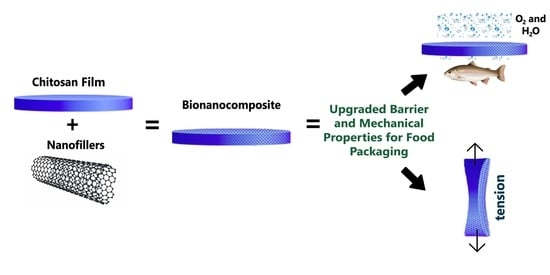

Understanding the Barrier and Mechanical Behavior of Different Nanofillers in Chitosan Films for Food Packaging

Abstract

1. Introduction

2. Nanotechnology as Reinforcement

2.1. Barrier Properties

2.1.1. Nanoclays

2.1.2. Cellulosic Nanofibers and Nanocrystals

2.1.3. Metal Oxides Nanoparticles and Carbon Nanotubes

2.2. Mechanical Properties

2.2.1. Nanoclays

2.2.2. Cellulosic Nanofibers and Nanocrystals

2.2.3. Metal Oxides

2.2.4. Carbon Nanotubes

3. Conclusions and Final Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Souza, V.G.L.; Fernando, A.L. Nanoparticles in food packaging: Biodegradability and potential migration to food—A review. Food Packag. Shelf Life 2016, 8, 63–70. [Google Scholar] [CrossRef]

- Fortunati, E.; Luzi, F.; Yang, W.; Kenny, J.M.; Torre, L.; Puglia, D. Bio-based nanocomposites in food packaging. In Nanomaterials for Food Packaging; Elsevier: Amsterdam, The Netherlands, 2018; pp. 71–110. ISBN 9780323512718. [Google Scholar]

- Lambert, S.; Wagner, M.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef] [PubMed]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.M.; Fernando, A.L. Chitosan Composites in Packaging Industry—Current Trends and Future Challenges. Polymers 2020, 12, 417. [Google Scholar] [CrossRef] [PubMed]

- Andrade, M.A.; Barbosa, C.H.; Souza, V.G.L.; Coelhoso, I.M.; Reboleira, J.; Bernardino, S.; Ganhão, R.; Mendes, S.; Fernando, A.L.; Vilarinho, F.; et al. Novel Active Food Packaging Films Based on Whey Protein Incorporated with Seaweed Extract: Development, Characterization, and Application in Fresh Poultry Meat. Coatings 2021, 11, 229. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Baraniak, B. Effect of candelilla wax on functional properties of biopolymer emulsion films—A comparative study. Food Hydrocoll. 2014, 41, 195–209. [Google Scholar] [CrossRef]

- Saratale, R.G.; Cho, S.K.; Ghodake, G.S.; Shin, H.S.; Saratale, G.D.; Park, Y.; Lee, H.S.; Bharagava, R.N.; Kim, D.S. Utilization of noxious weed water hyacinth biomass as a potential feedstock for biopolymers production: A novel approach. Polymers 2020, 12, 1704. [Google Scholar] [CrossRef] [PubMed]

- Suwanamornlert, P.; Kerddonfag, N.; Sane, A.; Chinsirikul, W.; Zhou, W.; Chonhenchob, V. Poly(lactic acid)/poly(butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag. Shelf Life 2020, 25, 100515. [Google Scholar] [CrossRef]

- Rodrigues, C.; Souza, V.G.L.; Rashad, M.; Pari, L.; Outzourhit, A.; Fernando, A.L. Mucilage extraction from Opuntia spp for production of biofilms. Eur. Biomass Conf. Exhib. Proc. 2019, 1459. [Google Scholar]

- Souza, V.G.L.; Pires, J.R.; Vieira, É.T.; Coelhoso, I.M.; Duarte, M.P.; Fernando, A.L. Shelf Life Assessment of Fresh Poultry Meat Packaged in Novel Bionanocomposite of Chitosan/Montmorillonite Incorporated with Ginger Essential Oil. Coatings 2018, 8, 177. [Google Scholar] [CrossRef]

- Pires, J.R.A.; de Souza, V.G.L.; Fernando, A.L. Chitosan/montmorillonite bionanocomposites incorporated with rosemary and ginger essential oil as packaging for fresh poultry meat. Food Packag. Shelf Life 2018, 17, 142–149. [Google Scholar] [CrossRef]

- Ali, A.; Ahmed, S. A review on chitosan and its nanocomposites in drug delivery. Int. J. Biol. Macromol. 2018, 109, 273–286. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Ferrer, A.; Tyagi, P.; Yin, Y.; Salas, C.; Pal, L.; Rojas, O.J. Nanocellulose in thin films, coatings, and plies for packaging applications: A review. BioResources 2017, 12, 2143–2233. [Google Scholar] [CrossRef]

- Noshirvani, N.; Ghanbarzadeh, B.; Rezaei, R.; Hashemi, M.; Rezaei Mokarram, R.; Hashemi, M.; Rezaei, R.; Hashemi, M. Novel active packaging based on carboxymethyl cellulose-chitosan-ZnO NPs nanocomposite for increasing the shelf life of bread. Food Packag. Shelf Life 2017, 11, 106–114. [Google Scholar] [CrossRef]

- Alves, V.L.C.D.; Rico, B.P.M.; Cruz, R.M.S.; Vicente, A.A.; Khmelinskii, I.; Vieira, M.C. Preparation and characterization of a chitosan film with grape seed extract- carvacrol microcapsules and its effect on the shelf-life of refrigerated Salmon (Salmo salar). Lwt Food Sci. Technol. 2018, 89, 525–534. [Google Scholar] [CrossRef]

- Kumar, S.; Mukherjee, A.; Dutta, J. Chitosan based nanocomposite fi lms and coatings: Emerging antimicrobial food packaging alternatives. Trends Food Sci. Technol. 2020, 97, 196–209. [Google Scholar] [CrossRef]

- Alves, V.D.; Costa, N.; Coelhoso, I.M. Barrier properties of biodegradable composite films based on kappa-carrageenan/pectin blends and mica flakes. Carbohydr. Polym. 2010, 79, 269–276. [Google Scholar] [CrossRef]

- Siracusa, V. Food Packaging Permeability Behaviour: A Report. Int. J. Polym. Sci. 2012, 2012, 302029. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Fernando, A.L.; Pires, J.R.A.; Rodrigues, P.F.; Lopes, A.A.S.S.; Fernandes, F.M.B. Physical properties of chitosan films incorporated with natural antioxidants. Ind. Crop. Prod. 2017, 107, 565–572. [Google Scholar] [CrossRef]

- Ferreira, A.R.V.; Torres, C.A.V.; Freitas, F.; Sevrin, C.; Grandfils, C.; Reis, M.A.M.; Alves, V.D.; Coelhoso, I.M. Development and characterization of bilayer films of FucoPol and chitosan. Carbohydr. Polym. 2016, 147, 8–15. [Google Scholar] [CrossRef]

- Tunç, S.; Duman, O.; Polat, T.G. Effects of montmorillonite on properties of methyl cellulose/carvacrol based active antimicrobial nanocomposites. Carbohydr. Polym. 2016, 150, 259–268. [Google Scholar] [CrossRef]

- Shankar, S.; Rhim, J. Bionanocomposite films for food packaging applications. Ref. Modul. Food Sci. 2018, 1–10. [Google Scholar] [CrossRef]

- Jamróz, E.; Kopel, P.; Tkaczewska, J.; Dordevic, D.; Jancikova, S.; Kulawik, P.; Milosavljevic, V.; Dolezelikova, K.; Smerkova, K.; Svec, P.; et al. Nanocomposite Furcellaran Films—the Influence of Nanofillers on Functional Properties of Furcellaran Films and Effect on Linseed Oil Preservation. Polymers 2019, 11, 2046. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Souza, V.G.L.; Fernando, A.L. Production of Nanocellulose from Lignocellulosic Biomass Wastes: Prospects and Limitations. In Innovation, Engineering and Entrepreneurship; Machado, J., Soares, F., Veiga, G., Eds.; Lecture Notes in Electrical Engineering; Springer International Publishing: Cham, Switzerland, 2019; Volume 505, pp. 719–725. ISBN 978-3-319-91333-9. [Google Scholar]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Rodrigues, P.F.; Lopes, A.; Silva, R.J.; Caldeira, J.; Duarte, M.P.; Fernandes, F.B.; Coelhoso, I.M.; et al. Physical and Morphological Characterization of Chitosan/Montmorillonite Films Incorporated with Ginger Essential Oil. Coatings 2019, 9, 700. [Google Scholar] [CrossRef]

