Evaluation of Novel Compatibility Strategies for Improving the Performance of Recycled Low-Density Polyethylene Based Biocomposites

Abstract

1. Introduction

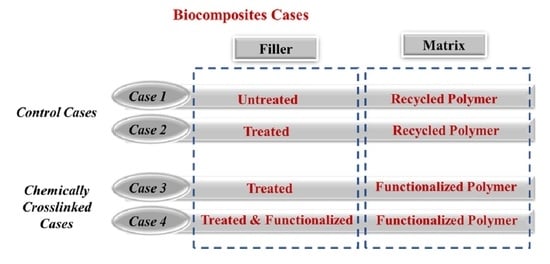

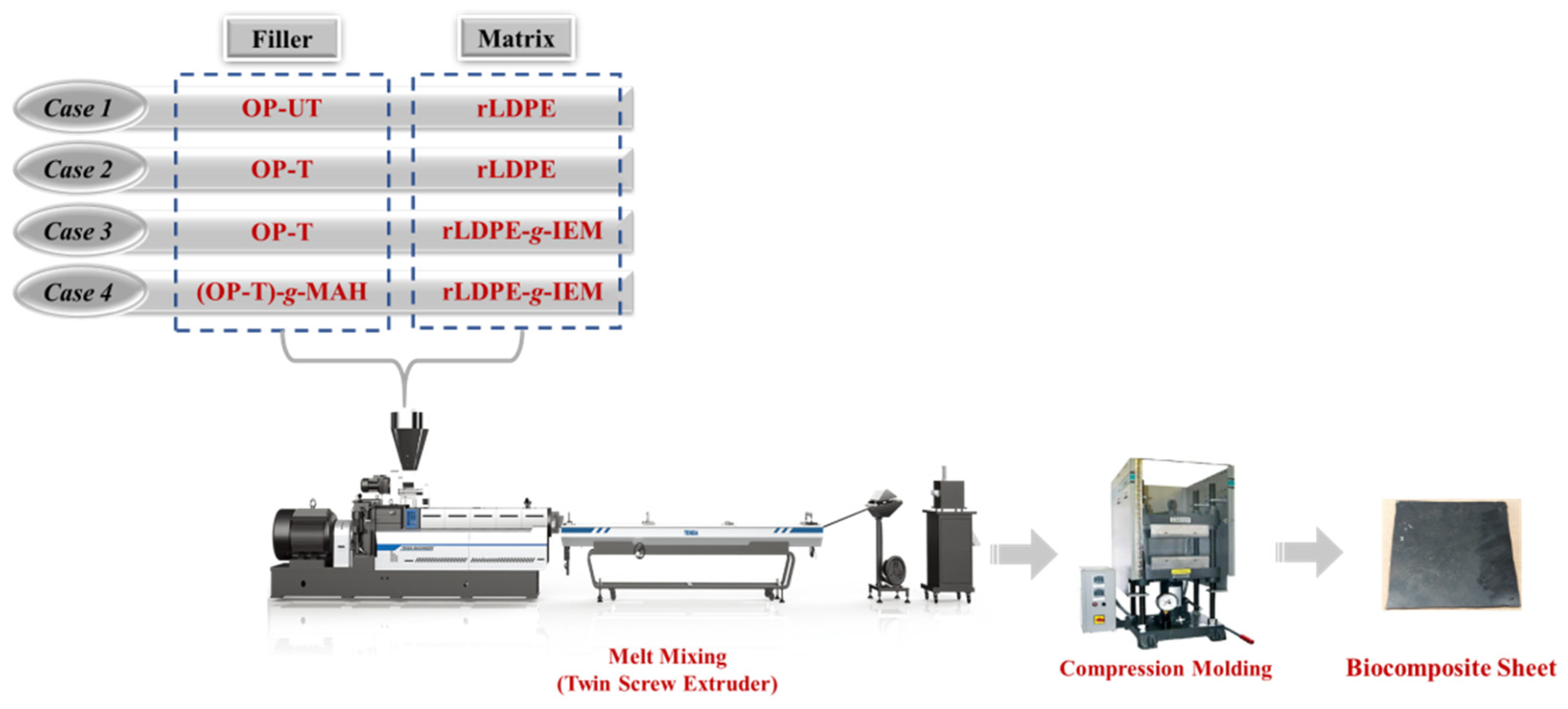

2. Materials and Methods

