Adhesion Improvement between PE and PA in Multilayer Rotational Molding

Abstract

1. Introduction

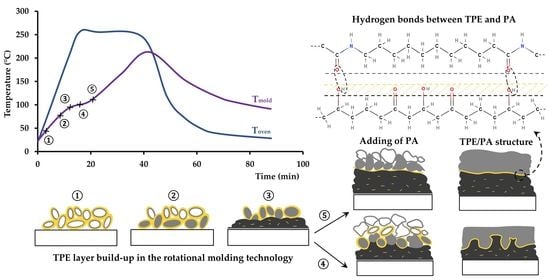

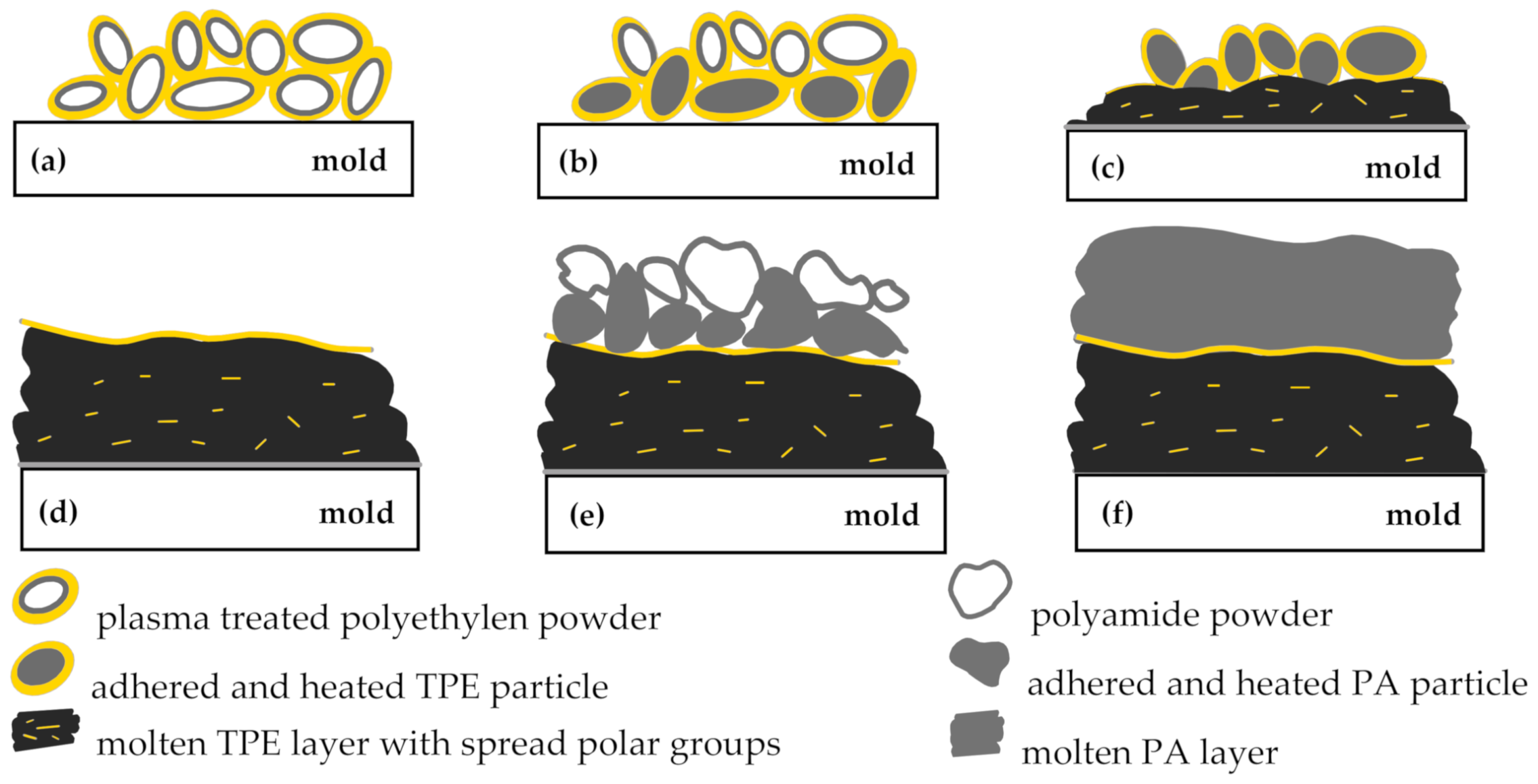

2. Materials and Methods

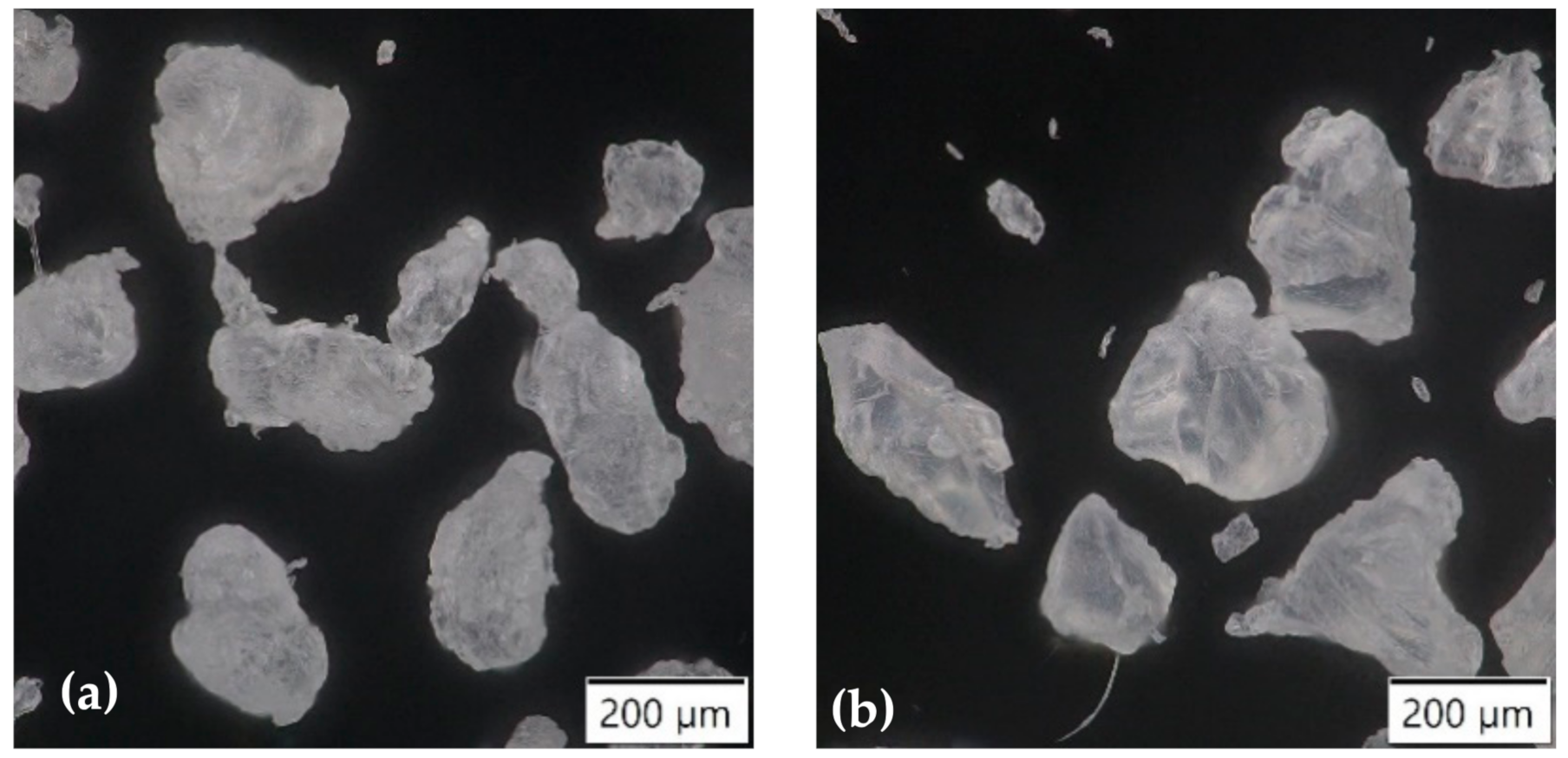

2.1. Materials Characterization

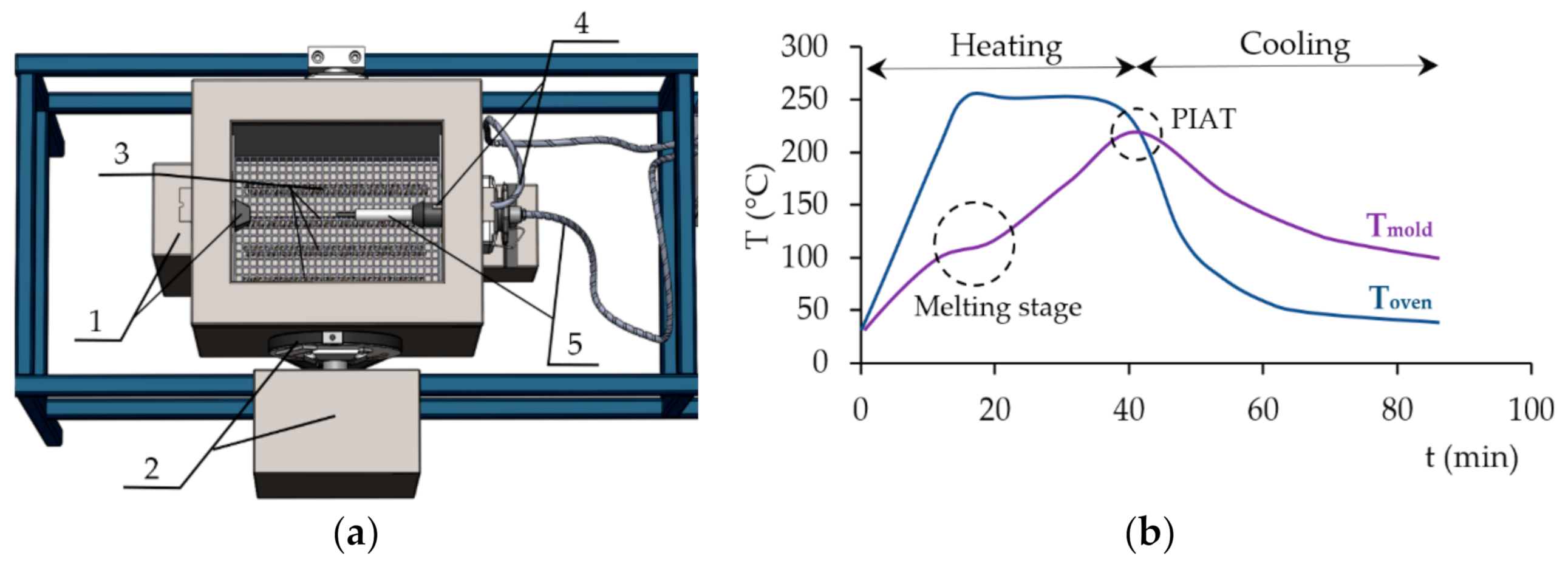

2.2. Description of the Rotomolding Machine

2.3. Specimens Preparation

