Experimental Study on the Thermoplastic Dripping and Flame Spread Behaviors of Energized Electrical Wire under Reduced Atmospheric Pressure

Abstract

1. Introduction

2. Experimental Methodology

3. Results and Discussion

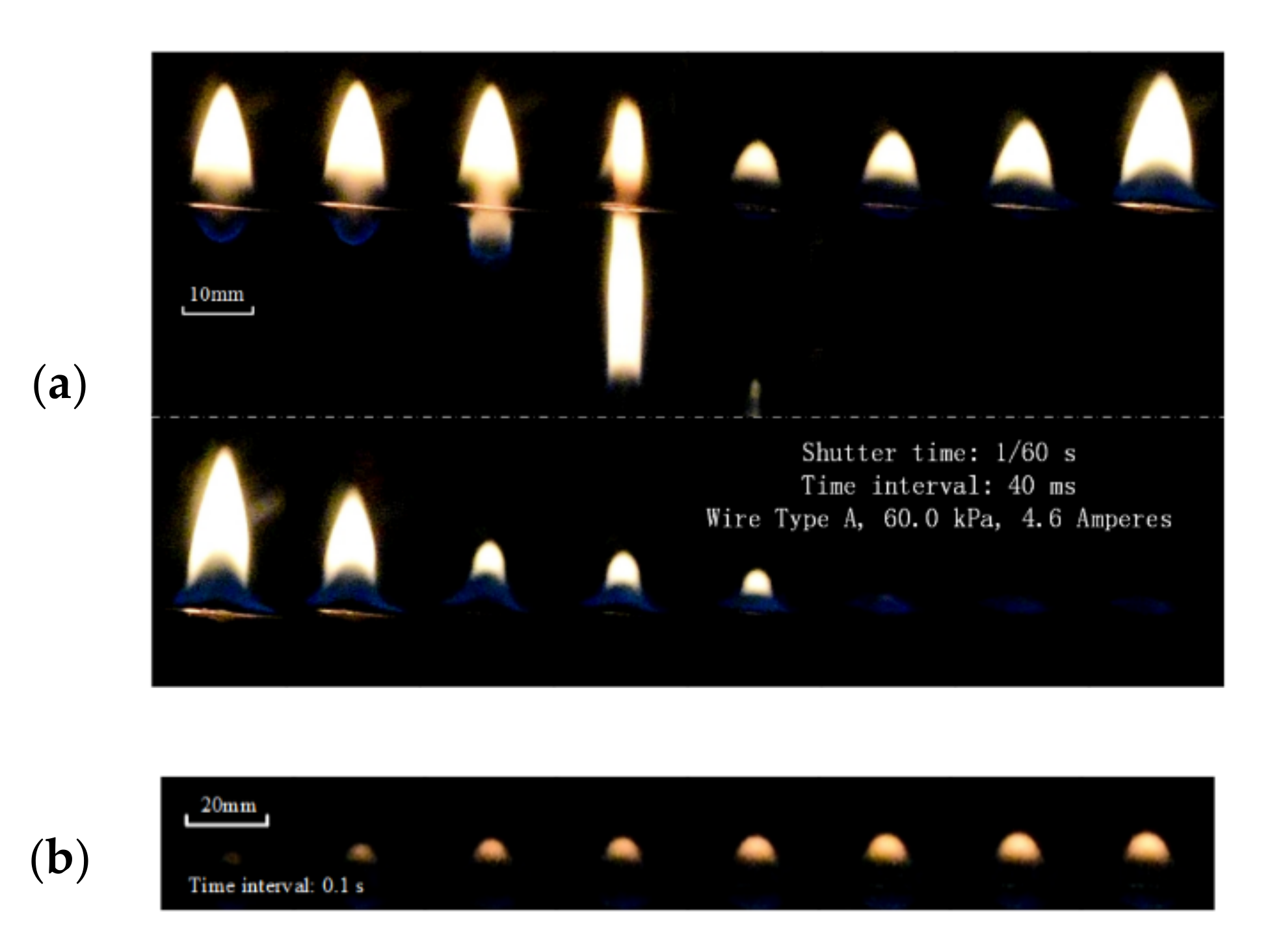

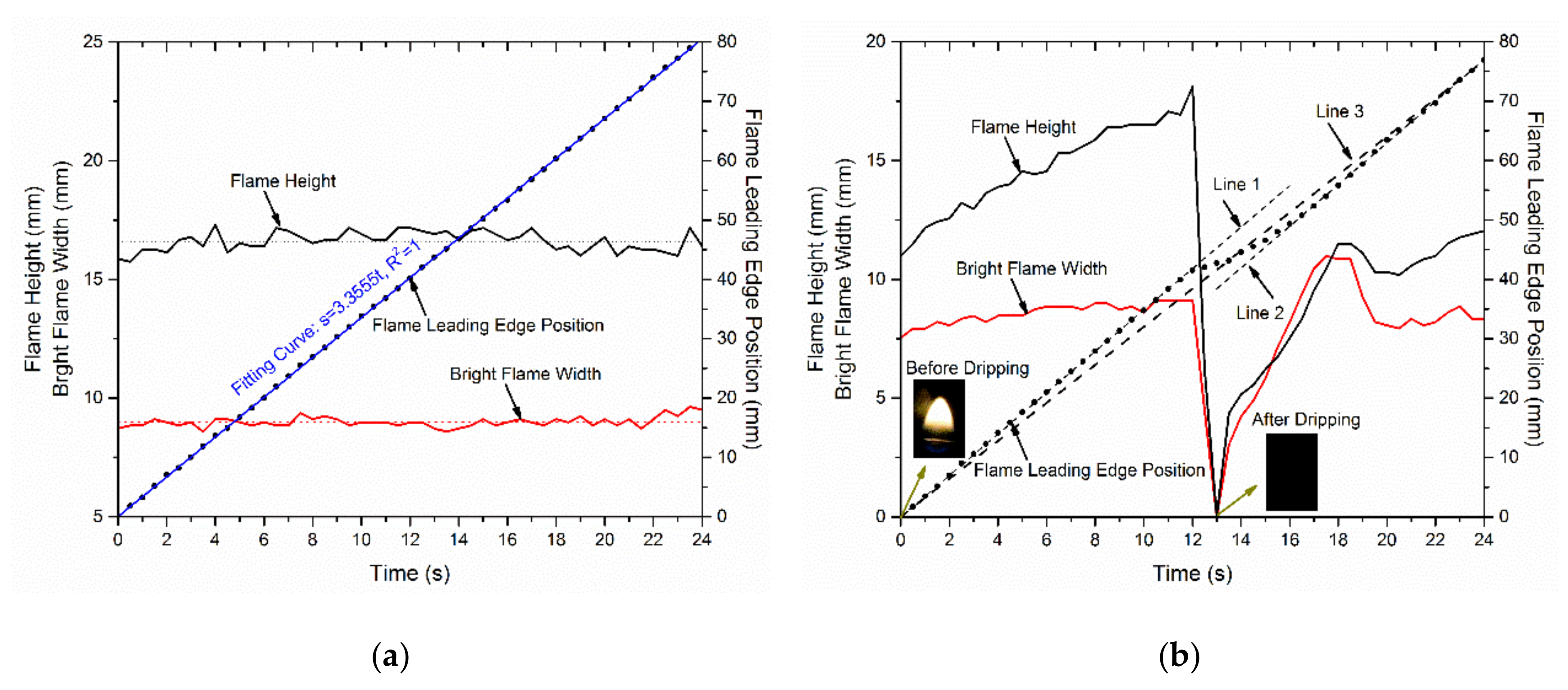

3.1. Flame Spread Rate (FSR)

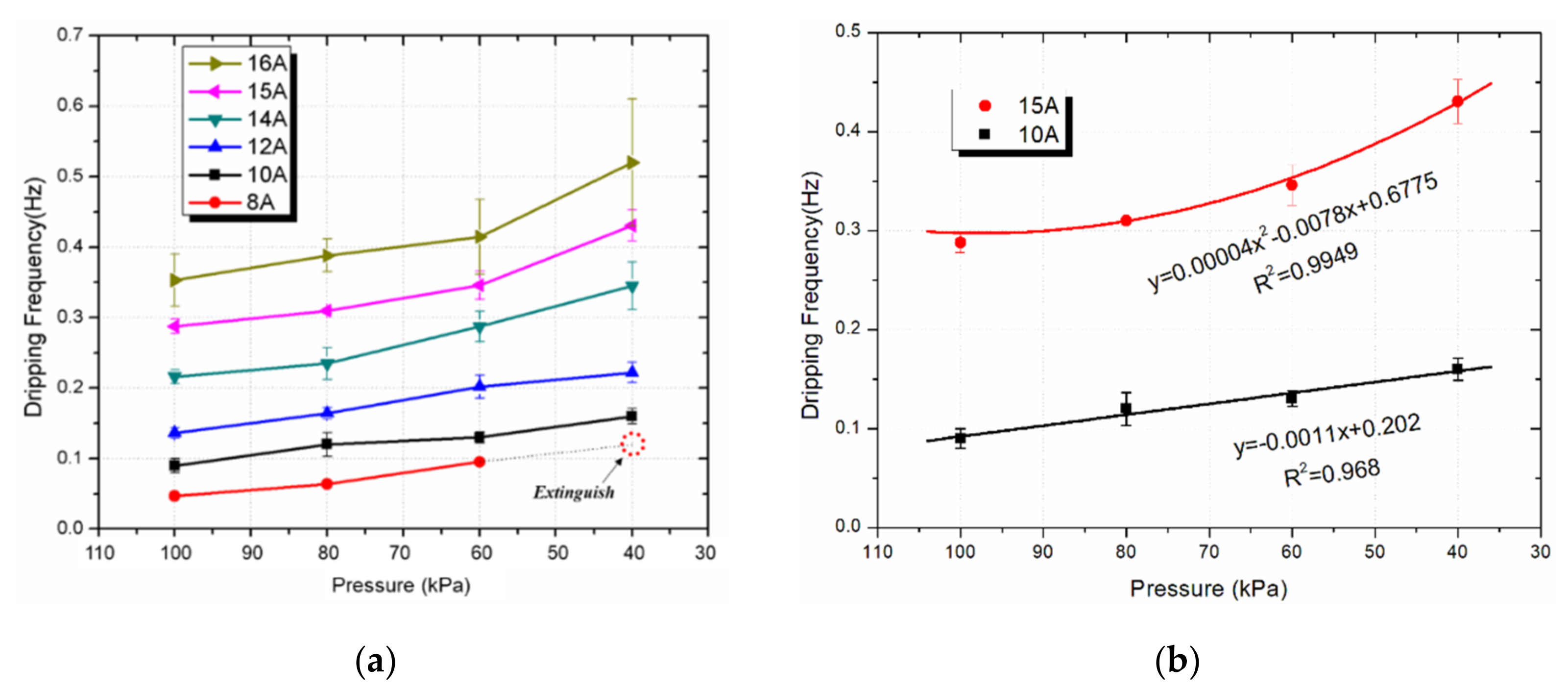

3.2. Dripping Frequency

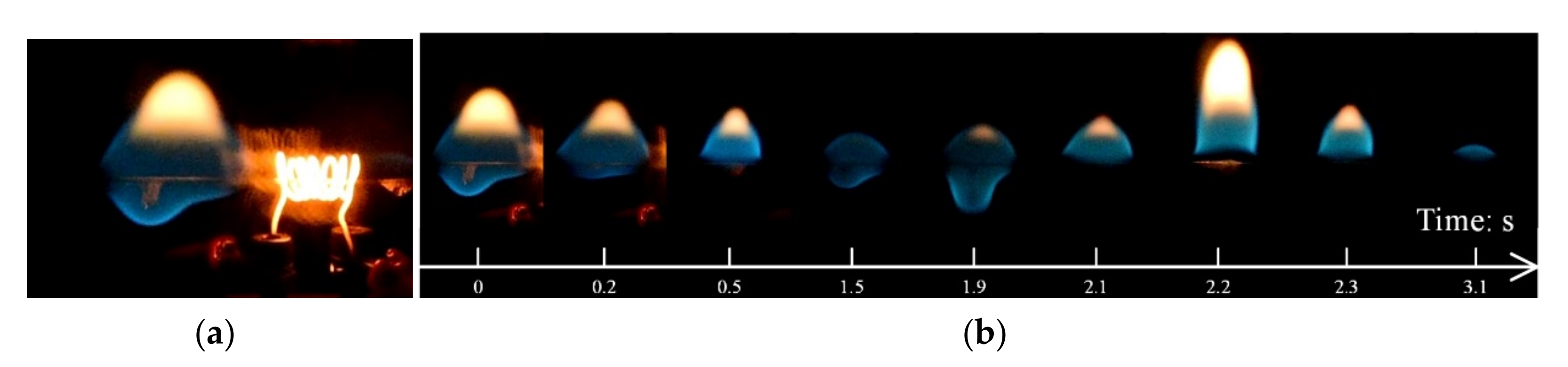

3.3. Flame Extinction Induced by Molten Dripping Behavior

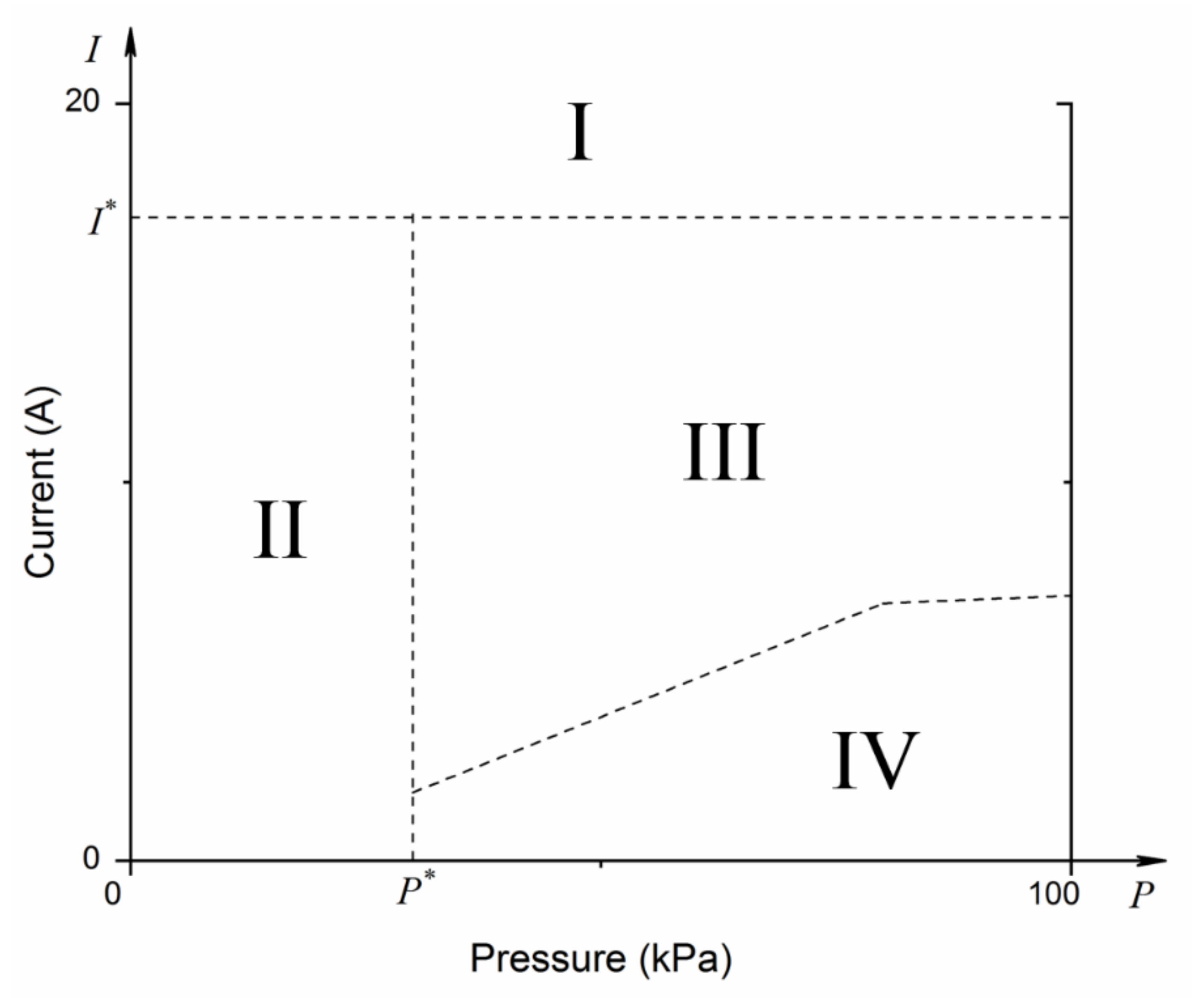

3.4. Critical Dripping Point

4. Conclusions

- It was known from experiments that the dripping frequency increased under lower ambient pressure, showing different trends under various electrical currents. Under a larger current, it increased more rapidly and the growth rate shows