2.1. Chemicals and Modifiers

2.2. Filler and Polymer

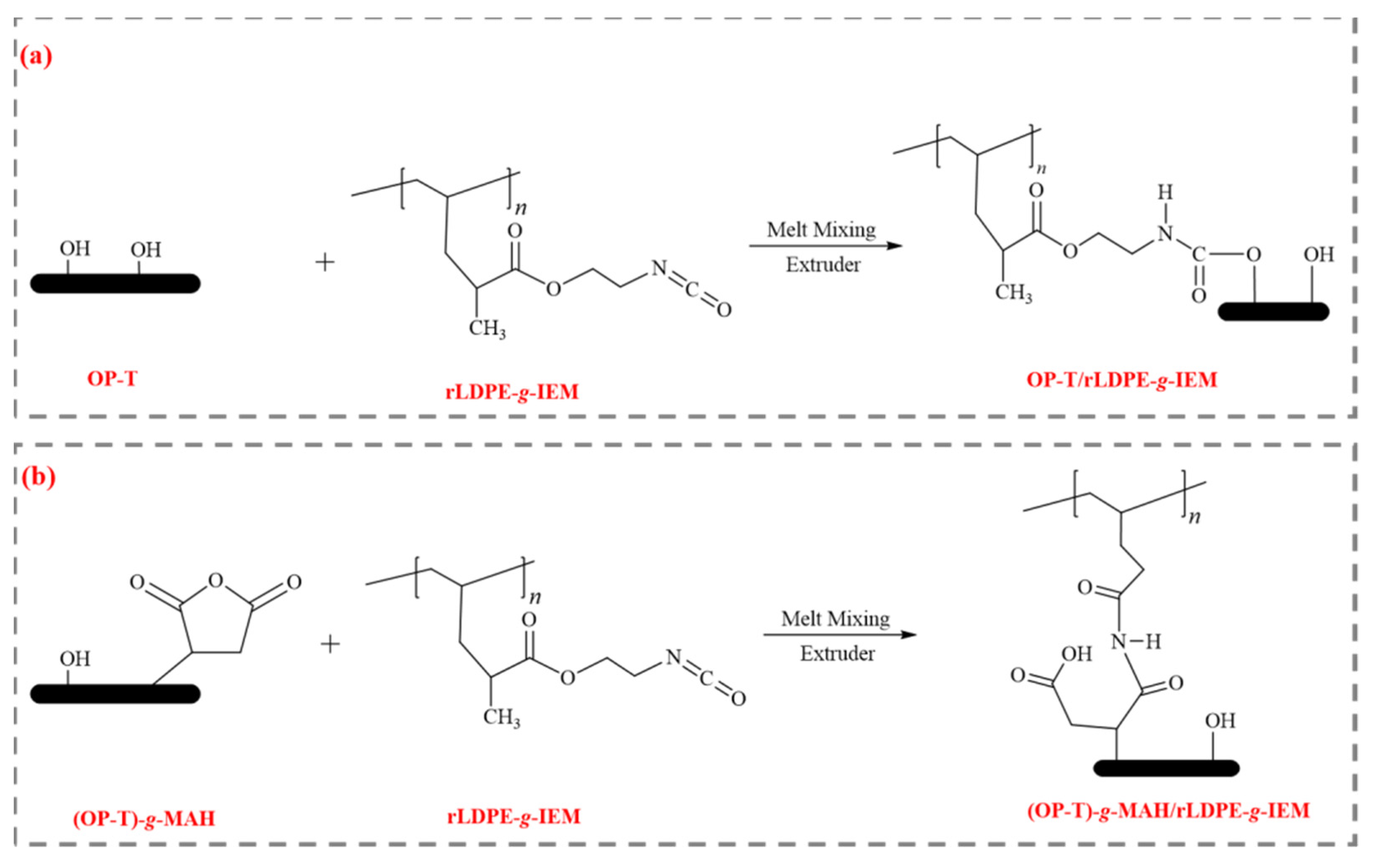

2.3. Chemical Functionalisation of Filler and Polymer

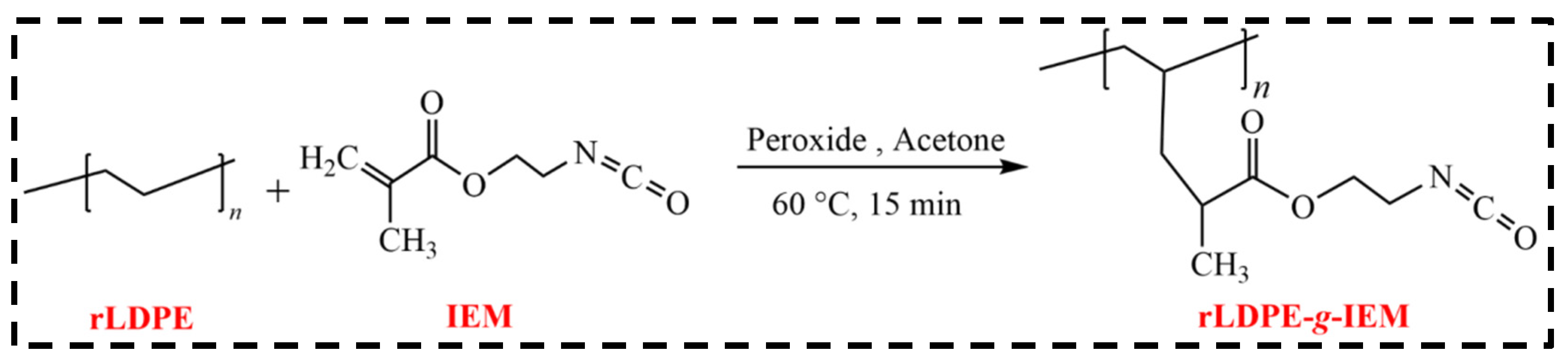

2.3.1. rLDPE-g-IEM

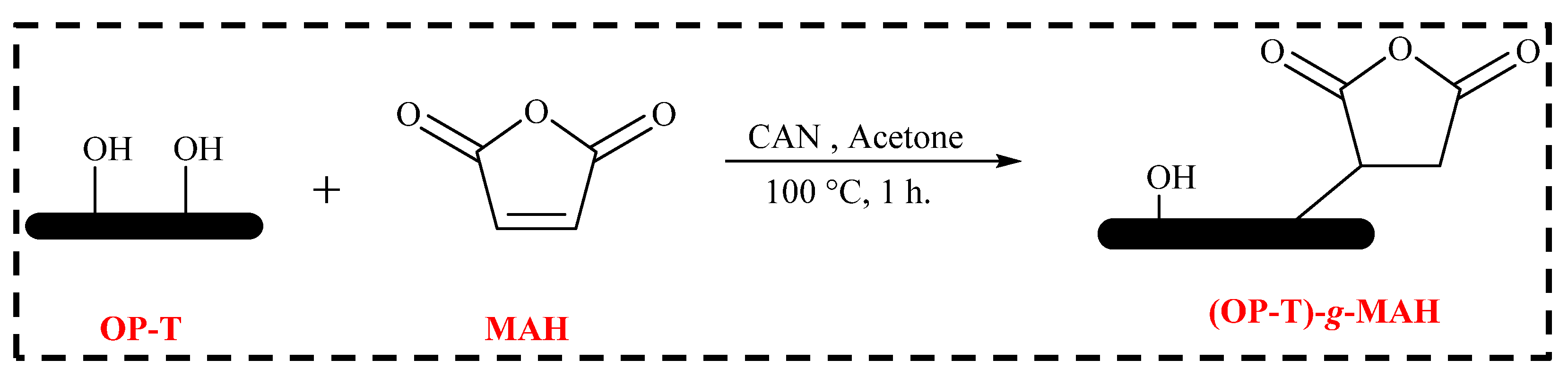

2.3.2. (OP-T)-g-MAH

