Carbon Nanotube Reinforced Poly(ε-caprolactone)/Epoxy Blends for Superior Mechanical and Self-Sensing Performance in Multiscale Glass Fiber Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing Process

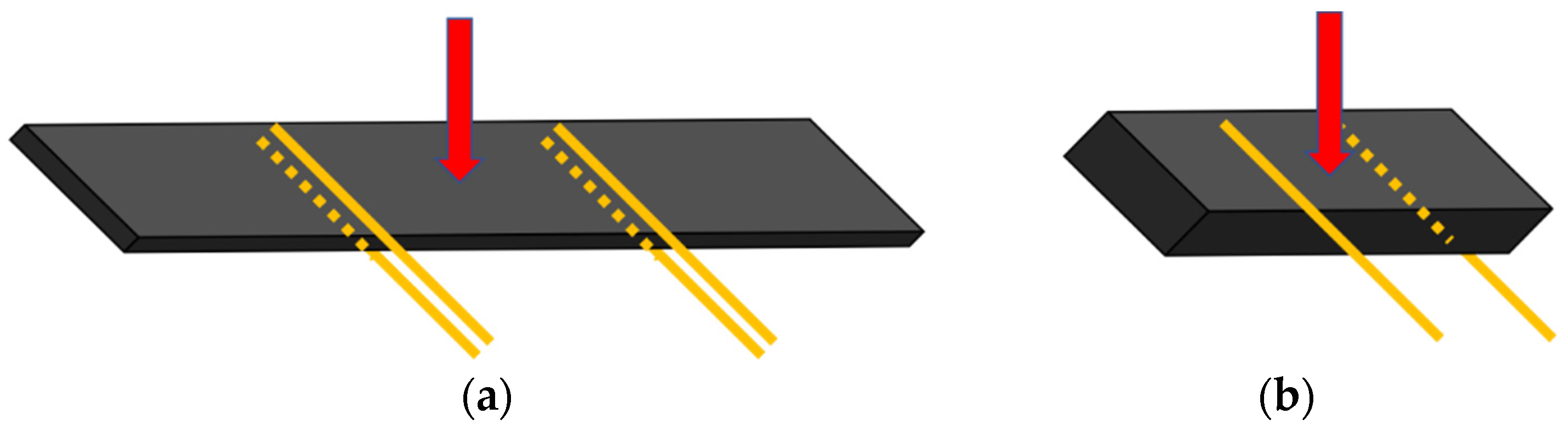

2.3. Electromechanical Tests

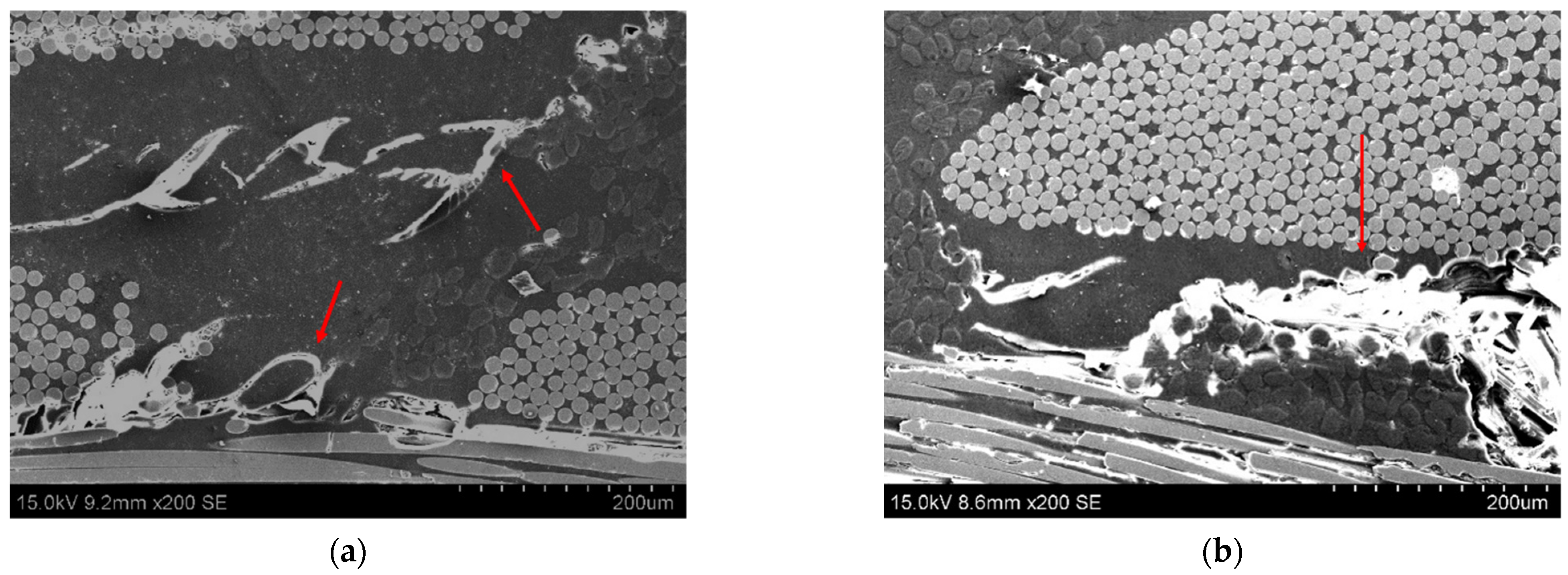

