Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Treatment

2.3. Premixes Preparation

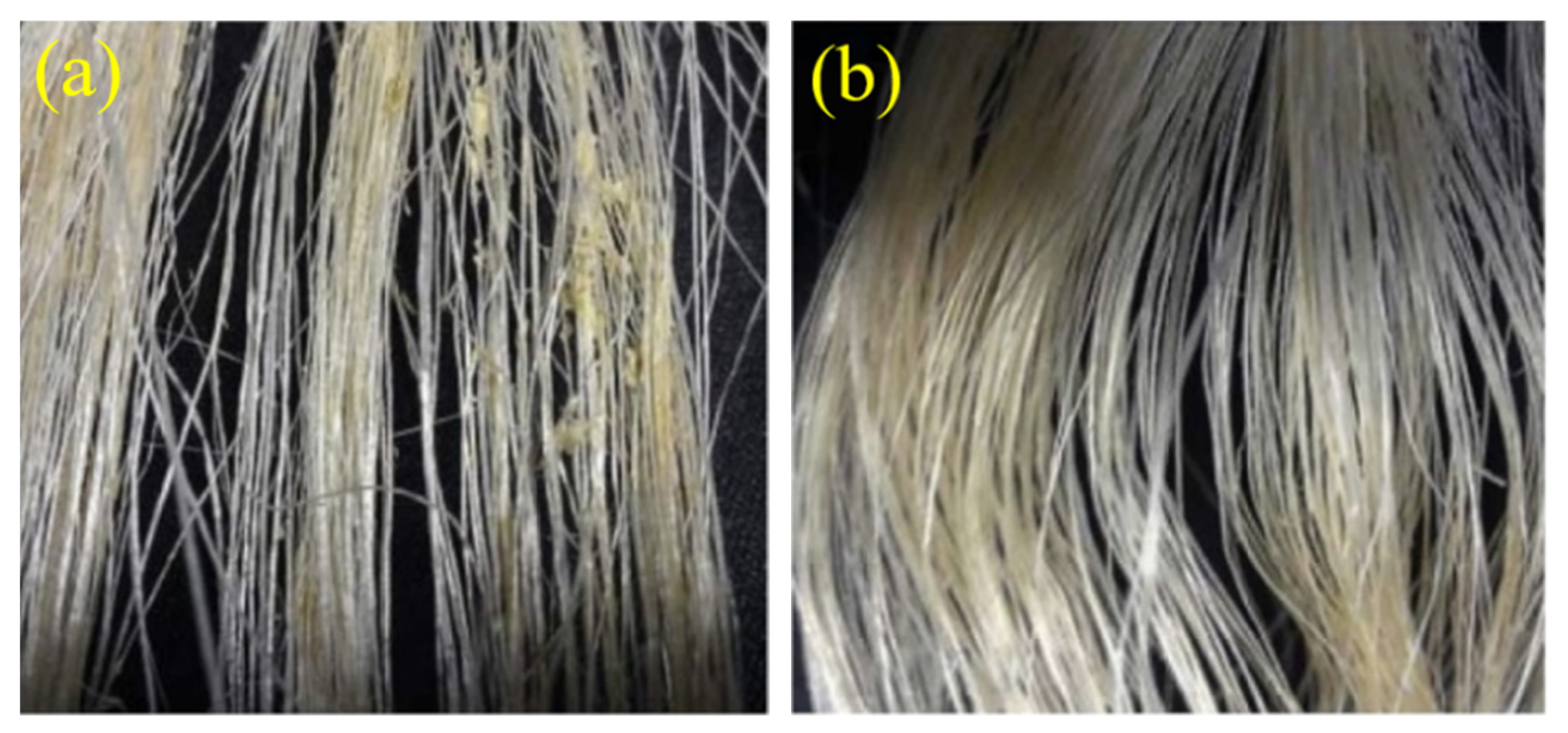

2.3.1. Preparation of Continuous Long Sisal Fiber/PLA Premixes

2.3.2. Preparation of Short Sisal Fiber/PLA Premixes

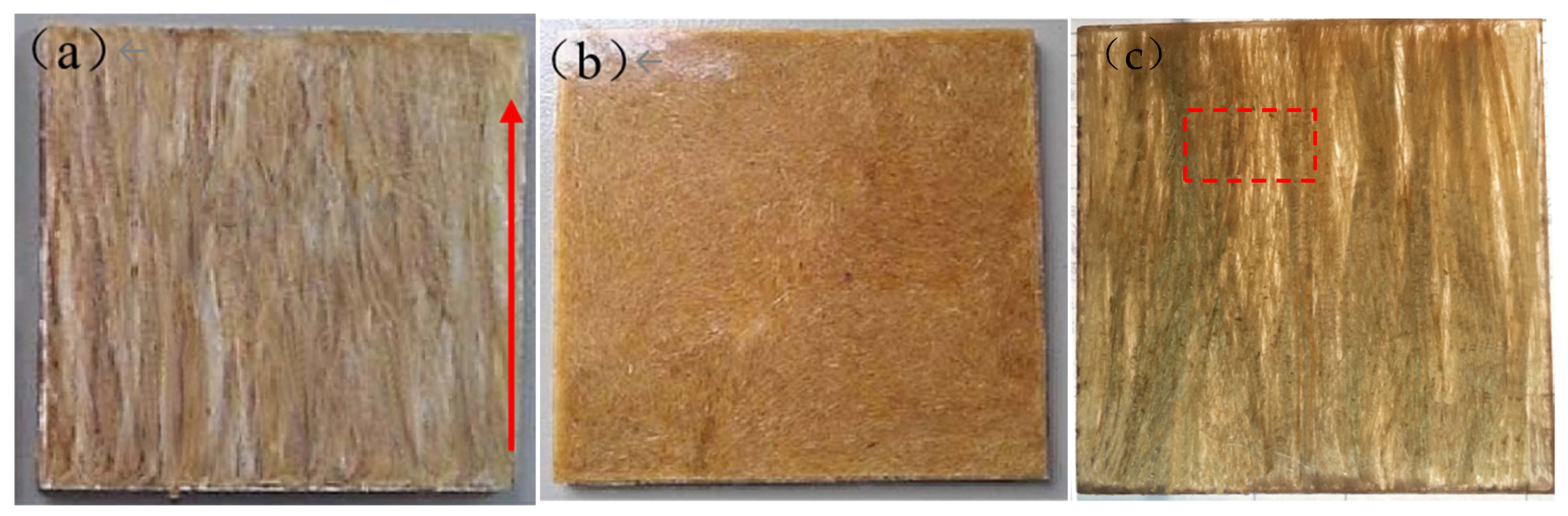

2.4. Molding of Composites

2.5. Composite Characteristics

2.5.1. Mechanical Tests

2.5.2. Scanning Electron Microscopy

3. Results and Discussion

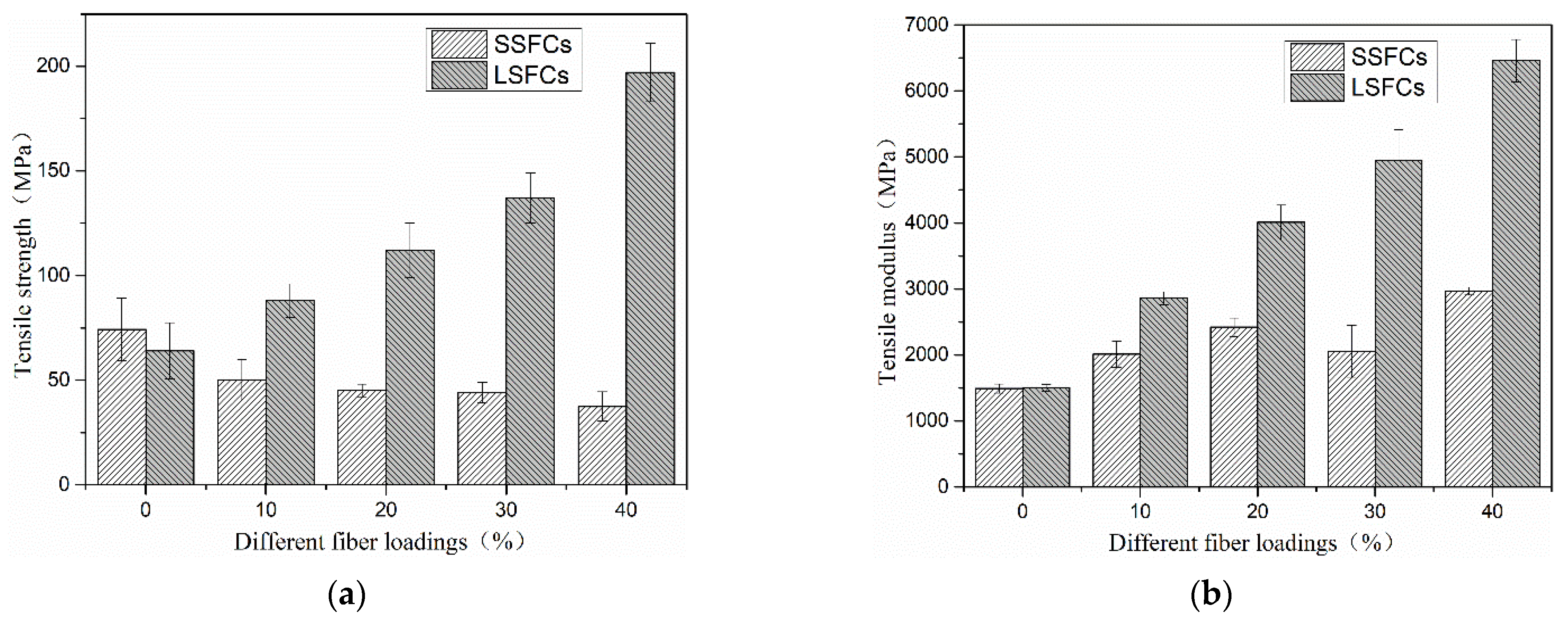

3.1. Tensile Tests

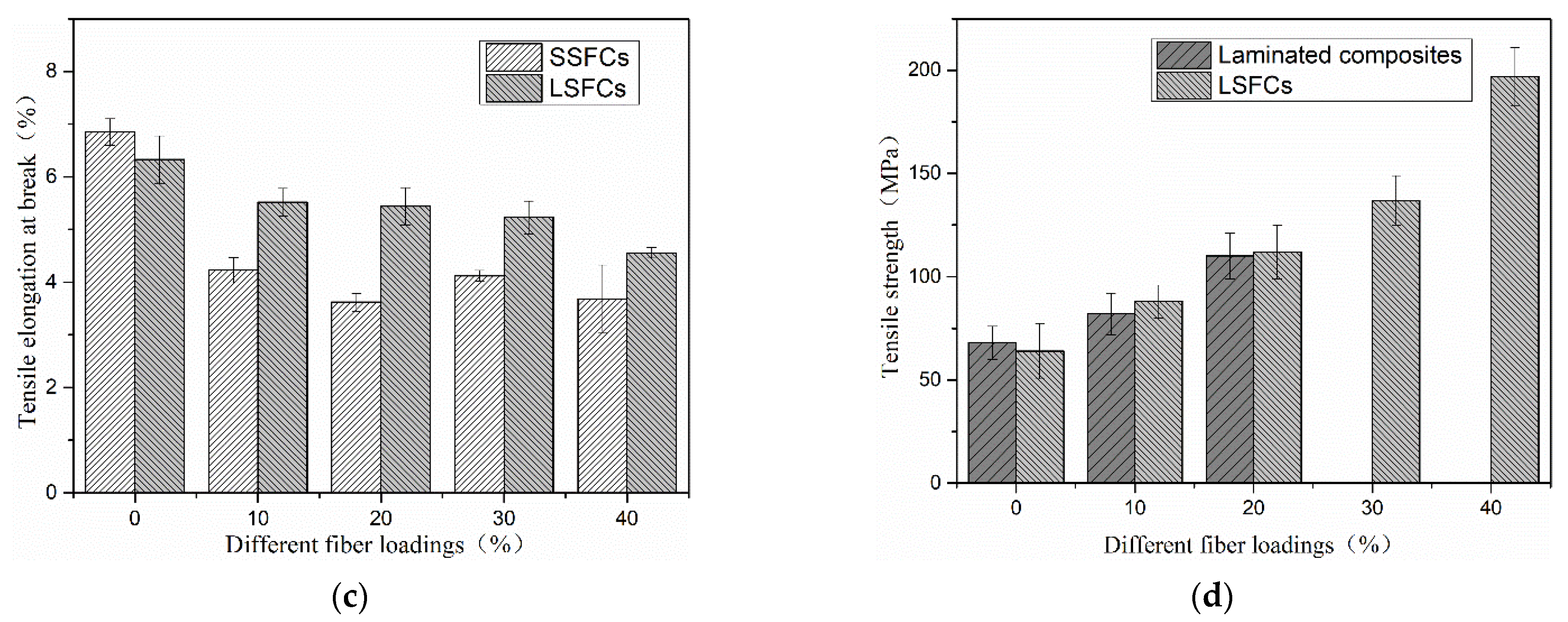

