Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Crystallization Analysis

3.2. Thermogravimetric Analysis

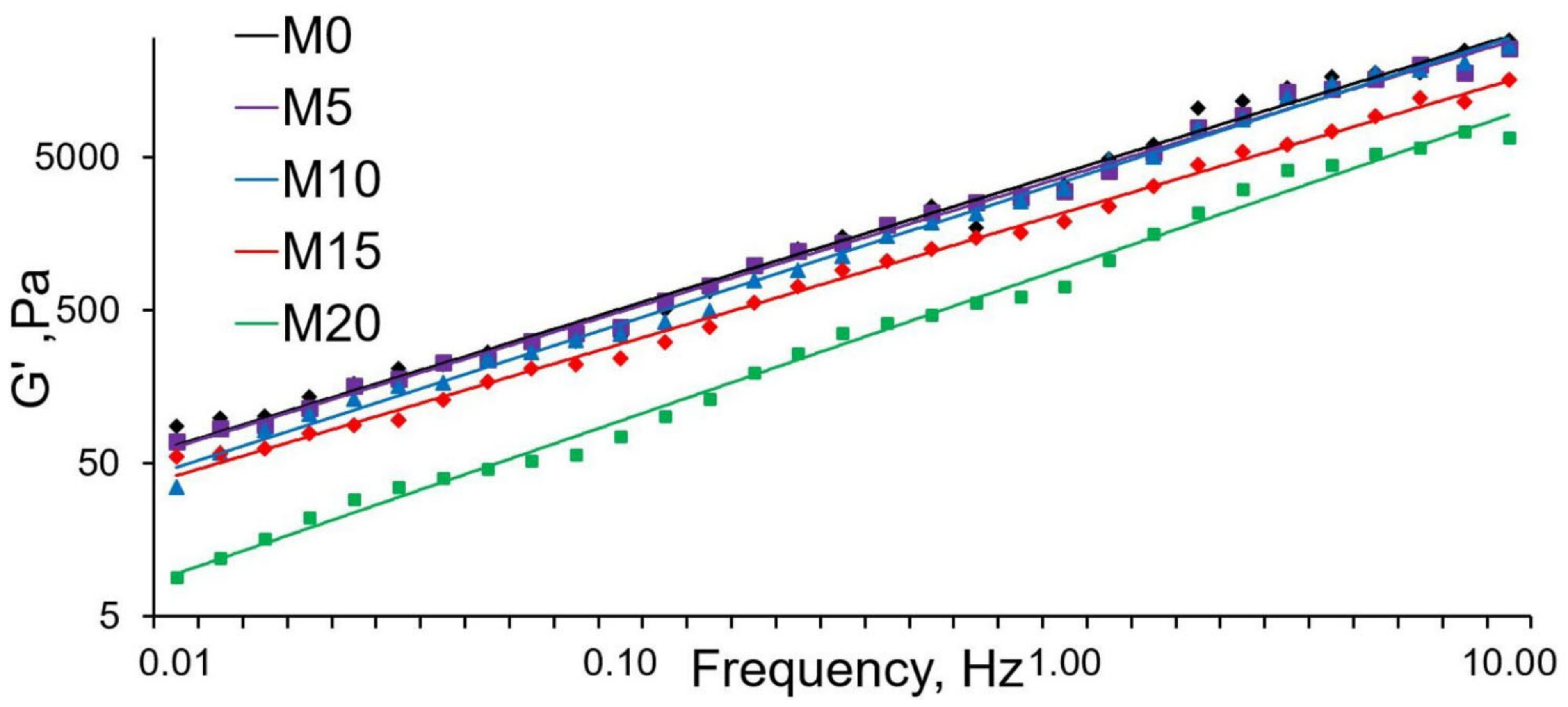

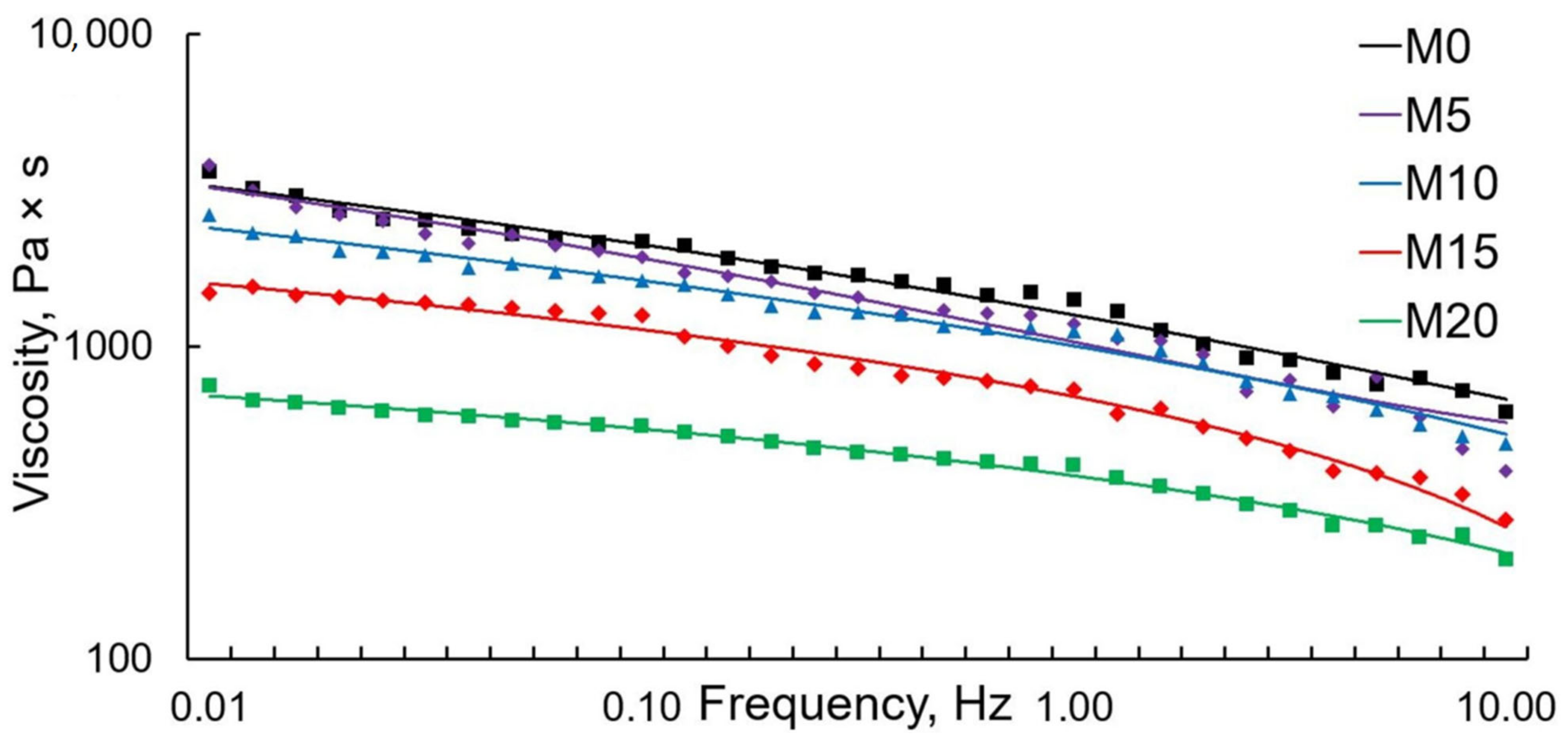

3.3. Rheological Behavior

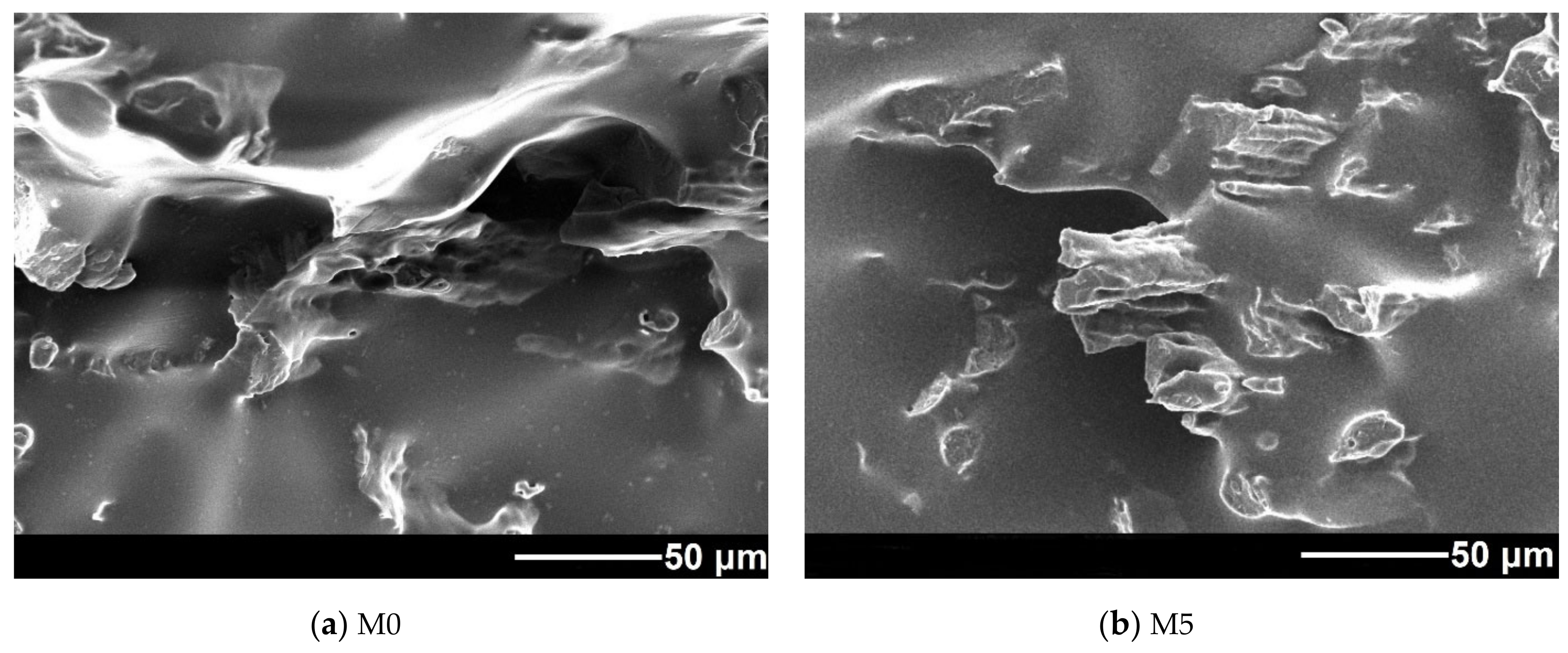

3.4. Morphology Study

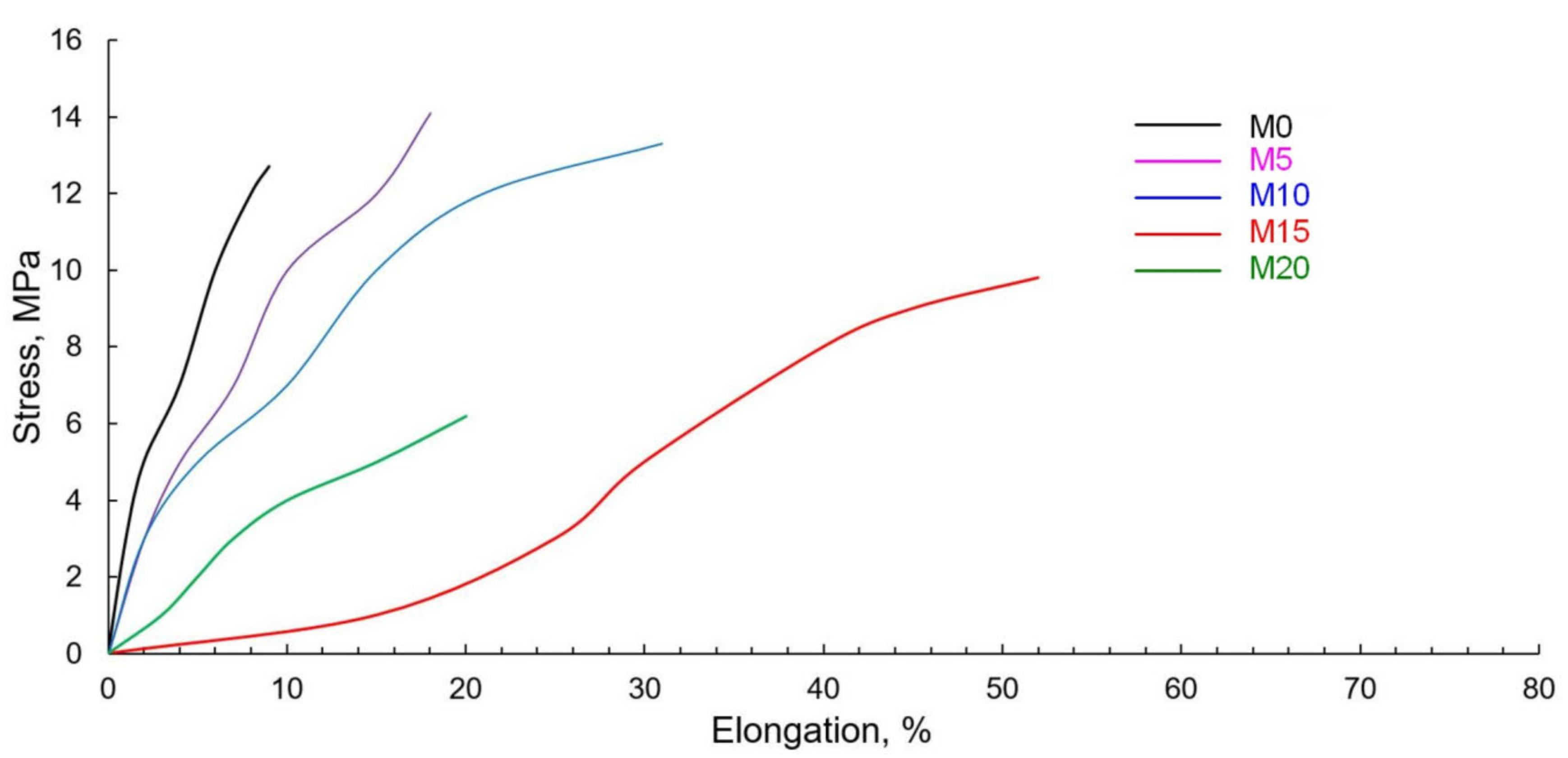

3.5. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bijarimi, M.; Ahmad, S.; Alam, A.K.M.M. Toughening effect of liquid natural rubber on the morphology and thermo-mechanical properties of the poly (lactic acid) ternary blend. Polym. Bull. 2017, 74, 3301–3317. [Google Scholar] [CrossRef]