2.4. Characterization of Multiscale Composites

3. Results

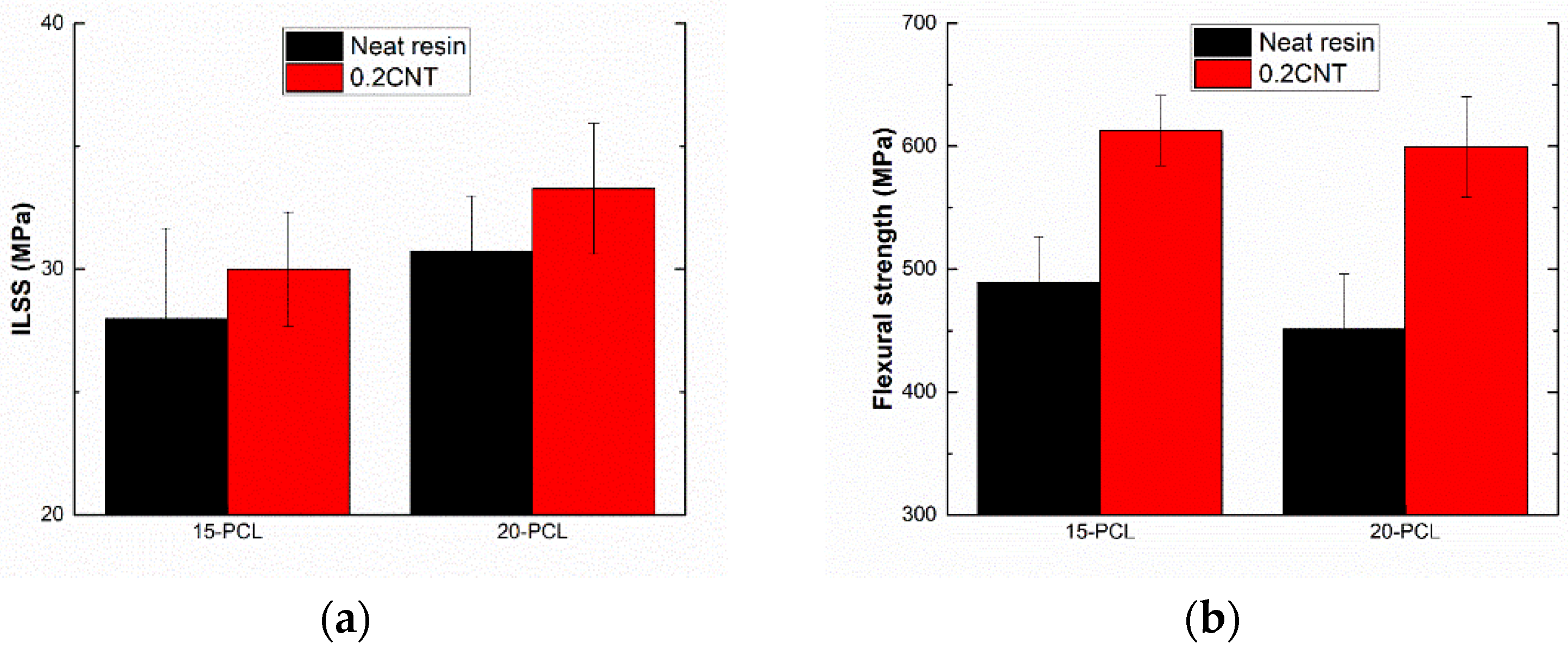

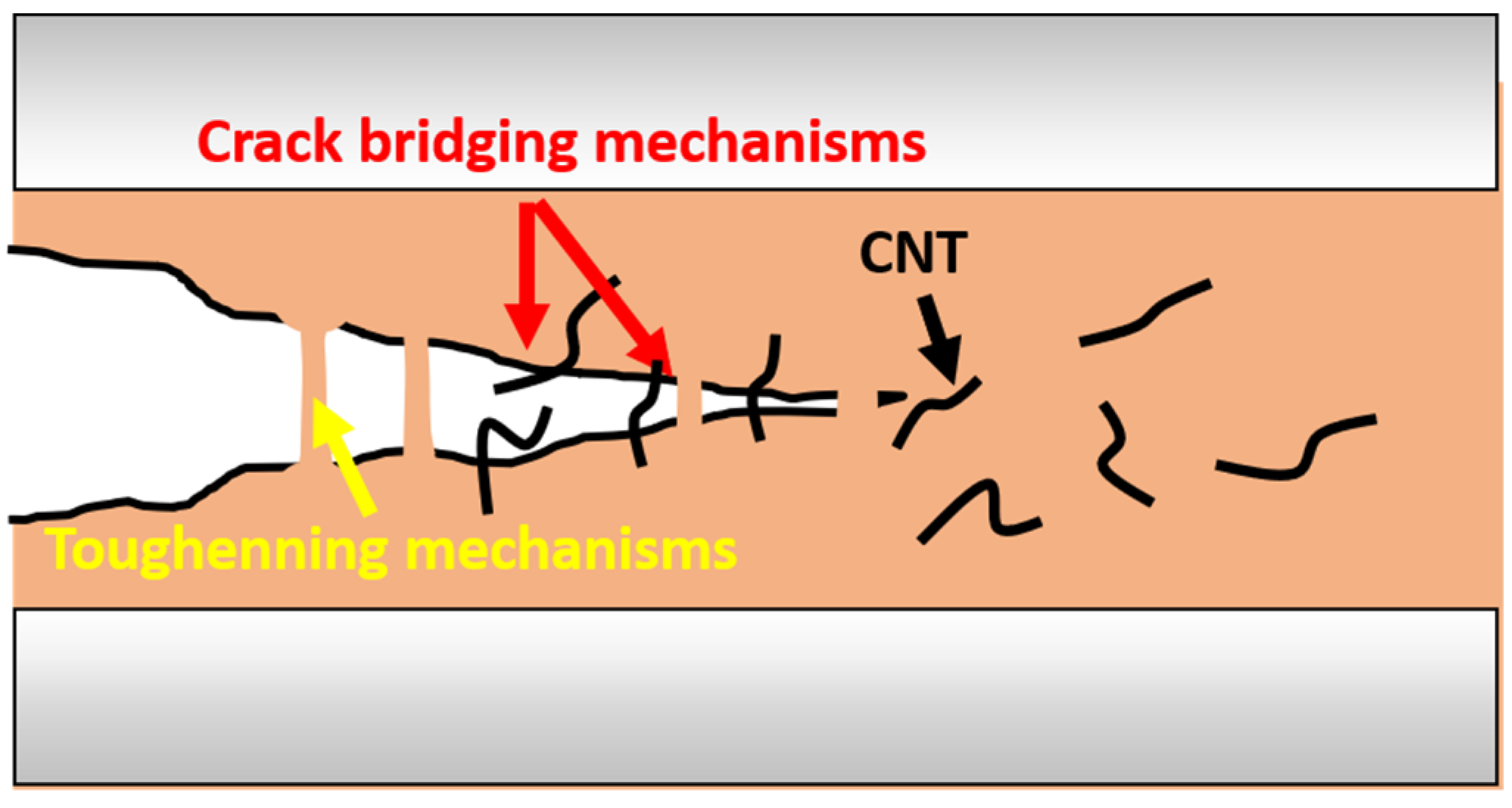

3.1. Mechanical Analysis

3.2. Electromechanical Analysis

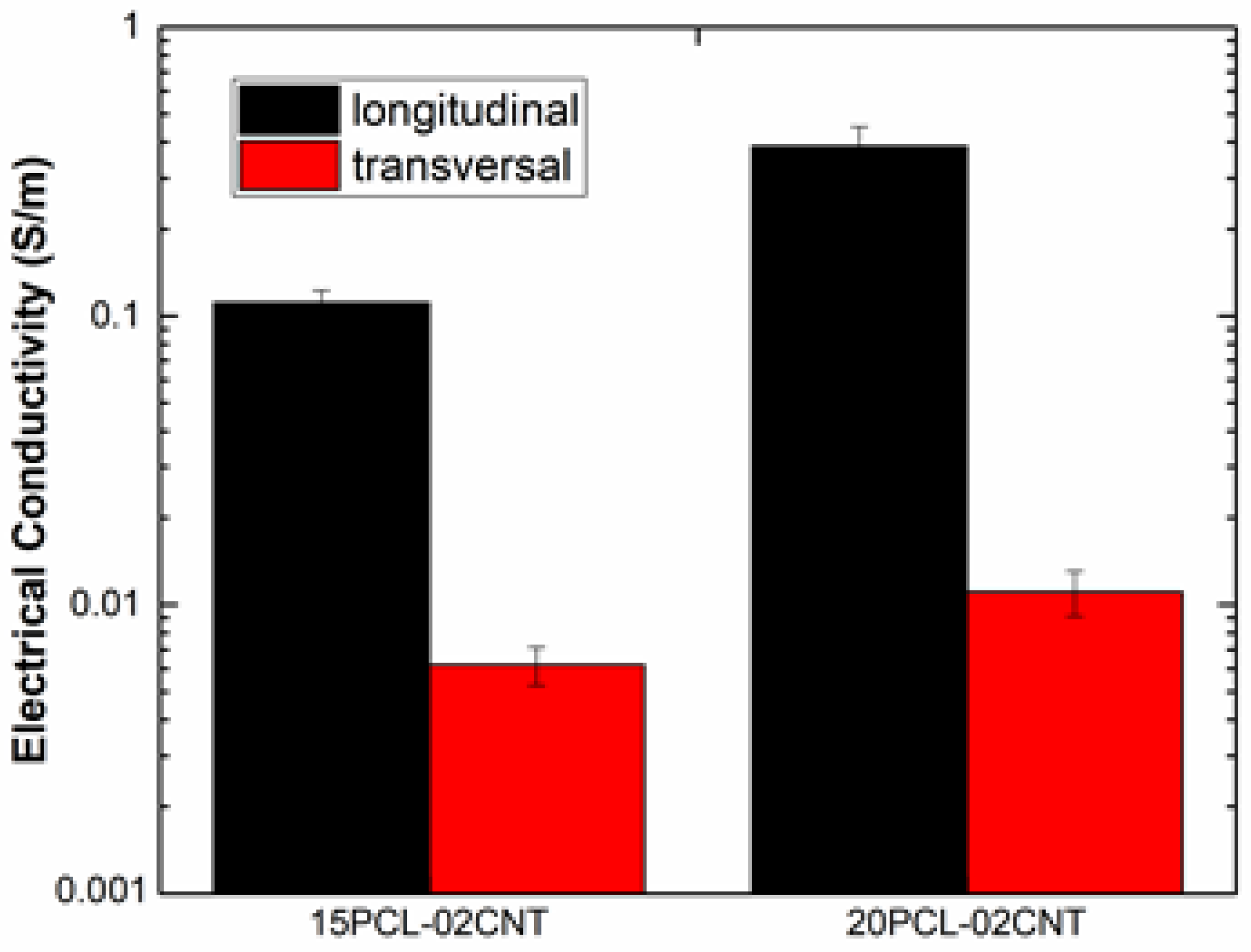

3.2.1. Electrical Conductivity Measurements

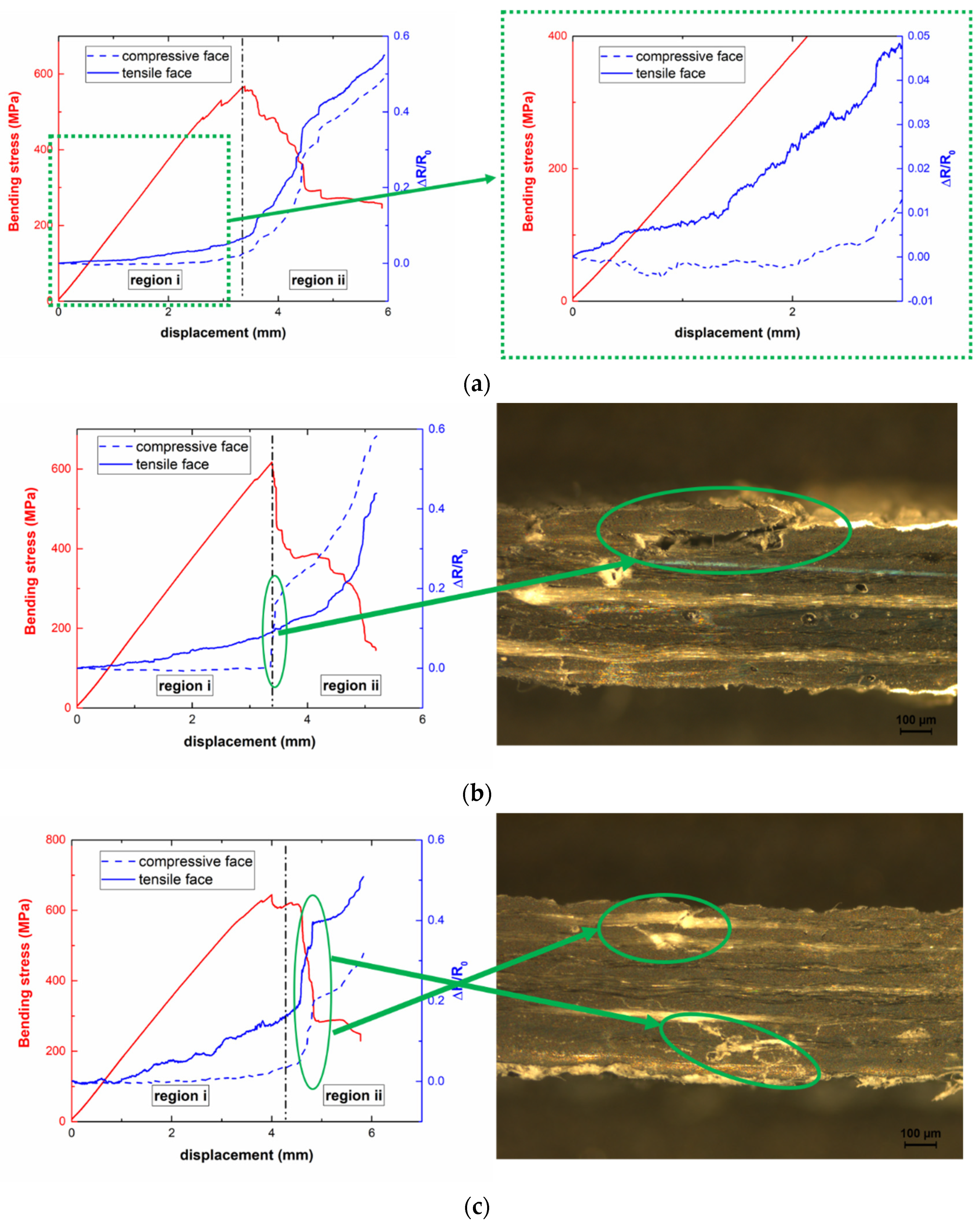

