Structural Design Calculation of Basalt Fiber Polymer-Modified RPC Beams Subjected to Four-Point Bending

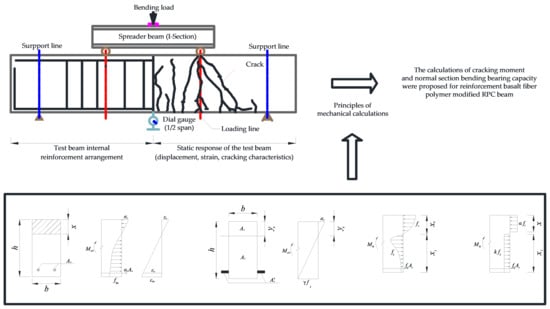

Abstract

:1. Introduction

2. Experimental Details

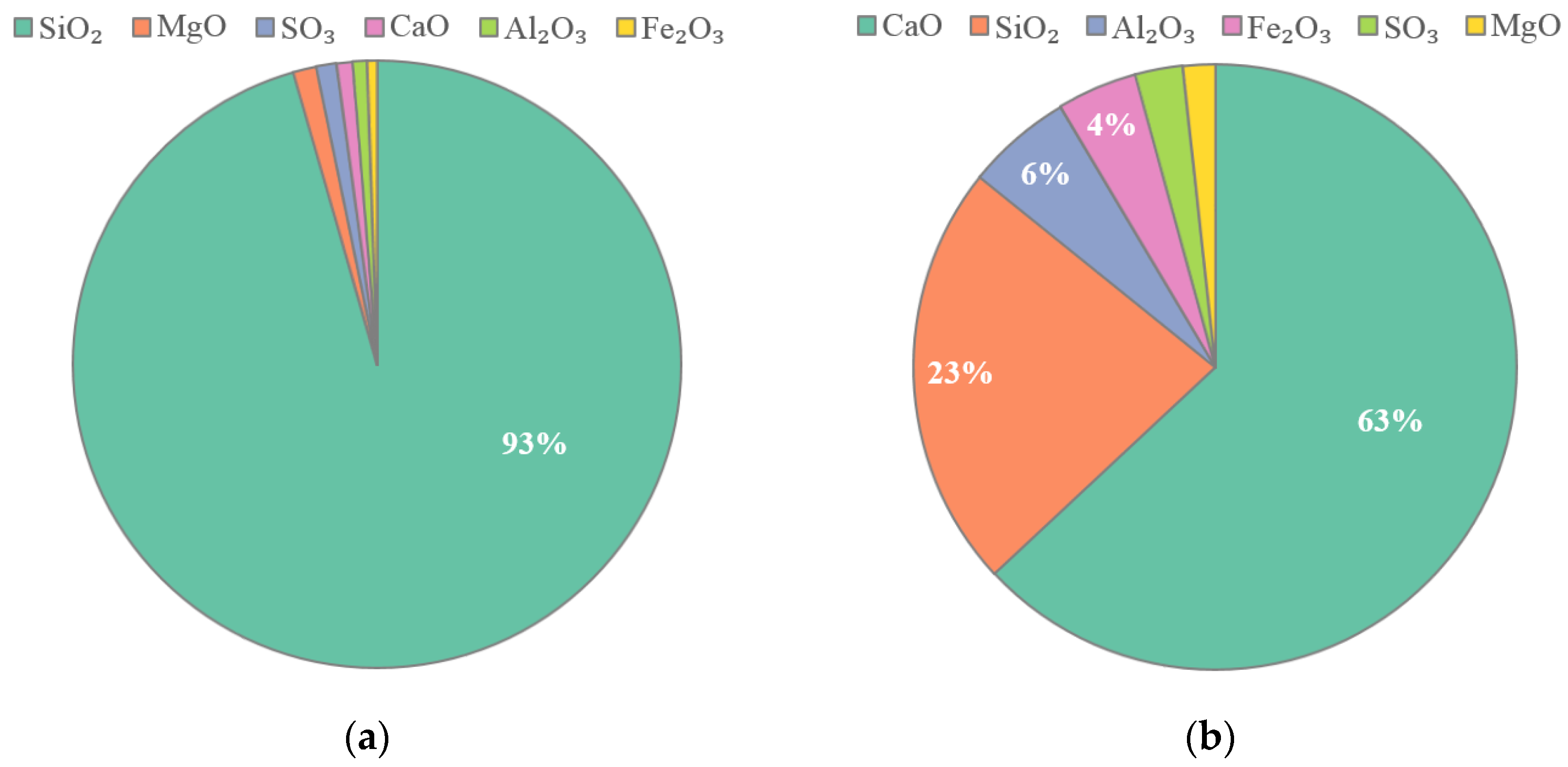