a transition from linear to power functions. The flame spread could be hardly sustained as the occurrence of dripping under reduced pressure;

- A unique phenomenon for wire fire is observed due to the dripping behavior at reduced pressure. When the fire was spreading along the wire, the bright flame disappeared for several seconds during the dripping and then showed again. While at atmospheric pressure of 20.0 kPa or below, the wire flame was extinguished after the occurrence of the dripping;

- When the pressure kept decreasing, the required electrical current to activate the dripping phenomenon was decreasing. The decreasing trend for the critical dripping point was nonlinear along with the pressure. The critical current changed smoothly during 100–80.0 kPa and decreased rapidly at 80.0–60.0 kPa. Additionally, the dripping phenomenon could stop or delay the flame spread, partly because of the short-term flame disappearance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| cross-sectional area (m2) | |

| dripping frequency (Hz) | |

| current (A) | |

| rated current (A) | |

| mass variation rate (g/s) | |

| ambient pressure (kPa) | |

| resistance per unit length (Ω/m) | |

| volume (m3) | |

| flame spread rate (mm/s) | |

| density (g/mm3) | |

| Subscripts | |

| critical dripping point | |

| insulation (polyethylene) | |

| gas | |

| flame | |

| limitation | |

| molten insulation |

References

- Kaseem, M.; Hamad, K.; Deri, F.; Ko, Y.G. Material properties of polyethylene/wood composites: A review of recent works. Polym. Sci. Ser. A 2015, 57, 689–703. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Park, J.H.; Ko, Y.G. Rheological properties of ABS/wood composites. Eur. J. Wood Wood Prod. 2015, 73, 701–703. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, K.; Liu, Z.; Chen, Y. Experimental study on thermal and fire behaviors of energized PE-insulated wires under overload currents. J. Therm. Anal. Calorim. 2020, 1–7. [Google Scholar] [CrossRef]

- Huang, X.; Nakamura, Y. A Review of Fundamental Combustion Phenomena in Wire Fires. Fire Technol. 2020, 56, 315–360. [Google Scholar] [CrossRef]

- Hu, L.; Zhang, Y.; Yoshioka, K.; Izumo, H.; Fujita, O. Flame spread over electric wire with high thermal conductivity metal core at different inclinations. Proc. Combust. Inst. 2015, 35, 2607–2614. [Google Scholar] [CrossRef]

- Lim, S.J.; Kim, M.; Park, J.; Fujita, O.; Chung, S.-H. Flame spread over electrical wire with AC electric fields: Internal circulation, fuel vapor-jet, spread rate acceleration, and molten insulator dripping. Combust. Flame 2015, 162, 1167–1175. [Google Scholar] [CrossRef]

- Miyamoto, K.; Huang, X.; Hashimoto, N.; Fujita, O.; Fernandez-Pello, C. Limiting oxygen concentration (LOC) of burning polyethylene insulated wires under external radiation. Fire Saf. J. 2016, 86, 32–40. [Google Scholar] [CrossRef]

- Osorio, A.F.; Mizutani, K.; Fernandez-Pello, C.; Gujita, O. Microgravity flammability limits of ETFE insulated wires exposed to external radiation. Proc. Combust. Inst. 2015, 35, 2683–3689. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, J.; Chen, X.; Lu, S. Pressure effect on flame spread over polyethylene-insulated copper core wire. Appl. Therm. Eng. 2017, 123, 1042–1049. [Google Scholar] [CrossRef]