- Pholharn, D.; Srithep, Y.; Morris, J. Melt compounding and characterization of poly (lactide) stereocomplex/natural rubber composites. Polym. Eng. Sci. 2018, 58, 713–718. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Rayon, E.; Samper, M.D.; Balart, R. Compatibilization and characterization of polylactide and biopolyethylene binary blends by non-reactive and reactive compatibilization approaches. Polymers 2020, 12, 1344. [Google Scholar] [CrossRef] [PubMed]

- Walha, F.; Lamnawar, K.; Maazouz, A.; Jaziri, M. Rheological, morphological and mechanical studies of sustainably sourced polymer blends based on poly(lactic acid) and polyamide 11. Polymers 2016, 8, 61. [Google Scholar] [CrossRef] [PubMed]

- Alias, N.F.; Ismail, H.; Ku Ishak, K.M. Tailoring Properties of polylactic acid/rubber/kenaf biocomposites: Effects of type of rubber and kenaf loading. BioResources 2020, 15, 5679–5695. [Google Scholar]

- Alias, N.F.; Ismail, H.; Ku Ishak, K.M. Comparison of type of rubber in PLA/rubber/kenaf biocomposite: Rheological, mechanical and morphological properties. Macromol. Symp. 2020, 391, 1900128. [Google Scholar] [CrossRef]

- Amran, N.A.M.; Ahmad, S.; Chen, R.S.; Shahdan, D. Tensile properties and thermal stability of nanocomposite poly-lactic acid/liquid natural rubber filled graphene nanoplates. AIP Conf. Proc. 2019, 2111, 030006. [Google Scholar]

- Piontek, A.; Vernaez, O.; Kabasci, S. Compatibilization of poly(lactic acid) (PLA) and bio-based ethylene-propylene-diene-rubber (EPDM) via reactive extrusion with different coagents. Polymers 2020, 12, 605. [Google Scholar] [CrossRef]