2.1. Materials and Mixture

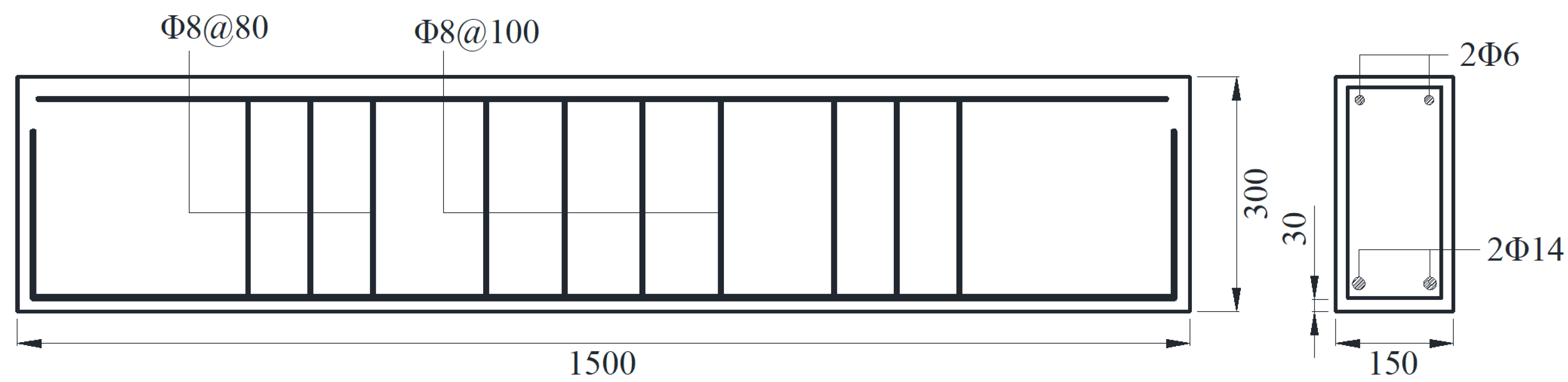

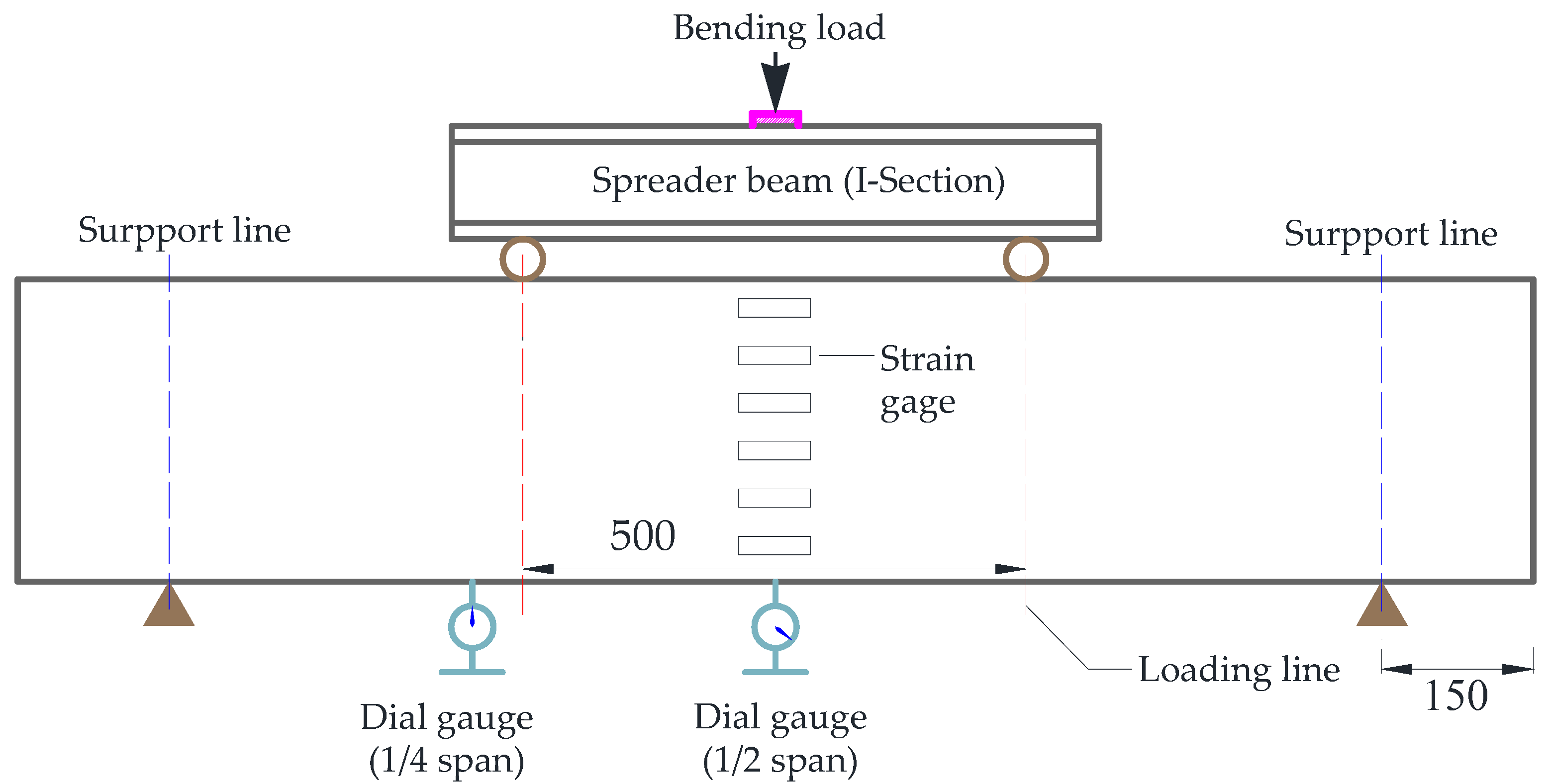

2.2. Specimen Preparation and Experimental Procedure

2.3. Experimental Setups

3. Results

3.1. Test Results

3.2. Cracking Moment Calculation

