Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing Using 3D Printing

2.3. Aging Process

2.4. Mechanical Characterization of the Printed Specimens

2.4.1. Three-Point Bending Tests

2.4.2. Transverse Impact Tests

3. Results and Discussion

3.1. Saliva Induced Aging

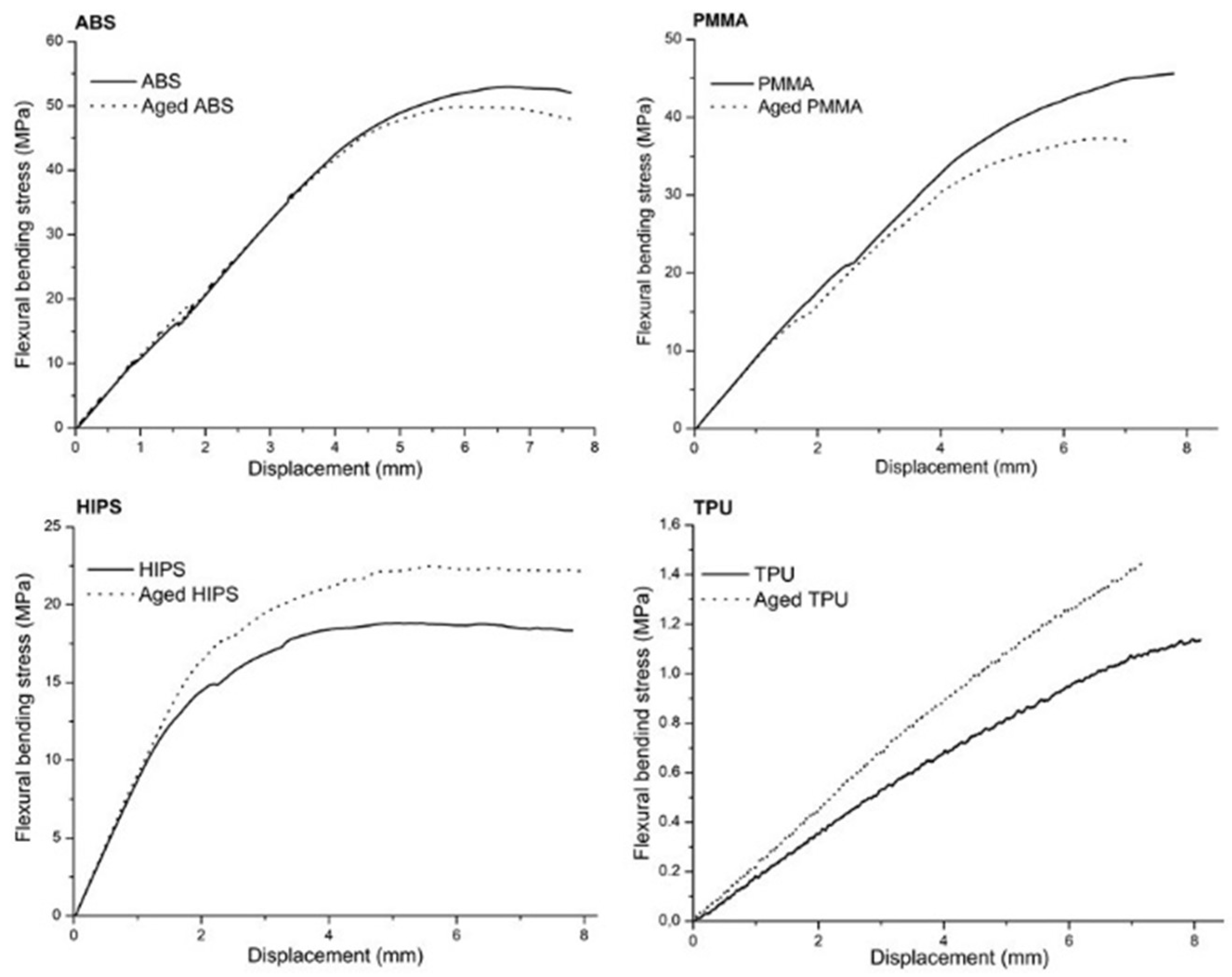

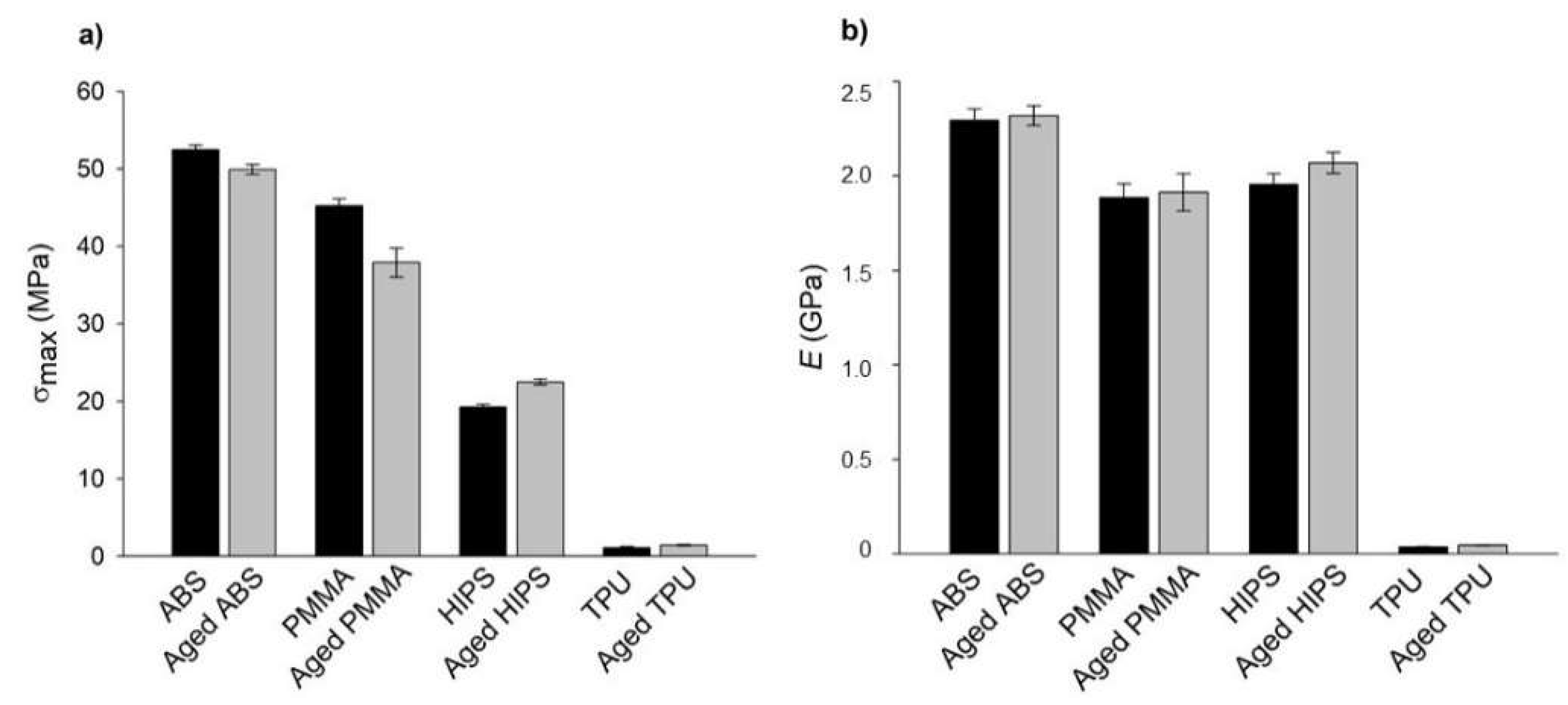

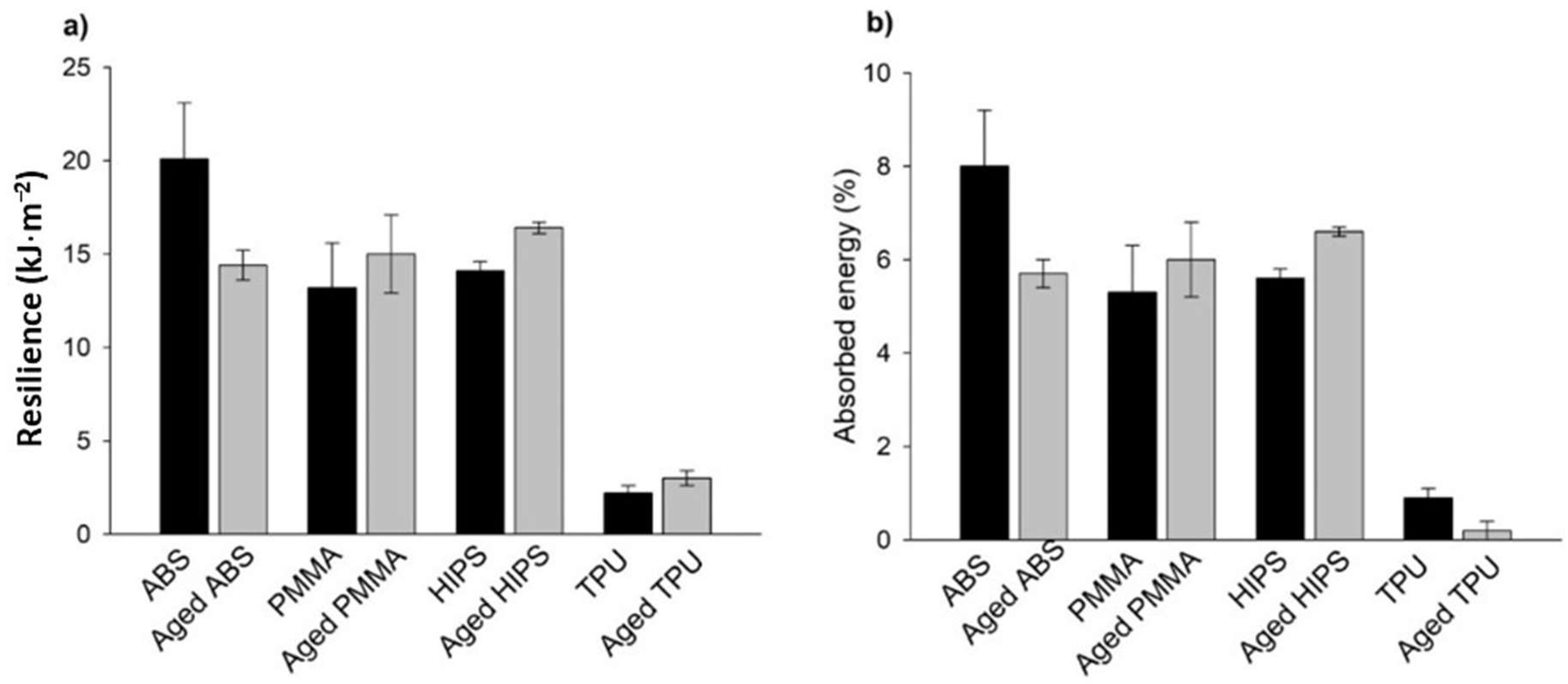

