Analysis of Fuel Cell Stack Performance Attenuation and Individual Cell Voltage Uniformity Based on the Durability Cycle Condition

Abstract

1. Introduction

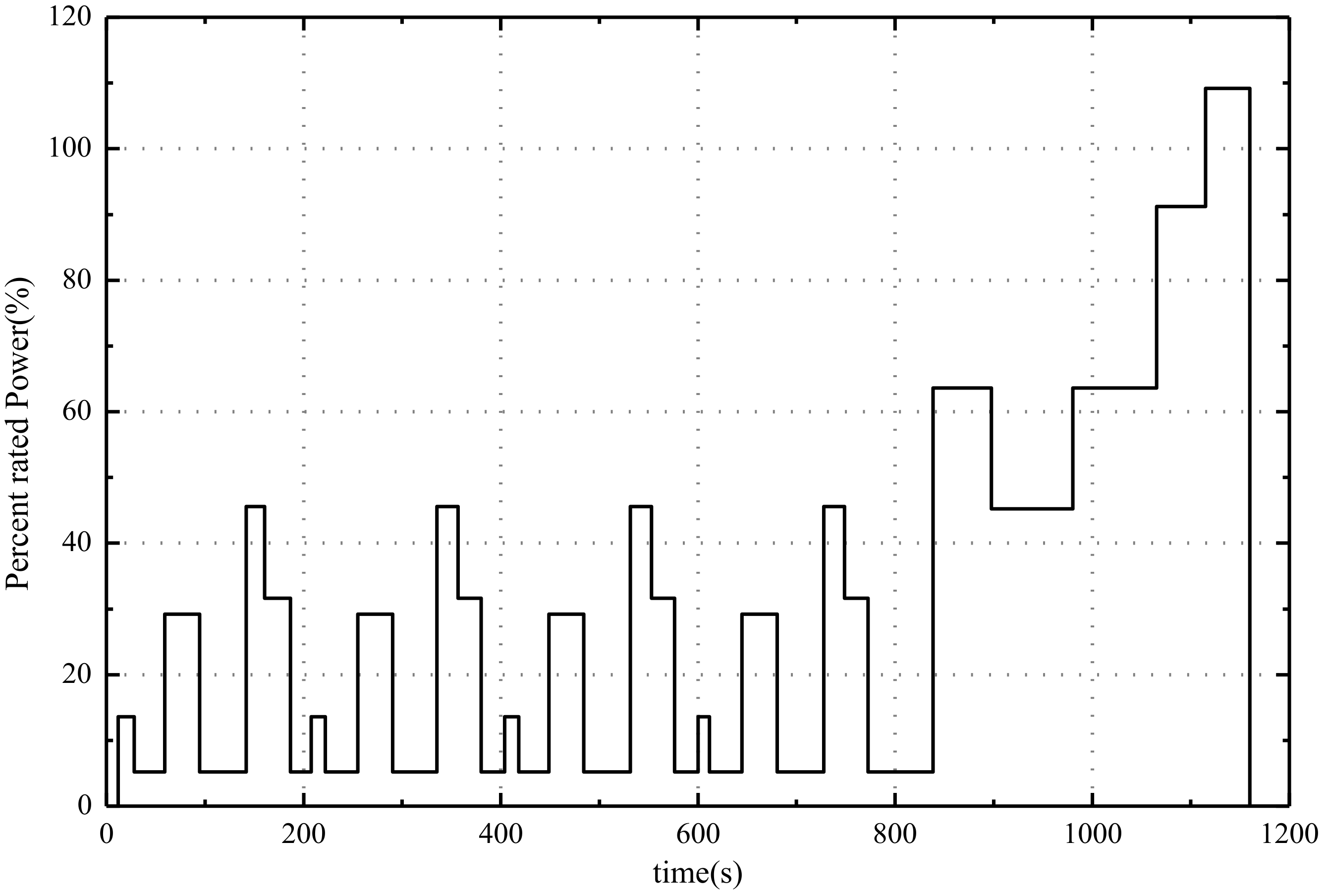

2. The Durability Cycle Test Setup

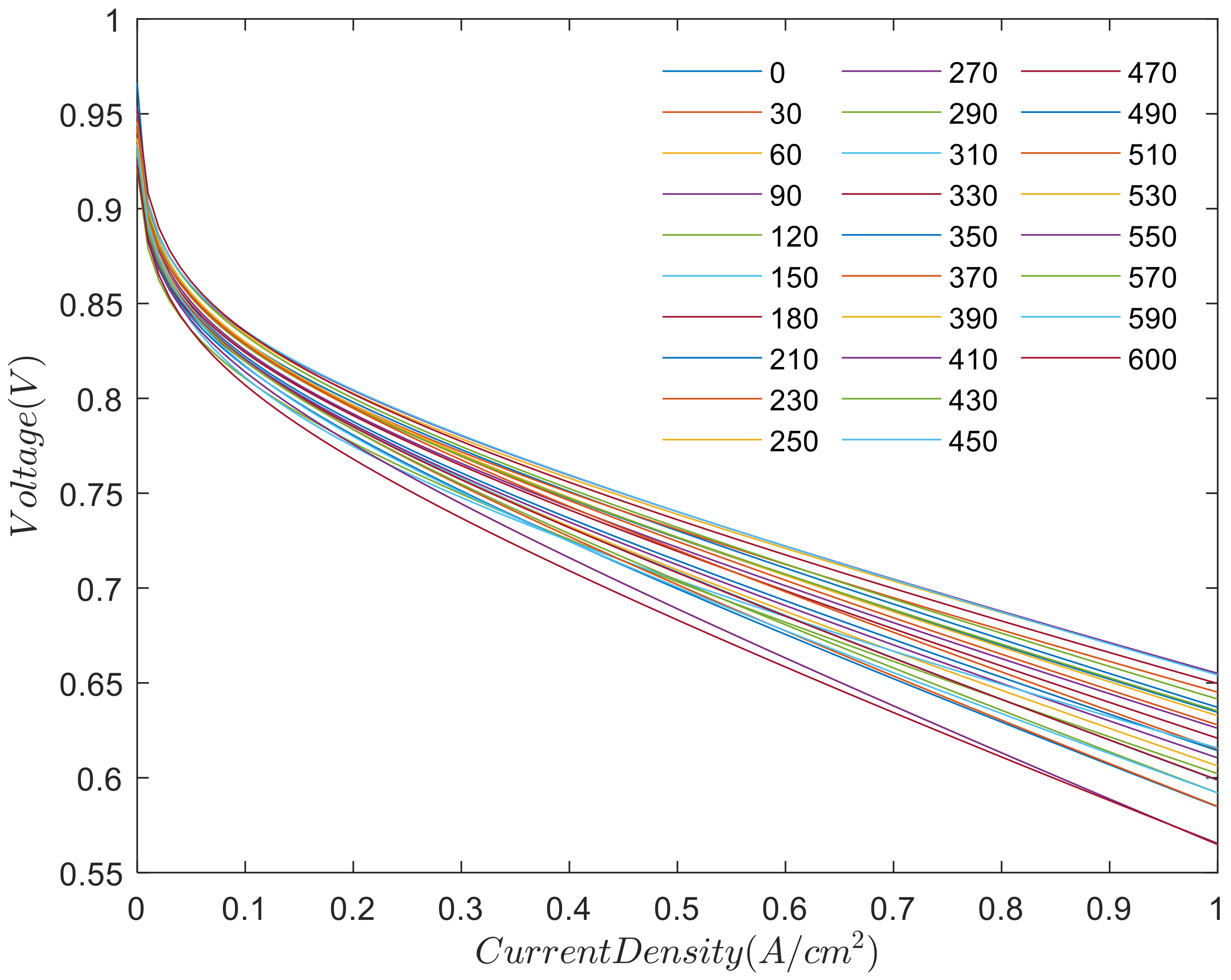

3. Polarization Curve of Fuel Cell Stack

4. Analysis and Evaluation of Fuel Cell Stack Performance

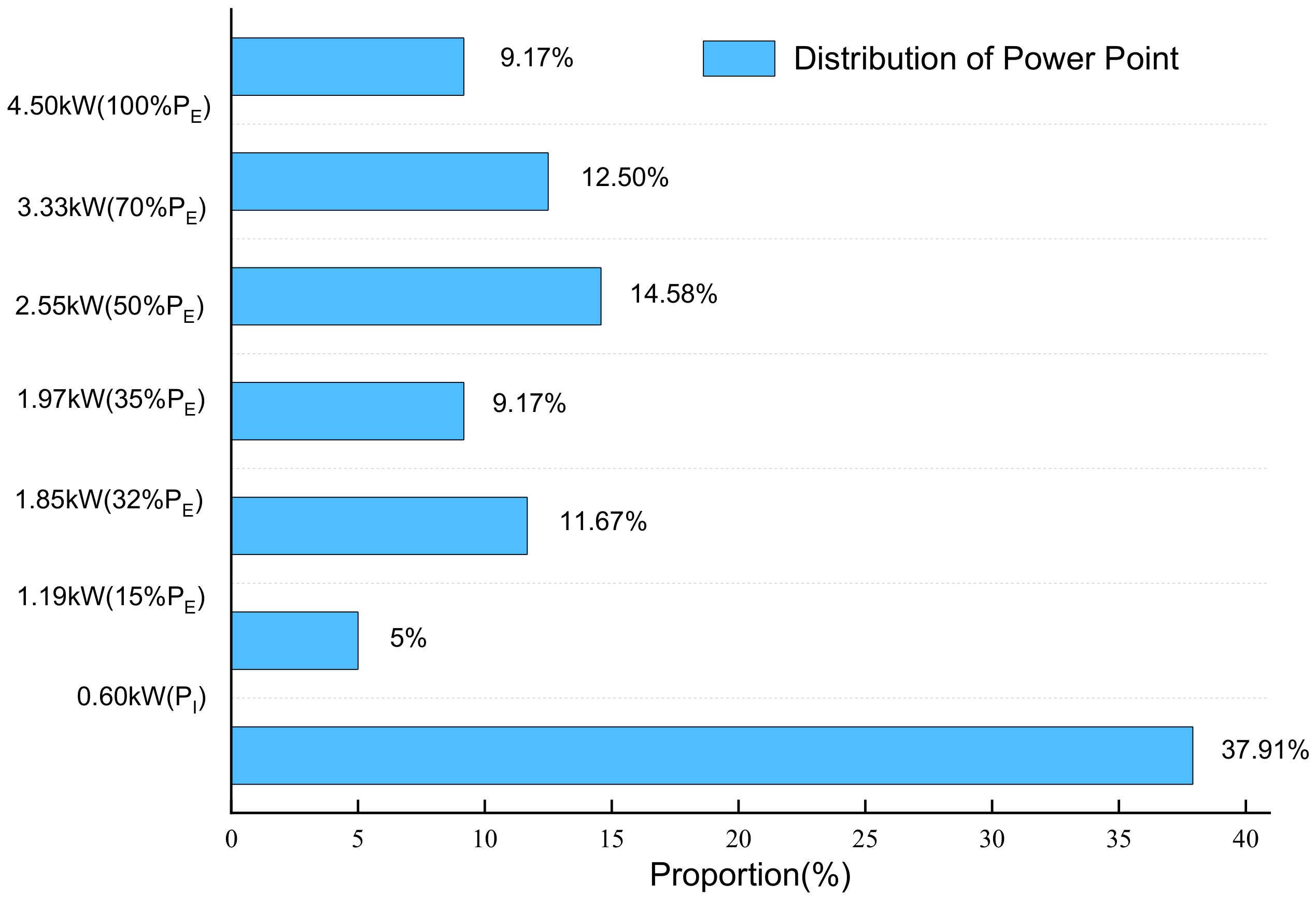

4.1. Common Current Density

4.2. Voltage Analysis of Fuel Cell Stack

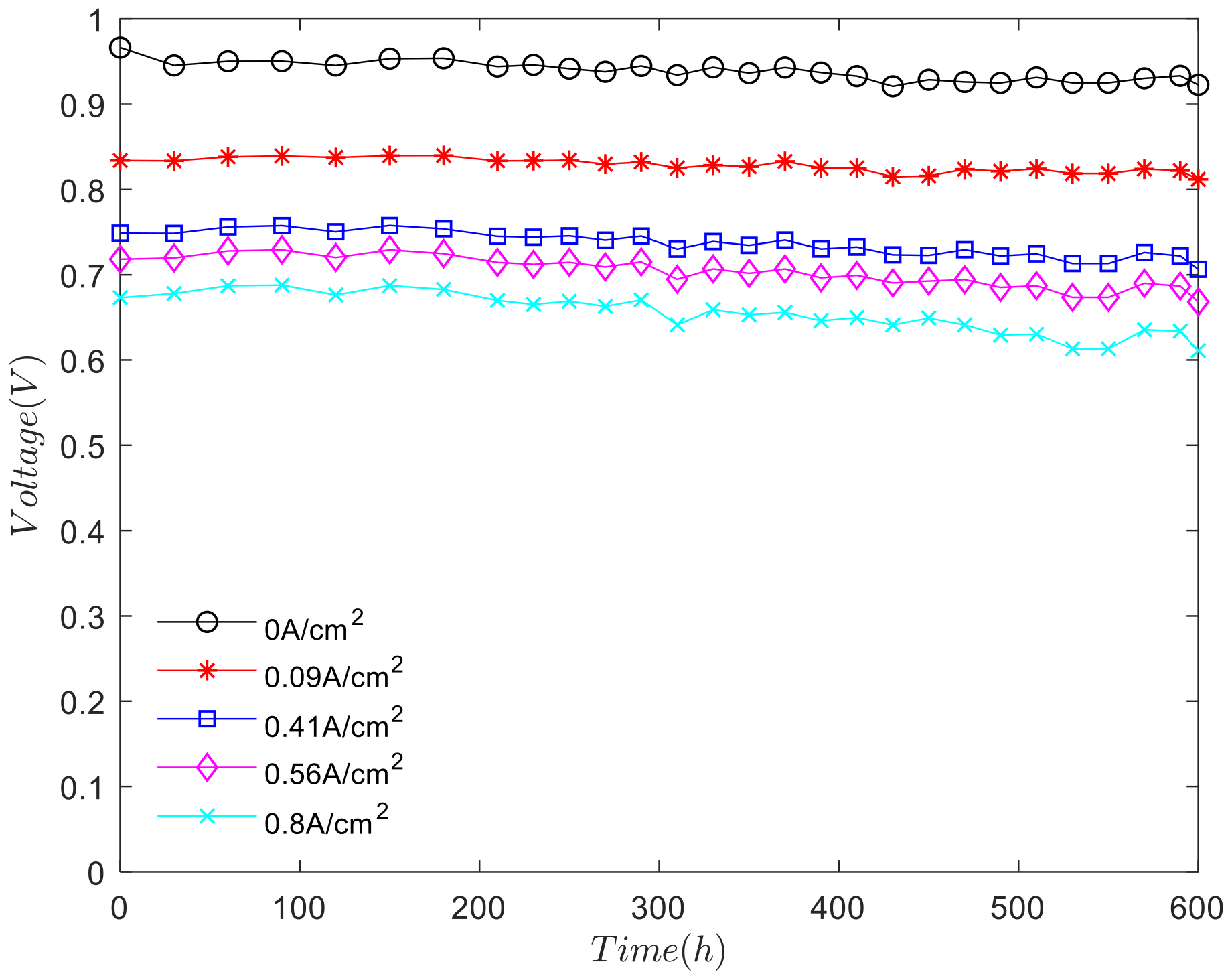

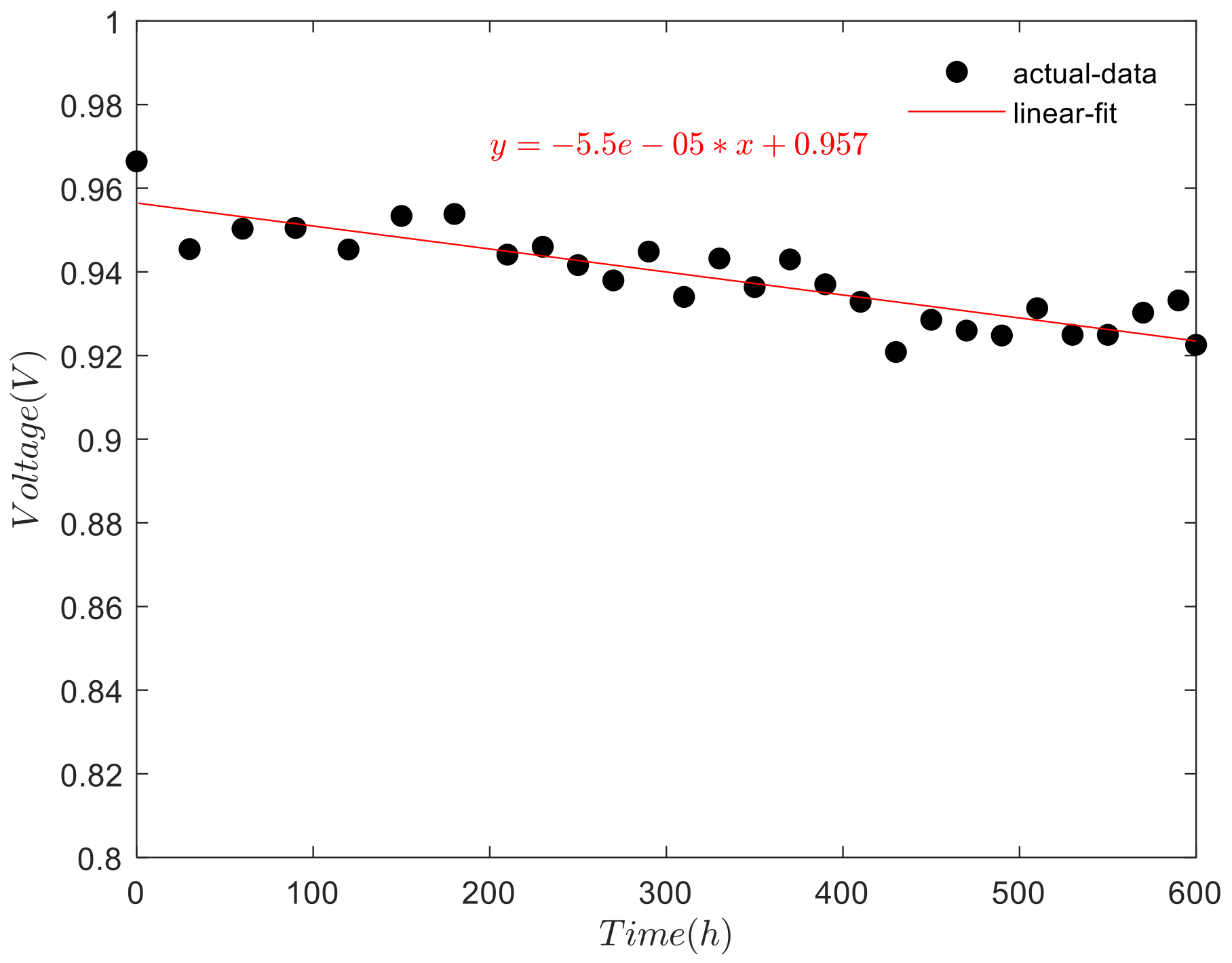

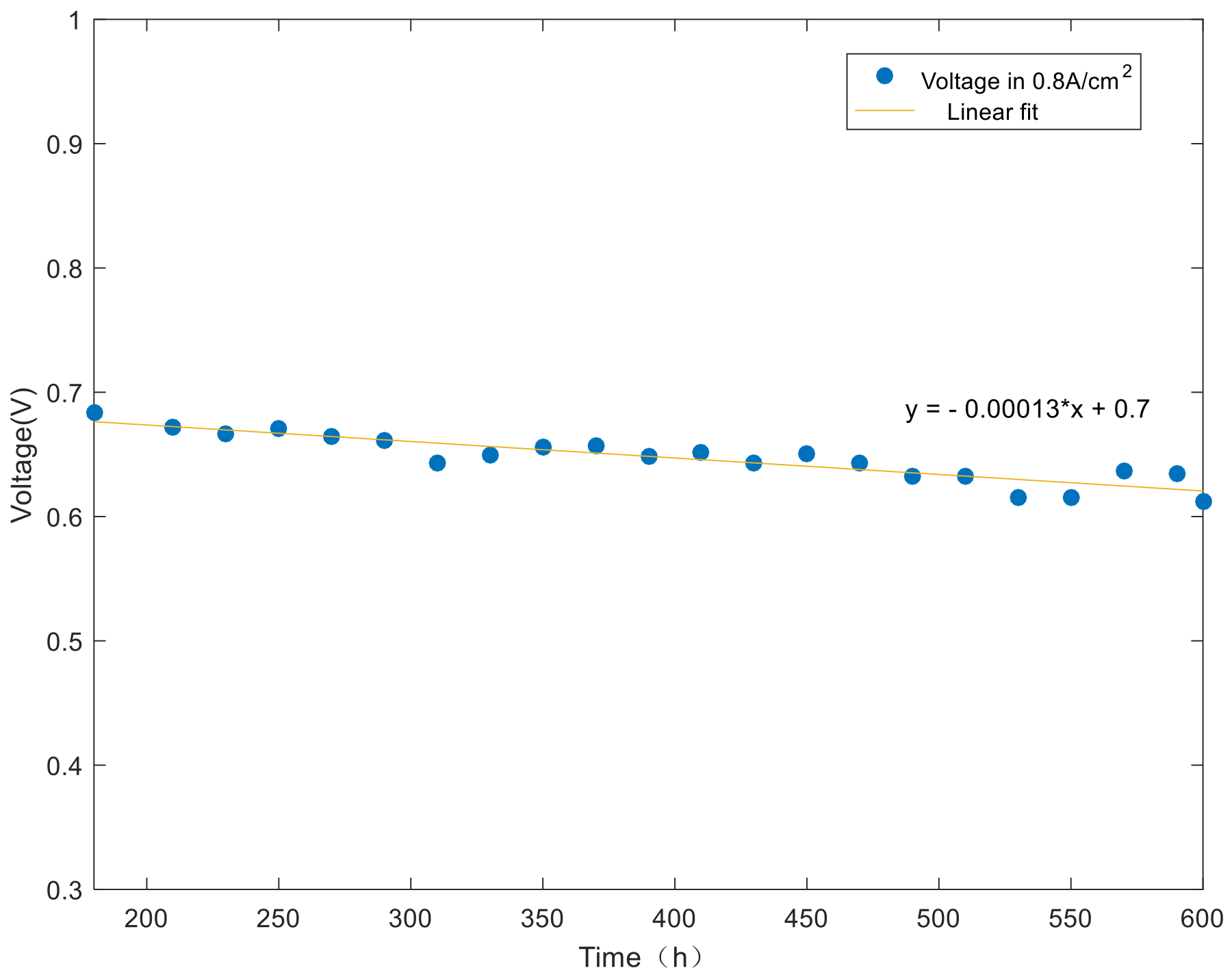

