1. Introduction

Laminar composites are made up of a series of lamina. By the choice of laminar architecture (like volume percent of the constituent materials and layer thickness) and constituent materials, laminar composites can be engineered to prepare a structure with required properties [

1]. Upon loading, the delamination of different layers is one of the main failure modes of laminar composites. Various ply-stitching techniques are employed to avoid delamination. Laminar composites are widely used in aerospace, automobile, and defense equipment due to their high stiffness, strength, low density, and resistance to corrosion [

2].

Hand lay-up, filament winding, and compression molding are the common conventional methods to fabricate laminar composites [

3,

4]. Blades of wind turbines, pressure vessels, gas cylinders, tanks, automobile panels, and bumpers are prepared using these techniques. In hand lay-up, the resins are infused manually by the help of rollers and brushes into fibers, which are in the form of stitched, bonded, knitted, or woven fabrics. However, uniformity and consistency cannot be achieved in this method. Filament winding is used for manufacturing hollow, oval, and circular sectioned products like pressure vessels, casings, gas cylinders, etc. [

5,

6]. Only convex shape components can be manufactured using this technique. Whereas in compression molding, heat and pressure are applied for specific time to manufacture different laminar composites [

7]. The use of dies and molds in compression molding increases the lead time and production cost. This technique is only feasible for high volume production and needs manpower for finishing of the product.

On the other hand, Fused Filament Fabrication (FFF), an innovative process, does not suffer from the aforementioned issues because it offers flexible and dye-free fabrication [

