Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Compositional Analysis

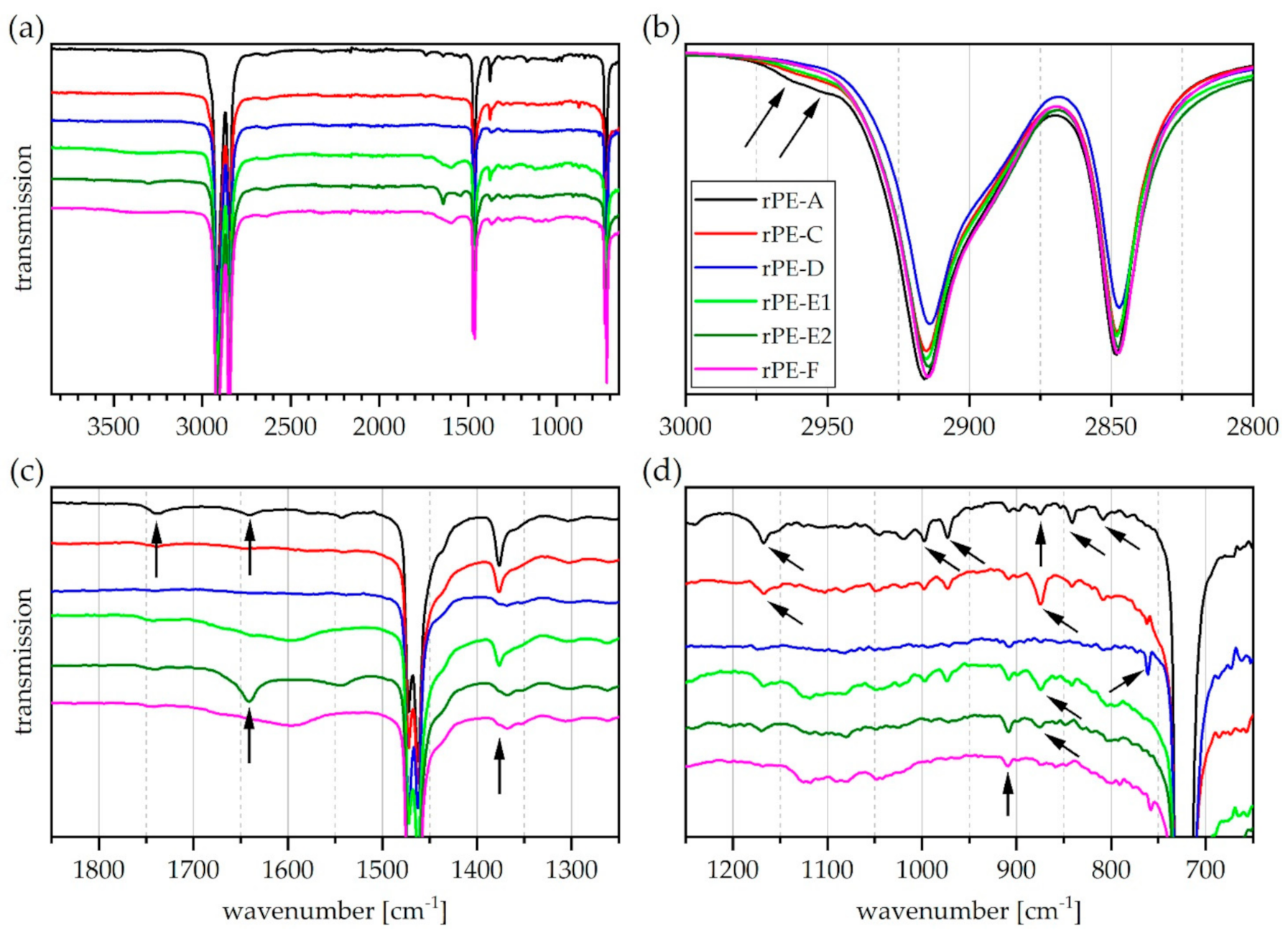

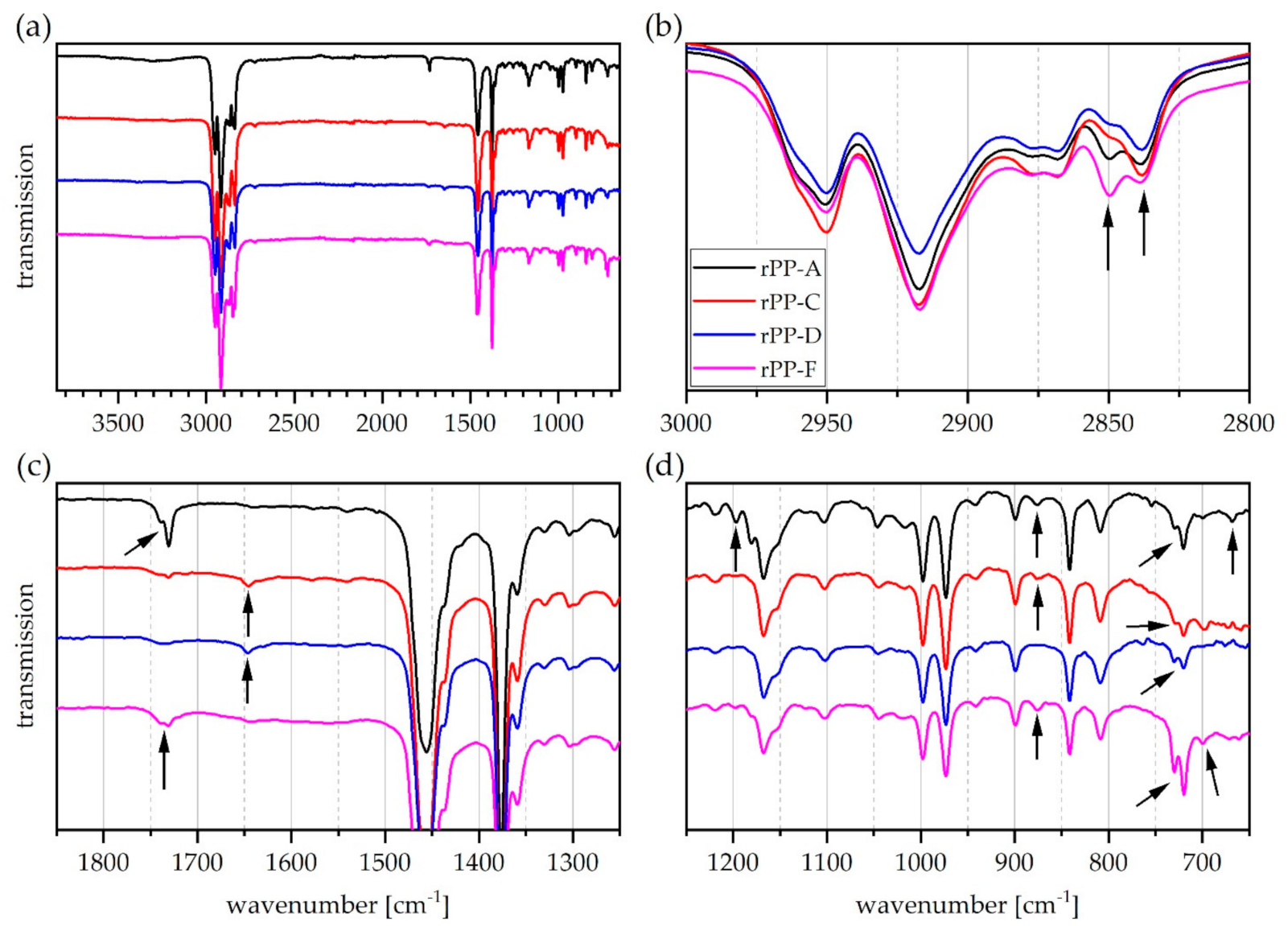

