Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch

Abstract

:1. Introduction

2. Materials and Methods

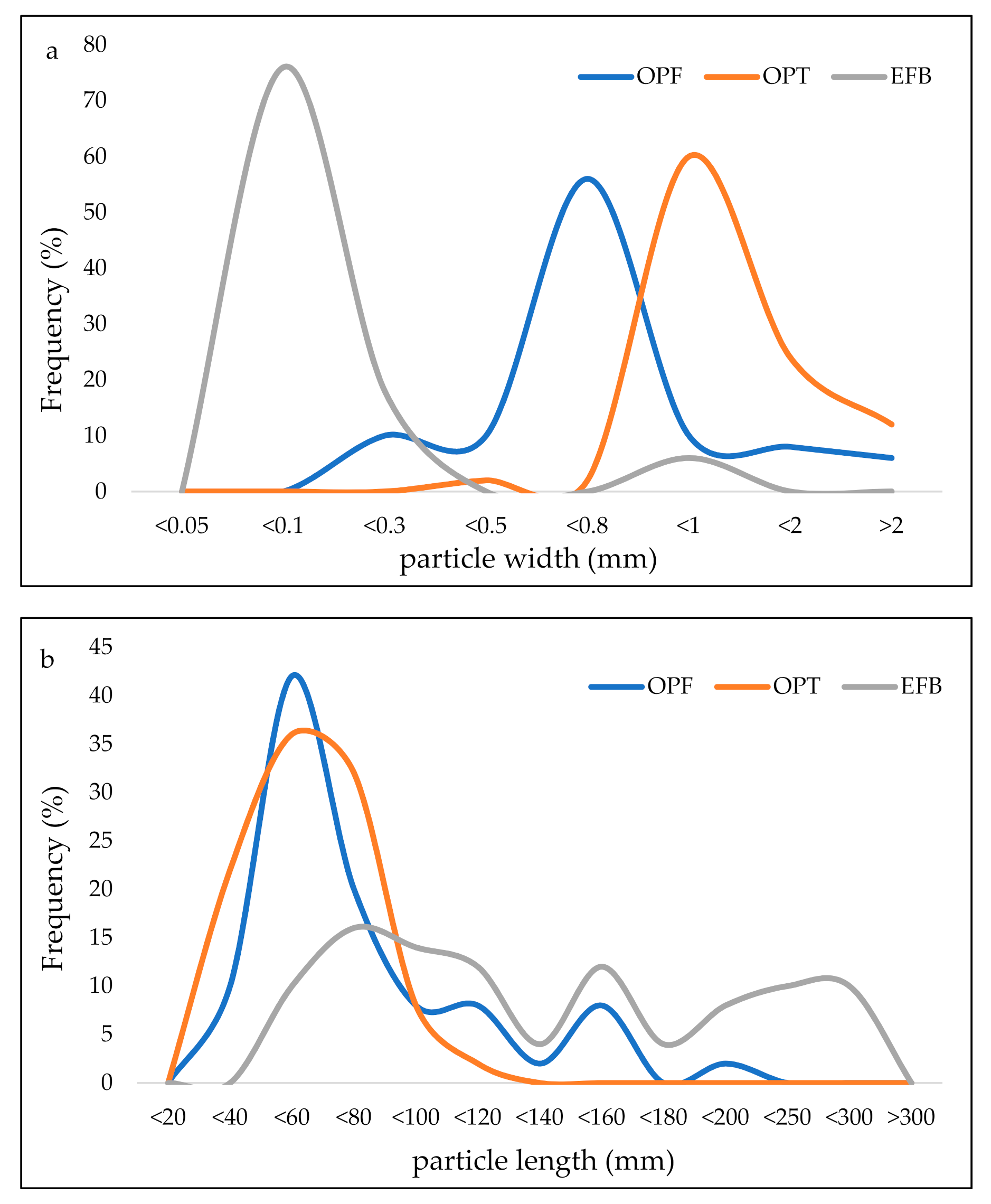

2.1. Preparation of Materials

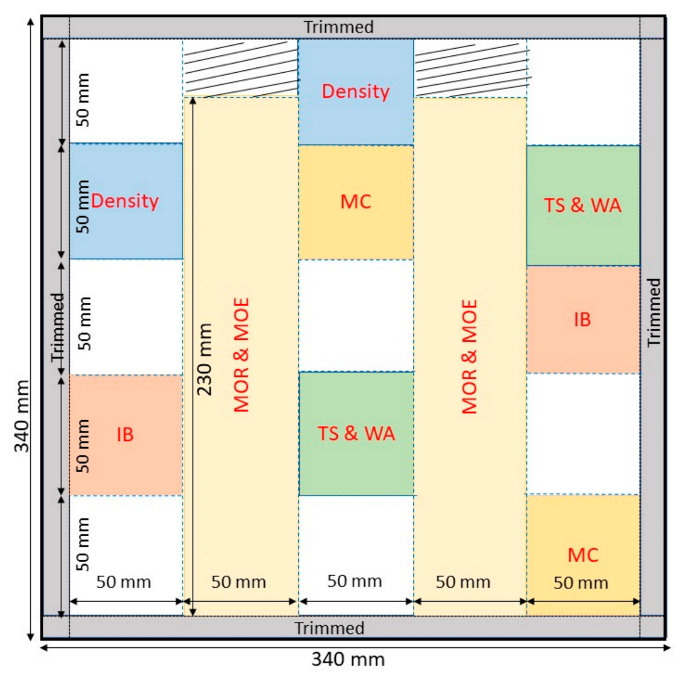

2.2. Fabrication of Particleboard

2.3. Properties Evaluation