2.4. The Testing Methods

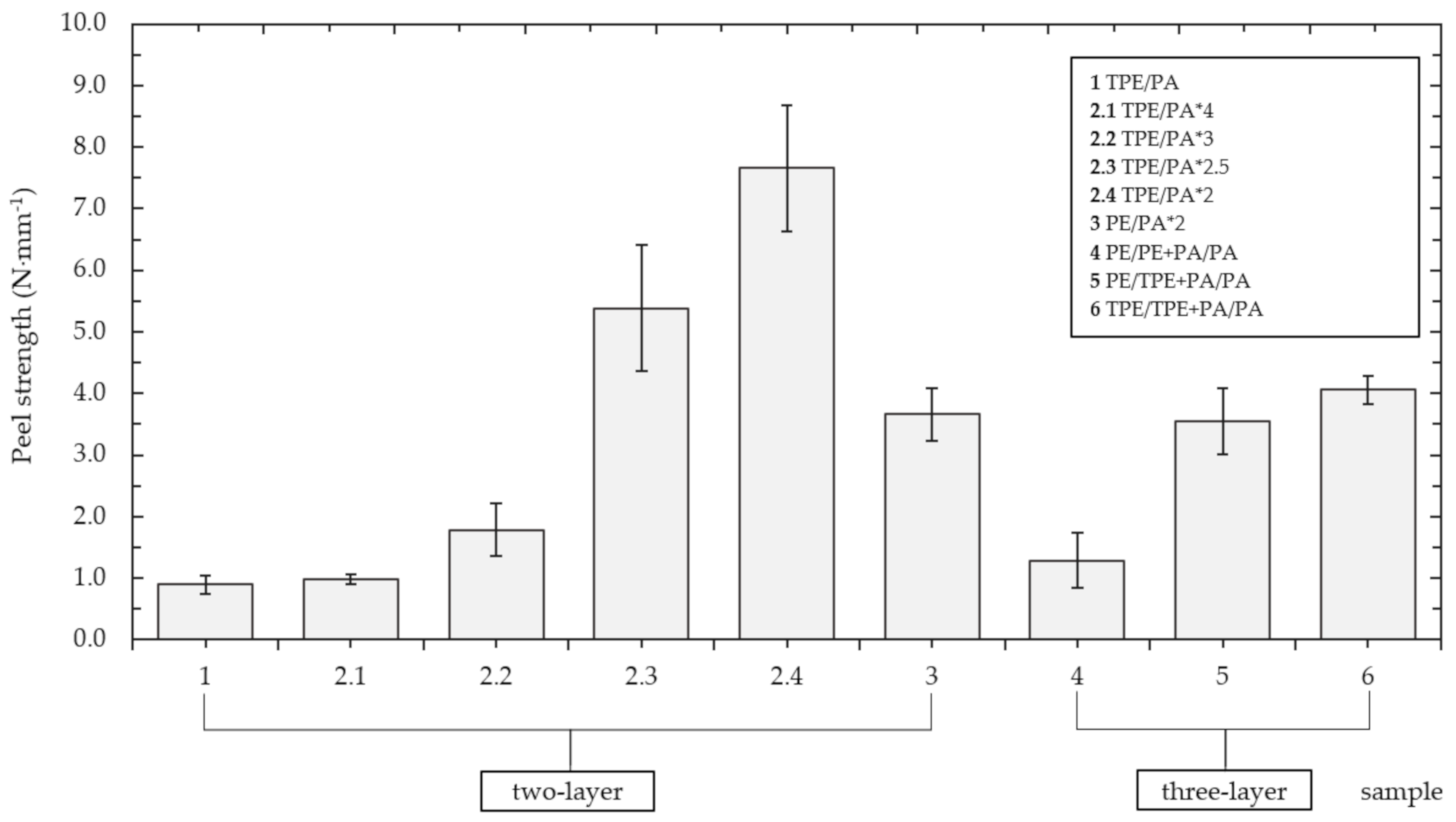

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beall, G. Rotational Molding: Design, Materials, Tooling, and Processing; Hanser/Gardner Publications: Munich, Germany; Cincinnati, OH, USA, 1998; ISBN 978-1-56990-260-8. [Google Scholar]

- Crawford, R.J.; Throne, J.L. Rotational Molding Technology; Plastics Design Library/William Andrew Publications: Norwich, NY, USA, 2002; ISBN 978-1-884207-85-3. [Google Scholar]

- Crawford, R.J.; Kearns, M.P. Practical Guide to Rotational Moulding, 2nd ed.; Smithers Rapra Technology: Shropshire, UK, 2012; ISBN 978-1-84735-924-7. [Google Scholar]

- Kutz, M. Applied Plastics Engineering Handbook: Processing, Materials, and Applications; Elsevier: Boston, MA, USA, 2016; ISBN 978-0-323-39040-8. [Google Scholar]

