Thermochemical Mechanism of the Epoxy-Glutamic Acid Reaction with Sn-3.0 Ag-0.5 Cu Solder Powder for Electrical Joining

Abstract

1. Introduction

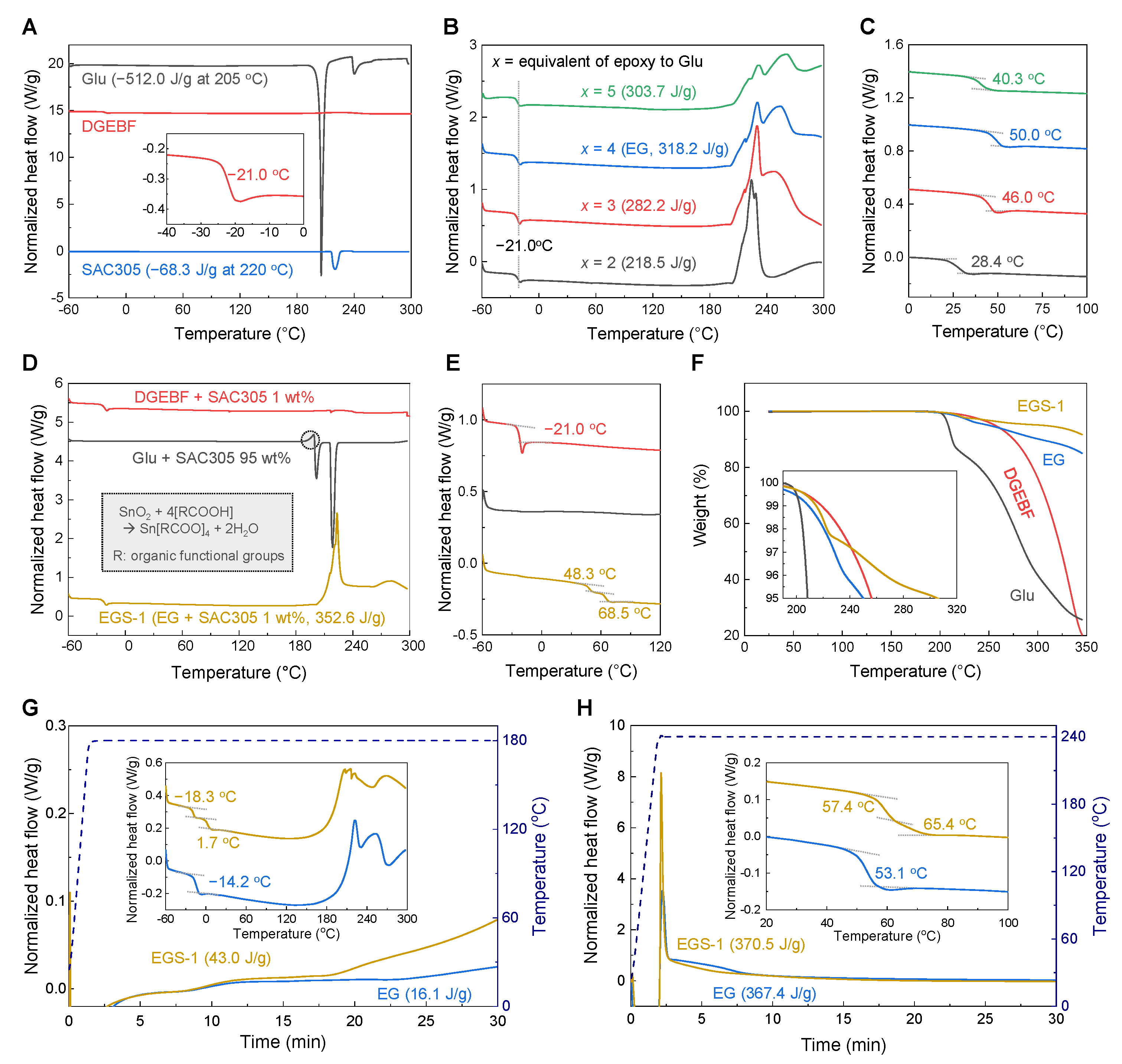

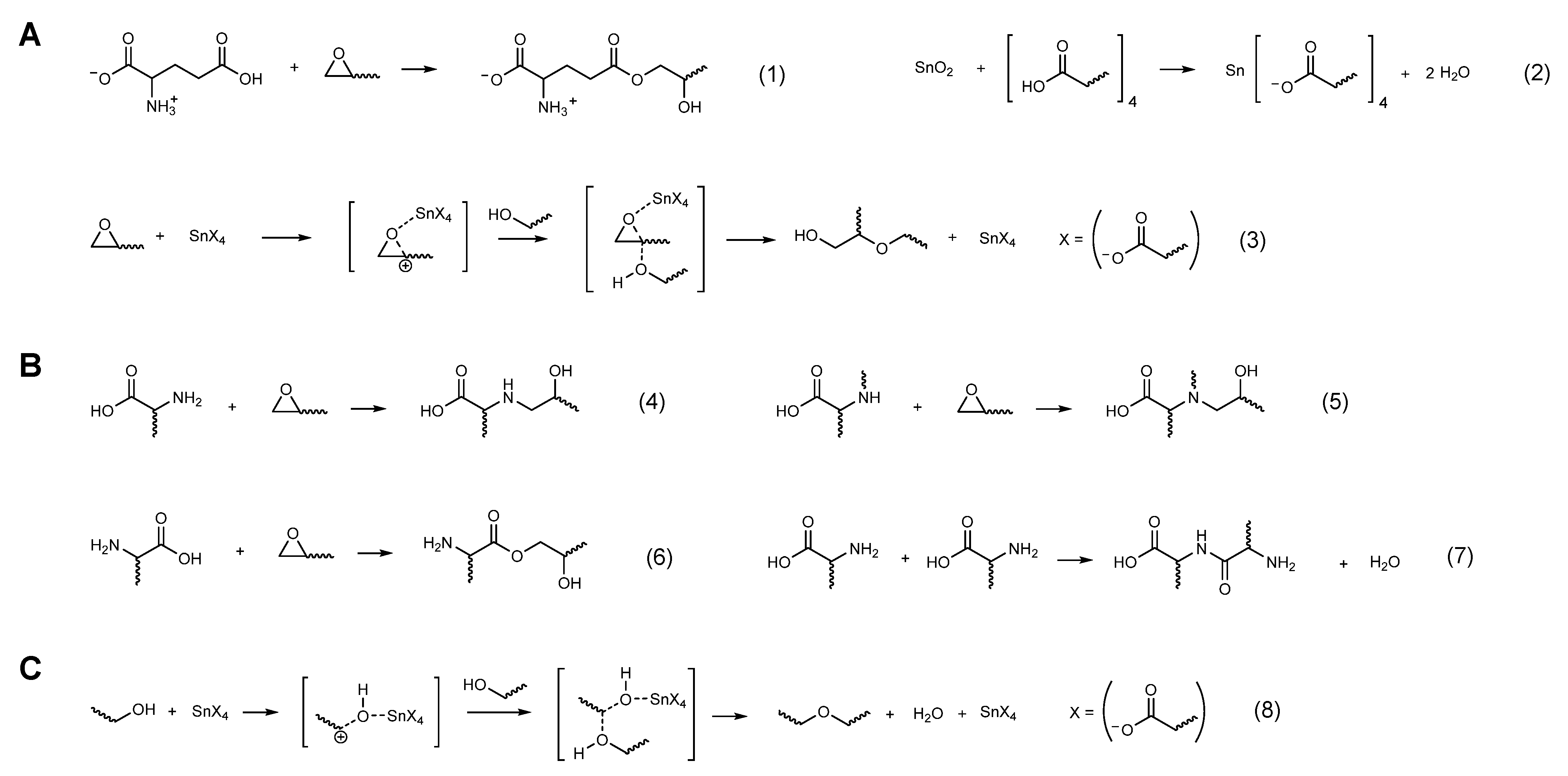

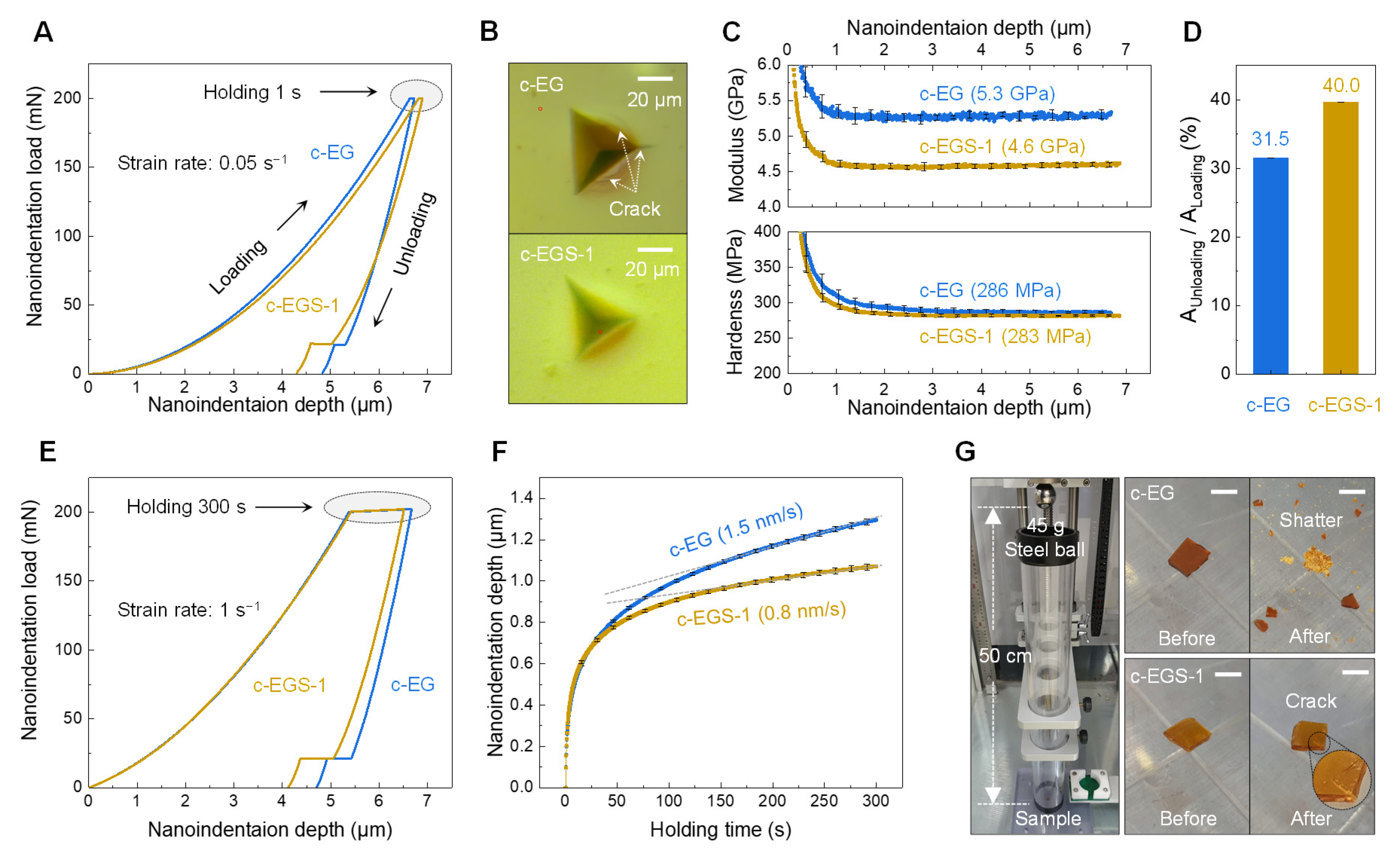

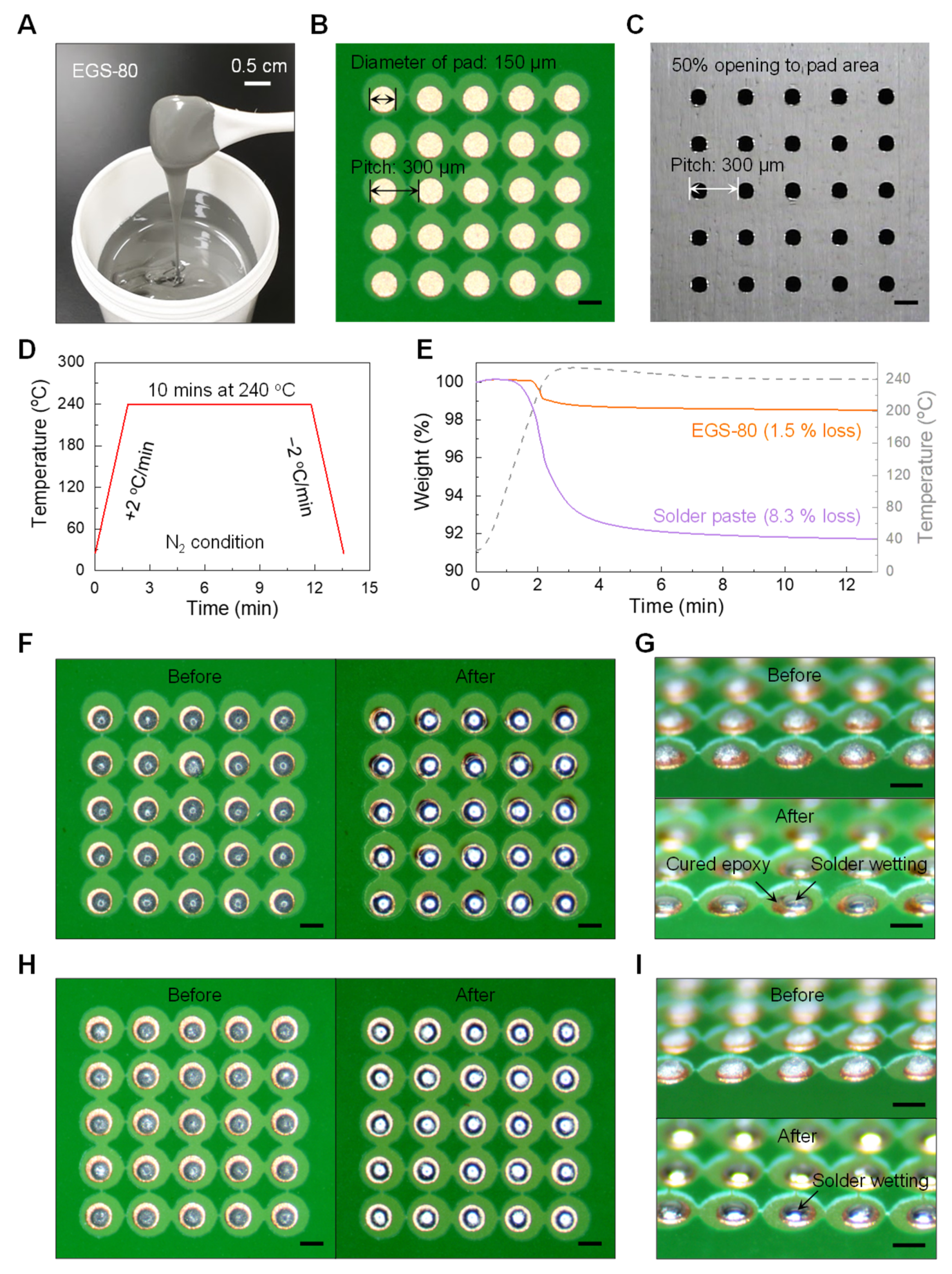

2. Materials and Methods

2.1. Materials

2.2. Formulation Preparation

2.3. Differential Scanning Calorimetry (DSC) Analysis

2.4. Thermogravimetric Analysis (TGA)

2.5. Fourier-Transform Infrared (FTIR) Analysis

2.6. Dissolution Test

2.7. High-Temperature Observation Test

2.8. Mechanical Characterization

2.9. Viscosity Measurement

2.10. Reflow Test

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joshi, S.; Borgesen, P. Solder Paste and Flux Technology. In Lead-Free Soldering Process Development and Reliability; Wiley: Hoboken, NJ, USA, 2020; pp. 73–93. [Google Scholar]

- Yin, Y.; Sun, Y.; Gao, L.; Fan, J.; Zhang, L.; Liu, M.; Hua, Z.; Yang, B.; Wang, Z.; Jianhang, F.; et al. 16-2: A 4-inch Full Color Active-matrix Mini-LED Display based on 0408 Chip and 500um Pixel. SID Symp. Dig. Tech. Pap. 2020, 51, 212–214. [Google Scholar] [CrossRef]

