |

| EN 17033:2018 | Plastics—Biodegradable mulch films for use in agriculture and horticulture—Requirements and test methods |

| ISO 17088:2012 | Specifications for compostable plastics |

| EN ISO 14855-1:2012 EN ISO 14855-2:2018 | Determination of the ultimate aerobic biodegradability of plastic materials under controlled composting conditions—Method by analysis of evolved carbon dioxide—Part 1: General method (ISO 14855-1:2012)—Part 2: Gravimetric measurement of carbon dioxide evolved in a laboratory-scale test (ISO 14855-2:2018) |

| EN ISO 16929:2019 | Plastics—Determination of the degree of disintegration of plastic materials under defined composting conditions in a pilot-scale test (ISO 16929:2019) |

| EN ISO 20200:2015 | Plastics—Determination of the degree of disintegration of plastic materials under simulated composting conditions in a laboratory-scale test (ISO 20200:2015) |

| ISO 23977-1:2020 ISO 23977-2:2020 | Plastics—Determination of the aerobic biodegradation of plastic materials exposed to seawater—Part 1: Method by analysis of evolved carbon dioxide—Part 2: Method by measuring the oxygen demand in closed respirometer |

| EN ISO 14853:2017 | Plastics—Determination of the ultimate anaerobic biodegradation of plastic materials in an aqueous system—Method by measurement of biogas production (ISO 14853:2016) |

| EN ISO 14851:2019 | Determination of the ultimate aerobic biodegradability of plastic materials in an aqueous medium—Method by measuring the oxygen demand in a closed respirometer (ISO 14851:2019) |

| EN ISO 14852:2018 | Determination of the ultimate aerobic biodegradability of plastic materials in an aqueous medium—Method by analysis of evolved carbon dioxide (ISO 14852:2018) |

| EN 17417:2020 | Determination of the ultimate biodegradation of plastics materials in an aqueous system under anoxic (denitrifying) conditions—Method by measurement of pressure increase |

| EN ISO 10634:2018 | Water quality—Preparation and treatment of poorly water-soluble organic compounds for the subsequent evaluation of their biodegradability in an aqueous medium (ISO 10634:2018) |

| EN ISO 14593:2005 | Water quality—Evaluation of ultimate aerobic biodegradability of organic compounds in aqueous medium—Method by analysis of inorganic carbon in sealed vessels (CO2 headspace test) (ISO 14593:1999) |

| EN ISO 11733:2004 | Water quality—Determination of the elimination and biodegradability of organic compounds in an aqueous medium—Activated sludge simulation test (ISO 11733:2004) |

| EN ISO 17556:2019 | Plastics—Determination of the ultimate aerobic biodegradability of plastic materials in soil by measuring the oxygen demand in a respirometer or the amount of carbon dioxide evolved (ISO 17556:2019) |

| EN ISO 11266:2020 | Soil quality—Guidance on laboratory testing for biodegradation of organic chemicals in soil under aerobic conditions (ISO 11266:1994) |

| EN ISO 15985:2017 | Plastics—Determination of the ultimate anaerobic biodegradation under high-solids anaerobic-digestion conditions—Method by analysis of released biogas (ISO 15985:2014) |

| EN ISO 18830:2017 | Plastics—Determination of aerobic biodegradation of non-floating plastic materials in a seawater/sandy sediment interface—Method by measuring the oxygen demand in closed respirometer (ISO 18830:2016) |

| EN ISO 19679:2020 | Plastics—Determination of aerobic biodegradation of non-floating plastic materials in a seawater/sediment interface—Method by analysis of evolved carbon dioxide (ISO 19679:2020) |

| ISO 13975:2019 | Plastics—Determination of the ultimate anaerobic biodegradation of plastic materials in controlled slurry digestion systems—Method by measurement of biogas production |

| ISO 22404:2019 | Plastics—Determination of the aerobic biodegradation of non-floating materials exposed to marine sediment—Method by analysis of evolved carbon dioxide |

| ISO/DIS 23517-1 (under development) | Plastics—Biodegradable mulch films for use in agriculture and horticulture Part 1: Requirements and test methods regarding biodegradation, ecotoxicity and control of constituents |

| Standard | Title |

|---|---|

| EN 17228:2019 | Plastics—Bio-based polymers, plastics, and plastics products—Terminology, characteristics and communication |

| EN 16760:2015 | Bio-based products—Life Cycle Assessment |

| EN 16751:2016 | Bio-based products—Sustainability criteria |

| EN 16575:2014 | Bio-based products–Vocabulary |

| EN 16640:2017 | Bio-based products—Bio-based carbon content—Determination of the bio-based carbon content using the radiocarbon method |

| EN 17351:2020 | Bio-based products—Determination of the oxygen content using an elemental analyser |

| CEN/TR 16957:2016 | Bio-based products—Guidelines for Life Cycle Inventory (LCI) for the End-of-life phase |

| CEN/TR 16721:2014 | Bio-based products—Overview of methods to determine the bio-based content |

| CEN/TR 17341:2019 | Bio-based products—Examples of reporting on sustainability criteria |

| CEN/TR 16208:2011 | Biobased products—Overview of standards |

| EN ISO 14040:2006 | Environmental management—Life cycle assessment—Principles and framework (ISO 14040:2006) |

| EN ISO 14044:2006 | Environmental management—Life cycle assessment—Requirements and guidelines (ISO 14044:2006) |

