Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis

Abstract

:1. Introduction

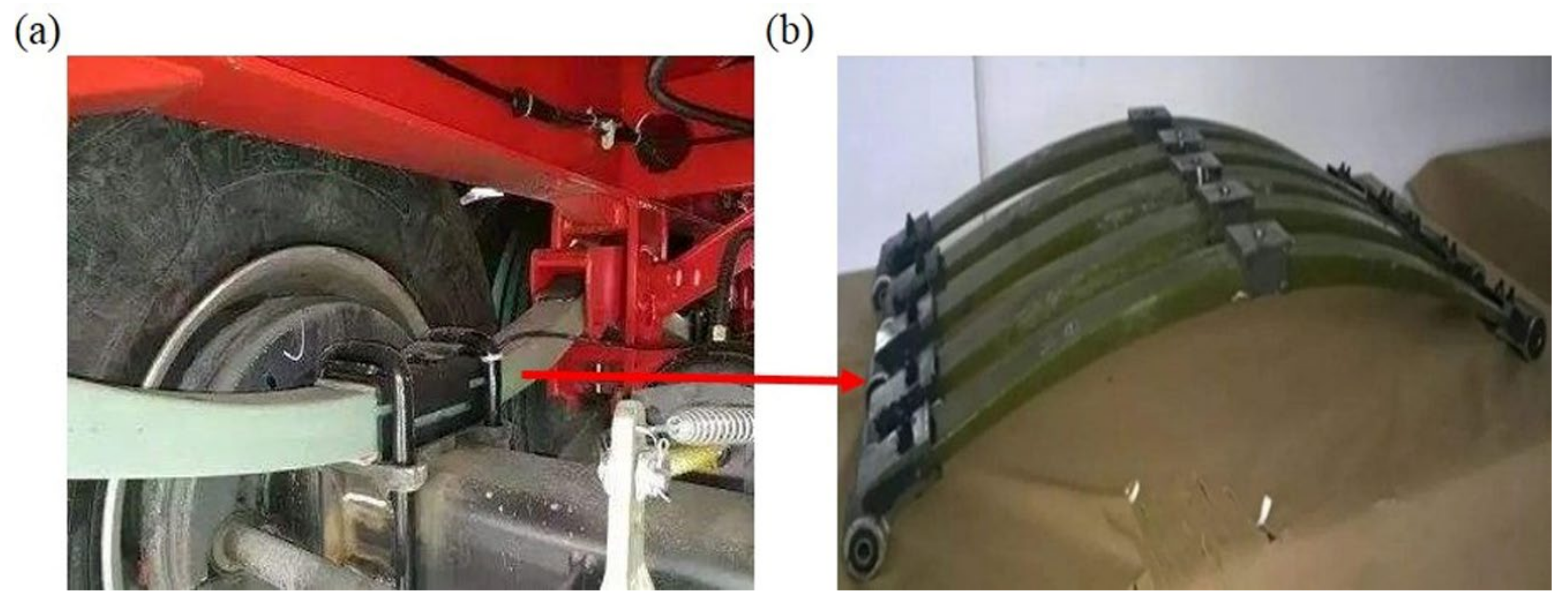

2. Design of Composite Leaf Spring

2.1. Requirements of Composite Structural Design