8,

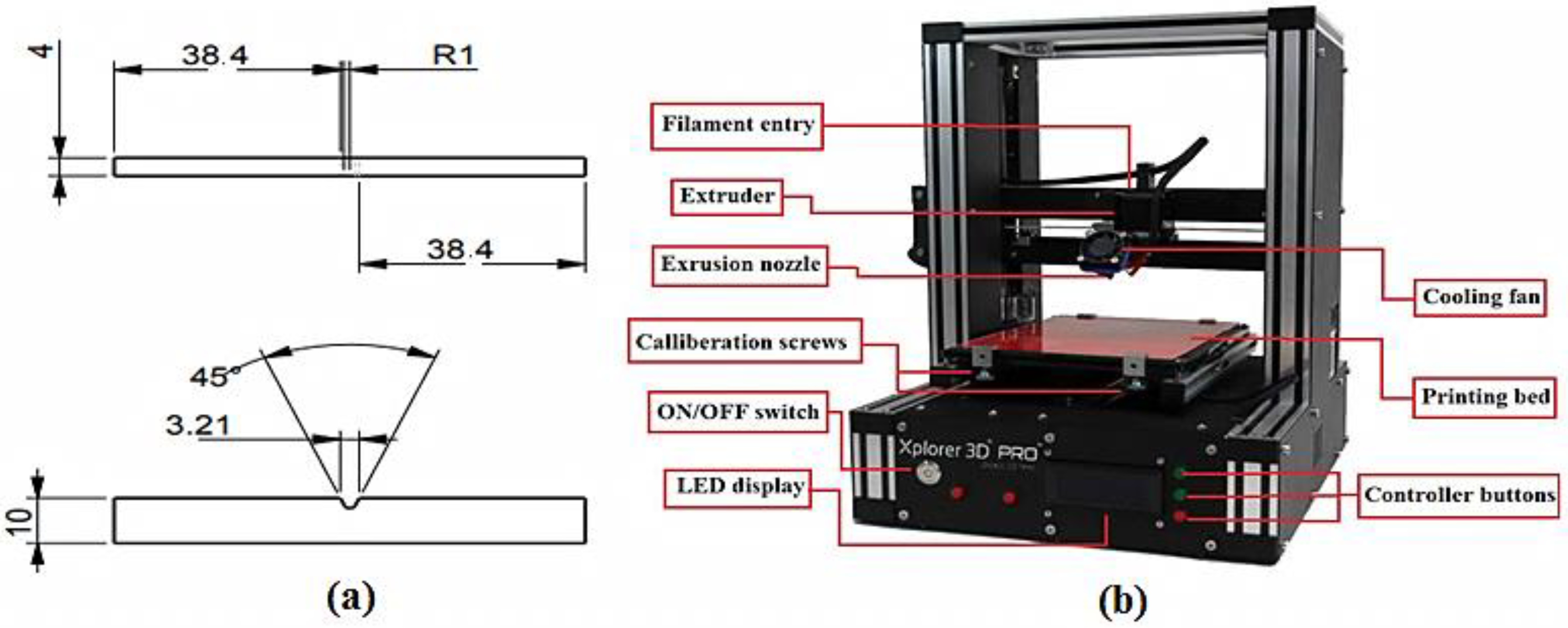

9]. It is one of the 3D printing techniques in which extruder gets the filament from the spool and material is melted in a heated nozzle and deposited in the form of layers on top of a heated platform [

10,

11,

12,

13]. The main advantage of FFF technology is to produce quick prototyping polymer samples [

14,

15]. The use of FFF technology has been increased in many applications due to its easy use, simplicity, low lead time, and cost effectiveness [

14,

16,

17]. FFF also has many applications in the field of aviation, design verification, medicine, tissue engineering, and prosthetics [

18,

19,

20]. In fact, studies have shown some advantages of FFF over conventional polymer processing techniques for enhancing material performance, e.g., impact strength of 3D printed PLA (printed using layer thickness of 0.2 mm, and plate temperature of 160 °C) is better than that of the injection molded PLA [

21].

Attempts have been made to enhance the mechanical properties of 3D-printed components with the addition of particles and fibers. This technique has been employed in the polymer industries to increase the structural strength of the 3D-printed components [

22]. Zhong et al. [

23] reinforced ABS filament with short glass fibers and on 3D printing, they observed an increase in the strength in comparison to unreinforced ABS filament. Hassan and Jwu [

24] prepared filaments by blending polycarbonate (PC) with ABS. It was depicted that impact toughness increased by increasing the amount of PC. Tekinalp et al. [

25] prepared composites using carbon fiber-reinforced ABS as 3D printing material and concluded that carbon fiber reinforced ABS offered better mechanical properties than unreinforced ABS. They also found that impact strength increased by decreasing the carbon fiber content. Kannan et al. [

