Electromagnetic Interference Shielding and Physical-Mechanical Characteristics of Rubber Composites Filled with Manganese-Zinc Ferrite and Carbon Black

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.2.1. Preparation and Curing of Rubber Compounds

2.2.2. Investigation of Physical-Mechanical Characteristics

2.2.3. Investigation of Shielding Characteristics

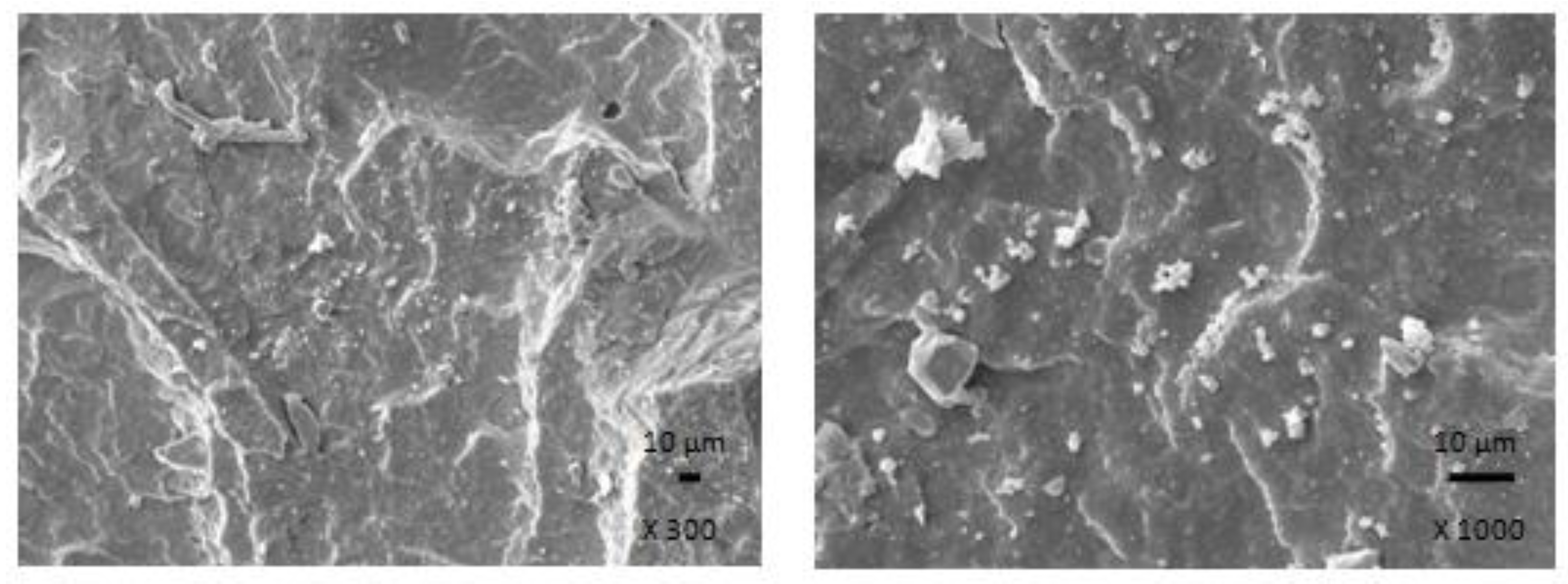

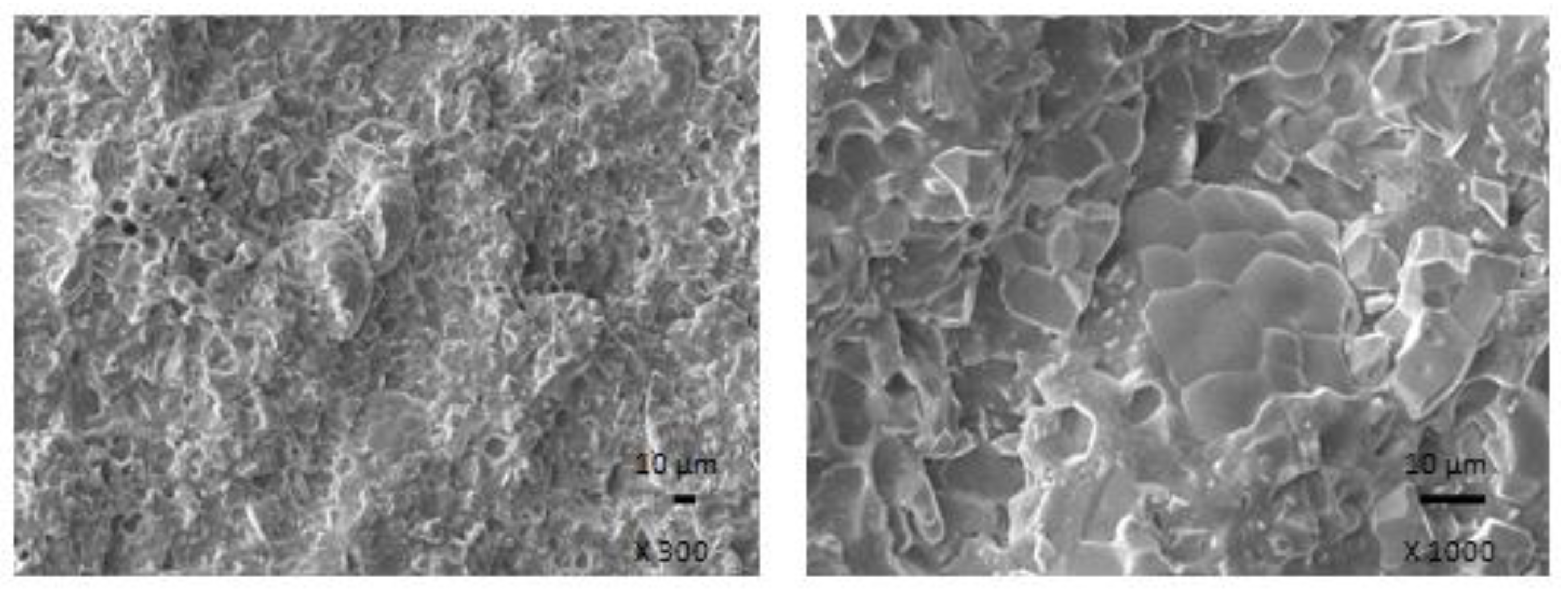

2.2.4. Microscopic Analysis

3. Results and Discussion

