Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Remove the Inner PE and Printing Pattern Coatings from the UPCs

2.3. Dissolution of p-UPCs and Preparation of Cellulose-Based Films

2.4. Characterization

2.4.1. The Degree of Polymerization (DP) of Cellulose in UPCs

2.4.2. Polarized Optical Microscopy of p-UPCs/AmimCl Solution

2.4.3. Ultraviolet and Visible (UV-Vis) Spectra of the Cellulose-Based Films

2.4.4. The Surface Hydrophilicity of the Cellulose-Based Films

2.4.5. Wide-Angle X-ray Diffraction (WAXD) of the CPs, UPCs, P-UPCs, PE Film, and Cellulose-Based Films

2.4.6. Fourier Transform Infrared (FTIR) Spectra of the CPs, UPCs, P-UPCs, PE Film, and Cellulose-Based Films

2.4.7. Mechanical Testing of the Cellulose-Based Films

2.4.8. Thermogravimetric Analysis (TGA) of the CPs, UPCs, P-UPCs, PE Film, and Cellulose-Based Films

2.4.9. Morphology of the Cellulose-Based Films

3. Results and Discussion

3.1. Pretreatment and Dissolution of Used Paper Cups

3.2. Transparency and Hydrophilicity of Cellulose-Based Gels and Films

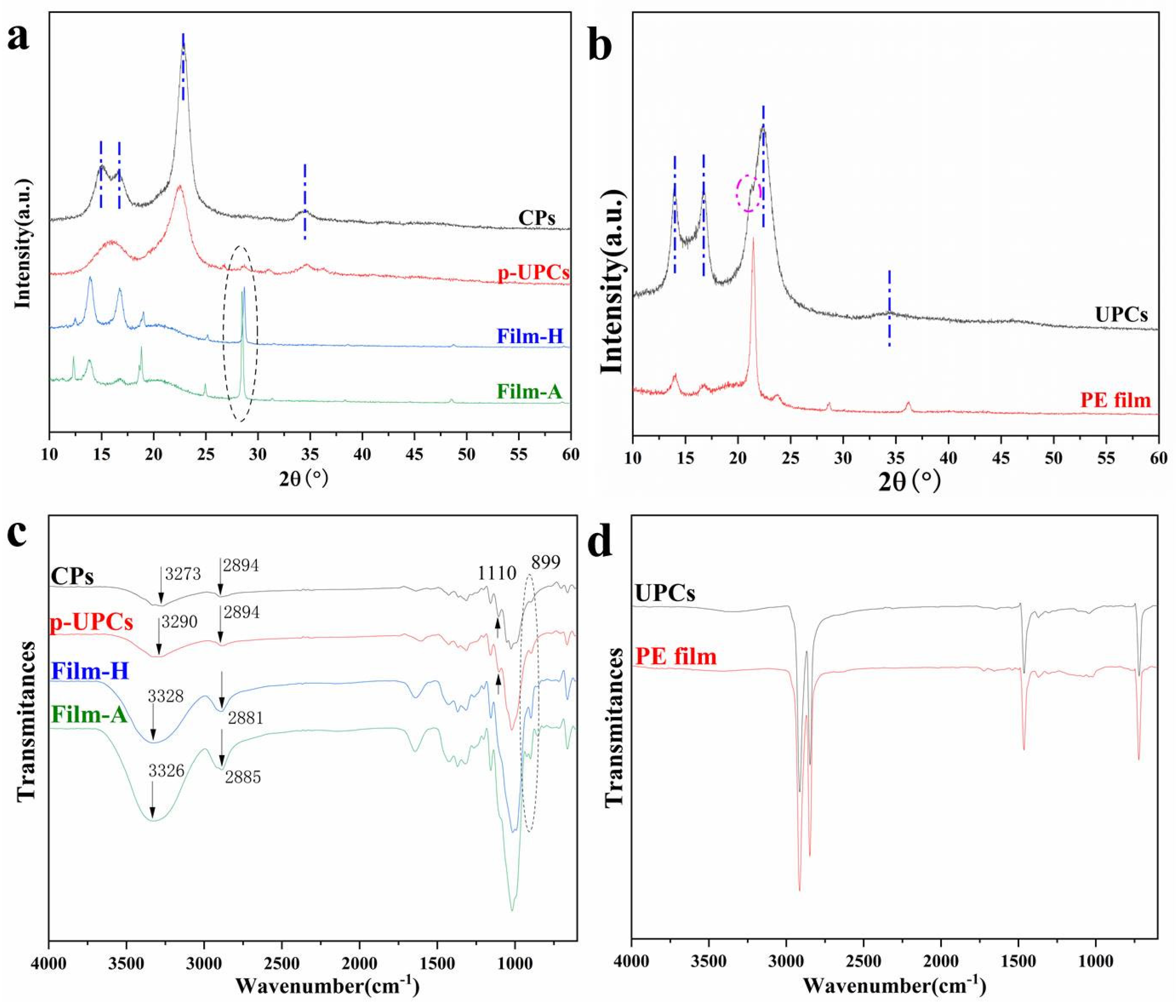

3.3. Structure and Crystallinity

3.4. Mechanical Property and Thermal Degradation

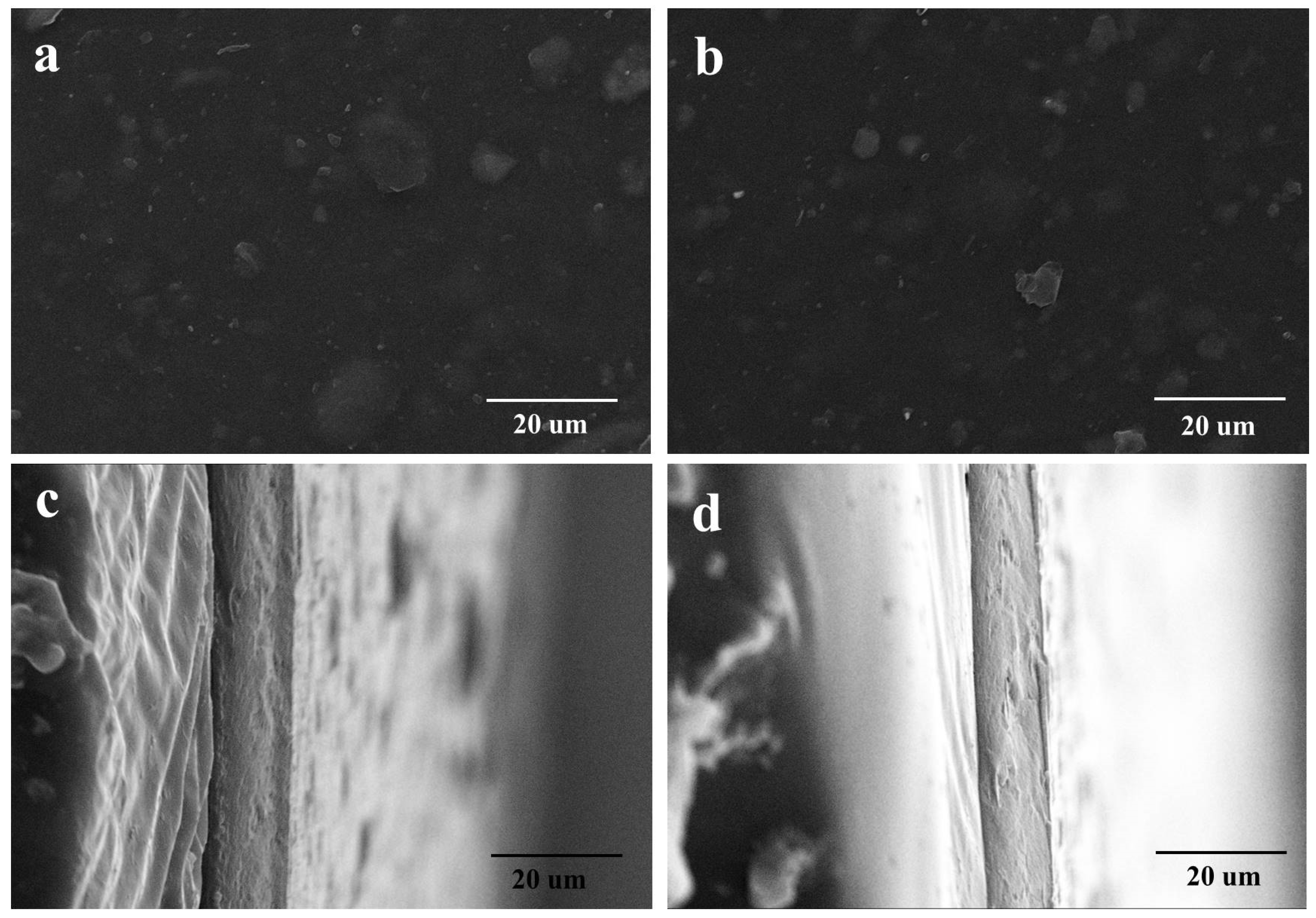

3.5. Morphology of Cellulose-Based Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, Y. Problems and resolutions in dealing with waste disposable paper cups. Sci. Prog. 2018, 101, 1–7. [Google Scholar]