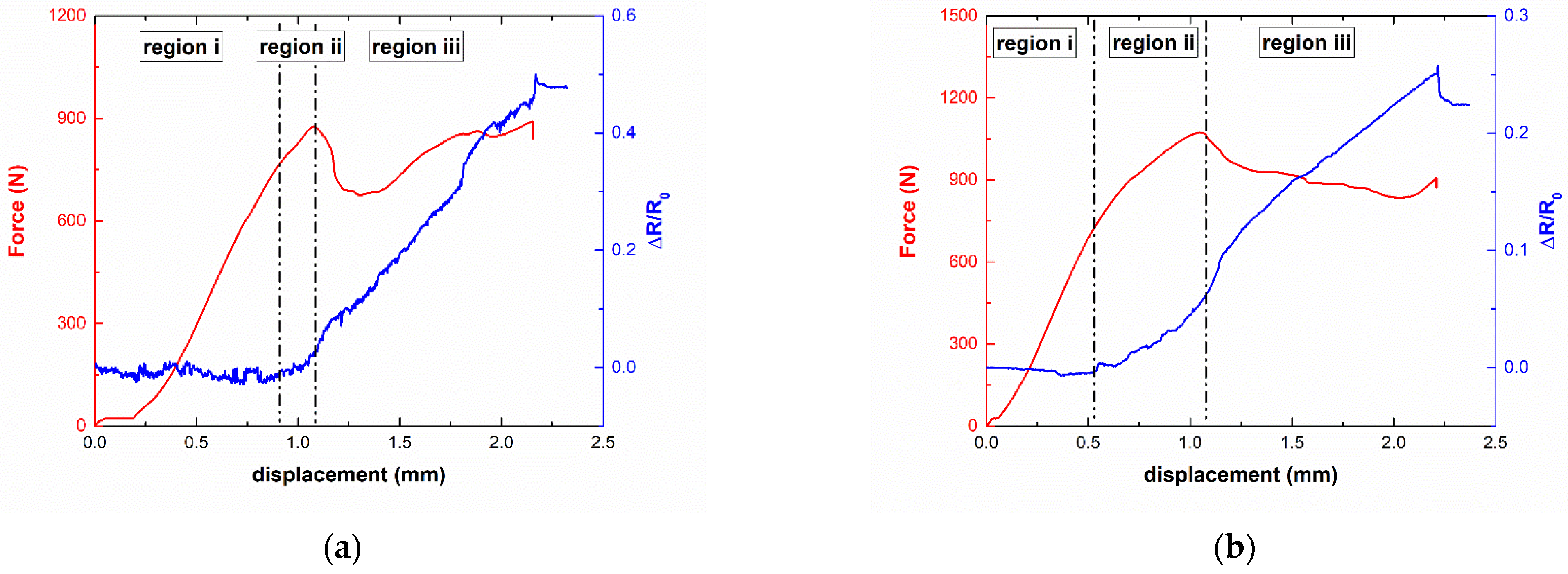

3.2.2. Electromechanical Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tran, P.; Nguyen, Q.T.; Lau, K. Fire performance of polymer-based composites for maritime infrastructure. Compos. Part B Eng. 2018, 155, 31–48. [Google Scholar] [CrossRef]

- Jensen, J.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Müller, J.P.; Krankenhagen, R. Optimizing thermographic testing of thick GFRP plates by assessing the real energy absorbed within the material. Compos. Struct. 2019, 215, 60–68. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, S.; Ye, S.; Feng, J. A feasible route to balance the mechanical properties of epoxy thermosets by reinforcing a PCL-PPC-PCL toughened system with reduced graphene oxide. Compos. Sci. Technol. 2016, 125, 108–113. [Google Scholar] [CrossRef]

- Xiang, Y.; Xu, S.; Zheng, S. Epoxy toughening via formation of polyisoprene nanophases with amphiphilic diblock copolymer. Eur. Polym. J. 2018, 98, 321–329. [Google Scholar] [CrossRef]