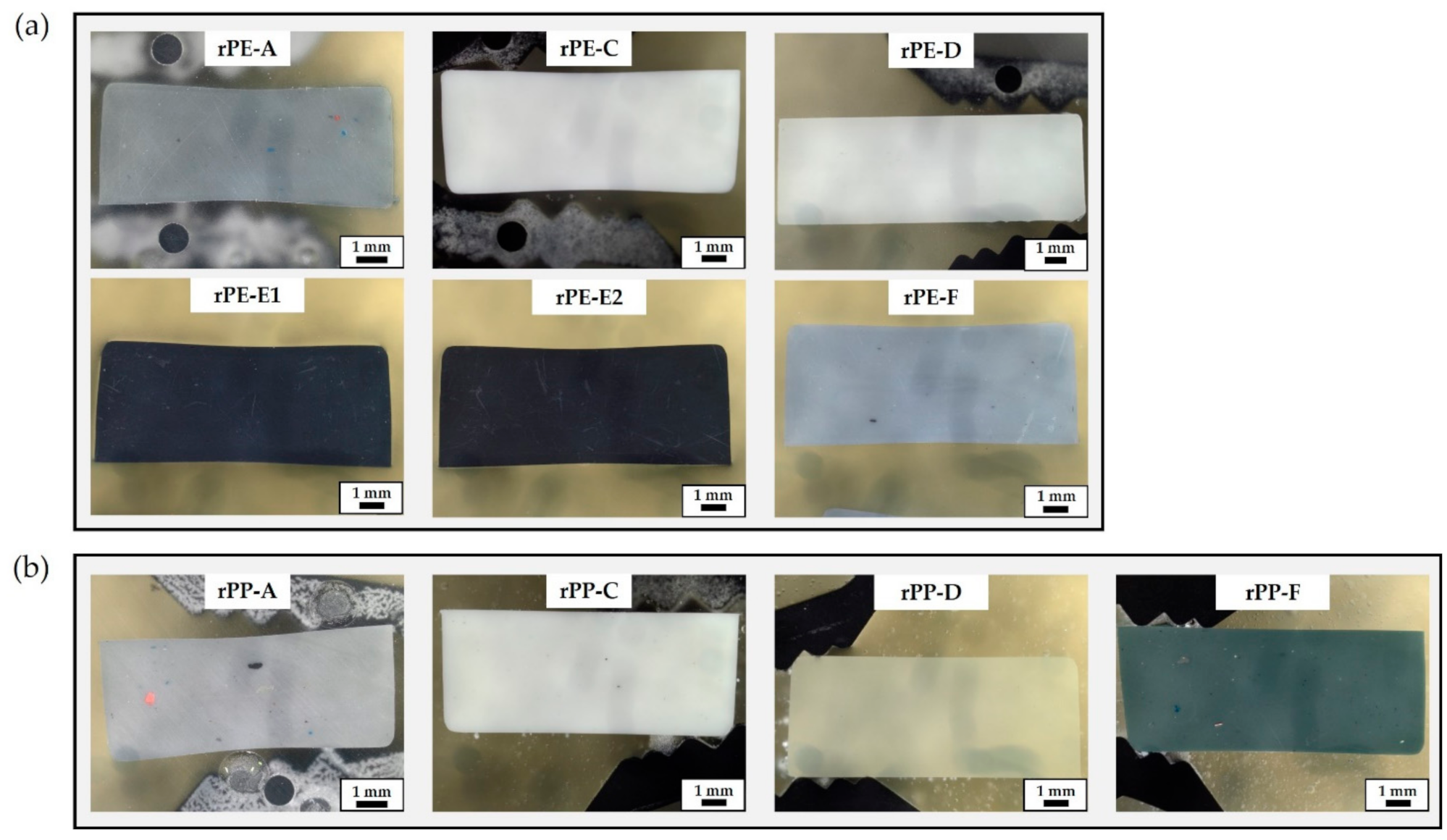

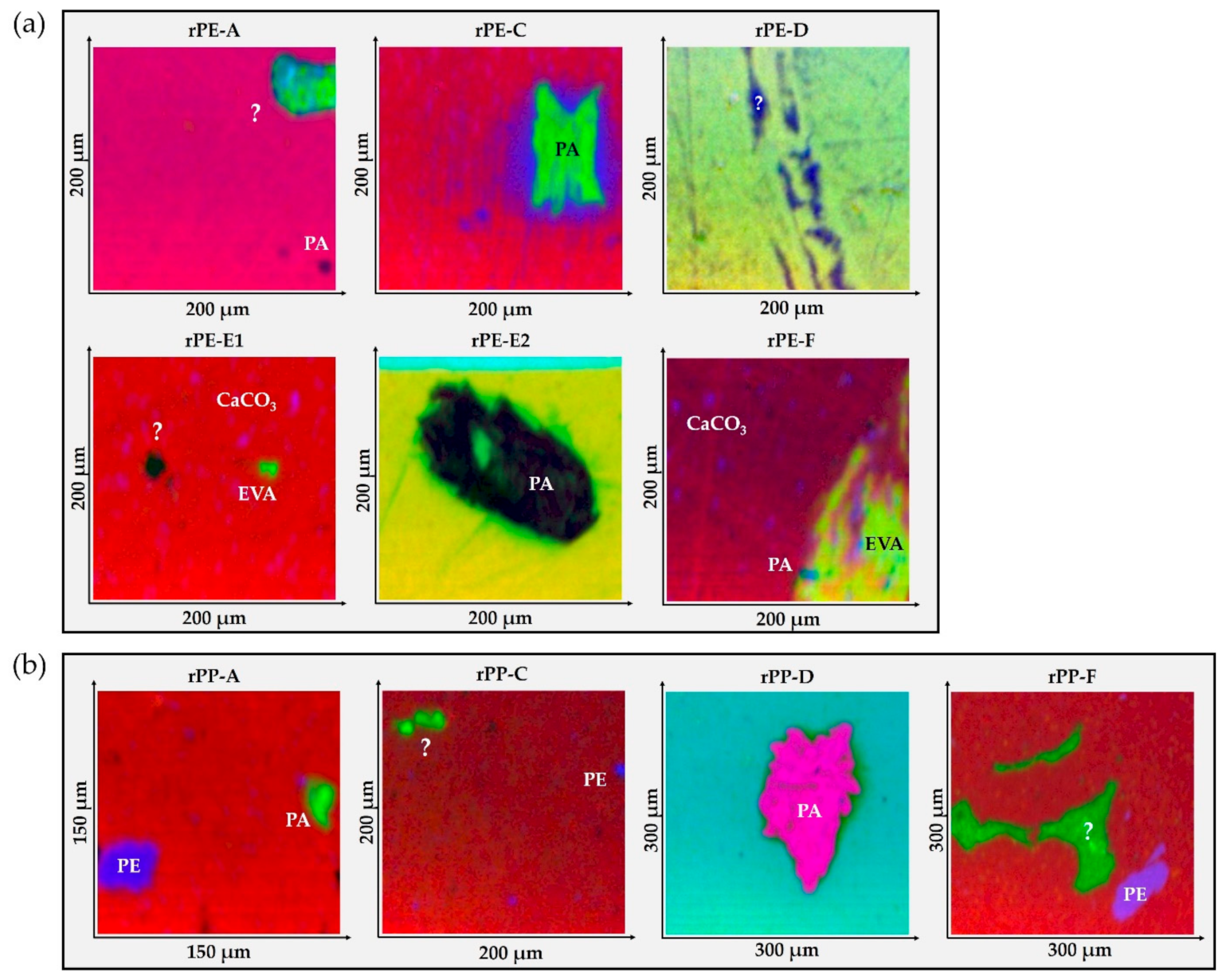

3.1.1. FTIR Spectroscopic Characterization and Imaging

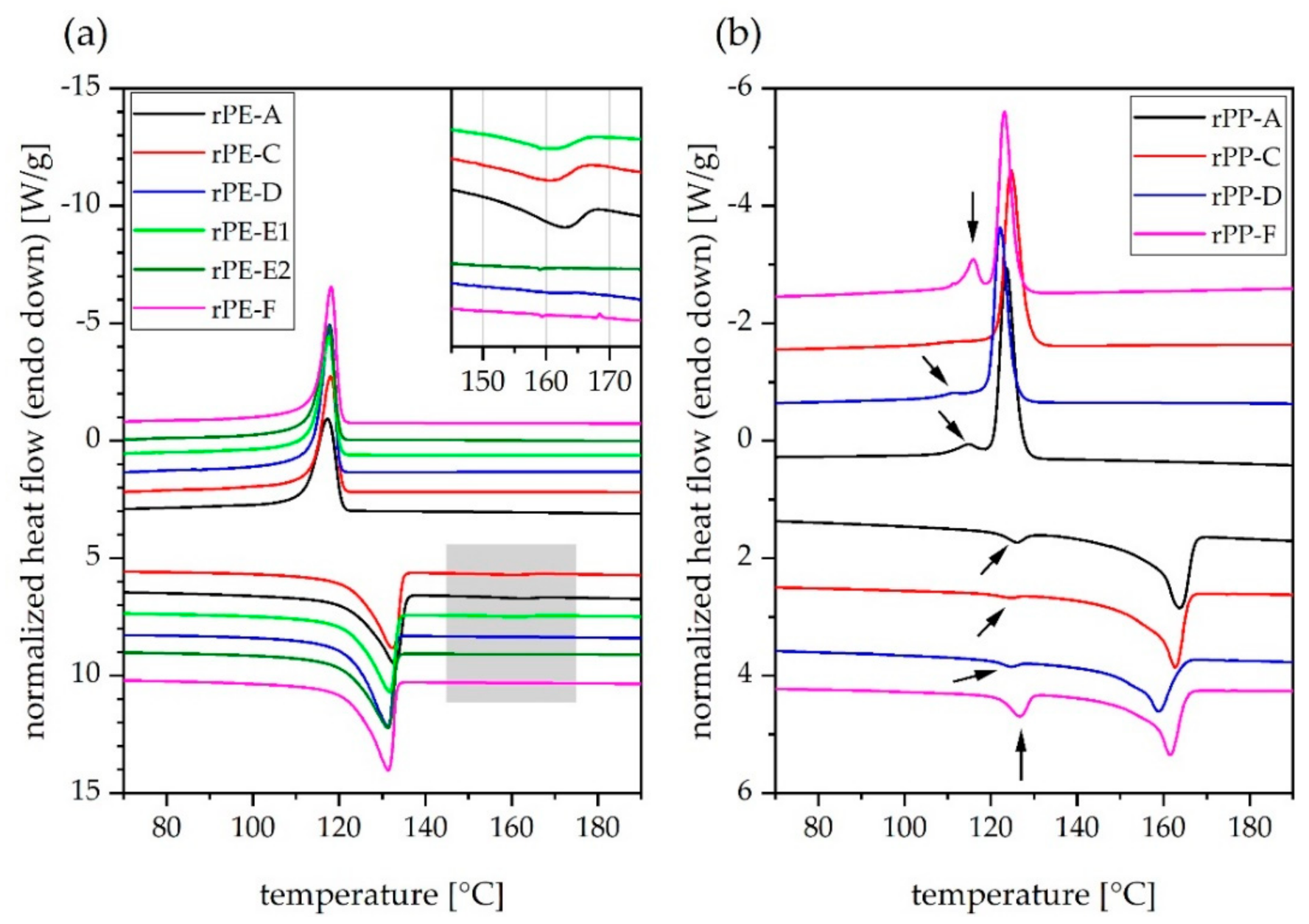