26] fabricated Ni-coated ABS plastics and it was determined that impact energy of the Ni-coated ABS was improved.

Carbon fiber-reinforced polymer composites are gaining popularity owing to their extensive high-end applications. Nowadays, it has become a common practice to build carbon fiber-based polymer components using the FFF technique. Although such composite components exhibit high strength, these suffer from poor toughness. Various studies have been carried out to investigate impact toughness of FFF-printed materials. Vidakis et al. [

27] performed experiments on ABS and ABS-plus samples using notched and unnotched specimens for standard Charpy’s impact test. They found that impact strength of 3D-printed specimens was lower than the parent bulk materials. Morales et al. [

28] analyzed the quasi-static and dynamic crush behavior of 3D-printed thin-walled hollow profiles made using polyamide matrix reinforced with continuous carbon (cCF/PA) and glass fibers (cGF/PA), and found that strain-hardening effect enhanced impact resistance of cGF/PA material, but not of cCF/PA. Fekete et al. [

29] proposed to blend PLA with rubber (up to 20 wt%) to enhance impact toughness after printing.

The FFF-built carbon fiber-based polymeric composites reported so far have been mainly fabricated as monolithic/single sheets [

21,

30]. As carbon fiber is a brittle material, one of the shortcomings of these monolithic composite sheets is thus their low impact toughness. The laminar structures, on the other hand, are believed to offer several benefits including high fracture toughness and outstanding specific strength [

31]: properties highly desired in mechanical structures [

32,

33]. The low toughness of the mentioned material, therefore, can be raised by coupling it with the laminate of a tougher material. 3D-printed composites with laminar structure, produced especially through FFF technology, are scarcely reported in the literature. Liu et al. [

