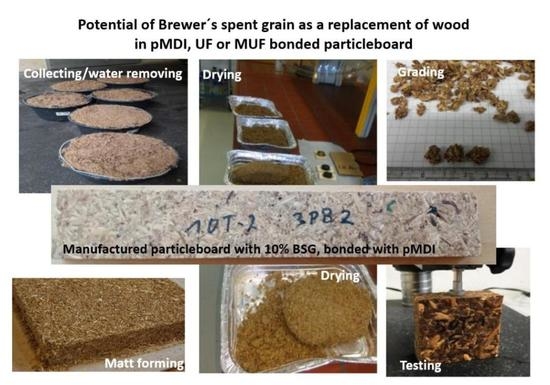

Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

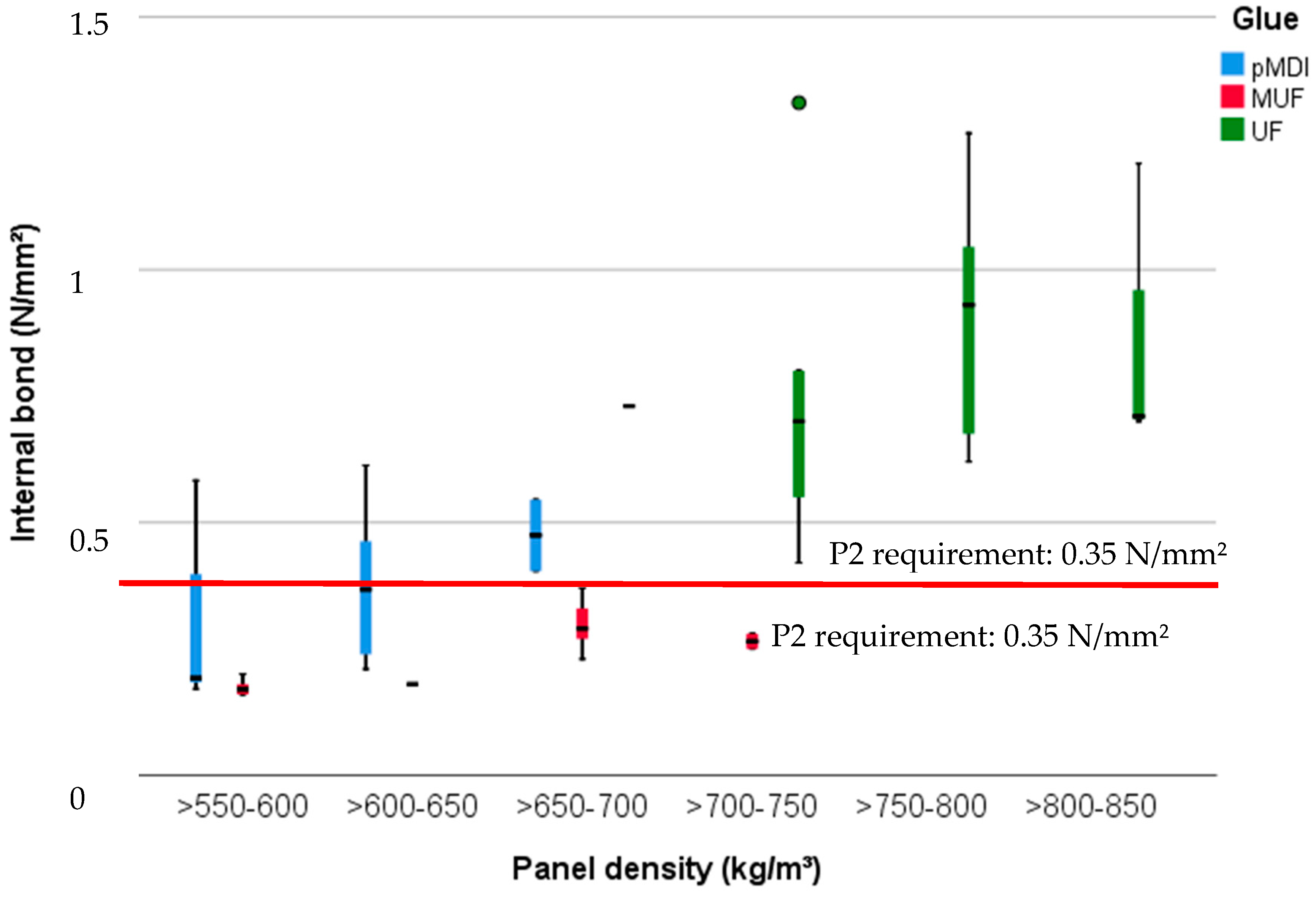

3.1. Internal Bond

3.2. Moduli of Eupture and Elasticity

3.3. Screw Withdrawal Resistance

3.4. Thickness Swelling and Water Absorption after 24 h

3.5. Morphological Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Prasad, R.K.; Chatterjee, S.; Mazumder, P.B.; Gupta, S.K.; Sharma, S.; Vairale, M.G.; Datta, S.; Dwivedi, S.K.; Gupta, D.K. Bioethanol production from waste lignocelluloses: A review on microbial degradation potential. Chemosphere 2019, 231, 588–606. [Google Scholar] [CrossRef] [PubMed]