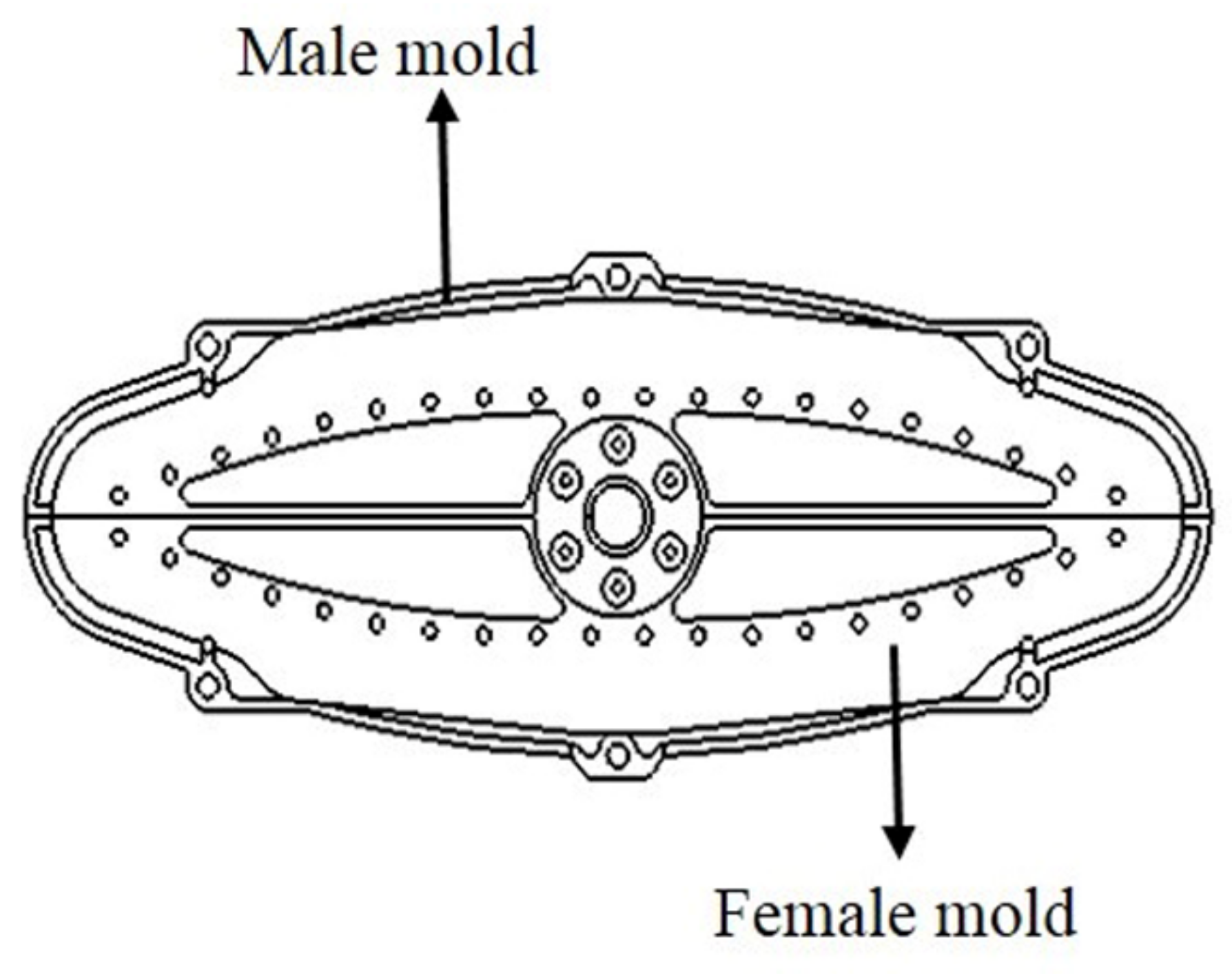

2.2. Structure Design of Composite Leaf Spring

2.3. Designed Structure of Composite Leaf Spring

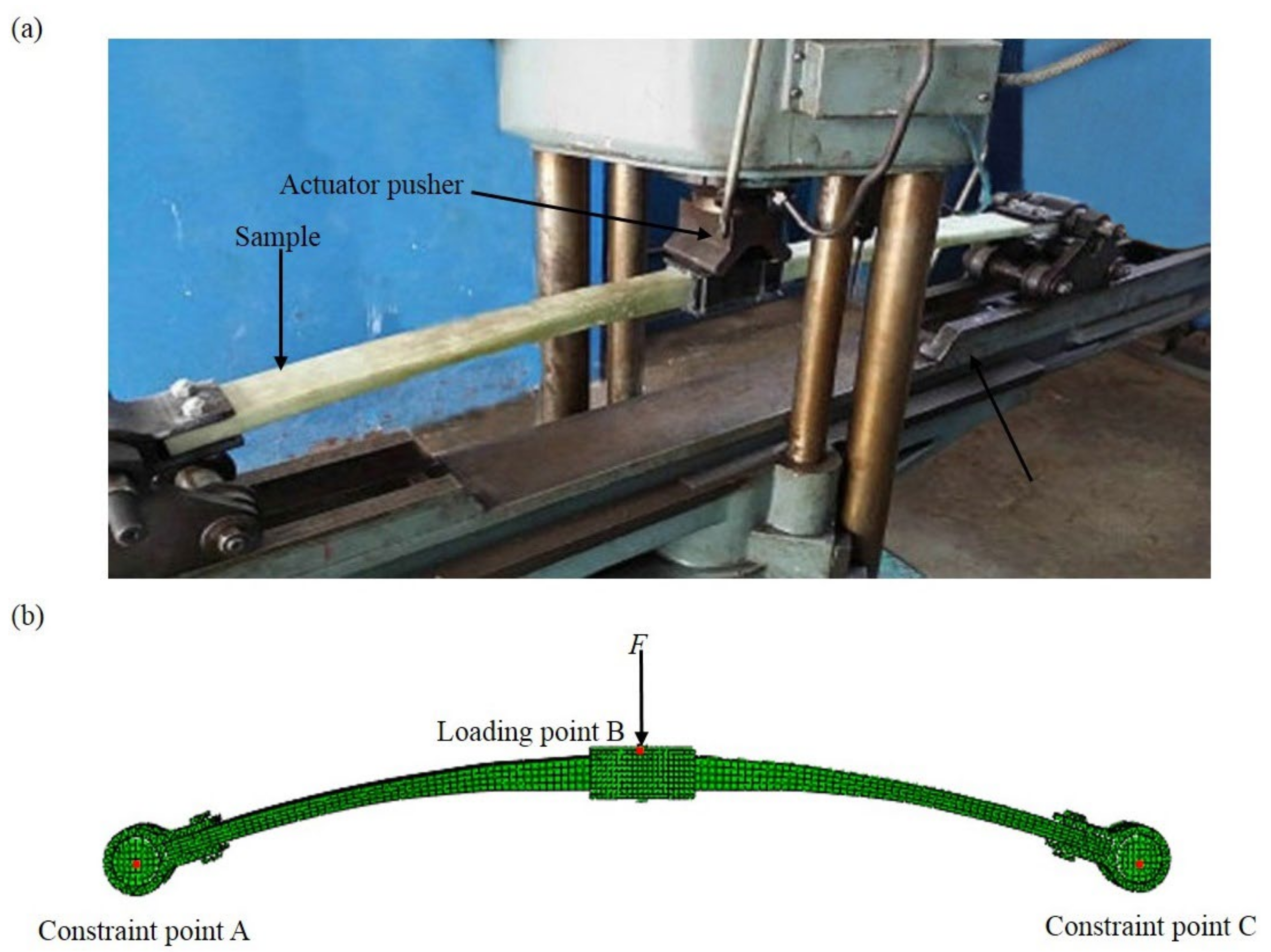

3. Experimental and Finite Element Analysis