Influence of Low-pH Beverages on the Two-Body Wear of CAD/CAM Monolithic Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Design

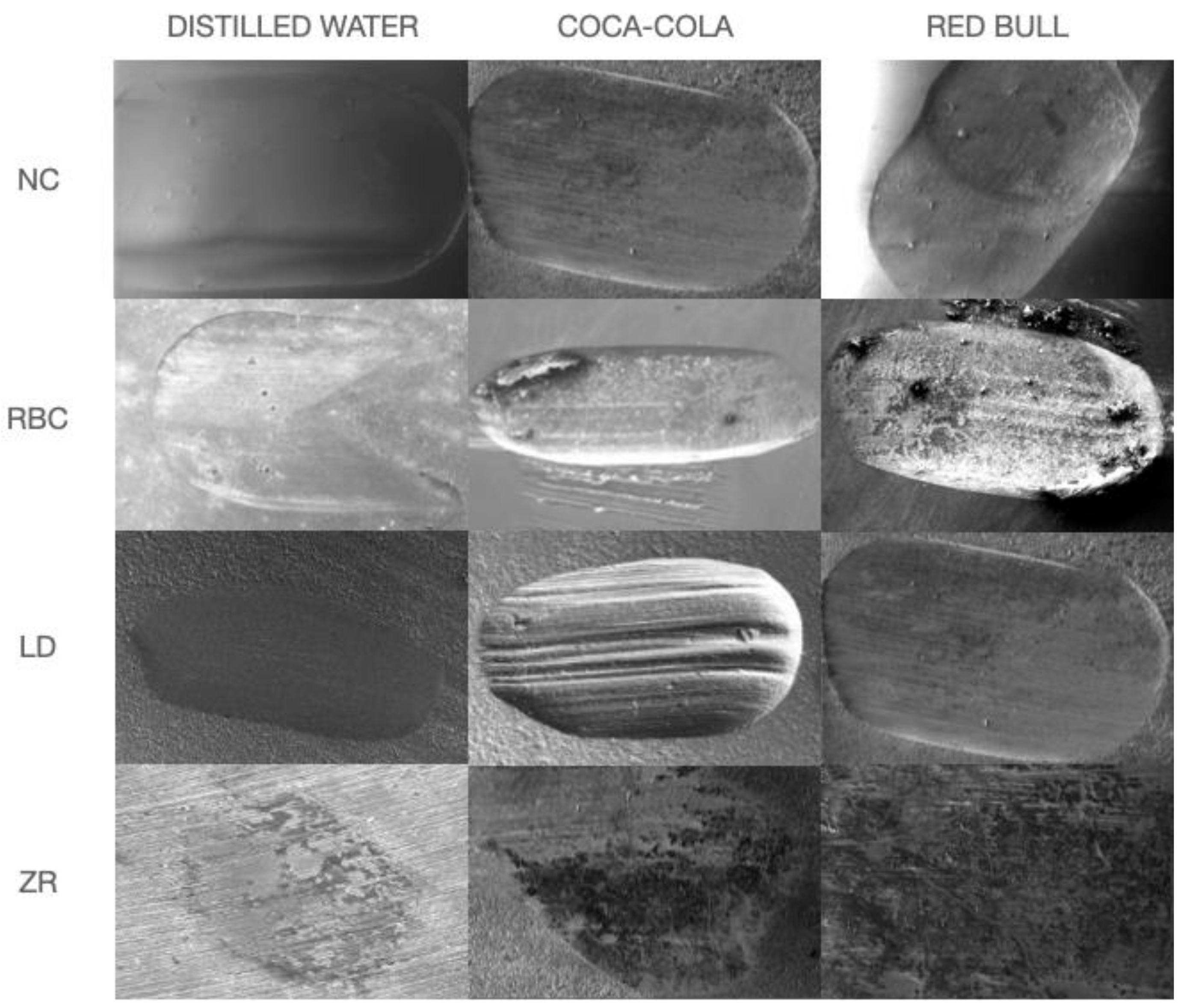

- “CAD/CAM monolithic material” in four levels: four different materials, commonly employed for worn dentition rehabilitation, were selected: nanohybrid CAD/CAM composite resin (NC, GrandioBlock, Voco GmbH, Cuxhaven, Germany), resin-based composite (RBC, Cerasmart 270, GC Corporation, Tokyo, Japan), lithium disilicate (LD, E-max CAD, Ivoclar, Shaan, Luxembourg), and high-translucency zirconia (ZR, Kuraray Noritake, Tokyo, Japan) (Table 1).