- Arumugam, K.; Renganathan, S.; Babalola, O.O.; Muthunarayanan, V. Investigation on paper cup waste degradation by bacterial consortium and Eudrillus eugeinea through vermicomposting. Waste Manag. 2018, 74, 185–193. [Google Scholar] [CrossRef]

- Foteinis, S. How small daily choices play a huge role in climate change: The disposable paper cup environmental bane. J. Clean. Prod. 2020, 255, 120294. [Google Scholar] [CrossRef]

- Biswal, B.; Kumar, S.; Singh, R.K. Production of Hydrocarbon Liquid by Thermal Pyrolysis of Paper Cup Waste. J. Waste Manag. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Nawaz, H.; Zhang, X.; Chen, S.; You, T.; Xu, F. Recent studies on cellulose-based fluorescent smart materials and their applications: A comprehensive review. Carbohydr. Polym. 2021, 267, 118135. [Google Scholar] [CrossRef]

- Zhang, C.; Mo, J.; Fu, Q.; Liu, Y.; Wang, S.; Nie, S. Wood-cellulose-fiber-based functional materials for triboelectric nanogenerators. Nano Energy 2021, 81, 105637. [Google Scholar] [CrossRef]

- Xia, Q.; Chen, C.; Yao, Y.; Li, J.; He, S.; Zhou, Y.; Li, T.; Pan, X.; Yao, Y.; Hu, L. A strong, biodegradable and recyclable lig-nocellulosic bioplastic. Nat. Sustain. 2021, 4, 627–635. [Google Scholar] [CrossRef]

- He, X.; Lu, W.; Sun, C.; Khalesi, H.; Mata, A.; Andaleeb, R.; Fang, Y. Cellulose and cellulose derivatives: Different colloidal states and food-related applications. Carbohydr. Polym. 2020, 255, 117334. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, C.; Liang, Z.; He, S.; Kuang, Y.; Song, J.; Mi, R.; Chen, G.; Jiao, M.; Hu, L. Lignin as a Wood-Inspired Binder Enabled Strong, Water Stable, and Biodegradable Paper for Plastic Replacement. Adv. Funct. Mater. 2019, 30, 1906307. [Google Scholar] [CrossRef]

- Wong, L.C.; Leh, C.P.; Goh, C.F. Designing cellulose hydrogels from non-woody biomass. Carbohydr. Polym. 2021, 264, 118036. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Wan, J.; Zhang, J.; Zhang, X.; Xu, L.; Wu, J.; He, J.; Zhang, J. Cellulose-based films prepared directly from waste newspapers via an ionic liquid. Carbohydr. Polym. 2016, 151, 223–229. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Luo, N.; Wan, J.; Xia, G.; Yu, J.; He, J.; Zhang, J. Directly Converting Agricultural Straw into All-Biomass Nano-composite Films Reinforced with Additional in Situ-Retained Cellulose Nanocrystals. ACS Sustain. Chem. Eng. 2017, 5, 5127–5133. [Google Scholar] [CrossRef]

- Lv, F.; Wang, C.; Zhu, P.; Zhang, C. Isolation and recovery of cellulose from waste nylon/cotton blended fabrics by 1-allyl-3-methylimidazolium chloride. Carbohydr. Polym. 2015, 123, 424–431. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Han, W.; Xu, Z.; Zhang, J.; Kong, F.; Zhang, J.; Zhang, X.; Jia, F. Complete recycling and valorization of waste textiles for value-added transparent films via an ionic liquid. J. Environ. Chem. Eng. 2021, 9, 106182. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Zhang, J.; Wang, J.; You, J.; Wang, Y.; Nawaz, H. Transparent cellulose/aramid nanofibers films with improved mechanical and ultraviolet shielding performance from waste cotton textiles by in-situ fabrication. Carbohydr. Polym. 2021, 273, 118569. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Zhao, T.S. Graphene sheets fabricated from disposable paper cups as a catalyst support material for fuel cells. J. Mater. Chem. A 2012, 1, 183–187. [Google Scholar] [CrossRef]

- Nagarajan, K.; Balaji, A.; Rajan, S.T.K.; Ramanujam, N. Preparation of bio-eco based cellulose nanomaterials from used disposal paper cups through citric acid hydrolysis. Carbohydr. Polym. 2020, 235, 115997. [Google Scholar] [CrossRef]

- Mitchell, J.; Vandeperre, L.; Dvorak, R.; Kosior, E.; Tarverdi, K.; Cheeseman, C. Recycling disposable cups into paper plastic composites. Waste Manag. 2014, 34, 2113–2119. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Li, H.; Fang, C.; Cheng, Y.; Tan, T.; Han, H. Synthesis and structure of carboxymethylcellulose with a high degree of substitution derived from waste disposable paper cups. Carbohydr. Polym. 2020, 237, 116040. [Google Scholar] [CrossRef] [PubMed]