- Bharimalla, A.K.; Deshmukh, S.P.; Vigneshwaran, N.; Patil, P.G.; Prasad, V.; Deshmukh, S.P.; Vigneshwaran, N.; Patil, P.G.; Prasad, V. Nanocellulose-Polymer Composites for Applications in Food Packaging: Current Status, Future Prospects and Challenges Nanocellulose-Polymer Composites for Applications in Food Packaging: Current. Polym. Plast. Technol. Eng. 2017, 56, 805–823. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.; Fernando, A.L. Novel Approaches for Chitin/Chitosan Composites in the Packaging Industry. In Chitin- and Chitosan-Based Biocomposites for Food Packaging Applications; Jacob, J., Loganathan, S., Thomas, S., Eds.; CRC Press: Boca Raton, FL, USA, 2020; pp. 87–96. ISBN 9780429299605. [Google Scholar]

- Sionkowska, A.; Michalska-Sionkowska, M.; Walczak, M. Preparation and characterization of collagen/hyaluronic acid/chitosan film crosslinked with dialdehyde starch. Int. J. Biol. Macromol. 2020, 149, 290–295. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Meng, Q.; Li, Q.; Liu, J.; Zhou, M.; Jin, Z.; Zhao, K. Chitosan derivatives and their application in biomedicine. Int. J. Mol. Sci. 2020, 21, 487. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.K.; Dhiman, T.K.; Lakshmi, G.B.V.S.; Berlina, A.N.; Solanki, P.R. A highly sensitive label-free amperometric biosensor for norfloxacin detection based on chitosan-yttria nanocomposite. Int. J. Biol. Macromol. 2020, 151, 566–575. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, F.; Pei, H.; Yan, K.; Cui, Z.; He, B.; Fang, K.; Li, J. Environmentally-friendly halloysite nanotubes@chitosan/polyvinyl alcohol/non-woven fabric hybrid membranes with a uniform hierarchical porous structure for air filtration. J. Memb. Sci. 2020, 594, 117445. [Google Scholar] [CrossRef]

- Ali, N.; Khan, A.; Bilal, M.; Malik, S.; Badshah, S.; Iqbal, H.M.N. Chitosan-based bio-composite modified with thiocarbamate moiety for decontamination of cations from the aqueous media. Molecules 2020, 25, 226. [Google Scholar] [CrossRef]

- Prokhorov, E.; Luna-Bárcenas, G. Negative electrical tunability of chitosan–graphene oxide nanocomposites. Appl. Phys. A Mater. Sci. Process. 2020, 126, 1–8. [Google Scholar] [CrossRef]

- Paul, D.R.; Robeson, L.M. Polymer nanotechnology: Nanocomposites. Polymer 2008, 49, 3187–3204. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Vieira, É.T.; Coelhoso, I.M.; Duarte, M.P.; Fernando, A.L. Activity of chitosan-montmorillonite bionanocomposites incorporated with rosemary essential oil: From in vitro assays to application in fresh poultry meat. Food Hydrocoll. 2019, 89, 241–252. [Google Scholar] [CrossRef]

- da Silva Scudeler, C.G.; de Lima Costa, T.; Cortez-Vega, W.R.; Prentice, C.; Fonseca, G.G. Development and characterization of Nile tilapia (Oreochromis niloticus) protein isolate-based biopolymer films incorporated with essential oils and nanoclay. Food Packag. Shelf Life 2020, 25, 100542. [Google Scholar] [CrossRef]

- Xu, D.; Qin, H.; Ren, D. Prolonged preservation of tangerine fruits using chitosan/montmorillonite composite coating. Postharvest Biol. Technol. 2018, 143, 50–57. [Google Scholar] [CrossRef]

- Liu, S.; Cai, P.; Li, X.; Chen, L.; Li, L.; Li, B. Effect of film multi-scale structure on the water vapor permeability in hydroxypropyl starch (HPS)/Na-MMT nanocomposites. Carbohydr. Polym. 2016, 154, 186–193. [Google Scholar] [CrossRef]

- Beigzadeh Ghelejlu, S.; Esmaiili, M.; Almasi, H. Characterization of chitosan-nanoclay bionanocomposite active films containing milk thistle extract. Int. J. Biol. Macromol. 2016, 86, 613–621. [Google Scholar] [CrossRef]

- Lee, M.H.; Kim, S.Y.; Park, H.J. Effect of halloysite nanoclay on the physical, mechanical, and antioxidant properties of chitosan films incorporated with clove essential oil. Food Hydrocoll. 2018, 84, 58–67. [Google Scholar] [CrossRef]

- Nouri, A.; Yaraki, M.T.; Ghorbanpour, M.; Agarwal, S.; Gupta, V.K. Enhanced Antibacterial effect of chitosan film using Montmorillonite/CuO nanocomposite. Int. J. Biol. Macromol. 2017, 109, 1219–1231. [Google Scholar] [CrossRef] [PubMed]

- Llanos, J.H.R.; Tadini, C.C. Preparation and characterization of bio-nanocomposite films based on cassava starch or chitosan, reinforced with montmorillonite or bamboo nanofibers. Int. J. Biol. Macromol. 2018, 107, 371–382. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, C.; Wang, P.; Zhang, Y.; Zhang, H. Electrospun chitosan/polycaprolactone nanofibers containing chlorogenic acid-loaded halloysite nanotube for active food packaging. Carbohydr. Polym. 2020, 247, 116711. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, P.; Hamedi, S.; Garmaroody, E.R.; Koosha, M. Antibacterial nanobiocomposite based on halloysite nanotubes and extracted xylan from bagasse pith. Int. J. Biol. Macromol. 2020, 160, 276–287. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yi, S.; Lu, R.; Sameen, D.E.; Ahmed, S.; Dai, J.; Qin, W.; Li, S.; Liu, Y. Preparation, characterization, and 3D printing verification of chitosan/halloysite nanotubes/tea polyphenol nanocomposite films. Int. J. Biol. Macromol. 2021, 166, 32–44. [Google Scholar] [CrossRef]

- ASTM International. ASTM D3985-05, Standard Test Method for Oxygen Gas Transmission Rate through Plastic Film and Sheeting Using a Coulometric Sensor; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Akrami-Hasan-Kohal, M.; Ghorbani, M.; Mahmoodzadeh, F.; Nikzad, B. Development of reinforced aldehyde-modified kappa-carrageenan/gelatin film by incorporation of halloysite nanotubes for biomedical applications. Int. J. Biol. Macromol. 2020, 160, 669–676. [Google Scholar] [CrossRef] [PubMed]

- Gómez, H.C.; Serpa, A.; Velásquez-Cock, J.; Gañán, P.; Castro, C.; Vélez, L.; Zuluaga, R. Vegetable nanocellulose in food science: A review. Food Hydrocoll. 2016, 57, 178–186. [Google Scholar] [CrossRef]

- Mondal, S. Preparation, properties and applications of nanocellulosic materials. Carbohydr. Polym. 2017, 163, 301–316. [Google Scholar] [CrossRef] [PubMed]

- Dehnad, D.; Emam-djomeh, Z.; Mirzaei, H. Optimization of physical and mechanical properties for chitosan—Nanocellulose biocomposites. Carbohydr. Polym. 2014, 105, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Pires, J.R.A.; Souza, V.G.L.; Fernando, A.L. Valorization of energy crops as a source for nanocellulose production—Current knowledge and future prospects. Ind. Crop. Prod. 2019, 140, 111642. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crop. Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Corsello, F.A.; Bolla, P.A.; Anbinder, P.S.; Serradell, M.A.; Amalvy, J.I.; Peruzzo, P.J. Morphology and properties of neutralized chitosan-cellulose nanocrystals biocomposite films. Carbohydr. Polym. 2017, 156, 452–459. [Google Scholar] [CrossRef]

- Yadav, M.; Behera, K.; Chang, Y.H.; Chiu, F.C. Cellulose nanocrystal reinforced chitosan based UV barrier composite films for sustainable packaging. Polymers 2020, 12, 202. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Mattoso, L.H.C.; Avena-Bustillos, R.J.; Filho, G.C.; Munford, M.L.; Wood, D.; McHugh, T.H. Nanocellulose reinforced chitosan composite films as affected by nanofiller loading and plasticizer content. J. Food Sci. 2010, 75, 1–7. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Guo, M.; Jin, T.Z.; Arabi, S.A.; He, Q.; Ismail, B.B.; Hu, Y.; Liu, D. Antimicrobial and UV Blocking Properties of Composite Chitosan Films with Curcumin Grafted Cellulose Nanofiber. Food Hydrocoll. 2021, 112, 106337. [Google Scholar] [CrossRef]

- Salari, M.; Khiabani, M.S.; Mokarram, R.R.; Ghanbarzadeh, B.; Kafil, H.S. Development and evaluation of chitosan based active nanocomposite films containing bacterial cellulose nanocrystals and silver nanoparticles. Food Hydrocoll. 2018, 84, 414–423. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, S.; Lan, W.; Qin, W. Fabrication of polylactic acid/carbon nanotubes/chitosan composite fibers by electrospinning for strawberry preservation. Int. J. Biol. Macromol. 2019, 121, 1329–1336. [Google Scholar] [CrossRef] [PubMed]