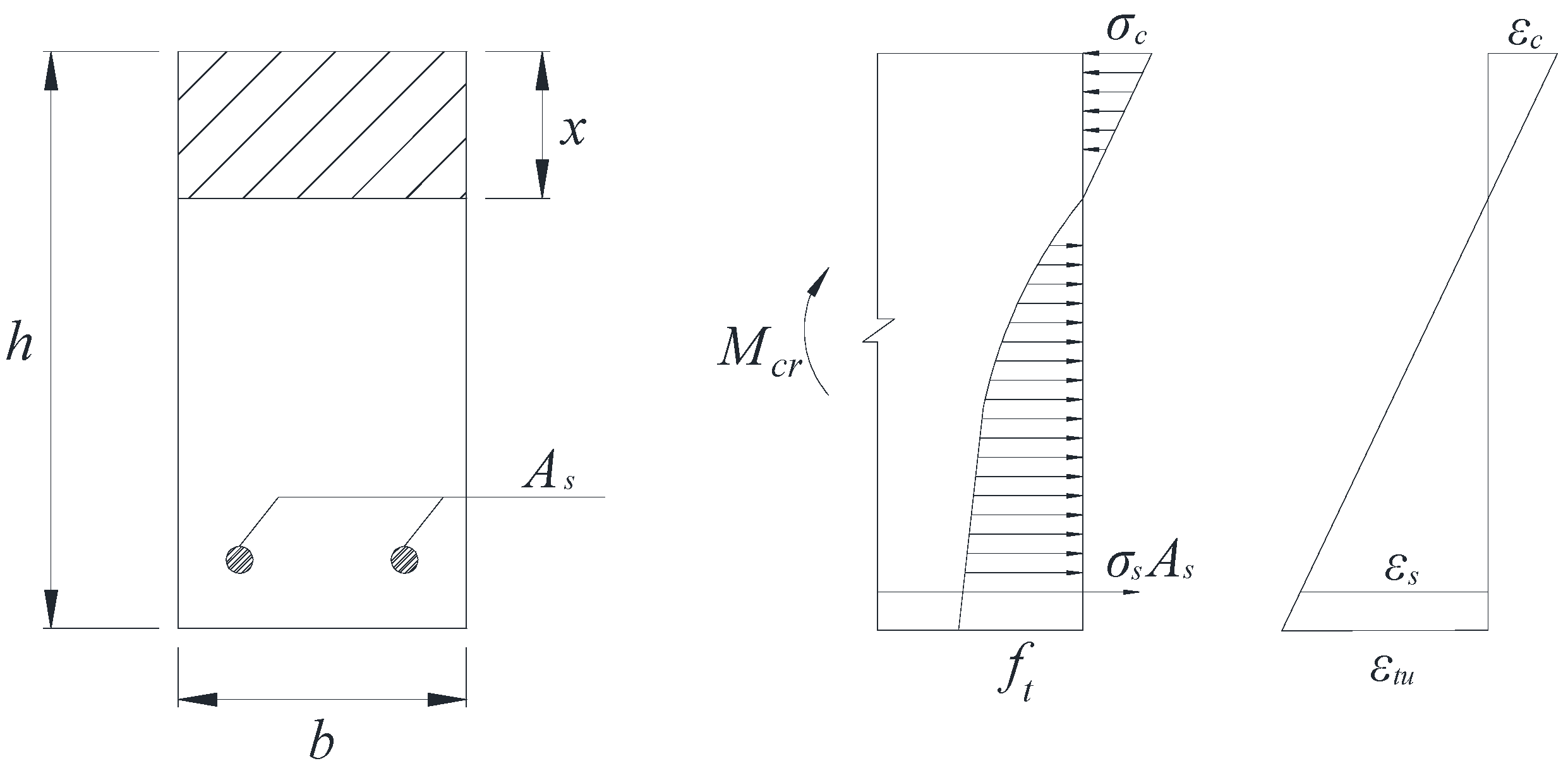

3.2.1. Calculation Principle of Cracking Moment

3.2.2. Calculation of

3.2.3. Calculation of

3.2.4. Calculations of and Cracking Moment

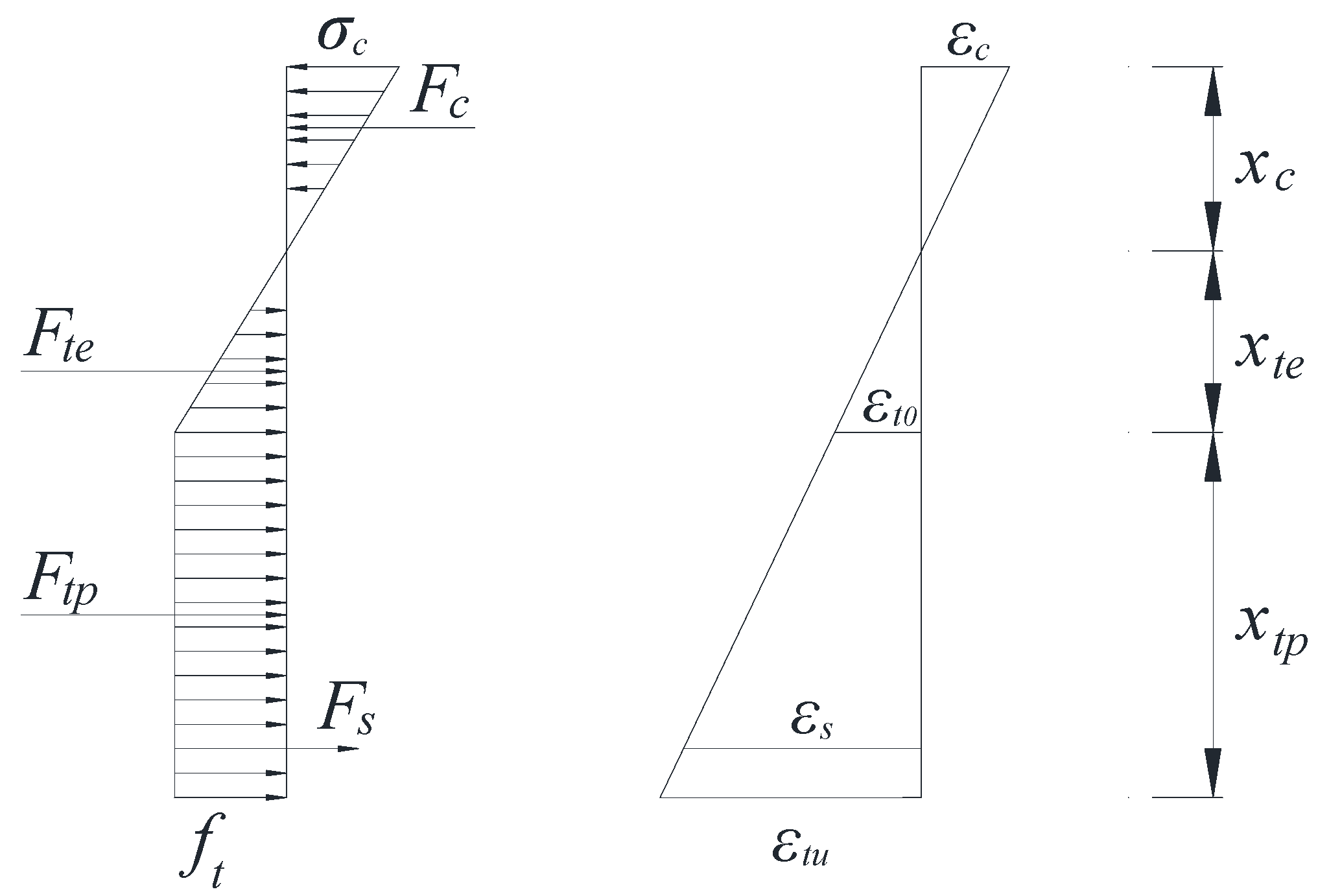

3.3. Calculation of Normal Section Bending Bearing Capacity

3.3.1. Basic Assumptions

3.3.2. Equivalent Rectangular Stress Pattern

3.3.3. Calculation of Normal Section Bending Bearing Capacity

3.3.4. Relative Pressure Zone Height and Reinforcement Ratio Range

4. Discussion

5. Conclusions

- (1)