- Ikram, R.; Jan, B.M.; Ahmad, W. Advances in synthesis of graphene derivatives using industrial wastes precursors; prospects and challenges. J. Mater. Res. Technol. 2020, 9, 15924–15951. [Google Scholar] [CrossRef]

- Abushammala, H.; Mao, J. A Review on the Partial and Complete Dissolution and Fractionation of Wood and Lignocelluloses Using Imidazolium Ionic Liquids. Polymers 2020, 12, 195. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Ruan, D.; Gao, S. Dissolution and regeneration of cellulose in NaOH/thiourea aqueous solution. J. Polym. Sci. Part B Polym. Phys. 2002, 40, 1521–1529. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of Cellose with Ionic Liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef] [PubMed]

- Xia, G.; Reddy, K.O.; Maheswari, C.U.; Jayaramudu, J.; Zhang, J.; Zhang, J.; Rajulu, A.V. Preparation and Properties of Biodegradable Spent Tea Leaf Powder/Poly(Propylene Carbonate) Composite Films. Int. J. Polym. Anal. Charact. 2015, 20, 377–387. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Zhang, J.; He, J. 1-Allyl-3-methylimidazolium Chloride Room Temperature Ionic Liquid: A New and Powerful Nonderivatizing Solvent for Cellulose. Macromolecules 2005, 38, 8272–8277. [Google Scholar] [CrossRef]

- Sun, N.; Rahman, M.; Qin, Y.; Maxim, M.L.; Rodríguez, H.; Rogers, R.D. Complete dissolution and partial delignification of wood in the ionic liquid 1-ethyl-3-methylimidazolium acetate. Green Chem. 2009, 11, 646–655. [Google Scholar] [CrossRef]

- Cao, Y.; Li, H.; Zhang, Y.; Zhang, J.; He, J. Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J. Appl. Polym. Sci. 2009, 116, 547–554. [Google Scholar] [CrossRef]

- Luo, N.; Lv, Y.; Wang, D.; Zhang, J.; Wu, J.; He, J.; Zhang, J. Direct visualization of solution morphology of cellulose in ionic liquids by conventional TEM at room temperature. Chem. Commun. 2012, 48, 6283–6285. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Li, Y.; Liu, X.; Zhang, X.; Wang, J.; Yao, X.; Zhang, S. Mechanistic study on the cellulose dissolution in ionic liquids by density functional theory. Chin. J. Chem. Eng. 2015, 23, 1894–1906. [Google Scholar] [CrossRef]

- Cao, Y.; Wu, J.; Meng, T.; Zhang, J.; He, J.; Li, H.; Zhang, Y. Acetone-soluble cellulose acetates prepared by one-step homogeneous acetylation of cornhusk cellulose in an ionic liquid 1-allyl-3-methylimidazolium chloride (AmimCl). Carbohydr. Polym. 2007, 69, 665–672. [Google Scholar] [CrossRef]

- Xia, G.; Zhou, Q.; Xu, Z.; Zhang, J.; Ji, X.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Cellulose-Based Films with Ultraviolet Shielding Performance Prepared Directly from Waste Corrugated Pulp. Polymers 2021, 13, 3359. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.; Zhou, X.; Ma, J.; Liu, X. Preparation and Characterization of Novel Regenerated Cellulose Films via Sol–Gel Technology. Ind. Eng. Chem. Res. 2013, 52, 17900–17906. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Z.; Zhou, Q.; Wang, L.; Xia, G.; Ji, X.; Zhang, J.; Zhang, J.; Nawaz, H.; Wang, J.; Peng, J. Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers 2021, 13, 4209. https://doi.org/10.3390/polym13234209

Xu Z, Zhou Q, Wang L, Xia G, Ji X, Zhang J, Zhang J, Nawaz H, Wang J, Peng J. Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers. 2021; 13(23):4209. https://doi.org/10.3390/polym13234209

Chicago/Turabian StyleXu, Zhen, Qiwen Zhou, Lixiang Wang, Guangmei Xia, Xingxiang Ji, Jinming Zhang, Jun Zhang, Haq Nawaz, Jie Wang, and Jianfeng Peng. 2021. "Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid" Polymers 13, no. 23: 4209. https://doi.org/10.3390/polym13234209

APA StyleXu, Z., Zhou, Q., Wang, L., Xia, G., Ji, X., Zhang, J., Zhang, J., Nawaz, H., Wang, J., & Peng, J. (2021). Transparent Cellulose-Based Films Prepared from Used Disposable Paper Cups via an Ionic Liquid. Polymers, 13(23), 4209. https://doi.org/10.3390/polym13234209