2.3.1. Thermogravimetric Analysis (TGA) of Citric Acid/Tapioca Starch Binder

2.3.2. Chemical Composition and Bulk Density of Oil Palm Biomasses

2.3.3. Mechanical Properties of Particleboard

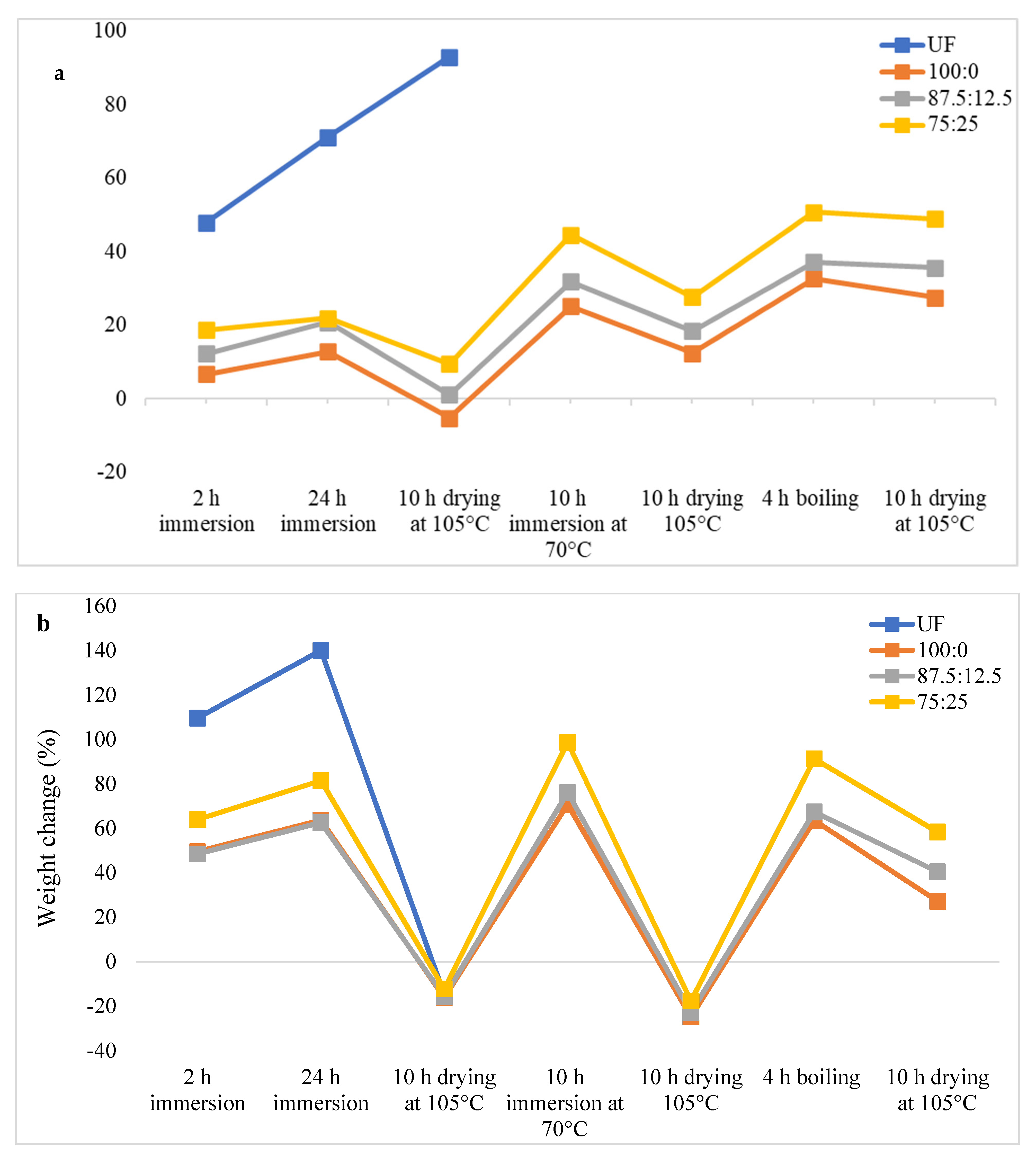

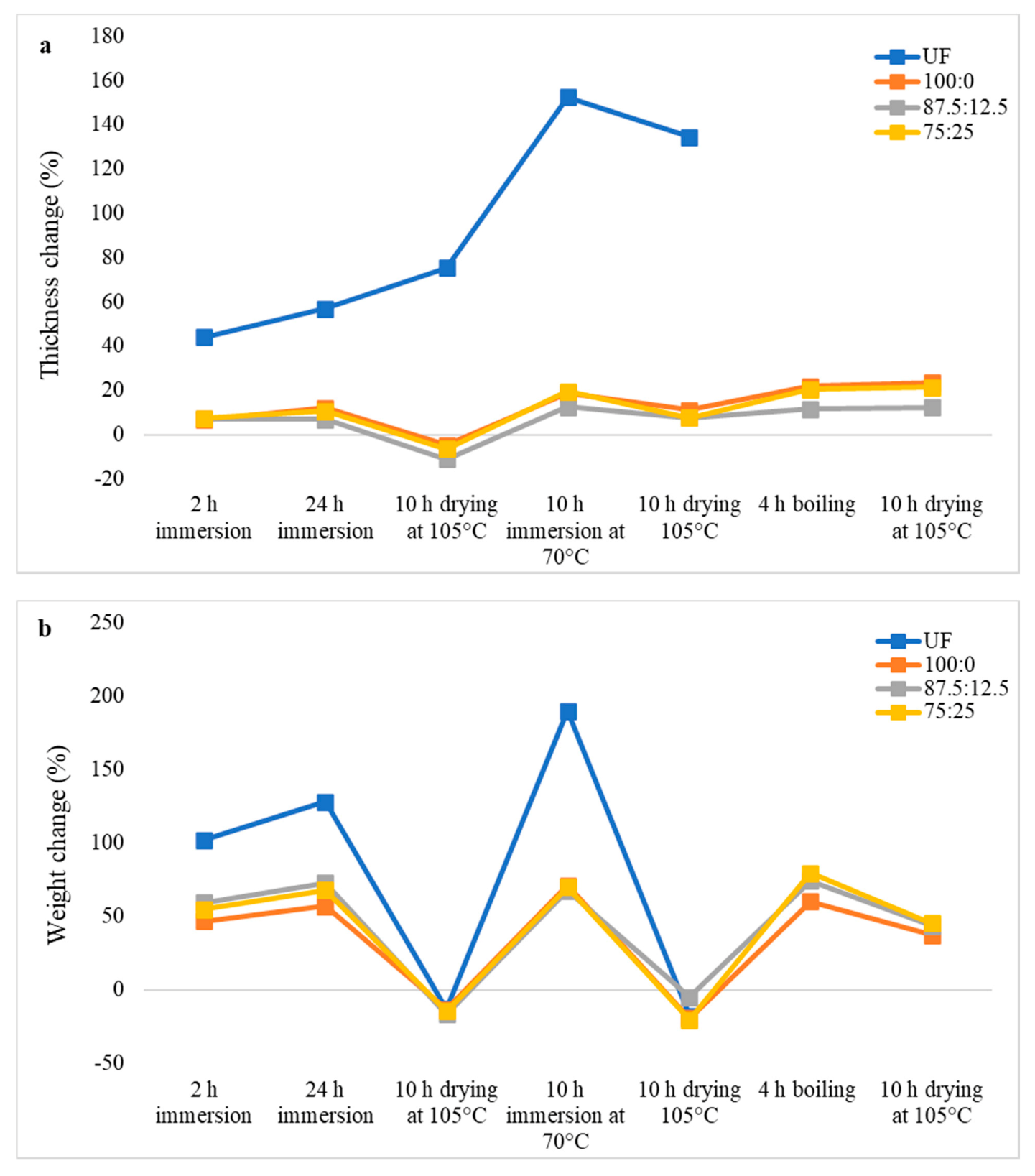

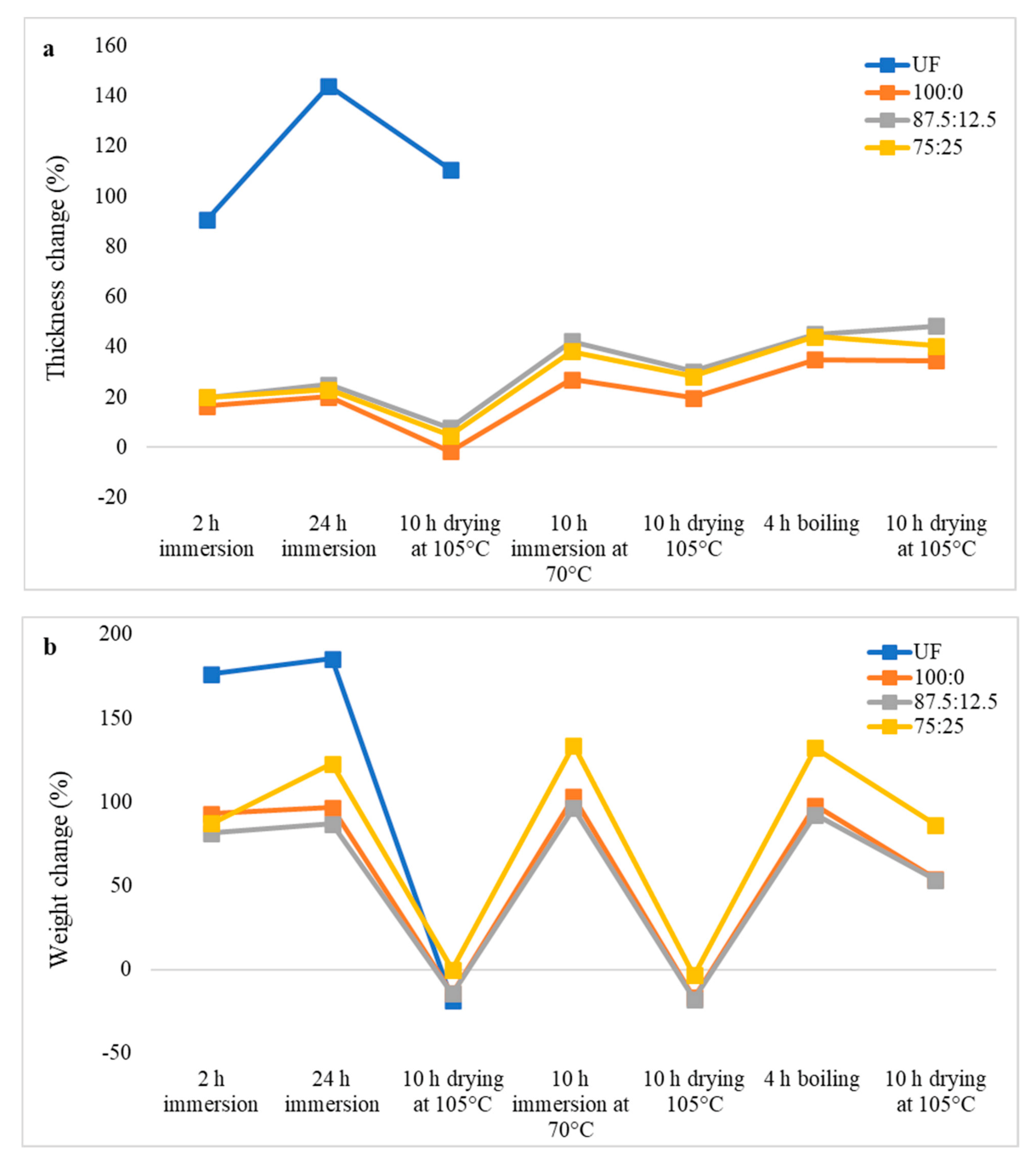

2.3.4. Physical Properties of Particleboard

- Drying at 105 °C for 10 h

- Immersion in water at 70 °C for 10 h

- Drying at 105 °C for 10 h

- Immersion in boiling water for 4 h

- Drying at 105 °C for 10 h

2.3.5. Statistical Analysis

3. Results and Discussion

3.1. Chemical Composition and Bulk Density

3.2. Thermogravimetric Analysis (TGA)

3.3. Mechanical Properties of the Particleboard

3.4. Physical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Malaysian Palm Oil Board (MPOB). Oil Palm Planted Area 2020. Available online: https://bepi.mpob.gov.my/index.php/en/area/area-2020/oil-palm-planted-area-as-at-dec-2020 (accessed on 18 August 2021).