3.2. Mechanical Properties of Printed Mono-Materials

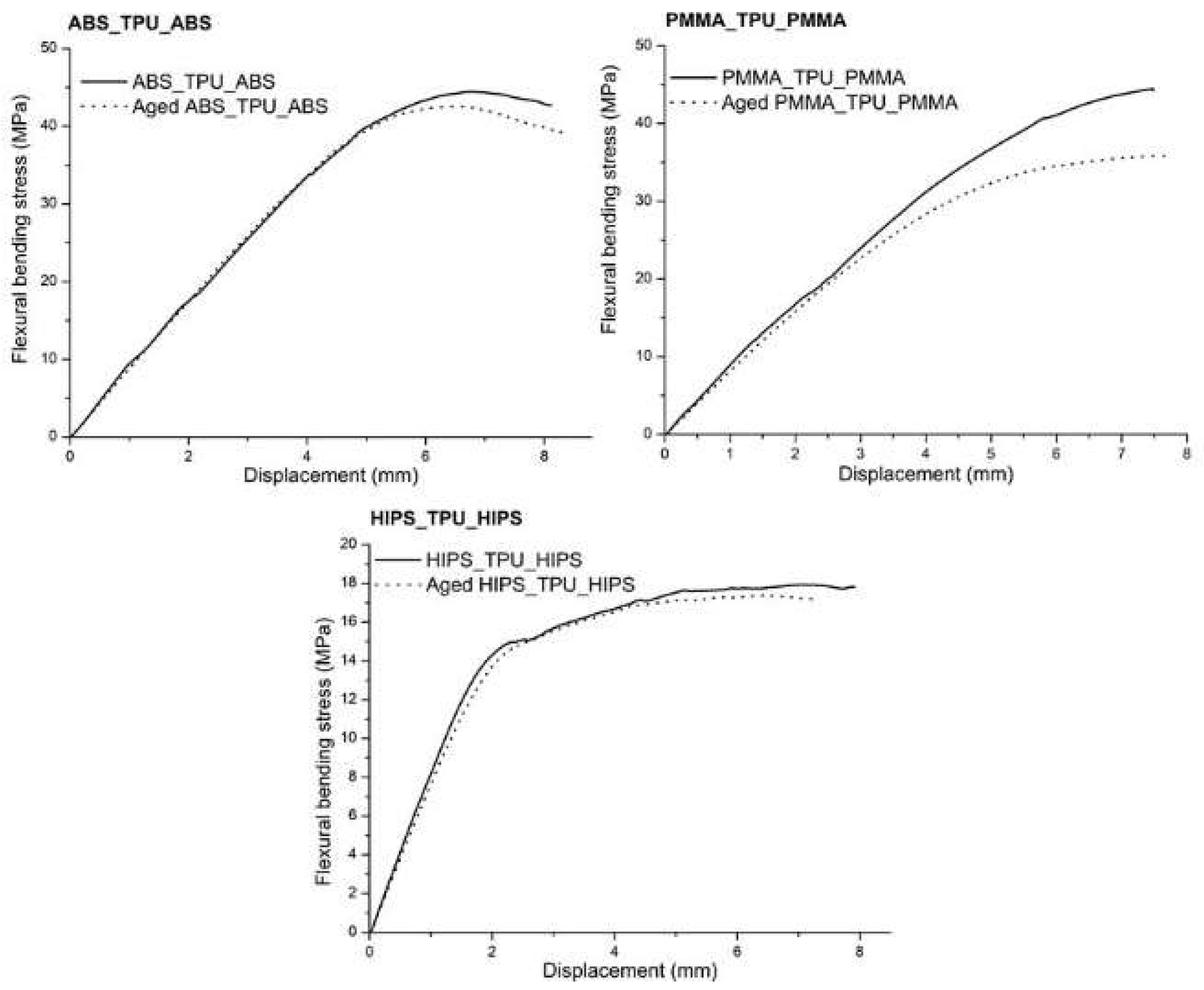

3.3. Mechanical Properties of Printed Sandwich Structures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lauwers, B.; Klocke, F.; Klink, A.; Tekkaya, A.E.; Neugebauer, R.; McIntosh, D. Hybrid Processes in Manufacturing. CIRP Ann. 2014, 63, 561–586. [Google Scholar] [CrossRef]