2.4. Composite Fabrication

2.5. Characterization

2.5.1. Chemical Characterization

2.5.2. Physical Properties

2.5.3. Mechanical Properties

2.5.4. Thermal Properties

3. Results and Discussion

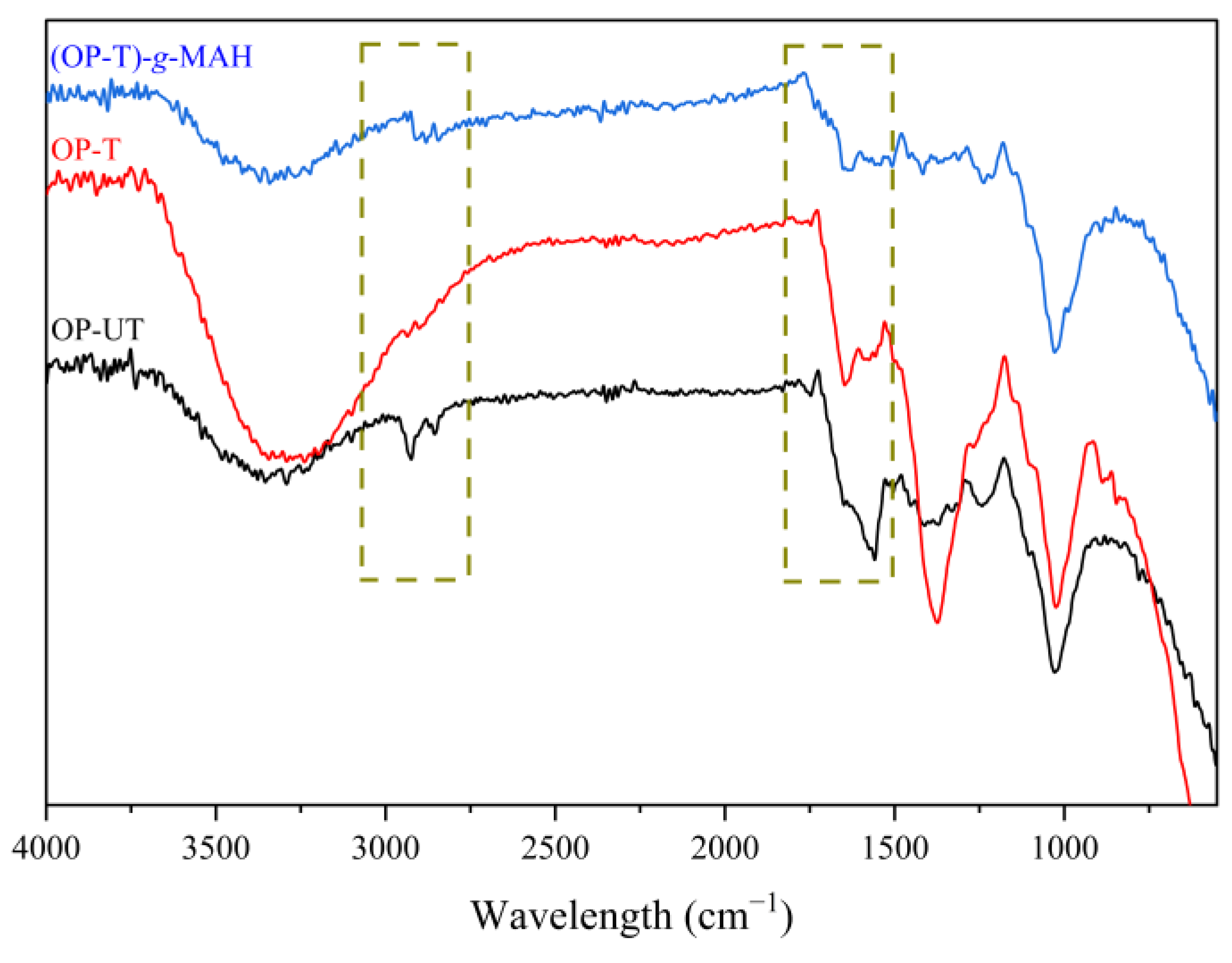

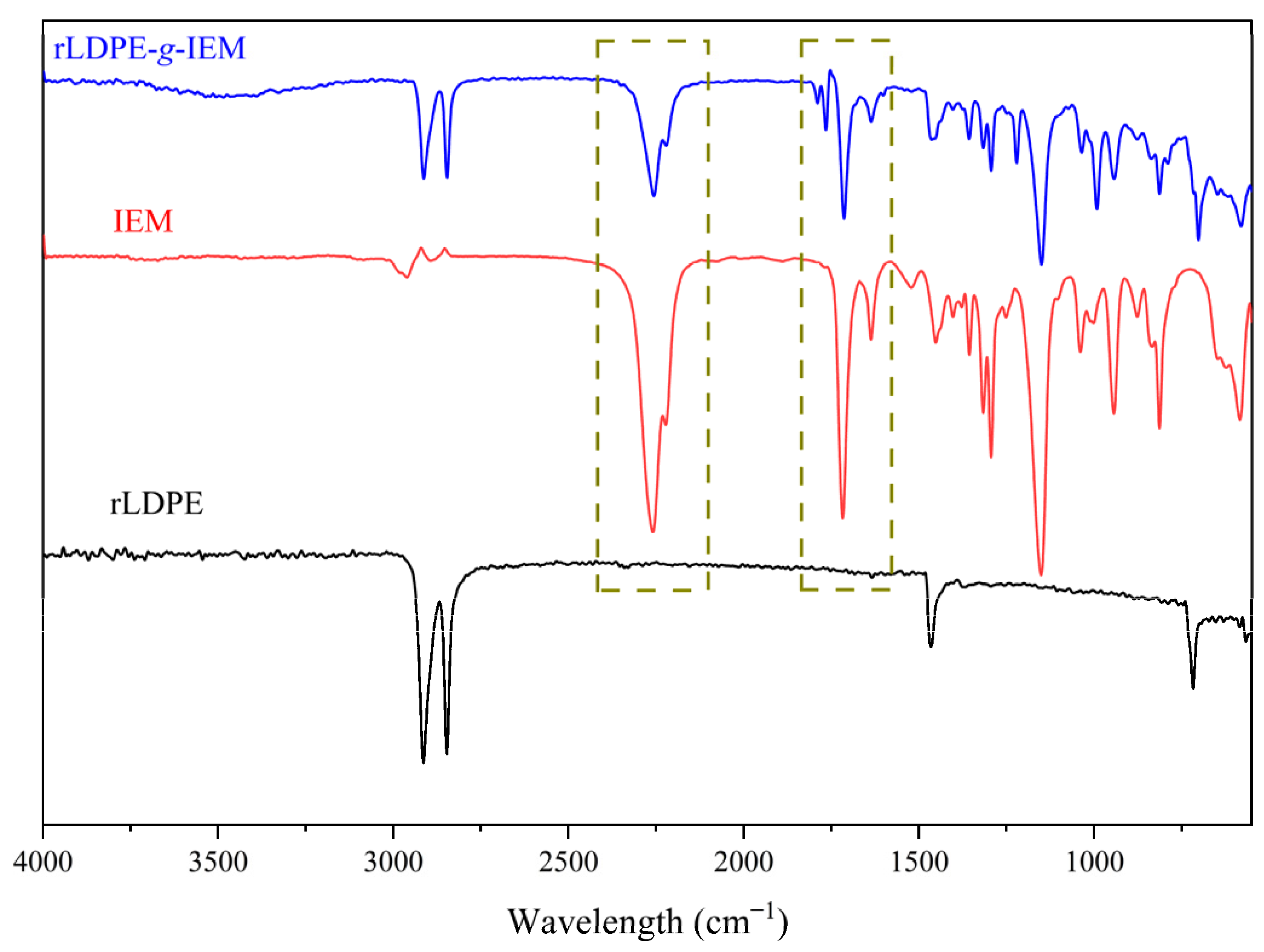