of Designed Composite Leaf Spring

3.1. Experiment of Composite Leaf Spring

3.2. Finite Element Analysis of Composite Leaf Spring

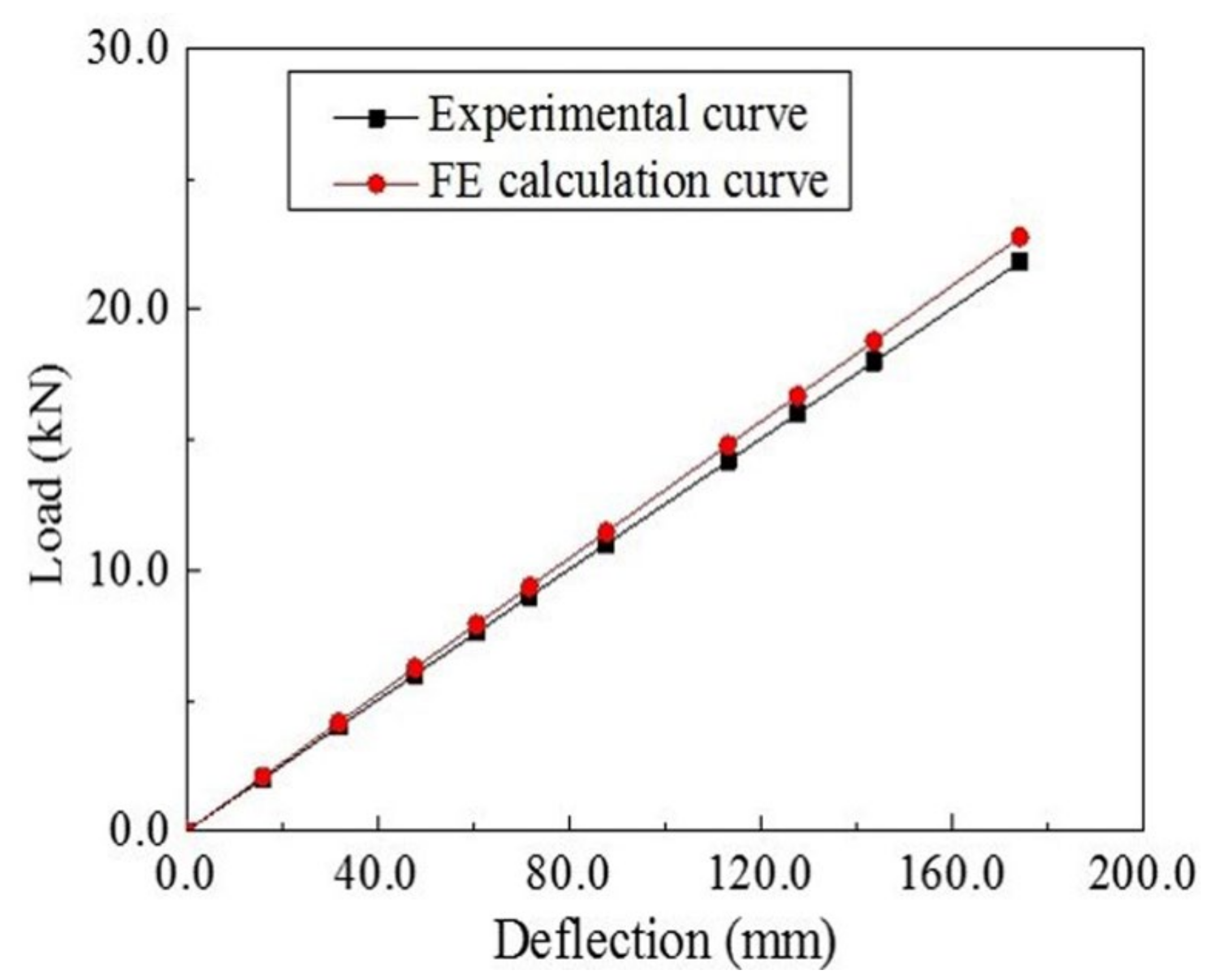

4. Results and Discussion