- Di Angelo, L.; Di Stefano, P.; Guardiani, E. Search for the Optimal Build Direction in Additive Manufacturing Technologies: A Review. J. Manuf. Mater. Process. 2020, 4, 71. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. A Comprehensive Review of Additive Manufacturing in Construction of Electrical Machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef] [Green Version]

- Braian, M.; Jönsson, D.; Kevci, M.; Wennerber, A. Geometrical accuracy of metallic objects produced with additive or subtractive manufacturing: A comparative in vitro study. Dent. Mater. 2018, 34, 978–993. [Google Scholar] [CrossRef]

- Piedade, A.P.; Gil, M.H.; Cavaco, M.C.; Andrade, M.E. Behaviour of catalase immobilised on poly(acrylonitrile)-g.co-hydroxyethyl methacrylate when used in a continuous system. Polym. Int. 1995, 38, 269–275. [Google Scholar] [CrossRef]

- Alves da Silva, M.; Beddows, C.G.; Gil, M.H.; Kotov, S.; Piedade, A.P. The application of radiation-induced processed copolymers to biocatalysts immobilisation. Radiat. Phys. Chem. 1990, 35, 98–101. [Google Scholar]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Pinho, A.C.; Buga, C.S.; Piedade, A.P. The chemistry behind 4D printing. Appl. Mater. Today. 2020, 19, 100611. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R.; Boparai, K.S.; Penna, R.; Fraternali, F. Dimensional accuracy analysis of coupled fused deposition modeling and vapour smoothing operations for biomedical applications. Compos. Part B Eng. 2017, 117, 138–149. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Baca Lopez, D.M.; Ahmad, R. Tensile Mechanical Behaviour of Multi-Polymer Sandwich Structures via Fused Deposition Modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef] [Green Version]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Duran, C.; Subbian, V.; Giovanetti, M.T.; Simkins, J.R.; Beyette, F.R. Experimental desktop 3D printing using dual extrusion and water-soluble polyvinyl alcohol. Rapid Prototyp. J. 2015, 21, 528–534. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Park, J.H.; Lee, N.K.; Lyu, M.Y.; Park, K.; Koo, M.S.; Cho, S.H.; Son, Y.; Park, S.H. Enhanced Solubility of the Support in an FDM-Based 3D Printed Structure Using Hydrogen Peroxide under Ultrasonication. Adv. Mater. Sci. Eng. 2020, 2018, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.-A.; Llumà, J.; Borros, S.; Reyes, G. Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Wendt, C.; Valerga, A.P.; Droste, O.; Batista, M.; Marcos, M. FEM based evaluation of fused layer modelling monolayers in tensile testing. Procedia Manuf. 2017, 13, 916–923. [Google Scholar] [CrossRef]

- Somireddy, M.; Czekanski, A. Mechanical characterization of additively manufactured parts by FE modeling of mesostructured. J. Manuf. Mater. Process. 2017, 1, 18. [Google Scholar]

- Somireddy, M.; De Moraes, D.A.; Czekanski, A. Flexural behavior of fdm parts: Experimental, analytical and numerical study. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2012. [Google Scholar]

- Huang, B.; Singamneni, S. Adaptive slicing and speed-and time-dependent consolidation mechanisms in fused deposition modeling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 111–126. [Google Scholar] [CrossRef]

- Zhang, Y.; Chou, Y. Three-dimensional finite element analysis simulations of the fused deposition modelling process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1663–1671. [Google Scholar] [CrossRef]

- Somireddy, M.; Czekanski, A.; Singh, C.V. Development of constitutive material model of 3D printed structure via FDM. Mater. Today Commun. 2018, 15, 143–152. [Google Scholar] [CrossRef]

- Barocio, E.; Brenken, B.; Favaloro, A.; Pipes, R.B. Extrusion deposition additive manufacturing of composite molds for high-temperature applications. In Proceedings of the International SAMPE Technical Conference, Seattle, WA, USA, 22–25 May 2017; pp. 1512–1523. [Google Scholar]