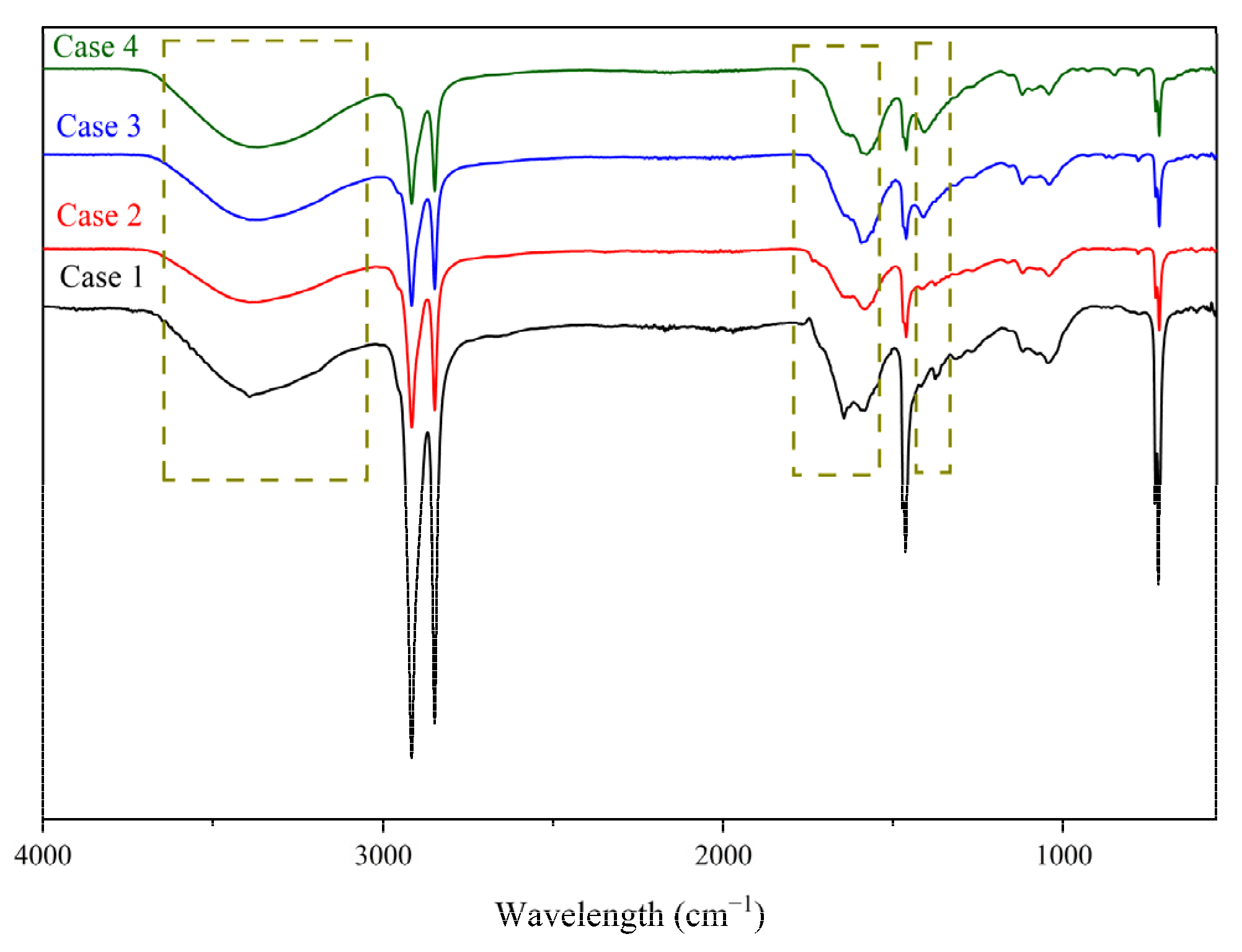

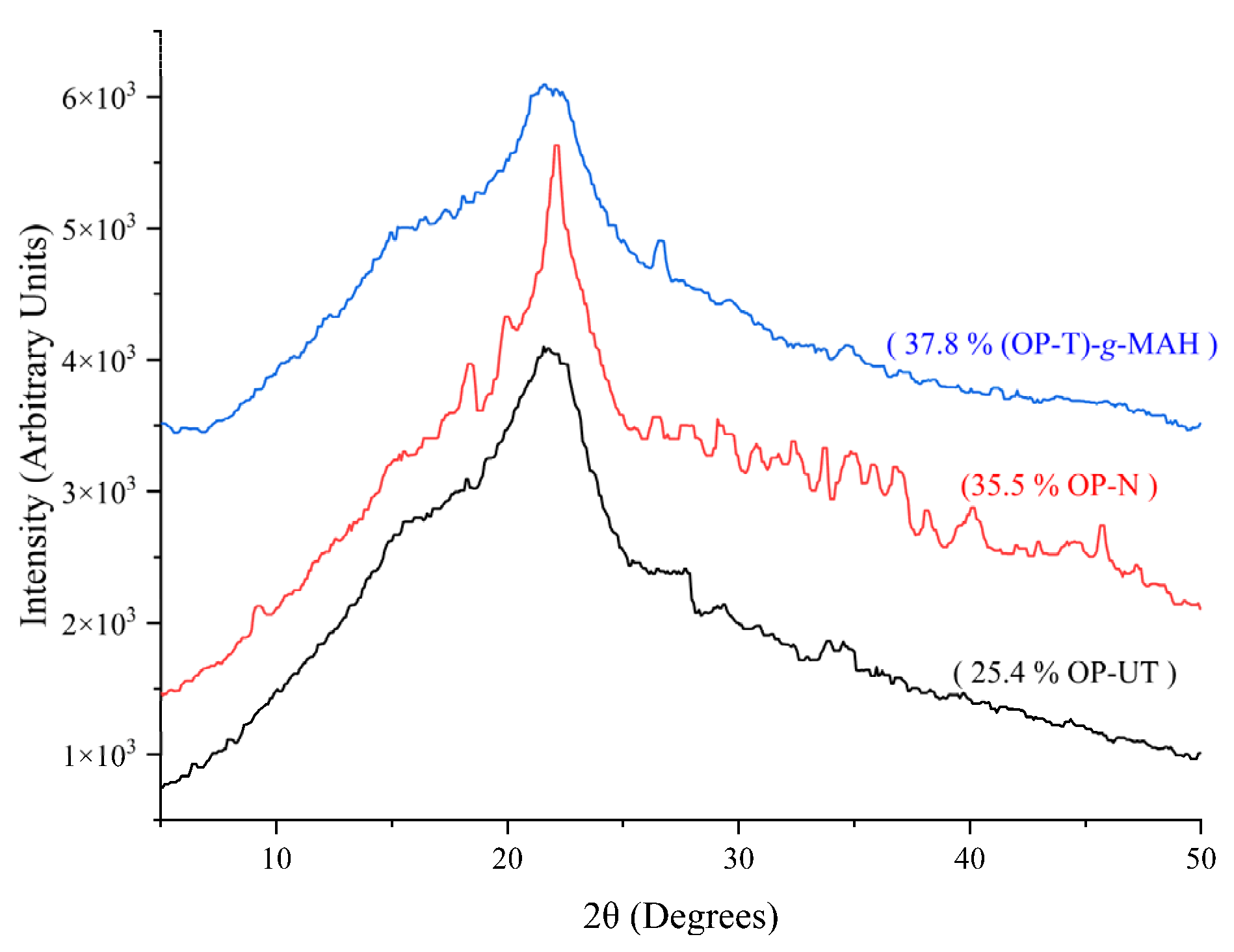

3.1. Chemical Characteristics

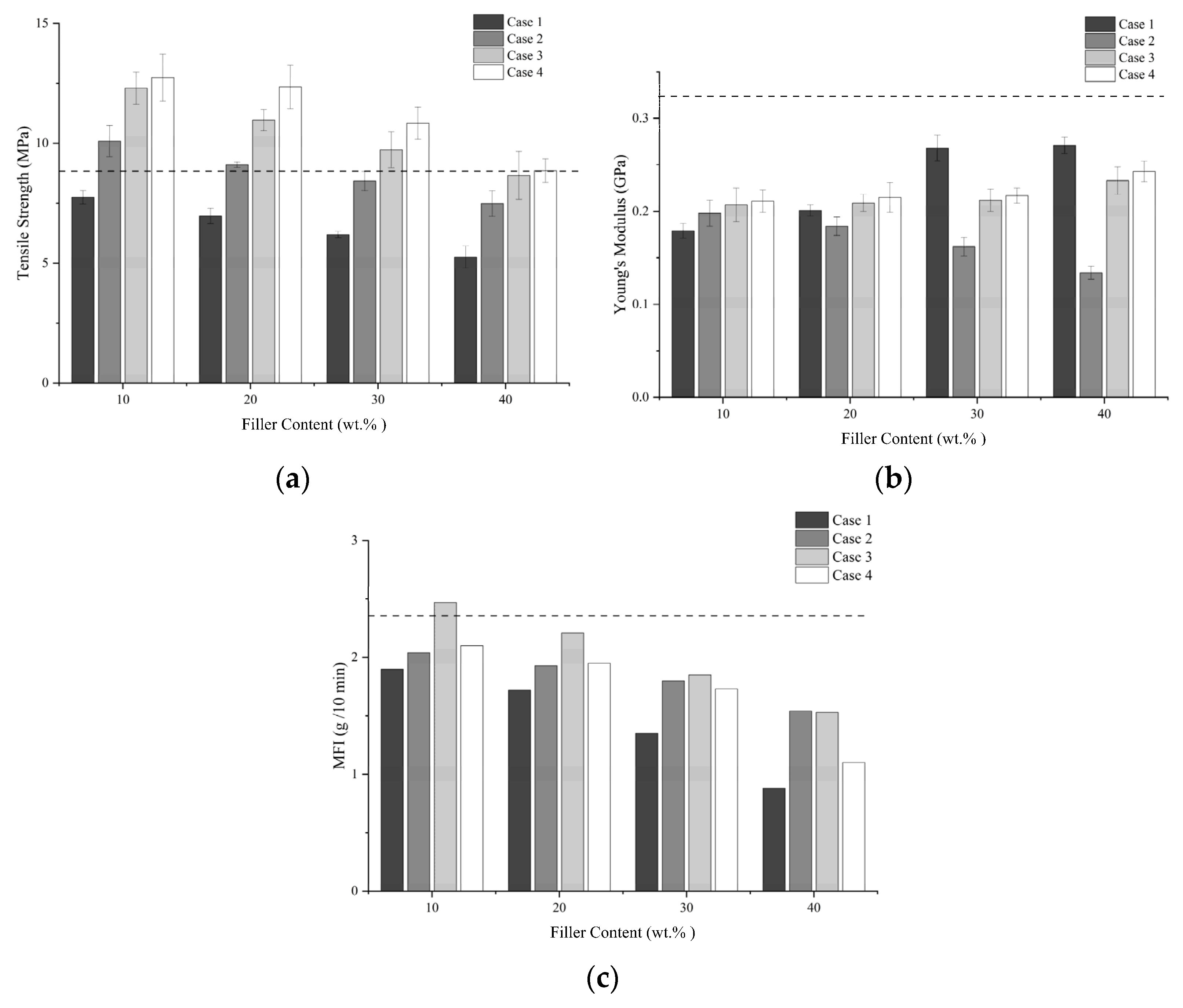

3.2. Tensile Properties

3.3. Physical Properties

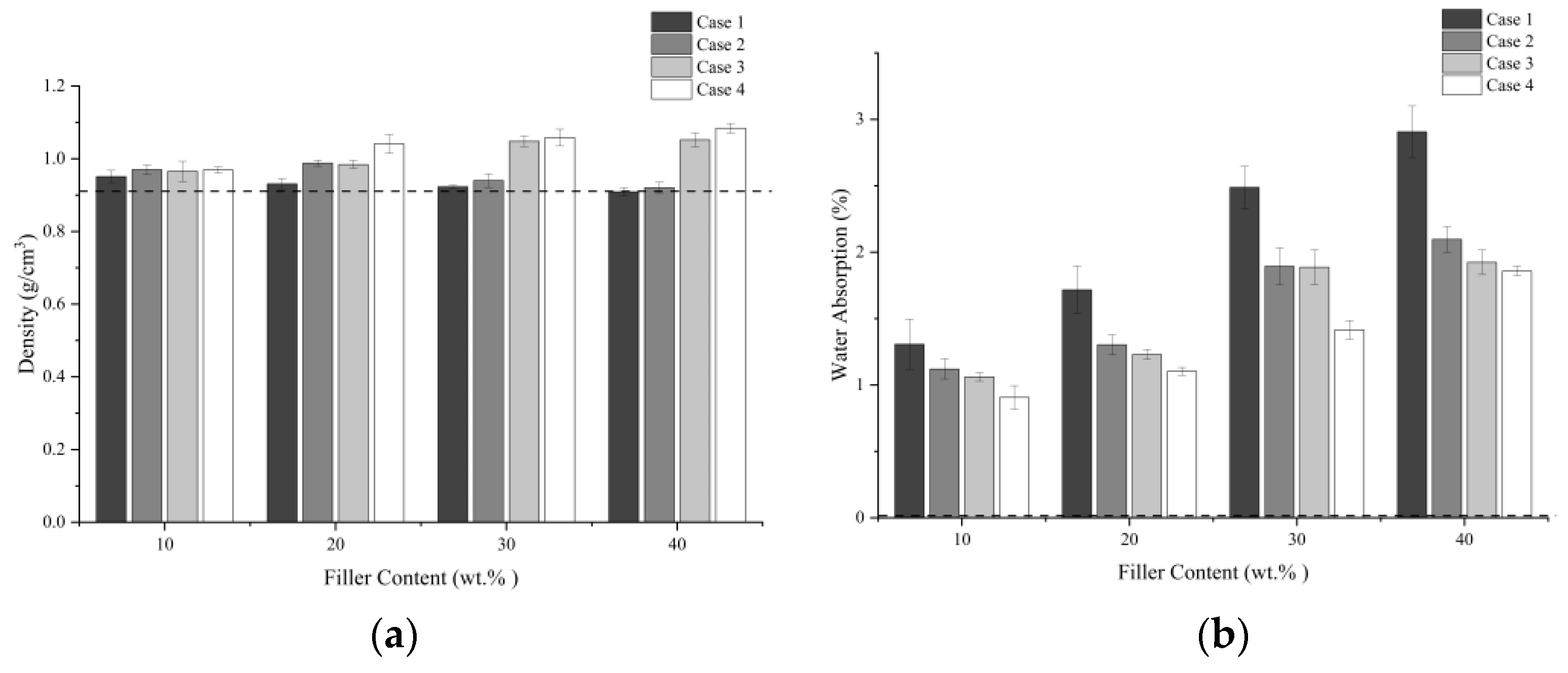

3.3.1. Density and Water Absorption