- Jun, Z.; Fei, Y.X.; Hailin, S. A highly reliable cleaning process. In Proceedings of the 2018 19th International Conference on Electronic Packaging Technology (ICEPT), Shanghai, China, 8–11 August 2018; pp. 834–839. [Google Scholar]

- Shen, L. The harmful factors affect human health and preventive measures in welding process. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering, Wuhan, China, 26–28 June 2010; pp. 3634–3637. [Google Scholar]

- Jang, K.-S.; Eom, Y.-S.; Moon, J.-T.; Oh, Y.-S.; Nam, J.-D. Catalytic Behavior of Sn/Bi Metal Powder in Anhydride-Based Epoxy Curing. J. Nanosci. Nanotechnol. 2009, 9, 7461–7466. [Google Scholar] [CrossRef] [PubMed]

- Eom, Y.-S.; Son, J.-H.; Bae, H.-C.; Choi, K.-S.; Lee, J.-H. Curing Kinetics and Chemorheological Behavior of No-flow Underfill for Sn/In/Bi Solder in Flexible Packaging Applications. ETRI J. 2016, 38, 1179–1189. [Google Scholar] [CrossRef]

- Jang, K.-S.; Eom, Y.-S.; Choi, K.-S.; Bae, H.-C. Crosslinkable deoxidizing hybrid adhesive of epoxy-diacid for electrical interconnections in semiconductor packaging. Polym. Int. 2018, 67, 1241–1247. [Google Scholar] [CrossRef]

- Jang, K.-S.; Eom, Y.-S.; Choi, K.-S.; Bae, H.-C. Synchronous curable deoxidizing capability of epoxy-anhydride adhesive: Deoxidation quantification via spectroscopic analysis. J. Appl. Polym. Sci. 2018, 135, 46639. [Google Scholar] [CrossRef]

- Eom, Y.; Jang, K.; Moon, J.; Nam, J.; Kim, J. Electrical and mechanical characterization of an anisotropic conductive adhesive with a low melting point solder. Microelectron. Eng. 2008, 85, 2202–2206. [Google Scholar] [CrossRef]

- Baek, J.; Jang, K.; Eom, Y.; Moon, J.; Kim, J.; Nam, J. Chemo-rheological characteristics of a self-assembling anisotropic conductive adhesive system containing a low-melting point solder. Microelectron. Eng. 2010, 87, 1968–1972. [Google Scholar] [CrossRef]

- Eom, Y.; Jang, K.; Moon, J.; Nam, J. Electrical Interconnection with a Smart ACA Composed of Fluxing Polymer and Solder Powder. ETRI J. 2010, 32, 414–421. [Google Scholar] [CrossRef]

- Eom, Y.-S.; Son, J.-H.; Jang, K.-S.; Lee, H.-S.; Bae, H.-C.; Choi, K.-S.; Choi, H.-S. Characterization of Fluxing and Hybrid Underfills with Micro-encapsulated Catalyst for Long Pot Life. ETRI J. 2014, 36, 343–351. [Google Scholar] [CrossRef]

- Moon, J.; Eom, Y.; Lee, J. Epoxy solder paste and its applications. J. Weld. Join. 2015, 33, 32–39. [Google Scholar] [CrossRef]

- Kang, M.-S.; Kim, D.-S.; Shin, Y.-E. The Effect of Epoxy Polymer Addition in Sn-Ag-Cu and Sn-Bi Solder Joints. Materials 2019, 12, 960. [Google Scholar] [CrossRef]

- Liu, L.; Xue, S.; Liu, S. Mechanical Property of Sn-58Bi Solder Paste Strengthened by Resin. Appl. Sci. 2018, 8, 2024. [Google Scholar] [CrossRef]

- Fukumoto, S.; Yoshida, K.; Mizokami, Y.; Matsushima, M.; Fujimoto, K. Development of Polyester-Modified Epoxy Resins for Self-Organization Soldering. Mater. Trans. 2019, 60, 858–864. [Google Scholar] [CrossRef]

- Fukumoto, S.; Wakimoto, R.; Yamauchi, K.; Matsushima, M.; Fujimoto, K. Solderability Using Thermoset Resin-Based Solder Pastes Covered with Thermoplastic Resin Film. Mater. Trans. 2018, 59, 1359–1366. [Google Scholar] [CrossRef]