- Sanuja, S.; Agalya, A.; Umapathy, M.J. Synthesis and characterization of zinc oxide-neem oil-chitosan bionanocomposite for food packaging application. Int. J. Biol. Macromol. 2015, 74, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan based ZnO nanoparticles loaded gallic-acid films for active food packaging. Food Chem. 2021, 334, 127605. [Google Scholar] [CrossRef] [PubMed]

- Kalaycıoğlu, Z.; Kahya, N.; Adımcılar, V.; Kaygusuz, H.; Torlak, E.; Akın-Evingür, G.; Erim, F.B. Antibacterial nano cerium oxide/chitosan/cellulose acetate composite films as potential wound dressing. Eur. Polym. J. 2020, 133, 109777. [Google Scholar] [CrossRef]

- Fernandes, C.; Calderon, V.S.; Ballesteros, L.F.; Cerqueira, M.A.; Pastrana, L.M.; Teixeira, J.A.; Ferreira, P.J.; Carvalho, S. Carbon-based sputtered coatings for enhanced chitosan-based films properties. Appl. Surf. Sci. 2018, 433, 689–695. [Google Scholar] [CrossRef]

- Boura-Theodoridou, O.; Giannakas, A.; Katapodis, P.; Stamatis, H.; Ladavos, A.; Barkoula, N.-M. Performance of ZnO/chitosan nanocomposite films for antimicrobial packaging applications as a function of NaOH treatment and glycerol/PVOH blending. Food Packag. Shelf Life 2020, 23, 100456. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Truşcă, R.-D.; Ilie, C.-I.; Oprea, O.-C.; Andronescu, E. Innovative Antimicrobial Chitosan/ZnO/Ag NPs/Citronella Essential Oil Nanocomposite—Potential Coating for Grapes. Foods 2020, 9, 1801. [Google Scholar] [CrossRef]

- Sanuja, S.; Agalya, A.; Umapathy, M.J. Studies on Magnesium Oxide Reinforced Chitosan Bionanocomposite Incorporated with Clove Oil for Active Food Packaging Application. Int. J. Polym. Mater. 2014, 63, 733–740. [Google Scholar] [CrossRef]

- Xu, Y.; Ren, X.; Hanna, M.A. Chitosan/clay nanocomposite film preparation and characterization. J. Appl. Polym. Sci. 2006, 99, 1684–1691. [Google Scholar] [CrossRef]

- Lavorgna, M.; Piscitelli, F.; Mangiacapra, P.; Buonocore, G.G. Study of the combined effect of both clay and glycerol plasticizer on the properties of chitosan films. Carbohydr. Polym. 2010, 82, 291–298. [Google Scholar] [CrossRef]

- Günister, E.; Pestreli, D.; Ünlü, C.H.; Atıcı, O.; Güngör, N. Synthesis and characterization of chitosan-MMT biocomposite systems. Carbohydr. Polym. 2007, 67, 358–365. [Google Scholar] [CrossRef]

- Lewandowska, K.; Sionkowska, A.; Kaczmarek, B.; Furtos, G. Characterization of chitosan composites with various clays. Int. J. Biol. Macromol. 2014, 65, 534–541. [Google Scholar] [CrossRef]

- Dias, M.V.; Machado Azevedo, V.; Borges, S.V.; Soares, N.D.F.F.; de Barros Fernandes, R.V.; Marques, J.J.; Medeiros, É.A.A. Development of chitosan/montmorillonite nanocomposites with encapsulated α-tocopherol. Food Chem. 2014, 165, 323–329. [Google Scholar] [CrossRef]

- Hong, S.I.; Lee, J.H.; Bae, H.J.; Koo, S.Y.; Lee, H.S.; Choi, J.H.; Kim, D.H.; Park, S.; Park, H.J. Effect of shear rate on structural, mechanical, and barrier properties of chitosan/montmorillonite nanocomposite film. J. Appl. Polym. Sci. 2009, 119, 2742–2749. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J. Food Eng. 2012, 111, 343–350. [Google Scholar] [CrossRef]

- Kasirga, Y.; Oral, A.; Caner, C. Preparation and characterization of chitosan/montmorillonite-K10 nanocomposites films for food packaging applications. Polym. Compos. 2012, 33, 1874–1882. [Google Scholar] [CrossRef]

- Giannakas, A.; Grigoriadi, K.; Leontiou, A.; Barkoula, N.M.; Ladavos, A. Preparation, characterization, mechanical and barrier properties investigation of chitosan-clay nanocomposites. Carbohydr. Polym. 2014, 108, 103–111. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, P.F.; Lopes, A.A.S.; Fernandes, F.M.B.; Duarte, M.P.; Coelhoso, I.M.; Fernando, A.L. Bionanocomposites of chitosan/montmorillonite incorporated with Rosmarinus officinalis essential oil: Development and physical characterization. Food Packag. Shelf Life 2018, 16, 148–156. [Google Scholar] [CrossRef]

- Giannakas, A.; Stathopoulou, P.; Tsiamis, G.; Salmas, C. The effect of different preparation methods on the development of chitosan/thyme oil/montmorillonite nanocomposite active packaging films. J. Food Process. Preserv. 2020, 44, e14327. [Google Scholar] [CrossRef]

- Potarniche, C.G.; Vuluga, Z.; Donescu, D.; Christiansen, J.D.C.; Eugeniu, V.; Radovici, C.; Serban, S.; Ghiurea, M.; Somoghi, R.; Beckmann, S. Morphology study of layered silicate/chitosan nanohybrids. Surf. Interface Anal. 2011, 44, 200–207. [Google Scholar] [CrossRef]

- Gierszewska, M.; Jakubowska, E.; Olewnik-kruszkowska, E. Effect of chemical crosslinking on properties of chitosan-montmorillonite composites. Polym. Test. 2019, 77, 105872. [Google Scholar] [CrossRef]

- Liang, B.; Shu, Y.; Wan, P.; Zhao, H.; Dong, S.; Hao, W. Genipin-enhanced nacre-inspired montmorillonite-chitosan film with superior mechanical and UV-blocking properties. Compos. Sci. Technol. 2019, 182, 107747. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Souza, V.G.L.; Fernando, A.L. Comparison of alkaline and ionic liquids pre-treatment applied to residues of perennial crops. Eur. Biomass Conf. Exhib. Proc. 2019, 1460–1463. [Google Scholar]

- Ng, H.; Sin, L.T.; Bee, S.; Tee, T.-T.; Rahmat, A.R. Review of Nanocellulose Polymer Composite Characteristics and Challenges. Polym. Plast. Technol. Eng. 2017, 56, 687–731. [Google Scholar] [CrossRef]

- Chaichi, M.; Hashemi, M.; Badii, F.; Mohammadi, A. Preparation and characterization of a novel bionanocomposite edible film based on pectin and crystalline nanocellulose. Carbohydr. Polym. 2017, 157, 167–175. [Google Scholar] [CrossRef]

- Rong, S.Y.; Mubarak, N.M.; Tanjung, F.A. Structure-property relationship of cellulose nanowhiskers reinforced chitosan biocomposite films. J. Environ. Chem. Eng. 2017, 5, 6132–6136. [Google Scholar] [CrossRef]

- Mujtaba, M.; Salaberria, A.M.; Andres, M.A.; Kaya, M.; Gunyakti, A.; Labidi, J. Utilization of flax (Linum usitatissimum) cellulose nanocrystals as reinforcing material for chitosan films. Int. J. Biol. Macromol. 2017, 104, 944–952. [Google Scholar] [CrossRef] [PubMed]

- El Achaby, M.; El Miri, N.; Aboulkas, A.; Zahouily, M.; Bilal, E.; Barakat, A.; Solhy, A. Processing and properties of eco-friendly bio-nanocomposite films filled with cellulose nanocrystals from sugarcane bagasse. Int. J. Biol. Macromol. 2017, 96, 340–352. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Liu, C.; Kang, K.; Zheng, Z.; Wang, S.; Tang, Z.; Yang, W. Isolation of nanocrystalline cellulose from rice straw and preparation of its biocomposites with chitosan: Physicochemical characterization and evaluation of interfacial compatibility. Compos. Sci. Technol. 2018, 154, 8–17. [Google Scholar] [CrossRef]

- Qian, S.; Zhang, H.; Yao, W.; Sheng, K. Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Compos. Part B 2018, 133, 203–209. [Google Scholar] [CrossRef]

- Gopi, S.; Amalraj, A.; Jude, S.; Thomas, S.; Guo, Q. Bionanocomposite films based on potato, tapioca starch and chitosan reinforced with cellulose nanofiber isolated from turmeric spent. J. Taiwan Inst. Chem. Eng. 2019, 96, 664–671. [Google Scholar] [CrossRef]

- Jacob, J.; Peter, G.; Thomas, S.; Haponiuk, J.T.; Gopi, S. Chitosan and polyvinyl alcohol nanocomposites with cellulose nano fibers from ginger rhizomes and its antimicrobial activities. Int. J. Biol. Macromol. 2019, 129, 370–376. [Google Scholar] [CrossRef]