- Brenken, B.; Barocio, E.; Favaloro, A.J.; Pipes, R.B. Simulation of semi-crystalline composites in the extrusion deposition additive manufacturing process. In Proceedings of the American Society for Composites, West Lafayette, IN, USA, 23–25 October 2017; pp. 90–102. [Google Scholar]

- Daniel, I.M.; Abot, J.L. Fabrication, testing and analysis of composite sandwich beams. Compos. Sci. Technol. 2000, 60, 2455–2463. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef] [Green Version]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material Additive Manufacturing of Sustainable Innovative Materials and Structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brischetto, S.; Ferro, C.G.; Torre, R.; Maggiore, P. 3D FDM production and mechanical behavior of polymeric sandwich specimens embedding classical and honeycomb cores. Curved Layer. Struct. 2018, 5, 80–94. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pinho, A.C.; Messias, A.; Piedade, A.P. Present status in polymeric mouthguards. A future area for additive manufacturing? Polymers 2020, 12, 1490. [Google Scholar] [CrossRef]

- Duty, C.; Failla, J.; Kim, S.; Smith, T.; Lindahl, J.; Kunc, V. Z-Pinning approach for 3D printing mechanically isotropic materials. Addit. Manuf. 2019, 27, 175–184. [Google Scholar] [CrossRef]

- Nugroho, A.; Ardiansyah, R.; Rusita, L.; Larasati, I.L. Effect of layer thickness on flexural properties of PLA (PolyLactid Acid) by 3D printing. J. Phys. Conf. Ser. 2018, 1130, 012017. [Google Scholar] [CrossRef]

- Ferreira, J.M.; Capela, C.; Manaia, J.; Costa, J.D. Mechanical properties of woven mat jute/epoxy composites. Mater. Res. 2016, 19, 702–710. [Google Scholar] [CrossRef] [Green Version]

- Jafari, R.; Cloutier, C.; Allahdini, A.; Momen, G. Recent progress and challenges with 3D printing of patterned hydrophobic and superhydrophobic surfaces. Int. J. Adv. Manuf. Technol. 2019, 103, 1225–1238. [Google Scholar] [CrossRef]

- Zulfi, A.; Munir, M.M.; Hapidin, D.A.; Rajak, A.; Edikresnha, D.; Iskandar, F.; Khairurrijal, K. Air filtration media from electrospun waste high-impact polystyrene fiber membrane. Mater. Res. Express. 2018, 5, 035049. [Google Scholar] [CrossRef]

- Mistry, P.; Chhabra, R.; Muke, S.; Narvekar, A.; Sathaye, S.; Jain, R.; Dandekar, P. Fabrication and characterization of starch-TPU based nanofibers for wound healing applications. Mater. Sci. Eng. C 2021, 119, 111316. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Li, X.; Chen, C.; Zheng, Z.; Chang, H. Monodisperse water-in-oil-in-water emulsions generation for synthesising alginate hydrogel microspheres via locally hydrophobic modification to PMMA microchannels. Sens. Actuators 2018, 255, 1048–1056. [Google Scholar] [CrossRef]

- Lin, C.Y. Alternative Form of Standard Linear Solid Model for Characterizing Stress Relaxation and Creep: Including a Novel Parameter for Quantifying the Ratio of Fluids to Solids of a Viscoelastic Solid. Front. Mater. 2020, 7, 11. [Google Scholar] [CrossRef]

- Song, D.; Li, C.; Liang, N.; Yang, F.; Jiang, J.; Sun, J.; Wu, G.; Ma, A.; Ma, X. Simultaneously improving corrosion resistance and mechanical properties of a magnesium alloy via equal-channel angular pressing and post water annealing. Mater. Des. 2019, 166, 107621. [Google Scholar] [CrossRef]