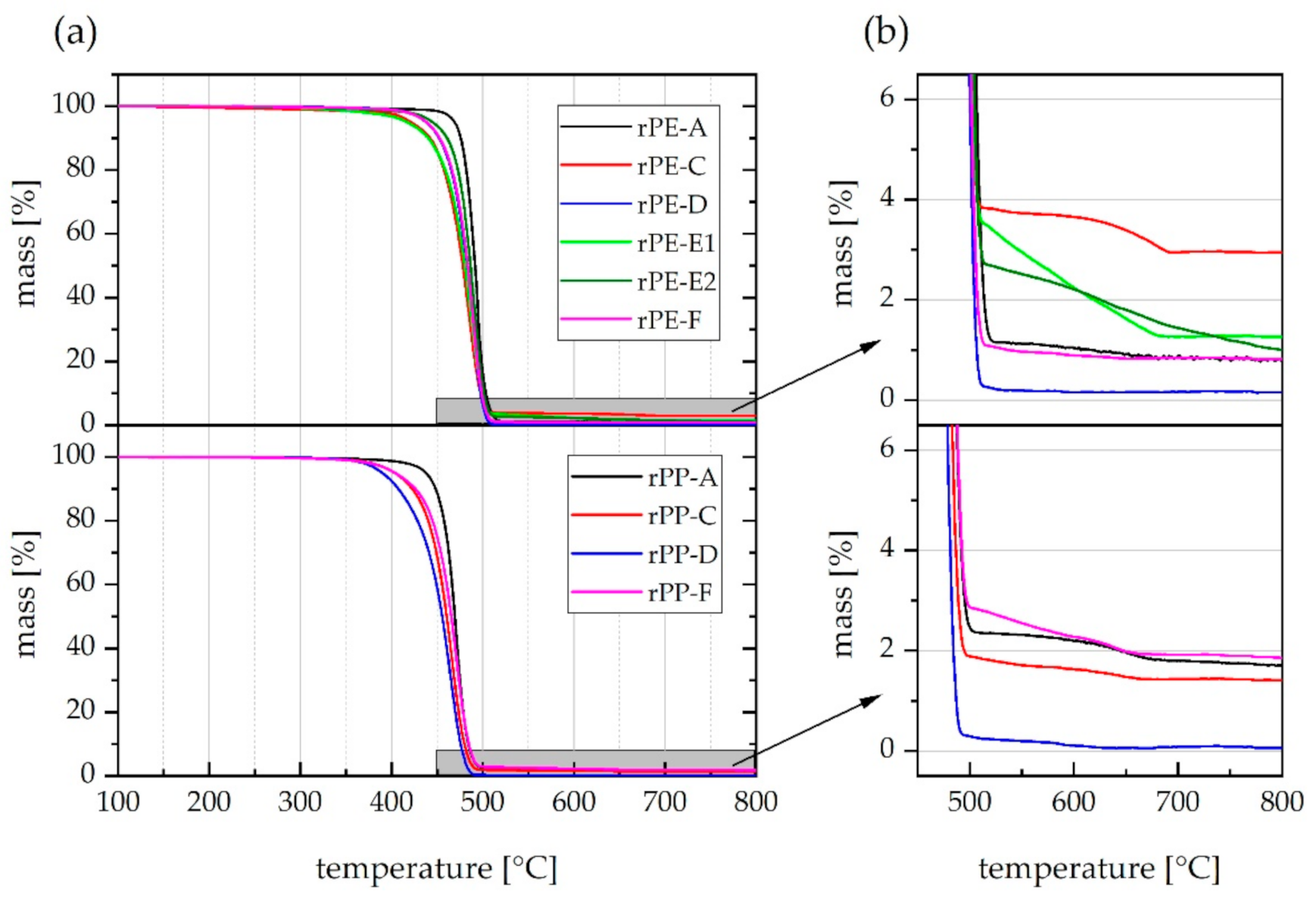

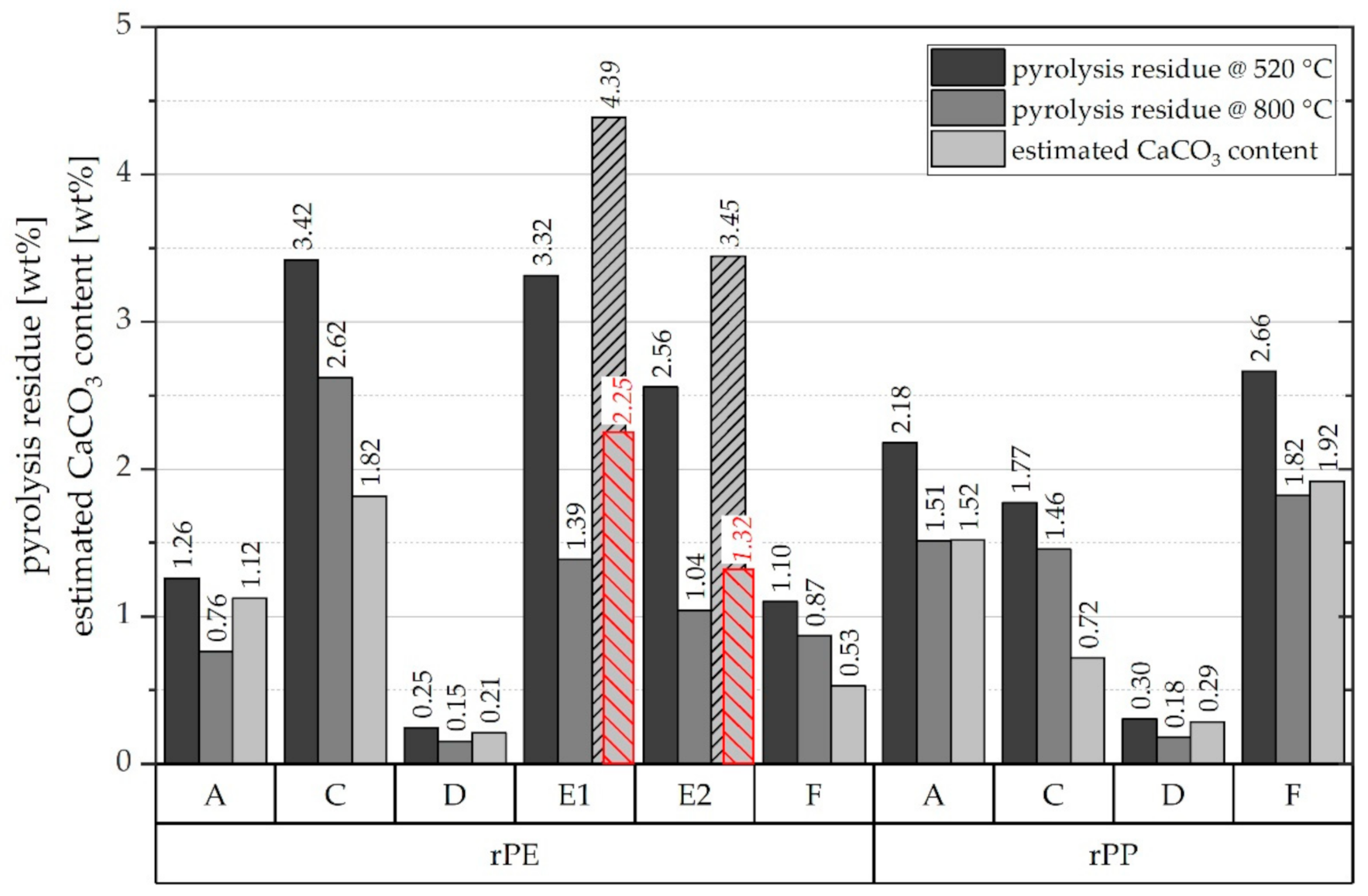

3.1.2. Thermo-Analytical Characterization

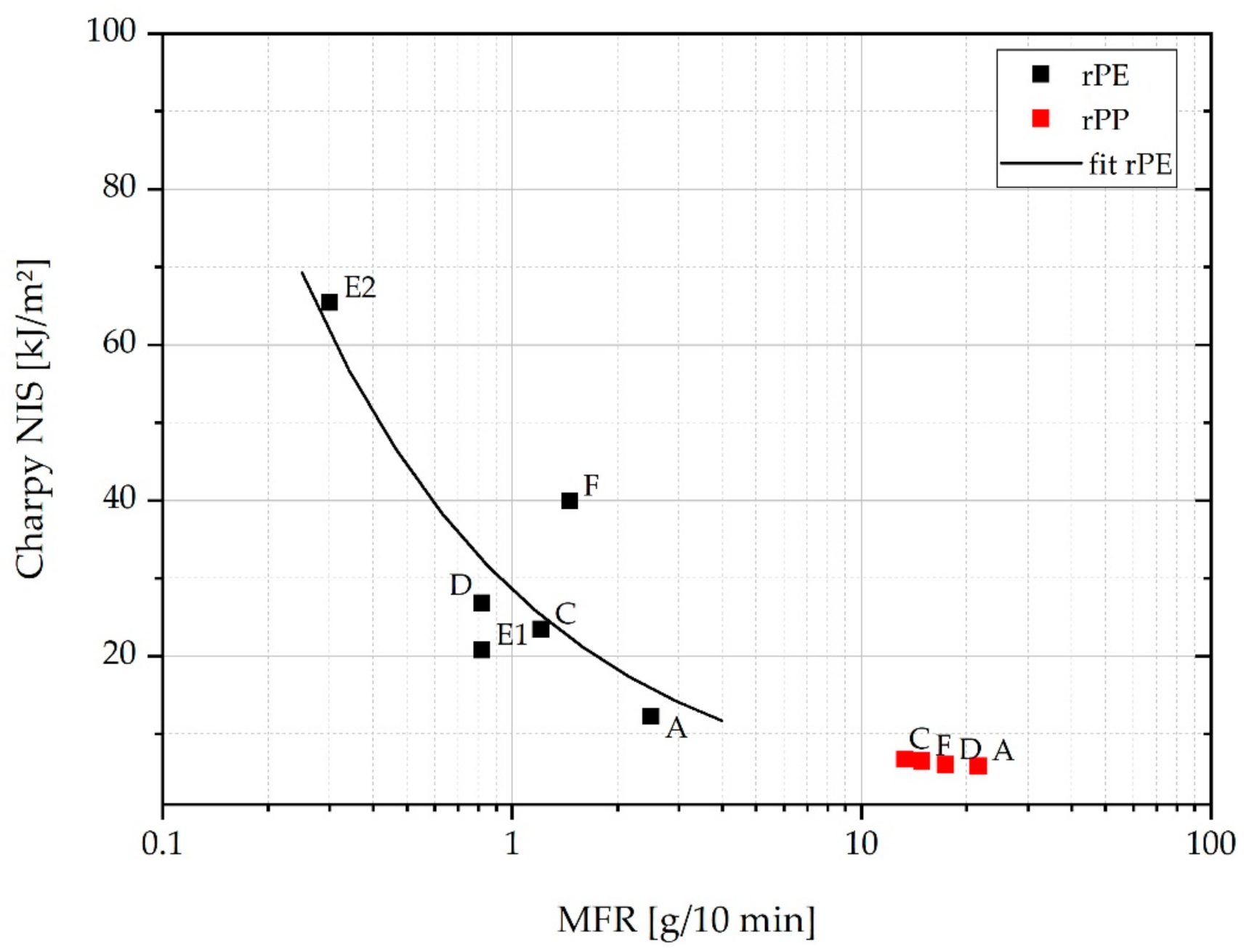

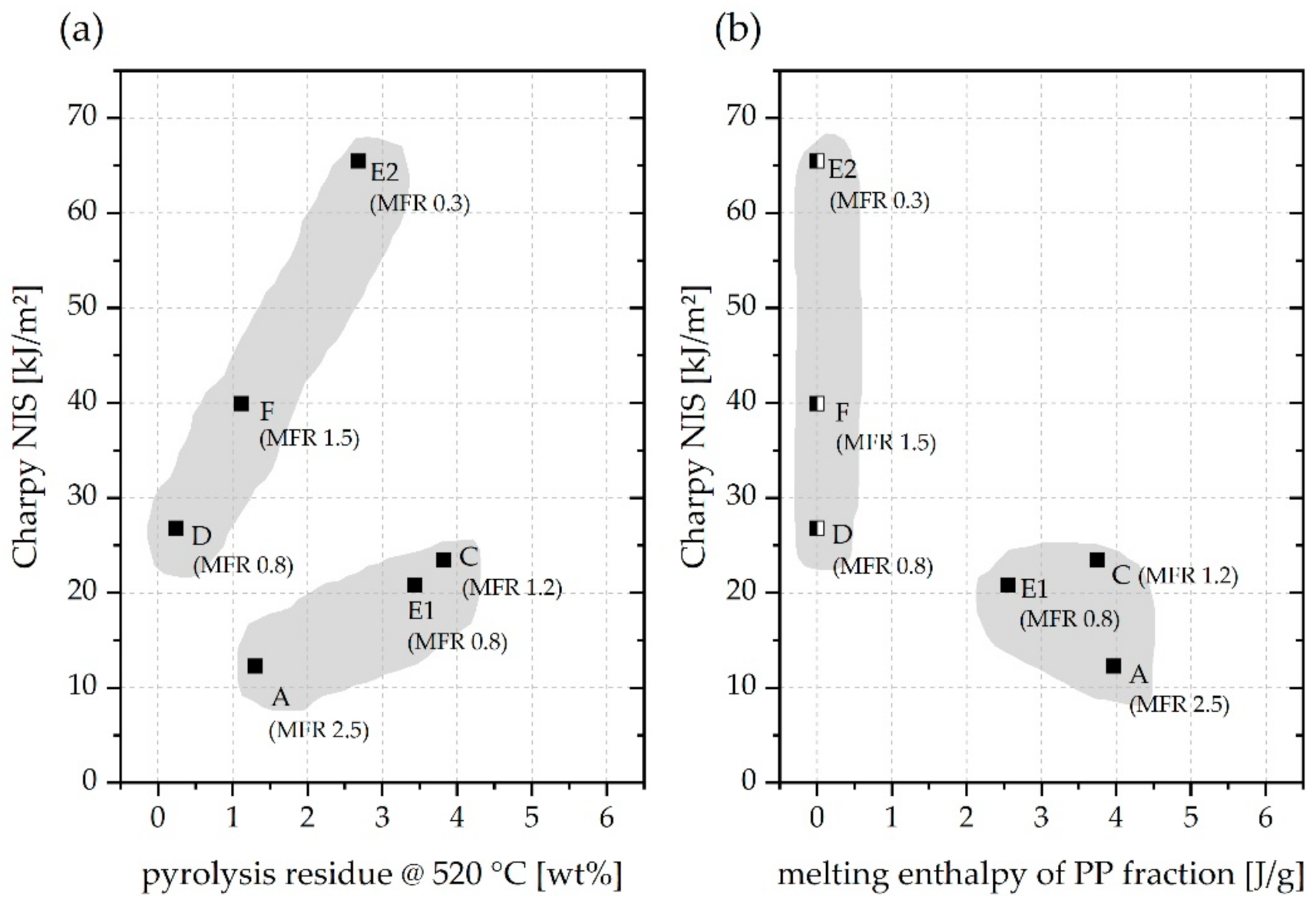