| EN ISO 14046:2016 | Environmental management—Water footprint—Principles, requirements and guidelines (ISO 14046:2014) |

| EN ISO 14067:2018 | Greenhouse gases—Carbon footprint of products—Requirements and guidelines for quantification (ISO 14067:2018) |

| ISO/TS 14072:2014 | Environmental management—Life cycle assessment—Requirements and guidelines for organizational life cycle assessment |

| ISO/TS 14048:2002 | Environmental management—Life cycle assessment—Data documentation format |

| ISO/TS 14071:2014 | Environmental management—Life cycle assessment—Critical review processes and reviewer competencies: Additional requirements and guidelines to ISO 14044:2006 |

| ISO 14045:2012 | Environmental management—Eco-efficiency assessment of product systems—Principles, requirements and guidelines |

| ISO/TR 14069:2013 | Greenhouse gases—Quantification and reporting of greenhouse gas emissions for organizations—Guidance for the application of ISO 14064-1 |

| ISO 22526-1:2020 ISO 22526-2:2020 ISO 22526-3:2020 | Plastics—Carbon and environmental footprint of biobased plastics—Part 1: General principles—Part 2: Material carbon footprint, amount (mass) of CO2 removed from the air and incorporated into polymer molecule—Part 3: Process carbon footprint, requirements and guidelines for quantification |

| ISO 16620-1:2015 ISO 16620-2:2019 ISO 16620-3:2015 ISO 16620-4:2016 ISO 16620-5:2017 | Plastics—Biobased content—Part 1: General principles—Part 2: Determination of biobased carbon content—Part 3: Determination of biobased synthetic polymer content—Part 4: Determination of biobased mass content—Part 5: Declaration of biobased carbon content, biobased synthetic polymer content and biobased mass content |

| Indicator | Units | Description |

|---|---|---|

| Global Warming Potential, GWP100 | kg CO2 eq | Indicator of the potential global warming due to all greenhouse gas emissions over a period of 100 years; CO2 as reference |

| Ozone Depletion Potential, ODP | kg CFC-11 eq | Indicator of the potential destruction of the stratospheric ozone layer due to emissions; freon-11 as reference |

| Photochemical Ozone Creation Potential, POCP | kg ethene eq | Indicator of the photochemical ozone creation potential due to emission of gases; ethene as reference |

| Acidification Potential, AP | kg SO2 eq | Indicator of the potential acidification of water and soil due to emissions causing acid rain; sulphur dioxide as reference |

| Eutrophication, EU | kg PO4 eq | Indicator of the over-supply of nutrients to the ecosystem due to the release of nitrogen and phosphorous containing compounds which leads to algae bloom; phosphate as reference |

| Human Toxicity, HT | kg DCB eq | Indicator of the impact on human health due to toxic substances release; 1,4-dichlorobenzene as reference |

| Ecotoxicity, ET | kg DCB eq | Indicator of the impact on the ecosystem due to toxic substances release; 1,4-dichlorobenzene as reference |

| Land Use, LU | m2 | Indicator of the land in use by the system under assessment |

| Water Use, WU | m3 | Indicator of the water in use by the system under assessment |

| Abiotic Resource Depletion, ADP | kg Sb eq | Indicator of the depletion of non-living primary resources such as minerals and metals; antimony as reference |

| Abiotic Resource Depletion–Fossil fuels, ADP-fossil | MJ | Indicator of the fossil energy consumed by the system under assessment |

| Category | Description |

|---|---|

| Advantages of bioplastics | Reducing fossil fuel dependency by using renewable resources, replacing existing plastics with bio-based counterparts (e.g., drop-in plastics) |

| Potential environmental benefits in terms of GWP reduction | |

| The use of compostable plastics, in applications where organic contamination is expected, simplifies waste management and returns carbon to soil as compost | |

| Anaerobic digestion of biodegradable plastics can produce large specific energy and contribute to achieve an optimal ratio of carbon to nitrogen in the process | |

| Biodegradable plastics could replace non-degradable plastics in products that are likely to leak in the environment, potentially mitigating plastic pollution | |

| Disadvantages of bioplastics | High production costs and, possibly, lower performance than common plastics |

| Lack of processability with common technologies or lack of know-how | |

| Small market volume does not justify major investments nor redesign of production frameworks and waste manager infrastructure | |

| Possible feedstock competition with biofuel and food industry | |

| Risk of fouling of recycling streams with biodegradable plastics | |

| Risk of landfilling biodegradable plastics resulting in GHG emissions | |

| Lack of dedicated composting and recycling infrastructure and logistics | |

| Uncertainty regarding biodegradability in different open environments |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229. https://doi.org/10.3390/polym13081229

Di Bartolo A, Infurna G, Dintcheva NT. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers. 2021; 13(8):1229. https://doi.org/10.3390/polym13081229

Chicago/Turabian StyleDi Bartolo, Alberto, Giulia Infurna, and Nadka Tzankova Dintcheva. 2021. "A Review of Bioplastics and Their Adoption in the Circular Economy" Polymers 13, no. 8: 1229. https://doi.org/10.3390/polym13081229

APA StyleDi Bartolo, A., Infurna, G., & Dintcheva, N. T. (2021). A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers, 13(8), 1229. https://doi.org/10.3390/polym13081229