- Kumar, R.; Rai, B.; Kumar, G. A simple approach for the synthesis of cellulose nanofiber reinforced Chitosan/PVP bio nanocomposite film for packaging. J. Polym. Environ. 2019, 27, 2963–2973. [Google Scholar] [CrossRef]

- Khan, A.; Khan, R.A.; Salmieri, S.; Le, C.; Riedl, B.; Bouchard, J.; Tan, V.; Kamal, M.R.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr. Polym. 2012, 90, 1601–1608. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Bras, J.; Viet, D.; Bruzzese, C.; Dufresne, A. Correlation between stiffness of sheets prepared from cellulose whiskers and nanoparticles dimensions. Carbohydr. Polym. 2011, 84, 211–215. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Kaewklin, P. Fabrication and characterization of chitosan-titanium dioxide nanocomposite film as ethylene scavenging and antimicrobial active food packaging. Food Hydrocoll. 2018, 84, 125–134. [Google Scholar] [CrossRef]

- Lan, W.; Wang, S.; Zhang, Z.; Liang, X.; Liu, X.; Zhang, J. Development of red apple pomace extract/chitosan-based films reinforced by TiO2 nanoparticles as a multifunctional packaging material. Int. J. Biol. Macromol. 2021, 168, 105–115. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, G.; Wang, Y.; Zhao, Y.; Su, H.; Tan, T. Preparation of chitosan-TiO2 composite film with efficient antimicrobial activities under visible light for food packaging applications. Carbohydr. Polym. 2017, 169, 101–107. [Google Scholar] [CrossRef]

- Mallakpour, S.; Madani, M. Effect of Functionalized TiO2 on Mechanical, Thermal and Swelling Properties of Chitosan-Based Nanocomposite Films. Polym. Plast. Technol. Eng. 2015, 54, 1035–1042. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Rodrigues, C.; Valente, S.; Pimenta, C.; Pires, J.R.A.; Alves, M.M.; Santos, C.F.; Coelhoso, I.M.; Fernando, A.L.L. Eco-Friendly ZnO/Chitosan Bionanocomposites Films for Packaging of Fresh Poultry Meat. Coatings 2020, 10, 110. [Google Scholar] [CrossRef]

- Li, L.; Deng, J.; Deng, H.; Liu, Z.; Xin, L. Synthesis and characterization of chitosan/ZnO nanoparticle composite membranes. Carbohydr. Res. 2010, 345, 994–998. [Google Scholar] [CrossRef] [PubMed]

- Mujeeb Rahman, P.; Abdul Mujeeb, V.M.; Muraleedharan, K.; Thomas, S.K. Chitosan/nano ZnO composite films: Enhanced mechanical, antimicrobial and dielectric properties. Arab. J. Chem. 2018, 11, 120–127. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Yong, H.; Qin, Y.; Liu, J.; Liu, J. Development of multifunctional food packaging films based on chitosan, TiO2 nanoparticles and anthocyanin-rich black plum peel extract. Food Hydrocoll. 2019, 94, 80–92. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Singh, Y. Effect of varying filler concentration on zinc oxide nanoparticle embedded chitosan films as potential food packaging material. J. Polym. Environ. 2017, 25, 1087–1098. [Google Scholar] [CrossRef]

- De Silva, R.T.; Mantilaka, M.M.M.G.P.G.; Ratnayake, S.P.; Amaratunga, G.A.J.; de Silva, K.M.N. Nano-MgO reinforced chitosan nanocomposites for high performance packaging applications with improved mechanical, thermal and barrier properties. Carbohydr. Polym. 2017, 157, 739–747. [Google Scholar] [CrossRef]

- Wang, Y.; Cen, C.; Chen, J.; Fu, L. MgO/carboxymethyl chitosan nanocomposite improves thermal stability, waterproof and antibacterial performance for food packaging. Carbohydr. Polym. 2020, 236, 116078. [Google Scholar] [CrossRef]

- Yadav, M.; Yop, K.; Jin, S.; Hui, D. Mechanical properties of Fe3O4/GO/chitosan composites. Compos. Part B 2014, 66, 89–96. [Google Scholar] [CrossRef]

- Wang, S.; Shen, L.; Zhang, W.; Tong, Y. Preparation and mechanical properties of chitosan/carbon nanotubes composites. Biomacromolecules 2005, 6, 3067–3072. [Google Scholar] [CrossRef]

- Tang, C.; Chen, N.; Zhang, Q.; Wang, K.; Fu, Q.; Zhang, X. Preparation and properties of chitosan nanocomposites with nanofillers of different dimensions. Polym. Degrad. Stab. 2009, 94, 124–131. [Google Scholar] [CrossRef]

- Razavi, R.; Zare, Y.; Yop, K. A model for tensile strength of polymer/carbon nanotubes nanocomposites assuming the percolation of interphase regions. Colloids Surf. A Physicochem. Eng. Asp. 2018, 538, 148–154. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Chang, Y. Preparation and properties of chitosan/carbon nanotube nanocomposites using poly (styrene sulfonic acid)—Modified CNTs. Carbohydr. Polym. 2009, 76, 232–238. [Google Scholar] [CrossRef]

- Thai Ong, Y.; Latif, A.; Hussein, S.; Zein, S.; Sudesh, K.; Huat, S. Poly(3-hydroxybutyrate)-functionalised multi-walled carbonnanotubes/chitosan green nanocomposite membranes andtheir application in pervaporation. Sep. Purif. Technol. 2011, 76, 419–427. [Google Scholar] [CrossRef]

- Aryaei, A.; Jayatissa, A.H.; Jayasuriya, A.C. Mechanical and biological properties of chitosan/carbon nanotube nanocomposite films. J. Biomed. Mater. Res. 2013, 102, 2704–2712. [Google Scholar] [CrossRef]

- Bakhtiari, S.S.E.; Karbasi, S.; Tabrizi, S.A.H.; Ebrahimi-Kahrizsangi, R. Chitosan/MWCNTs composite as bone substitute: Physical, mechanical, bioactivity, and biodegradation evaluation. Polym. Compos. 2019, 40, E1622–E1632. [Google Scholar] [CrossRef]

- Wang, J.; Gong, C.; Wen, S.; Liu, H.; Qin, C.; Xiong, C.; Dong, L. A facile approach of fabricating proton exchange membranes by incorporating polydopamine- functionalized carbon nanotubes into chitosan. Int. J. Hydrogen Energy 2019, 44, 6909–6918. [Google Scholar] [CrossRef]

- Ke, G.; Guan, W.; Tang, C.; Guan, W.; Zeng, D. Covalent functionalization of multiwalled carbon nanotubes with a low molecular weight chitosan. Biomacromolecules 2007, 8, 322–326. [Google Scholar] [CrossRef]

- Iamsamai, C.; Hannongbua, S.; Ruktanonchai, U. The effect of the degree of deacetylation of chitosan on its dispersion of carbon nanotubes. Carbon N. Y. 2010, 48, 25–30. [Google Scholar] [CrossRef]

- Bibi, S.; Price, G.J.; Yasin, T.; Nawaz, M. Eco-friendly synthesis and catalytic application of chitosan/gold/carbon nanotube nanocomposite films. RSC Adv. 2016, 6, 60180–60186. [Google Scholar] [CrossRef]

- Bibi, S.; Jamil, A.; Yasin, T.; Aftab, M.; Nawaz, M.; Price, G.J. Ultrasound promoted synthesis and properties of chitosan nanocomposites containing carbon nanotubes and silver nanoparticles. Eur. Polym. J. 2018, 105, 297–303. [Google Scholar] [CrossRef]

- Rai, S.; Dutta, P.K.; Mehrotra, G.K. Lignin incorporated antimicrobial chitosan film for food packaging application. J. Polym. Mater. 2017, 34, 171–183. [Google Scholar]

- Yang, W.; Fortunati, E.; Bertoglio, F.; Owczarek, J.S.; Bruni, G.; Kozanecki, M.; Kenny, J.M.; Torre, L.; Visai, L.; Puglia, D. Polyvinyl alcohol/chitosan hydrogels with enhanced antioxidant and antibacterial properties induced by lignin nanoparticles. Carbohydr. Polym. 2018, 181, 275–284. [Google Scholar] [CrossRef] [PubMed]

- Jaganathan, G.; Manivannan, K.; Lakshmanan, S.; Sithique, M.A. Fabrication and characterization of Artocarpus heterophyllus waste derived lignin added chitosan biocomposites for wound dressing application. Sustain. Chem. Pharm. 2018, 10, 27–32. [Google Scholar] [CrossRef]