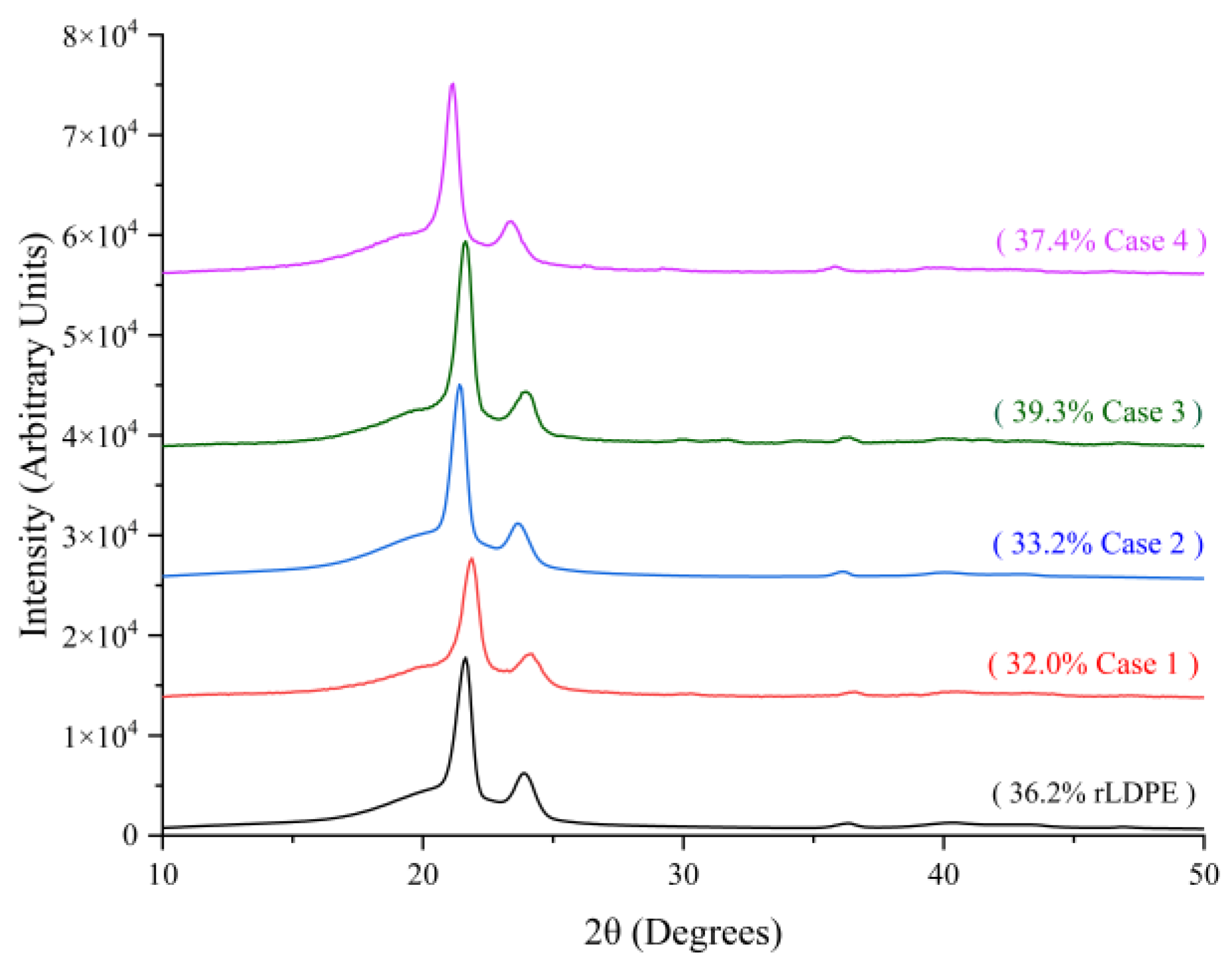

3.3.2. X-ray Diffraction

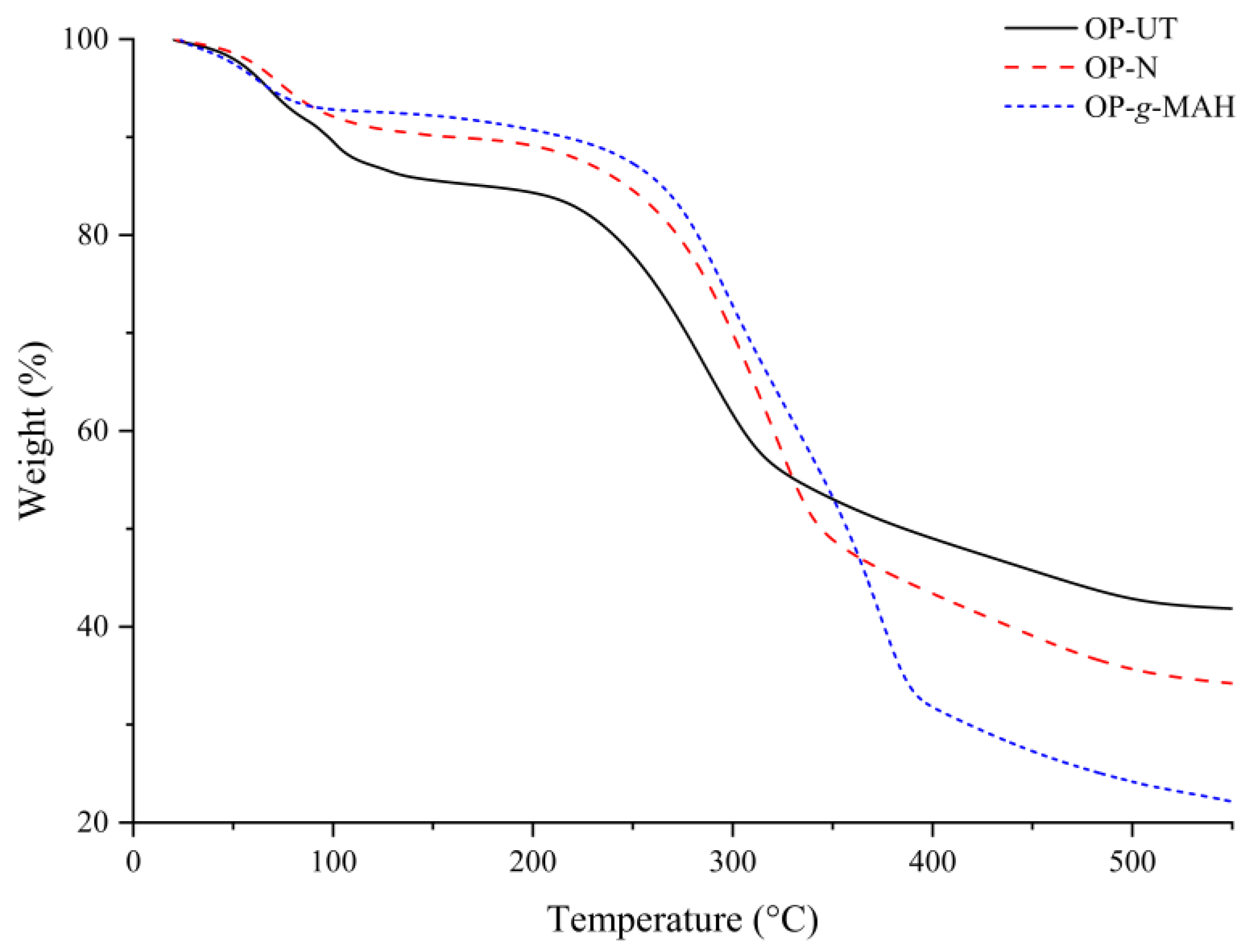

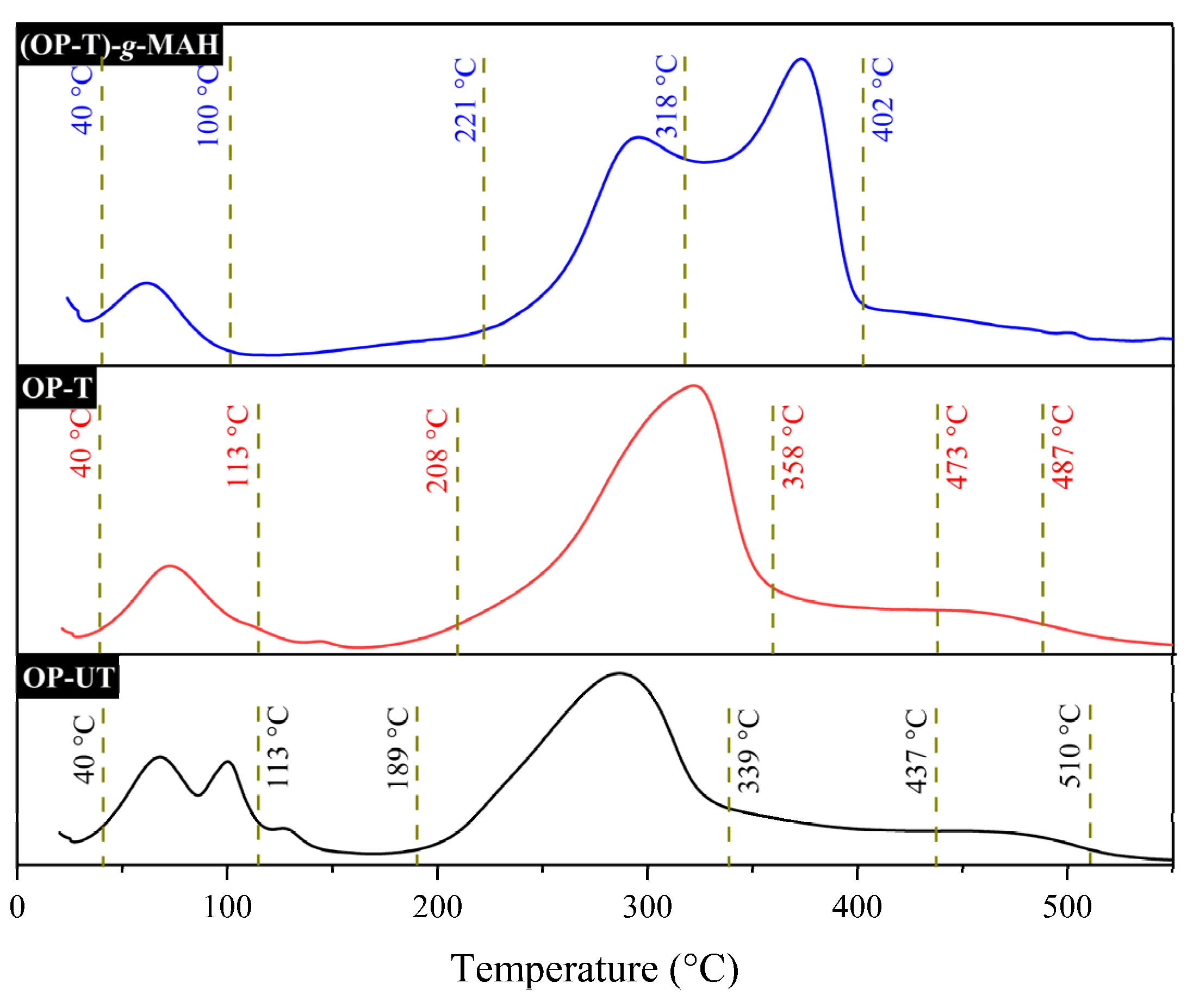

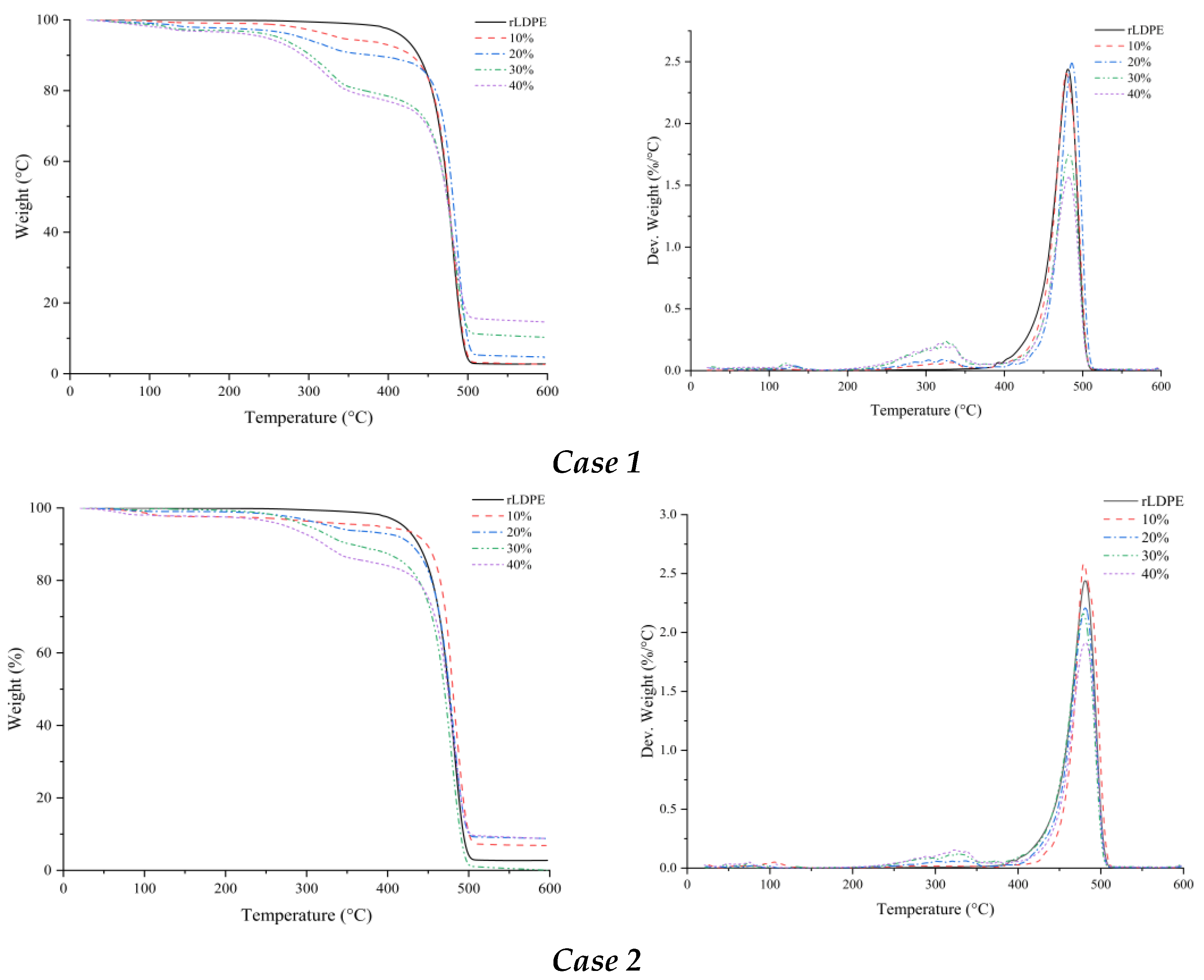

3.4. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kumar, S.D.; Sankar, L.P.; Sathish, T.; Vijayan, V.; Parthiban, A.; Kamalakannan, R.; Rajkumar, S. Improving the Mechanical Properties of Natural Fiber Composites of Hemp Fiber with Ramie and Banana Fiber through Compression Molding Method. Adv. Mater. Sci. Eng. 2021, 2021, 1–8. [Google Scholar] [CrossRef]