4.2.1. Voltage Attenuation under Fixed Currents

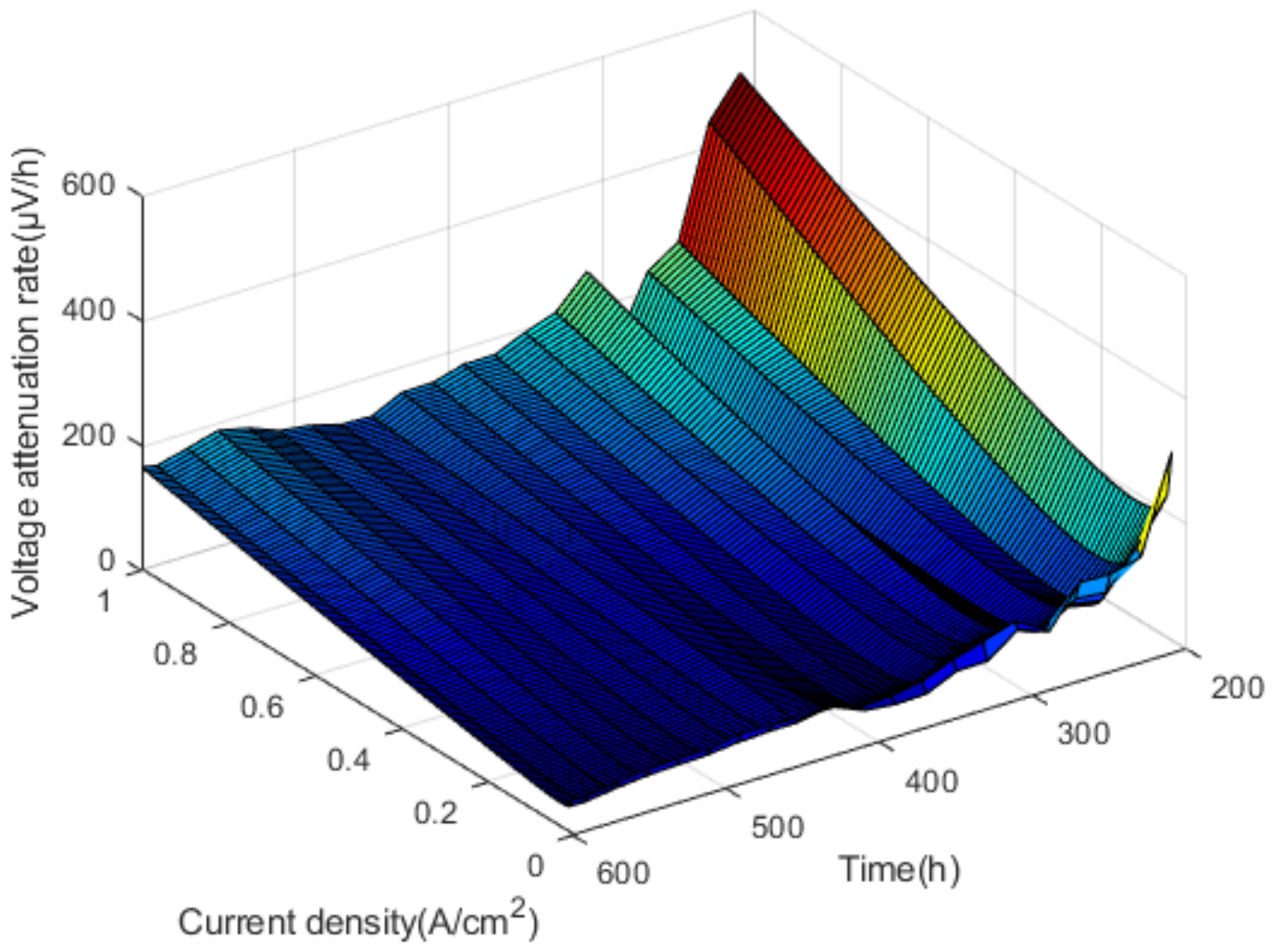

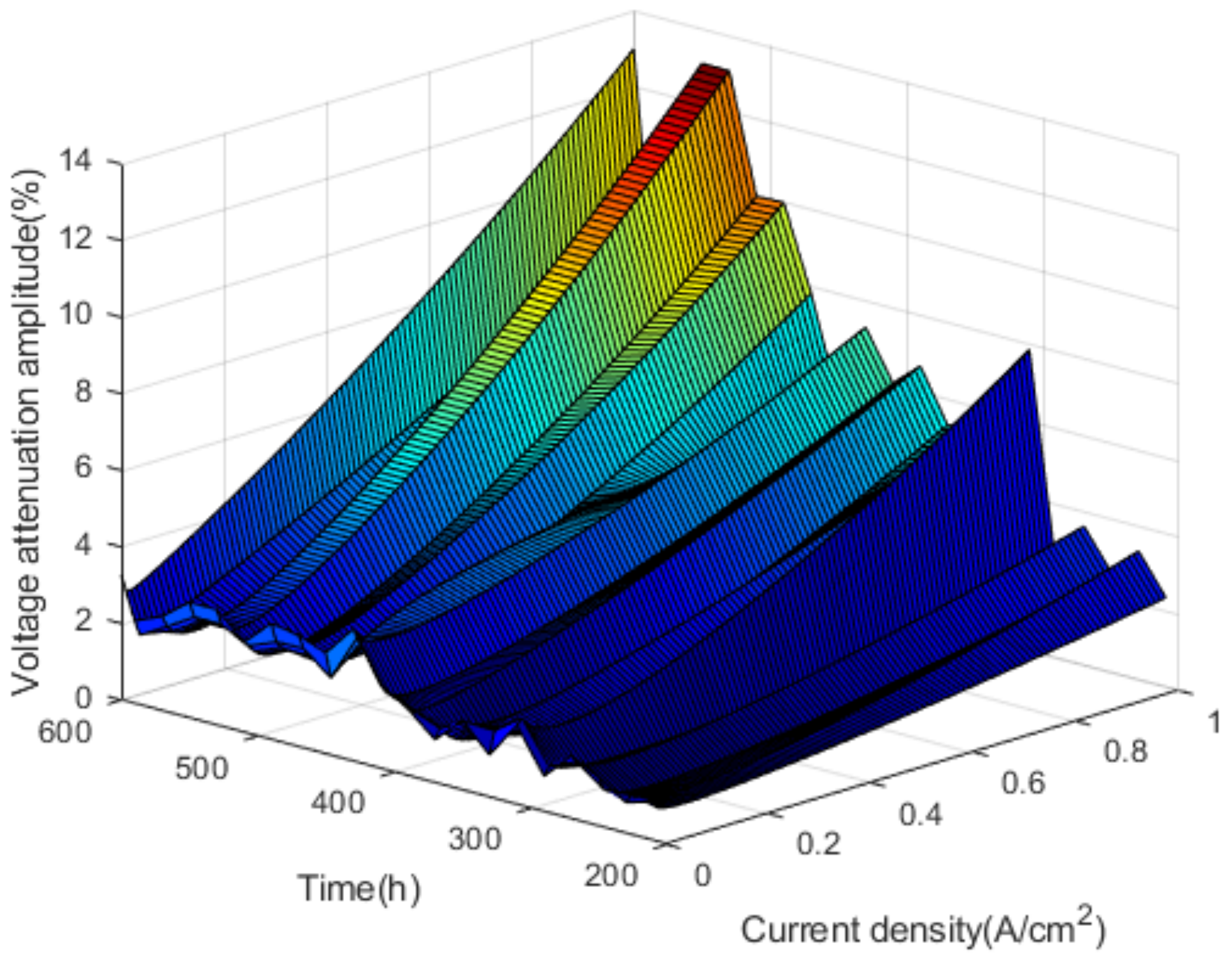

4.2.2. Whole Voltage Attenuation

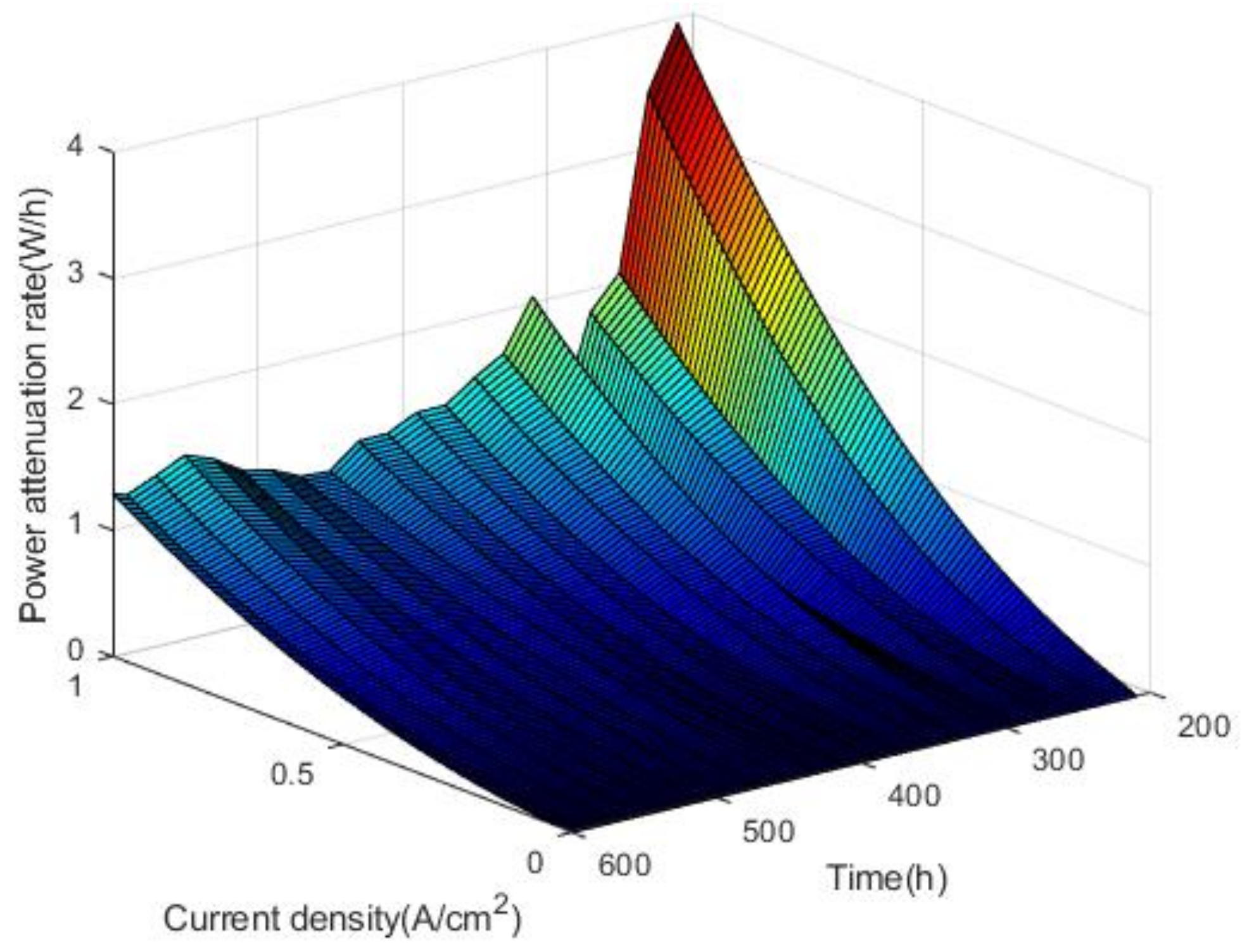

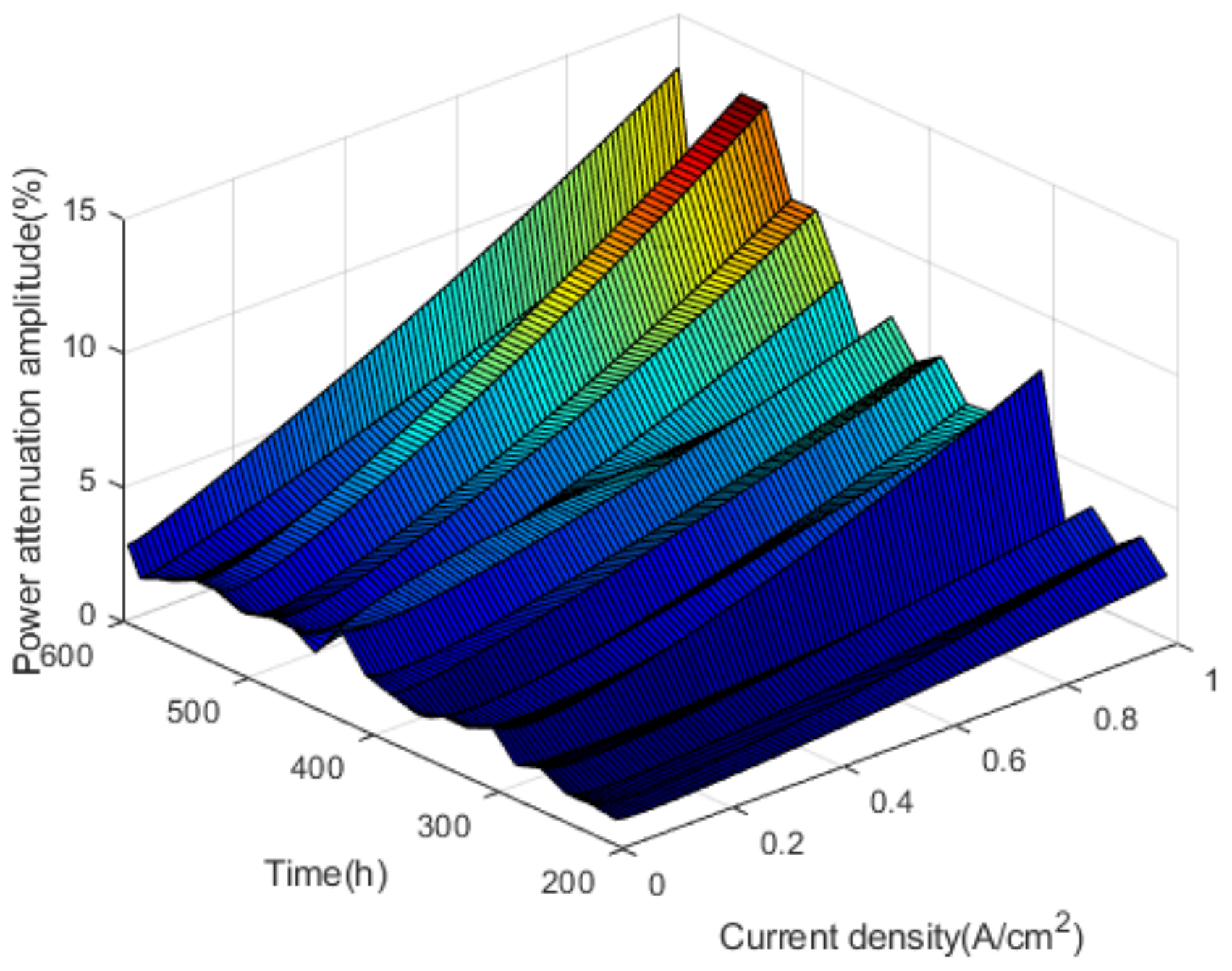

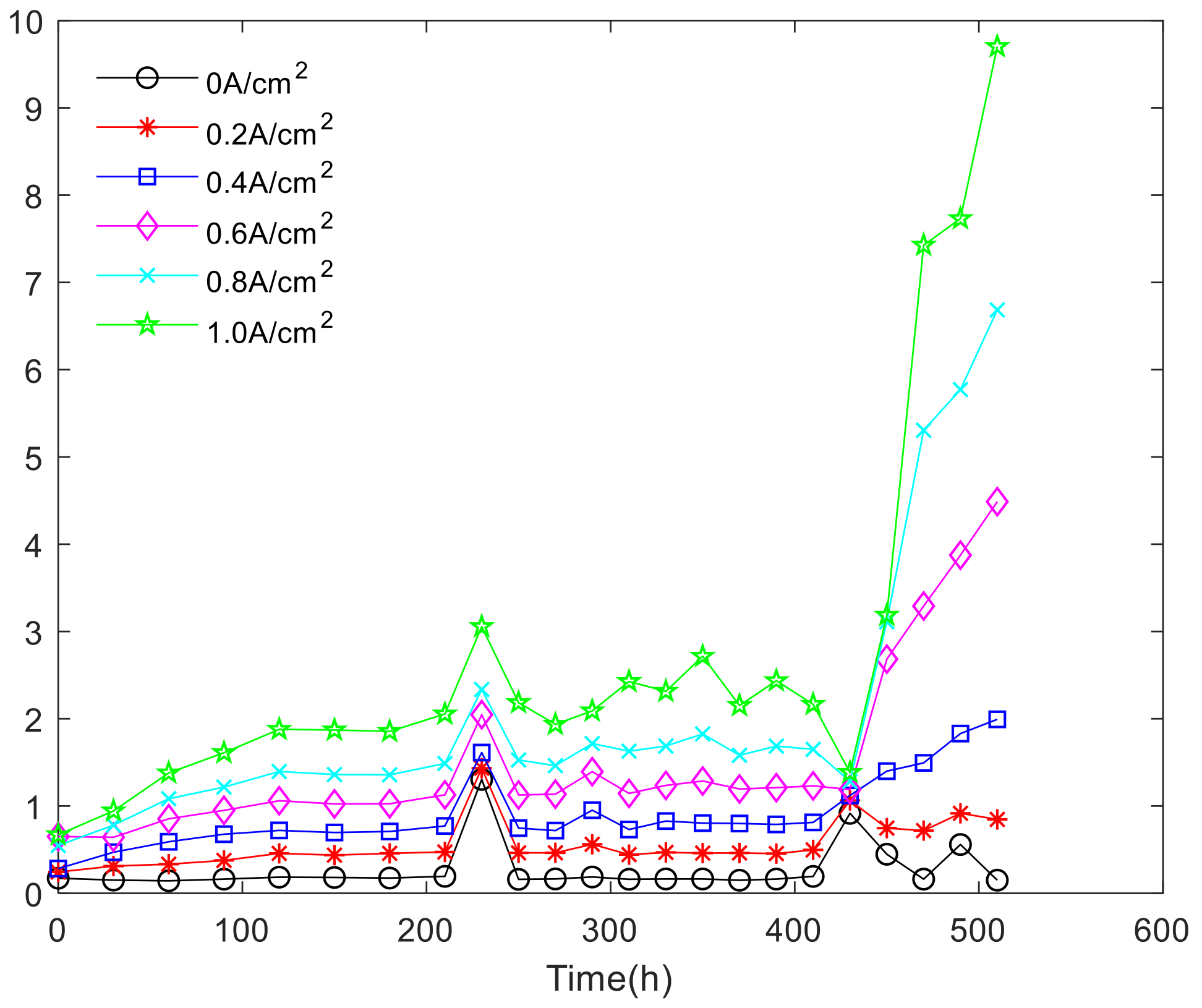

4.3. Power Analysis of Fuel Cell Stack

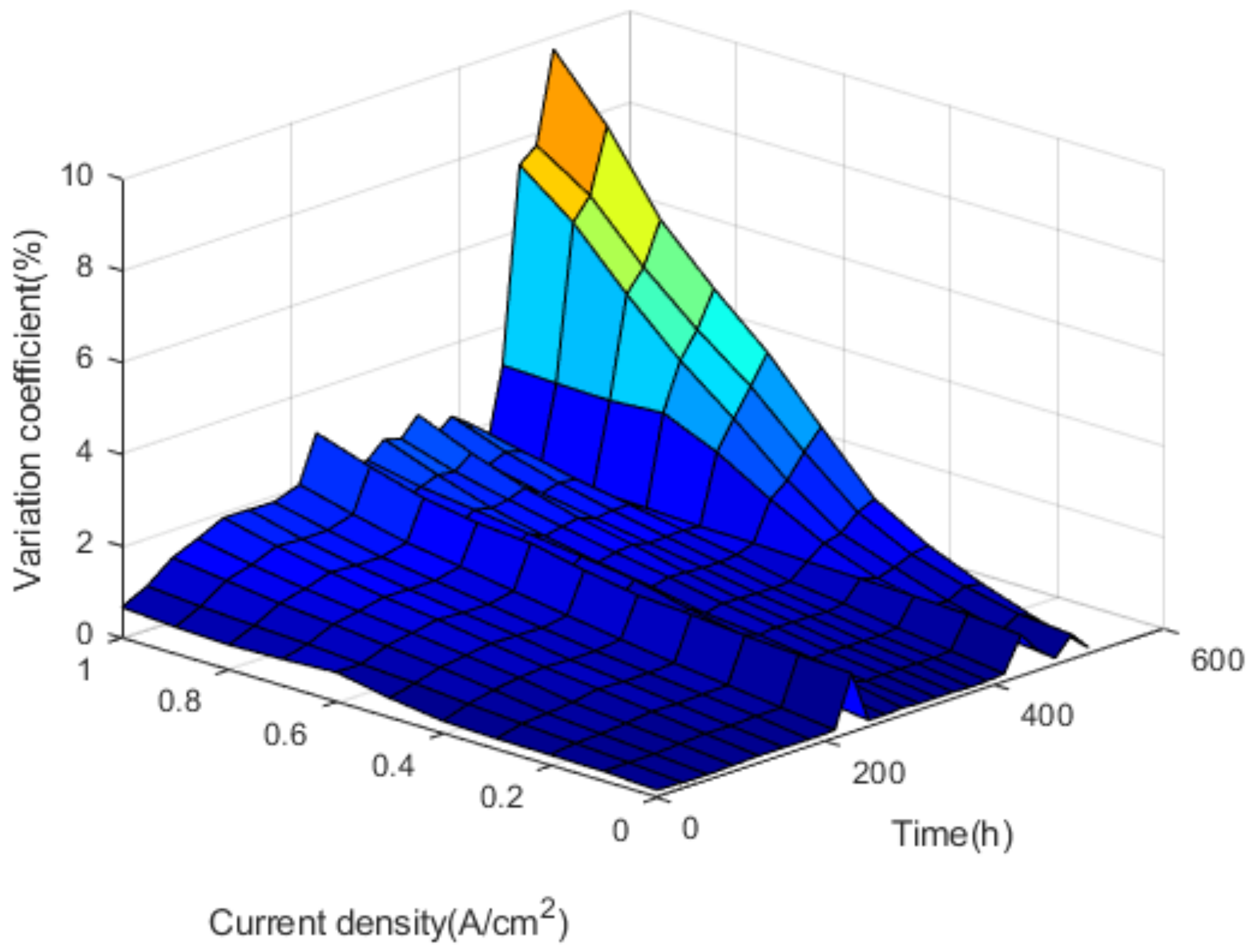

5. Analysis of Individual Cell Voltage Uniformity of Fuel Cell Stack

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vichard, L.; Petrone, R.; Harel, F.; Ravey, A.; Venet, P.; Hissel, D. Long term durability test of open-cathode fuel cell system under actual operating conditions. Energy Convers. Manag. 