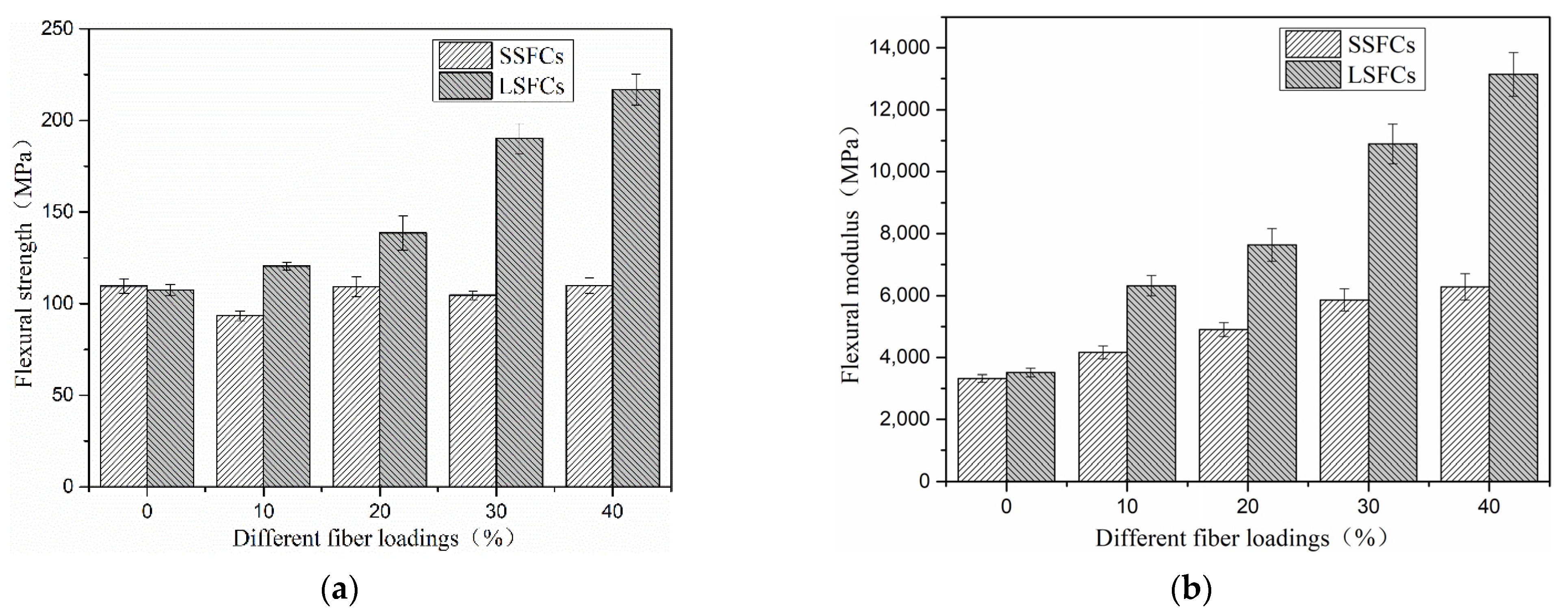

3.2. Flexural Tests

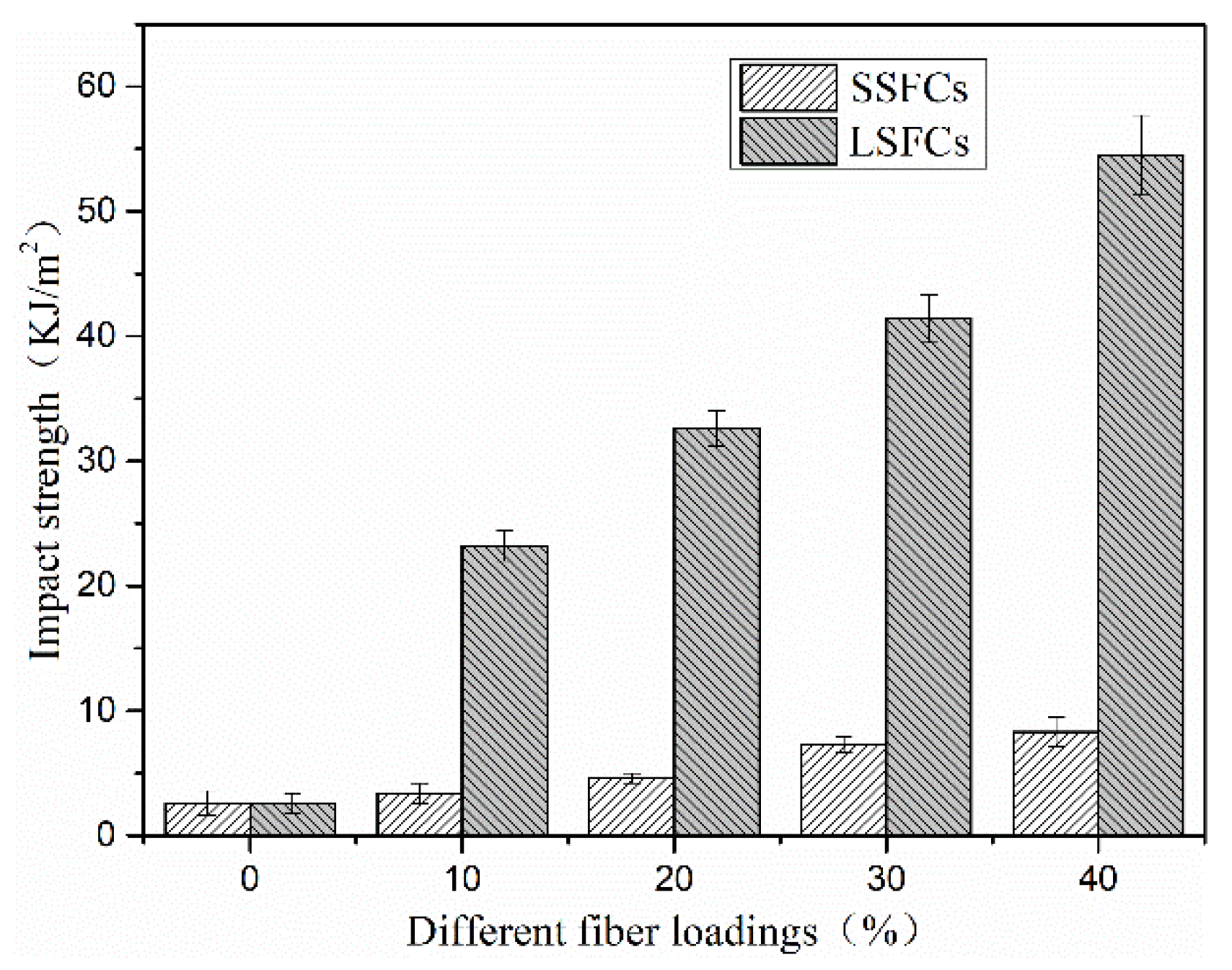

3.3. Impact Strength

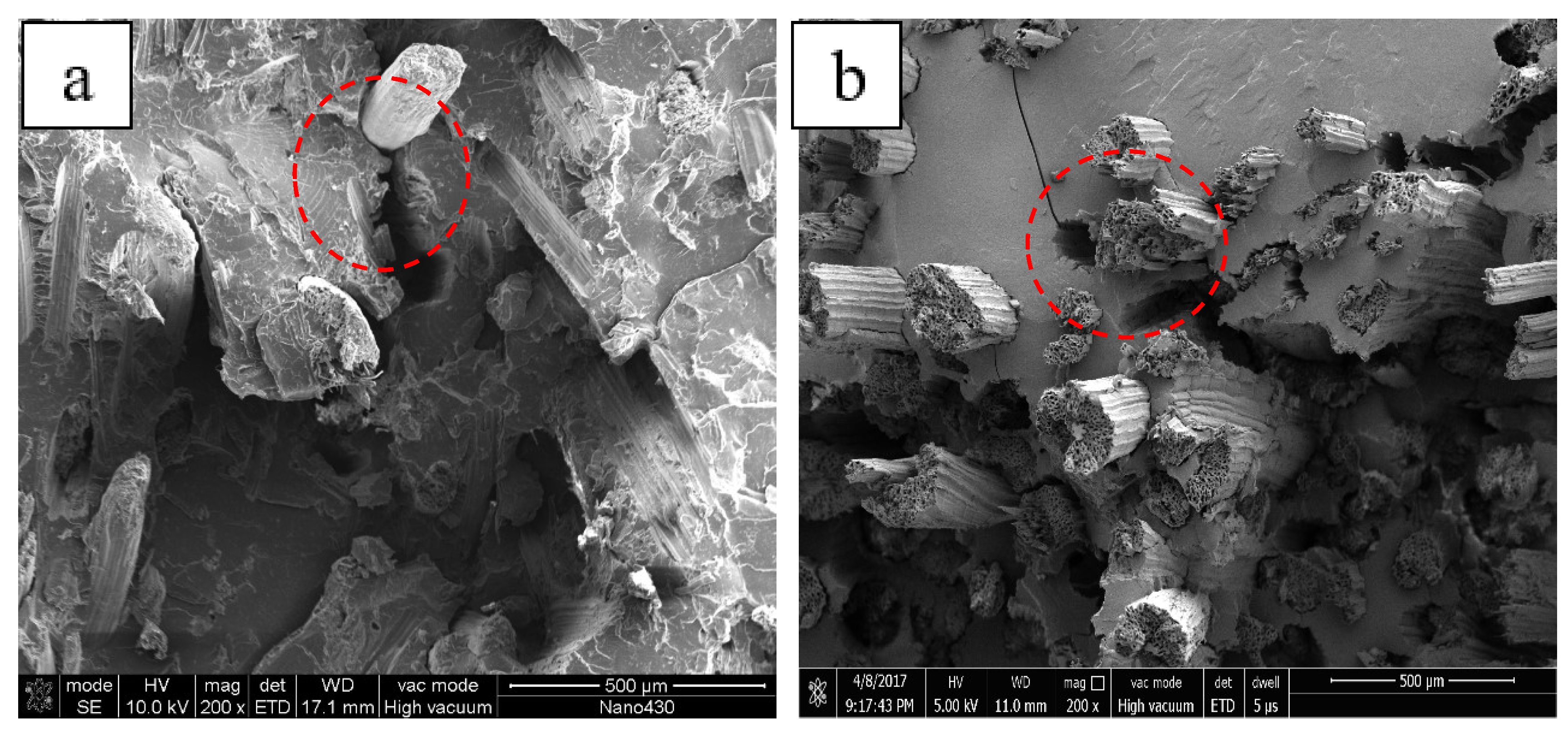

3.4. SEM Microstructure of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Paul, V.; Kanny, K.; Redhi, G.G. Mechanical, thermal and morphological properties of a bio-based composite derived from banana plant source. Compos. Part A Appl. Sci. Manuf. 2015, 68, 90. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. The state of the art. In Monomers Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536. [Google Scholar] [CrossRef]

- Hartmann, M.H. High Molecular Weight Polylactic Acid Polymers; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on L-polylactide and jute fibres Compos. Sci. Technol. 2003, 63, 1287. [Google Scholar]

- Sdergrd, A.; Stolt, M. Enzymatic Depolymerization of Synthetic Polyesters by Microbial Carboxylesterases. Prog. Polym. Sci. 2002, 27, 1123. [Google Scholar]

- Tsuji, H. Poly(lactide) Stereocomplexes: Formation, Structure, Properties, Degradation, and Applications. Macromol. Biosci. 2005, 7, 569–597. [Google Scholar] [CrossRef] [PubMed]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly (lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338. [Google Scholar] [CrossRef]

- Chaitanya, S.; Singh, I. Processing of PLA/sisal fiber biocomposites using direct- and extrusion-injection molding. Mater. Manuf. Proc. 2017, 32, 468. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Kazemi, Y.; Rodrigue, D.; Park, C.B. Facile production of biodegradable PCL/PLA in situ nanofibrillar composites with unprecedented compatibility between the blend components. Chem. Eng. J. 2018, 351, 976. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as re-inforcement of poly (lactic acid) via injection moulding. Ind. Crops Prod. 2019, 137, 260. [Google Scholar] [CrossRef]

- Pappu, A.; Saxena, M.; Thakur, V.K.; Sharma, A.; Haque, R. Facile extraction, processing and characterization of biorenewable sisal fibers for multifunctional ap-plications. J. Macromol. Sci. Part A 2016, 53, 424. [Google Scholar] [CrossRef]

- Joseph, P.V.; Rabello, M.S.; Mattoso, L.H.C.; Joseph, K.; Thomas, S. Environmental effects on the degradation behaviour of sisal fibre reinforced polypropylene composites. Compos. Sci. Technol. 2002, 62, 1357. [Google Scholar] [CrossRef]

- Ott, E.; Spurlin, H.M.; Grafflin, M.W. Cellulose and Cellulose Derivatives, Part II; Interscience: New York, NY, USA, 1954. [Google Scholar]

- Seki, Y. Innovative multifunctional siloxane treatment of jute fiber surface and its effect on the mechanical properties of jute/thermoset composites. Mater. Sci. Eng. A 2009, 508, 247. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377. [Google Scholar] [CrossRef]

- Joseph, K.; Thomas, S.; Pavithran, C. Effect of chemical treatment on the tensile properties of short sisal fibre-reinforced polyethylene com-posites. Polymer 1996, 37, 5139. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a coupling agent on the performance of jute–PP composites. J. Reinf. Plast. Compos. 2004, 23, 625. [Google Scholar] [CrossRef]