- Mészáros, L.; Kara, Y.; Fekete, T.; Molnár, K. Development of self-reinforced low-density polyethylene using γ-irradiation cross-linked polyethylene fibres. Radiat. Phys. Chem. 2020, 170, 108655. [Google Scholar] [CrossRef]

- Mazzanti, V.; Pariante, R.; Bonanno, A.; de Ballesteros, O.R.; Mollica, F.; Filippone, G. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos. Sci. Technol. 2019, 180, 51–59. [Google Scholar] [CrossRef]

- Aranda-García, F.J.; González-Pérez, M.M.; Robledo-Ortíz, J.R.; La Rosa, C.S.-D.; Espinoza, K.; Ramírez-Arreola, D.E. Influence of processing time on physical and mechanical properties of composite boards made of recycled multilayer containers and HDPE. J. Mater. Cycles Waste Manag. 2020, 22, 2020–2028. [Google Scholar] [CrossRef]

- Ravichandran, S.; Vengatesan, E.; Ramakrishnan, A. Synthesis and dynamic mechanical analysis of fiber reinforced low-density polyethylene hybrid polymer composites. Mater. Today Proc. 2019, 27, 177–180. [Google Scholar] [CrossRef]

- Kuan, H.T.N.; Tan, M.Y.; Shen, Y.; Yahya, M.Y. Mechanical properties of particulate organic natural filler-reinforced polymer composite: A review. Compos. Adv. Mater. 2021, 30, 263498332110075. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and challenges in sustainability, compatibility, and production of eco-composites: A state-of-art review. J. Appl. Polym. Sci. 2021, 51284, 51284. [Google Scholar] [CrossRef]

- Grillo, C.C.; Saron, C. Wood-plastic from Pennisetum Purpureum Fibers and Recycled Low-density Polyethylene. J. Nat. Fibers 2020, 1–14. [Google Scholar] [CrossRef]

- Alzebdeh, K.I.; Nassar, M.M.A.; Al-Hinai, N. Development of New Eco-Composites From Natural Agro-Residues and Recycled Polymers. In Proceedings of the Volume 3: Advanced Materials: Design, Processing, Characterization, and Applications, Virtual, 16–19 November 2020; pp. 1–7. [Google Scholar]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An overview: Natural fiber reinforced hybrid composites, chemical treatments and application areas. Mater. Today Proc. 2020, 27, 2828–2834. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Saikrishnan, S.; Tzoganakis, C.; Mekonnen, T. A comprehensive review of global production and recycling methods of polyolefin (PO) based products and their post-recycling applications. Sustain. Mater. Technol. 2020, 25, e00188. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Damage mechanics and energy absorption capabilities of natural fiber reinforced elastomeric based bio composite for sacrificial structural applications. Def. Technol. 2021, 17, 161–176. [Google Scholar] [CrossRef]

- Severino, P.R.P.; Braga, N.F.; Morgado, G.F.D.M.; Marini, J.; Ferro, O.; Passador, F.R.; Montagna, L.S. The use of recycled low-density polyethylene films from protective prepreg for the development of nanocomposites with bentonite clay. J. Appl. Polym. Sci. 2021, 138, 50559. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A review on natural fiber reinforced composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Nuryawan, A.; Hutauruk, N.O.; Purba, E.Y.S.; Masruchin, N.; Batubara, R.; Risnasari, I.; Satrio, F.K.; Rahmawaty; Basyuni, M.; McKay, D. Properties of wood composite plastics made from predominant Low Density Polyethylene (LDPE) plastics and their degradability in nature. PLoS ONE 2020, 15, e0236406. [Google Scholar] [CrossRef]

- Nassar, M.M.; Munam, A.; Alzebdeh, K.I.; Al Fahdi, R.; Abu Tarboush, B.J. Efficient methods of surface functionalization of lignocellulosic waste toward surface clickability enhancement. Compos. Interfaces 2021, 1–17. [Google Scholar] [CrossRef]

- Zwawi, M. A Review on Natural Fiber Bio-Composites; Surface Modifications and Applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Ovalı, S.; Sancak, E. Investigation of Mechanical Properties of Jute Fiber Reinforced Low Density Polyethylene Composites. J. Nat. Fibers 2020, 1–18. [Google Scholar] [CrossRef]

- Tavares, T.D.; Antunes, J.C.; Ferreira, F.; Felgueiras, H.P. Biofunctionalization of Natural Fiber-Reinforced Biocomposites for Biomedical Applications. Biomolecules 2020, 10, 148. [Google Scholar] [CrossRef] [PubMed]

- Joglekar, J.J.; Munde, Y.; Jadhav, A.; Bhutada, D.; Radhakrishnan, S.; Kulkarni, M. Mechanical and morphological properties of Citrus Maxima waste powder filled Low-Density polyethylene composites. Mater. Today Proc. 2021, 3–8. [Google Scholar] [CrossRef]

- Lee, C.; Khalina, A.; Lee, S. Importance of Interfacial Adhesion Condition on Characterization of Plant-Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent advancements of plant-based natural fiber–reinforced composites and their applications. Compos. Part B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Kouhi, M.; Butan, S.; Li, Y.; Shakour, E.; Banu, M. Role of Chemically Functionalization of Bamboo Fibers on Polyethylene-Based Composite Performance: A Solution for Recycling. Polymers 2021, 13, 2564. [Google Scholar] [CrossRef] [PubMed]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.; Johnson, R.D.J.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent advancement in the natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A.; Rylski, A. Cellulose Modification for Improved Compatibility with the Polymer Matrix: Mechanical Characterization of the Composite Material. Materials 2020, 13, 5519. [Google Scholar] [CrossRef] [PubMed]

- Aggarwal, P.K.; Raghu, N.; Karmarkar, A.; Chuahan, S. Jute–polypropylene composites using m-TMI-grafted-polypropylene as a coupling agent. Mater. Des. 2013, 43, 112–117. [Google Scholar] [CrossRef]

- Singh, A.K.; Bedi, R.; Kaith, B.S. Mechanical properties of composite materials based on waste plastic—A review. Mater. Today: Proc. 2020, 26, 1293–1301. [Google Scholar] [CrossRef]

- Nurazzi, N.; Asyraf, M.; Khalina, A.; Abdullah, N.; Aisyah, H.; Rafiqah, S.; Sabaruddin, F.; Kamarudin, S.; Norrrahim, M.; Ilyas, R.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.; Modak, J.M.; Chanda, M. Mechanical properties of wood–fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Datta, M.; Das, D.; Nath, D. Fiber length – the persuadable factor in making natural fiber composite: A review. Res. J. Text. Appar. 2021. [Google Scholar] [CrossRef]

- Chowdhury, I.H.; Abdelwahab, M.A.; Misra, M.; Mohanty, A.K. Sustainable Biocomposites from Recycled Bale Wrap Plastic and Agave Fiber: Processing and Property Evaluation. ACS Omega 2021, 6, 2856–2864. [Google Scholar] [CrossRef]

- Gebremedhin, N.; Rotich, G.K. Manufacturing of Bathroom Wall Tile Composites from Recycled Low-Density Polyethylene Reinforced with Pineapple Leaf Fiber. Int. J. Polym. Sci. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Suárez, L.; Castellano, J.; Díaz, S.; Tcharkhtchi, A.; Ortega, Z. Are Natural-Based Composites Sustainable? Polymers 2021, 13, 2326. [Google Scholar] [CrossRef]