- Brischetto, S.; Torre, R. Honeycomb Sandwich Specimens Made of PLA and Produced Via 3D FDM Printing Process: An Experimental Study. J. Aircr. Spacecr. Technol. 2020, 4, 54–69. [Google Scholar] [CrossRef]

- Zhou, Y.; Raphael, R.M. Solution pH alters mechanical and electrical properties of phosphatidylcholine membranes: Relation between interfacial electrostatics, intramembrane potential, and bending elasticity. Biophys. J. 2007, 92, 2451–2462. [Google Scholar] [CrossRef] [Green Version]

- Alaimo, G.; Marconi, S.; Costato, L.; Auricchio, F. Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos. Part B Eng. 2017, 113, 371–380. [Google Scholar] [CrossRef]

- Torres, J.M.; Wang, C.; Coughlin, E.B.; Bishop, J.P.; Register, R.A.; Riggleman, R.A.; Stafford, C.M.; Vogt, B.D. Influence of chain stiffness on thermal and mechanical properties of polymer thin films. Macromolecules 2011, 44, 9040–9045. [Google Scholar] [CrossRef]

- Coto, N.P.; Brito e Dias, R.; Costa, R.A.; Antoniazzi, T.F.; de Carvalho, E.P.C. Mechanical behavior of ethylene vinyl acetate copolymer (EVA) used for fabrication of mouthguards and interocclusal splints. Braz. Dent. J. 2007, 18, 324–328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karaganeva, R.; Pinner, S.; Tomlinson, D.; Burden, A.; Taylor, R.; Yates, J.; Winwood, K. Effect of mouthguard design on retention and potential issues arising with usability in sport. Dent. Traumatol. 2019, 35, 73–79. [Google Scholar] [CrossRef]

- Liu, X.F.; Liu, B.W.; Luo, X.; Guo, D.M.; Zhong, H.Y.; Chen, L.; Wang, Y.Z. A novel phosphorus-containing semi-aromatic polyester toward flame retardancy and enhanced mechanical properties of epoxy resin. Chem. Eng. J. 2020, 380, 122471. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Y.; Meng, Y.; Anusonti-Inthra, P.; Wang, S. Preparing cellulose nanocrystal/acrylonitrile-butadiene-styrene nanocomposites using the master-batch method. Carbohydr. Polym. 2015, 125, 352–359. [Google Scholar] [CrossRef] [PubMed]

- Szatyłowicz, H.; Krygowski, T.M. Varying electronegativity: Effect of the nature and strength of H-bonding in anilide/aniline/anilinium complexes on the electronegativity of NH- / NH2 / NH3+ groups. J. Mol. Struct. 2007, 844–845, 200–207. [Google Scholar] [CrossRef]

- Dias, R.B.; Coto, N.P.; Batalha, G.F.; Driemeier, L. Systematic study of Ethylene-Vinyl Acetate (EVA) in the manufacturing of protector devices for the orofacial system. Arch. Mater. Sci. Eng. 2017, 86, 24–31. [Google Scholar] [CrossRef] [Green Version]

- Tham, W.L.; Chow, W.S.; Ishak, Z.A.A. Simulated body fluid and water absorption effects on poly(methyl methacrylate)/hydroxyapatite denture base composites. Express Polym. Lett. 2010, 4, 517–528. [Google Scholar] [CrossRef]

- Rattan, S.; Li, L.; Lau, H.K.; Crosby, A.J.; Kiick, K.L. Micromechanical characterization of soft, biopolymeric hydrogels: Stiffness, resilience, and failure. Soft Matter. 2018, 14, 3478–3489. [Google Scholar] [CrossRef]