2020, 212, 112813. [Google Scholar] [CrossRef]

- Yuan, X.-Z.; Li, H.; Zhang, S.; Martin, J.; Wang, H. A review of polymer electrolyte membrane fuel cell durability test protocols. J. Power Sources 2011, 196, 9107–9116. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, G.; Tu, Z.; Zhan, Z.; Pan, M. Effect of gas shutoff sequences on the degradation of proton exchange membrane fuel cells with dummy load during startup and shutdown cycles. Electrochim. Acta 2012, 71, 181–193. [Google Scholar] [CrossRef]

- Schmittinger, W.; Vahidi, A. A review of the main parameters influencing long-term performance and durability of PEM fuel cells. J. Power Sources 2008, 180, 1–14. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, X.Z.; Martin, J.J.; Wang, H.; Zhang, J.; Shen, J.; Wu, S.; Merida, W. A review of PEM fuel cell durability: Degradation mechanisms and mitigation strategies. J. Power Sources 2008, 184, 104–119. [Google Scholar] [CrossRef]

- Bose, A.C.; Babburi, P.; Kumar, R.; Myers, D.J.; Mawdsley, J.R.; Milhuff, J. Performance of individual cells in polymer electrolyte membrane fuel cell stack under-load cycling conditions. J. Power Sources 2013, 243, 964–972. [Google Scholar] [CrossRef]