4.1. Experimental Analysis of Composite Leaf Spring

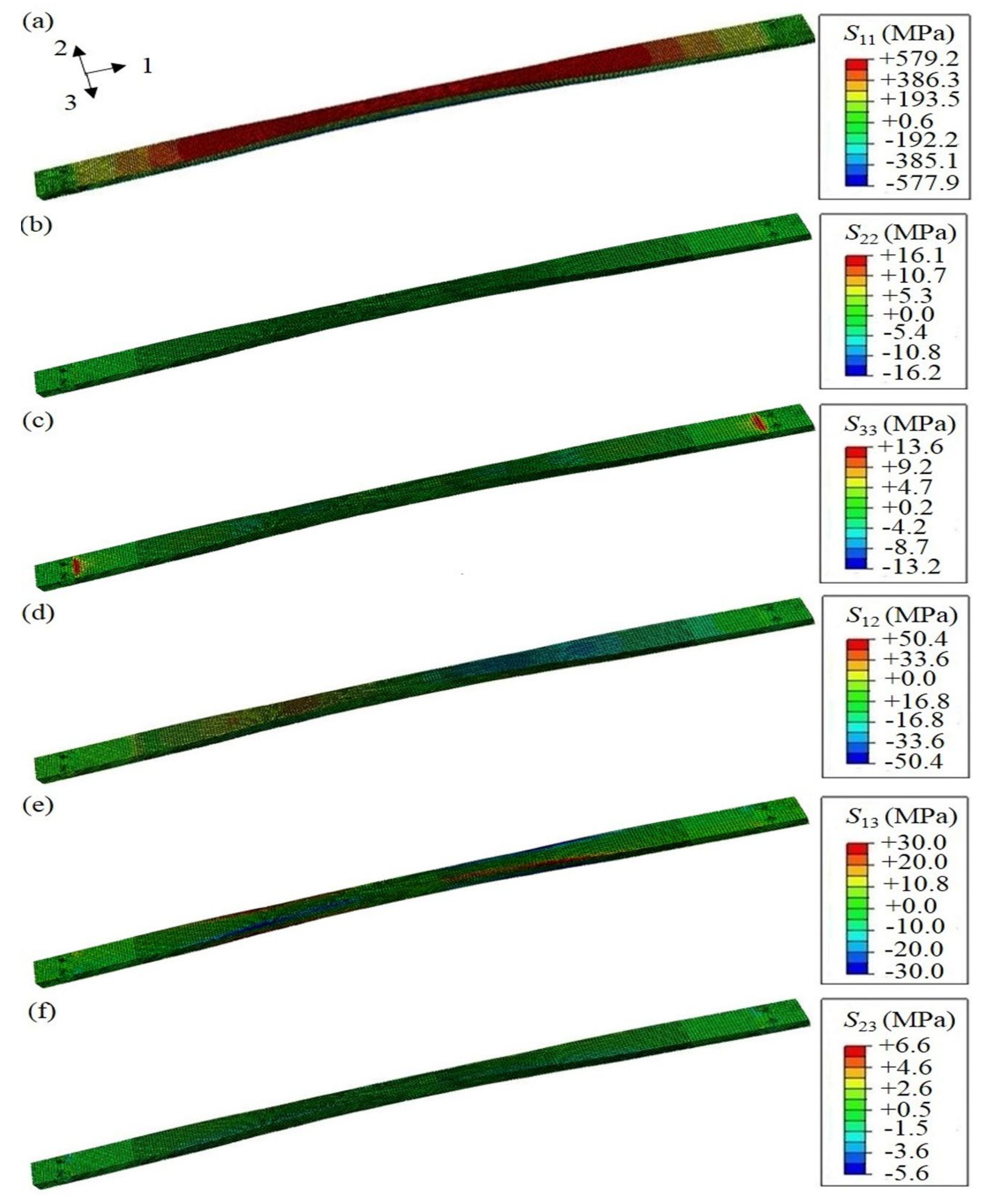

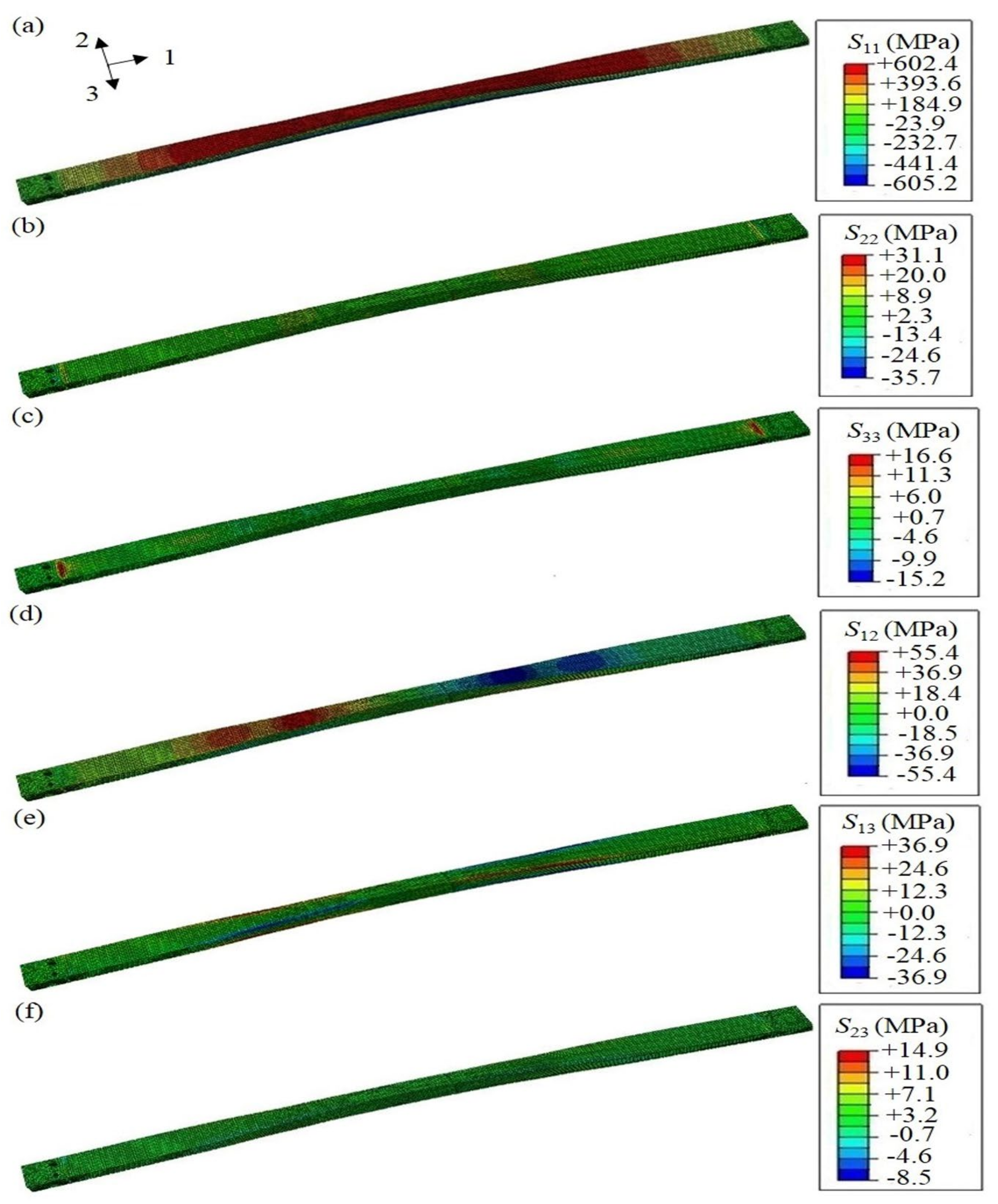

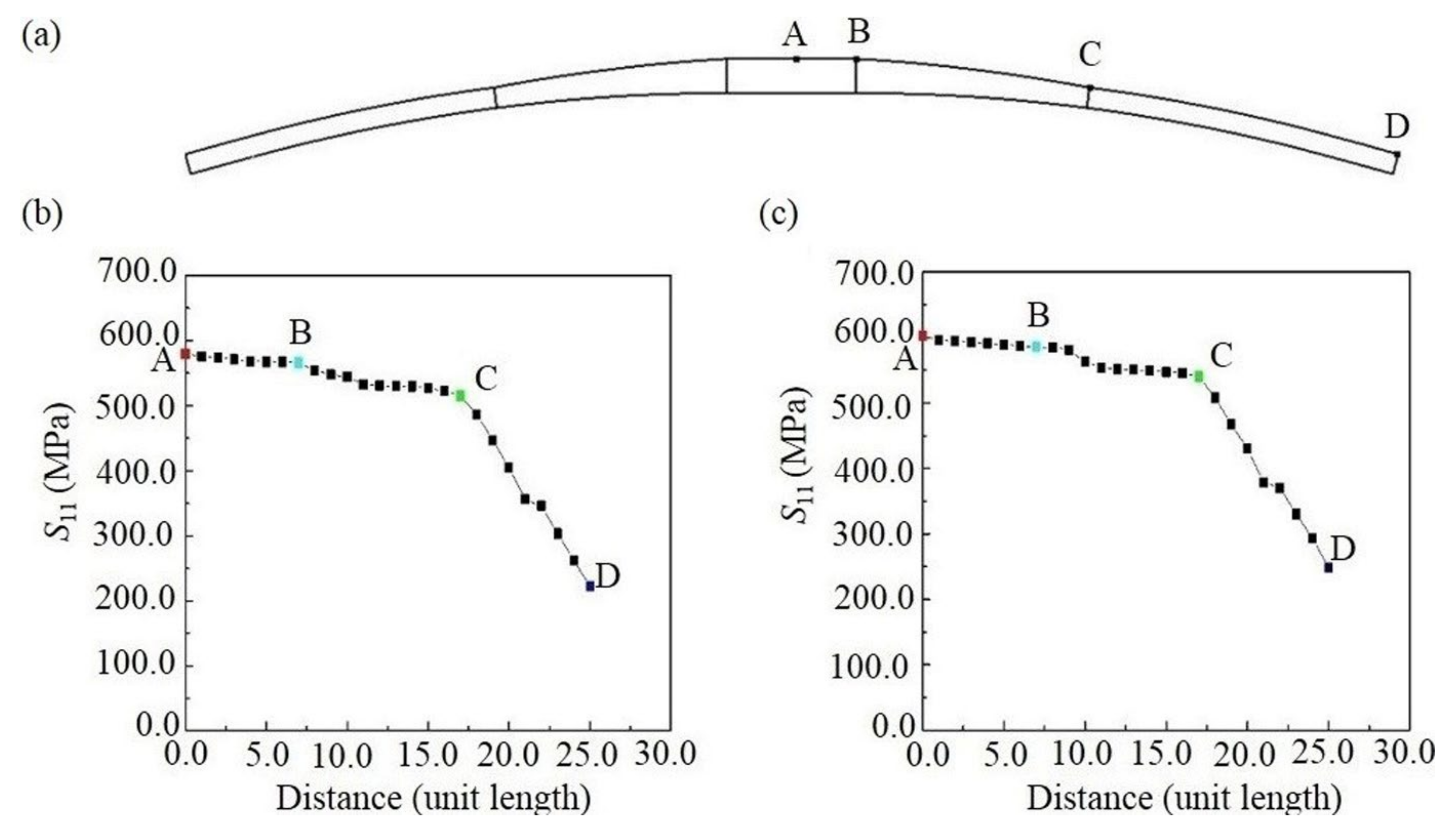

4.2. Finite Element Analysis of Composite Leaf Spring

4.3. Discussion of Structural Design of Composite Leaf Spring

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Measurement of the Mechanical Property Parameters of E-Glass Fiber/Epoxy Composite Material Samples