- Chang, W.C.; Harkin-Jones, E.; Kearns, M.; McCourt, M. Multilayered Glass Fibre-reinforced Composites In Rotational Moulding. AIP Conf. Proc. 2011, 1353, 708–713. [Google Scholar] [CrossRef]

- López-Bañuelos, R.H.; Moscoso, F.J.; Ortega-Gudiño, P.; Mendizabal, E.; Rodrigue, D.; González-Núñez, R. Rotational Molding of Polyethylene Composites Based on Agave Fibers. Polym. Eng. Sci. 2012, 52, 2489–2497. [Google Scholar] [CrossRef]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and Abaca Fiber-Reinforced Plastic Composites Obtained by Rotational Molding Process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- Hanana, F.E.; Chimeni, D.Y.; Rodrigue, D. Morphology and Mechanical Properties of Maple Reinforced LLDPE Produced by Rotational Moulding: Effect of Fibre Content and Surface Treatment. Polym. Polym. Compos. 2018, 26, 299–308. [Google Scholar] [CrossRef]

- Sari, P.S.; Thomas, S.; Spatenka, P.; Ghanam, Z.; Jenikova, Z. Effect of Plasma Modification of Polyethylene on Natural Fibre Composites Prepared via Rotational Moulding. Compos. Part B Eng. 2019, 177, 107344. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Krawczak, A.; Wesoły, K.; Szostak, M. Rotational Molding of Biocomposites with Addition of Buckwheat Husk Filler. Structure-Property Correlation Assessment for Materials Based on Polyethylene (PE) and Poly(Lactic Acid) PLA. Compos. Part B Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- Flaconnèche, B.; Martin, J.; Klopffer, M. Permeability, Diffusion and Solubility of Gases in Polyethylene, Polyamide 11 and Poly (Vinylidene Fluoride). Oil Gas Sci. Technol. 2001, 56, 261–278. [Google Scholar] [CrossRef]

- Spence, A.G.; Knepper, J.R.; Grimes, D.D.; Centro Inc. Multi-Layer Rotationally Molded Low Permeation Vessels and Method for Manufacture Thereof. U.S. Patent No. 8,911,842,B2, 16 December 2014. [Google Scholar]

- Liu, S.-J.; Yang, C.-H. Rotational Molding of Two-Layered Polyethylene Foams. Adv. Polym. Technol. 2001, 20, 108–115. [Google Scholar] [CrossRef]

- Jansri, E.; O-Charoen, N. Polypropylene/Polyethylene Two-Layered by One-Step Rotational Molding. J. Polym. Eng. 2018, 38, 685–694. [Google Scholar] [CrossRef]

- Sakaki, H.; Takashima, E.; Matsuda, S.; Kishi, K. Polypropylene/Polyethylene Multilayer Rotational Molding. J. Adhes. Soc. Jpn. 2010, 46, 473–478. [Google Scholar] [CrossRef]

- Löhner, M.; Drummer, D. Multi-Layer Rotational Molding of PE-PA Utilizing a Multiphase Interlayer to Generate Mechanical Adhesion. In Proceedings of the SPE Proceedings ANTEC 2016, Indianapolis, IN, USA, 23–25 May 2016. [Google Scholar]

- Löhner, M.; Drummer, D. Experimental Studies on the Bonding Strength and Fracture Behavior of Incompatible Materials Bonded by Mechanical Adhesion in Multilayer Rotational Molding. J. Polym. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Löhner, M.; Drummer, D. Influence of Particle Size in Multi-Layer Rotational Molding with a Multiphase Interlayer to Generate Mechanical Adhesion. In Proceedings of the SPE ANTEC 2017, Anaheim, CA, USA, 8–10 May 2017. [Google Scholar]

- O’brien, G.S.; Bonnet, A. Multi-Layer Rotational Moulding. U.S. Patent WO2005115753A1, 8 December 2005. [Google Scholar]

- Maziers, E. Multilayer Rotational Moulding. European Patent E.P.1422059B1, 25 April 2012. [Google Scholar]

- Ebnesajjad, S.; Ebnesajjad, C. Surface Treatment of Materials for Adhesive Bonding; Elsevier Science & Technology Books: Norwich, CT, USA, 2013; ISBN 978-0-323-26504-1. [Google Scholar]

- Zeng, H. Polymer Adhesion, Friction, and Lubrication; John Wiley & Sons, Incorporated: Somerset, MA, USA, 2013; ISBN 978-1-118-50513-7. [Google Scholar]

- Tcharkhtchi, A.; Barcelo, P.; Mazabraud, P.; Jousse, F.; Kearns, M.P. Study of Adhesion Between Two Layers in Multilayer Rotomolded Products. Adv. Eng. Mater. 2002, 4, 475–478. [Google Scholar] [CrossRef]

- Píchal, J.; Hladík, J.; Špatenka, P. Atmospheric-Air Plasma Surface Modification of Polyethylene Powder: Atmospheric-Air Plasma Surface Modification of Polyethylene Powder. Plasma Process. Polym. 2009, 6, 148–153. [Google Scholar] [CrossRef]

- Vandencasteele, N.; Reniers, F. Plasma-Modified Polymer Surfaces: Characterization Using XPS. J. Electron. Spectrosc. Relat. Phenom. 2010, 178, 394–408. [Google Scholar] [CrossRef]