- Cleghorn, S.; Mayfield, D.; Moore, D.; Moore, J.; Rusch, G.; Sherman, T.; Sisofo, N.; Beuscher, U. A polymer electrolyte fuel cell life test: 3 years of continuous operation. J. Power Sources 2006, 158, 446–454. [Google Scholar] [CrossRef]

- Pahon, E.; Morando, S.; Petrone, R.; Péra, M.C.; Hissel, D.; Yousfi-Steiner, N.; Jemei, S.; Gouriveau, R.; Chamagne, D.; Moçoteguy, P.; et al. Long-term tests duration reduction for PEMFC mu-CHP application. Int. J. Hydrogen Energy 2017, 42, 1527–1533. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, L.; Peng, C.; Chen, Z.; Zhang, Y.; Fan, Q. Catalyst Microstructure Examination of PEMFC Membrane Electrode Assemblies vs. Time. J. Electrochem. Soc. 2004, 151, A48–A52. [Google Scholar] [CrossRef]

- Wahdame, B.; Candusso, D.; François, X.; Harel, F.; Péra, M.C.; Hissel, D.; Kauffmann, J.M. Comparison between two PEM fuel cell durability tests performed at constant current and under solicitations linked to transport mission profile. Int. J. Hydrogen Energy 2007, 32, 4523–4536. [Google Scholar] [CrossRef]

- Zhongjun, H.O.; Quan, G.A.; Youqi, M.A. Study on durability of the fuel cell power system for the bus application. J. Mech. Eng. 2013, 46, 4. [Google Scholar]

- Liu, Y.N.; Wang, Y.Y.; Huang, G.; Hou, Y.P. Performance degradation law of fuel cell system for stationary power plant. Battery Bimon. 2013, 4, 199–200. [Google Scholar]

- Zhao, J.; Shahgaldi, S.; Li, X.; Liu, Z.S. Experimental Observations of Microstructure Changes in the Catalyst Layers of Proton Exchange Membrane Fuel Cells under Wet-Dry Cycles. J. Electrochem. Soc. 2018, 165, F3337–F3345. [Google Scholar] [CrossRef]

- Pei, P.; Chang, Q.; Tang, T. A quick evaluating method for automotive fuel cell lifetime. Int. J. Hydrog. Energy 2008, 33, 3829–3836. [Google Scholar] [CrossRef]