- Mohammad Padzil, F.N.M.; Lee, S.H.; Ainun, Z.M.A.; Lee, C.H.; Abdullah, L.C. Potential of oil palm empty fruit bunch resources in nanocellulose hydrogel production for versatile applications: A review. Materials 2020, 13, 1245. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khalil, H.S.A.; Alwani, M.S.; Omar, A.K.M. Chemical composition, anatomy, lignin distribution, and cell wall structure of Malaysian plant waste fibers. BioResources 2006, 1, 220–232. [Google Scholar] [CrossRef]

- Griffin, W.; Michalek, J.; Matthews, H.; Hassan, M. Availability of biomass residues for co-firing in Peninsular Malaysia: Implications for cost and GHG emissions in the electricity sector. Energies 2014, 7, 804–823. [Google Scholar] [CrossRef] [Green Version]

- Lathrop, E.C.; Naffziger, T.R. Evaluation of fibrous agricultural residue for structural building board products-III. A process for the manufacture of high-grade products from wheat straw. Tappi 1994, 32, 319–330. [Google Scholar]

- Penniston, K.L.; Nakada, S.Y.; Holmes, R.P.; Assimos, D.G. Quantitative assessment of citric acid in lemon juice, lime juice, and commercially-available fruit juice products. J. Endourol. 2008, 22, 567–570. [Google Scholar] [CrossRef] [PubMed]

- Umemura, K.; Ueda, T.; Munawar, S.S.; Kawai, S. Application of citric acid as natural adhesive for wood. J. Appl. Polym. Sci. 2012, 123, 1991–1996. [Google Scholar] [CrossRef]

- Lee, S.H.; Tahir, P.M.; Lum, W.C.; Tan, L.P.; Bawon, P.; Park, B.D.; Al Edrus, S.S.O.; Abdullah, U.H. A review on citric acid as green modifying agent and binder for wood. Polymers 2020, 12, 1692. [Google Scholar] [CrossRef] [PubMed]

- Umemura, K.; Sugihara, O.; Kawai, S. Investigation of a new natural adhesive composed of citric acid and sucrose for particleboard. J. Wood Sci. 2013, 59, 203–208. [Google Scholar] [CrossRef] [Green Version]

- Widyorini, R.; Nugraha, P.; Rahman, M.; Prayitno, T. Bonding ability of a new adhesive composed of citric acid-sucrose for particleboard. BioResources 2016, 11, 4526–4535. [Google Scholar] [CrossRef]

- Widyorini, R.; Umemura, K.; Kusumaningtyas, A.R.; Prayitno, T.A. Effect of starch addition on properties of citric acid-bonded particleboard made from bamboo. BioResources 2017, 12, 8068–8077. [Google Scholar]

- Widyorini, R.; Umemura, K.; Isnan, R.; Putra, D.R.; Awaludin, A.; Prayitno, T.A. Manufacture and properties of citric acid-bonded particleboard made from bamboo materials. Eur. J. Wood Wood Prod. 2016, 74, 57–65. [Google Scholar] [CrossRef]

- Kusumah, S.S.; Umemura, K.; Guswenrivo, I.; Yoshimura, T.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard II: Influences of pressing temperature and time on particleboard properties. J. Wood Sci. 2017, 63, 161–172. [Google Scholar] [CrossRef] [Green Version]

- Santoso, M.; Widyorini, R.; Prayitno, T.A.; Sulistyo, J. Bonding performance of maltodextrin and citric acid for particleboard made from nipa fronds. J. Korean Wood Sci. Technol. 2017, 45, 432–443. [Google Scholar]

- Syamani, F.A.; Kusumah, S.S.; Astari, L.; Prasetiyo, K.W.; Wibowo, E.S.; Subyakto. Effect of pre-drying time and citric acid content on Imperata cylindrica particleboards properties. IOP Conf. Ser. Earth Environ. Sci. 2018, 209, 01203. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental evaluation of a new giant reed (Arundo Donax L.) composite using citric acid as a natural binder. Agronomy 2019, 9, 882. [Google Scholar] [CrossRef] [Green Version]