- Šourková, H.; Špatenka, P. Plasma Activation of Polyethylene Powder. Polymers 2020, 12, 2099. [Google Scholar] [CrossRef]

- Yoshida, S.; Hagiwara, K.; Hasebe, T.; Hotta, A. Surface Modification of Polymers by Plasma Treatments for the Enhancement of Biocompatibility and Controlled Drug Release. Surf. Coat. Technol. 2013, 233, 99–107. [Google Scholar] [CrossRef]

- Horakova, M.; Spatenka, P.; Hladik, J.; Hornik, J.; Steidl, J.; Polachova, A. Investigation of Adhesion Between Metal and Plasma-Modified Polyethylene: Investigation of Adhesion Between Metal and Plasma-Modified Polyethylene. Plasma Process. Polym. 2011, 8, 983–988. [Google Scholar] [CrossRef]

- Arpagaus, C.; Oberbossel, G.; Rudolf von Rohr, P. Plasma Treatment of Polymer Powders—From Laboratory Research to Industrial Application. Plasma Process. Polym. 2018, 15, 1800133. [Google Scholar] [CrossRef]

- Xie, J.; Xin, D.; Cao, H.; Wang, C.; Zhao, Y.; Yao, L.; Ji, F.; Qiu, Y. Improving Carbon Fiber Adhesion to Polyimide with Atmospheric Pressure Plasma Treatment. Surf. Coat. Technol. 2011, 206, 191–201. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, C.; Chen, P.; Yu, Q.; Li, W. Modification of Carbon Fiber by Air Plasma and Its Adhesion with BMI Resin. RSC Adv. 2014, 4, 26881. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Martínez, M.A. Influence of Plasma Treatment on the Adhesion between a Polymeric Matrix and Natural Fibres. Cellulose 2017, 24, 1791–1801. [Google Scholar] [CrossRef]

- Fazeli, M.; Florez, J.P.; Simão, R.A. Improvement in Adhesion of Cellulose Fibers to the Thermoplastic Starch Matrix by Plasma Treatment Modification. Compos. Part B Eng. 2019, 163, 207–216. [Google Scholar] [CrossRef]

- Haji, A.; Hadizadeh, M.; Ferasat, E.; Movaghatian, D. Effect of Plasma Treatment on Glass Fiber/Epoxy Resin Composite. 2019. Available online: https://www.researchgate.net/profile/Aminoddin_Haji/publication/332547684_EFFECT_OF_PLASMA_TREATMENT_ON_GLASS_FIBEREPOXY_RESIN_COMPOSITE/links/5cbc0b07a6fdcc1d49a3e6cc/EFFECT-OF-PLASMA-TREATMENT-ON-GLASS-FIBER-EPOXY-RESIN-COMPOSITE.pdf (accessed on 20 November 2020).

- Novacek, V.; Vackova, T.; Spatenka, P.; Jenikova, Z. Application of Low Temperature Plasma Treatment for Thermoplastic Composites. In Proceedings of the 2017 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM) 2017 Intl Aegean Conference on Electrical Machines and Power Electronics (ACEMP), Brasov, Romania, 25–27 May 2017; pp. 1027–1032. [Google Scholar]

- Weberová, Z. Low-Pressure Cold Plasma Surface Treatment for Adhesion Improvement in Composite Structures. In Proceedings of the SVC Annual Technical Conference Proceedings, Long Beach, CA, USA, 27 April–2 May 2019. [Google Scholar]

- Oliveira, M.J.; Cramez, M.C.; Garcia, C.B.; Kearns, M.P.; Maziers, E. Effect of the Processing Conditions on the Microstructure and Properties of Rotational Molded Polyamide 11. J. Appl. Polym. Sci. 2008, 108, 939–946. [Google Scholar] [CrossRef]

- Noeske, M.; Degenhardt, J.; Strudthoff, S.; Lommatzsch, U. Plasma Jet Treatment of Five Polymers at Atmospheric Pressure: Surface Modifications and the Relevance for Adhesion. Int. J. Adhes. Adhes. 2004, 24, 171–177. [Google Scholar] [CrossRef]

- Fombuena, V.; Balart, R.; Sánchez-Nácher, L.; Fenollar, O.; España, J.M. Atmospheric Plasma Treatment of Polyethylene Substrates for Improved Mechanical Performance of Adhesion Joints. Bull. Transilv. Univ. Brasov. Eng. Sci. 2011, 4, 8. [Google Scholar]

- Mandolfino, C.; Lertora, E.; Gambaro, C. Influence of Cold Plasma Treatment Parameters on the Mechanical Properties of Polyamide Homogeneous Bonded Joints. Surf. Coat. Technol. 2017, 313, 222–229. [Google Scholar] [CrossRef]

- Károly, Z.; Kalácska, G.; Zsidai, L.; Mohai, M.; Klébert, S. Improvement of Adhesion Properties of Polyamide 6 and Polyoxymethylene-Copolymer by Atmospheric Cold Plasma Treatment. Polymers 2018, 10, 1380. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Selvarajan, V.; Deshmukh, R.R.; Gao, C. Modification of Surface Properties of Polypropylene (PP) Film Using DC Glow Discharge Air Plasma. Appl. Surf. Sci. 2009, 255, 3965–3971. [Google Scholar] [CrossRef]

- Gao, Z.; Sun, J.; Peng, S.; Yao, L.; Qiu, Y. Surface Modification of a Polyamide 6 Film by He/CF4 Plasma Using Atmospheric Pressure Plasma Jet. Appl. Surf. Sci. 2009, 256, 1496–1501. [Google Scholar] [CrossRef]