- Soles, E. Wood and Agricultural Residues: Research on Use for Feed, Fuels and Chemicals: Conference on Feed, Fuels and Chemicals from Wood and Agricultural Residues; Elsevier: Oxford, UK, 1983. [Google Scholar]

- Saal, U.; Weimar, H.; Mantau, U. Wood Processing Residues. Adv. Biochem. Eng. Biotechnol. 2019, 166, 27–41. [Google Scholar]

- Klitkou, A.; Fevolden, A.; Capasso, M. (Eds.) From Waste to Value: Valorisation Pathways for Organic Waste Streams in Bioeconomies; Routledge: London, UK; Taylor & Francis Group: New York, NY, USA, 2019. [Google Scholar]

- Mussatto, S.I.; Roberto, I.C. Acid hydrolysis and fermentation of brewer’s spent grain to produce xylitol. J. Sci. Food Agric. 2005, 85, 2453–2460. [Google Scholar] [CrossRef]

- Fillaudeau, L.; Blanpain-Avet, P.; Daufin, G. Water, wastewater and waste management in brewing industries. J. Clean. Prod. 2006, 14, 463–471. [Google Scholar] [CrossRef]

- Statista. Worldwide Beer Production. 2020. Available online: https://www.statista.com/statistics/270275/worldwide-beer-production (accessed on 15 December 2020).

- Mussatto, S.I. Biotechnology for Agro-Industrial Residues: Biotechnological Potential of Brewing Industry By-Products; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Aliyu, S.; Muntari, B. Brewer’s spent grain: A review of its potentials and applications. Afr. J. Biotechnol. 2011, 10, 324–331. [Google Scholar]

- Olajire, A.A. The brewing industry and environmental challenges. J. Clean. Prod. 2020, 256, 102817. [Google Scholar] [CrossRef]

- Ferreira, A.M.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers 2019, 11, 923. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Crawshaw, R. Co-Product Feeds. Animal Feeds from the Food and Drinks Industries; Nottingham University Press: Nottingham, UK, 2004. [Google Scholar]

- Klímek, P.; Wimmer, R.; Kumar Mishra, P.; Kúdela, J. Utilizing brewer’s-spent-grain in wood-based particleboard manufacturing. J. Clean. Prod. 2017, 141, 812–817. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Roberto, I.C. Brewers’ spent grain: Generation, characteristics and potential applications. J. Cereal Sci. 2006, 43, 1–14. [Google Scholar] [CrossRef]

- dos Santos Mathias, T.R.; de Mello, P.P.; Servulo, E. Solid wastes in brewing process: A review. J. Brew. Distill. 2014, 5, 1–9. [Google Scholar]

- Özvural, E.B.; Vural, H.; Gökbulut, İ.; Özboy-Özbaş, Ö. Utilization of brewer’s spent grain in the production of Frankfurters. Int. J. Food Sci. Technol. 2009, 44, 1093–1099. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; İbanoglu, S. The recycling of brewer’s processing by-product into ready-to-eat snacks using extrusion technology. J. Cereal Sci. 2008, 47, 469–479. [Google Scholar] [CrossRef]

- Arendt, E.K.; Zannini, E. Cereal Grains for the Food and Beverage Industries; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Steiner, J.; Procopio, S.; Becker, T. Brewer’s spent grain: Source of value-added polysaccharides for the food industry in reference to the health claims. Eur. Food Res. Technol. 2015, 241, 303–315. [Google Scholar] [CrossRef]

- Queirós, C.S.; Cardoso, S.; Lourenço, A.; Ferreira, J.; Miranda, I.; Lourenço, M.J.V.; Pereira, H. Characterization of walnut, almond, and pine nut shells regarding chemical composition and extract composition. Biomass Conv. Bioref. 2020, 10, 175–188. [Google Scholar] [CrossRef]

- Barbu, M.C.; Sepperer, T.; Tudor, E.M.; Petutschnigg, A. Walnut and Hazelnut Shells: Untapped Industrial Resources and Their Suitability in Lignocellulosic Composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Wang, D.; Sun, X.S. Low density particleboard from wheat straw and corn pith. Ind. Crops Prod. 2002, 15, 43–50. [Google Scholar] [CrossRef]

- Yasin, M.; Bhutto, A.W.; Bazmi, A.A.; Karim, S. Efficient utilization of rice-wheat straw to produce value-added composite products. Int. J. Chem. Environ. Eng. 2010, 1, 2. [Google Scholar]