References

- Jancirani, J.; Assarudeen, H. A review on structural analysis and experimental investigation of fiber reinforced composite leaf spring. J. Reinf. Plast. Comp. 2015, 34, 95–100. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Ramesh Kumar, S.; Venkatesh, G.; Nishanthan, S. Analysis of leaf spring using Carbon/Glass epoxy and EN45 using ANSYS: A comparison. Mater. Today. Proc. 2018, 5, 14512–14519. [Google Scholar] [CrossRef]

- Ke, J.; Wu, Z.Y.; Chen, X.Y.; Ying, Z.P. A review on material selection, design method and performance investigation of composite leaf springs. Compos. Struct. 2019, 226, 111277. [Google Scholar] [CrossRef]

- Oztoprak, N.; Gunes, M.D.; Tanoglu, M.; Aktas, E.; Egilmez Oguz, O.; Senocak, C.; Kulac, G. Developing polymer composite-based leaf spring systems for automotive industry. Sci. Eng. Compos. Mater. 2018, 25, 1167. [Google Scholar] [CrossRef]

- Khatkar, V.; Behera, B.K. Experimental investigation of composite leaf spring reinforced with various fiber architecture. Adv. Compos. Mater. 2020, 29, 129–145. [Google Scholar] [CrossRef]

- Jamadar, N.I.; Kivade, S.B.; Raushan, R. Failure analysis of composite mono leaf spring using modal flexibility and curvature method. J. Fail. Anal. Prev. 2018, 18, 782–790. [Google Scholar] [CrossRef]

- Jamadar, N.I.; Kivade, S.B.; Tati, P. Prediction of residual fatigue life of composite mono leaf spring based on stiffness degradation. J. Fail. Anal. Prev. 2018, 18, 1516–1525. [Google Scholar] [CrossRef]

- Kamaleldin Gaffar Abbas, M.; Niakan, A.; Chia, C.M.; Teo, P. Design and numerical analysis of leaf spring using composite materials. Key. Eng. Mat. 2016, 723, 305–310. [Google Scholar] [CrossRef]

- Lyu, M.Y.; Choi, T.G. Research trends in polymer materials for use in lightweight vehicles. Int. J. Precis. Eng. Man. 2015, 16, 213–220. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Chen, G. Lightweight design of automotive front side rail based on robust optimisation. Thin. Wall. Struct. 2007, 45, 670–676. [Google Scholar] [CrossRef]

- Almeida, F.S.; Awruch, A.M. Design optimization of composite laminated structures using genetic algorithms and finite element analysis. Compos. Struct. 2009, 88, 443–454. [Google Scholar] [CrossRef]

- Cherruault, J.Y.; Hou, J.P.; Jeronimidis, G.; Mayer, R.; Chvojan, J. Testing of fibre composite leaf spring for heavy axle loads. J. Thermoplastic. Compos. 2011, 23, 111–132. [Google Scholar] [CrossRef]

- Shi, W.K.; Qian, C.; Chen, Z.Y.; Song, Q.Q.; Yang, S.X. Establishment of theoretical model of composite leaf springs by using the mechanics of composite materials. J. Reinf. Plast. Comp. 2017, 36, 1316–1326. [Google Scholar] [CrossRef]

- Zuo, Y.; Mosallam, A.; Xin, H.; Liu, Y.; He, J. Flexural performance of a hybrid GFRP-concrete bridge deck with composite T-shaped perforated rib connectors. Compos. Struct. 2018, 194, 263–278. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and three-dimensional finite element modeling of circular concrete columns partially wrapped with FRP strips. Polymers 2018, 10, 253. [Google Scholar]

- Xie, F.; Chen, J.; Yu, Q.-Q.; Dong, X. Behavior of cross arms inserted in concrete-filled circular GFRP tubular columns. Materials 2019, 12, 2280. [Google Scholar] [CrossRef] [Green Version]

- Fu, Q.N.; Tan, K.H. Parametric effects on composite floor systems under column removal scenario. Eng. Struct. 2019, 187, 161–176. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.F. Axial strength of eccentrically loaded FRP-confined short concrete columns. Polymers 2020, 12, 1261. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, L.T.; Tam, L.-H.; Yan, L.B.; He, L. Effect of bearing length on web crippling behavior of pultruded GFRP channel section. Compos. Struct. 2020, 253, 112810. [Google Scholar] [CrossRef]

- Wu, C.; Zhang, Z.; Xu, N.; Tam, L.-H. Experimental study on the group effect of GFRP-timber bolted connection in tension. China. Civil. Eng. J. 2021, 54, 38–48. [Google Scholar]

- Wu, C.; Zhang, Z.X.; Tam, L.-H.; Feng, P.; He, L. Group effect of GFRP-timber bolted connections in tension. Compos. Struct. 2021, 262, 113637. [Google Scholar] [CrossRef]