- Sousa, A.M.; Pinho, A.C.; Piedade, A.P. Mechanical properties of 3D printed mouthguards: Influence of layer height and device thickness. Mater. Des. 2021, 203, 109624. [Google Scholar] [CrossRef]

| Configuration | Filament | Tprinting (°C) | Tbed (°C) | Ps (mm/s) |

|---|---|---|---|---|

| Mono-Material | ABS | 220 | 110 | 50 |

| HIPS | 220 | 110 | 50 | |

| PMMA | 220 | 110 | 50 | |

| TPU | 220 | 110 | 15 | |

| Sandwich Structure | ABS-TPU-ABS | 220 | 110 | 15 |

| HIPS-TPU-HIPS | 220 | 110 | 15 | |

| PMMA-TPU-PMMA | 220 | 110 | 15 |

| Test | Material | Length (mm) | Width (mm) | Thickness (mm) | |||

|---|---|---|---|---|---|---|---|

| Dry | Aged | Dry | Aged | Dry | Aged | ||

| 3PB | ABS | 59.8 * | 59.9 * | 10.0 * | 10.0 * | 2.1 * | 2.1 * |

| HIPS | 59.8 * | 59.7 ± 0.1 | 9.8 ± 0.4 | 10.0 * | 2.1 * | 2.1 * | |

| PMMA | 59.9 * | 60.2 ± 0.1 | 10.2 * | 10.2 * | 2.1 * | 2.1 * | |

| TPU | 59.9± 0.2 | 60.2 ± 0.1 | 10.4 ± 0.2 | 10.4 ± 0.2 | 2.1 ± 0.2 | 2.1 ± 0.2 | |

| ABS-TPU-ABS | 60.3 ± 0.1 | 60.3 ±0.1 | 10.4 ± 0.1 | 10.4 ± 0.1 | 2.4 ± 0.1 | 2.4 ± 0.1 | |

| HIPS-TPU-HIPS | 60.3 ± 0.1 | 60.2 ± 0.1 | 10.4 ± 0.1 | 10.3 ± 0.1 | 2.3 * | 2.4 * | |

| PMMA-TPU-PMMA | 60.1 ± 0.1 | 60.3 ± 0.1 | 10.4 ± 0.1 | 10.4 ± 0.1 | 2.5 * | 2.5 * | |

| Transverse impact | ABS | 79.5 ± 0.1 | 79.6 ± 0.1 | 9.9 * | 9.9 * | 2.1 * | 2.1 * |

| HIPS | 79.6 ± 0.1 | 79.5 * | 9.9 * | 9.9 * | 2.1 * | 2.1 * | |

| PMMA | 79.8 ± 0.1 | 80.0 ± 0.1 | 10.1 ± 0.1 | 10.1 ± 0.1 | 2.1 * | 2.1 * | |

| TPU | 80.2 ± 0.1 | 80.3 ± 0.1 | 10.5 ± 0.3 | 10.6 ± 0.1 | 2.1 ± 0.1 | 2.2 ± 0.2 | |

| ABS-TPU-ABS | 84.0 ± 0.1 | 84.1 * | 10.7 * | 10.8 * | 2.4 * | 2.4 * | |

| HIPS-TPU-HIPS | 84.0 ± 0.1 | 84.0 ± 0.1 | 10.8 * | 10.8 * | 2.4 * | 2.4 * | |

| PMMA-TPU-PMMA | 84.1 ± 0.1 | 84.3 ± 0.2 | 10.9 ± 0.1 | 10.9 ± 0.1 | 2.5 * | 2.5 * | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pinho, A.C.; Piedade, A.P. Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances. Polymers 2021, 13, 4030. https://doi.org/10.3390/polym13224030

Pinho AC, Piedade AP. Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances. Polymers. 2021; 13(22):4030. https://doi.org/10.3390/polym13224030

Chicago/Turabian StylePinho, Ana C., and Ana P. Piedade. 2021. "Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances" Polymers 13, no. 22: 4030. https://doi.org/10.3390/polym13224030

APA StylePinho, A. C., & Piedade, A. P. (2021). Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances. Polymers, 13(22), 4030. https://doi.org/10.3390/polym13224030