- Lee, C.-J.; Bang, J.-O.; Jung, S.-B. Effect of black residue on the mechanical properties of Sn-58Bi epoxy solder joints. Microelectron. Eng. 2019, 216, 111055. [Google Scholar] [CrossRef]

- Sharma, A.; Jung, D.H.; Cheon, J.S.; Jung, J.P. Epoxy Polymer Solder Pastes for Micro-Electronic Packaging Applications. J. Weld. Join. 2019, 37, 7–14. [Google Scholar] [CrossRef]

- Weiss, I.M.; Muth, C.; Drumm, R.; Kirchner, H.O.K. Thermal decomposition of the amino acids glycine, cysteine, aspartic acid, asparagine, glutamic acid, glutamine, arginine and histidine. BMC Biophys. 2018, 11, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.I.; Xiao, F.; Moon, K.S.; Wong, C.P. Novel curing agent for lead-free electronics: Amino acid. J. Polym. Sci. Part A Polym. Chem. 2006, 44, 1020–1027. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, F.; Wong, C.P. Novel, environmentally friendly crosslinking system of an epoxy using an amino acid: Tryptophan-cured diglycidyl ether of bisphenol A epoxy. J. Polym. Sci. Part A Polym. Chem. 2007, 45, 181–190. [Google Scholar] [CrossRef]

- Ramakrishna, H.V.; Harish, H.S.; Manjuvani, J.; Bhaskar, V.; Kumar, R.; Patil, V.; Sarkar, S. Engineered Flux for Low Temperature Solders. In Proceedings of the SMTA International 2018, Rosemont, IL, USA, 14–18 October 2018. [Google Scholar]

- Tundo, P.; Perosa, A.; Zecchini, F. Methods and Reagents for Green Chemistry; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 9780470124086. [Google Scholar]

- Solder Paste Task Group. J-STD-005 Requirements for Soldering Pastes; Solder Paste Task Group: Arlington, VA, USA, 1995. [Google Scholar]

- Edsall, J.T.; Blanchard, M.H. The Activity Ratio of Zwitterions and Uncharged Molecules in Ampholyte Solutions. The Dissociation Constants of Amino Acid Esters. J. Am. Chem. Soc. 1933, 55, 2337–2353. [Google Scholar] [CrossRef]

- Altmann, N.; Halley, P.J.; Nicholson, T.M. Dynamic percolation grid Monte Carlo simulation. Korea Aust. Rheol. J. 2007, 19, 7–16. [Google Scholar]

- Chen, J.-H.; Lo, S.-C.; Hsu, S.-C.; Hsu, C.-Y. Fabrication and Characteristics of SnAgCu Alloy Nanowires for Electrical Connection Application. Micromachines 2018, 9, 644. [Google Scholar] [CrossRef] [PubMed]

- Thomas, R.; Sinturel, C.; Thomas, S.; El Akiaby, E.M.S. Introduction. In Micro- and Nanostructured Epoxy/Rubber Blends; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014; Volume 9783527333, pp. 1–30. ISBN 9783527666874. [Google Scholar]

- Saito, S.; Nakasato, K.; Katoh, Y.; Oshibe, Y.; Ishidoya, M. Application of thermal latent carboxylic acid derivatives to Pb-free microsoldering. Mater. Trans. 2004, 45, 759–764. [Google Scholar] [CrossRef]

- Onard, S.; Martin, I.; Chailan, J.F.; Crespy, A.; Carriere, P. Nanostructuration in thin epoxy-amine films inducing controlled specific phase etherification: Effect on the glass transition temperatures. Macromolecules 2011, 44, 3485–3493. [Google Scholar] [CrossRef]

- González, M.G.; Cabanelas, J.C.; Baselga, J. Applications of FTIR on Epoxy Resins—Identification, Monitoring the Curing Process, Phase Separation and Water Uptake. In Infrared Spectroscopy—Materials Science, Engineering and Technology; InTech: London, UK, 2012; Volume 16, pp. 261–283. [Google Scholar]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. In Encyclopedia of Analytical Chemistry; John Wiley & Sons, Ltd.: Chichester, UK, 2006; pp. 1–23. [Google Scholar]