- Sohni, S.; Hashim, R.; Nidaullah, H.; Lamaming, J.; Sulaiman, O. Chitosan/nano-lignin based composite as a new sorbent for enhanced removal of dye pollution from aqueous solutions. Int. J. Biol. Macromol. 2019, 132, 1304–1317. [Google Scholar] [CrossRef] [PubMed]

| Model | Filler Type | Aspect Ratio (α) | Formula |

|---|---|---|---|

| Nielsen | Ribbon | α = w/t (length is infinite, w is the width, t is the thickness) | (P0/P)(1 − ϕ) = 1 + αϕ/2 |

| Cussler (regular array) | Ribbon | α = w/t (length is infinite, w is the width, t is the thickness) | (P0/P)(1 − ϕ) = 1 + (αϕ)2/4 |

| Cussler (random array) | Ribbon | α = w/t (length is infinite, w is the width, t is the thickness) | (P0/P)(1 − ϕ) = (1 + αϕ/3)2 |

| Gusev and Lusti | Disk | α = d/t (circular shape, d is the diameter, t is the thickness) | (P0/P)(1 − ϕ) = exp[(αϕ/3.47)0.71] |

| Fredrickson and Bicerano | Disk | α = d/t (circular shape, d is the diameter, t is the thickness) | (P0/P)(1 − ϕ) = 4(1 + x + 0.1245x2)/(2 + x)2, where x = αϕ/2ln(α/2) |

| Bharadwaj | Disk | α = d/t (circular shape, d is the diameter, t is the thickness) | (P0/P)(1 − ϕ) = 1 + 0.667αϕ(S + 0.5), where S is the orientation factor from -0.5 to 1. |

| Formulation | Incorporation Method | Water Vapor Permeability (Percentage Relatively to Control) | Oxygen Permeability (Percentage Relatively to Control) | Ref |

|---|---|---|---|---|

| 2% (w/v) Ch (deacetylation degree of 75–85%); Glycerol 25% (w/w Ch) | Mechanical stirring and ultrasonic homogenizer | Ch + 1% MMTNa: Decreased 31% Ch + 3% MMTNa: Decreased 56% Ch + 5% MMTNa: Decreased 38% | Not Performed | [39] |

| 1.5% (w/v) Ch (deacetylation degree of 75%); Glycerol 30% (w/w Ch) | Rotor–stator homogenizer (Ultra-Turrax) and ultrasonic homogenizer | Ch + 2.5% MMTNa: Increased 25% | Ch + 2.5% MMTNa: Decreased 47% | [25] |

| 1% (w/v) Ch (deacetylation degree of about 75%); Glycerol 40% (w/w Ch) | Mechanical stirring and ultrasonic homogenizer | Ch + 5% HNT: Decreased 2% Ch + 10% HNT: Decreased 5% Ch + 15% HNT: Decreased 10% Ch + 20% HNT: Decreased 13% Ch + 25% HNT: Decreased 14% Ch + 30% HNT: Decreased 16% | Not Performed | [40] |

| 2% (w/v) Ch (deacetylation degree greater than 75%); Glycerol 25% (w/w Ch) | Mechanical stirring and ultrasonic probes | Ch + 1% MMT: Decreased 28% | Ch + 1%MMT: Decreased 12% | [41] |

| Ch + 3% MMT: Decreased 37% | Ch + 3%MMT: Decreased 55% | |||

| Ch + 5% MMT: Decreased 17% | Ch + 5%MMT: Decreased 37% | |||

| Ch + 1% MMTCuO-20: Decreased 26% | Ch + 1%MMTCuO-20: Decreased 31% | |||

| Ch + 3% MMTCuO-20: Decreased 39% | Ch + 3%MMTCuO-20: Decreased 60% | |||

| Ch + 5% MMTCuO-20: Decreased 35% | Ch + 5%MMTCuO-20: Decreased 49% | |||

| Ch + 1% MMTCuO-90: Decreased 72% | Ch + 1%MMTCuO-90: Decreased 47% | |||

| Ch + 3% MMTCuO-90: Decreased 77% | Ch + 3%MMTCuO-90: Decreased 79% | |||

| Ch + 5% MMTCuO-90: Decreased 76% | Ch + 5%MMTCuO-90: Decreased 55% | |||

| 1% (w/w) Ch (deacetylation degree greater than 85%); Glycerol 30% (w/w Ch) of chitosan | Nanoparticles were dispersed stirred at 400 rotational frequency and immersed in an ultrasound bath | Ch + 0.5% MMT: Increased 16% | Ch + 0.5% MMT: Increased 89% | [42] |

| Ch + 1% MMT: Decreased 19% | Ch + 1% MMT: Increased 225% | |||

| 3% (v/v) Ch (deacetylation degree of about 95%); Polycaprolactone 12% (w/w Ch) | Mechanical stirring and ultrasonic homogenizer | Ch + 2% HNT: Decreased 15% Ch + 4% HNT: Decreased 23% Ch + 6% HNT: Decreased 25% | Not Performed | [43] |

| 1.5% (w/w) Ch (deacetylation degree of about 90%) | Mechanical stirring and ultrasonic homogenizer | Ch + 0.5% MMTNa: Decreased 2.7% | Ch + 0.5% MMTNa: Decreased 32% | [37] |

| Ch + 1% MMTNa: Decreased 7.4% | Ch + 1% MMTNa: Decreased 61% | |||

| Ch + 2% MMTNa: Decreased 4.0% | Ch + 2% MMTNa: Decreased 51% | |||

| 0.2% (v/v) Ch (deacetylation degree of about 75%); carboxymethyl cellulose 1% (w/w Ch) | Mechanical stirring | Ch + 5% HNT: Decreased 60% Ch + 7% HNT: Decreased 71% Ch + 10% HNT: Decreased 75% | Not Performed | [44] |

| 2% (w/w) Ch (deacetylation degree of about 90%) | Mechanical stirring | Ch + 25% HNT: Decreased 6,1% Ch + 42% HNT: Decreased 15% Ch + 66% HNT: Decreased 29% Ch + 100% HNT: Decreased 20% | Not Performed | [45] |

| Formulation | Incorporation Method | Water Vapor Permeability (Percentage Relatively to Control) | Oxygen Permeability (Percentage Relatively to Control) | Ref |

|---|---|---|---|---|

| 2% (w/v) Ch (deacetylation degree not specified) | Mechanical stirring and ultrasonic homogenizer | Ch + 1% CNC: Decreased 34% Ch + 3% CNC: Decreased 16% Ch + 5% CNC: Decreased 38% Ch + 10% CNC: Decreased 25% | Not Performed | [53] |

| 1% (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring and ultrasonic homogenizer | Ch + 2% CNC: Decreased 24% Ch + 4% CNC: Decreased 29% Ch + 6% CNC: Decreased 34% Ch + 8% CNC: Decreased 37% | Not Performed | [54] |

| 3% (w/v) Ch (degree of deacetylation 94%); | Mechanical stirring | Ch + 10% CNC: Decreased 32% Ch + 20% CNC: Decreased 28% | Not Performed | [55] |

| 2% (w/v) Ch (deacetylation degree not specified) | Mechanical stirring | Ch + 10% CGTOCNF: Decreased 6% | Ch + 10% CGTOCNF: Increased 13% | [56] |

| Ch + 17% CGTOCNF: Increased 2% | Ch + 17% CGTOCNF: Increased 16% | |||

| Ch + 25% CGTOCNF: Decreased 4% | Ch + 25% CGTOCNF: Increased 3% | |||

| Ch + 33% CGTOCNF: Decreased 7% | Ch + 33% CGTOCNF: Increased 62% | |||

| 1% (w/v) Ch (deacetylation degree 75–85%); | Nanoparticles were dispersed with the aid of mechanical stirring | Ch + 2% BCNC: Decreased 9% Ch + 4% BCNC: Decreased 20% Ch + 6% BCNC: Decreased 27% | Not Performed | [57] |

| Formulation | Incorporation Method | Water Vapor Permeability (Percentage Relatively to Control) | Oxygen Permeability (Percentage Relatively to Control) | Ref |

|---|---|---|---|---|

| 1% (w/v) Ch; 2% (w/v) purified CNT in dimethylformamide; 6 different PLA/CNT /Ch concentrations (0, 1, 3, 5, 7, 9% Ch) | Nanotubes were dispersed with stirring and electrospinning | PLA/CNTs/Ch-1%: Decreased 30% PLA/CNTs/Ch-3%: Decreased 64% PLA/CNTs/Ch-5%: Decreased 71% PLA/CNTs/Ch-7%: Decreased 75% PLA/CNTs/Ch-9%: Decreased 54% | Not performed | [58] |

| 1 g of Ch in the 1% acetic acid solution; | Metal oxides were sonicated to be dispersed | Ch + 0.1% ZnONP: Decreased 21% Ch + 0.3% ZnONP: Decreased 31% Ch + 0.5% ZnONP: Decreased 56% | Not performed | [59] |

| 2% (w/v) Ch | Metal oxides were dispersed with stirring | Ch + 30ZnO: Decreased 66% | Ch + 30ZnO: Decreased 7.5% | [60] |