- “Acidic beverage” in three levels: a two-body wear test was performed with samples immersed in three liquid mediums: distilled water, Coca-Cola, and Red Bull.

2.2. Sample Preparation

2.3. Wear Simulation Test

2.4. Sample Scan and Analysis

2.5. SEM Analysis

2.6. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.F.A.; Bonfante, E.A. A New Classification System for All-Ceramic and Ceramic-like Restorative Materials. Int. J. Prosthodont. 2016, 28, 227–235. [Google Scholar] [CrossRef] [Green Version]

- Sripetchdanond, J.; Leevailoj, C. Wear of human enamel opposing monolithic zirconia, glass ceramic, and composite resin: An in vitro study. J. Prosthet. Dent. 2014, 112, 1141–1150. [Google Scholar] [CrossRef] [PubMed]

- Söderholm, K.J.; Richards, N.D. Wear resistance of composites: A solved problem? Gen. Dent. 1998, 46, 256–263. [Google Scholar]

- Shimane, T.; Endo, K.; Zheng, J.H.; Yanagi, T.; Ohno, H. Wear of opposing teeth by posterior composite resins--evaluation of newly developed wear test methods. Dent. Mater. J. 2010, 29, 713–720. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sookhakiyan, M.; Tavana, S.; Azarnia, Y.; Bagheri, R. Fracture Toughness of Nanohybrid and Hybrid Composites Stored Wet and Dry up to 60 Days. J. Dent. Biomater. 2017, 4, 341–346. [Google Scholar]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.-F. Evaluation of Mechanical and Optical Behavior of Current Es-thetic Dental Restorative CAD/CAM Composites. J. Mech. Behav. Biomed. Mater. 2016, 55, 1–9. [Google Scholar] [CrossRef]

- Belli, R.; Wendler, M.; de Ligny, D.; Cicconi, M.R.; Petschelt, A.; Peterlik, H.; Lohbauer, U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dent. Mater. 2017, 33, 84–98. [Google Scholar] [CrossRef] [PubMed]

- Mainjot, A.K.; Dupont, N.M.; Oudkerk, J.C.; Dewael, T.Y.; Sadoun, M.J. From Artisanal to CAD-CAM Blocks: State of the Art of Indirect Composites. J. Dent. Res. 2016, 95, 487–495. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Pan, J.; Zhang, S.; Malmstrom, H.S.; Ren, Y.-F. Effectiveness of resin-based materials against erosive and abrasive enamel wear. Clin. Oral Investig. 2016, 21, 463–468. [Google Scholar] [CrossRef]

- Silva, N.R.; Thompson, V.P.; Valverde, G.B.; Coelho, P.G.; Powers, J.M.; Farah, J.W.; Esquivel-Upshaw, J. Comparative reliability analyses of zirconium oxide and lithium disilicate restorations in vitro and in vivo. J. Am. Dent. Assoc. 2011, 142, 4S–9S. [Google Scholar] [CrossRef]

- Albashaireh, Z.S.; Ghazal, M.; Kern, M. Two-body wear of different ceramic materials opposed to zirconia ceramic. J. Prosthet. Dent. 2010, 104, 105–113. [Google Scholar] [CrossRef]

- Fan, H.-Y.; Gan, X.-Q.; Liu, Y.; Zhu, Z.-L.; Yu, H.-Y. The Nanomechanical and Tribological Properties of Restorative Dental Composites after Exposure in Different Types of Media. J. Nanomater. 2014, 2014, 759038. [Google Scholar] [CrossRef]

- Pace, F.; Pallotta, S.; Tonini, M.; Vakil, N.; Porro, G.B. Systematic review: Gastro-oesophageal reflux disease and dental lesions. Aliment. Pharmacol. Ther. 2008, 27, 1179–1186. [Google Scholar] [CrossRef]

- Johansson, A.K.; Omar, R.; Carlsson, G.E.; Johansson, A. Dental erosion and its growing importance in clinical practice: From past to present. Int. J. Dent. 2012, 2012, 632907. [Google Scholar] [CrossRef]