34] employed 3D printing (bio-plotter) to produce hybrid bi-layer (polycaprolactone/Gel/nano-hydroxyapatite) scaffold for guided bone regeneration. Khan et al. [

33] studied the interfacial bonding between two laminates in different delamination modes. They made the laminates with Acrylonitrile Butadiene Styrene (ABS) and Carbon-fiber reinforced Polylactic Acid (C-PLA) by varying the printing parameters. The results showed that the printing speed and nozzle temperature are the important parameters affecting the interfacial bonding. This is reasoned to the fact that these parameters influence fusion of the layers, the main mechanism that controls interfacial bonding and relies on heat available during bonding, which further depends on the printing parameters.

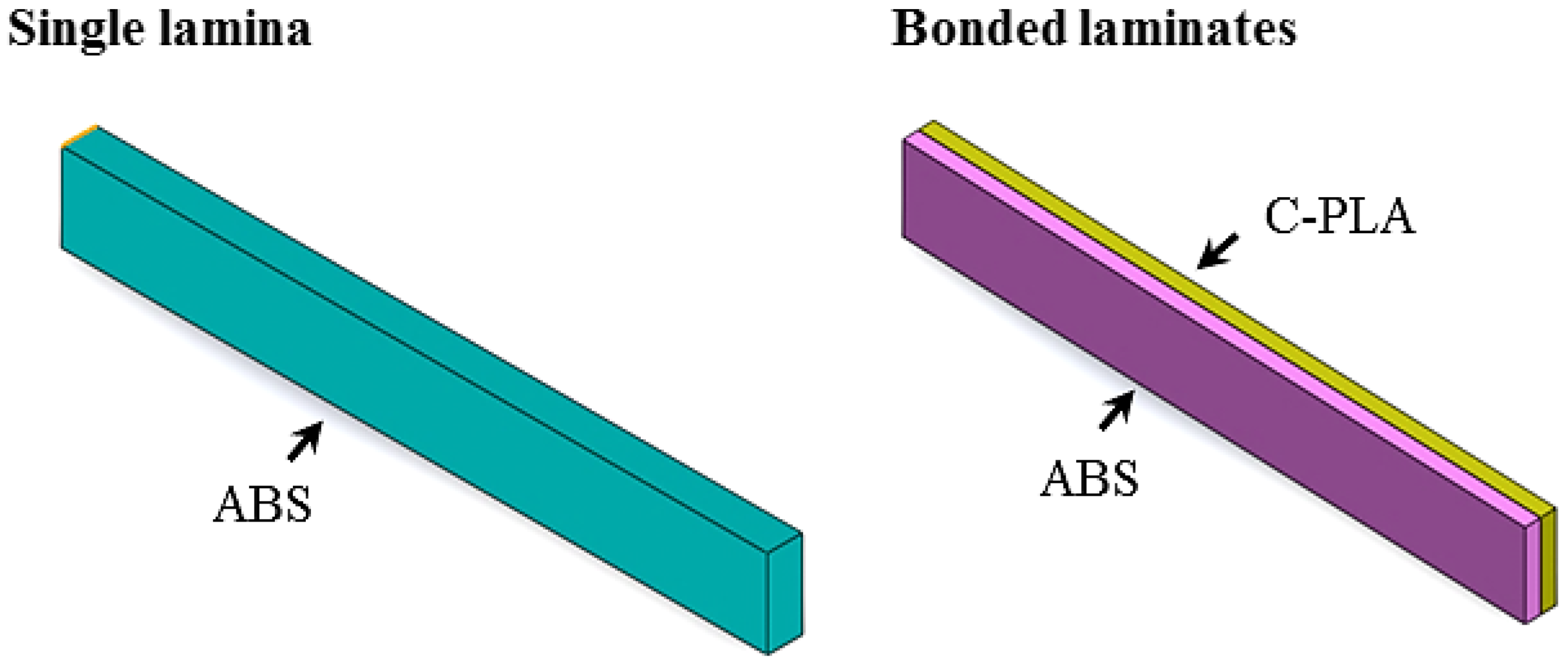

From the above literature analysis, it is concluded that impact toughness of the FFF-built laminar composites is not reported in the literature. Further, the idea to enhance the toughness of carbon fiber-based polymer composites by overlaying it with a tougher polymer is yet unexplored. The present study is aimed at developing a laminar composite (composed of two laminates) and characterizing its impact toughness in order to examine usefulness of the proposed idea. The laminates are fabricated in two filament materials, namely, Carbon-fiber reinforced Polylactic Acid (C-PLA) and Acrylonitrile Butadiene Styrene (ABS), thus resulting in a laminar hybrid composite. The reason of choosing C-PLA is that it is a carbon-filled composite filament with a high strength and stiffness available commercially. The ABS was selected as it is a polymer alloy with a reasonable mix of various mechanical properties and high toughness, thereby supplementing low toughness of C-PLA lamina. The hybrid composite is made by varying boundary wall configuration and printing parameters, namely, layer thickness (LT), raster angle (RA), fill density (FD), and clad ratio (CR). The toughness of the printed composite samples is determined by performing an impact test. The results confirm that superimposing ABS on C-PLA lamina can substantially raise the toughness of C-PLA sheet. Moreover, an optimum set of parameters yielding high toughness is also proposed.

3. Results and Discussion

Table 3 presents the impact toughness results, a response variable in the statistical analysis. The highest value of impact toughness for the C-PLA/ABS laminar composite was found to be 23,465.6 kJ/m

2 for test No. 3 against the following 3D printing parameters: LT = 0.5mm, RA = 45°, CR = 1 and FD = 40%. While the lowest value of impact toughness was 7672.8 kJ/m

2 for test No. 14 against the following 3D printing parameters: LT = 0.1 mm, RA = 0°, CR = 0.5, and FD = 100%.