- Rajendran, I.; Vijayarangan, S. Optimal design of a composite leaf spring using genetic algorithms. Compu. Struct. 2001, 79, 1121–1129. [Google Scholar] [CrossRef]

- Kueh, J.T.J.; Faris, T. Finite element analysis on the static and fatigue characteristics of composite multi-leaf spring. J. Zhejiang Univ. Sci. A. 2012, 13, 159–164. [Google Scholar] [CrossRef]

- Lo, K.H.; Mccusker, J.J.; Gottenberg, W.G. Composite leaf spring for tank trailer suspensions. J. Reinf. Plast. Comp. 1987, 6, 100–112. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rezaei, D. Analysis and optimization of a composite leaf spring. Compos. Struct. 2003, 60, 317–325. [Google Scholar] [CrossRef]

- Minton, J.P.; Dearman, J.R.; Knight, W.B.; Ketcham, A.S. An evaluation of the physical response of malignant tumor implants to pulsed laser radiation. Wiley 1960, 121, 538–544. [Google Scholar]

- Al-Qureshi, H.A. Automobile leaf springs from composite materials. J. Mater. Process. Tech. 2001, 118, 58–61. [Google Scholar] [CrossRef]

- Carello, M.; Airale, A.G.; Ferraris, A.; Messana, A.; Sisca, L. Static design and finite element analysis of innovative CFRP transverse leaf spring. Appl. Compos. Mater. 2017, 24, 1493–1508. [Google Scholar] [CrossRef]

- Ghuku, S.; Saha, K. Stiffness analysis of leaf spring system under large deformation. P I. Mech. Eng. C-J. Mec. 2020, 234, 2487–2508. [Google Scholar] [CrossRef]

- Ke, J.; Qian, C.; Wu, Z.Y.; Hu, X.D.; Yuan, Y.H. A theoretical model used for determining the stiffness of composite leaf springs with a main spring and an auxiliary spring. J. Braz. Soc. Mech. Sci. 2020, 42, 58. [Google Scholar] [CrossRef]

- Qian, C.; Shi, W.K.; Chen, Z.Y.; Yang, S.X.; Song, Q.Q. Fatigue reliability design of composite leaf springs based on ply scheme optimization. Compos. Struct. 2017, 168, 40–46. [Google Scholar] [CrossRef]

- Sancaktar, E.; Gratton, M. Design, analysis, and optimization of composite leaf springs for light vehicle applications. Compos. Struct. 1999, 44, 195–204. [Google Scholar] [CrossRef]

- Yang, S.X.; Shi, W.K.; Chen, Z.Y.; Qian, C.; Yang, C.H.; Hang, L.L. Composite mechanics and energy method based stiffness prediction model for composite leaf springs. Mech. Based. Des. Struc. 2019, 47, 375–386. [Google Scholar] [CrossRef]

- QC/T 474-2011. Buses-Ride Comfort-Evaluation Value and Limits; QC Auto-Industry: Beijing, China, 2011. [Google Scholar]

- Saini, P.; Goel, A.; Kumar, D. Design and analysis of composite leaf spring for light vehicles. IJIRSET 2013, 2, 1–10. [Google Scholar]

- Ashok, D.; Malikarjun, M.V.; Mamilla, V.R. Design and structural analysis of composite multileaf spring. IJETED 2012, 7, 177–183. [Google Scholar]

- Wang, J.S.; Li, Z.K.; Jiang, Q.B. The analysis of composite leaf spring by finite element method and experimental measurements. In Proceedings of the FISITA 2012 World Automotive Congress, Beijing, China, 27–30 November 2012; pp. 823–829.

- Dasgaonkar, M.; Hambar, A.; Baskar, P. Design optimization and analysis of leaf spring using static load conditions. IJRASET 2016, 4, 643–648. [Google Scholar]

- Geng, L.C.; He, J.W.; Zhao, T.L. Structural design and analysis of composite leaf spring for a certain type of bus. BJ. Auto. Eng. 2012, 2, 21–24. [Google Scholar]

- Yan, F.F.; Yao, W.X.; Liu, H. Statistical analysis of safety factor of composite materials. Tr. NUAA. 2009, 41, 655–659. [Google Scholar]

- Yu, W.J.; Kim, H.C. Double tapered FRP beam for automotive suspension leaf spring. Compos. Struct. 1988, 9, 279–300. [Google Scholar] [CrossRef]

- Rajesh, S.; Bhaskar, G.B. Response of composite leaf springs to low velocity impact loading. Appl. Mech. Mater. 2014, 591, 47–50. [Google Scholar] [CrossRef]

- Cohen, D. Influence of filament winding parameters on composite vessel quality and strength. Compos. Part A-Appl. S. 1997, 28, 1035–1047. [Google Scholar] [CrossRef]

- Hazra, T.; Gu, J.; Taheri, F. An innovative cost effective approach towards tension control in aut. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation, Beijing, China, 7–10 August 2011; pp. 961–966. [Google Scholar]

- Mertiny, P.; Ellyin, F. Influence of the filament winding tension on physical and mechanical properties of reinforced composites. Compos. Part A-Appl. S. 2002, 33, 1615–1622. [Google Scholar] [CrossRef]

- Su, Z.J.; Liang, G.Z.; Zeng, J.F.; Wang, H.Q. Study progress in wet winding technology of resin matrix composites. Fiber. Reinforced Plastics/Composite. 2005, 1, 46–49. [Google Scholar]