- Dukarska, D.; Czarnecki, R.; Dziurka, D.; Mirski, R. Construction particleboards made from rapeseed straw glued with hybrid pMDI/PF resin. Eur. J. Wood Prod. 2017, 75, 175–184. [Google Scholar] [CrossRef]

- Hýsková, P.; Hýsek, Š.; Schönfelder, O.; Šedivka, P.; Lexa, M.; Jarský, V. Utilization of agricultural rests: Straw-based composite panels made from enzymatic modified wheat and rapeseed straw. Ind. Crops Prod. 2020, 144, 112067. [Google Scholar] [CrossRef]

- Cosereanu, C.; Cerbu, C. Morphology, physical, and mechanical properties of particleboard made from rape straw and wood particles glued with urea-formaldehyde resin. BioResources 2019, 14, 2903–2918. [Google Scholar]

- Bektas, I.; Guler, C.; Kalaycioğlu, H.; Mengeloglu, F.; Nacar, M. The Manufacture of Particleboards using Sunflower Stalks (Helianthus annuus L.) And Poplar Wood (Populus alba L.). J. Compos. Mater. 2005, 39, 467–473. [Google Scholar] [CrossRef]

- Réh, R.; Vrtielka, J. Modification of the core layer of particleboard with hemp shives and its influence on the particleboard properties. Acta Fac. Xylologiae 2013, 55, 51–59. [Google Scholar]

- Nakanishi, E.Y.; Cabral, M.R.; Fiorelli, J.; dos Santos, V.; Christoforo, A.L.; Junior, H.S. Study of the production process of 3-layer sugarcane-bamboo-based particleboards. Constr. Build. Mater. 2018, 183, 618–625. [Google Scholar] [CrossRef]

- Klímek, P.; Meinlschmidt, P.; Wimmer, R.; Plinke, B.; Schirp, A. Using sunflower (Helianthus annuus L.), topinambour (Helianthus tuberosus L.) and cup-plant (Silphium perfoliatum L.) stalks as alternative raw materials for particleboards. Ind. Crops Prod. 2016, 92, 157–164. [Google Scholar] [CrossRef]

- EN 326:1994 Wood-Based Panels—Sampling, Cutting and Inspection—Part 1: Sampling and Cutting of Test Pieces and Expression of Test Results; European Committee for Standardization: Brussels, Belgium, 1994.

- EN 323:1993 Wood-Based Panels; Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317:1993 Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310:1993 Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319:1993 Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 320:1993 Fibreboards; Determination of Resistance to Axial Withdrawal of Screws; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 322:1993 Wood-Based Panels; Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 1993.

- Yamaguchi, N. Screw Resistance. In In Situ Assessment of Structural Timber; RILEM State of the Art Reports; Kasal, B., Tannert, T., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 81–86. [Google Scholar]

- EN 312:2010 Particleboards—Specifications; European Committee for Standardization: Brussels, Belgium, 2010.

- Schwarzenbrunner, R.; Barbu, M.C.; Petutschnigg, A.; Tudor, E.M. Water-Resistant Casein-Based Adhesives for Veneer Bonding in Biodegradable Ski Cores. Polymers 2020, 12, 1745. [Google Scholar] [CrossRef]

- Lu, Y.; Shi, Q. Larch tannin adhesive for particleboard. Eur. J. Wood Prod. 1995, 53, 17–19. [Google Scholar] [CrossRef]

- Tudor, E.M.; Barbu, M.C.; Petutschnigg, A.; Réh, R.; Krišťák, Ľ. Analysis of Larch-Bark Capacity for Formaldehyde Removal in Wood Adhesives. Int. J. Environ. Res. Public Health 2020, 17, 764. [Google Scholar] [CrossRef] [Green Version]

| Board | Density (kg/m3) | Glue Type | Glue Amount (%) | Moisture Content (%) | Press Temperature (°C) | Press Time (s) |

|---|---|---|---|---|---|---|

| pMDI0BSG | 600 | pMDI | 4 | 11 | 220 | 130 |

| pMD10BSG | 630 | pMDI | 4 | 11 | 220 | 130 |

| pMD30BSG | 600 | pMDI | 4 | 11 | 220 | 130 |

| pMD50BSG | 600 | pMDI | 4 | 11 | 220 | 130 |

| UF0BSG | 750 | UF | 14 | 9 | 180 | 450 |

| UF10BSG | 750 | UF | 14 | 9 | 180 | 450 |

| UF30BSG | 750 | UF | 14 | 9 | 180 | 450 |

| UF50BSG | 790 | UF | 14 | 9 | 180 | 450 |

| MUF0BSG | 670 | MUF | 13 | 9 | 180 | 450 |

| MUF10BSG | 570 | MUF | 13 | 9 | 180 | 450 |

| MUF30BSG | 690 | MUF | 13 | 9 | 180 | 450 |

| IB | MOR | MOE | TS | WA | SW | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| p | η2 | p | η2 | p | η2 | p | η2 | p | η2 | p | η2 | |