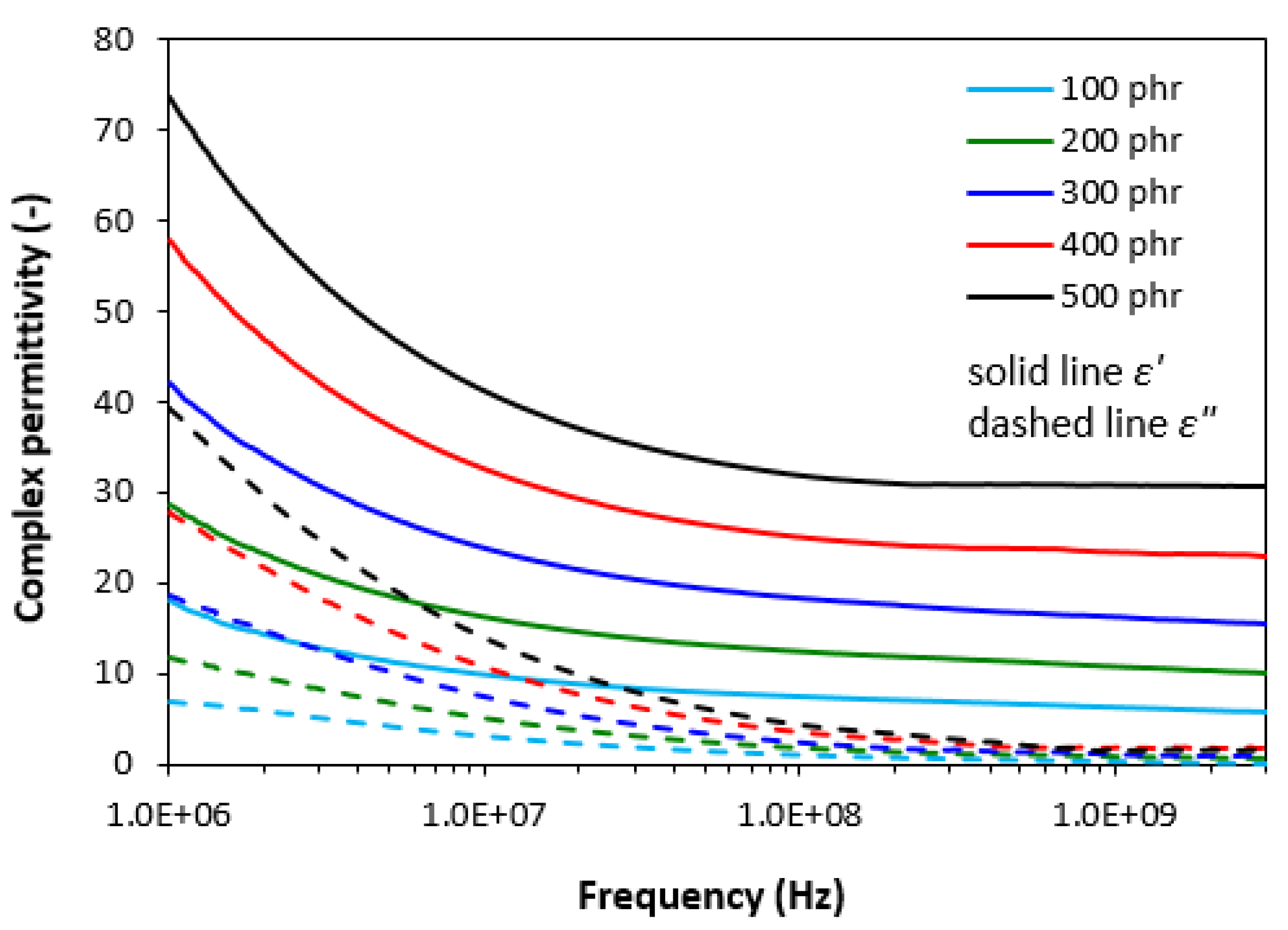

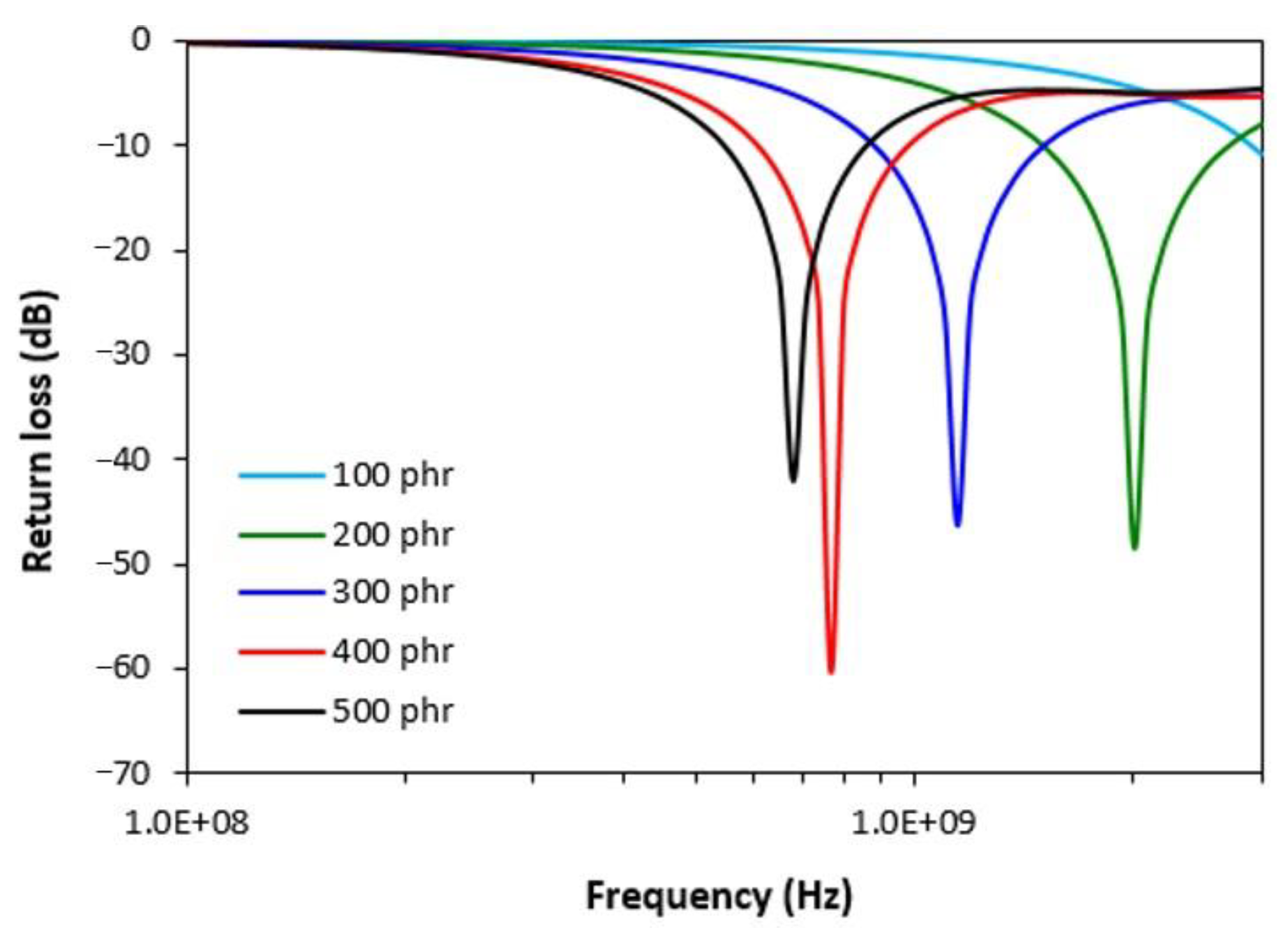

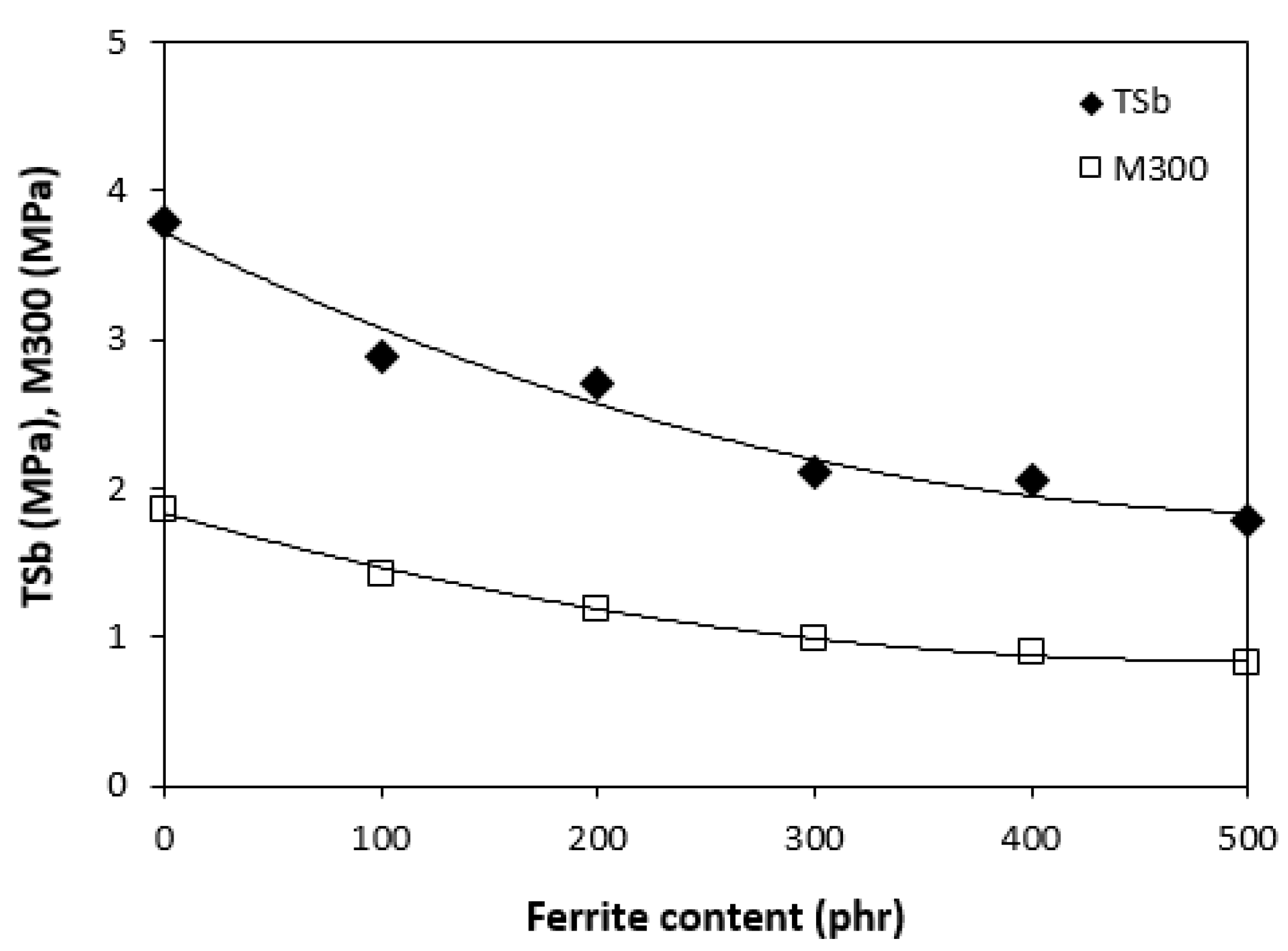

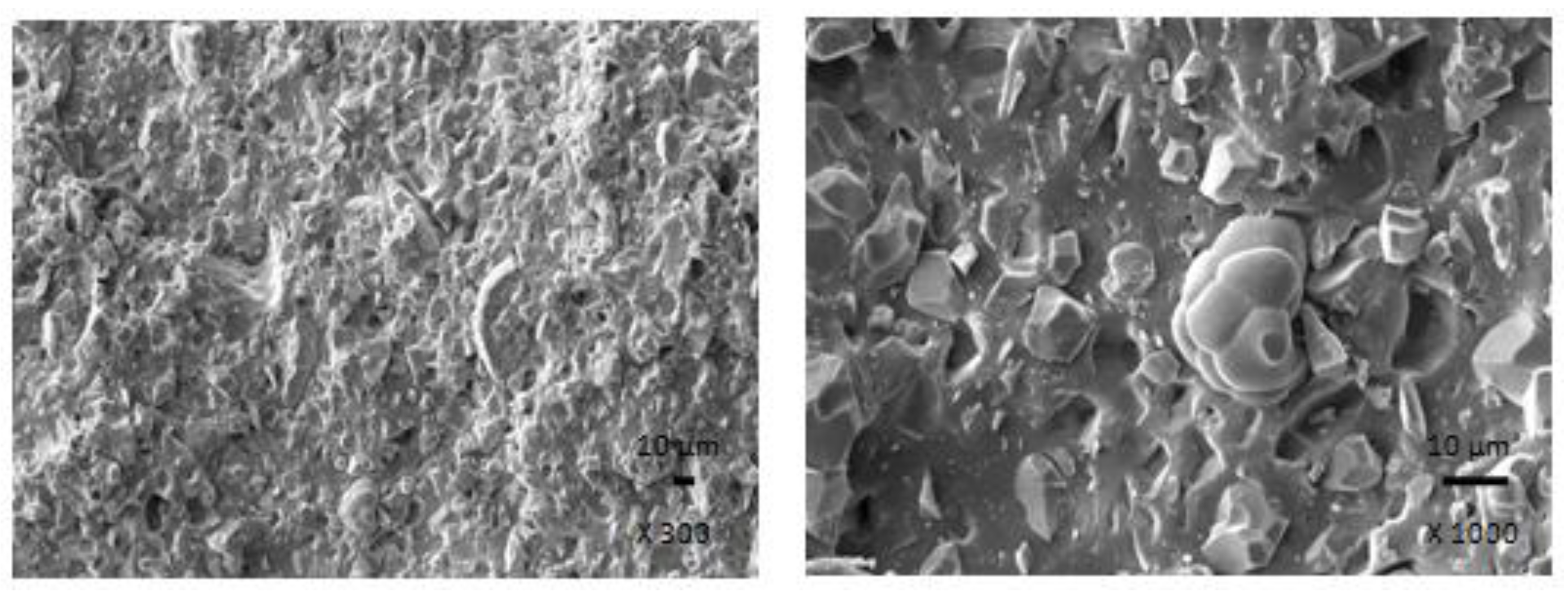

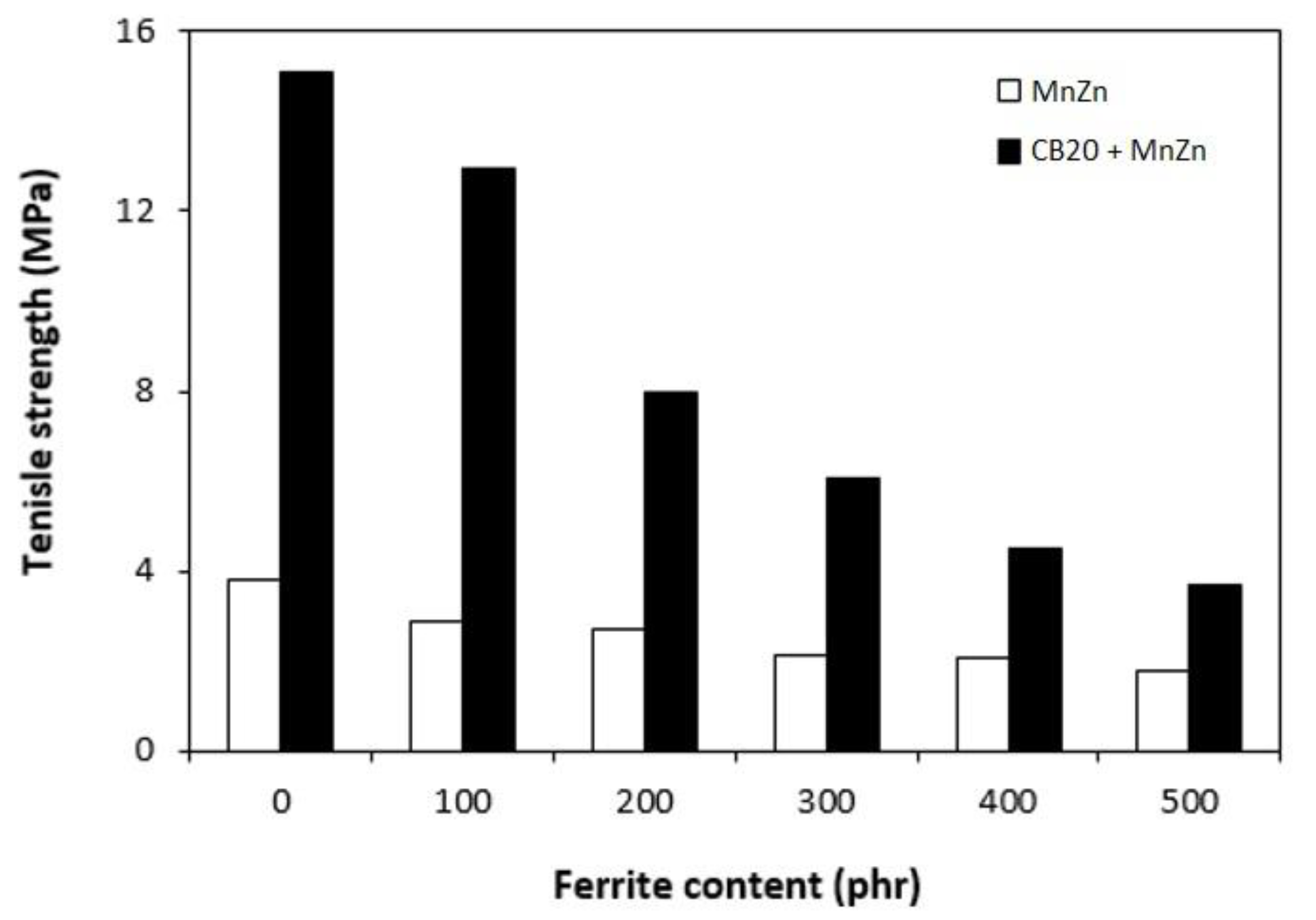

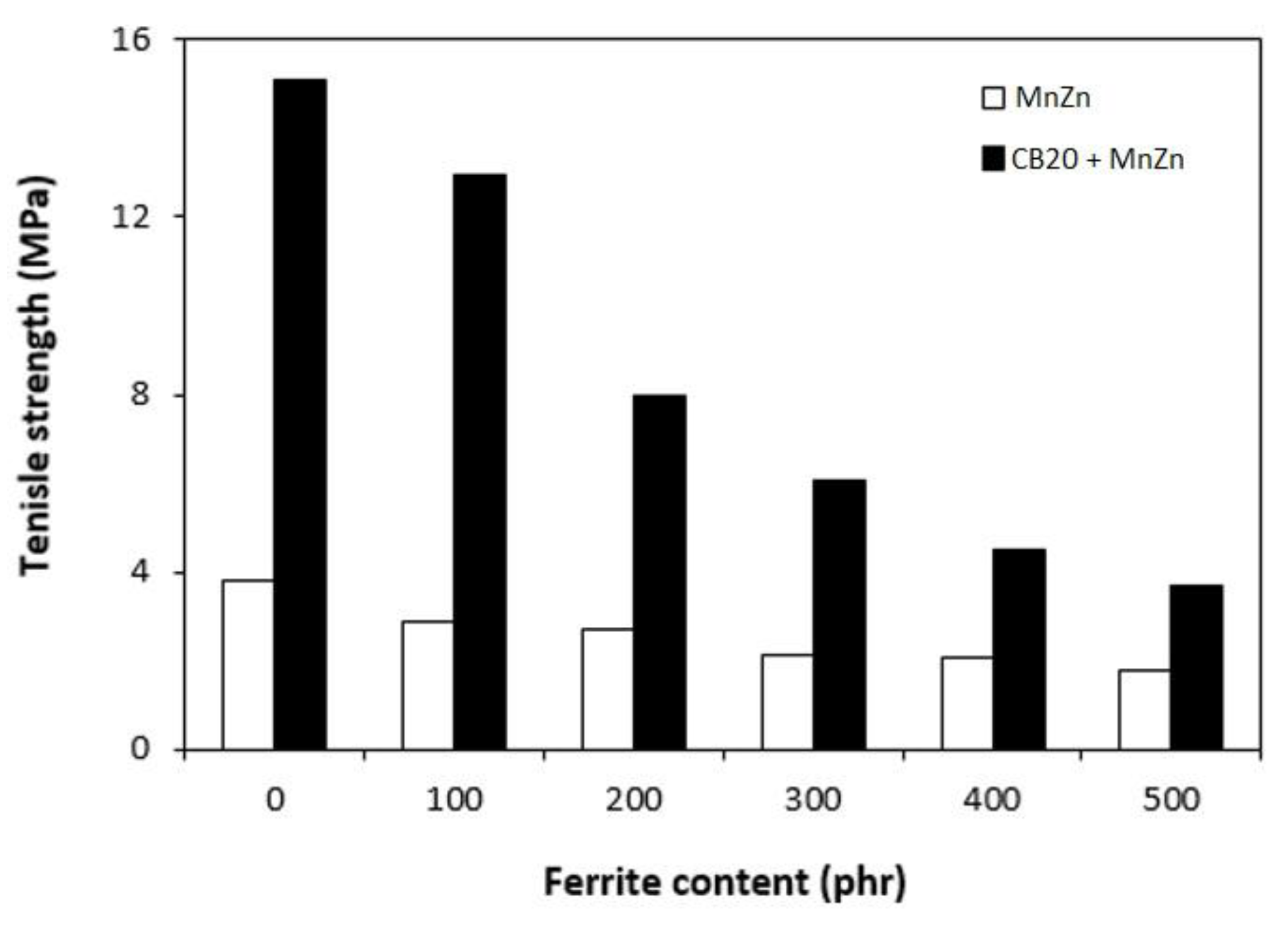