| Ch + 50ZnO: Decreased 77% | Ch + 50ZnO: Decreased 10% | |||

| Ch + 70ZnO: Decreased 87% | Ch + 70ZnO: Decreased 41% | |||

| 0.5% (w/v) Ch; 1% cellulose acetate (CelAc) solution; 0.25% glycerol | Metal oxides were dispersed in formic acid and after were mixed with the polymer solution | Ch-CelAc-CeO2-0.1%: Increased 36% Ch-CelAc-CeO2-1%: Increased 157% | Not performed | [61] |

| Ch (0.2 g) was dispersed in 50.0 mL acidic water (0.5% v/v acetic acid | Metal oxides were dispersed in water and sonicated in an ultrasonic bath | CMC-Ch-OL-ZnONPs 0.5%: Increased 5.1% CMC-Ch-OL-ZnONPs 1%: Increased 20% CMC-Ch-OL-ZnONPs 2%: Increased 28% | Not performed | [14] |

| 1.5% (w/v) Ch in a 1% (v/v) l-(β)-lactic acid; 0.5% glycerol (w/v); 3 different acetylene flux (4 sccm, 12 sccm, 20 sccm) | Carbon-based coatings were dispersed with radio-frequency reactive magnetron sputtering | Ch-Acetylene 4 sccm: Increased 34% | Ch-Acetylene 4 sccm: Increased 14% | [62] |

| Ch-Acetylene 4 sccm: Increased 12% | Ch-Acetylene 12 sccm: Decreased 42% | |||

| Ch-Acetylene 4 sccm: Increased 11% | Ch-Acetylene 20 sccm: Decreased 81% | |||

| 1% (w/v) Ch; 20% glycerol (w/v Ch) | Metal oxides weredispersed with refluxed | ChG7ZnO: Decreased 81% (The other results are not showed) | Not performed | [63] |

| 0.6% (w/v) Ch; 4 different ZnONP concentrations (0.165, 0.33, 0.66, 0.99g in 15 mL Water) | Metal oxides were dispersed with vigorous stirring | Ch/ZnO 0.165 g: Decreased 13% Ch/ZnO 0.33 g: Decreased 17% Ch/ZnO 0.66 g: Decreased 8.0% Ch/ZnO 0.99 g: Decreased 6.8% | Not performed | [64] |

| 1% (w/v) Ch and 1% (w/w of Ch) of MgO NP | Metal oxides weredispersed with vigorous stirring | Decreased 53% | Not performed | [65] |

| Formulation | Incorporation Method | Tensile Strength (Relatively to Control) | Elongation at Break (Relatively to Control) | Elastic Modulus (Relatively to Control) | Ref |

|---|---|---|---|---|---|

| 1.5% (w/v) Ch (deacetylation degree of 75–85%); Glycerol 40% (w/w) of chitosan | Mechanical stirring and ultrasonic homogenizer | 1% MMTNa: Increased ~ 20–30% | 1% MMTNa: Decreased ~ 5% | Not performed | [71] |

| 3% MMTNa: Increased ~ 50% | 3% MMTNa: Decreased ~ 15% | ||||

| 5% MMTNa: Increased ~ 50% | 5% MMTNa: Decreased ~ 20% | ||||

| 7% MMTNa:Increased ~ 20–30% | 7% MMTNa:Decreased ~ 10–15% | ||||

| 9% MMTNa: Increased ~ 20–30% | 9% MMTNa: Decreased ~ 10–15% | ||||

| 11% MMTNa: Increased ~ 20–30% | 11% MMTNa: Decreased ~ 10–15% | ||||

| 2% (w/v) Ch (deacetylation degree of 88.8%); Glycerol 40% (w/w) of chitosan | Mechanical stirring and rotor–stator homogenizer (Ultra-Turrax) | 1% MMTNa: Increased ~ 5% | 1% MMT: Decreased ~ 5% | Not performed | [72] |

| 3% MMTNa: Increased ~ 20% | 3% MMT: Decreased ~ 19% | ||||

| 5% MMTNa: Increased ~ 15% | 5% MMT: Decreased ~ 14% | ||||

| 1% MMTNa + 0.5% REO: Increased ~ 18% | 1% MMTNa + 0.5%REO: Increased ~ 18% | ||||

| 3% MMTNa + 0.5% REO: Increased ~ 21% | 3% MMTNa + 0.5% REO: Increased ~ 21% | ||||

| 5% MMTNa + 0.5% REO: Increased ~ 37% | 5% MMTNa + 0.5% REO: Increased ~ 37% | ||||

| 1% and 2% (w/v) Ch (deacetylation degree of 75–85%); Glycerol 30% (w/w) of chitosan | Reflux-solution method | 1% Ch + 3% MMTNa: Increased ~ 3% | 1% Ch + 3% MMTNa: Decreased ~ 64% | 1% Ch + 3% MMTNa: Increased ~ 21% | [74] |

| 1% Ch + 5% MMTNa: Increased ~ 17% | 1% Ch + 5% MMTNa: Decreased ~ 38% | 1% Ch + 5% MMTNa: Increased ~ 35% | |||

| 1% Ch + 10%MMTNa: Increased ~ 19% | 1% Ch + 10% MMTNa: Decreased ~ 60% | 1% Ch + 10%MMTNa: Increased ~ 27% | |||

| 2% Ch + 3% MMTNa:Increased ~ 69% | 2% Ch + 3% MMTNa: Decreased ~ 61% | 2% Ch + 3% MMTNa:Increased ~ 100% | |||

| 2% Ch + 5% MMTNa: Increased ~ 22% | 2% Ch + 5% MMTNa: Decreased ~ 68% | 2% Ch + 5% MMTNa: Increased ~ 43% | |||

| 2% Ch + 10% MMTNa: Decreased ~ 1% | 2% Ch + 10% MMTNa: Decreased ~ 75% | 2% Ch + 10% MMTNa: Increased ~ 80% | |||

| 1% (w/v) Ch (deacetylation degree greater than 85%); Glycerol 30% (w/w) of chitosan | Mechanical stirring and ultrasonic homogenizer | 0.5% MMTNa: Decreased ~ 75% | 0.5% MMTNa: Increased ~ 20% | 0.5%MMTNa: Decreased ~ 98% | [42] |

| 1% MMTNa: Decreased ~ 57% | 1%MMTNa: Increased ~ 23% | 1%MMTNa: Decreased ~ 97% | |||

| 1.5% (w/v) Ch (deacetylation degree of 75%); Glycerol 30% (w/w) of chitosan | Rotor–stator homogenizer (Ultra-Turrax) and ultrasonic bath | 2.5% MMTNa: Increased ~ 82% | 2.5% MMTNa: Decreased ~ 52% | 2.5% MMTNa: Increased ~ 137% | [75] |

| 2.5% MMTCa: Increased ~ 70% | 2.5% MMTCa: Decreased ~ 65% | 2.5% MMTCa: Increased ~ 184% | |||

| 2.5% MMT20: Increased ~ 70% | 2.5% MMT20: Decreased ~ 23% | 2.5% MMT20: Increased ~ 110% | |||

| 1.5% (w/v) Ch (deacetylation degree of 75%); Glycerol 30% (w/w) of chitosan | Rotor–stator homogenizer (Ultra-Turrax) and ultrasonic homogenizer | 2.5% MMTNa + 0.5% GEO: Decreased ~ 10% | 2.5% MMTNa + 0,5% GEO: Increased ~ 25% | 2.5% MMTNa+0.5%GEO: Decreased ~ 37% | [25] |

| 2.5% MMTNa + 1% GEO: Decreased ~ 26% | 2.5% MMTNa + 1% GEO: Increased~ 85% | 2.5% MMTNa + 1% GEO: Decreased ~ 57% | |||

| 2.5% MMTNa+2%GEO: Decreased ~ 35% | 2.5% MMTNa + 2% GEO: Increased ~ 100% | 2.5% MMTNa + 2% GEO: Decreased ~ 77% | |||

| 2% (w/v) Ch (deacetylation degree of 75–85%) | Reflux-solution method | 5% MMTNa: Increased ~ 16% | 5% MMTNa: Decreased ~ 48% | 5% MMTNa: Increased ~ 20% | [76] |

| 5% OrgMMT: Increased ~ 14% | 5% OrgMMT: Decreased ~ 15% | 5% OrgMMT: Increased ~ 18% | |||

| 5% MMTNa + TO: Increased ~ 9% | 5% MMTNa + TO: Decreased ~ 19% | 5% MMTNa+TO: Increased ~ 2% | |||

| 5% OrgMMT + TO: Increased ~ 11% | 5% OrgMMT + TO: Decreased ~ 54% | 5% OrgMMT+TO: Increased ~ 6% |

| Formulation | Incorporation Method | Tensile Strength (Relatively to Control) | Elongation at Break (Relatively to Control) | Elastic Modulus (Relatively to Control) | Ref |