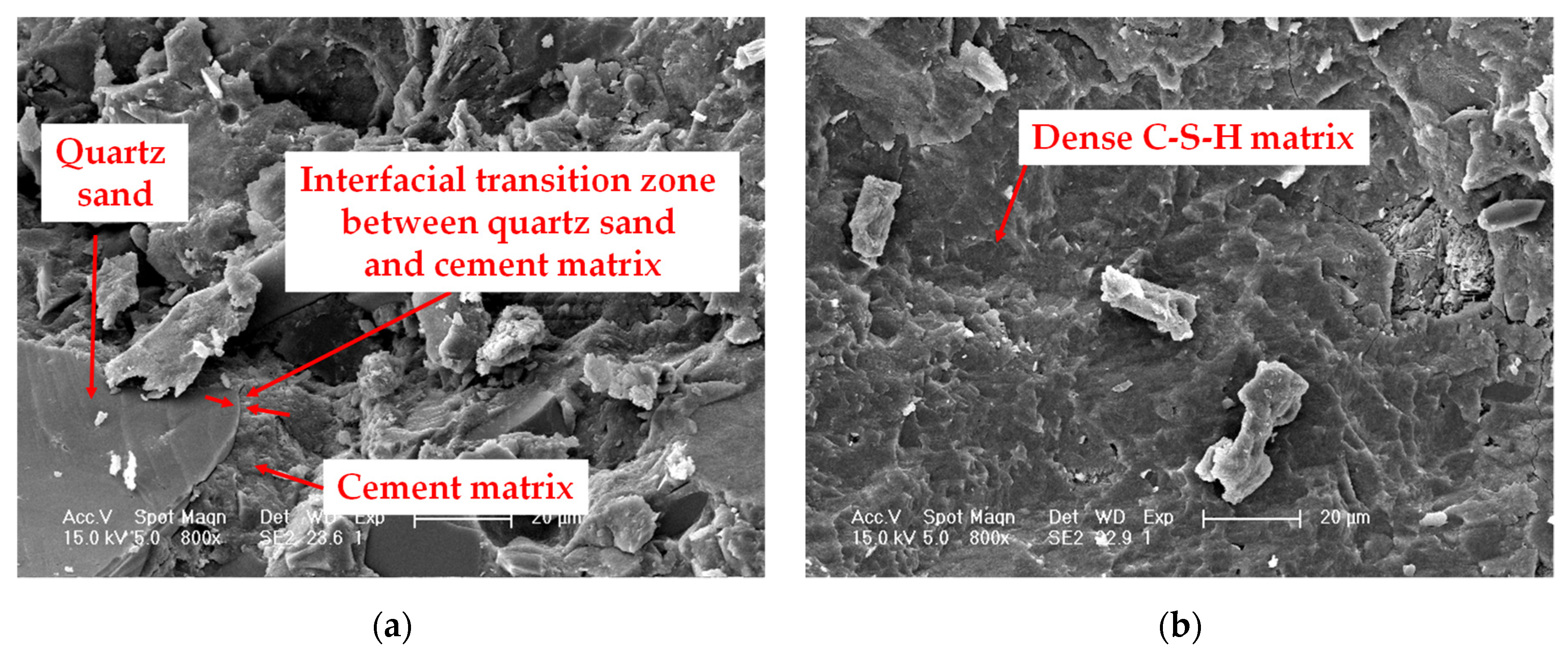

- The hydration products of basalt fiber polymer-modified RPC are mainly dense C–S–H matrix and the thickness of the interfacial transition zone between the aggregate quartz sand and the cement matrix is negligible.

- (2)

- Basalt fibers treated with coupling agents in RPC materials are distributed in a random direction, and the basalt fibers are tightly bonded to the RPC matrix.

- (3)

- The section resistance moment plasticity influence coefficient of the reinforcement basalt fiber polymer-modified RPC simply supported beam is 1.7; the relative height of the compressive area is 0.48; the minimum and maximum reinforcement ratios of HRB335 rebar are 0.71% and 18%, respectively.

- (4)

- The established formulas for cracking moment and normal section bending bearing capacity is reasonably accurate. The research results of this paper can provide references for the design of reinforcement basalt fiber polymer-modified RPC simply supported beam and promote the wide application of basalt fiber polymer-modified RPC materials in practical engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edwin, R.; Gruyaert, E.; de Belie, N. Influence of intensive vacuum mixing and heat treatment on compressive strength and microstructure of reactive powder concrete incorporating secondary copper slag as supplementary cementitious material. Constr. Build. Mater. 2017, 155, 400–412. [Google Scholar] [CrossRef]

- Chen, X.; Wan, D.; Jin, L.; Qian, K.; Fu, F. Experimental studies and microstructure analysis for ultra high-performance reactive powder concrete. Constr. Build. Mater. 2019, 229, 116924. [Google Scholar] [CrossRef]