- Mafla, A.C.; Cerón-Bastidas, X.A.; Munoz-Ceballos, M.E.; Vallejo-Bravo, D.C.; Fajardo-Santacruz, M.C. Prevalence and Extrinsic Risk Factors for Dental Erosion in Adolescents. J. Clin. Pediatr. Dent. 2017, 41, 102–111. [Google Scholar] [CrossRef]

- Papagianni, C.E.; Van Der Meulen, M.J.; Naeije, M.; Lobbezoo, F. Oral health-related quality of life in patients with tooth wear. J. Oral Rehabil. 2013, 40, 185–190. [Google Scholar] [CrossRef] [PubMed]

- Lussi, A.; Megert, B.; Shellis, R.P.; Wang, X. Analysis of the erosive effect of different dietary substances and medications. Br. J. Nutr. 2012, 107, 252–262. [Google Scholar] [CrossRef] [Green Version]

- Shellis, R.P.; Featherstone, J.D.B.; Lussi, A. Understanding the Chemistry of Dental Erosion. Erosive Tooth Wear 2014, 25, 163–179. [Google Scholar]

- Scotti, N.; Comba, A.; Gambino, A.; Manzon, E.; Breschi, L.; Paolino, D.; Pasqualini, D.; Berutti, E. Influence of Operator Ex-perience on Non-Carious Cervical Lesion Restorations: Clinical Evaluation with Different Adhesive Systems. Am. J. Dent. 2016, 29, 33–38. [Google Scholar]

- Breschi, L.; Maravic, T.; Cunha, S.R.; Comba, A.; Cadenaro, M.; Tjäderhane, L.; Pashley, D.H.; Tay, F.R.; Mazzoni, A. Dentin bond-ing systems: From dentin collagen structure to bond preservation and clinical applications. Dent. Mater. 2018, 34, 78–96. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maravic, T.; Mazzoni, A.; Comba, A.; Scotti, N.; Checchi, V.; Breschi, L. How Stable is Dentin as a Substrate for Bonding? Curr. Oral Health Rep. 2017, 4, 248–257. [Google Scholar] [CrossRef]

- Badra, V.V.; Faraoni, J.J.; Ramos, R.P.; Palma-Dibb, R.G. Influence of different beverages on the microhardness and surface roughness of resin composites. Oper. Dent. 2005, 30, 213–219. [Google Scholar]

- Milleding, P.; Wennerberg, A.; Alaeddin, S.; Karlsson, S.; Simon, E. Surface Corrosion of Dental Ceramics in Vitro. Biomaterials 1999, 20, 733–746. [Google Scholar] [CrossRef]

- Botto, D.; Lavella, M. High temperature tribological study of cobalt-based coatings reinforced with different percentages of alumina. Wear 2014, 318, 89–97. [Google Scholar] [CrossRef]

- Sankar, A.; Kumar, M.; Kumar, K.; Pranitha, K.; Kishore, K.; Rajavardhan, K. Erosive potential of cola and orange fruit juice on tooth colored restorative materials. Ann. Med Health Sci. Res. 2014, 4, 208–212. [Google Scholar] [CrossRef] [Green Version]

- Han, L.; Okamoto, A.; Fukushima, M.; Okiji, T. Evaluation of Flowable Resin Composite Surfaces Eroded by Acidic and Al-coholic Drinks. Dent. Mater. J. 2008, 27, 455–465. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scribante, A.; Bollardi, M.; Chiesa, M.; Poggio, C.; Colombo, M. Flexural Properties and Elastic Modulus of Different Esthetic Restorative Materials: Evaluation after Exposure to Acidic Drink. BioMed Res. Int. 2019, 2019, 5109481. [Google Scholar] [CrossRef]

- Kitchens, M.; Owens, B.M. Effect of Carbonated Beverages, Coffee, Sports and High Energy Drinks, and Bottled Water on the in vitro Erosion Characteristics of Dental Enamel. J. Clin. Pediatr. Dent. 2007, 31, 153–159. [Google Scholar] [CrossRef]

- Chan, A.S.; Tran, T.T.K.; Hsu, Y.H.; Liu, S.Y.S.; Kroon, J. A systematic review of dietary acids and habits on dental erosion in adoles-cents. Int. J. Paediatr. Dent. 2020, 30, 713–733. [Google Scholar] [CrossRef] [PubMed]