3.2. Technological Characterization

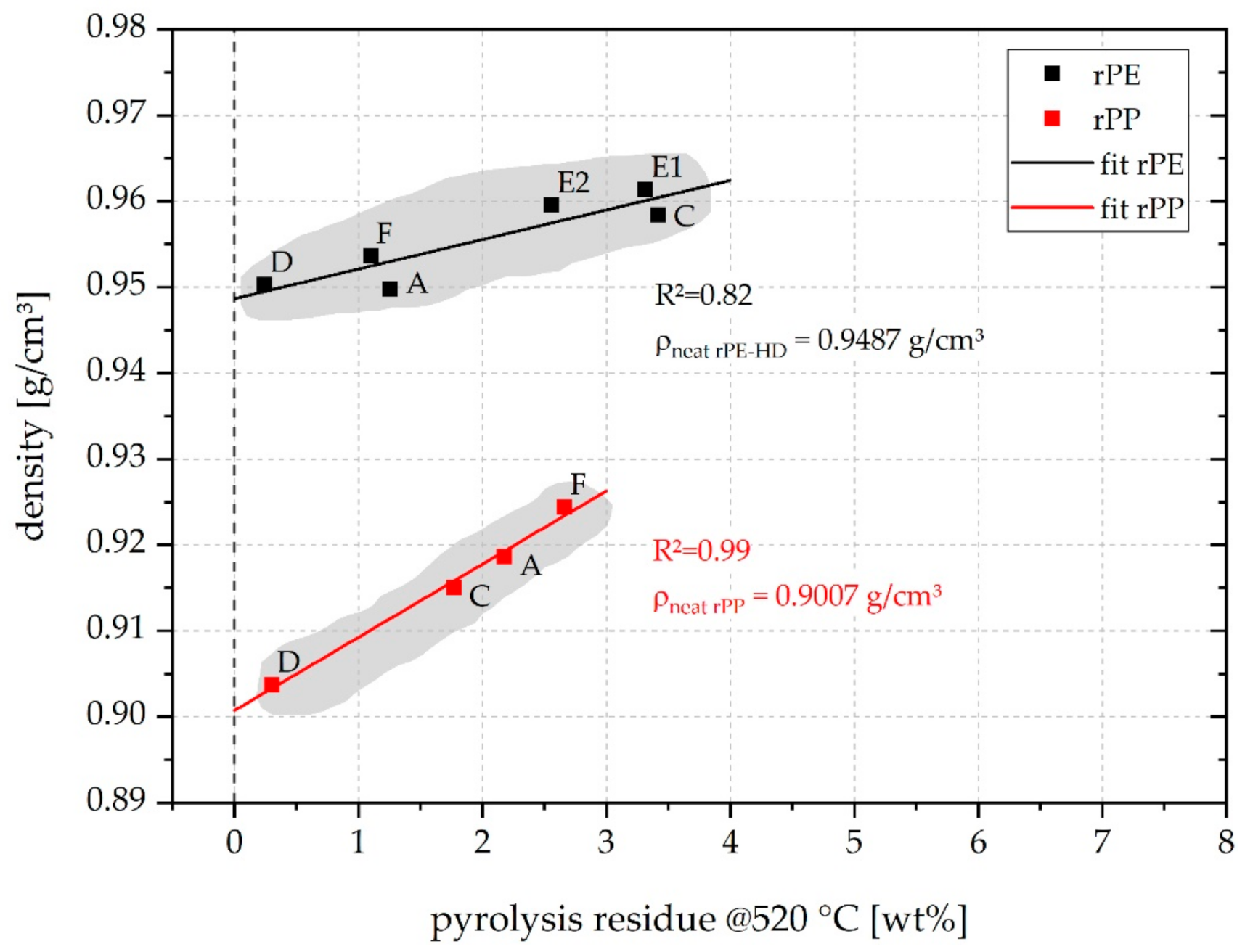

3.3. Structure–Property Relationships

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- A European Strategy for Plastics in a Circular Economy: COM(2018) 28 Final. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2018%3A28%3AFIN (accessed on 13 May 2021).