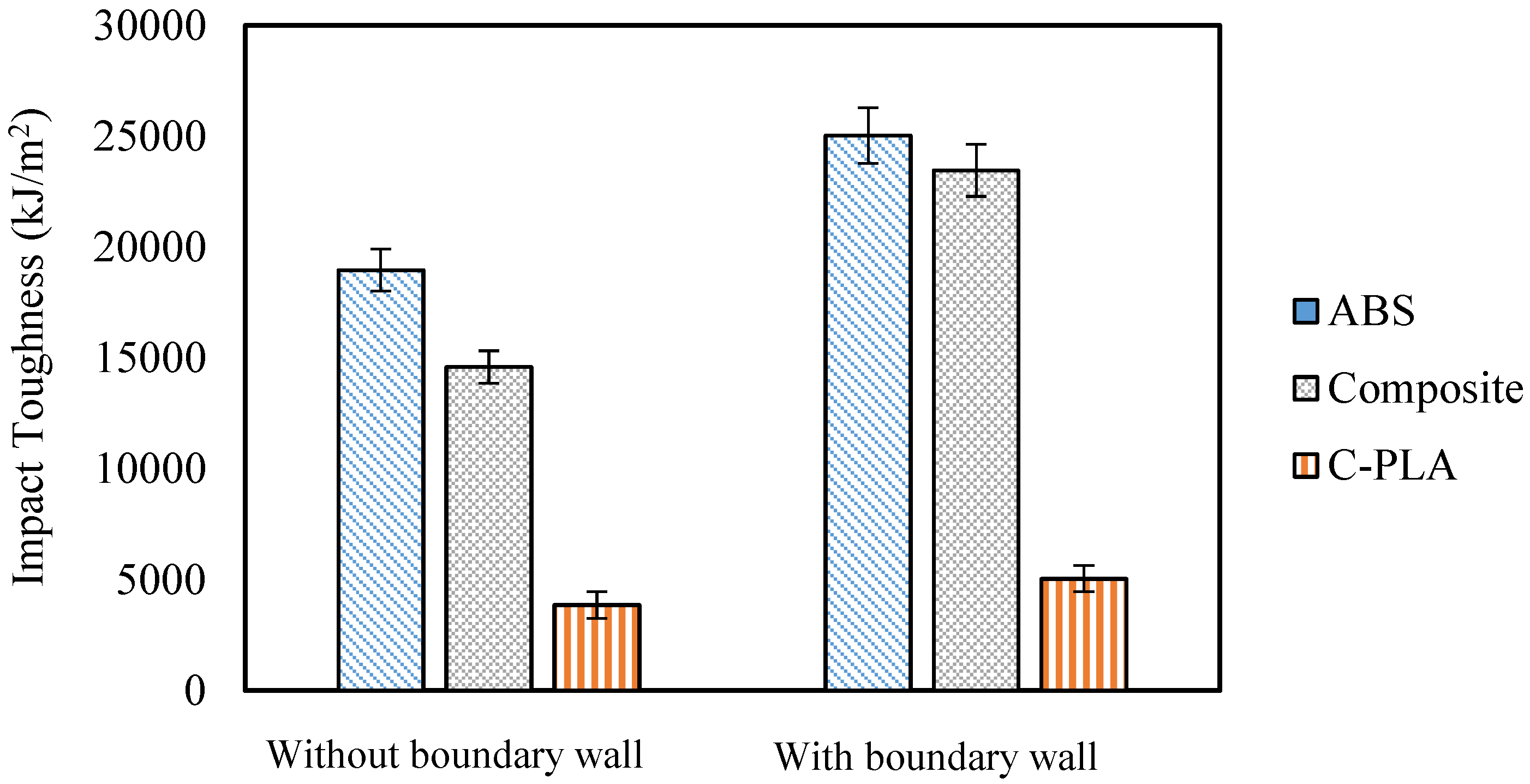

The percentage improvement in impact toughness due to laying ABS on C-PLA sheet is presented in

Table 4. The impact toughness of bi-sheets laminar composite (C-PLA/ABS) and equivalent monolithic C-PLA sheet was determined, employing the same printing and testing conditions. As can be noticed, an increase ranging from 280 to 365% is obtained by adopting the proposed idea.

Analysis of Variance (ANOVA) was performed on the results in order to identify the significant parameters affecting the impact toughness of the composite. A parameter with

p-value ≤ 0.05 (95% confidence level) was regarded as significant. This can be noticed from

Table 5 that LT with

p-value < 0.0001 is the most significant 3D printing parameter.