- Zdeb, T. Effect of vacuum mixing and curing conditions on mechanical properties and porosity of reactive powder concretes. Constr. Build. Mater. 2019, 209, 326–339. [Google Scholar] [CrossRef]

- Sultan, H.; Alyaseri, I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements. Constr. Build. Mater. 2020, 261, 120555. [Google Scholar] [CrossRef]

- Chan, Y.; Chu, S. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cement. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Hassan, A.; Kawakami, M. Steel-free composite slabs made of reactive powder materials and fiber-reinforced concrete. Aci. Struct. J. 2005, 102, 709–718. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part. B-Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.; Zhu, B.; Lyu, X.; Gao, X.; Liang, C. Mechanical Properties and Freeze–Thaw Durability of Basalt Fiber Reactive Powder Concrete. Appl. Sci. 2020, 10, 5682. [Google Scholar] [CrossRef]

- Liu, H.; Lyu, X.; Zhang, Y.; Luo, G.; Li, W. Bending Resistance and Failure Type Evaluation of Basalt Fiber RPC Beam Affected by Notch and Interfacial Damage Using Acoustic Emission. Appl. Sci. 2020, 10, 1138. [Google Scholar] [CrossRef] [Green Version]

- Kannan, R.; Mathangi, D.; Sudha, C.; Neelamgam, M. Experimental investigation of reactive powder concrete exposed to elevated temperatures. Constr. Build. Mater. 2020, 261, 119593. [Google Scholar]

- Sakr, M.A.; Osama, B.; El Korany, T.M. Modeling of ultra-high performance fiber reinforced concrete columns under eccentric loading. Structures 2021, 32, 2195–2210. [Google Scholar] [CrossRef]

- Chand, U. Prediction of Flexural Behavior of Fiber-Reinforced High-Performance Concrete. In Recycled Waste Materials—Proceedings of EGRWSE 2019; Agnihotri, A.K., Reddy, K.R., Bansal, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 193–198. [Google Scholar]