- GB/T 1450.1-2005. Fibre-Reinforced Plastics Composites-Determination of Interlaminar Shear Strength; GB National: Beijing, China, 2005. [Google Scholar]

- GB/T 3355-2005. Test Method for Longitudinal Transverse Shear (L-T Shear) Properties of Fiber Reinforced Plastics; GB National: Beijing, China, 2005. [Google Scholar]

- GB/T 3856-2005. Test Method for Compression Properties of Unidirectional Fiber Reinforced Plastics; GB National: Beijing, China, 2005. [Google Scholar]

- GB/T 32376-2015. Elastic Constants Test Method for Fibre Reinforced Composites; GB National: Beijing, China, 2015. [Google Scholar]

- Arun, B.; Chithambaranathan, P. Static analysis of hybrid composite leaf spring. IJESRT 2014, 3, 77–80. [Google Scholar]

| Parameter | Value |

|---|---|

| Maximum mass, Mmax (kg) | 13 |

| Bending stiffness, k (N·mm−1) | 124 ± 12 |

| Full load, F1 (N) | 10,912 |

| Limit load, F2 (N) | 23,312 |

| Safety coefficient, N | 1.3 |

| Span, L (mm) | 1388 |

| Maximum cross-sectional area, Smax (mm2) | 2300 |

| Maximum width, bmax (mm) | 92 |

| Maximum thickness, hmax (mm) | 40 |

| Allowable stress, [σ] (MPa) | 673 |

| Parameter | Result |

|---|---|

| Cross-sectional area, S (mm2) | 2000 |

| Maximum thickness, hmax (mm) | 37.1 |

| Length of transition section, lt (mm) | 248 |

| Maximum width, bmax (mm) | 90 |

| Maximum deflection, wmax (mm) | 180 |

| Bending stiffness, k (N·mm−1) | 129.5 |

| Maximum stress, σmax (MPa) | 580 |

| Tension System (N/Layers) | Winding Speed (r·min−1) | Curing Process |

|---|---|---|

| 60/4 + 40/4 + 20/3 | 3 | 85 °C/30 min + 95 °C/1 h + 105 °C/30 min + 120 °C/1 h |

| Parameter | Value |

|---|---|

| Elastic modulus along length direction, E1 (GPa) | 52.5 |

| Elastic modulus along thickness direction, E2 (GPa) | 15 |

| Elastic modulus along width direction, E3 (GPa) | 15 |

| Shear modulus along length-thickness direction, G12 (GPa) | 5.0 |

| Shear modulus along length-width direction, G13 (GPa) | 5.0 |

| Shear modulus along thickness-width direction, G23 (GPa) | 1.8 |

| Main Poisson’s ratio along length-thickness direction, μ12 | 0.3 |

| Main Poisson’s ratio along length-width direction, μ13 | 0.3 |

| Main Poisson’s ratio along thickness-width direction, μ23 | 0.1 |

| Tensile strength along length direction, X1 (MPa) | 1300 |

| Compressive strength along length direction, Y1 (MPa) | 875 |

| Tensile strength along thickness direction, X2 (MPa) | 48 |

| Compressive strength along thickness direction, Y2 (MPa) | 141 |

| Tensile strength along width direction, X3 (MPa) | 48 |

| Compressive strength along width direction, X3 (MPa) | 141 |

| Interlaminar shear strength, σILSS (MPa) | 74.7 |

| Longitudinal and transverse shear strength, στ±45° (MPa) | 48.7 |

| Parameter | FE Result (MPa) | Material Strength Requirements (MPa) | |

|---|---|---|---|

| Under Full Loading Condition | Under Limit Loading Condition | ||

| Tensile strength along length direction | 577.9 | 605.2 | 1000 |

| Compressive strength along length direction | 579.2 | 602.4 | 673.1 |

| Tensile strength along thickness direction | 16.2 | 35.7 | 34.6 |

| Compressive strength along thickness direction | 16.1 | 31.1 | 108.5 |

| Tensile strength along width direction | 13.2 | 15.2 | 34.6 |

| Compressive strength along width direction | 13.6 | 16.6 | 108.5 |

| Longitudinal and transverse shear strength, στ±45° | 30.0 | 36.9 | 37.5 |

| Interlaminar shear strength, σILSS | 50.8 | 57.0 | 57.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; He, J.; Gu, Y.; Zhang, Z.; Yu, Z.; Zhou, A.; Tam, L.-h.; Wu, C. Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis. Polymers 2021, 13, 1193. https://doi.org/10.3390/polym13081193

Ma L, He J, Gu Y, Zhang Z, Yu Z, Zhou A, Tam L-h, Wu C. Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis. Polymers. 2021; 13(8):1193. https://doi.org/10.3390/polym13081193

Chicago/Turabian StyleMa, Linlin, Jingwu He, Yizhuo Gu, Zuoguang Zhang, Zechuan Yu, Ao Zhou, Lik-ho Tam, and Chao Wu. 2021. "Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis" Polymers 13, no. 8: 1193. https://doi.org/10.3390/polym13081193

APA StyleMa, L., He, J., Gu, Y., Zhang, Z., Yu, Z., Zhou, A., Tam, L.-h., & Wu, C. (2021). Structure Design of GFRP Composite Leaf Spring: An Experimental and Finite Element Analysis. Polymers, 13(8), 1193. https://doi.org/10.3390/polym13081193