- van der Heijden, S.; Daelemans, L.; De Schoenmaker, B.; De Baere, I.; Rahier, H.; VAN Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer moulded glass fibre epoxy laminates by polycaprolactone electrospun nanofibres. Compos. Sci. Technol. 2014, 104, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Daelemans, L.; Cohades, A.; Meireman, T.; Beckx, J.; Spronk, S.; Kersemans, M.; De Baere, I.; Rahier, H.; Michaud, V.; VAN Paepegem, W.; et al. Electrospun nanofibrous interleaves for improved low velocity impact resistance of glass fibre reinforced composite laminates. Mater. Des. 2018, 141, 170–184. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Cheung, S.C.P.; Wang, C.H. The effect of carbon nanofibres on self-healing epoxy/poly(ε-caprolactone) blends. Compos. Sci. Technol. 2012, 72, 1952–1959. [Google Scholar] [CrossRef]

- Cohades, A.; Michaud, V. Damage recovery after impact in E-glass reinforced poly(ε-caprolactone)/epoxy blends. Compos. Struct. 2017, 180, 439–447. [Google Scholar] [CrossRef]

- Mostaani, F.; Moghbeli, M.R.; Karimian, H. Electrical conductivity, aging behavior, and electromagnetic interference (EMI) shielding properties of polyaniline/MWCNT nanocomposites. J. Thermoplast. Compos. Mater. 2018, 31, 1393–1415. [Google Scholar] [CrossRef]

- Chen, J.; Han, J.; Xu, D. Thermal and electrical properties of the epoxy nanocomposites reinforced with purified carbon nanotubes. Mater. Lett. 2019, 246, 20–23. [Google Scholar] [CrossRef]

- Guo, Y.; Zuo, X.; Xue, Y.; Tang, J.; Gouzman, M.; Fang, Y.; Zhou, Y.; Wang, L.; Yu, Y.; Rafailovich, M.H. Engineering thermally and electrically conductive biodegradable polymer nanocomposites. Compos. Part B Eng. 2020, 189, 107905. [Google Scholar] [CrossRef]

- Cardoso, S.M.; Chalivendra, V.B.; Shukla, A.; Yang, S. Damage detection of rubber toughened nanocomposites in the fracture process zone using carbon nanotubes. Eng. Fract. Mech. 2012, 96, 380–391. [Google Scholar] [CrossRef]

- Avilés, F.; Oliva, A.; Ventura, G.; May-Pat, A.; Oliva-Avilés, A. Effect of carbon nanotube length on the piezoresistive response of poly (methyl methacrylate) nanocomposites. Eur. Polym. J. 2019, 110, 394–402. [Google Scholar] [CrossRef]

- Cortés, A.; Sánchez-Romate, X.X.F.; Jiménez-Suárez, A.; Campo, M.; Prolongo, M.G.; Ureña, A.; Prolongo, S.G. 3D printed anti-icing and de-icing system based on CNT/GNP doped epoxy composites with self-curing and structural health monitoring capabilities. Smart Mater. Struct. 2021, 30, 025016. [Google Scholar] [CrossRef]

- Cortés, A.; Sánchez-Romate, X.F.; Jiménez-Suárez, A.; Campo, M.; Ureña, A.; Prolongo, S.G. Mechanical and Strain-Sensing Capabilities of Carbon Nanotube Reinforced Composites by Digital Light Processing 3D Printing Technology. Polymers 2020, 12, 975. [Google Scholar] [CrossRef] [PubMed]

- Daňová, R.; Olejnik, R.; Slobodian, P.; Matyas, J. The Piezoresistive Highly Elastic Sensor Based on Carbon Nanotubes for the Detection of Breath. Polymers 2020, 12, 713. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shahbaz, S.R.; Berkalp, Ö.B.; Hassan, S.Z.U.; Siddiqui, M.S.; Bangash, M.K. Fabrication and analysis of integrated multifunctional MWCNTS sensors in glass fiber reinforced polymer composites. Compos. Struct. 2021, 260, 113527. [Google Scholar] [CrossRef]

- Kravchenko, O.G.; Pedrazzoli, D.; Bonab, V.S.; Manas-Zloczower, I. Conductive interlaminar interfaces for structural health monitoring in composite laminates under fatigue loading. Mater. Des. 2018, 160, 1217–1225. [Google Scholar] [CrossRef]

- Al-Bahrani, M.; Cree, A. A simple criterion to evaluate the degree of damage in composite materials after sudden impact loads by exploiting the MWCNTs piezoresistive property. Carbon 2019, 150, 505–517. [Google Scholar] [CrossRef]

- Al-Sabagh, A.; Taha, E.; Kandil, U.; Awadallah, A.; Nasr, G.-A.M.; Taha, M.R. Monitoring Moisture Damage Propagation in GFRP Composites Using Carbon Nanoparticles. Polymers 2017, 9, 94. [Google Scholar] [CrossRef] [Green Version]

- Bekas, D.G.; Khodaei, Z.S.; Aliabadi, F.M.H.; Aliabadi, M.H. A smart multi-functional printed sensor for monitoring curing and damage of composite repair patch. Smart Mater. Struct. 2019, 28, 085029. [Google Scholar] [CrossRef]

- Dai, H.; Thostenson, E.T. Scalable and multifunctional carbon nanotube-based textile as distributed sensors for flow and cure monitoring. Carbon 2020, 164, 28–41. [Google Scholar] [CrossRef]