- Pandiyaraj, K.N.; Selvarajan, V.; Deshmukh, R.R.; Yoganand, P.; Balasubramanian, S.; Maruthamuthu, S. Low Pressure DC Glow Discharge Air Plasma Surface Treatment of Polyethylene (PE) Film for Improvement of Adhesive Properties. Plasma Sci. Technol. 2013, 15, 56–63. [Google Scholar] [CrossRef]

- Palaskar, S.S.; Kale, R.D.; Deshmukh, R.R. Application of Atmospheric Pressure Plasma for Adhesion Improvement in Polyurethane Coating on Polypropylene Fabrics. J. Coat. Technol. Res. 2020, 17, 485–501. [Google Scholar] [CrossRef]

- Song, J.; Bringuier, A.; Kobayashi, S.; Baker, A.M.; Macosko, C.W. Adhesion between Polyethylenes and Different Types of Polypropylenes. Polym. J. 2012, 44, 939–945. [Google Scholar] [CrossRef]

- Williams, T.S.; Yu, H.; Hicks, R.F. Atmospheric Pressure Plasma Activation of Polymers and Composites for Adhesive Bonding. Rev. Adhes. Adhes. 2013, 1, 46–87. [Google Scholar] [CrossRef]

- Löhner, M.; Drummer, D. Characterization of Layer Built-up and Inter-Layer Boundaries in Rotational Molding of Multi-Material Parts in Dependency of the Filling Strategy. J. Polym. Eng. 2017, 37, 411–420. [Google Scholar] [CrossRef]

| Properties | Dowlex™ 2629.10UE | Rilsan® Roto 11 | |

|---|---|---|---|

| Density | g∙cm−3 | 0.935 | 1.05 |

| Melt flow index (MFI) (190 °C/2.16 kg) | g/10 min | 4.0 | 3.8 |

| Tensile strength | MPa | 17.5 | 48 |

| Flexural modulus | MPa | 645 | 1300 |

| Impact strength (23 °C) | J | 72 | 65 |

| Type | Amount of Powder (g) | Adding Time of Next Layer (min) | Processing Parameters | |||||

|---|---|---|---|---|---|---|---|---|

| 1st Layer | 2nd Layer | 3rd Layer | 2nd Layer | 3rd Layer | ||||

| 2 layers | TPE/PA | 100; 150 | 100; 150 | none | 5.1 | none | Oven temperature | 250 °C |

| TPE/PA*4 | 100 | 100 | 4 | |||||

| TPE/PA*3 | 3 | PIAT | 210 °C | |||||

| TPE/PA*2.5 | 2.5 | |||||||

| TPE/PA*2 | 100; 150 | 100; 150 | 2 | Rotation speed | 10 rpm | |||

| PE/PA*2 | 2 | |||||||

| 3 layers | PE/PE + PA/PA | 66 and 100 | 33,5 + 33,5 and 50 + 50 | 66 and 100 | 5.1 | 5 | Rocking f. | 2 cycles pm |