- Lee, J.M.; Hong, J.S.; Ahn, K.H. Particle percolation in a poly (lactic acid)/calcium carbonate nanocomposite with a small amount of a secondary phase and its influence on the mechanical properties. Polym. Compos. 2019, 40, 4023–4032. [Google Scholar] [CrossRef]

- Mustafa, S.N.I.S.; Man, S.H.C.; Hassan, A.; Baharulrazi, N. Enhancement of toughness and thermal properties of polylactic acid/liquid epoxidized natural rubber/graphene oxide composites. AIP Conf. Proc. 2020, 2267, 020062. [Google Scholar]

- Klinkajorn, J.; Tanrattanakul, V. The effect of epoxide content on compatibility of poly (lactic acid)/epoxidized natural rubber blends. J. Appl. Polym. Sci. 2020, 137, 48996. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Ishida, T.; Kosugi, K.; Kawahara, S.; Nghia, P.T. Crystallization behavior and mechanical property of epoxidized natural rubber/poly (lactic acid) blend. Kgk Kautsch. Gummi Kunstst. 2018, 71, 32–38. [Google Scholar]

- Mongkolvai, A.; Chuayjuligit, S.; Chaiwutthinan, P.; Larpkasemsuk, A.; Boonmahitthisud, A. Preparation and properties of poly (lactic acid)/epoxidized natural rubber/nano-silica composites. Key Eng. Mater. 2018, 773, 20–24. [Google Scholar] [CrossRef]

- Tessanan, W.; Chanthateyanonth, R.; Yamaguchi, M.; Phinyocheep, P. Improvement of mechanical and impact performance of poly (lactic acid) by renewable modified natural rubber. J. Clean. Prod. 2020, 276, 123800. [Google Scholar] [CrossRef]

- Sathornluck, S.; Choochottiros, C. Modification of epoxidized natural rubber as a PLA toughening agent. J. Appl. Polym. Sci. 2019, 136, 48267. [Google Scholar] [CrossRef]

- Sookprasert, P.; Hinchiranan, N. Morphology, mechanical and thermal properties of poly (lactic acid)(PLA)/natural rubber (NR) blends compatibilized by NR-graft-PLA. J. Mater. Res. 2017, 32, 708–800. [Google Scholar] [CrossRef]

- Huang, J.; Fan, J.; Yuan, D.; Zhang, S.; Chen, Y. Facile preparation of supertoughened polylactide-based thermoplastic vulcanizates without sacrificing the stiffness based on the selective distribution of silica. Ind. Eng. Chem. Res. 2020, 59, 9950–9958. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly (lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef]

- Phetphaisit, C.W.; Wapanyakul, W.; Phinyocheep, P. Effect of modified rubber powder on the morphology and thermal and mechanical properties of blown poly (lactic acid)–hydroxyl epoxidized natural rubber films for flexible film packaging. J. Appl. Polym. Sci. 2019, 136. [Google Scholar] [CrossRef]

- Ali, F.B.; Awale, R.G.; Fakhruldin, H.; Anuar, H. Plasticizing poly (lactic acid) using epoxidized palm oil for environmental friendly packaging material. Malays. J. Anal. Sci. 2016, 20, 1153–1158. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Samper, R.D.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Plasticization effect of epoxidized cottonseed oil (ECSO) on poly (lactic acid). Ind. Crop. Prod. 2017, 104, 278–286. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Lopez, J.; Ferrandiz, S.; Peltzer, M.A. Characterization of PLA-limonene blends for food packaging applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Yuan, D.; Chen, Z.; Chen, K.; Mou, W.; Chen, Y. Phenolic resin-induced dynamically vulcanized polylactide/natural rubber blends. Polym. Plast. Technol. Eng. 2016, 55, 1115–1123. [Google Scholar] [CrossRef]

- Wang, W.; Huang, J.; Gong, Z.; Fan, J.; Cao, L.; Chen, Y. Biobased PLA/NR-PMMA TPV with balanced stiffness-toughness: In-situ interfacial compatibilization, performance and toughening model. Polym. Test. 2020, 81, 106268. [Google Scholar] [CrossRef]

- Si, W.J.; Yuan, W.; Li, Y.; Chen, Y.; Zeng, J. Tailoring toughness of fully biobased poly (lactic acid)/natural rubber blends through dynamic vulcanization. Polym. Test. 2018, 65, 249–255. [Google Scholar] [CrossRef]