- Thomas, A.; Kim, J.; Tallman, T.; Bakis, C. Damage detection in self-sensing composite tubes via electrical impedance tomography. Compos. Part B Eng. 2019, 177, 107276. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Faller, L.-M.; Farahani, M.; Zangl, H. Structural health monitoring of adhesive joints under pure mode I loading using the electrical impedance measurement. Eng. Fract. Mech. 2021, 245, 107585. [Google Scholar] [CrossRef]

- Seyhan, A.T.; Tanoglu, M.; Schulte, K. Mode I and mode II fracture toughness of E-glass non-crimp fabric/carbon nanotube (CNT) modified polymer based composites. Eng. Fract. Mech. 2008, 75, 5151–5162. [Google Scholar] [CrossRef] [Green Version]

- Plagianakos, T.; Muñoz, K.; Guillamet, G.; Prentzias, V.; Quintanas-Corominas, A.; Jimenez, M.; Karachalios, E. Assessment of CNT-doping and hot-wet storage aging effects on Mode I, II and I/II interlaminar fracture toughness of a UD Graphite/Epoxy material system. Eng. Fract. Mech. 2019, 224, 106761. [Google Scholar] [CrossRef]

- El Assami, Y.; Drissi-Habti, M.; Raman, V. Stiffening offshore composite wind-blades bonding joints by carbon nanotubes reinforced resin–A new concept. J. Struct. Integr. Maint. 2020, 5, 87–103. [Google Scholar] [CrossRef]

- Drissi-Habti, M.; El Assami, Y.; Raman, V. Multiscale Toughening of Composites with Carbon Nanotubes—Continuous Multiscale Reinforcement New Concept. J. Compos. Sci. 2021, 5, 135. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Martín, J.; Jiménez-Suárez, A.; Prolongo, S.G.; Ureña, A. Mechanical and strain sensing properties of carbon nanotube reinforced epoxy/poly(caprolactone) blends. Polymers 2020, 190, 122236. [Google Scholar] [CrossRef]

- Jiménez-Suárez, A.; Martín, J.; Sánchez-Romate, X.F.; Prolongo, S. Carbon nanotubes to enable autonomous and volumetric self-heating in epoxy/polycaprolactone blends. Compos. Sci. Technol. 2020, 199, 108321. [Google Scholar] [CrossRef]

- Jiménez-Suárez, A.; Campo, M.; Gaztelumendi, I.; Markaide, N.; Sánchez, M.; Ureña, A. The influence of mechanical dispersion of MWCNT in epoxy matrix by calendering method: Batch method versus time controlled. Compos. Part B Eng. 2013, 48, 88–94. [Google Scholar] [CrossRef]

- Gude, M.R.; Prolongo, S.G.; Ureña, A. Toughening effect of carbon nanotubes and carbon nanofibres in epoxy adhesives for joining carbon fibre laminates. Int. J. Adhes. Adhes. 2015, 62, 139–145. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Gries, T.; Veit, D.; Quadflieg, T.; Mohr, B.; Kolloch, M. Effect of nanomaterial on mode I and mode II interlaminar fracture toughness of woven carbon fabric reinforced polymer composites. Eng. Fract. Mech. 2017, 180, 73–86. [Google Scholar] [CrossRef]

- Ismail, N.H.; Akindoyo, J.O.; Mariatti, M. Solvent mediated dispersion of carbon nanotubes for glass fibre surface modification—Suspensions stability and its effects on mechanical, interlaminar and dynamic mechanical properties of modified glass fibre reinforced epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106091. [Google Scholar] [CrossRef]

- Daelemans, L.; Van Der Heijden, S.; De Baere, I.; Rahier, H.; VAN Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef]

- Chen, J.L.; Huang, H.M.; Li, M.S.; Chang, F.C. Transesterification in homogeneous poly (ε-caprolactone)–Epoxy blends. J. Appl. Polym. Sci. 1999, 71, 75–82. [Google Scholar] [CrossRef] [Green Version]

- Cohades, A.; Manfredi, E.; Plummer, C.J.; Michaud, V. Thermal mending in immiscible poly(ε-caprolactone)/epoxy blends. Eur. Polym. J. 2016, 81, 114–128. [Google Scholar] [CrossRef] [Green Version]

- Jiménez-Suárez, A.; Del Rosario, G.; Sánchez-Romate, X.X.; Prolongo, S.G. Influence of Morphology on the Healing Mechanism of PCL/Epoxy Blends. Materials 2020, 13, 1941. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.L.; Chang, F.C. Temperature-dependent phase behavior in poly(ϵ-caprolactone)–Epoxy blends. Polymer 2001, 42, 2193–2199. [Google Scholar] [CrossRef]

- Barone, L.; Carciotto, S.; Cicala, G.; Recca, A. Thermomechanical properties of epoxy/poly (ε-caprolactone) blends. Polymer Eng. Sci. 2006, 46, 1576–1582. [Google Scholar] [CrossRef]