- Liao, R.; Xu, J.; Umemura, K. Low density sugarcane bagasse particleboard bonded with citric acid and sucrose: Effect of board density and additive content. BioResources 2016, 11, 2174–2185. [Google Scholar] [CrossRef]

- Zhou, H.X.; Hua, L.S.; Tahir, P.M.; Ashaari, Z.; Al-Edrus, S.S.O.; Ibrahim, N.A.; Abdullah, L.C.; Mohamad, S.F. Physico-Mechanical and Biological Durability of Citric Acid-Bonded Rubberwood Particleboard. Polymers 2021, 13, 98. [Google Scholar]

- Lee, S.H.; Lum, W.C.; Zaidon, A.; Maminski, M. Microstructural, mechanical and physical properties of post heat-treated melamine-fortified urea formaldehyde-bonded particleboard. Eur. J. Wood Wood Prod. 2015, 73, 607–616. [Google Scholar] [CrossRef]

- JIS A 5908. Particleboards. Japanese Industrial Standards (JIS); Japanese Standards Association: Tokyo, Japan, 2003. [Google Scholar]

- TAPPI Standard T222 os-74. Acid-Insoluble Lignin in Wood and Pulp; Technical Association of the Pulp and Paper Industry (TAPPI): Atlanta, Georgia, 1974. [Google Scholar]

- TAPPI Standard T203 os-74. Alpha-, Beta-, Gamma-Cellulose in Pulp; Technical Association of the Pulp and Paper Industry (TAPPI): Atlanta, Georgia, 1974. [Google Scholar]

- Wise, L.E.; Murphy, M.; D’Addieco, A.A. Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Paper Trade J 1946, 122, 35–43. [Google Scholar]

- Lee, S.H.; Ashaari, Z.; Chen, L.W.; San, H.P.; Peng, T.L.; Chow, M.J.; Chai, E.W.; Chin, K.L. Properties of particleboard with oil palm trunk as core layer in comparison to three-layer rubberwood particleboard. J. Oil Palm Res. 2015, 27, 67–74. [Google Scholar]

- Kusumah, S.S.; Umemura, K.; Yoshioka, K.; Miyafuji, H.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind. Crop. Prod. 2016, 84, 34–42. [Google Scholar] [CrossRef] [Green Version]

- Abdul Khalil, H.P.S.; Jawaid, M.; Hassan, A.; Paridah, M.T.; Zaidon, A. Oil palm biomass fibres and recent advancement in oil palm biomass fibres based hybrid biocomposites. In Composites and Their Applications, 1st ed.; Hu, N., Ed.; InTechOpen: London, UK, 2012. [Google Scholar]

- John, M.J.; Francis, B.; Varughese, K.T.; Thomas, S. Effect of chemical modification on properties of hybrid fiber biocomposites. Compos.-A Appl. Sci. Manuf. 2008, 39, 352–363. [Google Scholar] [CrossRef]

- Grigoriu, A.; Passialis, C.; Voulgaridis, E. Experimental particleboards from kenaf plantations grown in Greece. Holz. Roh. Werkst. 2000, 58, 309–314. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Hill, C.A.S.; Gkaraveli, A.; Ntalos, G.A.; Karastergiou, S.P. Bamboo chips (Bambusa vulgaris) as an alternative lignocellulosic raw material for particleboard manufacture. Holz. Roh. Werkst. 2004, 62, 36–39. [Google Scholar] [CrossRef]

- Silva, N.T.; Nascimento, N.F.; Cividanes, L.S.; Bertran, C.A.; Thim, G.P. Kinetics of cordierite crystallization from diphasic gels. J. Solgel. Sci. Technol. 2008, 47, 140–147. [Google Scholar] [CrossRef]

- Chen, W.C.; Judah, S.N.M.S.M.; Ghazali, S.K.; Munthoub, D.I.; Alias, H.; Mohamad, Z.; Abd Majid, R. The Effects of Citric Acid on Thermal and Mechanical Properties of Crosslinked Starch Film. Chem. Eng. Trans. 2021, 83, 199–204. [Google Scholar]

- Ali, I.; Ahmad, M.; Ganat, T. Development of a new formulation for enhancing the rheological and filtration characteristics of low-solids WBMs. J. Pet. Sci. Eng. 2021, 205, 108921. [Google Scholar] [CrossRef]

- Hashim, R.; Nadhari, W.N.A.W.; Sulaiman, O.; Kawamura, F.; Hiziroglu, S.; Sato, M.; Sugimoto, T.; Seng, T.G.; Tanaka, R. Characterization of raw materials and manufactured binderless particleboard from oil palm biomass. Mater. Des. 2011, 32, 246–254. [Google Scholar] [CrossRef]