- Zingaila, T.; Augonis, M. Influence of Partial Use of UHPC on the Cracking Moment of Flexural Composite Beams. In Proceedings of the 20th International Scientific Conference (Mechanika 2015), Kaunas, Lithuania, 23–24 April 2015; p. 281. [Google Scholar]

- Zhang, Y.; Zhu, Y.; Yeseta, M.; Meng, D.; Shao, X.; Dang, Q.; Chen, G. Flexural behaviors and capacity prediction on damaged reinforcement concrete (RC) bridge deck strengthened by ultra-high performance concrete (UHPC) layer. Constr. Build. Mater. 2019, 215, 347–359. [Google Scholar] [CrossRef]

- Yang, I.-H.; Joh, C.; Kim, B.-S. Flexural response predictions for ultra-high-performance fibre-reinforced concrete beams. Mag. Concr. Res. 2012, 64, 113–127. [Google Scholar] [CrossRef]

- Ujike, I.; Sogo, H.; Takasuga, D.; Konishi, Y.; Numata, M. Cracking and deformation of RC beams strengthened with reactive powder composite. In Proceedings of the 6th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Catania, Italy, 17–22 June 2007; Volume 2, p. 903. [Google Scholar]

- Turker, K.; Hasgul, U.; Birol, T.; Yavas, A.; Yazici, H. Hybrid fiber use on flexural behavior of ultra high performance fiber reinforced concrete beams. Compos. Struct. 2019, 229, 111400. [Google Scholar] [CrossRef]

- Sim, C.; Tadros, M.; Gee, D.; Asaad, M. Flexural design of precast, prestressed ultra-high-performance concrete members. PCI J. 2020, 65, 35–61. [Google Scholar] [CrossRef]

- Prem, P.R.; Murthy, A.R.; Verma, M. Theoretical modelling and acoustic emission monitoring of RC beams strengthened with UHPC. Constr. Build. Mater. 2018, 158, 670–682. [Google Scholar] [CrossRef]

- Guo, M.; Ji, W. Study on nonlinear flexural behavior of RPC-NC composite beams. In Proceedings of the 3rd International Conference on Railway Engineering: Construction and Maintenance of Railway Infrastructure in Complex Environment, Beijing, China, 1 July 2014; pp. 531–537. [Google Scholar]

- Chi, C.; Pei, C. Finite element analysis of Reactive Powder Concrete beam flexural properties. In Proceedings of the 2017 6th International Conference on Energy, Environment and Sustainable Development, Zhuhai, China, 11–12 March 2017; pp. 231–236. [Google Scholar]

- Chen, M.; Pei, C. Influence of different kinds of steel fibers on flexural behavior of ultra-high performance concrete beam by ANSYS. In Proceedings of the 2017 5th International Conference on Machinery, Materials and Computing Technology, Beijing, China, 25 March 2017; Hou, H., Han, Z., Eds.; Atlantis Press: Paris, France, 2017; pp. 162–167. [Google Scholar]

- Qi, J.; Cheng, Z.; Wang, J.; Tang, Y. Flexural behavior of steel-UHPFRC composite beams under negative moment. Structures 2020, 24, 640–649. [Google Scholar] [CrossRef]

- Hasgul, U.; Turker, K.; Birol, T.; Yavas, A. Flexural behavior of ultra-high-performance fiber reinforced concrete beams with low and high reinforcement ratios. Struct. Concr. 2018, 19, 1577–1590. [Google Scholar] [CrossRef]

- Cao, X.; Yang, Z.-X.; Zhu, W.-X.; Peng, H.Z.; Fu, F.; Wang, L.; Qian, K. Experimental study on flexural behavior of new type of prestressed reactive powder concrete sound barrier for high-speed rail. Struct. Concr. 2021, 22, 623–636. [Google Scholar] [CrossRef]

- Cao, X.; Wang, H.; Chang, J.; Lingzhi, J. Computational Analysis of Cracking Moment of High Strength Reinforced Reactive Powder Concrete Beam. In Electrical and Control Engineering & Materials Science and Manufacturing, Proceedings of Joint Conferences of the 6th (Icece 2015) and the 4th (Icmsm 2015), Shanghai, China, 14–15 August 2015; WSPC: Singapore, 2016; pp. 629–638. [Google Scholar]