- Reddy, A.; Norris, D.F.; Momeni, S.S.; Waldo, B.; Ruby, J.D. The pH of beverages in the United States. J. Am. Dent. Assoc. 2016, 147, 255–263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alnasser, M.; Finkelman, M.; Papathanasiou, A.; Suzuki, M.; Ghaffari, R.; Ali, A. Effect of acidic pH on surface roughness of esthetic dental materials. J. Prosthet. Dent. 2019, 122, 567. [Google Scholar] [CrossRef]

- Backer, A.D.; Munchow, E.; Eckert, G.J.; Hara, A.; Platt, J.A.; Bottino, M.C. Effects of Simulated Gastric Juice on CAD/CAM Resin Composites-Morphological and Mechanical Evaluations. J. Prosthodont. 2015, 26, 424–431. [Google Scholar] [CrossRef]

- Curtis, A.; Shortall, A.; Marquis, P.; Palin, W. Water uptake and strength characteristics of a nanofilled resin-based composite. J. Dent. 2008, 36, 186–193. [Google Scholar] [CrossRef] [PubMed]

- Wongkhantee, S.; Patanapiradej, V.; Maneenut, C.; Tantbirojn, D. Effect of acidic food and drinks on surface hardness of enamel, dentine, and tooth-coloured filling materials. J. Dent. 2006, 34, 214–220. [Google Scholar] [CrossRef]

- Mayworm, C.D.; Camargo, S.; Bastian, F.L. Influence of artificial saliva on abrasive wear and microhardness of dental composites filled with nanoparticles. J. Dent. 2008, 36, 703–710. [Google Scholar] [CrossRef]

- Zhang, F.; Reveron, H.; Spies, B.C.; Van Meerbeek, B.; Chevalier, J. Trade-off between fracture resistance and translucency of zir-conia and lithium-disilicate glass ceramics for monolithic restorations. Acta Biomater. 2019, 91, 24–34. [Google Scholar] [CrossRef] [PubMed]

- Vanoorbeek, S.; Vandamme, K.; Lijnen, I.; Naert, I. Computer-aided designed/computer-assisted manufactured composite resin versus ceramic single-tooth restorations: A 3-year clinical study. Int. J. Prosthodont. 2010, 23, 223–230. [Google Scholar] [PubMed]

- Mörmann, W.H.; Stawarczyk, B.; Ender, A.; Sener, B.; Attin, T.; Mehl, A. Wear characteristics of current aesthetic dental restorative CAD/CAM materials: Two-body wear, gloss retention, roughness and Martens hardness. J. Mech. Behav. Biomed. Mater. 2013, 20, 113–125. [Google Scholar] [CrossRef] [Green Version]

- Fasbinder, D.J. Clinical performance of chairside CAD/CAM restorations. J. Am. Dent. Assoc. 2006, 137, 22S–31S. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, A.C.; Hahnel, S.; König, A.; Brambilla, E. Resin Composite Blocks for Dental CAD/CAM Applications Reduce Bio-film Formation in Vitro. Dent. Mater. 2020, 36, 603–616. [Google Scholar] [CrossRef]

- Bollen, C.M.; Lambrechts, P.; Quirynen, M. Comparison of Surface Roughness of Oral Hard Materials to the Threshold Sur-face Roughness for Bacterial Plaque Retention: A Review of the Literature. Dent. Mater. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Anusavice, K.J.; Kakar, K.; Ferree, N. Which Mechanical and Physical Testing Methods Are Relevant for Predicting the Clini-cal Performance of Ceramic-Based Dental Prostheses? Clin. Oral Implants Res. 2007, 18, 218–231. [Google Scholar] [CrossRef] [PubMed]

- De Jager, N.; Feilzer, A.; Davidson, C. The influence of surface roughness on porcelain strength. Dent. Mater. 2000, 16, 381–388. [Google Scholar] [CrossRef]

- Heintze, S.D.; Cavalleri, A.; Forjanic, M.; Zellweger, G.; Rousson, V. Wear of Ceramic and Antagonist--a Systematic Evaluation of Influencing Factors in Vitro. Dent. Mater. 2008, 24, 433–449. [Google Scholar] [CrossRef] [PubMed]