3.1. Effects of 3D Printing Parameters on Impact Toughness

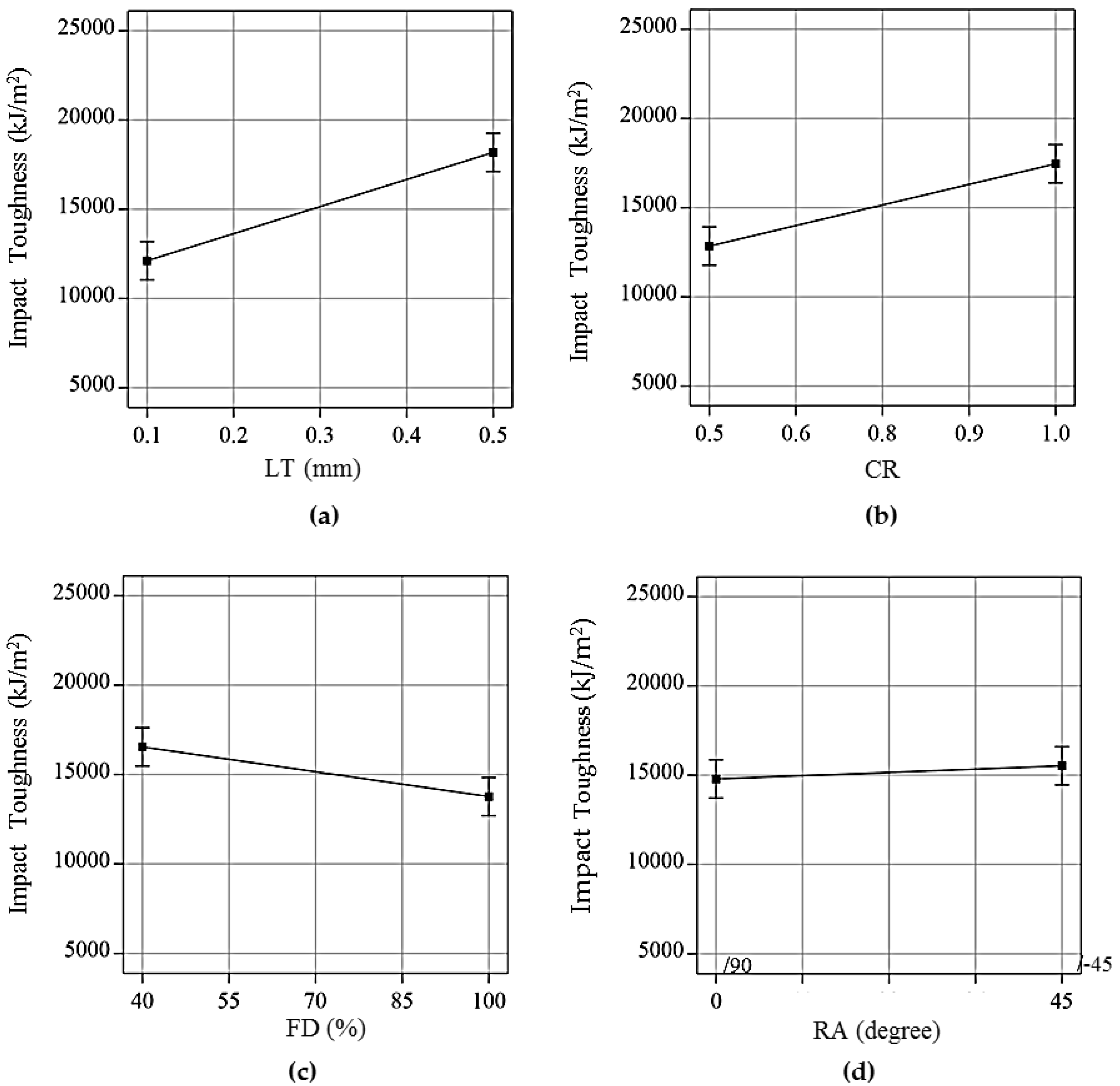

Figure 6a shows that impact toughness of the hybrid composite increases as the LT increases. This is due to the fact that the material experiences lesser number of thermal cycles, which in turn minimizes the likelihood of interlayer cracking [

43]. Moreover, at higher LT, each layer has better homogeneity within itself, which leads to uniform molecular bonding, therefore offering greater resistance to the penetration [

41]. As a result, this enables the material to withstand greater impact energy leading to higher impact toughness. This finding is in agreement with Santhakumar et al. [

44] and Shubham et al. [

41], who 3D printed monolithic composites of Polycarbonate and ABS, respectively.

Figure 6b depicts the effect of CR on the impact toughness. There was an increase in the impact toughness with the increase in the CR. In fact, an increase in the CR means a corresponding increase in the volume fraction of ABS material. Being ductile than the C-PLA, the ABS material has tendency to absorb more impact energy than C-PLA. As a result, the impact toughness of ABS/C-PLA composite increased as the CR increased.

Contrary to the effects of LT and CR,

Figure 6c illustrates that the FD has inverse relation with the impact toughness, i.e., impact toughness increased with the decrease in the FD. This may be reasoned to the fact that the porosity in the composite structure increases with the reduction in FD, which improves the ability of material to absorb impact energy at failure. This finding agrees with Joseph et al. [

45] who studied the influence of varying FD on the impact toughness of monolithic composite sheets. Isfahani et al. [

46] performed impact tests on hollow, solid, and hybrid polyester fiber composites. They concluded that any decrease in the FD creates hollow spaces, which reduces the density of fiber and improves the ability of energy absorption, consequently increasing the impact toughness. The present findings are in agreement with Isfahani et al. [

46] and can be attributed to increased energy absorption ability due to increase in porosity in the structure.