- Mustafa, S.N.I.S.; Man, S.H.C.; Baharulrazi, N.; Mohamad, Z.; Hassan, A.; Yusof, N.H. Mechanical and thermal properties of polylactic acid/liquid epoxidized natural rubber blends. Chem. Eng. Trans. 2020, 78, 103–108. [Google Scholar] [CrossRef]

- Rogovina, S.; Zhorina, L.; Gatin, A.; Prut, E.; Kuznetsova, O.; Yakhina, A.; Olkhov, A.; Samoylov, N.; Grishin, M.; Iordanskii, A.; et al. Biodegradable polylactide-poly(3-Hydroxybutyrate) compositions obtained via blending under shear deformations and electrospinning. Characterization and environmental application. Polymers 2020, 12, 1088. [Google Scholar] [CrossRef]

- Rosli, N.A.; Ahmad, I.; Anuar, F.H.; Abdullah, I. The contribution of eco-friendly bio-based blends on enhancing the thermal stability and biodegradability of poly (lactic acid). J. Clean. Prod. 2018, 198, 987–995. [Google Scholar] [CrossRef]

- Bitinis, N.; Verdejo, R.; Cassagnau, P.; Lopez-Monchado, M.A. Structure and properties of polylactide/natural rubber blends. Mater. Chem. Phys. 2011, 129, 823–831. [Google Scholar] [CrossRef]

- Salehiyan, R.; Ray, S.S.; Stadler, F.G.; Ojijo, V. Rheology–microstructure relationships in melt-processed polylactide/poly (vinylidene fluoride) blends. Materials 2018, 11, 2450. [Google Scholar] [CrossRef]

- Tábi, T.; Hajba, S. Cross effect of natural rubber and annealing on the properties of poly(lactic acid). Periodica Polytech. Mech. Eng. 2019, 64, 270. [Google Scholar] [CrossRef]

- Mohammad, N.N.B.; Arsad, A.; Sani, N.A.; Basri, M.H. Effect of compatibilisers on thermal and morphological properties of polylactic acid/natural rubber blends. Chem. Eng. Trans. 2017, 56, 1027–1032. [Google Scholar] [CrossRef]

- Abdullah, N.A.S.; Mohamad, Z.; Man, S.H.C.; Baharulrazi, N.; Majid, R.A.; Jusoh, M.; Ngadi, N. Thermal and toughness enhancement of poly (lactic acid) bio-nanocomposites. Chem. Eng. Trans. 2019, 72, 427–432. [Google Scholar] [CrossRef]

- Xia, M.; Lang, W.; Yang, Y.; Yu, J.; Wu, N.; Wang, Q. The microstructure of GNR and the mechanical properties of biobased PLA/GNR thermoplastic vulcanizates with excellent toughness. Materials 2019, 12, 294. [Google Scholar] [CrossRef] [PubMed]

- Mohamad, Z.; Syahida, N.N.N.; Othman, N.; Baharulrazi, N.; Man, S.H.C.; Jusoh, M.; Majid, R.A. Properties enhancement of polylactic acid biocomposite. Chem. Eng. Trans. 2018, 63, 361–366. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, L.; Yuan, D.; Chen, Y. Design of super-tough co-continuous PLA/NR/SiO2 TPVs with balanced stiffness-toughness based on reinforced rubber and interfacial compatibilization. Compos. Sci. Technol. 2018, 165, 231–239. [Google Scholar] [CrossRef]

- Yuan, D.; Ding, J.; Mou, W.; Wang, Y.; Chen, Y. Bio-based polylactide/epoxidized natural rubber thermoplastic vulcanizates with a co-continuous phase structure. Polym. Test. 2017, 64, 200–206. [Google Scholar] [CrossRef]

- Buys, Y.F.; Aznan, A.N.A.; Anuar, H. Mechanical properties, morphology, and hydrolytic degradation behavior of polylactic acid/natural rubber blends. IOP Conf. Ser. Mater. Sci. Eng. 2018, 290, 012077. [Google Scholar] [CrossRef]

- Shahdan, D.; Chen, R.S.; Ahmad, S.; Zailan, F.D.; Ali, A.M. Assessment of mechanical performance, thermal stability and water resistance of novel conductive poly (lactic acid)/modified natural rubber blends with low loading of polyaniline. Polym. Int. 2018, 67, 1070–1080. [Google Scholar] [CrossRef]