- Preis, V.; Behr, M.; Handel, G.; Schneider-Feyrer, S.; Hahnel, S.; Rosentritt, M. Wear performance of dental ceramics after grinding and polishing treatments. J. Mech. Behav. Biomed. Mater. 2012, 10, 13–22. [Google Scholar] [CrossRef]

| Name | Manufacturer | Classification | Composition (*) |

|---|---|---|---|

| Grandio Blocs (NC) | VOCO GmbH, Cuxhaven, Germany | Nanohybrid Composite | 86% w/w of and glass-ceramic fillers, functionalized silicon dioxide nanoparticles, Bis-GMA, UDMA, TEGDMA |

| Cerasmart 270 (RBC) | GC Dental Products, Tokyo, Japan | Resin-based composite | 71% w/w of barium and silica nanoparticles, Bis-MEPP, UDMA, dimethacrylate |

| E-Max CAD (LD) | Ivoclar Vivadent, Shaan, Luxemburg | Lithium Disilicate | SiO2 60–65%; K2O 15–19%; Al2O3 6–10.5%; other oxides and pigments 0–8% |

| Katana ML (ZR) | Kuraray Noritake, Tokyo, Japan | High-translucency Zirconia | Zr 60%, O 30%, Hf 1.3% |

| Volumetric Wear (mm3) | |||

|---|---|---|---|

| Water | Coca-Cola | Redbull | |

| RBC | 0.28 a,A ± 0.08 | 0.34 a,B ± 0.11 | 0.34 a,B ± 0.09 |

| NC | 0.29 a,A ± 0.06 | 0.36 a,B ± 0.07 | 0.36 a,B ± 0.04 |

| ZR | 0.01 c,A ± 0.003 | 0.02 c,A ± 0.02 | 0.02 c,A ± 0.02 |

| LD | 0.16 b,A ± 0.09 | 0.20 b,A ± 0.08 | 0.21 b,A ± 0.09 |

| Surface Roughness Ra (µm) | |||

|---|---|---|---|

| Water | Coca-Cola | Redbull | |

| RBC | 2.08 a,A ± 0.33 | 2.43 a,A ± 0.34 | 2.43 a,A ± 0.92 |

| NC | 2.50 a,A ± 0.20 | 3.04 a,A ± 0.79 | 3.40 a,B ± 0.70 |

| ZR | 1.49 b,A ± 0.24 | 1.36 b,A ± 0.08 | 1.39 b,A ± 0.46 |

| LD | 1.87 b,A ± 0.71 | 1.73 b,A ± 0.71 | 1.69 b,A ± 0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scotti, N.; Ionescu, A.; Comba, A.; Baldi, A.; Brambilla, E.; Vichi, A.; Goracci, C.; Ciardiello, R.; Tridello, A.; Paolino, D.; et al. Influence of Low-pH Beverages on the Two-Body Wear of CAD/CAM Monolithic Materials. Polymers 2021, 13, 2915. https://doi.org/10.3390/polym13172915

Scotti N, Ionescu A, Comba A, Baldi A, Brambilla E, Vichi A, Goracci C, Ciardiello R, Tridello A, Paolino D, et al. Influence of Low-pH Beverages on the Two-Body Wear of CAD/CAM Monolithic Materials. Polymers. 2021; 13(17):2915. https://doi.org/10.3390/polym13172915

Chicago/Turabian StyleScotti, Nicola, Andrei Ionescu, Allegra Comba, Andrea Baldi, Eugenio Brambilla, Alessandro Vichi, Cecilia Goracci, Raffaele Ciardiello, Andrea Tridello, Davide Paolino, and et al. 2021. "Influence of Low-pH Beverages on the Two-Body Wear of CAD/CAM Monolithic Materials" Polymers 13, no. 17: 2915. https://doi.org/10.3390/polym13172915

APA StyleScotti, N., Ionescu, A., Comba, A., Baldi, A., Brambilla, E., Vichi, A., Goracci, C., Ciardiello, R., Tridello, A., Paolino, D., & Botto, D. (2021). Influence of Low-pH Beverages on the Two-Body Wear of CAD/CAM Monolithic Materials. Polymers, 13(17), 2915. https://doi.org/10.3390/polym13172915