Figure 6d shows that the RA did not have any substantial effect on the impact toughness. On the other hand, it has been reported as an influential parameter for tensile strength of FFF structures [

47,

48]. In fact, the specimens in this specific case were fabricated with a boundary wall with a fixed raster angle of 0°. The raster angle was changed just in the inner portion of the specimen, as shown in

Figure 6d. From the results, it seems that change in the raster of inner portion of sample had no effect on the impact toughness, probably because the impact load was mainly withstood by the boundary wall.

Table 6 compares the present study with the past studies with respect to the effects of various 3D printing parameters on the impact toughness. The past studies mainly investigated the effect of 3D printing parameters on the impact strength of monolithic sheets, i.e., single sheet printed in one or multiple materials. On the other hand, the present study focused on hybrid composite with laminar structure contrary to the monolithic structure in past studies. Comparing the effect of layer thickness on two types of the structures, the results for monolithic structure made in Santhakumar et al. [

25] agrees with that of the laminar structure made in the present study. However, the results reported by Shubham et al. [

41] completely contradicts the current study, thereby pointing out the probable role of material type, thereby pointing out the combined effect of parameters and material type on the toughness of 3D-printed structures. With regards to the infill density, its effect is the same in both the monolithic and laminar structures, thereby indicating that nature of the fill density effect remains unchanged regardless of the type of structure or material.

3.2. Empirical Model and Optimization

An empirical model was developed to correlate a response with the complete range of conditions of the entire design. For this purpose, the regression analysis was done using DX-10 software. The following empirical model was yielded for the only response, i.e., impact toughness:

Experiments were performed to validate the model, as shown in

Table 7. The error in the predicted and experimental values was reported less than 5%, which confirms that the model can likely predict the impact toughness of hybrid C-PLA/ABS laminar composite.

The desirability function as described by Costa [

49] was used for optimization:

where D = collective desirability of all responses, d

i = desirability of individual response, and r

i = weightage of each response.

As studied above, the impact toughness of the specimen was affected by the 3D printing parameters. Optimum conditions were developed to attain appropriate impact toughness. Optimization was done with an iterative manner and 100 solutions were achieved.

For optimization in this study, LT of 0.5 mm, CR of 1, FD of 40%, and RA of 45° were determined to be the best 3D printing parameters. To verify these 3D printing conditions, a sample was 3D printed and tested. The predicted and actual strength were 22,361.7 and 23,465.6 kJ/m2, respectively, with a difference of 4.7%. It can be observed that optimized results are in agreement with the experimental results.