- Jia, J.; Du, X.; Chen, C.; Sun, X.; Mai, Y.-W.; Kim, J.-K. 3D network graphene interlayer for excellent interlaminar toughness and strength in fiber reinforced composites. Carbon 2015, 95, 978–986. [Google Scholar] [CrossRef]

- Panchagnula, K.K.; Kuppan, P. Improvement in the mechanical properties of neat GFRPs with multi-walled CNTs. J. Mater. Res. Technol. 2019, 8, 366–376. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, Z.; Huang, Z.; Zhang, C.; Tusiime, R.; Zhou, J.; Sun, Z.; Liu, Y.; Yu, M.; Zhang, H. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105696. [Google Scholar] [CrossRef]

- Moriche, R.; Sanchez, M.; Jiménez-Suárez, A.; Prolongo, S.; Ureña, A. Electrically conductive functionalized-GNP/epoxy based composites: From nanocomposite to multiscale glass fibre composite material. Compos. Part B Eng. 2016, 98, 49–55. [Google Scholar] [CrossRef]

- Li, J.; Ma, P.C.; Chow, W.S.; To, C.K.; Tang, B.Z.; Kim, J.-K. Correlations between Percolation Threshold, Dispersion State, and Aspect Ratio of Carbon Nanotubes. Adv. Funct. Mater. 2007, 17, 3207–3215. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.X.F.; Moriche, R.; Jiménez-Suárez, A.; Sánchez, M.; Prolongo, S.G.; Ureña, A. Sensitive response of GNP/epoxy coatings as strain sensors: Analysis of tensile-compressive and reversible cyclic behavior. Smart Mater. Struct. 2020, 29, 065012. [Google Scholar] [CrossRef]

- He, Z.; Byun, J.-H.; Zhou, G.; Park, B.-J.; Kim, T.-H.; Lee, S.-B.; Yi, J.-W.; Um, M.-K.; Chou, T.-W. Effect of MWCNT content on the mechanical and strain-sensing performance of Thermoplastic Polyurethane composite fibers. Carbon 2019, 146, 701–708. [Google Scholar] [CrossRef]

- Sánchez-Romate, X.F.; Artigas, J.; Jiménez-Suárez, A.; Sánchez, M.; Güemes, A.; Ureña, A. Critical parameters of carbon nanotube reinforced composites for structural health monitoring applications: Empirical results versus theoretical predictions. Compos. Sci. Technol. 2019, 171, 44–53. [Google Scholar] [CrossRef]

| Cycle | Distance between Rolls (GAP1/GAP2 in µm) |

|---|---|

| Cycle 1 | 120/40 |

| Cycle 2 | 60/20 |

| Cycle 3 | 45/15 |

| Cycles 4 to 7 | 15/5 |

| PCL Content (wt.%) | MWCNT Content (wt.%) | Designation |

|---|---|---|

| 15 | 0 | 15PCL-Neat |

| 0.2 | 15PCL-0.2CNT | |

| 20 | 0 | 20PCL-Neat |

| 0.2 | 20PCL-0.2CNT |

| Condition | Sensitivity, S, at ε = 0.015 | |

|---|---|---|

| Tensile Face | Compressive Face | |

| 15PCL-02CNT | 1.1 ± 0.5 | 0.2 ± 0.2 |

| 20PCL-02CNT | 3.0 ± 0.8 | −0.1 ± 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Romate, X.F.; Alvarado, A.; Jiménez-Suárez, A.; Prolongo, S.G. Carbon Nanotube Reinforced Poly(ε-caprolactone)/Epoxy Blends for Superior Mechanical and Self-Sensing Performance in Multiscale Glass Fiber Composites. Polymers 2021, 13, 3159. https://doi.org/10.3390/polym13183159

Sánchez-Romate XF, Alvarado A, Jiménez-Suárez A, Prolongo SG. Carbon Nanotube Reinforced Poly(ε-caprolactone)/Epoxy Blends for Superior Mechanical and Self-Sensing Performance in Multiscale Glass Fiber Composites. Polymers. 2021; 13(18):3159. https://doi.org/10.3390/polym13183159

Chicago/Turabian StyleSánchez-Romate, Xoan F., Andrés Alvarado, Alberto Jiménez-Suárez, and Silvia G. Prolongo. 2021. "Carbon Nanotube Reinforced Poly(ε-caprolactone)/Epoxy Blends for Superior Mechanical and Self-Sensing Performance in Multiscale Glass Fiber Composites" Polymers 13, no. 18: 3159. https://doi.org/10.3390/polym13183159

APA StyleSánchez-Romate, X. F., Alvarado, A., Jiménez-Suárez, A., & Prolongo, S. G. (2021). Carbon Nanotube Reinforced Poly(ε-caprolactone)/Epoxy Blends for Superior Mechanical and Self-Sensing Performance in Multiscale Glass Fiber Composites. Polymers, 13(18), 3159. https://doi.org/10.3390/polym13183159