- Li, X.; Panigrahi, S.; Tabil, L.G. A study on flax fiber-reinforced polyethylene biocomposites. Appl. Eng. Agric. 2009, 25, 525. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-based renewable green composites from agricultural residues and their hybrids. Biomacromolecules 2010, 11, 1654. [Google Scholar] [CrossRef] [PubMed]

- Duc, A.; Vergnes, B.; Budtova, T. Polypropylene/natural fibres composites: Analysis of fibre dimensions after compounding and observa-tions of fibre rupture by rheo-optics. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1727. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Drapier, S.; Ferreira, M.; Duigou, L.A.; Liotier, P.J.; Ouagne, P.; Soulat, D.; et al. Specific features of flax fibres used to manufacture composite materials. Int. J. Mater. Form. 2019, 12, 1023. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2007, 40, 446. [Google Scholar] [CrossRef]

- Lv, Z.; Wu, H.W.; Pei, Y.; Lan, B. Improvement of interfacial adhesion and mechanical properties of sisal fiber-reinforced poly (lactic acid) composites with added bisoxazoline. Polym. Compos. 2020, 41, 1841. [Google Scholar]

- Ray, D.; Sarkar, B.K.; Rana, A.K.; Bose, N.R. Effect of alkali treated jute fibres on composite properties. Bull. Mater. Sci. 2001, 24, 129. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. Polym. Environ. 2007, 15, 25. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Thomas, S.; Pillai, C.K.S.; Prasad, V.S.; Groeninckx, G.; Sarkissova, M. The thermal and crystallisation studies of short sisal fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2003, 34, 253. [Google Scholar] [CrossRef]

- Subasinghe, A.D.L.; Das, R.; Bhattacharyya, D. Fiber dispersion during compounding/injection molding of PP/kenaf composites: Flammability and mechanical properties. Mater. Des. 2015, 86, 500. [Google Scholar] [CrossRef]

- Duan, J.P.; Wu, H.W.; Fu, W.C.; Hao, M.Y. Mechanical properties of hybrid sisal/coir fibers reinforced polylactide biocomposites. Polym. Compos. 2018, 39, E188. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Gupta, V.K. Effect of layering pattern on the mechanical properties of jute-linen reinforced polypropylene hybrid laminated composites. Mater. Today Proc. 2019, 18, 4182. [Google Scholar] [CrossRef]

- Joseph, P.V.; Joseph, K.; Thomas, S. Effect of processing variables on the mechanical properties of sisal-fiber-reinforced polypropylene composites. Compos. Sci. Technol. 1999, 59, 1625. [Google Scholar] [CrossRef]

- Brahim, S.; Cheikh, R. Influence of fibre orientation and volume fraction on the tensile properties of unidirectional Al-fa-polyester composite. Compos. Sci. Technol. 2007, 67, 140. [Google Scholar] [CrossRef]

- Youngs, A. Advanced Composite, the Latest Development; ASM Int.: Grand Rapids, MI, USA, 1989. [Google Scholar]

- Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers. J. Mater. Sci. 2008, 43, 775. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres–A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Z.; Wu, H.; Liu, R.; Wu, C. Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance. Polymers 2021, 13, 1124. https://doi.org/10.3390/polym13071124

Liang Z, Wu H, Liu R, Wu C. Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance. Polymers. 2021; 13(7):1124. https://doi.org/10.3390/polym13071124

Chicago/Turabian StyleLiang, Zhifang, Hongwu Wu, Ruipu Liu, and Caiquan Wu. 2021. "Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance" Polymers 13, no. 7: 1124. https://doi.org/10.3390/polym13071124

APA StyleLiang, Z., Wu, H., Liu, R., & Wu, C. (2021). Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance. Polymers, 13(7), 1124. https://doi.org/10.3390/polym13071124