3.3. Types of Failure and Fracture Mechanism

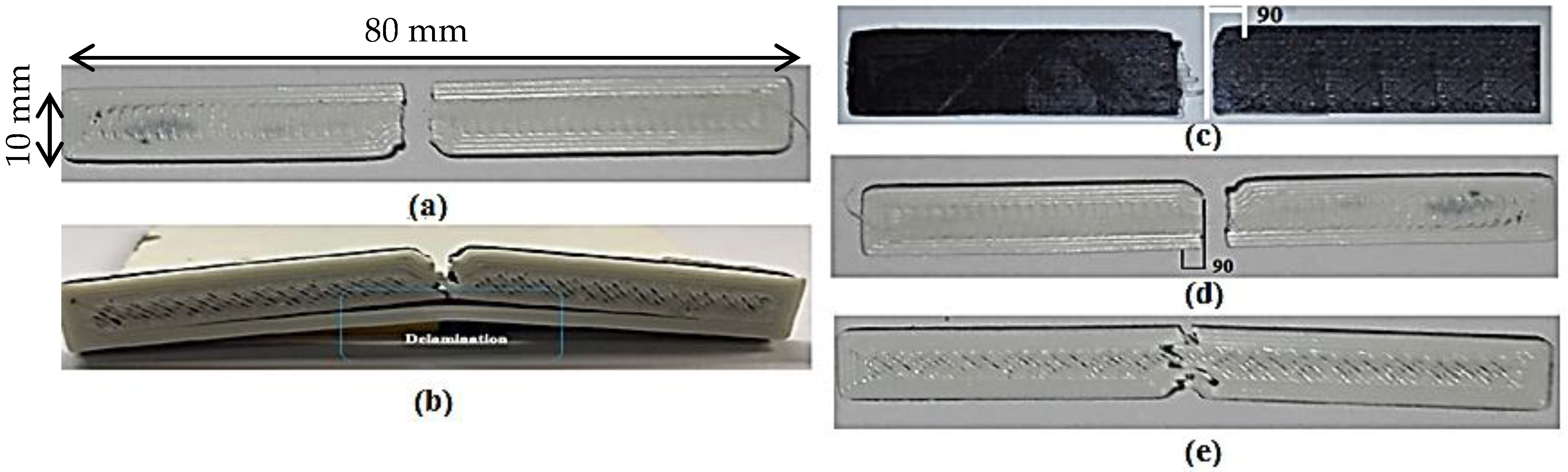

As shown in

Figure 7a,b, two types of failures were observed in the composite samples, namely, type A and type B. In the type A failure (

Figure 7a), both laminates fractured simultaneously as a hammer hit the sample without any delamination. This type of failure was observed in the samples with lower values of CR (0.5) and LT (0.1 mm). In fact, when CR = 0.5, the proportion of brittle C-PLA (67%) was greater than that of ductile ABS (33%). Moreover, when LT was low (say 0.1 mm), the material experiences greater number of thermal cycles thereby leading to interlayer cracking LT = 0.1 mm [

1]. These two factors as a result led to brittle failure (i.e., type A).

The type B failure differed from type A in a sense that it included delamination of ABS boundary wall besides fracturing of remainder composite (

Figure 7b). This kind of failure was observed in samples with higher values of CR (1) and LT (0.5 mm). Higher CR means greater volume of ductile ABS than that of brittle C-PLA. Further, high LT reduces the number of thermal cycles, thus reducing interlayer cracking. These conditions as a result promotes nature of fracture from brittle to ductile. This fact is evidenced from

Figure 7b, whereby the failure is dictated by delamination and zigzag fracture. Out of 16 samples produced in this work, 12 samples failed according to the type A and 4 failed according to the type B as listed in

Table 8.

Further, it was observed that the C-PLA lamina of the composite always fractured in a brittle manner making an angle of 90° with the loading axis for both of 0°/90° and 45°/−45° rasters (

Figure 7c). The fracture in ABS lamina, however, showed dependence on the raster angle: fractured at an angle of 90° for the raster of 0°/90° and at about 40° (with respect to loading axis) for the raster of 45°/−45° as shown in

Figure 7d,e. In other words, as observable from

Figure 7d,e, the fracture in ABS lamina tends to propagate along the raster direction.

Figure 8 shows the SEM images of fractured surfaces of the representative samples of C-PLA/ABS laminar composite (i.e., 3 and 5). In the case of fractured C-PLA sheet, two types of voids/pores can be noticed. Large voids, which have very low density, represent absence of material flow during printing. Small voids, which have much higher density, signify breaking and pull out of carbon fibers, thereby suggesting that failure in the C-PLA sheet initiated probably due to breaking of fibers once the impact load exceeded the fiber strength (

Figure 8). The breaking of both fiber and PLA matrix indicates that the impact load was jointly borne by the two with main contributions from the fibers. Further, no interlayer cracking is observed in the C-PLA sheet showing that the printed layers remained intact during impact loading because of strong interlayer adhesion. On the other hand, interlayer cracking can be observed in the ABS lamina, specifically near the pores (

Figure 8), thereby indicating poor interlayer adhesion and suggesting that breaking of the ABS beads might had initiated from the pores. Such cracks can be also observed at the C-PLA/ABS interface. In case of ABS lamina, the entire load was borne by the ABS matrix contrary to matrix and fibers in the C-PLA sheet.