| PE/TPE + PA/PA | ||||||||

| TPE/TPE + PA/PA | Max. angle of rocking | ±45° | ||||||

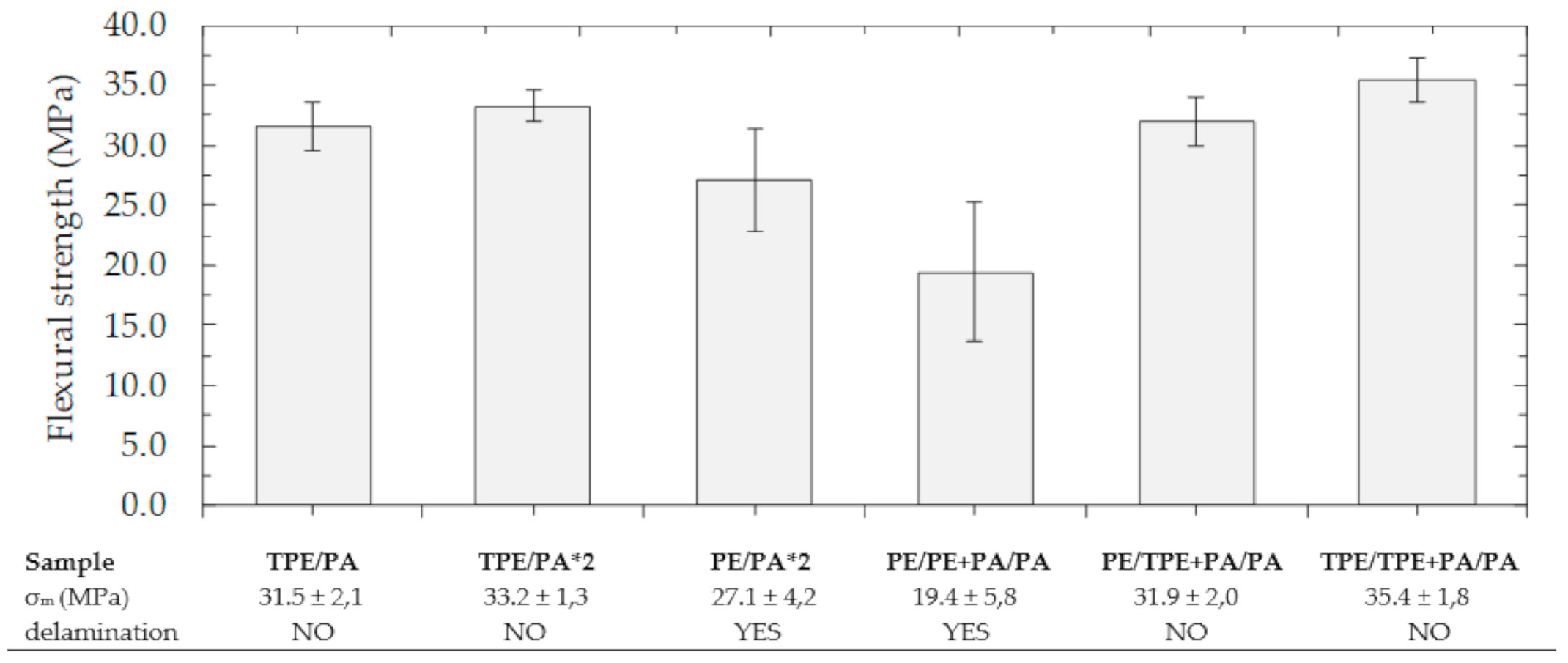

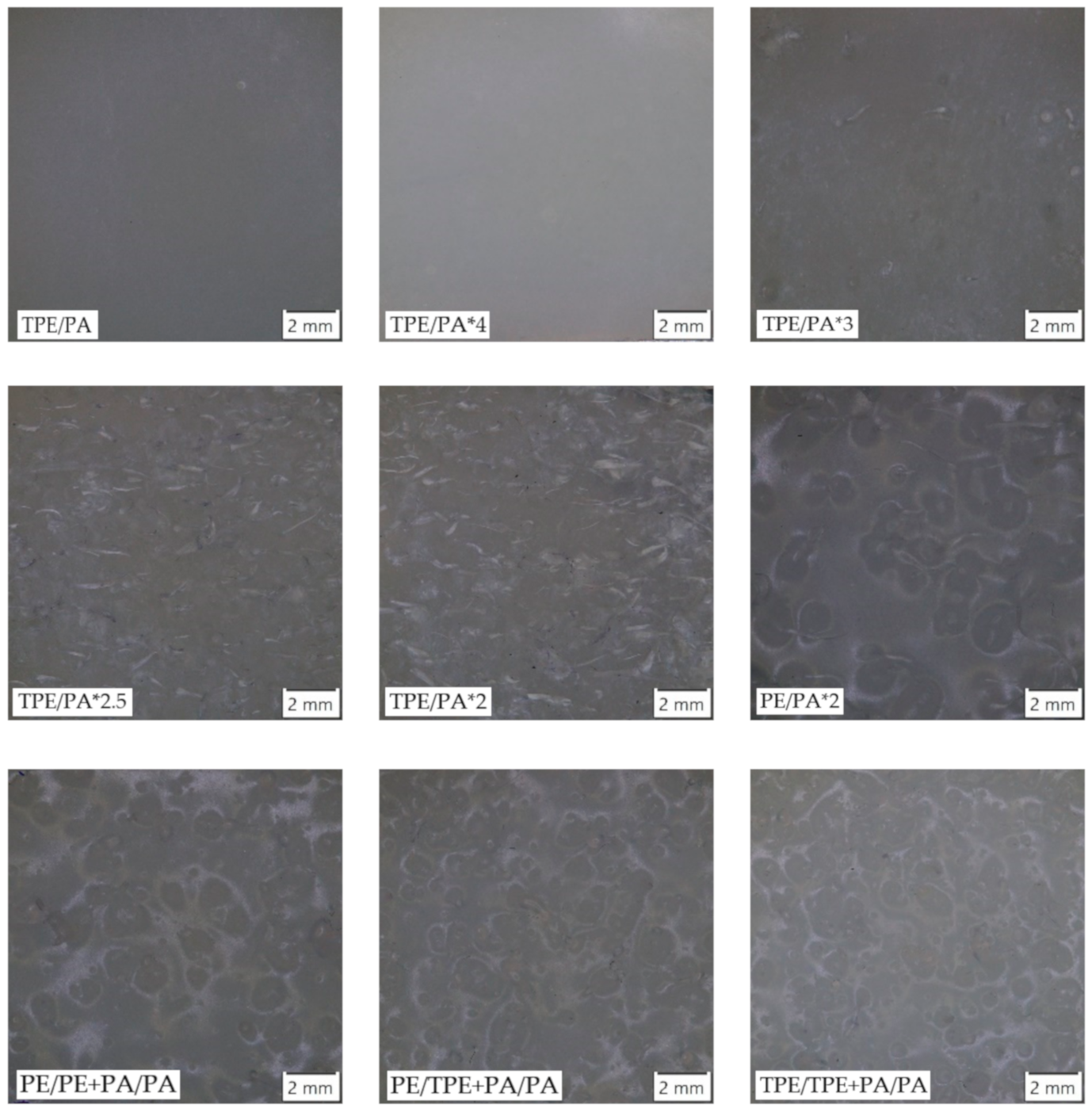

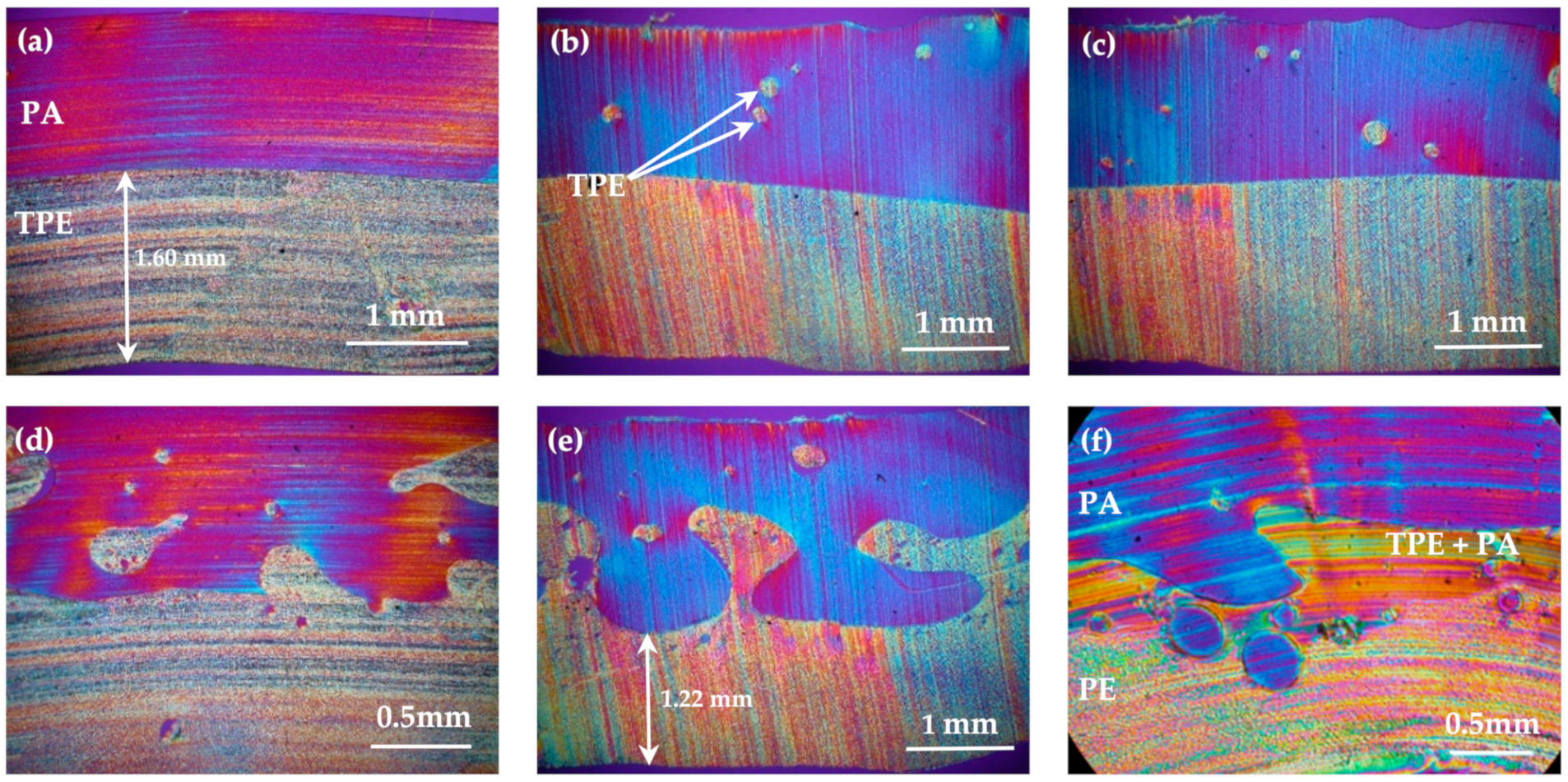

| Specimen | P.S. (N∙mm−1) | Rz (µm) | Ra (µm) | Rc (µm) |

|---|---|---|---|---|

| TPE/PA | 0.897 | 3.664 | 0.750 | 2.050 |

| TPE/PA*4 | 0.984 | 3.161 | 0.559 | 1.438 |

| TPE/PA*3 | 1.787 | 57.427 | 9.318 | 6.052 |

| TPE/PA*2.5 | 5.387 | 263.615 | 51.745 | 137.241 |

| TPE/PA*2 | 7.657 | 353.328 | 67.225 | 137.387 |

| PE/PA*2 | 3.662 | 241.898 | 41.287 | 42.260 |

| PE/PE + PA/PA | 1.290 | 225.576 | 41.536 | 40.469 |

| PE/TPE + PA/PA | 3.553 | 140.517 | 25.605 | 30.658 |

| TPE/TPE + PA/PA | 4.059 | 350.452 | 61.186 | 68.037 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sezemský, J.; Špatenka, P. Adhesion Improvement between PE and PA in Multilayer Rotational Molding. Polymers 2021, 13, 331. https://doi.org/10.3390/polym13030331

Sezemský J, Špatenka P. Adhesion Improvement between PE and PA in Multilayer Rotational Molding. Polymers. 2021; 13(3):331. https://doi.org/10.3390/polym13030331

Chicago/Turabian StyleSezemský, Jan, and Petr Špatenka. 2021. "Adhesion Improvement between PE and PA in Multilayer Rotational Molding" Polymers 13, no. 3: 331. https://doi.org/10.3390/polym13030331

APA StyleSezemský, J., & Špatenka, P. (2021). Adhesion Improvement between PE and PA in Multilayer Rotational Molding. Polymers, 13(3), 331. https://doi.org/10.3390/polym13030331