- Huang, J.; Mou, W.; Wang, W.; Lv, F.; Chen, Y. Influence of DCP content on the toughness and morphology of fully biobased ternary PLA/NR-PMMA/NR TPVs with co-continuous phase structure. Polym. Plast. Technol. Mater. 2020, 59, 674–684. [Google Scholar] [CrossRef]

- Phattarateera, S.; Pattamaprom, C. The effect of dynamic vulcanization on the mechanical and thermal properties of stereocomplex PLLA/PDLA/rubber blends. IOP Conf. Ser. Mater. Sci. Eng. 2019, 652, 012026. [Google Scholar] [CrossRef]

- Agnihotri, S.; Shukla, S.; Pradeep, S.A.; Pilla, S. Biobased thermosetting cellular blends: Exploiting the ecological advantage of epoxidized soybean oil in structural foams. Polymer 2019, 177, 111–119. [Google Scholar] [CrossRef]

- Sahoo, K.; Mohanty, S.; Nayak, S.K. Synthesis and characterization of bio-based epoxy blends from renewable resource based epoxidized soybean oil as reactive diluent. Chin. J. Polym. Sci. 2015, 33, 137–152. [Google Scholar] [CrossRef]

| Samples | Tg, °C | Tc, °C | Tm, °C | X, % |

|---|---|---|---|---|

| M0 | 59.4 ± 0.1 | 108.6 ± 0.1 | 151.7 ± 0.1 | 8.5 ± 0.4 |

| M5 | 54.9 ± 0.1 | 98.9 ± 0.1 | 151.2 ± 0.1 | 8.3 ± 0.4 |

| M10 | 52.6 ± 0.1 | 109.8 ± 0.1 | 150.1 ± 0.1 | 8.2 ± 0.4 |

| M15 | 51.0 ± 0.1 | 98.6 ± 0.1 | 150.2 ± 0.1 | 6.1 ± 0.5 |

| M20 | 50.9 ± 0.1 | 101.8 ± 0.1 | 148.8 ± 0.1 | 6.2 ± 0.5 |

| Sample | 5% Mass Loss Temperatures, °C | 10% Mass Loss Temperatures, °C | 50% Mass Loss Temperatures, °C | 90% Mass Loss Temperatures, °C |

|---|---|---|---|---|

| Initial PLA | 293 | 301 | 328 | 344 |

| M0 | 295 | 314 | 338 | 435 |

| M5 | 282 | 311 | 342 | 435 |

| M10 | 251 | 293 | 343 | 433 |

| M15 | 250 | 288 | 343 | 444 |

| M20 | 244 | 274 | 344 | 448 |

| PLA | M0 | M5 | M10 | M15 | M20 | |

|---|---|---|---|---|---|---|

| τ, Mpa | 55.0 ± 1.7 | 12.7 ± 0.6 | 14.1 ± 0.6 | 13.3 ± 0.5 | 9.8 ± 1.2 | 6.2 ± 1.9 |

| ε, % | 5 ± 1.3 | 9 ± 2.5 | 18 ± 3.9 | 31 ± 3.7 | 52 ± 7.1 | 20 ± 6.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burkov, A.; Kraev, A.; Grishin, M.; Vesnin, R.; Fomin, S.; Iordanskii, A. Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil. Polymers 2021, 13, 1101. https://doi.org/10.3390/polym13071101

Burkov A, Kraev A, Grishin M, Vesnin R, Fomin S, Iordanskii A. Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil. Polymers. 2021; 13(7):1101. https://doi.org/10.3390/polym13071101

Chicago/Turabian StyleBurkov, Andrey, Alexander Kraev, Maxim Grishin, Roman Vesnin, Sergey Fomin, and Alexey Iordanskii. 2021. "Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil" Polymers 13, no. 7: 1101. https://doi.org/10.3390/polym13071101

APA StyleBurkov, A., Kraev, A., Grishin, M., Vesnin, R., Fomin, S., & Iordanskii, A. (2021). Structural Features and Properties’ Characterization of Polylactic Acid/Natural Rubber Blends with Epoxidized Soybean Oil. Polymers, 13(7), 1101. https://doi.org/10.3390/polym13071101