- PlasticsEurope. The Circular Economy for Plastics: A European Overview. 2019. Available online: https://www.plasticseurope.org/de/resources/publications/2606-circular-economy-plastics-european-overview (accessed on 10 April 2020).

- Directive (EU) 2018/852 of the European Parliament and of the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32018L0852 (accessed on 13 May 2021).

- Directive (EU) 2019/904 of the European Parliament and of the Council: On the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/eli/dir/2019/904/oj (accessed on 13 May 2021).

- A new Circular Economy Action Plan for a Cleaner and More Competitive Europe: COM(2020) 98 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0098 (accessed on 13 May 2021).

- PlasticsEurope. Plastics–the Facts 2020: An Analysis of European Plastics Production, Demand and Waste Data. 2020. Available online: https://www.plasticseurope.org/en/resources/publications/4312-plastics-facts-2020 (accessed on 13 May 2021).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Plastics Recyclers Europe; Eunomia. HDPE & PP Market in Europe State of Play: Production, Collection and Recycling Data. 2020. Available online: https://www.plasticsrecyclers.eu/downloads (accessed on 20 March 2021).

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; García-Muñoz, R.A. Incorporation of recycled high-density polyethylene to polyethylene pipe grade resins to increase close-loop recycling and Underpin the circular economy. J. Clean. Prod. 2020, 276, 124081. [Google Scholar] [CrossRef]

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef] [PubMed]

- Gall, M.; Lang, R.W.; Fischer, J.; Niehoff, A.; Schmidt, S. Characterization of post-use polyethylene and polypropylene recyclate blends for pipe applications. In Proceedings of the 19th Plastic Pipes Conference PPXIX, Las Vegas, NV, USA, 24–26 September 2018. [Google Scholar]

- Lang, R.W.; Bradler, P.R.; Fischer, J.; Poehlmann, D.; Schmidt, S.; Niehoff, A. Quality and performance assessment of in-plant and post-use PE recyclates for pipe applications. In Proceedings of the 18th Plastic Pipes Conference PPXVIII, Berlin, Germany, 12–14 September 2016. [Google Scholar]

- Cecon, V.S.; Da Silva, P.F.; Curtzwiler, G.W.; Vorst, K.L. The challenges in recycling post-consumer polyolefins for food contact applications: A. review. Resour. Conserv. Recycl. 2021, 167, 105422. [Google Scholar] [CrossRef]

- Radusin, T.; Nilsen, J.; Larsen, S.; Annfinsen, S.; Waag, C.; Eikeland, M.S.; Pettersen, M.K.; Fredriksen, S.B. Use of recycled materials as mid layer in three layered structures-new possibility in design for recycling. J. Clean. Prod. 2020, 259, 120876. [Google Scholar] [CrossRef]

- Stürzel, M.; Mihan, S.; Mülhaupt, R. From Multisite Polymerization Catalysis to Sustainable Materials and All-Polyolefin Composites. Chem. Rev. 2016, 116, 1398–1433. [Google Scholar] [CrossRef]

- Gahleitner, M.; Paulik, C. Polypropylene and Other Polyolefins. In Brydson’s Plastics Materials, 8th ed.; Gilbert, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 279–309. ISBN 9780323358248. [Google Scholar]

- Chum, P.S.; Swogger, K.W. Olefin polymer technologies—History and recent progress at The Dow Chemical Company. Prog. Polym. Sci. 2008, 33, 797–819. [Google Scholar] [CrossRef]

- Galli, P.; Vecellio, G. Technology: Driving force behind innovation and growth of polyolefins. Prog. Polym. Sci. 2001, 26, 1287–1336. [Google Scholar] [CrossRef]

- Ronca, S. Polyethylene. In Brydson’s Plastics Materials, 8th ed.; Gilbert, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 247–278. ISBN 9780323358248. [Google Scholar]

- Geier, S.; Schmitz, H.; Göschel, U.; Eyerer, P.; Ostrowicki, A.; Woicke, N.; Ulrich, C.; Lutz, W.; Eschl, J.; Rüb, G.; et al. Synthetische Kunststoffe. In Kunststoffe: Eigenschaften und Anwendungen; mit 275 Tabellen, 8, neu bearb. und erw. Aufl.; Domininghaus, H., Elsner, P., Eyerer, P., Hirth, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 115–1201. ISBN 978-3-642-16172-8. [Google Scholar]

- Yin, S.; Tuladhar, R.; Shi, F.; Shanks, R.A.; Combe, M.; Collister, T. Mechanical reprocessing of polyolefin waste: A review. Polym. Eng. Sci. 2015, 55, 2899–2909. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Boldizar, A.; Jansson, A.; Gevert, T.; Möller, K. Simulated recycling of post-consumer high density polyethylene material. Polym. Degrad. Stab. 2000, 68, 317–319. [Google Scholar] [CrossRef]

- Jansson, A.; Möller, K.; Gevert, T. Degradation of post-consumer polypropylene materials exposed to simulated recycling—mechanical properties. Polym. Degrad. Stab. 2003, 82, 37–46. [Google Scholar] [CrossRef]

- Jansson, A.; Kenneth, M.; Thomas, H. Chemical degradation of a polypropylene material exposed to simulated recycling. Polym. Degrad. Stab. 2004, 84, 227–232. [Google Scholar] [CrossRef]

- Mendes, A.A.; Cunha, A.M.; Bernardo, C.A. Study of the degradation mechanisms of polyethylene during reprocessing. Polym. Degrad. Stab. 2011, 96, 1125–1133. [Google Scholar] [CrossRef]

- Jin, H.; Gonzalez-Gutierrez, J.; Oblak, P.; Zupančič, B.; Emri, I. The effect of extensive mechanical recycling on the properties of low density polyethylene. Polym. Degrad. Stab. 2012, 97, 2262–2272. [Google Scholar] [CrossRef]

- Luzuriaga, S.; Kovářová, J.; Fortelný, I. Degradation of pre-aged polymers exposed to simulated recycling: Properties and thermal stability. Polym. Degrad. Stab. 2006, 91, 1226–1232. [Google Scholar] [CrossRef]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. An overview of the challenges and trade-offs in closing the loop of post-consumer plastic waste (PCPW): Focus on recycling. J. Hazard. Mater. 2019, 380, 120887. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Luijsterburg, B.; Goossens, H. Assessment of plastic packaging waste: Material origin, methods, properties. Resour. Conserv. Recycl. 2014, 85, 88–97. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; van Geem, K.M.; Ragaert, K.; de Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef]

- Brouwer, M.T.; van Thoden Velzen, E.U.; Augustinus, A.; Soethoudt, H.; de Meester, S.; Ragaert, K. Predictive model for the Dutch post-consumer plastic packaging recycling system and implications for the circular economy. Waste Manag. 2018, 71, 62–85. [Google Scholar] [CrossRef]

- Eriksen, M.K.; Christiansen, J.D.; Daugaard, A.E.; Astrup, T.F. Closing the loop for PET, PE and PP waste from households: Influence of material properties and product design for plastic recycling. Waste Manag. 2019, 96, 75–85. [Google Scholar] [CrossRef]

- van Belle, A.; Demets, R.; Mys, N.; van Kets, K.; Dewulf, J.; van Geem, K.; de Meester, S.; Ragaert, K. Microstructural Contributions of Different Polyolefins to the Deformation Mechanisms of Their Binary Blends. Polymers 2020, 12, 1171. [Google Scholar] [CrossRef]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, e2000415. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Ragaert, K.; Hubo, S.; Delva, L.; Veelaert, L.; Du Bois, E. Upcycling of contaminated post-industrial polypropylene waste: A design from recycling case study. Polym. Eng. Sci. 2018, 58, 528–534. [Google Scholar] [CrossRef]

- Gall, M.; Steinbichler, G.; Lang, R.W. Learnings about design from recycling by using post-consumer polypropylene as a core layer in a co-injection molded sandwich structure product. Mater. Design 2021, 202, 109576. [Google Scholar] [CrossRef]

- Garofalo, E.; Di Maio, L.; Scarfato, P.; Pietrosanto, A.; Protopapa, A.; Incarnato, L. Study on Improving the Processability and Properties of Mixed Polyolefin Post-Consumer Plastics for Piping Applications. Polymers 2020, 13, 71. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 3167:2014: Plastics–Multipurpose Test Specimens, 2014 08, 83.080.01. Available online: https://www.iso.org/standard/65105.html (accessed on 13 May 2021).