- Vanderbilt, D.P.; English, J.P.; Fleming, G.L.; McNeely, G.W.; Cowsar, D.R.; Dunn, R.L. Biodegradable Polyamides Based on 4,4′-Spirobibutyrolactone. In Progress in Biomedical Polymers; Gebelein, C.G., Dunn, R.L., Eds.; Springer: Boston, MA, USA, 1990; pp. 249–262. ISBN 978-1-4899-0768-4. [Google Scholar]

- Sengupta, P.K.; Krimm, S. Vibrational analysis of peptides, polypeptides, and proteins. XXXII. α-Poly(L-glutamic acid). Biopolymers 1985, 24, 1479–1491. [Google Scholar] [CrossRef]

- Sumayya, A.; Panicker, C.Y.; Varghese, H.T.; Harikumar, B. Vibrational spectroscopic studies and AB initio calculations of L-glutamic acid 5-amide. Rasayan J. Chem. 2008, 1, 548–555. [Google Scholar]

- Blank, W.J.; He, Z.A.; Picci, M. Catalysis of the epoxy-carboxyl reaction. J. Coat. Technol. 2002, 74, 33–41. [Google Scholar] [CrossRef]

- Liu, F.; de Oliveira Vigier, K.; Pera-Titus, M.; Pouilloux, Y.; Clacens, J.-M.; Decampo, F.; Jérôme, F. Catalytic etherification of glycerol with short chain alkyl alcohols in the presence of Lewis acids. Green Chem. 2013, 15, 901. [Google Scholar] [CrossRef]

- Mitsudome, T.; Matsuno, T.; Sueoka, S.; Mizugaki, T.; Jitsukawa, K.; Kaneda, K. Direct synthesis of unsymmetrical ethers from alcohols catalyzed by titanium cation-exchanged montmorillonite. Green Chem. 2012, 14, 610. [Google Scholar] [CrossRef]

- Kuang, X.; Shi, Q.; Zhou, Y.; Zhao, Z.; Wang, T.; Qi, H.J. Dissolution of epoxy thermosets via mild alcoholysis: The mechanism and kinetics study. RSC Adv. 2018, 8, 1493–1502. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Wang, C.-S.; Leu, T.-S. Synthesis and characterization of polyimides containing naphthalene pendant group and flexible ether linkages. Polymer 2000, 41, 3581–3591. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.W.; Zeng, K. Analysis of nanoindentation creep for polymeric materials. J. Appl. Phys. 2004, 95, 3655–3666. [Google Scholar] [CrossRef]

- Pan, J.; Bath, J.; Zhou, X.; Willie, D. Backward and Forward Compatibility. In Lead-Free Soldering; Bath, J., Ed.; Springer: Boston, MA, USA, 2007; pp. 173–197. ISBN 978-0-387-68422-2. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, G.-M.; Jang, K.-S.; Choi, K.-S.; Joo, J.; Yun, H.-G.; Lee, C.; Eom, Y.-S. Thermochemical Mechanism of the Epoxy-Glutamic Acid Reaction with Sn-3.0 Ag-0.5 Cu Solder Powder for Electrical Joining. Polymers 2021, 13, 957. https://doi.org/10.3390/polym13060957

Choi G-M, Jang K-S, Choi K-S, Joo J, Yun H-G, Lee C, Eom Y-S. Thermochemical Mechanism of the Epoxy-Glutamic Acid Reaction with Sn-3.0 Ag-0.5 Cu Solder Powder for Electrical Joining. Polymers. 2021; 13(6):957. https://doi.org/10.3390/polym13060957

Chicago/Turabian StyleChoi, Gwang-Mun, Ki-Seok Jang, Kwang-Seong Choi, Jiho Joo, Ho-Gyeong Yun, Chanmi Lee, and Yong-Sung Eom. 2021. "Thermochemical Mechanism of the Epoxy-Glutamic Acid Reaction with Sn-3.0 Ag-0.5 Cu Solder Powder for Electrical Joining" Polymers 13, no. 6: 957. https://doi.org/10.3390/polym13060957

APA StyleChoi, G.-M., Jang, K.-S., Choi, K.-S., Joo, J., Yun, H.-G., Lee, C., & Eom, Y.-S. (2021). Thermochemical Mechanism of the Epoxy-Glutamic Acid Reaction with Sn-3.0 Ag-0.5 Cu Solder Powder for Electrical Joining. Polymers, 13(6), 957. https://doi.org/10.3390/polym13060957