| Model | 0.000 | 0.75 | 0.000 | 0.82 | 0.000 | 0.78 | 0.000 | 0.84 | 0.000 | 0.75 | 0.000 | 0.88 |

| Density type | 0.000 | 0.61 | 0.000 | 0.59 | 0.000 | 0.60 | 0.147 | 0.08 | 0.000 | 0.33 | 0.000 | 0.31 |

| Glue | 0.000 | 0.68 | 0.000 | 0.75 | 0.000 | 0.75 | 0.127 | 0.25 | 0.000 | 0.33 | 0.001 | 0.62 |

| BSG content | 0.106 | 0.07 | 0.020 | 0.11 | 0.013 | 0.11 | 0.022 | 0.13 | 0.001 | 0.18 | 0.002 | 0.22 |

| Sample | Density (kg/m3) | IB (N/mm2) | MOR (N/mm2) | MOE (N/mm2) | SW (N/mm) |

|---|---|---|---|---|---|

| pMDI0BSG | 600 | 0.48 a (0.14) | 9.67 a (1.4) | 1787 a (232.2) | 63 a (8.95) |

| pMDI10BSG | 630 | 0.44 a (0.07) | 7.7 b (1.3) | 1425 b (244.4) | 54 a (5.94) |

| pMDI30BSG | 600 | 0.22 b (0.05) | 5.82 c (1.08) | 1127 c (187) | 41 b (5.92) |

| pMDI50BSG | 600 | 0.21 b (0.02) | 5.1 c (0.83) | 882 d (134) | 30 b (4.05) |

| UF0BSG | 750 | 0.91 c (0.14) | 19.64 c (1.09) | 3967 e (38.77) | 143 c (5.93) |

| UF10BSG | 750 | 1.18 c (0.12) | 16 d (0.22) | 3057 e (157.7) | 139 c (6.67) |

| UF30BSG | 750 | 0.65 d (0.05) | 13.67 e (0.98) | 2666 f (103.5) | 90 d (7.91) |

| UF50BSG | 790 | 0.65 d (0.12) | 13.21 e (0.44) | 2599 f (60.54) | 76 e (10.32) |

| MUF0BSG | 670 | 0.26 b (0.03) | 8.17 b (0.74) | 2013 g (62.28) | 92 f (11.76) |

| MUF10BSG | 570 | 0.17 b (0.01) | 10.46 a (1.16) | 2345 g (212.5) | 133 c (36.9) |

| MUF30BSG | 690 | 0.31 e (0.05) | 11.2 f (1.2) | 2693 f (219.4) | 116 d (17.82) |

| Sample | TS 24 h (%) | WA 24 h (%) |

|---|---|---|

| pMDI0BSG | 17 a (1.71) | 51 a (7.26) |

| pMDI10BSG | 23 b (1.05) | 84 b (6.45) |

| pMDI30BSG | 26 b (1.16) | 92 b (2.40) |

| pMDI50BSG | 30 c (0.80) | 105 c (4.47) |

| UF0BSG | 26 b (2.65) | 60 a (6.72) |

| UF10BSG | 23 b (1.16) | 58 a (4.87) |

| UF30BSG | 30 c (1.63) | 63 a (1.77) |

| UF50BSG | 26 b (2.72) | 59 a (11.20) |

| MUF0BSG | 34 d (2.65) | 80 b (4.62) |

| MUF10BSG | 28 c (1.729 | 83 b (9.30) |

| MUF30BSG | 29 c (1.16) | 75 b (2.48) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbu, M.C.; Montecuccoli, Z.; Förg, J.; Barbeck, U.; Klímek, P.; Petutschnigg, A.; Tudor, E.M. Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard. Polymers 2021, 13, 319. https://doi.org/10.3390/polym13030319

Barbu MC, Montecuccoli Z, Förg J, Barbeck U, Klímek P, Petutschnigg A, Tudor EM. Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard. Polymers. 2021; 13(3):319. https://doi.org/10.3390/polym13030319

Chicago/Turabian StyleBarbu, Marius Cătălin, Zeno Montecuccoli, Jakob Förg, Ulrike Barbeck, Petr Klímek, Alexander Petutschnigg, and Eugenia Mariana Tudor. 2021. "Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard" Polymers 13, no. 3: 319. https://doi.org/10.3390/polym13030319

APA StyleBarbu, M. C., Montecuccoli, Z., Förg, J., Barbeck, U., Klímek, P., Petutschnigg, A., & Tudor, E. M. (2021). Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard. Polymers, 13(3), 319. https://doi.org/10.3390/polym13030319