- Xie, J.; Wood, D.L.; Wayne, D.M.; Zawodzinski, T.A.; Atanassov, P.; Borup, R.L. Durability of PEFCs at High Humidity Conditions. J. Electrochem. Soc. 2005, 152, A104–A113. [Google Scholar] [CrossRef]

- Chang, Y.; Zhao, J.; Shahgaldi, S.; Qin, Y.; Yin, Y.; Li, X. Modelling of mechanical microstructure changes in the catalyst layer of a polymer electrolyte membrane fuel cell. Int. J. Hydrog. Energy 2020, 45, 13. [Google Scholar] [CrossRef]

- Yuan, X.-Z.; Zhang, S.; Sun, J.C.; Wang, H. A review of accelerated conditioning for a polymer electrolyte membrane fuel cell. J. Power Sources 2011, 196, 9097–9106. [Google Scholar] [CrossRef]

- Bae, S.J.; Kim, S.-J.; Park, J.I.; Park, C.W.; Lee, J.-H.; Song, I.; Lee, N.; Kim, K.-B.; Park, J.-Y. Lifetime prediction of a polymer electrolyte membrane fuel cell via an accelerated startup–shutdown cycle test. Int. J. Hydrogen Energy 2012, 37, 9775–9781. [Google Scholar] [CrossRef]

- Panha, K.; Fowler, M.; Yuan, X.-Z.; Wang, H. Accelerated durability testing via reactants relative humidity cycling on PEM fuel cells. Appl. Energy 2012, 93, 90–97. [Google Scholar] [CrossRef]

- Bloom, I.; Walker, L.K.; Basco, J.K.; Malkow, T.; Saturnio, A.; De Marco, G.; Tsotridis, G. A comparison of Fuel Cell Testing protocols—A case study: Protocols used by the U.S. Department of Energy, European Union, International Electrotechnical Commission/Fuel Cell Testing and Standardization Network, and Fuel Cell Technical Team. J. Power Sources 2013, 243, 451–457. [Google Scholar] [CrossRef]

- Pei, P.; Chen, H. Main factors affecting the lifetime of Proton Exchange Membrane fuel cells in vehicle applications: A review. Appl. Energy 2014, 125, 60–75. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Rahmoeller, K.M.; Hurst, J.H.; Kukreja, R.S.; Atwan, M.; Maslyn, A.J.; Gittleman, C.S. Accelerated Stress Testing of Fuel Cell Membranes Subjected to Combined Mechanical/Chemical Stressors and Cerium Migration. J. Electrochem. Soc. 2018, 165, F3217–F3229. [Google Scholar] [CrossRef]

- Jeon, Y.; Juon, S.M.; Hwang, H.; Park, J.; Shul, Y.-G. Accelerated Life-time Tests including Different Load Cycling Protocols for High Temperature Polymer Electrolyte Membrane Fuel Cells. Electrochim. Acta 2014, 148, 15–25. [Google Scholar] [CrossRef]

- Li, P.; Pei, P.; He, Y.; Yuan, X.; Chao, P.; Wang, X. Mechanisms of accelerated degradation in the front cells of PEMFC stacks and some mitigation strategies. Chin. J. Mech. Eng. 2013, 26, 1250–1258. [Google Scholar] [CrossRef]

- Hicks, M.; Pierpont, D. Application of Accelerated Testing and Statistical Lifetime Modeling to Membrane Electrode Assembly Development. In Polymer Electrolyte Fuel Cell Durability; Springer: Berlin, Germany, 2009; pp. 385–396. [Google Scholar]

| Parameters | Values |

|---|---|

| Relative humidity of hydrogen | without humidification |

| Relative humidity of gas | 80% |

| Stoichiometry of hydrogen | 1.2 |

| Stoichiometry of air | 2.5 |

| Inlet temperature of hydrogen | 60 °C |

| Inlet temperature of air | 60 °C |

| Inlet pressure of hydrogen | 50 kPa |

| Inlet pressure of air | without pressurization |

| Outlet temperature of coolant | 60 °C |

| Physical characteristics | Length | 357 mm |

| Width | 490 mm | |

| Height | 180 mm | |

| Number of fuel cells | 75 | |

| Effective working area of membrane(cm2) | - | |

| Electrochemical characteristics | Rated power | 6.55 kW |

| Rated current | 135 A | |

| Rated voltage | 48.53 V | |

| Rated efficiency | 51.76% | |

| Peak power | 7.35 kW | |

| Peak current | 160 A | |

| Operating conditions | Fuel | Mixture of hydrogen and nitrogen or reforming product, target hydrogen volume ratio: 80–100% (dry) |

| Operating pressure | <300 mbar (g) | |

| Relative humidity | 80–100% RH | |

| Oxidant | Air | |

| Operating pressure | <300 mbar (g) | |

| Maximum pressure difference between hydrogen and oxygen | 200 mbar (g) | |

| Relative humidity | 95–100% RH | |

| Coolant | Deionized water and/or propylene glycol or ethylene or ethylene glycol, <50% ethylene glycol | |

| Fuel cell temperature | 50–60 °C (inlet) |

| Name | Characteristic Power | Power (kW) | Average Single Cell Voltage (V) | Current Density (A/cm2) | Current (A) |

|---|---|---|---|---|---|

| Open circuit voltage | 0 | 0 | 0.96 | 0. | 0.0 |

| Idle speed | Idle Power | 0.6 | 0.82 | 0.09 | 28.9 |

| Common power | 15% PE | 1.19 | 0.79 | 0.18 | 56.5 |

| 32% PE | 1.85 | 0.77 | 0.29 | 90.2 | |

| 35% PE | 1.97 | 0.76 | 0.31 | 96.0 | |

| 50% PE | 2.55 | 0.74 | 0.41 | 128.0 | |

| 70% PE | 3.33 | 0.71 | 0.56 | 173.2 | |

| Rated power | PE | 4.5 | 0.66 | 0.80 | 249.6 |

| High Power | Peak power | 4.9 | 0.63 | 1.00 | 312.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.; Xu, S.; Gao, Y. Analysis of Fuel Cell Stack Performance Attenuation and Individual Cell Voltage Uniformity Based on the Durability Cycle Condition. Polymers 2021, 13, 1199. https://doi.org/10.3390/polym13081199

Shen C, Xu S, Gao Y. Analysis of Fuel Cell Stack Performance Attenuation and Individual Cell Voltage Uniformity Based on the Durability Cycle Condition. Polymers. 2021; 13(8):1199. https://doi.org/10.3390/polym13081199

Chicago/Turabian StyleShen, Chunjuan, Sichuan Xu, and Yuan Gao. 2021. "Analysis of Fuel Cell Stack Performance Attenuation and Individual Cell Voltage Uniformity Based on the Durability Cycle Condition" Polymers 13, no. 8: 1199. https://doi.org/10.3390/polym13081199

APA StyleShen, C., Xu, S., & Gao, Y. (2021). Analysis of Fuel Cell Stack Performance Attenuation and Individual Cell Voltage Uniformity Based on the Durability Cycle Condition. Polymers, 13(8), 1199. https://doi.org/10.3390/polym13081199