- Boruszewski, P.; Borysiuk, P.; Mamiński, M.; Czechowska, J. Mat compression measurements during low-density particleboard manufacturing. BioResources 2016, 11, 6909–6919. [Google Scholar] [CrossRef] [Green Version]

- Norul Izani, M.A.; Paridah, M.T.; Astimar, A.A.; Mohd, N.; Anwar, U.M.K. Mechanical and dimensional stability properties of medium-density fibreboard produced from treated oil palm empty fruit bunch. J. Appl. Sci. 2012, 12, 561–567. [Google Scholar] [CrossRef] [Green Version]

- Ghani, A.; Bawon, P.; Ashaari, Z.; Wahab, M.W.; Hua, L.S.; Chen, L.W. Addition of propylamine as formaldehyde scavenger for urea formaldehyde-bonded particleboard. Wood Res. 2017, 62, 329–334. [Google Scholar]

- Hashim, R.; Wan Nadhari, W.N.A.; Sulaiman, O.; Sato, M.; Hiziroglu, S.; Kawamura, F.; Sugimoto, T.; Seng, T.G.; Tanaka, R. Properties of binderless particleboard panels manufactured from oil palm biomass. BioResources 2012, 7, 1352–1365. [Google Scholar]

- Osman, N.F.; Bawon, P.; Lee, S.H.; Zaki, P.H.; Al-Edrus, S.S.O.; Halip, J.A.; Atkhar, M.S.M. Characterization of Particleboard Made from Oil Heat-Treated Rubberwood Particles at Different Mixing Ratios. BioResources 2020, 15, 6795–6810. [Google Scholar] [CrossRef]

| Biomasses | Oil Palm Frond | Oil Palm Trunk | Empty Fruit Bunch |

|---|---|---|---|

| Lignin (%) | 19.93 ± 0.26 | 26.47 ± 0.46 | 21.17 ± 0.88 |

| Holocellulose (%) | 75.26 ± 0.21 | 71.99 ± 0.48 | 75.49 ± 0.67 |

| Cellulose (%) | 39.95 ± 0.23 | 42.47 ± 0.19 | 45.30 ± 0.41 |

| Hemicellulose (%) | 35.32 ± 0.41 | 29.52 ± 0.41 | 30.19 ± 0.38 |

| Extractive (%) | 4.80 ± 0.07 | 1.54 ± 0.01 | 3.34 ± 0.12 |

| Moisture content (%) | 7.41 ± 0.01 | 5.82 ± 0.01 | 6.70 ± 0.01 |

| Bulk density (kg/m3) | 560.80 ± 15.73 | 460.00 ± 11.91 | 670.20 ± 22.40 |

| Binder | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) |

|---|---|---|---|

| Oil palm frond | |||

| UF | 6.89 ± 1.57 d,e,f | 972.75 ± 51.5 e | 0.22 ± 0.06 d,e |

| 100CA:0 starch | 7.32 ± 0.65 c,d,e | 2299.49 ± 250.38 a | 0.52 ± 0.13 a |

| 87.5CA:12.5 starch | 9.28 ± 0.63 a,b | 2471.98 ± 143.67 a | 0.46 ± 0.16 ab |

| 75 CA:25 starch | 10.24 ± 0.53a | 2329.84 ± 114.77a | 0.34 ± 0.07bcd |

| Oil palm trunk | |||

| UF | 6.44 ± 0.45 e,f,g | 578.12 ± 60.48 f | 0.25 ± 0.02 c,d,e |

| 100CA:0 starch | 8.75 ± 0.93 a,b,c | 1711.96 ± 150.82 b,c | 0.44 ± 0.02 a,b |

| 87.5CA:12.5 starch | 8.24 ± 0.75 b,c,d | 1873.79 ± 62.28 b | 0.40 ± 0.03 a,b |

| 75 CA:25 starch | 5.64 ± 0.52 f,g,h | 1500.05 ± 65.13 c,d | 0.37 ± 0.04 b,c |

| Empty fruit bunch | |||

| UF | 4.49 ± 0.33 h | 854.04 ± 63.81 e | 0.12 ± 0.01 e |

| 100CA:0 starch | 5.08 ± 0.35 g,h | 1287.28 ± 93.51 d | 0.35 ± 0.02 b,c,d |

| 87.5CA:12.5 starch | 7.15 ± 0.92 c,d,e,f | 1285.17 ± 50.57 d | 0.25 ± 0.03 c,d,e |