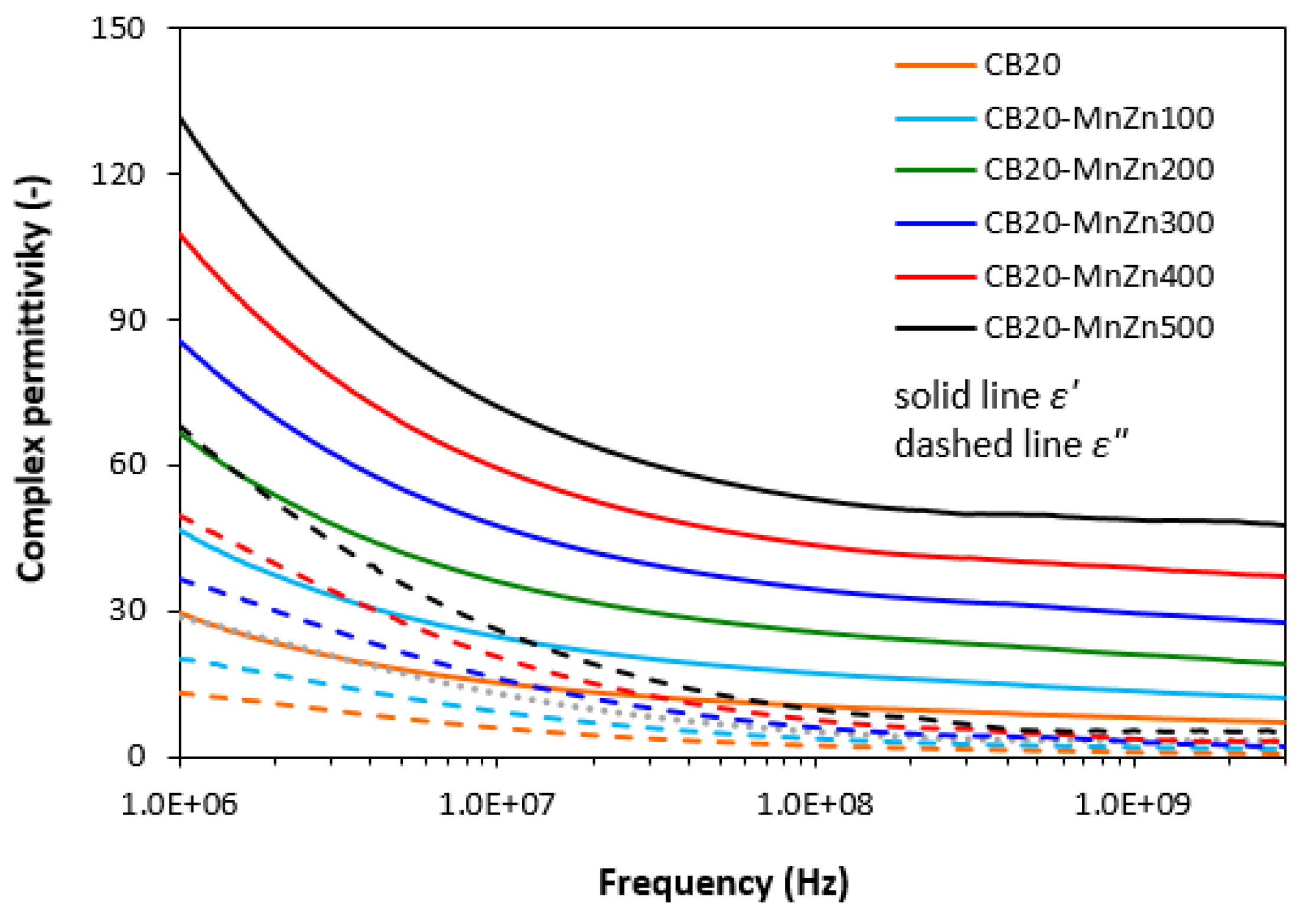

3.1. Influence of Ferrite on Physical-Mechanical and Shielding Characteristics of Composites

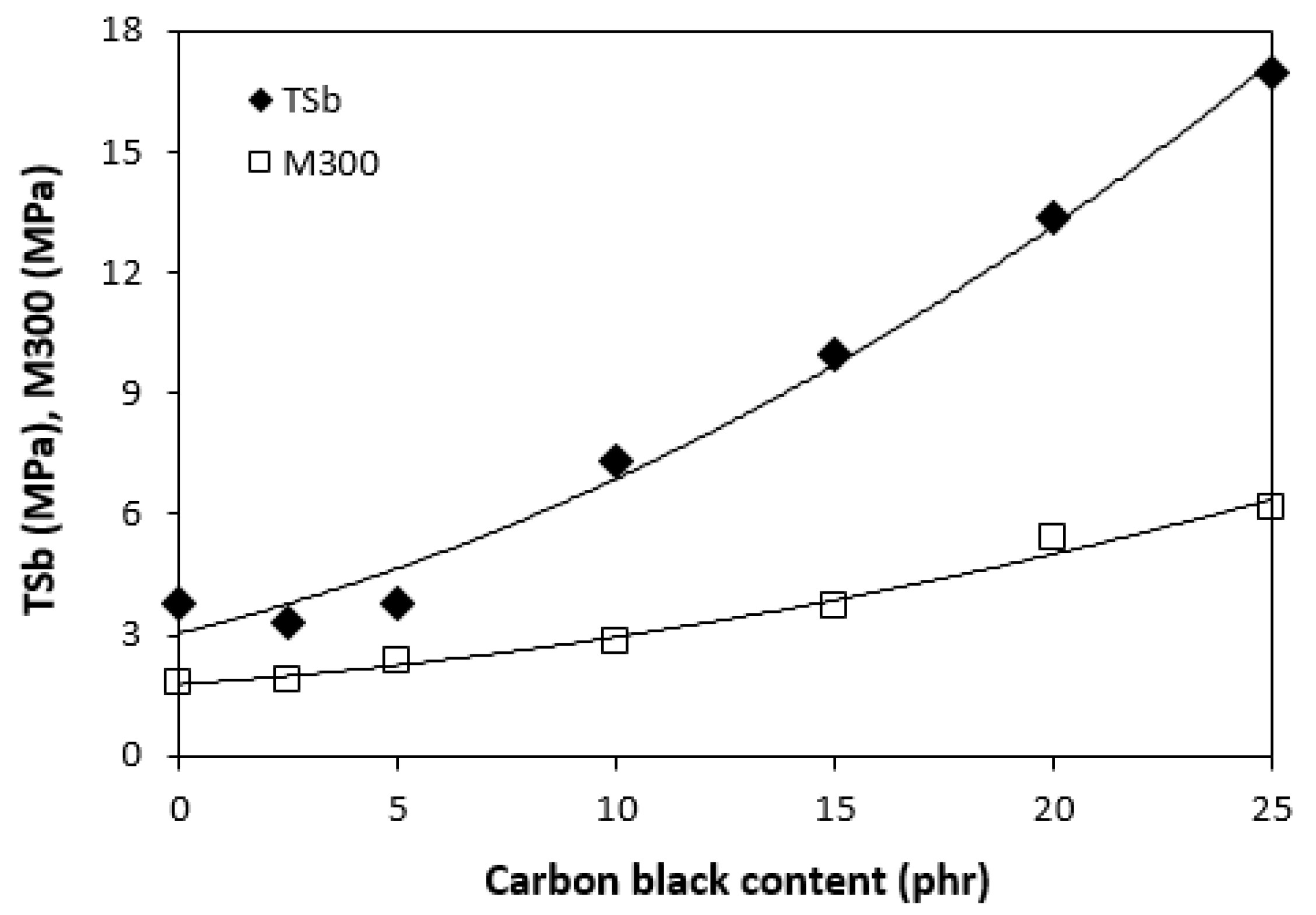

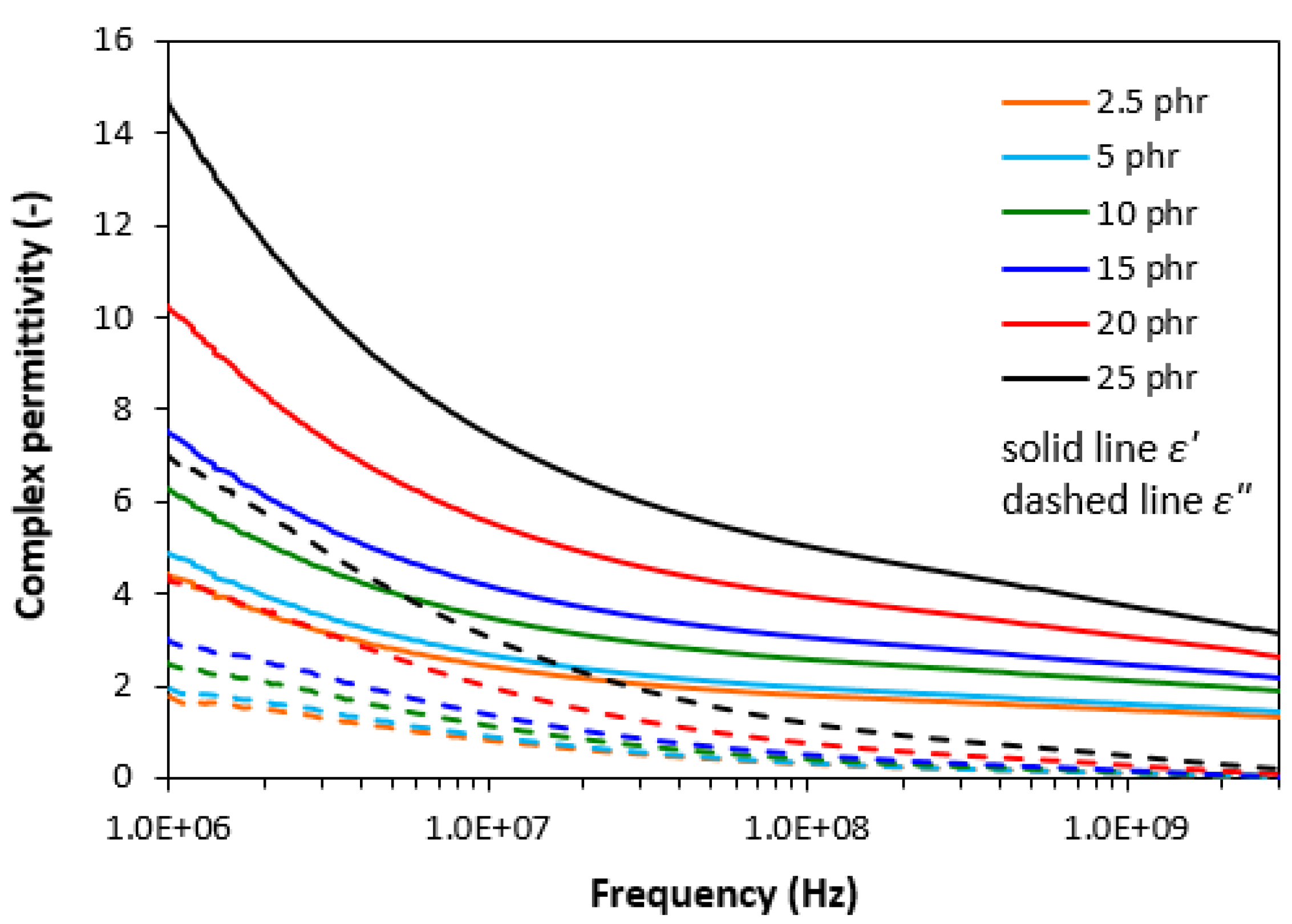