- Funari, M.F.; Verre, S. The Effectiveness of the DIC as a Measurement System in SRG Shear Strengthened Reinforced Concrete Beams. Crystals 2021, 11, 265. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Cascardi, A.; Balsamo, A.; Aiello, M.A. Uniaxial Experimental Tests on Full-Scale Limestone Masonry Columns Confined with Glass and Basalt FRCM Systems. J. Compos. Constr. 2020, 24, 04020050. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Methods for Chemical Analysis of Silicate Rocks—Part 28: Determination of 16 Major and Minor Elements Content (GB/T 14506.28-2010); China Standards Press: Beijing, China, 2010. (In Chinese)

- Liu, H.; Liu, S.; Wang, S.; Gao, X.; Gong, Y. Effect of mix proportion parameters on behaviors of basalt fiber RPC based on box-behnken model. Appl. Sci. 2019, 9, 2031. [Google Scholar] [CrossRef] [Green Version]

- State Bureau of Quality Technical Supervision. Method of Testing Cement-Determination of Strength (GB/T 17671-1999); China Construction Industry Press: Beijing, China, 1999. (In Chinese)

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Test Standard for Test Methods for Concrete Structures (GBJ50152-2012); China Construction Industry Press: Beijing, China, 2012; pp. 11–25. (In Chinese)

| Water | Cement | Silica Fume | Quartz Sand | Quartz Powder | Basalt Fiber | Water Reducer | |

|---|---|---|---|---|---|---|---|

| 0.15 mm~0.3 mm | 0.3 mm~0.6 mm | ||||||

| 151.5 | 841.8 | 210.4 | 364.2 | 582.8 | 311.4 | 12 | 52.6 |

| Teat Beam Number | Erecting Steel Bar | Stirrup | Main Rebar | |||

|---|---|---|---|---|---|---|

| Type | Diameter (mm) | Type | Diameter (mm) | Type | Diameter (mm) | |

| Beam-1 | HPB 300 | 6 | HPB 300 | 8 | HRB 335 | 12 |

| Beam-2 | HPB 300 | 6 | HPB 300 | 8 | HRB 335 | 14 |

| Beam-3 | HPB 300 | 6 | HPB 300 | 8 | HRB 335 | 16 |

| Teat Beam | Cracking Moment (kN·m) | Ultimate Failure Bending Moment (kN·m) |

|---|---|---|

| Beam-1 | 15.05 | 39.40 |

| Beam-2 | 15.75 | 47.00 |

| Beam-3 | 17.50 | 52.20 |

| Teat Beam | (kN·m) | (kN·m) | |

|---|---|---|---|

| Beam-1 | 15.78 | 15.05 | 1.05 |

| Beam-2 | 16.23 | 15.75 | 1.03 |

| Beam-3 | 16.73 | 17.50 | 0.96 |

| Teat Beam | (kN·m) | (kN·m) | |

|---|---|---|---|

| Beam-1 | 43.00 | 39.40 | 1.09 |

| Beam-2 | 49.02 | 47.00 | 1.04 |

| Beam-3 | 55.88 | 52.20 | 1.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Y.; Yang, J.; He, X.; Lyu, X.; Liu, H. Structural Design Calculation of Basalt Fiber Polymer-Modified RPC Beams Subjected to Four-Point Bending. Polymers 2021, 13, 3261. https://doi.org/10.3390/polym13193261

Gong Y, Yang J, He X, Lyu X, Liu H. Structural Design Calculation of Basalt Fiber Polymer-Modified RPC Beams Subjected to Four-Point Bending. Polymers. 2021; 13(19):3261. https://doi.org/10.3390/polym13193261

Chicago/Turabian StyleGong, Yafeng, Jianxing Yang, Xin He, Xiang Lyu, and Hanbing Liu. 2021. "Structural Design Calculation of Basalt Fiber Polymer-Modified RPC Beams Subjected to Four-Point Bending" Polymers 13, no. 19: 3261. https://doi.org/10.3390/polym13193261

APA StyleGong, Y., Yang, J., He, X., Lyu, X., & Liu, H. (2021). Structural Design Calculation of Basalt Fiber Polymer-Modified RPC Beams Subjected to Four-Point Bending. Polymers, 13(19), 3261. https://doi.org/10.3390/polym13193261