| 75 CA:25 starch | 4.49 ± 0.40 h | 772.51 ± 64.69 e,f | 0.23 ± 0.03 c,d,e |

| Binder | TS2h (%) | TS24h (%) | WA2h (%) | WA24h (%) |

|---|---|---|---|---|

| Oil palm frond | ||||

| UF | 48.07 ± 1.15 d | 71.22 ± 2.51 e | 109.60 ± 5.31 h | 140.01 ± 2.85 g |

| 100CA:0 starch | 6.73 ± 0.63 a | 12.85 ± 1.00 b | 49.46 ± 2.40 a,b | 63.69 ± 1.24 a,b |

| 87.5CA:12.5 starch | 12.27 ± 0.47 b | 20.84 ± 1.11 c | 48.48 ± 2.81 a,b | 62.60 ± 2.87 a,b |

| 75 CA:25 starch | 18.77 ± 1.10 c | 22.01 ± 1.99 c | 63.91 ± 2.15 d | 81.46 ± 5.00 d |

| Oil palm trunk | ||||

| UF | 44.19 ± 3.08 d | 56.96 ± 4.12 d | 102.10 ± 1.43 g | 128.01 ± 4.03 f |

| 100CA:0 starch | 6.65 ± 0.51 a | 12.11 ± 0.70 b | 46.97 ± 1.91 a | 57.25 ± 1.15 a |

| 87.5CA:12.5 starch | 6.95 ± 0.40 a | 7.28 ± 1.00 a | 59.56 ± 1.99 c,d | 73.01 ± 1.55 c |

| 75 CA:25 starch | 7.38 ± 0.84 a | 10.60 ± 0.60 a,b | 55.00 ± 0.84 b,c | 68.01 ± 1.37 b,c |

| Empty fruit bunch | ||||

| UF | 90.86 ± 5.11 e | 144.02 ± 4.55 f | 176.64 ± 6.58 i | 185.55 ± 4.71 h |

| 100CA:0 starch | 16.53 ± 0.44 c | 20.11 ± 0.94 c | 93.29 ± 3.17 f | 96.68 ± 3.07 e |

| 87.5CA:12.5 starch | 20.04 ± 1.34 c | 24.63 ± 0.78 c | 81.79 ± 2.89 e | 87.24 ± 3.63 d |

| 75 CA:25 starch | 19.96 ± 1.07 c | 23.01 ± 1.27 c | 87.26 ± 2.45 e,f | 123.02 ± 6.09 f |

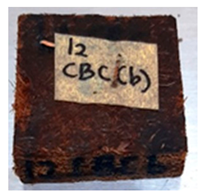

| Binder | Before | After |

|---|---|---|

| Oil palm frond | ||

| UF |  |   |

| 100CA:0 starch |  |  |

| 87.5CA:12.5 starch |  |  |

| 75CA:25 starch |  |  |

| Oil palm trunk | ||

| UF |  |   |

| 100CA:0 starch |  |  |

| 87.5CA:12.5 starch |  |  |

| 75CA:25 starch |  |  |

| Empty fruit bunch | ||

| UF |  |   |

| 100CA:0 starch |  |  |

| 87.5CA:12.5 starch |  |  |

| 75CA:25 starch |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zakaria, R.; Bawon, P.; Lee, S.H.; Salim, S.; Lum, W.C.; Al-Edrus, S.S.O.; Ibrahim, Z. Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch. Polymers 2021, 13, 3494. https://doi.org/10.3390/polym13203494

Zakaria R, Bawon P, Lee SH, Salim S, Lum WC, Al-Edrus SSO, Ibrahim Z. Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch. Polymers. 2021; 13(20):3494. https://doi.org/10.3390/polym13203494

Chicago/Turabian StyleZakaria, Radiah, Paiman Bawon, Seng Hua Lee, Sabiha Salim, Wei Chen Lum, Syeed Saifulazry Osman Al-Edrus, and Zawawi Ibrahim. 2021. "Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch" Polymers 13, no. 20: 3494. https://doi.org/10.3390/polym13203494

APA StyleZakaria, R., Bawon, P., Lee, S. H., Salim, S., Lum, W. C., Al-Edrus, S. S. O., & Ibrahim, Z. (2021). Properties of Particleboard from Oil Palm Biomasses Bonded with Citric Acid and Tapioca Starch. Polymers, 13(20), 3494. https://doi.org/10.3390/polym13203494