- Nakamura, Y.; Yoshimura, N.; Ito, H.; Azumaya, K.; Fujita, O. Flame spread over electric wire in sub-atmospheric pressure. Proc. Combust. Inst. 2009, 32, 2559–2566. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, K.; Lu, Y.; Zhang, X. An experimental study on flame spread over electrical wire with high conductivity copper core and controlling heat transfer mechanism under sub-atmospheric pressures. Int. J. Therm. Sci. 2019, 141, 141–149. [Google Scholar] [CrossRef]

- Kong, W.; Wang, B.; Zhang, W.; Ai, Y.; Lao, S. Study on Prefire Phenomena of Wire Insulation at Microgravity. Microgravity Sci. Technol. 2008, 20, 107–113. [Google Scholar] [CrossRef]

- Takahashi, S.; Takeuchi, H.; Ito, H.; Nakamura, Y.; Fujita, O. Study on unsteady molten insulation volume change during flame spreading over wire insulation in microgravity. Proc. Combust. Inst. 2013, 34, 2657–2664. [Google Scholar] [CrossRef]

- Fujita, O. Solid combustion research in microgravity as a basis of fire safety in space. Proc. Combust. Inst. 2015, 35, 2487–2502. [Google Scholar] [CrossRef]

- Nagachi, M.; Mitsui, F.; Citerne, J.-M.; Dutilleul, H.; Guibaud, A.; Jomaas, G.; Legros, G.; Hashimoto, N.; Fujita, O. Can a spreading flame over electric wire insulation in concurrent flow achieve steady propagation in microgravity? Proc. Combust. Inst. 2018, 37, 4155–4162. [Google Scholar] [CrossRef]

- Fujita, O.; Kyono, T.; Kido, Y.; Ito, H.; Nakamura, Y. Ignition of electrical wire insulation with short-term excess electric current in microgravity. Proc. Combust. Inst. 2011, 33, 2617–2623. [Google Scholar] [CrossRef]

- Takano, Y.; Fujita, O.; Shigeta, N.; Nakamura, Y.; Ito, H. Ignition limits of short-term overloaded electric wires in microgravity. Proc. Combust. Inst. 2013, 34, 2665–2673. [Google Scholar] [CrossRef]

- Huang, X.; Nakamura, Y.; Williams, F.A. Ignition-to-spread transition of externally heated electrical wire. Proc. Combust. Inst. 2013, 34, 2505–2512. [Google Scholar] [CrossRef]

- Novak, C.J.; Stoliarov, I.S.; Keller, M.R.; Quintiere, J.G. An analysis of heat flux induced arc formation in a resi-dential electrical cable. Fire Saf. J. 2013, 55, 61–68. [Google Scholar] [CrossRef]

- Du, J.-H.; Tu, R.; Zeng, Y.; Pan, L.; Zhang, R.-C. An experimental study on the thermal characteristics and heating effect of arc-fault from Cu core in residential electrical wiring fires. PLoS ONE 2017, 12, e0182811. [Google Scholar] [CrossRef]

- Fang, J.; Zhao, S.; Wang, J.; Xue, Y.; He, X.; Zhang, Y.M. Sub-atmospheric bursting ignition of fluorinated ethylene propylene wire insulation. Fire Saf. J. 2018, 100, 45–50. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, T.; Wei, R.; Wang, J. Experimental study of flame spread over PE -insulated single copper core wire under varying pressure and electric current. Fire Mater. 2020, 44, 835–843. [Google Scholar] [CrossRef]

- Guan, J.-F.; Fang, J.; Xue, Y.; Wang, J.-W.; Wang, J.-J.; Zhang, Y.-M. Morphology and concentration of smoke from fluorinated ethylene propylene wire insulation in microgravity under forced airflow. J. Hazard. Mater. 2016, 320, 602–611. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, Y.; Konno, Y.; Huang, X.; Nakaya, S.; Tsue, M.; Hashimoto, N.; Fujita, O.; Fernandez-Pello, C. Laser piloted ignition of electrical wire in microgravity. Proc. Combust. Inst. 2019, 37, 4211–4219. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J. Thermal stabilities of drops of burning thermoplastics under the UL 94 vertical test conditions. J. Hazard. Mater. 2013, 246–247, 103–109. [Google Scholar] [CrossRef]