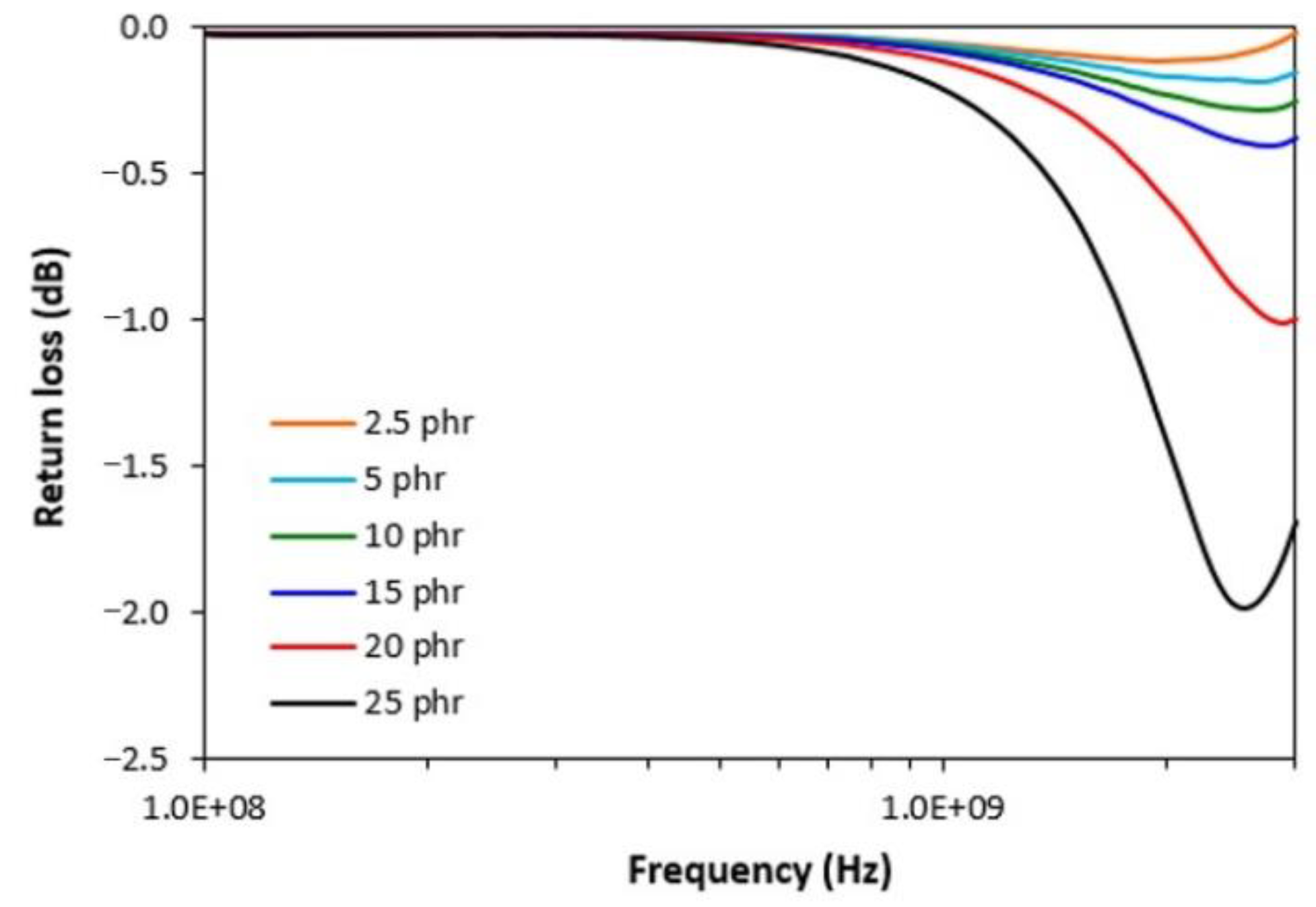

3.2. Influence of Carbon Black on Physical-Mechanical and Shielding Characteristics of Composites

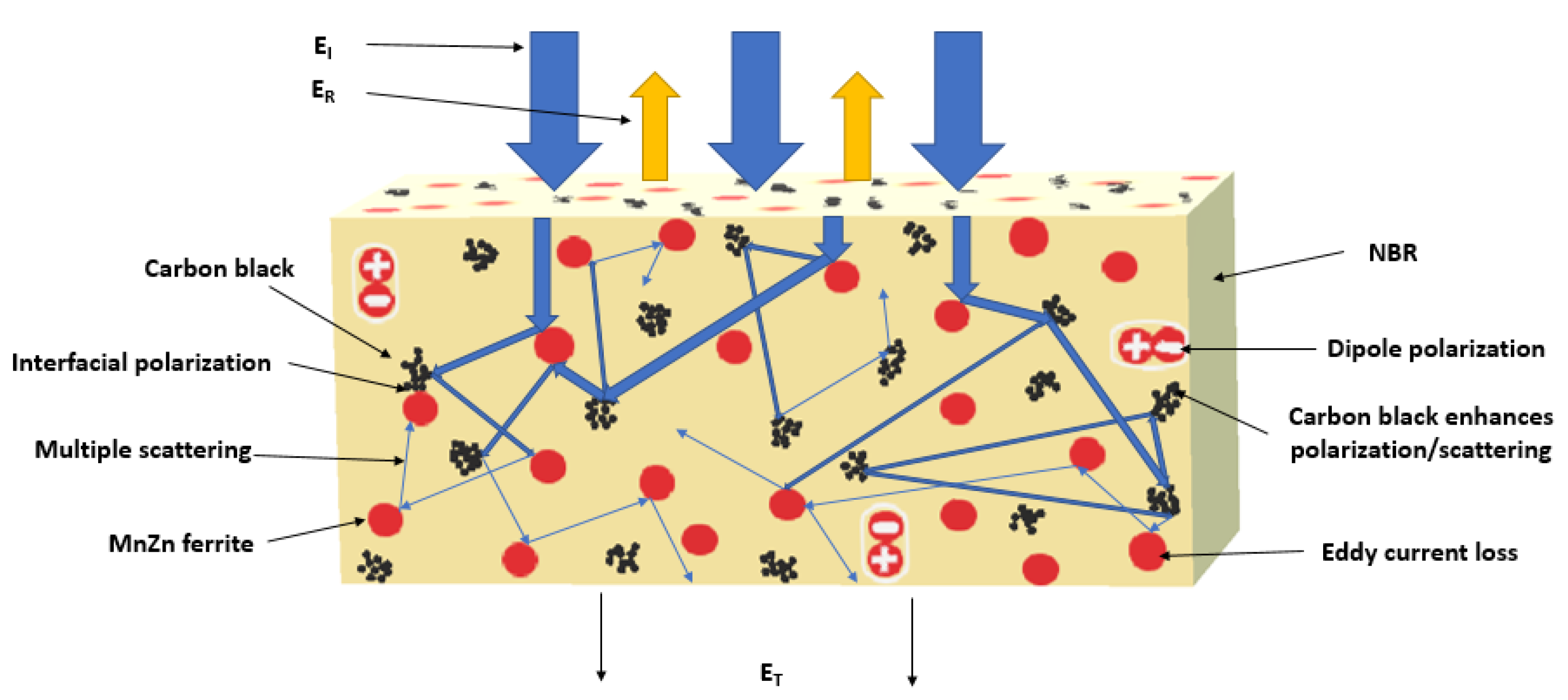

3.3. Influence of Combination of Carbon Black and Ferrite on Physical-Mechanical and Shielding Characteristics of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mathur, P.; Raman, S. Electromagnetic interference (EMI): Measurement and reduction techniques. J. Electron. Mater. 2020, 49, 2975–2998. [Google Scholar] [CrossRef]