- Fakirov, S. A new approach to plastic recycling via the concept of microfibrillar composites. Adv. Ind. Eng. Polym. Res. 2021, 4, 187–198. [Google Scholar] [CrossRef]

- Al-Oqla, F.M. Flexural Characteristics and Impact Rupture Stress Investigations of Sustainable Green Olive Leaves Bio-composite Materials. J. Polym. Environ. 2021, 29, 892–899. [Google Scholar] [CrossRef]

- Sider, I.; Nassar, M.M.A. Chemical Treatment of Bio-Derived Industrial Waste Filled Recycled Low-Density Polyethylene: A Comparative Evaluation. Polymers 2021, 13, 2682. [Google Scholar] [CrossRef] [PubMed]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A.; Al-Jahwari, F.; Sider, I. Polymer powder and pellets comparative performances as bio-based composites. Iran. Polym. J. 2021, 30, 269–283. [Google Scholar] [CrossRef]

- Farhan, M.A.; Alsalami, F.M.A. Synthesis and Characterization of Starch Grafted Maleic Anhydride and Substituted it with Drug Copolymer. J. Iraqi Ind. Res. 2017, 4, 70–80. [Google Scholar]

- Wang, C.; Bai, S.; Yue, X.; Long, B.; Choo-Smith, L.-P. Relationship between chemical composition, crystallinity, orientation and tensile strength of kenaf fiber. Fibers Polym. 2016, 17, 1757–1764. [Google Scholar] [CrossRef]

- Terinte, N.; Ibbett, R.; Schuster, K.C. Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): Comparison between measurement techniques. Lenzinger Berichte 2011, 89, 118–131. [Google Scholar]

- McKeen, L.W. Introduction to Plastics and Elastomers. In Effect of Temperature and Other Factors on Plastics and Elastomers; Elsevier BV: Amsterdam, The Netherlands, 2008; pp. 1–39. [Google Scholar]

- Abbass, A.; Paiva, M.C.; Oliveira, D.V.; Lourenço, P.B.; Fangueiro, R. Insight into the Effects of Solvent Treatment of Natural Fibers Prior to Structural Composite Casting: Chemical, Physical and Mechanical Evaluation. Fibers 2021, 9, 54. [Google Scholar] [CrossRef]

- Cho, D.; Yoon, S.B.; Drzal, T. Cellulose-Based Natural Fiber Topography and the Interfacial Shear Strength of Henequen/Unsaturated Polyester Composites: Influence of Water and Alkali Treatments. Compos. Interfaces 2009, 16, 769–779. [Google Scholar] [CrossRef]

- Owolabi, F.A.T.; Ghazali, A.; Abdul Khalil, H.P.S.; Hassan, A.; Arjmandi, R.; Fazita, M.R.N.; Haafiz, M.K.M. Isolation and Characterization of Microcrystalline Cellulose from Oil Palm Fronds Using Chemomechanical Process. Wood Fiber Sci. 2016, 48, 1–11. [Google Scholar]

- Lisperguer, J.; Nuñez, C.; Perez-Guerrero, P. Structure and Thermal Properties of Maleated Lignin-Recycled Polystyrene Composites. J. Chil. Chem. Soc. 2013, 58, 1937–1940. [Google Scholar] [CrossRef][Green Version]

- Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effects of Matrix Modification on the Mechanical Properties of Wood⁻Polypropylene Composites. Polymers 2017, 9, 712. [Google Scholar] [CrossRef] [PubMed]

- Wong, C.S.; Badri, K.H. Chemical Analyses of Palm Kernel Oil-Based Polyurethane Prepolymer. Mater. Sci. Appl. 2012, 03, 78–86. [Google Scholar] [CrossRef]

- Reignier, J.; Méchin, F.; Sarbu, A. Chemical gradients in PIR foams as probed by ATR-FTIR analysis and consequences on fire resistance. Polym. Test. 2021, 93, 106972. [Google Scholar] [CrossRef]

- Xi, X.; Pizzi, A.; Delmotte, L. Isocyanate-Free Polyurethane Coatings and Adhesives from Mono- and Di-Saccharides. Polymers 2018, 10, 402. [Google Scholar] [CrossRef] [PubMed]

- Kreye, O.; Mutlu, H.; Meier, M.A.R. Sustainable routes to polyurethane precursors. Green Chem. 2013, 15, 1431–1455. [Google Scholar] [CrossRef]

- Pearson, H.A.; Urban, M.W. Simple click reactions on polymer surfaces leading to antimicrobial behavior. J. Mater. Chem. B 2014, 2, 2084–2087. [Google Scholar] [CrossRef] [PubMed]

- Ismail, N.; Radzuan, N.M.; Sulong, A.; Muhamad, N.; Haron, C.C. The Effect of Alkali Treatment on Physical, Mechanical and Thermal Properties of Kenaf Fiber and Polymer Epoxy Composites. Polymers 2021, 13, 2005. [Google Scholar] [CrossRef] [PubMed]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef]

- Carotenuto, G.; De Nicola, S.; Ausanio, G.; Massarotti, D.; Nicolais, L.; Pepe, G.P. Synthesis and characterization of electrically conductive polyethylene-supported graphene films. Nanoscale Res. Lett. 2014, 9, 475. [Google Scholar] [CrossRef]

- Chun, K.S.; Yeng, C.M.; May, C.P.; Yeow, T.K.; Kiat, O.T.; How, C.K. Effect of coupling agent content on properties of composites made from polylactic acid and chrysanthemum waste. J. Vinyl Addit. Technol. 2020, 26, 10–16. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F.; Keer, L.M. Influence of Surface Modification on the Microstructure and Thermo-Mechanical Properties of Bamboo Fibers. Materials 2015, 8, 6597–6608. [Google Scholar] [CrossRef]

- Balla, V.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part. B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Lau, K.-T.; Hung, P.-Y.; Zhu, M.-H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part. B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, X.; Chen, Z.; Wan, M.; Wu, Q. Thermal Stability and Flame Resistance of the Coextruded Wood-Plastic Composites Containing Talc-Filled Plastic Shells. Int. J. Polym. Sci. 2020, 2020, 1–9. [Google Scholar] [CrossRef]

- Jeske, H.; Schirp, A.; Cornelius, F. Development of a thermogravimetric analysis (TGA) method for quantitative analysis of wood flour and polypropylene in wood plastic composites (WPC). Thermochim. Acta 2012, 543, 165–171. [Google Scholar] [CrossRef]

| Property and Unit | Value |

|---|---|

| Tensile Strength (MPa) | 8.78 ± 0.19 |

| Young’s Modulus (GPa) | 0.33 ± 0.02 |

| Water Absorption (%) | 0.04 ± 0.008 |

| Density (g/cm3) | 0.902 ± 0.012 |

| MFI (g/10 min) | 2.36 ± 0.25 |

| Filler Content (wt.%) | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| rLDPE | 36.2 | |||

| 10 | 32.5 | 37.2 | 39.7 | 42.9 |

| 20 | 32.0 | 33.2 | 39.3 | 37.4 |

| 30 | 27.3 | 30.9 | 33.2 | 34.9 |

| 40 | 25.8 | 30.5 | 30.3 | 35.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nassar, M.M.A.; Sider, I. Evaluation of Novel Compatibility Strategies for Improving the Performance of Recycled Low-Density Polyethylene Based Biocomposites. Polymers 2021, 13, 3486. https://doi.org/10.3390/polym13203486

Nassar MMA, Sider I. Evaluation of Novel Compatibility Strategies for Improving the Performance of Recycled Low-Density Polyethylene Based Biocomposites. Polymers. 2021; 13(20):3486. https://doi.org/10.3390/polym13203486

Chicago/Turabian StyleNassar, Mahmoud M. A., and Ishaq Sider. 2021. "Evaluation of Novel Compatibility Strategies for Improving the Performance of Recycled Low-Density Polyethylene Based Biocomposites" Polymers 13, no. 20: 3486. https://doi.org/10.3390/polym13203486

APA StyleNassar, M. M. A., & Sider, I. (2021). Evaluation of Novel Compatibility Strategies for Improving the Performance of Recycled Low-Density Polyethylene Based Biocomposites. Polymers, 13(20), 3486. https://doi.org/10.3390/polym13203486