- ISO. ISO 17855–2:2016: Plastics–Polyethylene (PE) Moulding and Extrusion Materials–Part 2: Preparation of Test Specimens and Determination of Properties, 2016 02, 83.080.20. Available online: https://www.iso.org/standard/66827.html (accessed on 13 May 2021).

- ISO. ISO 1873–2:2007: Plastics–Polypropylene (PP) Moulding and Extrusion Materials–Part 2: Preparation of Test Specimens and Determination of Properties, 2007 09, 83.080.20. Available online: https://www.iso.org/standard/42465.html (accessed on 13 May 2021).

- ISO. ISO 1183–1:2019: Plastics–Methods for Determining the Density of Non-Cellular Plastics–Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method, 2019 03, 83.080.01. Available online: https://www.iso.org/standard/74990.html (accessed on 13 May 2021).

- ISO. ISO 1133–1:2011: Plastics–Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics–Part 1: Standard Method, 2011 12, 83.080.20. Available online: https://www.iso.org/standard/44273.html (accessed on 13 May 2021).

- ISO. ISO 179–1:2010: Plastics–Determination of Charpy Impact Properties–Part 1: Non-Instrumented Impact Test, 2nd ed., 2010 06, 83.080.01. Available online: https://www.iso.org/standard/44852.html (accessed on 13 May 2021).

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; Repr. as Paperback; Wiley: Chichester, UK, 2010; ISBN 978-0-470-09307-8. [Google Scholar]

- Noda, I.; Dowrey, A.E.; Haynes, J.L.; Marcott, C. Group Frequency Assignments for Major Infrared Bands Observed in Common Synthetic Polymers. In Physical Properties of Polymers Handbook, 2nd ed.; Mark, J.E., Ed.; Springer: New York, NY, USA, 2007; pp. 395–406. ISBN 978-0-387-31235-4. [Google Scholar]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez, C.V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.-J.; et al. Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef] [PubMed]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 2002, 21, 557–563. [Google Scholar] [CrossRef]

- Andreassen, E. Infrared and Raman spectroscopy of polypropylene. In Polypropylene: An A-Z Reference; Karger-Kocsis, J., Ed.; Springer: Dordrecht, The Netherlands, 1999; pp. 320–328. ISBN 978-94-010-5899-5. [Google Scholar]

- Hummel, D.O. Atlas of Plastics Additives; Springer: Berlin/Heidelberg, Germany, 2002; ISBN 978-3-540-42414-7. [Google Scholar]

- Gall, M.; Schweighuber, A.; Buchberger, W.W.; Lang, R. Plastic Bottle Cap Recycling—Characterization of Recyclate Composition and Opportunities for Design for Circularity. Sustainability 2020, 12, 10378. [Google Scholar] [CrossRef]

- Naranjo, A.; del Pilar Noriega, E.M.; Osswald, T.A.; Roldán-Alzate, A.; Sierra, J.D. Spectroscopy. In Plastics Testing and Characterization: Industrial Applications; Naranjo, A., Pilar Noriega, E., Md Osswald, T.A., Roldán-Alzate, A., Sierra, J.D., Eds.; Hanser/Hanser Gardner: Munich, Germany, 2008; pp. 7–53. ISBN 978-3-446-41315-3. [Google Scholar]

- Teh, J.W.; Rudin, A.; Keung, J.C. A review of polyethylene–polypropylene blends and their compatibilization. Adv. Polym. Technol. 1994, 13, 1–23. [Google Scholar] [CrossRef]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Differential Scanning Calorimetry (DSC). In Thermal Analysis of Plastics: Theory and Practice; Ehrenstein, G.W., Riedel, G., Trawiel, P., Eds.; Hanser: Munich, Germany, 2004; pp. 1–110. ISBN 978-3-446-22673-9. [Google Scholar]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Thermogravimetry (TG). In Thermal Analysis of Plastics: Theory and Practice; Ehrenstein, G.W., Riedel, G., Trawiel, P., Eds.; Hanser: Munich, Germany, 2004; pp. 139–171. ISBN 978-3-446-22673-9. [Google Scholar]

- Gall, M.; Wiener, M.; Chagas de Oliveira, C.; Lang, R.W.; Hansen, E.G. Building a circular plastics economy with informal waste pickers: Recyclate quality, business model, and societal impacts. Resour. Conserv. Recycl. 2020, 156, 104685. [Google Scholar] [CrossRef]

- Gahleitner, M.; Tranninger, C.; Doshev, P. Heterophasic copolymers of polypropylene: Development, design principles, and future challenges. J. Appl. Polym. Sci. 2013, 130, 3028–3037. [Google Scholar] [CrossRef]

- Grein, C. Toughness of Neat, Rubber Modified and Filled β-nucleated Polypropylene: From Fundamentals to Applications. In Intrinsic Molecular Mobility and Toughness of Polymers; Kausch, H.-H., Altstädt, V., Eds.; Springer: Berlin, Germany, 2005; pp. 43–104. ISBN 978-3-540-26162-9. [Google Scholar]

- Rothon, R.; DeArmitt, C. Fillers (Including Fiber Reinforcements). In Brydson’s Plastics Materials, 8th ed.; Gilbert, M., Ed.; Butterworth-Heinemann is an imprint of Elsevier; Elsevier: Amsterdam, The Netherlands, 2017; pp. 169–204. ISBN 9780323358248. [Google Scholar]

- ISO. ISO 17855–1:2014: Plastics–Polyethylene (PE) Moulding and Extrusion Materials–Part 1: Designation System and Basis for Specifications, 2014 10, 83.080.20. Available online: https://www.iso.org/standard/60831.html (accessed on 13 May 2021).

- Bartczak, Z.; Argon, A.S.; Cohen, R.E.; Weinberg, M. Toughness mechanism in semi-crystalline polymer blends: II. High-density polyethylene toughened with calcium carbonate filler particles. Polymer 1999, 40, 2347–2365. [Google Scholar] [CrossRef]

- Deshmane, C.; Yuan, Q.; Misra, R.D.K. On the fracture characteristics of impact tested high density polyethylene–calcium carbonate nanocomposites. Mater. Sci. Eng. A 2007, 452-453, 592–601. [Google Scholar] [CrossRef]

- Teh, J.W. Structure and properties of polyethylene–polypropylene blend. J. Appl. Polym. Sci. 1983, 28, 605–618. [Google Scholar] [CrossRef]

- Lovinger, A.J.; Williams, M.L. Tensile properties and morphology of blends of polyethylene and polypropylene. J. Appl. Polym. Sci. 1980, 25, 1703–1713. [Google Scholar] [CrossRef]

- Tai, C.M.; Li, R.K.Y.; Ng, C.N. Impact behaviour of polypropylene/polyethylene blends. Polym. Test. 2000, 19, 143–154. [Google Scholar] [CrossRef]