- Driessen, S.; Napp, A.; Schmiedchen, K.; Kraus, T.; Stunder, D. Electromagnetic interference in cardiac electronic implants caused by novel electrical appliances emitting electromagnetic fields in the intermediate frequency range: A systematic review. Eurospace 2019, 21, 219–229. [Google Scholar] [CrossRef]

- Raagulan, K.; Braveenth, R.; Kim, B.M.; Lim, K.J.; Lee, S.B.; Kim, M.; Chai, K.Y. An effective utilization of MXene and its effect on electromagnetic interference shielding: Flexible, free-standing and thermally conductive composite from MXene-AT-poly (p-aminophenol)–polyaniline co-polymer. RSC Adv. 2020, 10, 1613–1633. [Google Scholar] [CrossRef]

- Leão, A.; Indrusiak, T.; Costa, M.F.; Soares, G.B. Exploring the potential use of clean scrap PVDF as matrix for conductive composites based on graphite, carbon black and hybrids: Electromagnetic interference shielding effectiveness (EMI SE). J. Polym. Environ. 2020, 28, 2091–2100. [Google Scholar] [CrossRef]

- Jaroszewski, M.; Thomas, S.; Rane, A.V. Advanced Materials for Electromagnetic Shielding: Fundamentals, Properties and Applications, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- do Amaral Junior, M.A.; Marcuzzo, J.S.; da Silva Pinheiro, B.; Lopes, B.H.K.; de Oliveira, A.P.S.; Matsushima, J.T.; Baldan, M.R. Study of reflection process for nickel coated activated carbon fiber felt applied with electromagnetic interference shielding. J. Mater. Res. Technol. 2019, 8, 4040–4047. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Huang, F.; Guo, Y.; Wang, Z.; Hui, D.; Zhou, Z. Graphene-based microwave absorbing composites: A review and prospective. Compos. Part B Eng. 2018, 137, 260–277. [Google Scholar] [CrossRef]

- Farida, E.; Bukit, N.; Ginting, E.M.; Bukit, B.F. The effect of carbon black composition in natural rubber compound. Case Stud. Therm. Eng. 2019, 16, 100566. [Google Scholar] [CrossRef]

- Gao, M.; Zheng, F.; Xu, J.; Zhang, S.; Bhosale, S.S.; Gu, J.; Hong, R. Surface modification of nano-sized carbon black for reinforcement of rubber. Nanotechnol. Rev. 2019, 8, 405–414. [Google Scholar] [CrossRef]

- Valenzuela, R. Novel applications of ferrites. Phys. Res. Int. 2012, 2012, 591839. [Google Scholar] [CrossRef]

- Ušák, E.; Ušáková, M.; Dosoudil, R.; Šoka, M.; Dobročka, E. Influence of iron substitution by selected rare-earth ions on the properties of NiZn ferrite fillers and PVC magneto-polymer composites. AIP Adv. 2018, 8, 047805. [Google Scholar] [CrossRef]

- Saqib, H.; Rahman, S.; Susilo, R.; Chen, B.; Dai, N. Structural, vibrational, electrical, and magnetic properties of mixed spinel ferrites Mg1-xZnxFe2O4 nanoparticles prepared by co-precipitation. AIP Adv. 2019, 9, 055306. [Google Scholar] [CrossRef]

- Ahmad, A.F.; Abbas, Z.; Aziz, S.A.; Obaiys, S.J.; Zainuddin, M.F. Synthesis and characterisation of nickel oxide reinforced with polycaprolactone composite for dielectric applications by controlling nickel oxide as a filler. Results Phys. 2018, 11, 427–435. [Google Scholar] [CrossRef]

- dos Santos Monteiro, E.; Kasal, R.B.; Moraes, N.C.; Mota de Melo, G.B.; dos Santos, J.C.A.; da Silva Figueired, A.B.H. Nanoparticles of Ni1-xZnxFe2O4 used as microwave absorbers in the X-band. Mater. Res. 2019, 22, e20190188. [Google Scholar] [CrossRef]

- Kasgoz, A. Quantifying dielectric and microwave absorption properties of barium titanate and strontium ferrite filled polymer composites. Polym. Polym. Compos. 2020. [Google Scholar] [CrossRef]

- Ravindren, R.; Mondal, S.; Bhawal, P.; Mohammad Nasim Ali, S.; Chandra Das, N. Superior electromagnetic interference shielding effectiveness and low percolation threshold through the preferential distribution of carbon black in the highly flexible polymer blend composites. Polym. Compos. 2019, 40, 1404–1418. [Google Scholar] [CrossRef]

- Liu, C.; Yu, C.; Sang, G.; Xu, P.; Ding, Y. Improvement in EMI shielding properties of silicone rubber/POE blends containing ILs modified with carbon black and MWCNTs. Appl. Sci. 2019, 9, 1774. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. X-band EMI shielding mechanisms and shielding effectiveness of high structure carbon black/polypropylene composites. J. Phys. D Appl. Phys. 2013, 46, 035304. [Google Scholar] [CrossRef]

- Jani, R.K.; Patra, M.K.; Saini, L.; Shukla, A.; Singh, C.P.; Vadera, S.R. Tuning of microwave absorption properties and electromagnetic interference (EMI) shielding effectiveness of nanosize conducting black-silicone rubber composites over 8–18 GHz. Prog. Electromagn. Res. 2017, 58, 193–204. [Google Scholar] [CrossRef]

- Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Hudec, I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Adv. 2021, 3, 123–172. [Google Scholar] [CrossRef]

- Li, Z.W.; Yang, Z.H. The studies of high-frequency magnetic properties and absorption characteristics for amorphous-filler composites. J. Magn. Magn. Mater. 2015, 391, 172–178. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Saadeh, W.H.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Zhu, J.; Gu, H.; Luo, Z.; Haldolaarachige, N.; Young, D.P.; Wei, S.; Guo, Z. Carbon nanostructure-derived polyaniline metacomposites: Electrical, dielectric, and giant magnetoresistive properties. Langmuir 2012, 28, 10246–10255. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhang, L.; Natsuki, T.; Fu, Y.Q.; Ni, Q.Q. Facile synthesis of BaTiO3 nanotubes and their microwave absorption properties. ACS Appl. Mater. Interfaces 2012, 4, 2101–2106. [Google Scholar] [CrossRef] [PubMed]

- Gupta, T.K.; Singh, B.P.; Singh, V.N.; Teotia, S.; Singh, A.P.; Elizabeth, I.; Dhakate, S.R.; Dhawan, S.K.; Mathur, R.B. MnO2 decorated graphene nanoribbons with superior permittivity and excellent microwave shielding properties. J. Mater. Chem. A 2014, 2, 4256–4263. [Google Scholar] [CrossRef]