|---|---|---|---|---|---|

| 1% (w/v) Ch (deacetylation degree of 88%) | Rotor–stator homogenizer (Ultra-Turrax) | 1% CNC: Increased ~ 9% | 1% CNC: Decreased ~ 25% | 1% CNC: Increased ~ 43% | [91] |

| 3% CNC: Increased ~ 17% | 3% CNC: Decreased ~ 40% | 3% CNC: Increased ~ 60% | |||

| 5% CNC: Increased ~ 25% | 5% CNC: Decreased ~ 55% | 5% CNC: Increased ~ 87% | |||

| 10% CNC: Increased ~ 24% | 10% CNC: Decreased ~ 55% | 10% CNC: Increased ~ 80% | |||

| 2% (w/v) Ch (deacetylation degree not specified) | Mechanical stirring and ultrasonic homogenizer | Ch + 1% CNC: Increased ~ 1% | Ch + 1% CNC: Decreased ~ 33% | Ch + 1% CNC: Increased ~ 13% | [53] |

| Ch + 3% CNC: Decreased ~ 3% | Ch + 3% CNC: Decreased ~ 14% | Ch + 3% CNC: Increased ~ 47% | |||

| Ch + 5% CNC: Increased ~ 18% | Ch + 5% CNC: Increased ~ 24% | Ch + 5% CNC: Increased ~ 32% | |||

| Ch + 10% CNC: Increased ~ 8% | Ch + 10% CNC: Increased ~ 28% | Ch + 10% CNC: Increased ~ 2% | |||

| 1% (w/v) Ch (deacetylation degree of 98%) | Mechanical stirring and Silent Crusher-Heidolph homogenizer | Ch + 5% CNC: Increased ~ 9% | 5% CNC: Increased ~ 22% | Ch + 1% CNC: Increased ~ 7% | [84] |

| Ch + 10% CNC: Increased ~ 11% | 10% CNC: Decreased ~ 2% | Ch + 3% CNC: Increased ~ 22% | |||

| Ch + 20% CNC: Increased ~ 24% | 20% CNC: Decreased ~ 5% | Ch + 5% CNC: Increased ~ 140% | |||

| Ch + 30% CNC: Increased ~ 17% | 30% CNC: Increased ~ 1% | Ch + 10% CNC: Increased ~ 86% | |||

| 4% (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring and ultrasonic homogenizer | 1% CNC: Increased ~ 5% | 1% CNC: Decreased ~ 15% | Not Performed | [86] |

| 3% CNC: Increased ~ 30% | 3% CNC: Decreased ~ 20% | ||||

| 5% CNC: Increased ~ 71% | 5% CNC: Decreased ~ 20% | ||||

| 8% CNC: Increased ~ 52% | 8% CNC: Decreased ~ 35% | ||||

| 10% CNC: Increased ~ 46% | 10% CNC: Decreased ~ 40% | ||||

| 15% CNC: Increased ~ 23% | 15% CNC: Decreased ~ 50% | ||||

| 20% CNC: Increased ~ 13% | 20% CNC: Decreased ~ 65% | ||||

| 1% (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring and ultrasonic homogenizer | Ch + 2% CNC: Increased ~ 5% | Ch + 2% CNC: Decreased ~ 23% | Ch + 2%CNC: Increased ~ 39% | [54] |

| Ch + 4% CNC: Increased ~ 39% | Ch + 4% CNC: Decreased ~ 55% | Ch + 4%CNC: Increased ~ 79% | |||

| Ch + 6% CNC: Increased ~ 35% | Ch + 6% CNC: Decreased ~ 58% | Ch + 6%CNC: Increased ~ 72% | |||

| Ch + 8% CNC: Increased ~ 32% | Ch + 8% CNC: Decreased ~ 59% | Ch + 8% CNC: Increased ~ 69% | |||

| Not specified % (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring and ultrasonic homogenizer | Ch + 1% CNF: Increased ~ 10% | Ch + 1% CNF: Decreased ~ 8% | Ch + 1% CNF: Increased ~ 7% | [88] |

| Ch + 3% CNF: Increased ~ 22% | Ch + 3% CNF: Decreased ~ 18% | Ch + 3% CNF: Increased ~ 14% | |||

| Ch + 5% CNF: Increased ~ 31% | Ch + 5% CNF: Decreased ~ 28% | Ch + 5% CNF: Increased ~ 18% | |||

| Ch + 7% CNF: Increased ~ 25% | Ch + 7% CNF: Decreased ~ 22% | Ch + 7% CNF: Increased ~ 14% | |||

| 1% (w/v) Ch (deacetylation degree of 75–80%) | Mechanical stirring and ultrasonic homogenizer | Ch + 1%CNF: Increased ~ 31% | Ch + 1% CNF: Decreased ~ 10% | Ch + 1% CNF: Increased ~ 20% | [89] |

| Ch + 3%CNF: Increased ~ 87% | Ch + 3% CNF: Decreased ~ 15% | Ch + 3% CNF: Increased ~ 43% | |||

| Ch + 5% CNF: Increased ~ 126% | Ch + 5% CNF: Decreased ~ 19% | Ch + 5% CNF: Increased ~ 89% | |||

| Ch + 7% CNF: Increased ~ 92% | Ch + 7% CNF: Decreased ~ 37% | Ch + 7% CNF: Increased ~ 51% | |||

| 1% (w/v) Ch (deacetylation degree of 75%) | Mechanical stirring and ultrasonic homogenizer | Ch + 2% BCNC: Increased ~ 28% | Ch + 2% BCNC: Decreased ~ 12% | Ch + 2% BCNC: Increased ~ 95% | [57] |

| Ch + 4% BCNC: Increased ~ 96% | Ch + 4% BCNC: Decreased ~ 30% | Ch + 4% BCNC: Increased ~ 206% | |||

| Ch + 6% BCNC: Increased ~ 65% | Ch + 6% BCNC: Decreased ~ 26% | Ch + 6% BCNC: Increased ~ 119% |

| Formulation | Incorporation Method | Tensile Strength (Relatively to Control) | Elongation at Break (Relatively to Control) | Elastic Modulus (Relatively to Control) | Ref |

|---|---|---|---|---|---|

| 2% (w/v) Ch (deacetylation degree of 75–85%) | Mechanical stirring and ultrasonic homogenizer | 5% TiO2: Increased ~ 40% | 5% TiO2: Increased ~ 35% | Not Performed | [97] |

| 10% TiO2: Increased ~ 63% | 10% TiO2: Decreased ~ 6% | ||||

| 15% TiO2: Increased ~ 100% | 15% TiO2: Decreased ~ 10% | ||||

| 2.5% (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring | 0.25% TiO2: Increased ~ 90% | 0.25%TiO2: Increased ~ 70% | Not Performed | [96] |

| 2% (w/v) Ch (deacetylation degree of 85%) | Controlled-temperature water bath shaker and ultrasonic homogenizer | 0.25% TiO2: Increased ~ 10% | 0.25% TiO2: Decreased ~ 5–15% | Not Performed | [94] |

| 0.5% TiO2: Increased ~ 20% | 0.5% TiO2: Decreased ~ 5–15% | ||||

| 1% TiO2: Increased ~ 50% | 1% TiO2: Decreased ~ 5–15% | ||||

| 2% TiO2: Increased ~ 25% | 2% TiO2: Decreased ~ 5–15% | ||||

| 2% (w/v) Ch (deacetylation degree of 90%) | Mechanical stirring | 0.5% TiO2: Increased ~ 21% | 0.5% TiO2: Decreased ~ 9% | Not Performed | [101] |

| 0.5% TiO2 + BPPE: Increased ~ 61% | 0.5% TiO2+0.5 BPPE%: Increased ~ 6% | ||||

| 2.5% (w/v) Ch (deacetylation degree of 85%) | Mechanical stirring | 10% TiO2: Increased ~ 40% | 10% TiO2: Increased ~ 15% | Not Performed | [95] |

| 10% TiO2+APE: Increased ~ 70% | 10% TiO2+5%APE: Increased ~ 22% | ||||

| 1% (w/v) Ch (deacetylation degree of 85%) | Mechanical stirring and ultrasonic homogenizer | 1% ZnO: Increased ~ 83% | 1% ZnO: Increased ~ 138% | Not Performed | [99] |

| 2% ZnO: Increased ~ 78% | 2% ZnO: Increased ~ 62% | ||||

| 3% ZnO: Increased ~ 70% | 3% ZnO: Increased ~ 36% | ||||

| 4% ZnO: Increased ~ 68% | 4% ZnO: Decreased ~ 12% | ||||

| 5% ZnO: Increased ~ 54% | 5% ZnO: Decreased ~ 33% | ||||

| 6% ZnO: Increased ~ 24% | 6% ZnO: Decreased ~ 47% | ||||

| 7% ZnO: Increased ~ 19% | 7% ZnO: Decreased ~ 59% | ||||

| 10% ZnO: Increased ~ 16% | 10% ZnO: Decreased ~ 61% | ||||

| Not specified % (w/v) Ch (deacetylation degree unknown) | Mechanical stirring and ultrasonic homogenizer | 0.1% ZnO: Increased ~ 15% | 0.1% ZnO: Increased ~ 30% | Not Performed | [59] |