- van Thoden Velzen, E.U.; Chu, S.; Alvarado Chacon, F.; Brouwer, M.T.; Molenveld, K. The impact of impurities on the mechanical properties of recycled polyethylene. Packag Technol. Sci. 2021, 34, 219–228. [Google Scholar] [CrossRef]

- Luijsterburg, B.J.; Jobse, P.S.; Spoelstra, A.B.; Goossens, J.G.P. Solid-state drawing of post-consumer isotactic poly(propylene): Effect of melt filtration and carbon black on structural and mechanical properties. Waste Manag. 2016, 54, 53–61. [Google Scholar] [CrossRef]

- Jmal, H.; Bahlouli, N.; Wagner-Kocher, C.; Leray, D.; Ruch, F.; Munsch, J.-N.; Nardin, M. Influence of the grade on the variability of the mechanical properties of polypropylene waste. Waste Manag. 2018, 75, 160–173. [Google Scholar] [CrossRef] [PubMed]

- Carmeli, E.; Tranchida, D.; Albrecht, A.; Müller, A.J.; Cavallo, D. A tailor-made Successive Self-nucleation and Annealing protocol for the characterization of recycled polyolefin blends. Polymer 2020, 203, 122791. [Google Scholar] [CrossRef]

- Larsen, Å.G.; Olafsen, K.; Alcock, B. Determining the PE fraction in recycled PP. Polym. Test. 2021, 96, 107058. [Google Scholar] [CrossRef]

- Curtzwiler, G.W.; Williams, E.B.; Hurban, E.; Greene, J.; Vorst, K.L. Certification markers for empirical quantification of post-consumer recycled content in extruded polyethylene film. Polym. Test. 2018, 65, 103–110. [Google Scholar] [CrossRef]

- Giles, H.F.; Wagner, J.R.; Mount, E.M. Screen Changers. In Extrusion: The Definitive Processing Guide and Handbook 1, Aufl.; Mount, E.M., III, Giles, H.F., Wagner, J.R., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 341–348. ISBN 9780815514732. [Google Scholar]

- Pachner, S.; Aigner, M.; Miethlinger, J. Modeling and optimization of melt filtration systems in polymer recycling. In Proceedings of the 32nd International Conference of the Polymer Processing Society–Conference Papers, Lyon, France, 25–29 July 2016; p. 80004. [Google Scholar]

- Pachner, S.; Aigner, M.; Miethlinger, J. A heuristic method for modeling the initial pressure drop in melt filtration using woven screens in polymer recycling. Polym. Eng. Sci. 2019, 59, 1105–1113. [Google Scholar] [CrossRef]

- McConney, M.E.; Singamaneni, S.; Tsukruk, V.V. Probing Soft Matter with the Atomic Force Microscopies: Imaging and Force Spectroscopy. Polym. Rev. 2010, 50, 235–286. [Google Scholar] [CrossRef]

- Dazzi, A.; Prater, C.B. AFM-IR: Technology and Applications in Nanoscale Infrared Spectroscopy and Chemical Imaging. Chem. Rev. 2017, 117, 5146–5173. [Google Scholar] [CrossRef]

- Song, M.; Hourston, D.J.; Grandy, D.B.; Reading, M. An application of micro-thermal analysis to polymer blends. J. Appl. Polym. Sci. 2001, 81, 2136–2141. [Google Scholar] [CrossRef]

| Polymer 1 | MFR 2 (g/10 min) | Density (g/cm3) | Melting Temperature (°C) | Crystallinity (%) | Impact Strength 3 (kJ/m2) |

|---|---|---|---|---|---|

| PE-HD | <0.1–60 | 0.94–0.97 | 128–136 | 60–80 | 6–n.b. |

| PE-LLD | 0.8–30 | 0.90–0.93 | 120–130 | 30–45 | n.b. |

| PE-LD | 0.4–90 | 0.915–0.935 | 105–115 | 40–50 | n.b. |

| PP h. isotactic | 0.3–1000 | 0.905–0.915 | 160–167 | 30–60 | 2–25 |

| PP r. | 0.3–100 | 0.900 | 135–150 | not stated | 5–50 |

| PP heco | 0.5–100 | 0.900–0.912 | 160–167 | not stated | 10–n.b. 2 |

| Name | Polymer | MFR 1 (g/10 min) | Density 2 (g/cm3) | Ash Content 2 (wt.%) | Mesh Size (µm) |

|---|---|---|---|---|---|

| rPE-A | PE-HD | ≤3 | 0.950 | ≤1 | 180 |

| rPE-C | PE-HD | 1.1–2.0 | 0.94–0.99 | <5 | not stated |

| rPE-D | PE-HD | 1.0 | 0.95 | ≤0.5 | ≤100 |

| rPE-E1 | PE-HD | 0.7–1.0 | ≥0.945 | not stated | 80 |

| rPE-E2 | PE-HD | 0.2–0.5 | ≥0.945 | not stated | 80 |

| rPE-F | PE-HD | 1.5 | 0.95 | not stated | not stated |

| rPP-A | PP | ≥20 | 0.916 | ≤2 | 180 |

| rPP-C | PP | 10–15 | 0.85–0.95 | <5 | not stated |

| rPP-D | PP | 18 | 0.90 | ≤0.5 | ≤100 |

| rPP-F | PP | 13 | 0.92 | not stated | not stated |

| Tm1 | ∆Hm1 | Tm2 | ∆Hm2 | Tc1 | ∆Hc1 | Tc2 | ∆Hc2 | |

|---|---|---|---|---|---|---|---|---|

| °C | J/g | °C | J/g | °C | J/g | °C | J/g | |

| rPE-A | 132.5 | 176.6 | 162.5 | 4.0 | 117.5 | 181.0 1 | - | - |

| rPE-C | 131.9 | 177.7 | 160.4 | 3.7 | 118.2 | 181.5 1 | - | - |

| rPE-D | 131.3 | 201.4 | - | - | 117.8 | 202.0 | - | - |

| rPE-E1 | 131.3 | 173.1 | 159.0 | 2.6 | 117.7 | 177.7 1 | - | - |

| rPE-E2 | 131.0 | 179.1 | - | - | 117.7 | 181.1 | - | - |

| rPE-F | 131.5 | 190.8 | - | - | 118.1 | 189.2 | - | - |

| rPP-A | 126.1 | 4.5 | 164.0 | 70.7 | 123.6 | 88.7 2 (79.2) 3 | 115.2 | (9.5) 3 |

| rPP-C | 124.4 | 1.2 | 162.6 | 74.4 | 124.9 | 85.7 2 | 110.3 | - |

| rPP-D | 124.5 | 2.1 | 158.9 | 56.7 | 122.1 | 77.9 2 | 110.8 | - |

| rPP-F | 126.8 | 12.2 | 161.8 | 59.8 | 123.1 | 83.4 2 (66.6) 3 | 115.8 | (16.8) 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gall, M.; Freudenthaler, P.J.; Fischer, J.; Lang, R.W. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers 2021, 13, 1574. https://doi.org/10.3390/polym13101574

Gall M, Freudenthaler PJ, Fischer J, Lang RW. Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers. 2021; 13(10):1574. https://doi.org/10.3390/polym13101574

Chicago/Turabian StyleGall, Markus, Paul J. Freudenthaler, Joerg Fischer, and Reinhold W. Lang. 2021. "Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates" Polymers 13, no. 10: 1574. https://doi.org/10.3390/polym13101574

APA StyleGall, M., Freudenthaler, P. J., Fischer, J., & Lang, R. W. (2021). Characterization of Composition and Structure–Property Relationships of Commercial Post-Consumer Polyethylene and Polypropylene Recyclates. Polymers, 13(10), 1574. https://doi.org/10.3390/polym13101574