- Wang, N.; Tu, R.; Ma, X.; Xie, Q.; Jiang, X. Melting behavior of typical thermoplastic materials—An experimental and chemical kinetics study. J. Hazard. Mater. 2013, 262, 9–15. [Google Scholar] [CrossRef]

- Xie, Q.; Cheng, X.; Ye, R. Experimental study on melting and flowing behavior of thermoplastics combustion based on a new setup with a T-shape trough. J. Hazard. Mater. 2009, 166, 1321–1325. [Google Scholar] [CrossRef]

- Xie, Q.; Tu, R.; Wang, N.; Ma, X.; Jiang, X. Experimental study on flowing burning behaviors of a pool fire with dripping of melted thermoplastics. J. Hazard. Mater. 2014, 267, 48–54. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Huang, X.; Nakaya, S.; Tsue, M.; Fernandez-Pello, C. Flame spread over horizontal and vertical wires: The role of dripping and core. Fire Saf. J. 2017, 91, 112–122. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Konno, Y.; Huang, X.; Nakaya, S.; Tsue, M.; Hashimoto, N.; Fujita, O.; Fernandez-Pello, C. Effect of insulation melting and dripping on opposed flame spread over laboratory simulated electrical wires. Fire Saf. J. 2018, 95, 1–10. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.; Tu, R.; Zhao, L.; Liu, J.; Zhang, Y.M. Molten thermoplastic dripping behavior induced by flame spread over wire insulation under overload currents. J. Hazard. Mater. 2016, 320, 628–634. [Google Scholar] [CrossRef]

- Wang, X.; He, H.; Zhao, L.; Fang, J.; Wang, J.; Zhang, Y.M. Ignition and Flame Propagation of Externally Heated Electrical Wires with Electric Currents. Fire Technol. 2015, 52, 533–546. [Google Scholar] [CrossRef]

- He, H.; Zhang, Q.; Wang, X.; Wang, F.; Zhao, L.; Zhang, Y.M. The Influence of Currents on the Ignition and Correlative Smoke Productions for PVC-Insulated Electrical Wires. Fire Technol. 2016, 53, 1275–1289. [Google Scholar] [CrossRef]

- Quintiere, J.G. Fundamentals of Fire Phenomena; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

| Wire Type | Core Diameter (mm) | Insulation Thickness (mm) | Rated Current (A) | Pressure (kPa) | Overload Currents (A) | Ratio of Overload to Rated |

|---|---|---|---|---|---|---|

| Polyethylene insulated copper wire | 0.5 | 0.15 | 0.78 | 20–100 | 4–16 | 5–20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, H.; Zhang, Q.; Shi, L.; Li, H.; Huang, D.; Zhang, Y. Experimental Study on the Thermoplastic Dripping and Flame Spread Behaviors of Energized Electrical Wire under Reduced Atmospheric Pressure. Polymers 2021, 13, 346. https://doi.org/10.3390/polym13030346

He H, Zhang Q, Shi L, Li H, Huang D, Zhang Y. Experimental Study on the Thermoplastic Dripping and Flame Spread Behaviors of Energized Electrical Wire under Reduced Atmospheric Pressure. Polymers. 2021; 13(3):346. https://doi.org/10.3390/polym13030346

Chicago/Turabian StyleHe, Hao, Qixing Zhang, Long Shi, Haihang Li, Dongmei Huang, and Yongming Zhang. 2021. "Experimental Study on the Thermoplastic Dripping and Flame Spread Behaviors of Energized Electrical Wire under Reduced Atmospheric Pressure" Polymers 13, no. 3: 346. https://doi.org/10.3390/polym13030346

APA StyleHe, H., Zhang, Q., Shi, L., Li, H., Huang, D., & Zhang, Y. (2021). Experimental Study on the Thermoplastic Dripping and Flame Spread Behaviors of Energized Electrical Wire under Reduced Atmospheric Pressure. Polymers, 13(3), 346. https://doi.org/10.3390/polym13030346