| 0.3% ZnO: Increased ~ 50% | 0.3% ZnO: Increased ~ 75% | ||||

| 0.5% ZnO: Increased ~ 70% | 0.5% ZnO: Increased ~ 90% | ||||

| 0.5% ZnO + NEO: Increased ~ 100% | 0.5% ZnO + NEO: Increased ~ 130% | ||||

| 2% (w/v) Ch (deacetylation degree of >75%) | Mechanical stirring | 1% ZnO: Increased ~ 32% | 1% ZnO: Decreased ~ 18% | 1% ZnO: Increased ~ 47% | [102] |

| 2% ZnO: Increased ~ 67% | 2% ZnO: Decreased ~ 57% | 2% ZnO: Increased ~ 81% | |||

| 2% (w/v) Ch (deacetylation degree of 85%) | Ultrasonic homogenizer | 0.5% ZnO: Increased ~ 103% | 0.5% ZnO: Decreased ~ 26% | Not Performed | [100] |

| 1% ZnO: Increased ~ 225% | 1% ZnO: Increased ~ 7% | ||||

| 1.5% ZnO: Increased ~ 182% | 1.5% ZnO: Decreased ~ 52% | ||||

| 2% ZnO: Increased ~ 122% | 2% ZnO: Decreased ~ 56% | ||||

| Not specified % (w/v) Ch (deacetylation degree of >75%) | Reflux-solution method | 3% ZnO: Decreased ~ 25% | 3% ZnO: Decreased ~ 3% | 3% ZnO: Decreased ~ 42% | [63] |

| 5% ZnO: Decreased ~ 20% | 5% ZnO: Increased ~ 35% | 5% ZnO: Decreased ~ 40% | |||

| 7% ZnO: Decreased ~ 15% | 7% ZnO: Increased ~ 65% | 7% ZnO: Decreased ~ 43% | |||

| 1% (w/v) Ch (deacetylation degree of 75%) | Mechanical stirring and ultrasonic homogenizer | 5% MgO: Increased ~ 86% | 5% MgO: Decreased ~ 13% | 5% MgO: Increased ~ 38% | [103] |

| 10% MgO: Increased ~ 26% | 10% MgO: Decreased ~ 25% | 10% MgO: Increased ~ 27% | |||

| 1% (w/v) CMCh (deacetylation degree of 90%) | Mechanical stirring and ultrasonic homogenizer | 0.5% MgO: Decreases ~ 30–35% | 0.5% MgO: Increased ~ 142% | 0.5% MgO: Increased ~ 24% | [104] |

| 1% MgO: Decreased ~ 10–15% | 1% MgO: Increased ~ 171% | 1% MgO: Increased ~ 88% |

| Formulation | Incorporation Method | Tensile Strength (Relatively to Control) | Elongation at Break (Relatively to Control) | Elastic Modulus (Relatively to Control) | Ref |

|---|---|---|---|---|---|

| 1% (w/v) Ch (deacetylation degree of 83%) | Rotor–stator homogenizer (Ultra-Turrax) and ultrasonic homogenizer | 0.2% MWCNT: Increased ~ 23% | 0.2% MWCNT: Decreased ~ 27% | 0.2% MWCNT: Increased ~ 49% | [106] |

| 0.4% MWCNT: Increased ~ 78% | 0.4% MWCNT: Decreased ~ 58% | 0.4% MWCNT: Increased ~ 94% | |||

| 0.8% MWCNT: Increased ~ 93% | 0.8% MWCNT: Decreased ~ 61% | 0.8% MWCNT: Increased ~ 99% | |||

| 2% MWCNT: Increased ~ 99% | 2% MWCNT: Decreased ~ 73% | 2% MWCNT: Increased ~ 97% | |||

| 3% (w/v) Ch (deacetylation degree of 85%) | Mechanical stirring | 0.1% MWCNT: Increased ~ 25% | 0.1% MWCNT: Increased ~ 45% | 0.1% MWCNT: Increased ~ 136% | [109] |

| 0.5% MWCNT: Increased ~ 59% | 0.5% MWCNT: Increased ~ 95% | 0.5% MWCNT: Increased ~ 288% | |||

| 1%MWCNT: Increased ~ 119% | 1% MWCNT: Increased ~ 150% | 1% MWCNT: Increased ~ 322% | |||

| 1.5%MWCNT: Increased ~ 162% | 1.5% MWCNT: Increased ~ 200% | 1.5%MWCNT: Increased ~ 384% | |||

| Not specified % (w/v) Ch (deacetylation degree of 75–85%) | Coating | 0.1% Raw-MWCNT: Increased ~ 2% | 0.1%Raw-MWCNT: Decreased ~ 6% | 0.1%Raw-MWCNT: Increased ~ 10% | [110] |

| 0.1% PHB–MWCNT: Increased ~ 42% | 0.1% PHB–MWCNT: Increased ~ 28% | 0.1% PHB–MWCNT: Increased ~ 24% | |||

| 2% (w/v) Ch (deacetylation degree of 75–85%) | Mechanical stirring and ultrasonic homogenizer | 0.1%MWCNT: Increased ~ 10% | 0.1% MWCNT: Decreased ~ 15% | 0.1% CNT: Increased ~ 10% | [111] |

| 0.5% MWCNT: Increased ~ 20% | 0.5% MWCNT: Decreased ~ 30% | 0.5% CNT: Increased ~ 40% | |||

| 0.5% MWCNT: Increased ~ 20% | 1% MWCNT: Decreased ~ 33% | 1% CNT: Increased ~ 47% | |||

| 1, 1.5, 2, and 2.5% (w/v) Ch (deacetylation degree of 75–85%) | Mechanical stirring and ultrasonic homogenizer | 1% Ch + 0.5% MWCNT: Increased ~ 44% | Not Performed | 1% Ch + 0.5% MWCNT: Increased ~ 19% | [112] |

| 1% Ch + 1% MWCNT: Increased ~ 31% | 1% Ch + 1% MWCNT: Increased ~ 5% | ||||

| 1.5% Ch + 0.5% MWCNT: Increased ~ 66% | 1.5% Ch + 0.5% MWCNT: Increased ~ 72% | ||||

| 1.5%Ch+1%MWCNT: Increased ~ 41% | 1.5% Ch + 1% MWCNT: Increased ~ 55% | ||||

| 2% Ch + 0.5% MWCNT: Increased ~ 113% | 2% Ch + 0.5% MWCNT: Increased ~ 143% | ||||

| 2% Ch + 1% MWCNT: Increased ~ 84% | 2% Ch + 1% MWCNT: Increased ~ 70% | ||||

| 2.5% Ch + 0.5% MWCNT: Increased ~ 176% | 2.5% Ch + 0.5% MWCNT: Increased ~ 195% | ||||

| 2.5% Ch + 1% MWCNT: Increased ~ 139% | 2.5% Ch + 1% MWCNT: Increased ~ 77% | ||||

| 2% (w/v) Ch (deacetylation degree of 92.5%) | Mechanical stirring and ultrasonic homogenizer | 1% MWCNT: Increased ~ 6% | 1% MWCNT: Increased ~ 57% | Not Performed | [113] |

| 2% MWCNT: Increased ~ 47% | 2% MWCNT: Increased ~ 70% | ||||

| 5% MWCNT: Increased ~ 17% | 5% MWCNT: Increased ~ 34% | ||||

| 10% MWCNT: Increased ~ 23% | 10% MWCNT: Increased ~ 53% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pires, J.; Paula, C.D.d.; Souza, V.G.L.; Fernando, A.L.; Coelhoso, I. Understanding the Barrier and Mechanical Behavior of Different Nanofillers in Chitosan Films for Food Packaging. Polymers 2021, 13, 721. https://doi.org/10.3390/polym13050721

Pires J, Paula CDd, Souza VGL, Fernando AL, Coelhoso I. Understanding the Barrier and Mechanical Behavior of Different Nanofillers in Chitosan Films for Food Packaging. Polymers. 2021; 13(5):721. https://doi.org/10.3390/polym13050721

Chicago/Turabian StylePires, João, Camila Damásio de Paula, Victor Gomes Lauriano Souza, Ana Luísa Fernando, and Isabel Coelhoso. 2021. "Understanding the Barrier and Mechanical Behavior of Different Nanofillers in Chitosan Films for Food Packaging" Polymers 13, no. 5: 721. https://doi.org/10.3390/polym13050721

APA StylePires, J., Paula, C. D. d., Souza, V. G. L., Fernando, A. L., & Coelhoso, I. (2021). Understanding the Barrier and Mechanical Behavior of Different Nanofillers in Chitosan Films for Food Packaging. Polymers, 13(5), 721. https://doi.org/10.3390/polym13050721