- Yadav, R.S.; Kuřitka, I.; Vilcakova, J.; Machovsky, M.; Skoda, D.; Urbánek, P.; Masař, M.; Jurča, M.; Urbánek, M.; Kalina, L.; et al. NiFe2O4 nanoparticles synthesized by dextrin from corn-mediated sol−gel combustion method and its polypropylene nanocomposites engineered with reduced graphene oxide for the reduction of electromagnetic pollution. ACS Omega 2019, 4, 22069–22081. [Google Scholar] [CrossRef] [PubMed]

- Wang, X. Investigation of electromagnetic shielding effectiveness of nanostructural carbon black/ABS composites. J. Electromagn. Anal. Appl. 2011, 3, 160–164. [Google Scholar] [CrossRef]

- Paul, R.P. Introduction to Electromagnetic Compatibility, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

| Characteristics | Values |

|---|---|

| Particle size (µm) | 0.1–30 |

| Specific surface area (m2/g) | 10.99 |

| Total porosity (%) | 59.72 |

| Density (g/cm3) | 4.87 |

| Electrical resistivity (Ω∙m) | 3 |

| Component | NBR | ZnO | Stearic Acid | CBS | Sulfur | Ferrite |

|---|---|---|---|---|---|---|

| Content (phr) | 100 | 3 | 2 | 1.5 | 1.5 | 0–500 |

| Component | NBR | ZnO | Stearic Acid | CBS | Sulfur | CB |

|---|---|---|---|---|---|---|

| Content (phr) | 100 | 3 | 2 | 1.5 | 1.5 | 0–25 |

| Component | NBR | ZnO | Stearic Acid | CBS | Sulfur | CB | Ferrite |

|---|---|---|---|---|---|---|---|

| Content (phr) | 100 | 3 | 2 | 1.5 | 1.5 | 20 | 0–500 |

| Content of Ferrite (phr) | RLmin (dB) | fm (MHz) | Δf (MHz) for RL at −10 dB | Δf (MHz) for RL at −20 dB |

|---|---|---|---|---|

| 100 | — | — | — | — |

| 200 | −48 | 2010 | 1220 | 370 |

| 300 | −46 | 1148 | 630 | 188 |

| 400 | −60 | 769 | 380 | 115 |

| 500 | −42 | 682 | 310 | 103 |

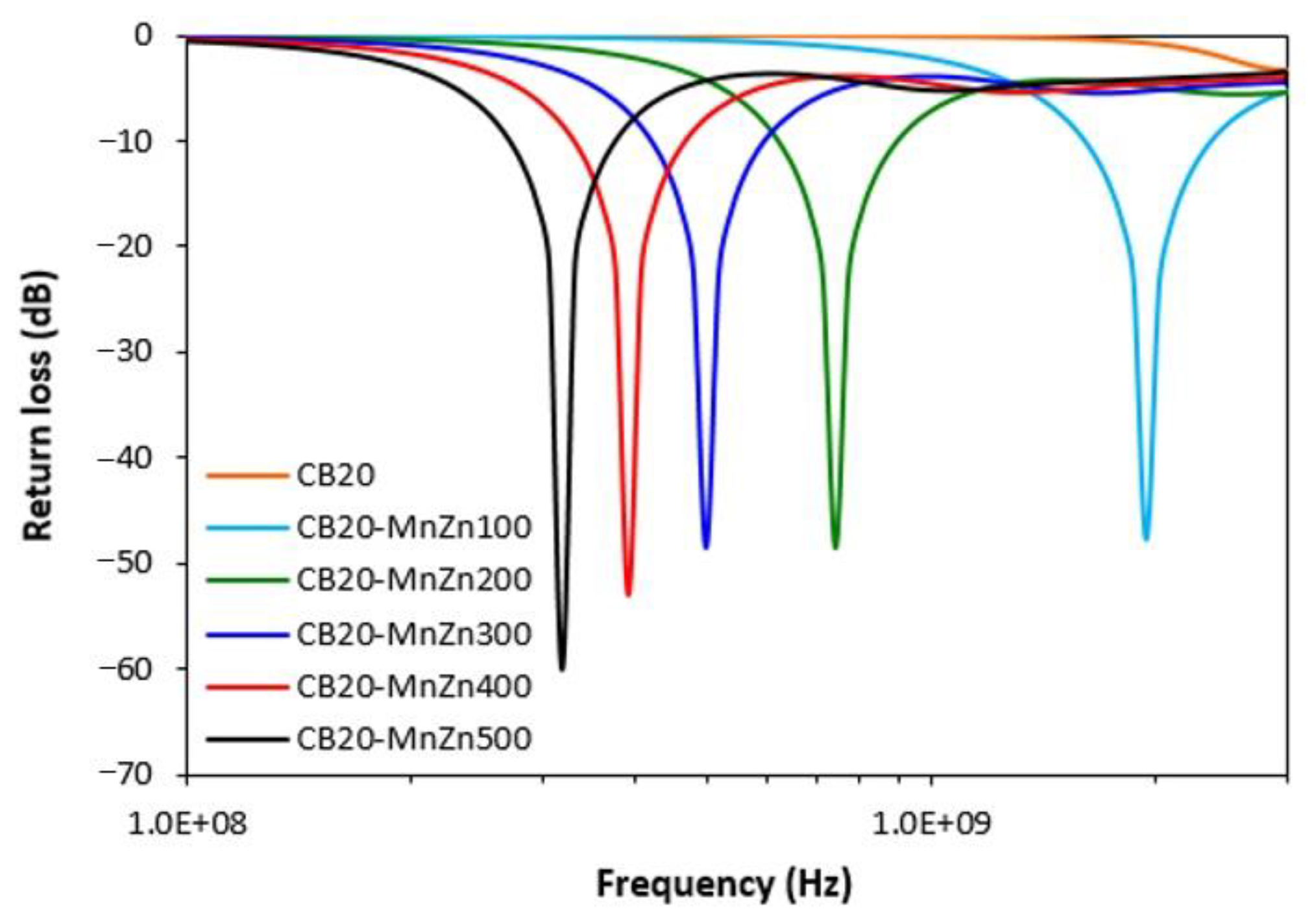

| Content of Ferrite (phr) | RLmin (dB) | fm (MHz) | Δf (MHz) for RL at −10 dB | Δf (MHz) for RL at −20 dB |

|---|---|---|---|---|

| 100 | −48 | 1931 | 750 | 158 |

| 200 | −49 | 739 | 270 | 73 |

| 300 | −49 | 495 | 170 | 54 |

| 400 | −53 | 390 | 140 | 42 |

| 500 | −60 | 319 | 110 | 21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Dosoudil, R.; Gořalík, M.; Hudec, I. Electromagnetic Interference Shielding and Physical-Mechanical Characteristics of Rubber Composites Filled with Manganese-Zinc Ferrite and Carbon Black. Polymers 2021, 13, 616. https://doi.org/10.3390/polym13040616

Kruželák J, Kvasničáková A, Hložeková K, Dosoudil R, Gořalík M, Hudec I. Electromagnetic Interference Shielding and Physical-Mechanical Characteristics of Rubber Composites Filled with Manganese-Zinc Ferrite and Carbon Black. Polymers. 2021; 13(4):616. https://doi.org/10.3390/polym13040616

Chicago/Turabian StyleKruželák, Ján, Andrea Kvasničáková, Klaudia Hložeková, Rastislav Dosoudil, Marek Gořalík, and Ivan Hudec. 2021. "Electromagnetic Interference Shielding and Physical-Mechanical Characteristics of Rubber Composites Filled with Manganese-Zinc Ferrite and Carbon Black" Polymers 13, no. 4: 616. https://doi.org/10.3390/polym13040616

APA StyleKruželák, J., Kvasničáková, A., Hložeková, K., Dosoudil, R., Gořalík, M., & Hudec, I. (2021). Electromagnetic Interference Shielding and Physical-Mechanical Characteristics of Rubber Composites Filled with Manganese-Zinc Ferrite and Carbon Black. Polymers, 13(4), 616. https://doi.org/10.3390/polym13040616